Page 1

Typ1 osa / CC 220

CPL Programming Instructions

Version

102

Page 2

Typ1 osa / CC 220

CPL Programming Instructions

1070 073 642-102 (93.06) GB

/Z25 QJ, D25 XA)

E 1993

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights.

Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 20.– DM

Page 3

Page 4

Flexible Automation

Contents

1. Introduction

Notes and Tips 1 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Basic elements of CPL

Program structure 2 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NC block 2 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPL block 2 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program start 2 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking 2 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parallel processing 2 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autostart 2 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clamp mode 2 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbolic names 2 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reserved instruction words 2 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constants 2 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integer constant (INTEGER) 2 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floating−point constant (REAL) 2 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Double−precision constant and double−precision operations 2 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Character string constant (STRING) 2 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables 2 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integer variable (INTEGER) 2 − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floating−point variable (REAL) 2 − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic variable (BOOLEAN) 2 − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character string variable (STRING) 2 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Array variable (ARRAY) 2 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIM 2 − 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of variables 2 − 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions 2 − 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NUL 2 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mathematical operations 2 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SQRT 2 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABS 2 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROUND 2 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INT 2 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIN, COS, TAN, ASIN, ACOS, ATAN 2 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic operations 2 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOT, AND, OR, XOR 2 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repeat instructions 2 − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPEAT − UNTIL 2 − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WHILE − DO − END 2 − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOR − STEP − TO − NEXT 2 − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unconditional jump instruction 2 − 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GOTO 2 − 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label 2 − 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Branch instruction 2 − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IF − THEN − ELSE − ENDIF 2 − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320

CPL Programming Instructions

Page

Contents 1

Page 5

Flexible Automation

3. Subroutines and cycles

Calling subroutines with G, P or Q addresses 3 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling modal subroutine calls 3 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling subroutines via any auxiliary or M functions 3 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPL program execution parallel to machining time 3 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling subroutines via the CALL function 3 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALL 3 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. System functions

General 4 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WAIT 4 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axis positions 4 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPOS 4 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MPOS 4 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PPOS 4 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AXO 4 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero offsets 4 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FXC 4 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tool compensations 4 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TC 4 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CS table 4 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TD 4 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active system data 4 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD 4 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BIN, BCD 4 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T word, part counter data 4 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDR 4 − 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable axis address 4 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AXP 4 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC interface 4 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication by means of variables 4 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface access 4 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IC 4 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MIC 4 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time recording 4 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATE, TIME 4 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOCK 4 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320

CPL Programming Instructions

5. String processing

Dimensioning character arrays 5 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading characters from an arbitrary location in a string 5 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MID$ 5 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying character strings 5 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MID$ 5 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length of a character string 5 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEN 5 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search for a character string 5 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTR 5 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents 2

Page 6

Flexible Automation

Character strings and numbers 5 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASC 5 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STR$ 5 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VAL 5 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal of leading or trailing blanks 5 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRIM$ 5 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming examples 5 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assignment: STRING expression −> character array 5 − 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comparison of STRING expressions 5 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chaining STRING expressions 5 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. File processing

Interface data 6 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequential file structure 6 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Random file structure 6 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening a file 6 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPENW, OPENR 6 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Writing a file 6 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRN# 6 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LJUST, NJUST 6 − 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REWRITE 6 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading a file 6 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INP# 6 − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading interface data 6 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INP# function 6 − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File end recognition 6 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EOF 6 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing a file 6 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSE 6 − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading the file pointer position 6 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILEPOS 6 − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the file pointer 6 − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEEK 6 − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File size determination 6 − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILESIZE 6 − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File deletion 6 − 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ERASE 6 − 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Text files (language changeover) 6 − 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TXT$ 6 − 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320

CPL Programming Instructions

7. Dialog programming

Comments and messages 7 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MSG 7 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REM 7 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

( ... ) 7 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data output 7 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP 7 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHR$( ) 7 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DLG, ENDDLG 7 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRN 7 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents 3

Page 7

Flexible Automation

Data input 7 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INP 7 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SFK 7 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSF 7 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INKEY 7 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Graphics programming

Type of line and color selection 8 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMD 8 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COL 8 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining the graphics range 8 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GWD 8 − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MWD 8 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line 8 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIN 8 − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circle 8 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIR 8 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling enclosed contours 8 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIL 8 − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear instructions 8 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLS 8 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLR 8 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLG 8 − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Text output in graphics mode 8 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPR 8 − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed CPL pictures 8 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting a fixed picture recording 8 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXB 8 − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Finish fixed picture recording 8 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXE 8 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display fixed pictures 8 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXB 8 − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

CC 220/320

CPL Programming Instructions

9. Screen editor 9 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Annex

11. Keywords

Contents 4

10 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Flexible Automation

1. Introduction

1. Introduction

The programming language CPL ("Customer Programming Language") was ba

sically developed to extend the range of capabilities offered byDIN programming

for the user. CPL makes it possible to create and store any machining sequence as

a part subroutine with variable notation. Despite its complexity, CPL is easily

learned as its main features and its choice of elements are based on the BASIC

standard. Structure elements similar to PASCAL are additionally available for ad

vanced applications.

CPL offers the following advantages:

‘ shorter program when repeat sequences and comparable routines are in

volved,

‘ simplified operation thanks to individual dialog programming,

‘ improved monitoring due to graphics programming,

‘ status−dependent program variations by accessing NC system data.

CPL Programming Instructions

CC 220/320

Notes and Tips

In addition, CPL permits intervention in the machine control system through com

munication with the programmable controller (PLC).

The CPL functions described in this manual can be used during the machining se

quence in both the main program and subroutines.

The present manual refers to software versions "Z25 QJ" of the CC 220/320 M

control and "D25XA" of CC 220 T.

NOTE !

Information concerning the current software version of ’your’ control is displayed in

the

and SOFTWARE VERSION softkeys.

This manual contains the information required − with respect to its title − for the

normal use of the control. For reasons of transparency, however, it cannot provide

all details for all possible combinations of functions. It is not possible, either, to con

sider any viable case of integration or operation since the control usually forms part

of major plants or systems.

If you desire more profound information, or if you have specific problems in han

dling the control which are not treated at all or not sufficiently in detail in this

manual, please contact your Bosch service department or our customer service

department.

group operating mode after depressing the DIAGNOSTIC CONTROL

The present description only refers to CPL programming of the CNC. For DIN pro

gramming, a separate manual is available.

1 − 1

Page 9

Flexible Automation

1. Introduction

For programming manufacturer−specific cycles please note the description pro

vided by the machine manufacturer.

By programming the control, you might influence the axis movements (e.g. posi

tioning, etc.), processing technology (e.g. feedrate, speed, etc.), and the process

ing sequence (e.g. tool change, compensation, output of auxiliary functions, etc.).

For this reason, general programming knowledge (e.g. for program logic, etc.) as

well as knowledge concerning the technology of the process involved is indispens

able.

Therefore, programming is reserved to personnel trained for this purpose.

WARNING!

Programming by personnel with insufficient or inexistent training or lack in experi

!

!

ence may result in severe damages to the machine, drives, tools, parts or even per

sonal injury!

First you should carefully test the programs without axis movement! For this pur

pose, the control provides the TEST ON softkey in the NC (AUTOMATIC) group op

erating mode. When this softkey is displayed in inverse video, no axis movements

will be carried out that are directly initiated by a part program.

CPL Programming Instructions

CC 220/320

BOSCH shall not be liable for consequential damages resulting from process

!

ing of an NC or CPL program, an individual NC block or manual movement of

the axes! BOSCH shall not be liable, either, for consequential damages which

could have been avoided by appropriate PLC programming!

Please note our comprehensive range of training courses on this subject. For more

information, please contact our training center in Erbach

(phone: −49−6062−78258).

1 − 2

Page 10

Flexible Automation

2. Basic Elements of CPL

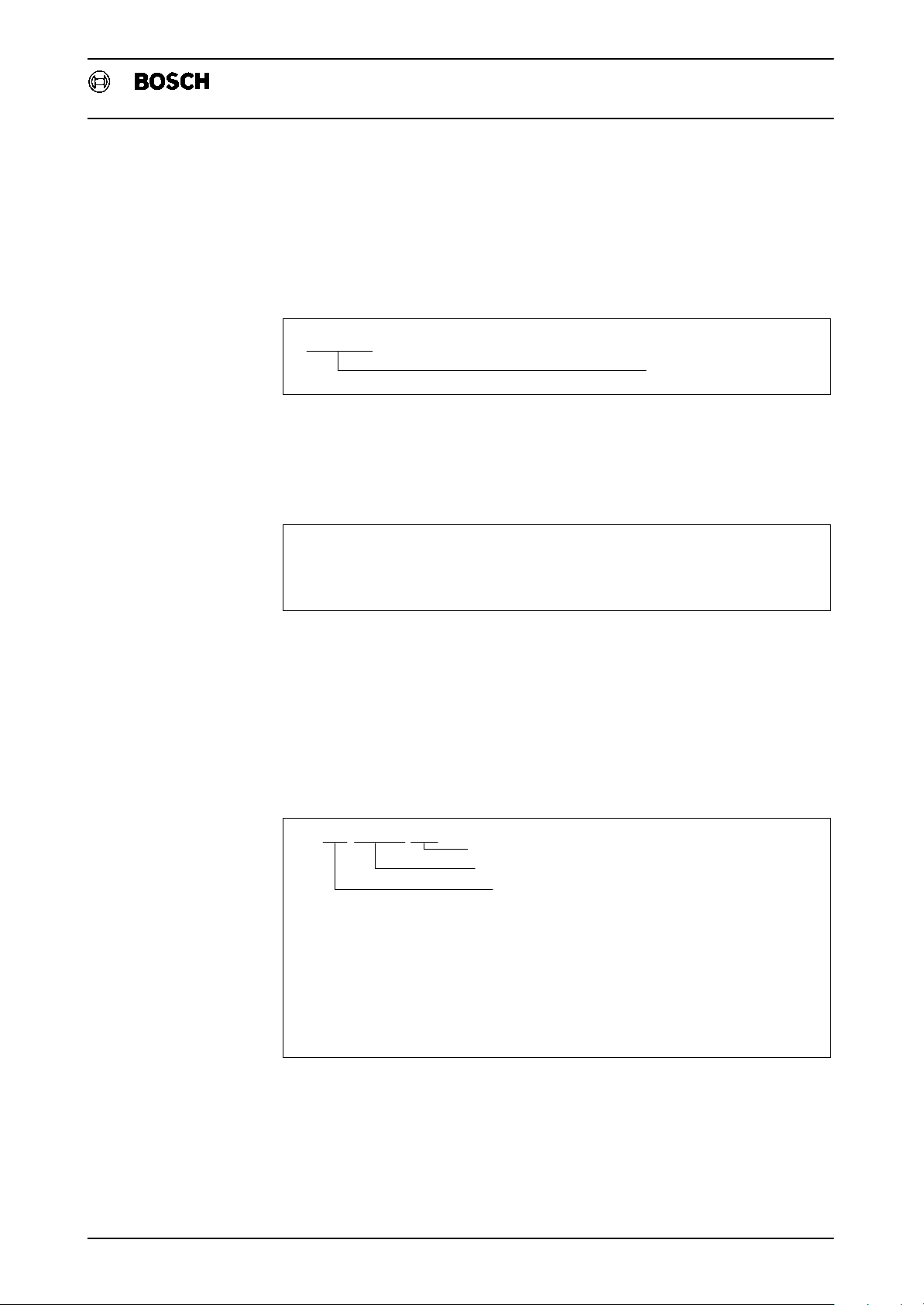

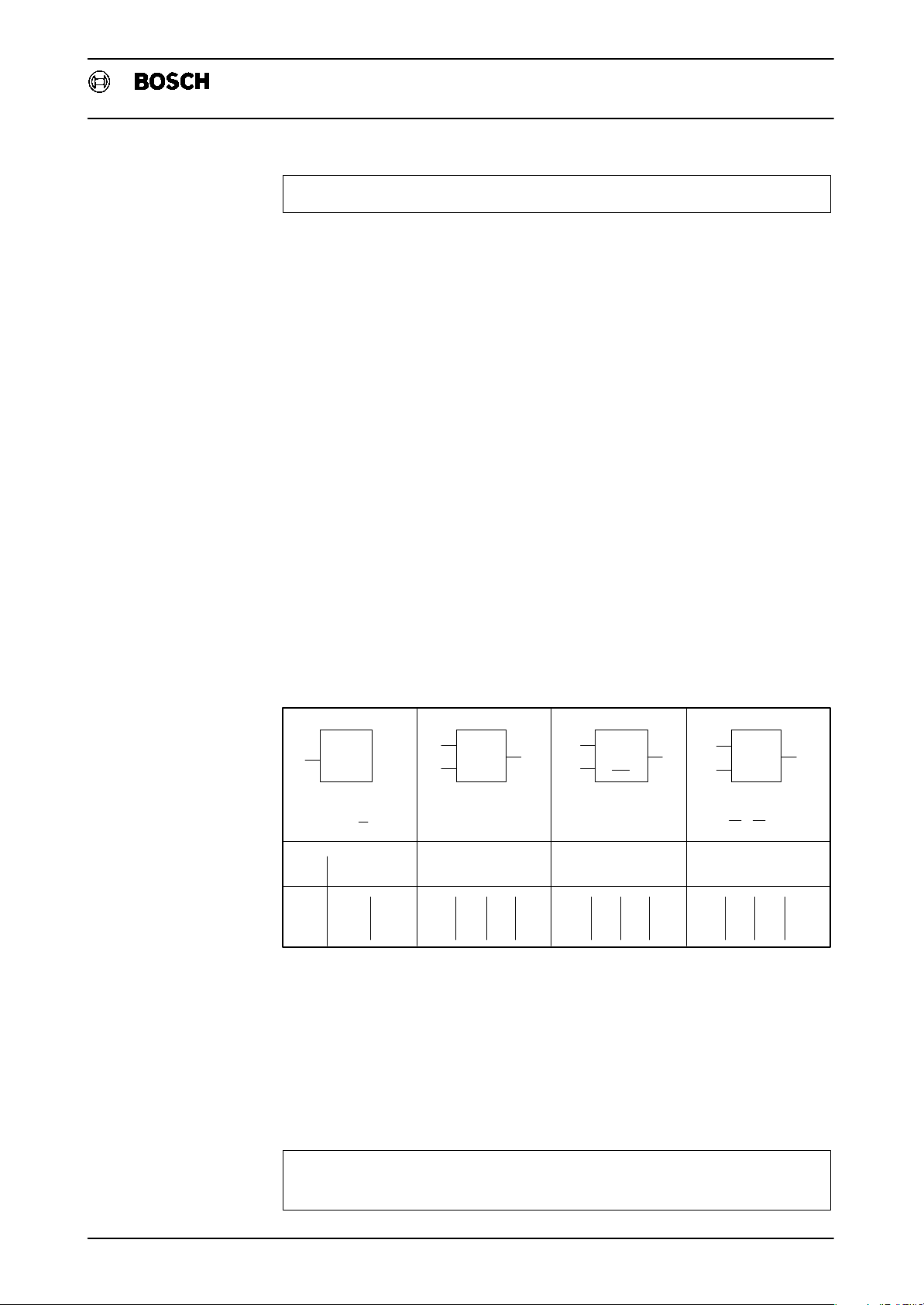

Program structure

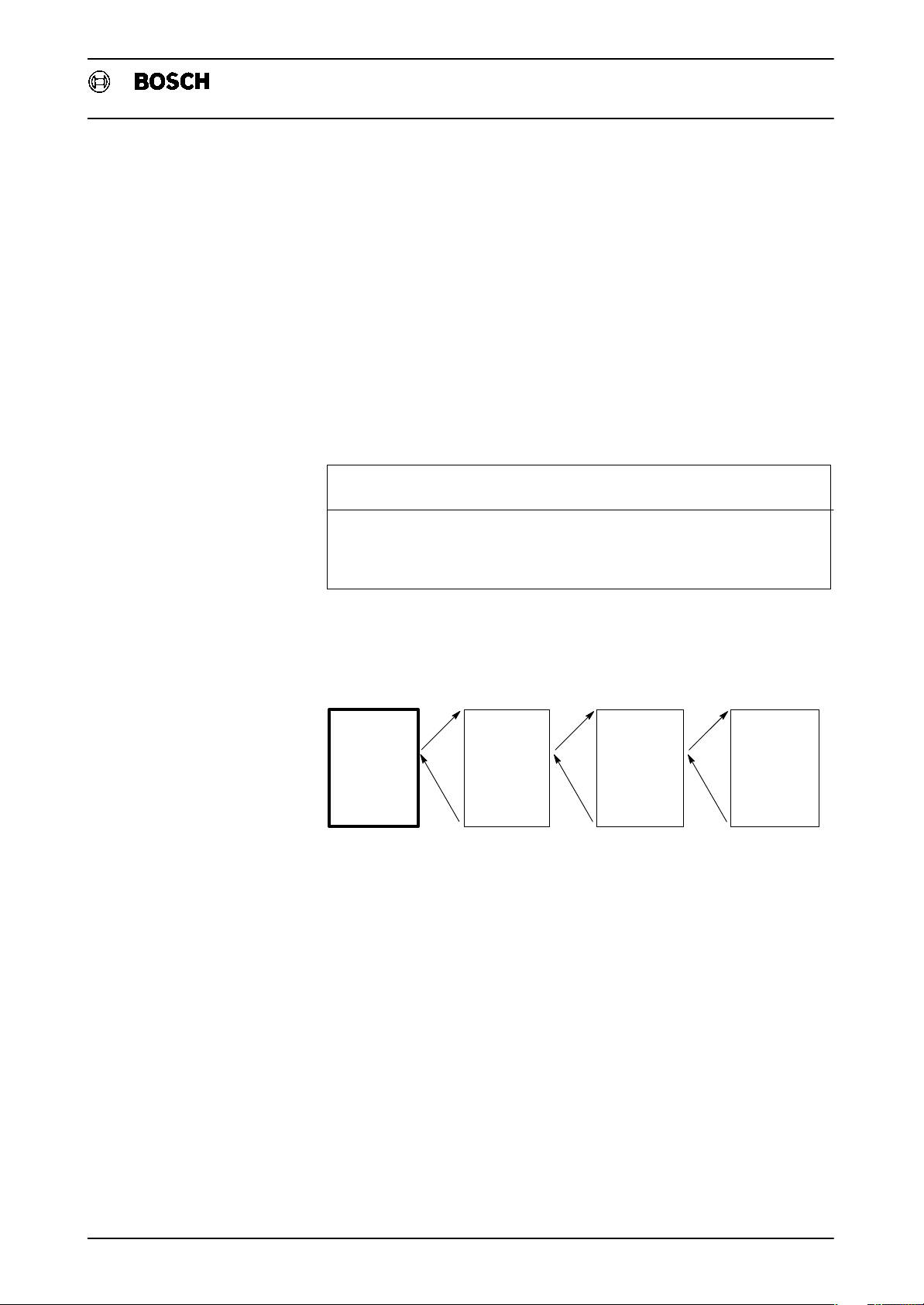

As a rule, a program is made up of two parts, one containing statements and the

other containing declarations; in the case of CPL, however, this second part is not

obligatory but can be useful. The declaration part can be used, for example, to add

comments on the names given to variables, to dimension array variables or pre−

assign variables. It can also be used to list invariable values in a list of constants,

reducing the amount of work involved in making any changes required later. This

will be described in more detail below. The statement part contains a symbolic de

scription of a program sequence using statements with symbolic names and oper

ators to connect data.

2. Basic Elements

CC 220/320

CPL Programming Instructions

P

R

O

G

R

A

M

Other programs or routines can be called up and run from a program by calling

subroutines. When they have been executed, the calling program continues its run

starting after the subroutine call concerned. Subroutines can also be called up in

other subroutines. Up to 7−fold nesting is possible in CPL.

Main

program

CPL statements are always written in capital letters taking into account form stan

dards. One form standard concerns the correct syntax of reserved instruction

words; this is important in order to prevent confusion with the names of variables.

The importance of "clean programing" increases with the length of the program.

This term is used to describe not only unmistakable names for constants and vari

ables, but also

DECLARATIONS

STATEMENTS

Sub−

routine

Sub−

routine

Sub−

routine

‘ structured programming,

‘ error tolerance and

‘ software ergonomics.

Structured programs are generally easy to understand. By combining comparable

sections or frequently required functions into (parameterized) subroutines or jump

destinations identified by an unmistakable label (name), programs are not only

easier to read, they also reduce the amount of duplication, since these functions

are usually also required in other routines. This type of programming does not ex

clude the need for the occasional programming tricks, but such tricks should then

be commented accordingly in the user’s own interest.

2 − 1

Page 11

Flexible Automation

NC block

2. Basic Elements

Error−tolerant ("Forgiving") programs are a very difficult matter, for the operator’s

creativity and imagination during the input dialog are, as a rule, very much greater

than those of the most creative and most imaginative programmers. Nevertheless,

it is important to make a program as crash−proof and error−tolerant as possible.

The number of input errors can also be reduced by ergonomic software. Menu op

tions, for example, can be emphasized optically without difficulty. The computer’s

capabilities should be utilized without going to extremes, particularly with regard to

the number of colors used. Further details can be found in DIN standard 66234.

A complete CPL statement is also known as a CPL block, in accordance with DIN

programming. Since both NC blocks and CPL blocks can be used simultaneously

during part programming, we shall briefly describe the structure of an NC block

here.

NC blocks are defined in DIN 66025 and contain standard information, such as pre

paratory functions, axis positioning and auxiliary functions. They must be pro

grammed either with an N block number or without any block number at all.

CPL Programming Instructions

CC 220/320

Example:

N100 G1 X150 Y100.525

or

G1 X150 Y100.525

Further details can be found in the Programming instructions P. − N o . 3822.

CPL also makes it possible to vary the word contents of an address in an NC block

(except N address), so that machining operations can be parameterized. However,

this cannot be used to influence the program flow during execution in a way that

had not yet been considered before linking the program. The following example

shows how variables can be used in a subroutine with the three parameters P1, P2

and P3.

2 − 2

Page 12

Flexible Automation

2. Basic Elements

CPL Programming Instructions

Example:

.

XVALUE=P1 : FEED=P2 : OFFSET TABLE=P3 : PROGEND=30

5

.

N10

G1

N20

.

N30

.

X XVALUE F

G22

K OFFSET TABLE

M

PROGEND

FEED*2+1000

Parameters are entered in the subroutine call of the main program.The square

brackets [ ] indicate that variables are used. In block N10 it is clear that not only

variable names but entire CPL expressions can be used inside the square brack

ets. Block N30 is only valid if the program also includes M2 or M30.

The following statements could influence the program flow:

WARNING!

Not permissible:

10 CYCLE=81 : TARGET=20

!

N20 G[CYCLE]

N30 G23 L[TARGET]

CC 220/320

CPL block

All addresses calling a subroutine and the addresses G23, G24, G33, G75 and G92

are not intended for variable notation.

A CPL block is made up of a statement or declaration combined with a line number.

If a CPL block ends with a colon ":", or with a ":<LINE FEED>", it must be followed

by another CPL block without a line number.

Example:

.

.

30 IF X%=3 THEN GOTO 150 ENDIF:

REM TARGET1

40 IF X%=4 THEN GOTO 200 ENDIF : REM TARGET2

50 WAIT : XPOS=MPOS(1) : YPOS=MPOS(2) : ZPOS=MPOS(3)

N100 G90

N110 G1 X XPOS Y YPOS Z ZPOS

.

.

A <LINE FEED> indicates the programmed end of a line. In edit mode, it is auto

matically inserted into the program text when ENTER is pressed. The <LINE

FEED> character is not visible on the screen or on the printout. If a CPL block does

not end with ":", it must be followed by a CPL block with line number or by an NC

block.

2 − 3

Page 13

Flexible Automation

Program start

2. Basic Elements

Usually, a program is selected in mode and started via CYCLE START. The

programs may exclusively consist of CPL blocks, or they may be composed of NC

blocks and CPL blocks.

CPL Programming Instructions

CC 220/320

Linking

Parallel processing

Autostart

If the control is in the highest level of the

chine parameter P4016 can be activated via the DIRECT CALL softkey or the inter

face input signal 6.1. NC and/or CPL instructions may be used in this program.

However, "M30−specific" actions will not be executed, i.e., the program will be

treated as a subroutine. The program is again started via CYCLE START.

When the program has been selected, or via the GENERATE LINK TAB. softkey, the

program is first examined for correct syntax and possible jump destinations and

subroutine calls. During this process called "linking", a so−called link table is gen

erated. Only programs that have already been linked can be started.

The CPL programs specified via machine parameter P4011 can be directly started

via a softkey provided that the link tables have been generated for these programs.

(

. Section 3 − Subroutines and cycles).

If the control is in the highest level of the mode, the CPL program defined

under [MAC] via parameter P4011 can be started via the CPL DIALOGUE softkey

or the interface input signal 6.3..

mode, a program defined in ma

Clamp mode

Since machine parameter P9916 can also be used to define the

first mode after start−up of the control, it is possible to automatically start a CPL

program with this feature.

In order to protect a program defined in P4011 against being interrupted without a

definition in parallel processing by a change of the mode, the interface input signal

6.4 "Clamp mode" should be set. If the signal is high, the mode is not changed if the

group mode keys are depressed.

It must be noted, however, that the system changes over to the highest level of the

currently active mode when the signal edges occur (when switching on and off).

Since the user should not notice the activation of this signal by the CPL program,

the activation instruction should be inserted directly at the beginning of the pro

gram.

mode as the

2 − 4

Page 14

Flexible Automation

Symbolic names

Symbolic programming is a typical feature of programming languages like CPL.

Symbolic names represent variable or invariable numerical values and logic in

structions for these data. The keywords reserved only for instruction words are

listed below.

Reserved instruction words

The keywords listed here must stand alone or be contained within special delimit

ing characters identifying them as instruction words. Reserved instruction words

must not be used when selecting variable names!

Example:

2. Basic Elements

CC 220/320

CPL Programming Instructions

GOTO 10

GOTO10

!

Jump to line 10

Arbitrary symbol name (variable): on its own, it leads

!

to the error message: "RUNTIME ERROR

2167=MISSING", because a value assignment for the

variable GOTO10 is expected.

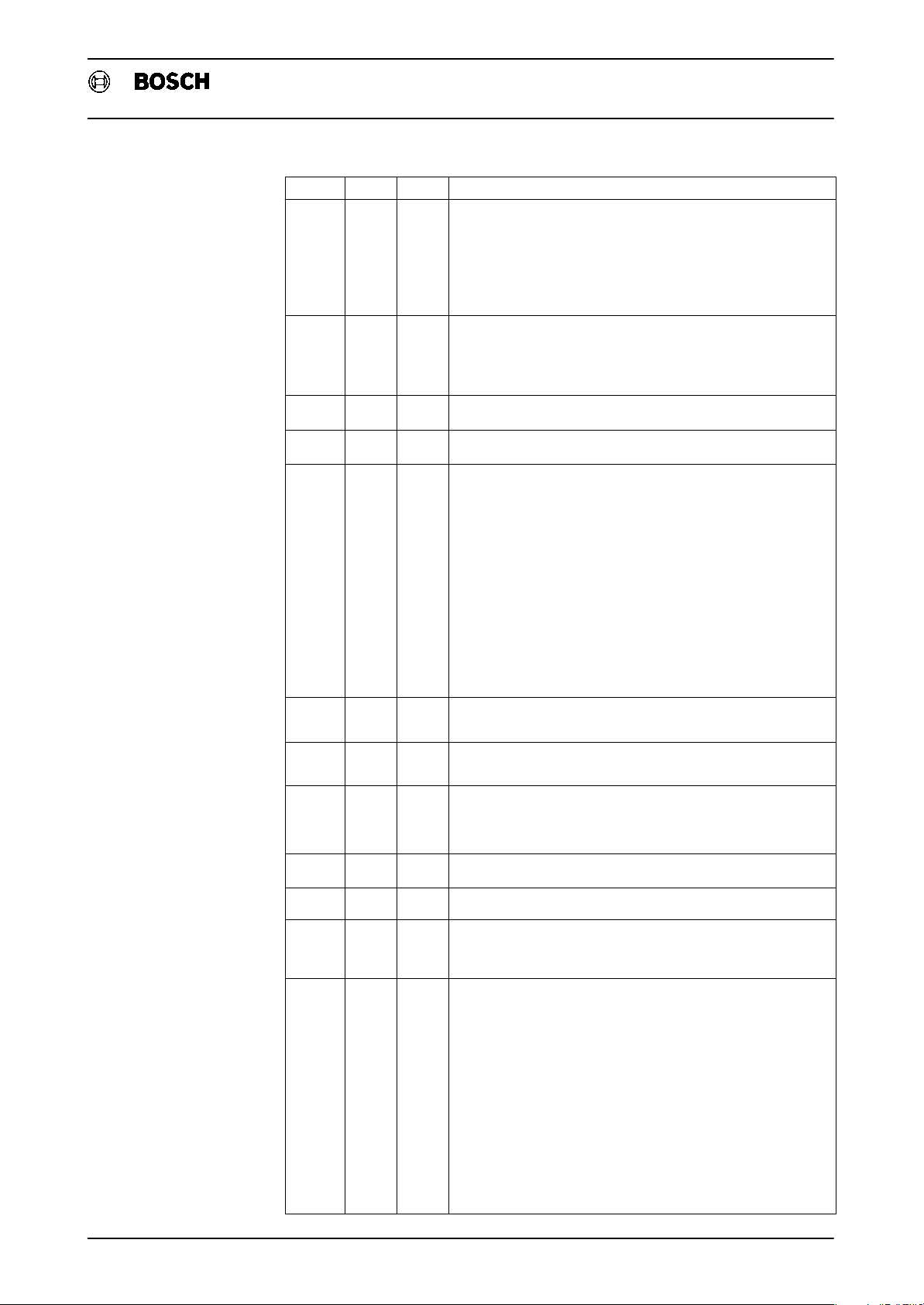

Keywords:

*)

CLS

*)

COL

COM

COS

CPOS

*)

CSF

*)*)

GPR

*)

GWD

NJUST

NUL

SIN

SQRT

STEP

STR$

G:

N:

S:

CALL

CHR$

*)

CIR

*)

CLG

CLOCK

CLOSE

*)

CLR

NEXT

NOT

SD

SDR

SEEK

*)

SFK

GMD

GOTO

ABS ATAN

A: B: C: D:

ACOS

AND

ASC

ASIN

ELSE

E:

END

*)

ENDDLG

ENDIF

L:

*)

P:

*)

LEN

LIN

PPOS

PRN

PRN#

AXO

AXP

EOF

ERASE

LJUST

BCD

BIN

F:

FALSE

FILEPOS

FILESIZE

*)

FIXB

*)

FIXE

MIC MPOS

M:

MID$

REM

R:

REPEAT

ROUND

REWRITE

*)

FOR

FXC

*)

FIL

*)

FIX

MWD

I:

O:

T:

TAN

DATE

DIM

*)

DLG

DO

*)

DSP

IC

IF

INKEY

*)

INP

OPENR

OPENW

TC

TD

TDR

THEN

INP#

INSTR

INT

OR

TIME

TRIM$

TRUE

TXT$

UNTIL

U:

*) Only with option: CPL with graphics/dialogue

V:

WAIT WHILE

W:

X: XORVAL

The following key characters are used by CPL:

#! ?," <−/ &

@

%$:( ) =>+*

][

The comma is normally used as a separating character. It is processed as a punc

tuation character only within character strings. The full stop is used as a decimal

2 − 5

Page 15

Flexible Automation

2. Basic Elements

CPL Programming Instructions

CC 220/320

point in decimal numbers and as a label identifier for jump destinations. The full

stop is interpreted as a punctuation character within character strings. In texts

(character strings), it is also possible to use the following characters: ~ ", ^" or

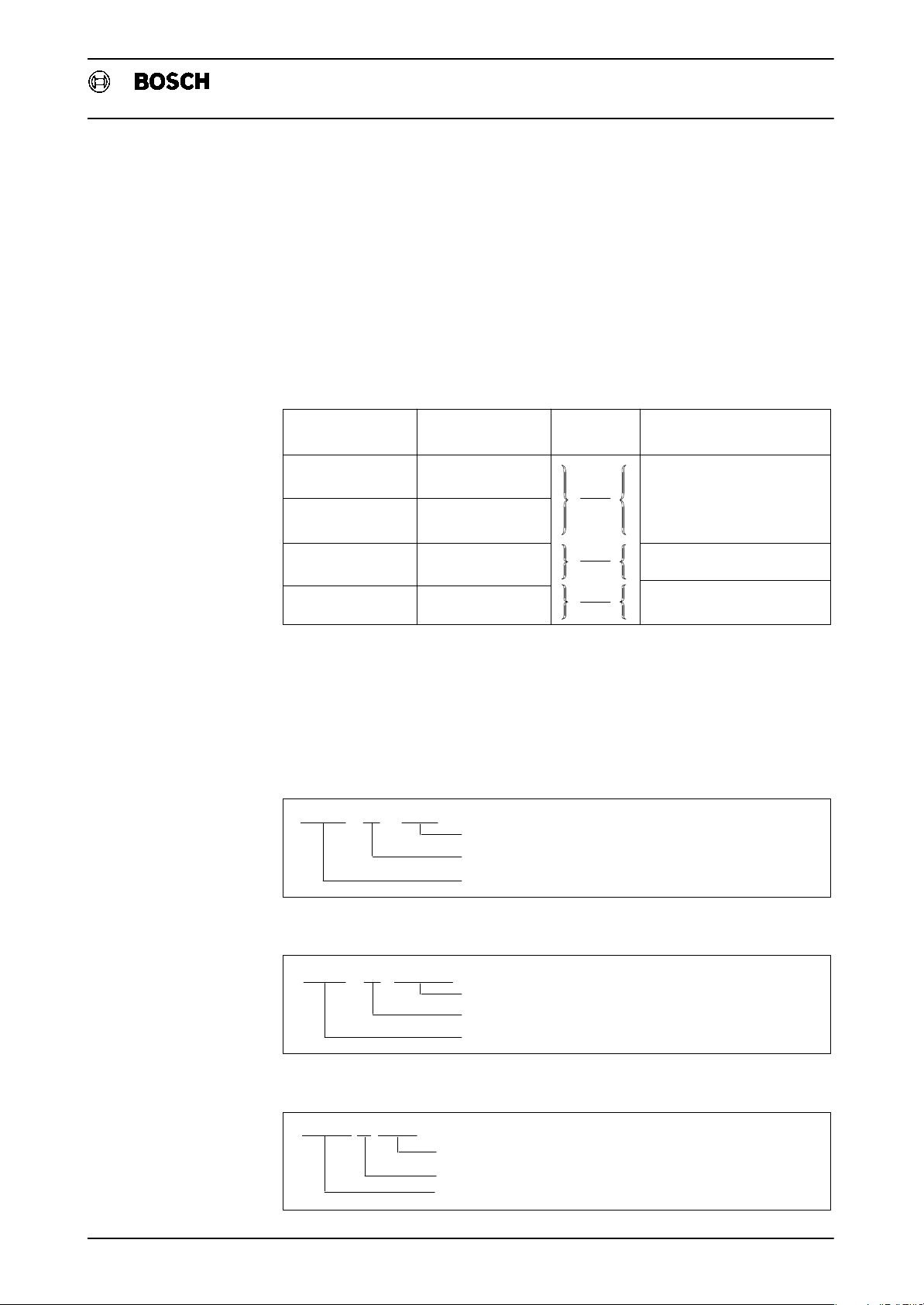

"", _" or z", ’ " or \". Differences between the keyboard symbol, representa

tion in NC mode and representation in graphic mode are shown by the following

table:

Constants

If numerical values are defined for the program sequence which are to remain un

changed (constant), it is possible to use these values in the instructions directly as

digits.

Integer constant (INTEGER)

Whole numbers (integers) are written without a decimal point.

Example:

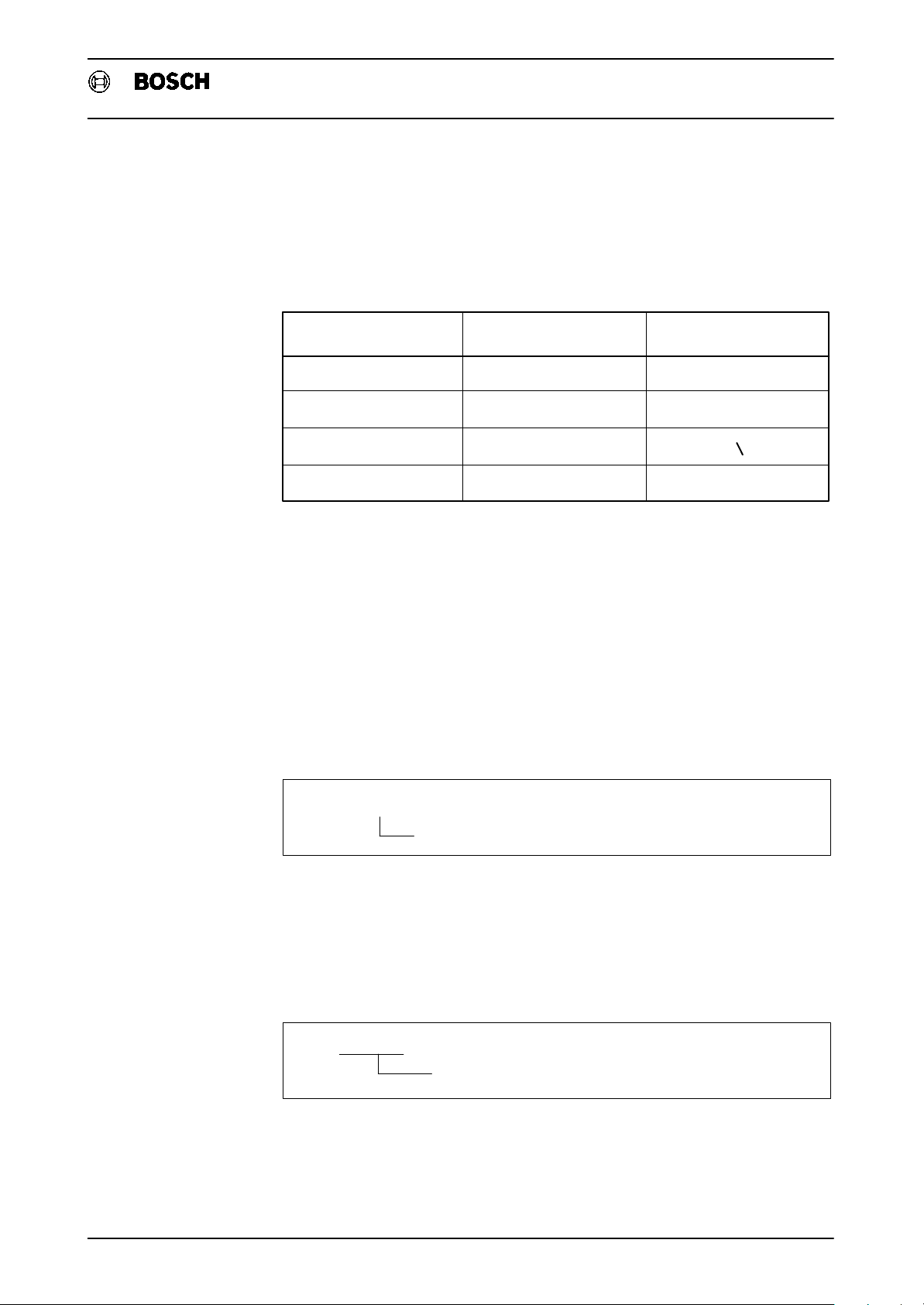

Keyboard symbol

( Panel )

_

n

’

._.

Representation

in NC mode

z

"

’

:

Representation

in graphic mode

_

n

:

NUMBER% = 4

Floating−point constant (REAL)

Real numbers (decimal numbers or fractions) are identified by a decimal point

(floating point).

Example:

PI = 3.141593

INTEGER constant

REAL constant

2 − 6

Page 16

Flexible Automation

2. Basic Elements

CPL Programming Instructions

Double−precision constant and double−precision operations

Constants which are assigned to a double−precision REAL variable or which are

compared with a double−precision REAL variable are represented with double

precision (i.e. exact to 15 places).

If double−precision REAL constants are desired when calculating expressions in

comparisons (IF, WHILE, REPEAT), the following rules must be observed:

In the comparison, it must be ensured that a double−precision REAL variable is

contained on the far left of the expression which is processed first. It must be re

membered here that bracketed expressions are processed first. Equally, it must

also be remembered that the double−precision REAL constant must be pro

grammed on the right side (2nd operand) of the operands to be compared. If these

rules are not observed, the constants are interpreted as single−precision REAL

constants.

CC 220/320

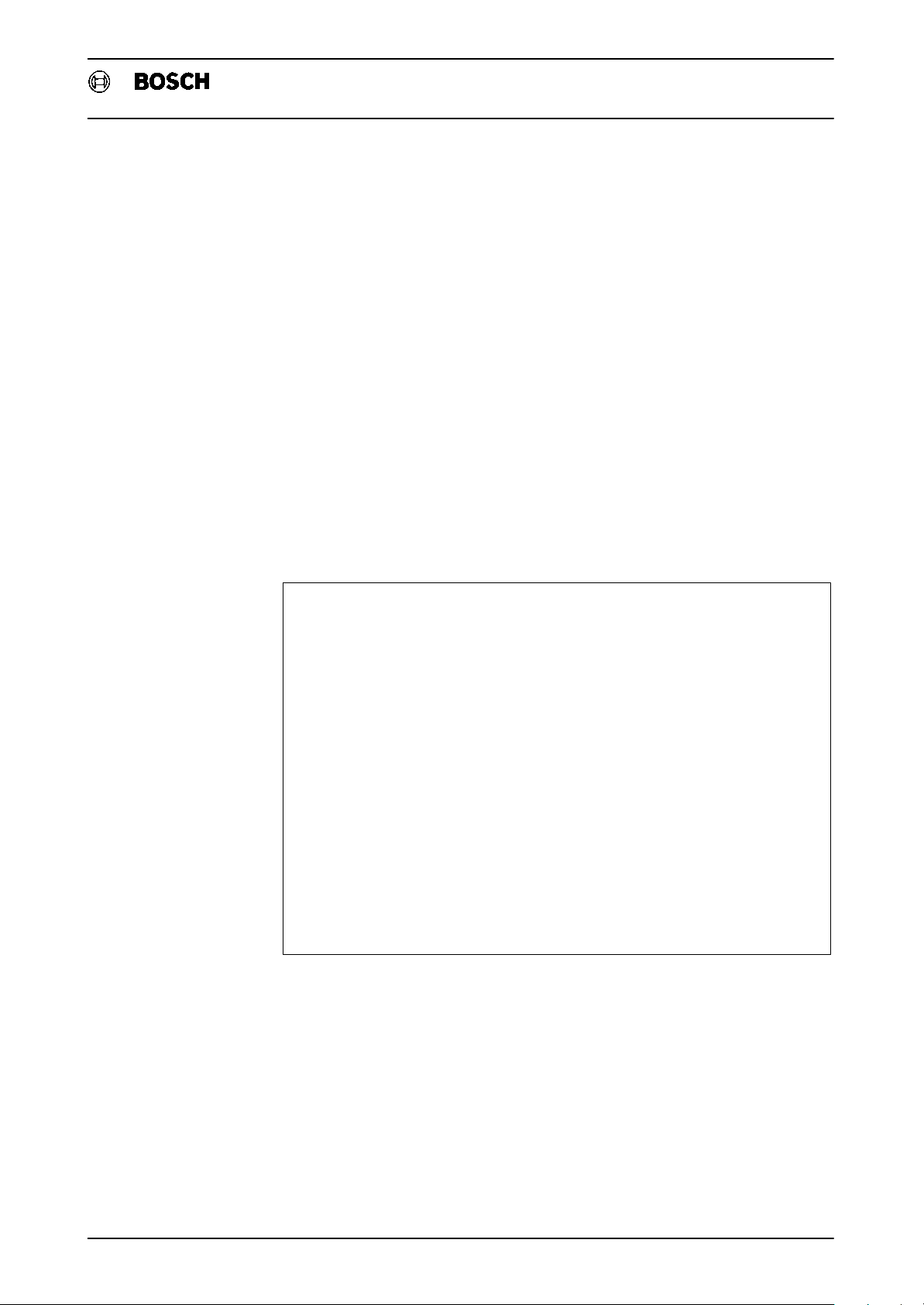

Example: Assignment of double−precision REAL constants and comparison of

variables with double−precision REAL constants

4 D5! = –1234.123456 + 12345 + 1234.234567

20 D0! = 123456789.123456

22 D1! = 1.12345678901234

24 D2! = –123456789012345

26 D3! = –1234.123456

The following interrogations lead to the result: E? = TRUE

28 IF D0! = 123456789.123456 THEN E? = TRUE ELSE E? = FALSE ENDIF

29 IF D1! = 1.12345678901234 THEN E? = TRUE ELSE E? = FALSE ENDIF

30 IF D2! = –123456789012345 THEN E? = TRUE ELSE E? = FALSE ENDIF

31 IF D3! = –1234.123456 THEN E? = TRUE ELSE E? = FALSE ENDIF

32 IF D0! + 2.1 + 3.1 = 123456789.123456 + 2.1 + 3.1 THEN

33 E? = TRUE

34 ELSE

35 E? = FALSE

36 ENDIF

37 IF (D0! + 2.1) + 3.1 = 123456789.123456 + 2.1 + 3.1 THEN

38 E? = TRUE

39 ELSE

40 E? = FALSE

41 ENDIF

2 − 7

Page 17

Flexible Automation

2. Basic Elements

CPL Programming Instructions

CC 220/320

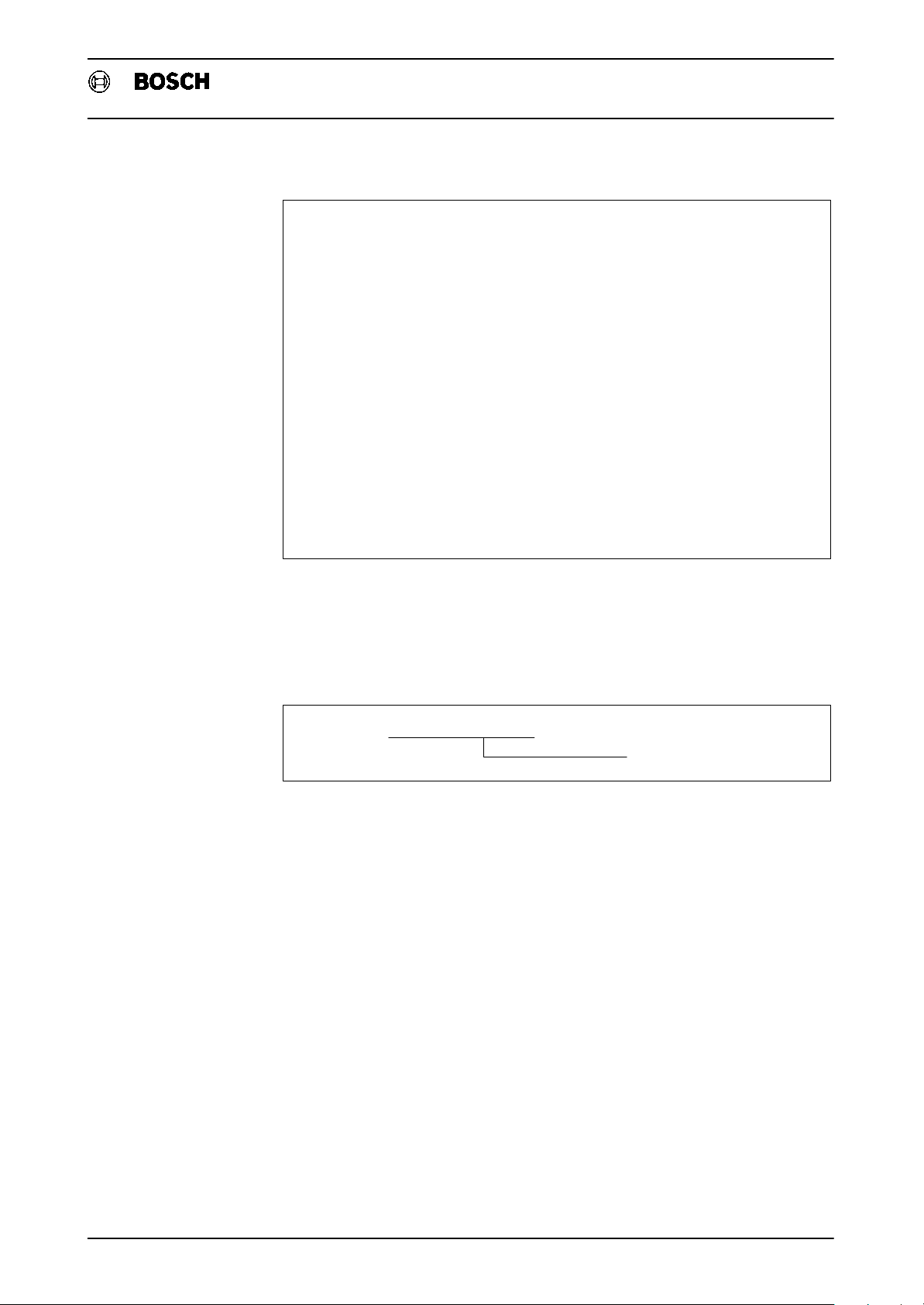

Example: Comparison of variables with single−precision REAL constants

20 D0! = 123456789.123456

22 D1! = 1.12345678901234

24 D2! = –123456789012345

26 D3! = –1234.123456

The following interrogations lead to the result: E? = FALSE:

42 IF 123456789.123456 = D0! THEN E? = TRUE ELSE E? = FALSE ENDIF

43 IF 1.12345678901234 = D1! THEN E? = TRUE ELSE E? = FALSE ENDIF

44 IF –123456789012345 = D2! THEN E? = TRUE ELSE E? = FALSE ENDIF

45 IF –1234.123456 = D3! THEN E? = TRUE ELSE E? = FALSE ENDIF

46 IF D0! + (2.1 + 3.1) = 123456789.123456 + 2.1 + 3.1 THEN

47 E? = TRUE

48 ELSE

49 E? = FALSE

50 ENDIF

46 IF 2.1 + D0! + 3.1 = 123456789.123456 + 2.1 + 3.1 THEN

47 E? = TRUE

48 ELSE

49 E? = FALSE

50 ENDIF

Character string constant (STRING)

A STRING constant is delimited by quotation marks.

Example:

EXAMPLE$ = "This is a character string"

Variables

If data is to be changeable (variable) during the program run, then such data items

are described using variables. Variables are arbitrary symbol names for which sev

eral conventions must be agreed in CPL. The most important convention is an un

ambiguous choice of the variable name. Variable names must not be reserved in

struction words (keywords). The variable name can consist of arbitrary letters and

digits, whereby a letter must be the first character. The first 8 characters of the vari

able name are significant, i.e. only these are used for distinguishing between vari

ables. The variable name itself may be longer, however, in order to permit better

documentation of a program. Conventions are also necessary as regards the

scope of variable action owing to the possibility of using subroutines and the pos

sible necessity of buffering variable values independently of the respective pro

gram.

STRING constant

2 − 8

Page 18

Flexible Automation

2. Basic Elements

CPL Programming Instructions

CC 220/320

A distinction is made between

‘ local variables

‘ global variables

‘ permanent variables

Local variables act only within the program in which they have been declared.

These variables are deleted after the program run when the program is quit and the

occupied program memory space is released again. In the case of a subroutine

call, a local variable name for the calling program is not defined for the subroutine

and may possibly be used again there. The original local variable is available again

with the value which it possessed directly before the subroutine call after the return

to the calling program. A 32 Kbytes memory location is available for local variables

in each program (subroutine).

Global variables are identified by a preceding # symbol followed by the variable

name. The stored values are preserved for the duration of a program run and can

be addressed by the main program and the related subroutine. Global variables

are no longer valid after the program end. A 32 Kbytes memory location is available

for global variables.

Permanent variables can be addressed by every active program under the desig

nation @1 ... @50. The variables of the INTEGER type are permanently preserved.

Deletion is possible only by specific overwriting. Permanent variables are not

stored in the variable memory area. Deletion of the whole memory therefore does

not affect permanent variables.

In order to permit the program to be read more easily, the designation of a perma

nent variable may be supplemented by appending letters to the number.

NUMBER% = 4

local INTEGER variable

#NUMBER% = 4

global INTEGER variable

36 = 4

@

permanent INTEGER variable

@

36QUANTITY = 4

permanent INTEGER variable

Depending on the type of data to be processed, it is expedient to reserve a suitable

memory area. Therefore, a distinction is made between variable types. In addition

to INTEGER variables, CPL features REAL, STRING, BOOLEAN and ARRAY vari

ables.

2 − 9

Page 19

Flexible Automation

Integer variable (INTEGER)

The INTEGER variable occupies 32 bits of memory space in each case. It is identi

fied by a % symbol attached to the variable name. The value range extends from

−2.147.483.648 to +2.147.483.647 .

Example:

NUMBER% = 4

Floating−point variable (REAL)

If no special identification follows the variable name, the variable is interpreted as a

REAL variable of single precision. In this case, the variable occupies 32 bits of the

memory area. The value range is +/−10

places before and after the decimal point.

2. Basic Elements

INTEGER variable

CC 220/320

CPL Programming Instructions

38

. This corresponds to 7 significant

Example:

PI = 3.141593

If a ! symbol follows the variable name, the variable is interpreted as a REAL vari

able of double precision. In this case, the variable occupies 64 bits of the memory

area. The value range is +/− 10

fore and after the decimal point.

Example:

PI! = 3.141592653589793

Logic variable (BOOLEAN)

Logic variables (BOOLEAN variables) can assume only one of the two values

TRUE and FALSE. They are used to store the truth value of assumptions which can

be tested later. Identification is done by means of a question mark following the

variable name.

REAL variable of single precision

308

. This corresponds to 15 significant places be

REAL variable of double precision

Example:

START? = FALSE

BOOLEAN variable

2 − 10

Page 20

Flexible Automation

2. Basic Elements

Character string variable (STRING)

A STRING variable is identified by a $ symbol following the variable name. The

pointer to the character string is stored in the variable if the variable is a simple,

non−dimensioned variable.

Example:

EXAMPLE$ = "This is a character string"

If the character string is a dimensioned field of characters (CHARACTER), these

characters can be processed with special character string instructions. (Refer to

the "Character string processing" section)

Example:

CC 220/320

CPL Programming Instructions

STRING variable

Array variable (ARRAY)

1 DIM ABC$(1)

2 DIM BCDE$(10)

3 ABC$ = ”Z”

4 BCDE$ = CHR$(90)

By using ARRAY variables, it is possible to reserve a one−dimensional or two−di

mensional field (ARRAY) in the memory area under a variable name. An array defi

nition is possible for REAL and INTEGER variables. The variable is indexed in order

to permit access to the individual array elements.

Example: Dimensioning an ARRAY variable

10 DIM ARRAYVAR(2,3)

INTEGER constants for array sizes (index)

Variable name (REAL variable)

DIM instruction word

Example: Access to ARRAY variables

.

100 ARRAYVAR(1,1) = MPOS(1)

110 ARRAYVAR(2,1) = CPOS(1)

120 ARRAYVAR(1,2) = MPOS(2)

130 ARRAYVAR(2,2) = CPOS(2)

140 ARRAYVAR(1,3) = MPOS(3)

150 ARRAYVAR(2,3) = CPOS(3)

2 − 11

Page 21

Flexible Automation

Overview of variables

2. Basic Elements

CPL Programming Instructions

CC 220/320

DIM

The index range or array size must be dimensioned before the first access to the

array variable with INTEGER constants. This is done with the DIM instruction.

DIM <variable name> (<array size1> [,<array size2>])

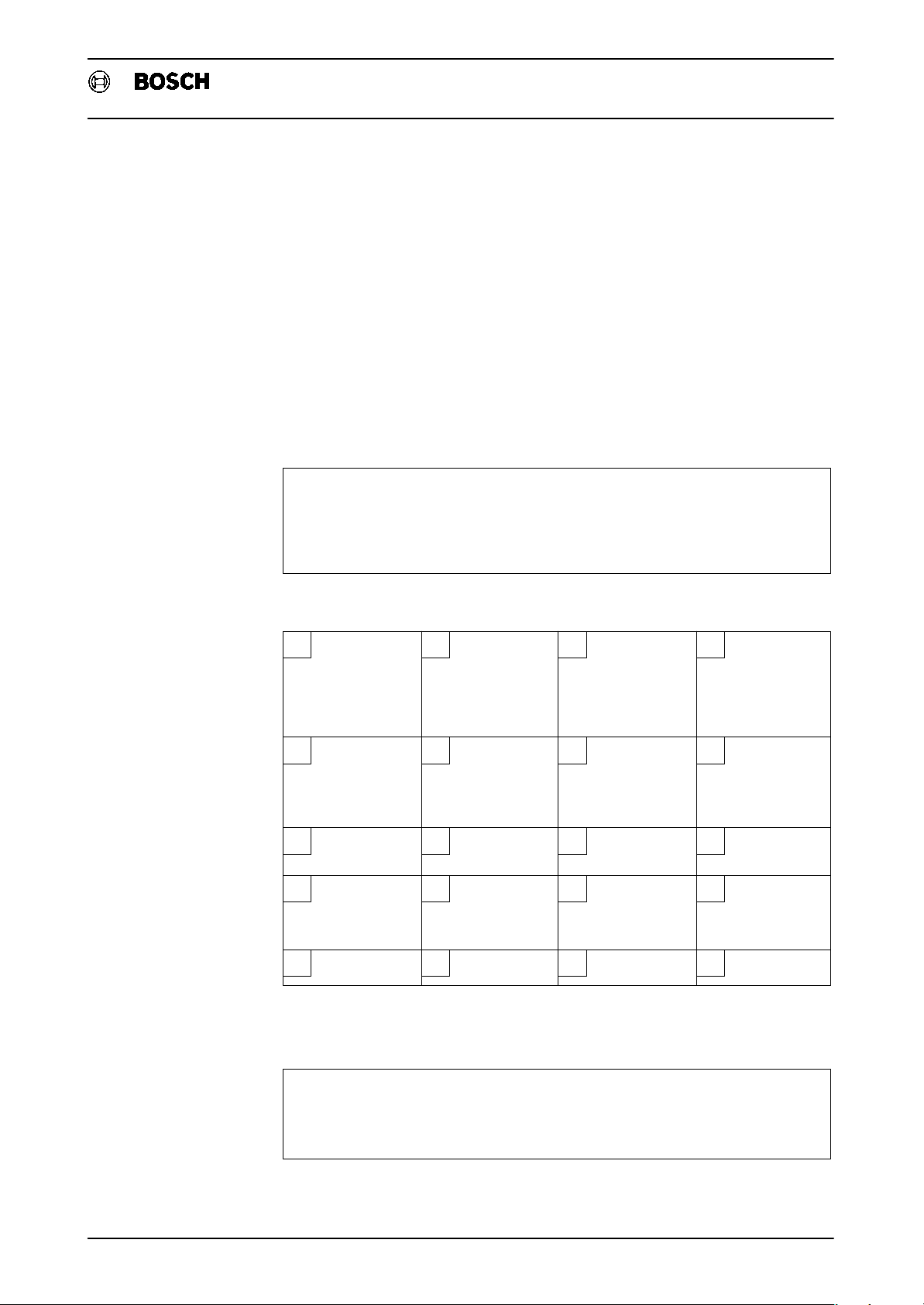

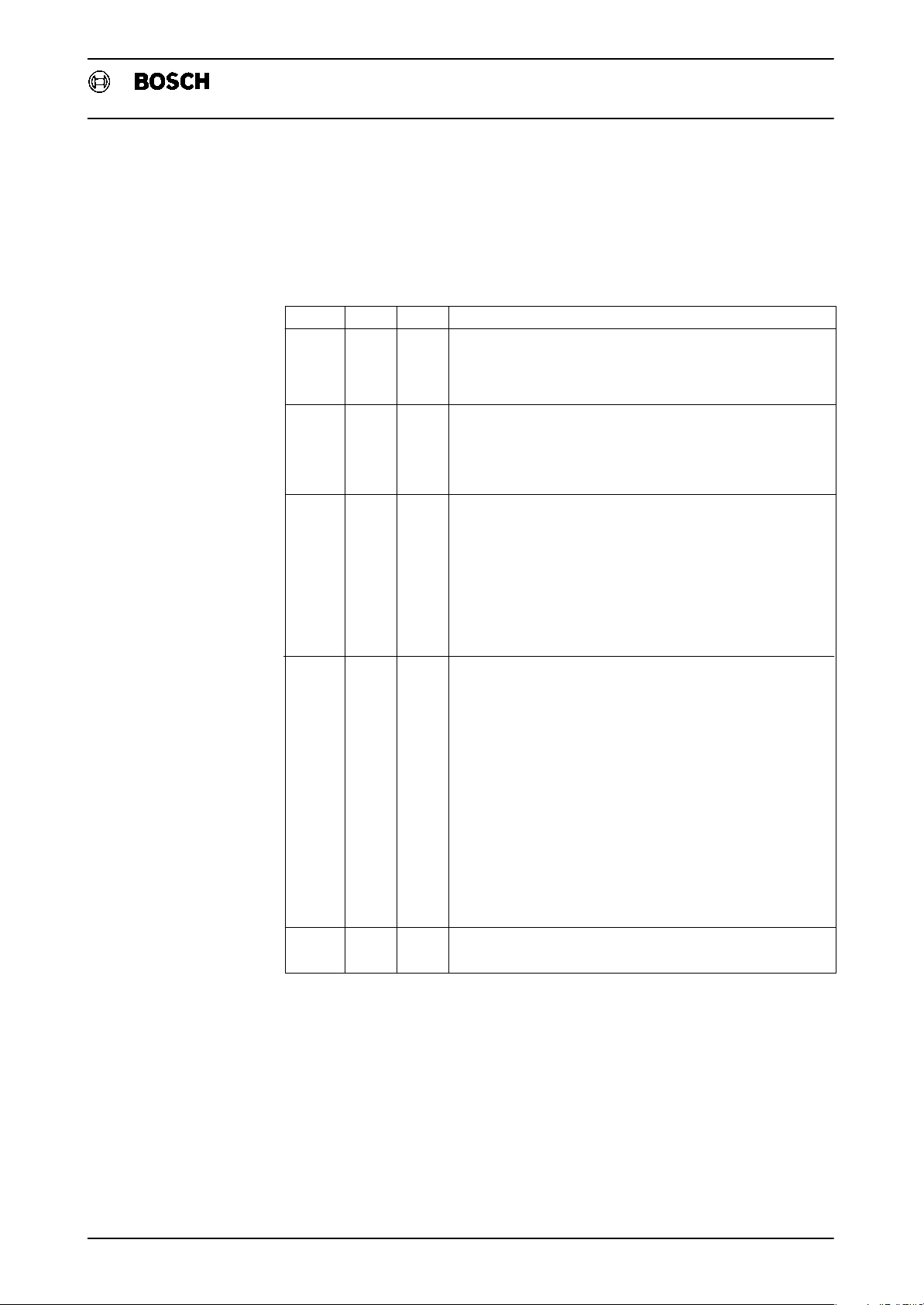

The following overview table summarizes the possibilities of using variables in

CPL:

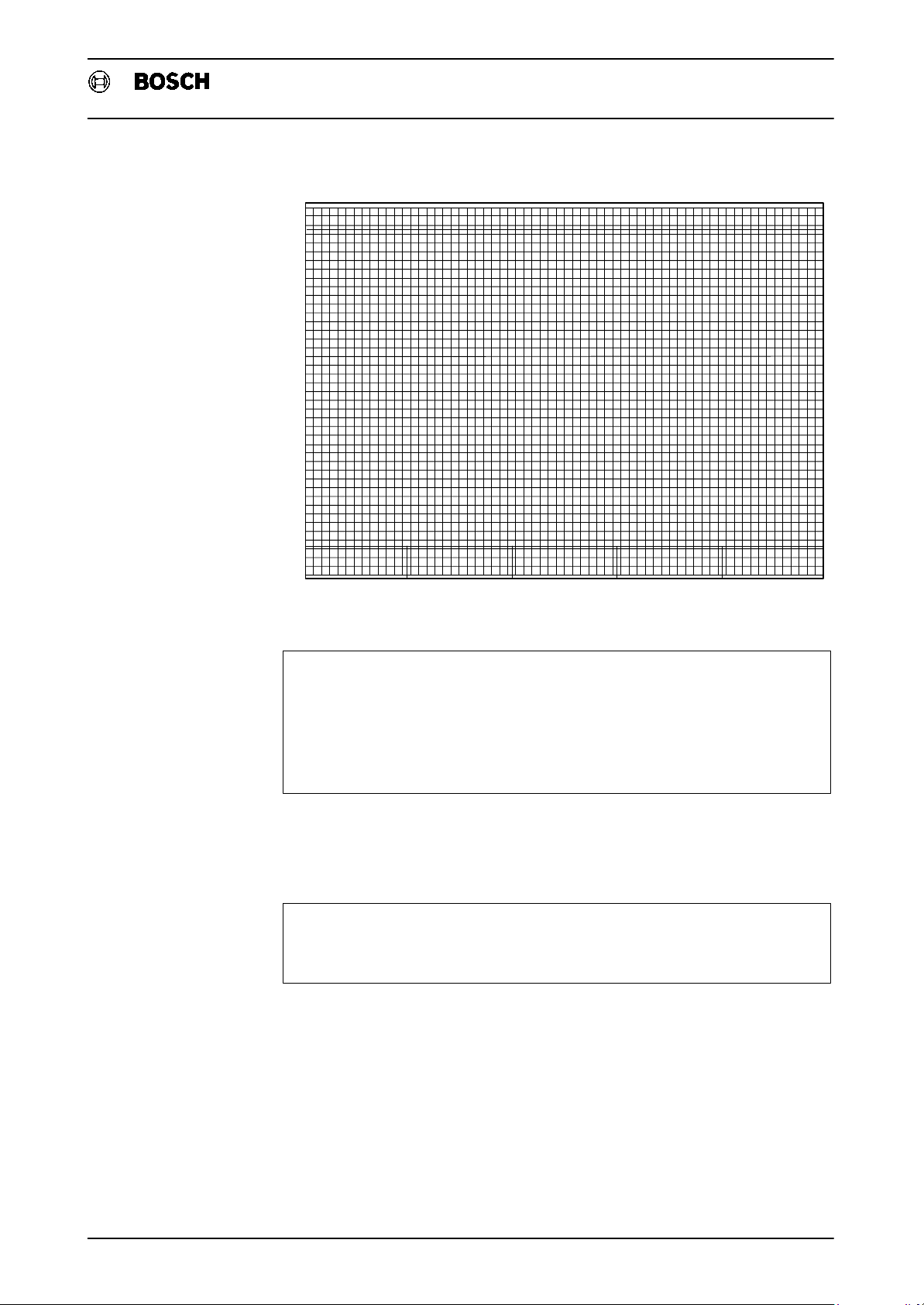

Variable group Variable name Variablen type

Instructions

local

global #

permanent

arrays max. 8 characters

@

max. 8 characters

max. 8 characters

1 − 50

REAL single−precision

REAL double−precision

!

BOOLEAN

?

STRING

$

INTEGER

%

% INTEGER

$ CHARACTER

REAL single−precision

% INTEGER

It is possible to assign values to local and global variables. This is done with the

equals symbol =".

Example: Value assignment for a BOOLEAN variable

START? = FALSE

value

assignment symbol

(logic) variable

Example: Value assignment for a REAL variable

X1MIN! = 2097.876

value (max. 7 digits)

assignment symbol

double−precision REAL variable

Example: Value assignment between variables

XSET = XMIN!

value (double−precision REAL variable)

assignment symbol

single−precision REAL variable

2 − 12

Page 22

Flexible Automation

2. Basic Elements

The variable to which a value is to be assigned must be on the left−hand side, and

the respective value on the right−hand side of the assignment symbol. This con

vention must be observed in particular if a variable value is to be assigned to

another variable.

CPL Programming Instructions

CC 220/320

NUL

If no value has been assigned to the variable #VARIABLE, it has the value NUL

(zero), i.e. the statement »#VARIABLE = NUL« is true. We can see here that the

equals symbol can also be contained in comparisons or conditions.

If a local or global variable is to be selectively deleted, this can be done by assign

ment of the value NUL (zero). A permanent variable cannot be deleted, it can only

be overwritten.

Example: Deleting a variable

Mathematical operations

In addition to the assignment of a value as a constant expression (digits) or as a

variable, the value of a CPL expression can also be assigned to a variable. Func

tions with constants and variables may be contained in a single CPL expression.

The simplest functions include the basic mathematical operations:

Addition » + «

Subtraction » − «

Multiplication » * «

Division » / «

The mathematic rule of multiplication and division before addition and subtraction

applies. In addition, it is possible to use brackets, whereby 7−fold nesting is pos

sible for simple expressions (without function calls).

Example:

XSET = NUL

XSET = 4/(100–I%)+XACTUAL

In addition, it is also possible to call mathematical functions which act on variables,

constants, or CPL expressions located directly after the respective instruction word

in round brackets. The function always refers to the internal numerical representa

tion of the initial value. This can be checked during program execution using the

"Debug" function. In the case of nested expressions, particularly with function

calls, attention must be paid to the maximum possible nesting depth which de

pends on the memory space required by the bracketed expressions during execu

tion.

2 − 13

Page 23

Flexible Automation

2. Basic Elements

CPL Programming Instructions

CC 220/320

SQRT

This function is used to form the square root of an initial value. The initial value must

not be negative, since negative values are not defined.

Example: SQRT

XSET = 4*SQRT(100+I%)

ABS

This function serves to supply the absolute value of the initial value, i.e. negative

values become positive, positive ones remain positive.

Example: ABS

XVALUE = 2 * SQRT(ABS(100+I%))

ROUND

This function converts the initial value into a whole number (INTEGER) by rounding

up or down, The initial value may be a REAL expression.

Example: ROUND

XVALUE% has the value 11

XVALUE% = ROUND(10.9)

!

INT

This function converts the initial value (REAL) into a whole number (INTEGER) by

cutting off the decimal places (rounding down). The initial value may be a constant

or variable.

Example: INT

XVALUE% has the value 10

XVALUE% = INT(10.9)

!

SIN, COS, TAN, ASIN, ACOS, ATAN

In the case of trigonometric functions, which process angles in degrees, it is expe

dient to identify the angles as double−precision REAL variables. 5 places are sig

nificant with single precision, and 12 places with double precision. The following

trigonometric functions can be used:

SIN

COS

TAN

Example:

sine function

–

cosine function

–

tangent function

–

2 − 14

ASIN

ACOS

ATAN

arc sine function

–

arc cosine function

–

arc tangent function

–

Page 24

Flexible Automation

Logic operations

2. Basic Elements

YVALUE! = SIN(ANGLE!)

CPL Programming Instructions

CC 220/320

Logic operations can be performed in binary form with logic variables and in deci

mal form with INTEGER variables. They can be represented with the usual logic

operation symbols, the »·« symbol and the »+« symbol (−not in CPL−), as shown

in the description of the binary operations below. Here, too, »multiplication and di

vision are performed before addition and subtraction«, i.e. the AND operation acts

before the OR operation. Up to 7−fold bracket nesting is possible.

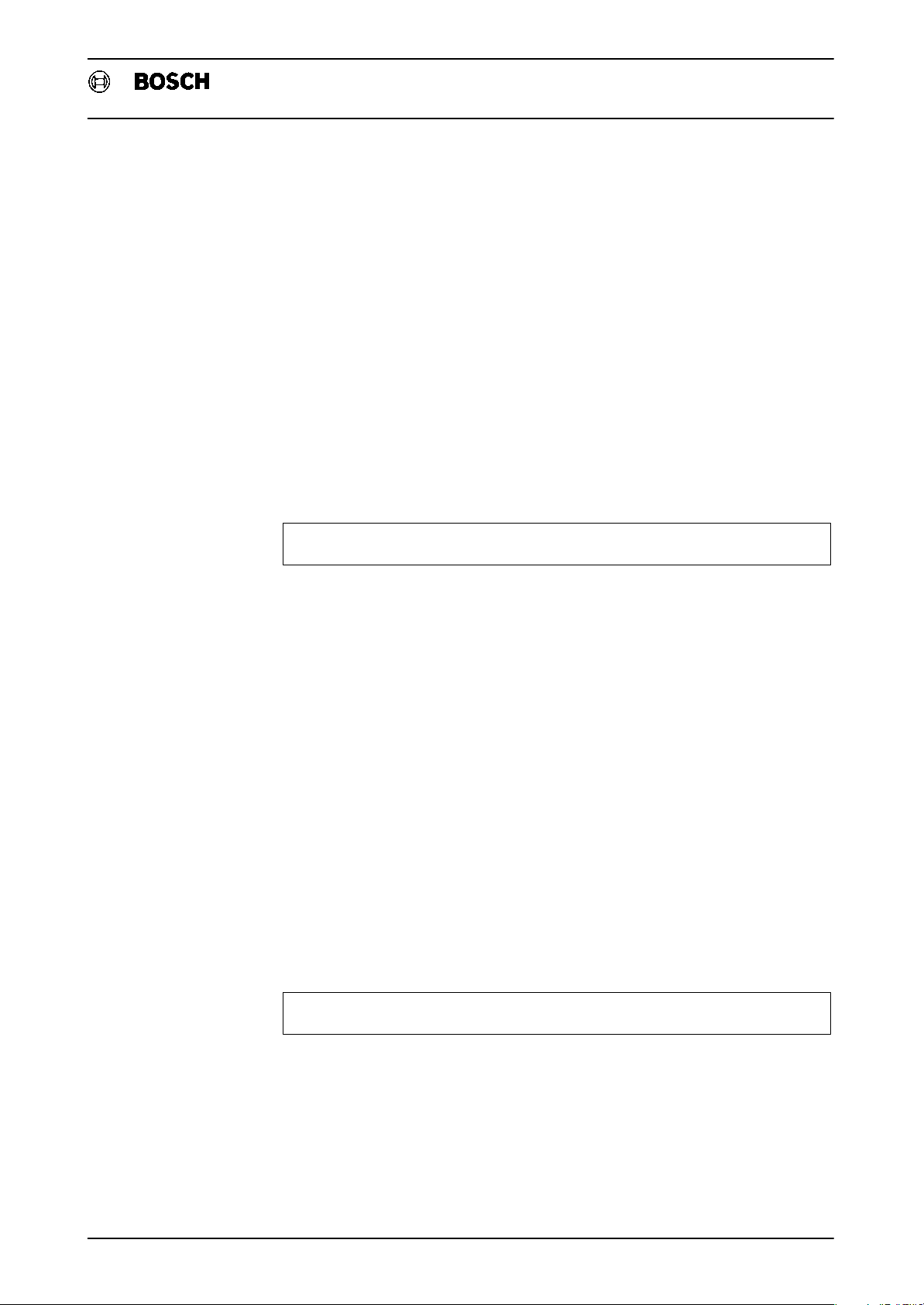

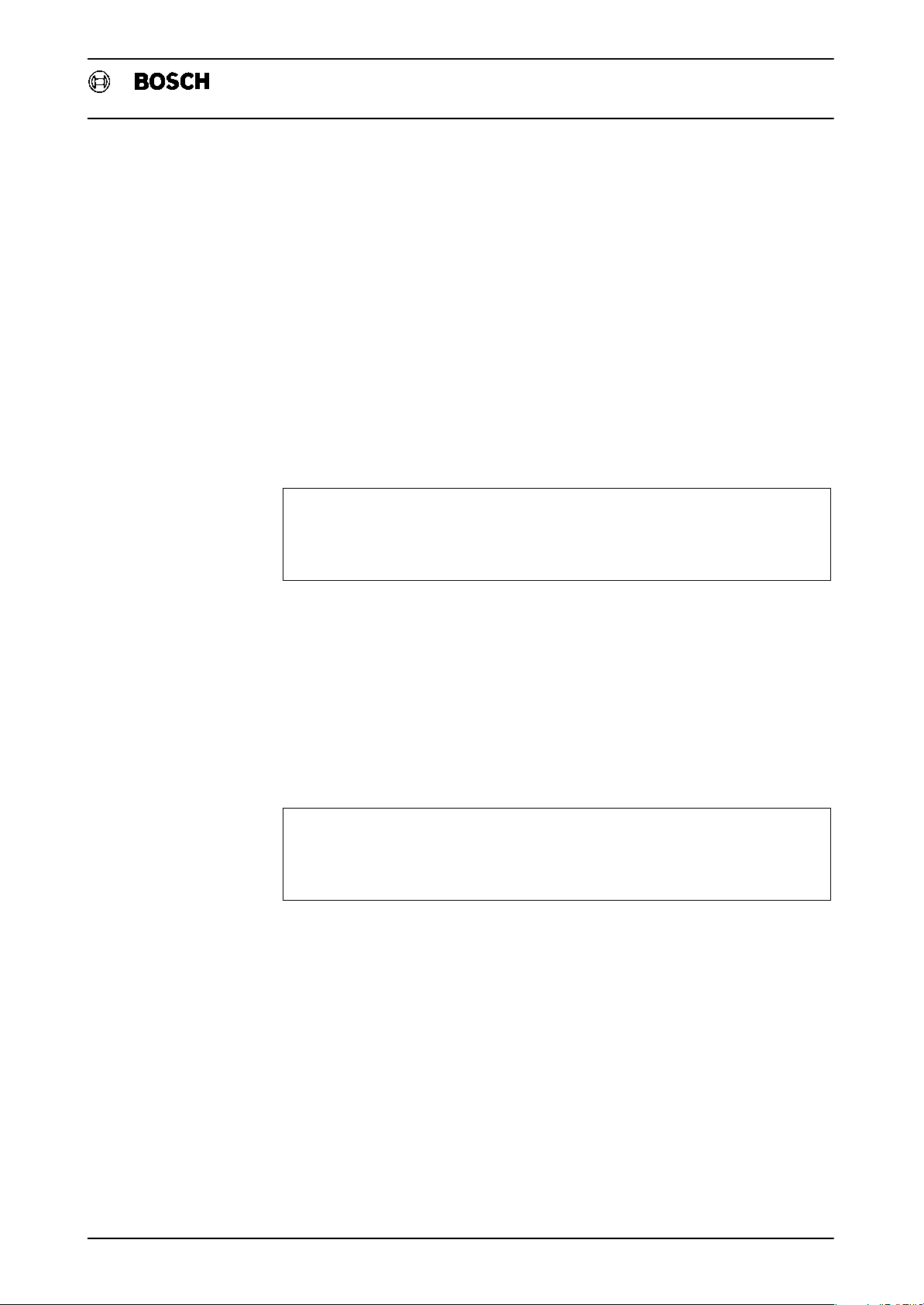

NOT, AND, OR, XOR

CPL provides four logic functions:

‘ the NOT function NOT ,

‘ the AND function AND ,

‘ the OR function OR

‘ and the EXCLUSIVE OR function XOR .

E1

E1

E2

A

1&>1=1

o− AA AA

NOT element AND element OR element XOR element

E1 = A E1 E1 + E2 = A E1

NOT AND OR XOR

0

−

L

E1 E1 E1

E2E2

.

E2 = A

0

L

−

0

0

L

0

0

0

L

0

L

0

L

L

0

0

L

0

L

0

E2

..

E2+E1 E2=A

L

L

0

0

L

L

L

0

L

L

L

0

L

0

L

0

0

L

Logic operations can be used for masking bits. Permanent variables are stored in

the dual−port memory area in the case of PLC coupling CC220/320−PC600 (refer

to respective manual). This area can also be addressed by the PLC. If certain signal

states are to be transferred from the PLC to the CC220/320, these can also be

coded in a permanent INTEGER variable. Logic operations are used in order to de

code these signal states again.

Example: Is bit 0 set in @20?

.

20 IF 20 AND 1 <> 0 THEN PRN#(0,”BIT 0 SET”)

30.ELSE PRN#(0,”BIT 0 NOT SET”) ENDIF

@

2 − 15

Page 25

Flexible Automation

Repeat instructions

2. Basic Elements

CPL Programming Instructions

CC 220/320

If one or more instructions − referred to as a "routine" in this manual − are to be

executed repeatedly under certain conditions, it is possible to program repeat in

structions. The repeated program run is also called a "loop".

REPEAT − UNTIL

If the loop abort condition is to be executed only after the routine has been exe

cuted for the first time, it is possible to say: "Repeat the routine until the condition is

satisfied !". The REPEAT loop thus has the following structure:

REPEAT <routine> UNTIL <condition>

Example: Programming a REPEAT loop

.

REPEAT

30

KEY%=INKEY

40

UNTIL KEY%=3

50

.

Wait loop until CTRL−C is pressed

WHILE − DO − END

If the abort condition is to be interrogated before the first loop run, the following de

scription would be possible: "While the condition is satisfied, do the routine!". The

WHILE loop is structured as follows:

WHILE <condition> DO <routine> END

Example: Programming a WHILE loop

.

WHILE IC(211)=TRUE DO

30

KEY%=INKEY

40

END

50

.

In both cases, the condition need not necessarily result directly from execution of

the routine, but may also be determined by the status of the interface signals or by

the changing value of a permanent variable. A condition may assume the state

»satisfied« or »not satisfied«. Interrogation for equality and inequality is permitted:

equals » = « greater than or equal to » >= « greater than » > «

not equal to » <> « less than or equal to » <= « less than » < «

Wait loop while interface 211 is high

2 − 16

Page 26

Flexible Automation

2. Basic Elements

CPL Programming Instructions

CC 220/320

FOR − STEP − TO − NEXT

If the abort condition is to result directly from routine execution, e.g., a tracking

counter is required which need not be programmed separately for the FOR−NEXT

loop. A counting variable (INTEGER) is defined whose initial and end counter val

ues must be specified. If the counting increment deviates from 1, the increment

(STEP) can be defined separately. The structure of a FOR−NEXT loop is as follows:

FOR <counting var.>=<initial value> [STEP <increment>] TO <end value>

<routine>

NEXT [<counting variable>]

Example: FOR−NEXT loop

.

FOR I%=1 TO 127

20

PRN#(1,”ORD.:”,I%,” CHAR.: ”,CHR$(I%))

30

NEXT I%

40

.

The characters with ordinal numbers 1 to 127 are written into a file. The ”I%" ap

pended to the ”NEXT” instruction in line 40 is only for clarity’s sake and can be

omitted.

It is also possible to program FOR−NEXT loops with variable step increments. The

step increment variable should be of the same variable type as the counting vari

able.

Example: FOR−NEXT loop with variable step increments

.

OPENW(1,”P222”,130,”TESTFILE”)

10

20

STEPNO%=2 : START%=1 : END%=3500 : NJUST

30

40

50

60

70

.

FOR COUNTER%=START% STEP STEPNO% TO END%

STEPNO%=ROUND(STEPNO%*SQRT(STEPNO%))

PRN#(1, ”COUNTER: ”,COUNTER%, ”INCREMENT: ”, STEPNO%)

NEXT

CLOSE(1)

The following is contained in the "Testfile" after execution of this program:

COUNTER: 1 INCREMENT: 3

COUNTER: 4 INCREMENT: 5

COUNTER: 9 INCREMENT: 11

COUNTER: 20 INCREMENT: 36

COUNTER: 56 INCREMENT: 216

COUNTER: 272 INCREMENT: 3175

COUNTER: 3447 INCREMENT: 178902

2 − 17

Page 27

Flexible Automation

Unconditional jump instruction

GOTO

Example: GOTO instruction

.

10

GOTO 120

.

10

GOTO N20

.

10.GOTO .DEST1

Unconditional program jumps are programmed with the GOTO instruction. A line

number, block number or label can be specified as the jump destination.

Label

2. Basic Elements

!

!

!

Jump to line 120

Jump to block N20

Jump to label .DEST1

CC 220/320

CPL Programming Instructions

A label can be written as a jump destination within a CPL block only. A label identi

fier consists of a space, decimal point and up to 8 significant ASCII characters,

whereby the first character must be a letter.

2 − 18

Page 28

Flexible Automation

Branch instruction

2. Basic Elements

CPL Programming Instructions

CC 220/320

IF − THEN − ELSE − ENDIF

A branch instruction can be formulated as follows:

If a certain condition is satisfied, then execute the routine, or else execute the other

routine!".

This results in the following instruction structure:

IF <condition> THEN <routine> [ELSE <alternative routine>] ENDIF

If the ELSE part is omitted, the program continues directly after the ENDIF instruc

tion in the event of non−satisfaction of the condition. Since a division in the pro

gram flow is involved in all cases with this instruction, it is called a branch. The

THEN and the ELSE routines are program branches which need not be processed

in all cases.

The condition is programmed in the same line as "IF". It is followed by "THEN" in

the same line.

Analogously to the abort conditions for the loop instructions, it is possible to use

arithmetic, trigonometric and logic operations in the condition of the IF instructions.

Nesting is also possible. The IF instruction can also be written without ELSE in

struction, however, it must always be terminated with an ENDIF instruction. Other

wise, the end of the routine or alternative routine will not be recognized. Since the

location of the ENDIF instruction depends on the program sequence logic, the

computer cannot always clearly recognize a missing ENDIF instruction. Mislead

ing error messages would occur in this case. The completeness of the IF instruc

tion must therefore be thoroughly verified by the programmer.

Example: Programming a loop with IF−THEN−ELSE−ENDIF

.

X = 1

10

.START

20

IF X>=100 THEN

30

40

50

60

70

90

.

.

ENDIF

.END

GOTO .END

ELSE X=X+2.75

GOTO .START

2 − 19

Page 29

Flexible Automation

2. Basic Elements

CC 220/320

CPL Programming Instructions

2 − 20

Page 30

Flexible Automation

3. Subroutines and Cycles

3. Subroutines and cycles

A subroutine call must always be contained in a separate block.

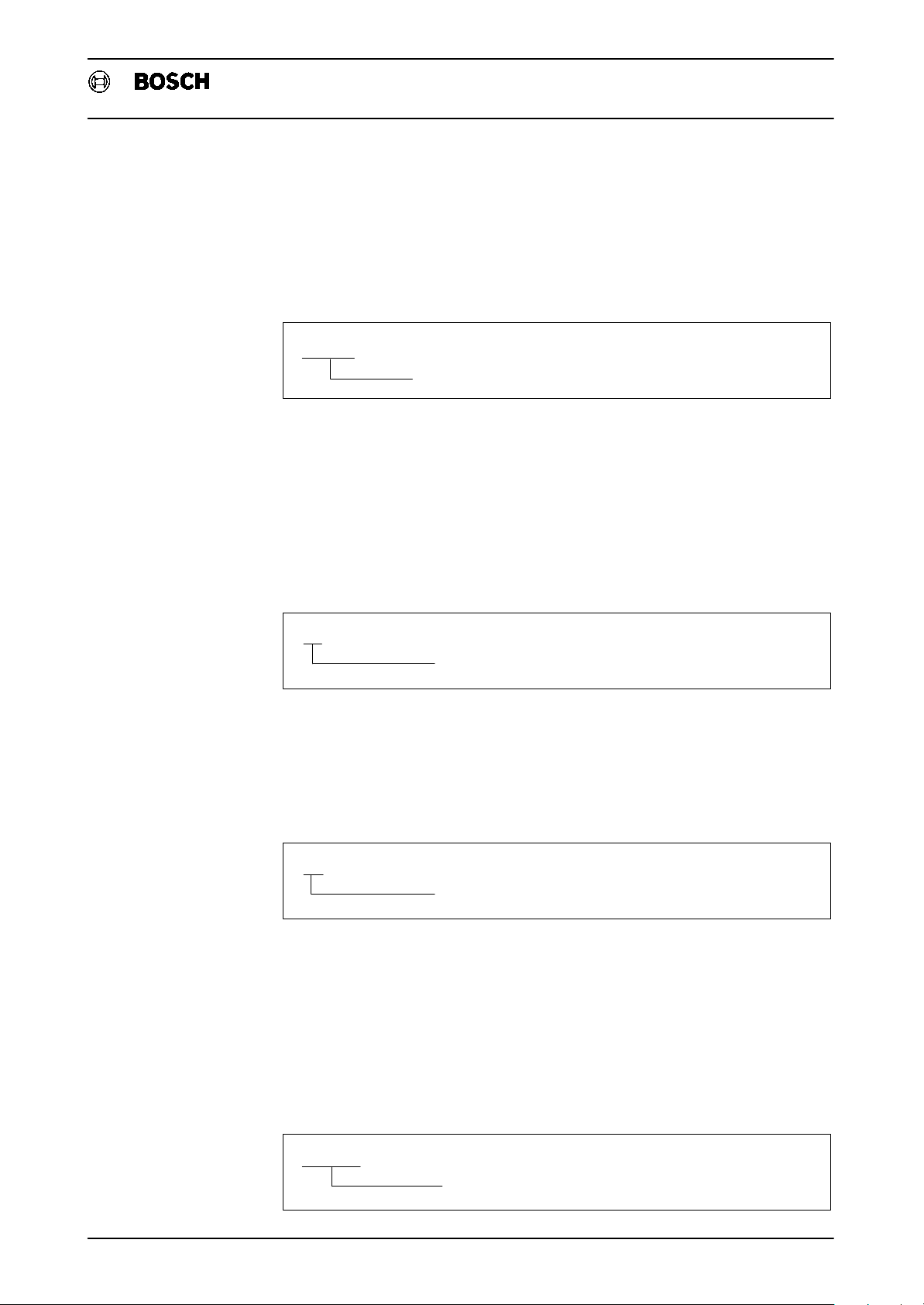

Calling subroutines with G, P or Q addresses

Pure CPL subroutines can be called from a DIN block via G22 or a P or Q address.

Refer to the Programming instructions P. − N o . 4219.

Up to 32 G functions can be defined in machine parameters P4000 to P4004 which

are then assigned to a specific part program number. It is also possible to deter

mine the number of parameters and a possible modal effect of the G function in this

definition. The modal effect of a G function is characterized by the fact that the part

program corresponding to the G function is called and executed after every NC

block containing an axis address.

Handling modal subroutine calls

CC 220/320

CPL Programming Instructions

The modal effect should be taken into account when calling other subroutines. It is

useful to cancel the modal effect by G80 before calling another modal G function in

order to avoid undesired superposition effects. It is necessary to distinguish be

tween subroutines executed from the part program memory and subroutines exe

cuted from the interface. Here are a few examples:

Examples: Modal subroutines executed from the part program memory

.

[

G81 1,2,3,4

N1

.

X100

N2

.

X110 P100

N3

.

X120 Q4711

N4

.

X130 G82 5,6,7

N5

.

X140 M321

N6

.

N7

G80

.

]

[

]

A modally active subroutine is pending

Positioning and execution of G81

Positioning and execution of G81 without execu

tion of subroutine 100

Positioning and execution of subroutine 4711 with

out execution of G81

Positioning and execution of G81 with subsequent

execution of G82

Positioning and execution of G81 without execu

tion of the subroutine call M321

The modal effect is canceled

3 − 1

Page 31

Flexible Automation

3. Subroutines and Cycles

Examples: Modal subroutines executed from the interface

.

G81 1,2,3,4

N1.

X100

N2

.

X110 P100

N3

.

X120 Q4711

N4

.

N5

X130 G82 5,6,7

.

N6

X140 M321

.

][

[]

Calling subroutines via any auxiliary or M functions

CC 220/320

CPL Programming Instructions

A modally active subroutine is pending

Positioning and execution of G81

Respective error messages:

RUNTIME ERROR 2140

MODAL SUBPRG.ACTIVE

A maximum of 16 M functions and 8 auxiliary functions can be defined via machine

parameters P4005 to P4009, i.e. they can be used for the assignment of addresses

and associated subroutines. M10, for example, can be used to call subroutine

P100. It is then only necessary to call the function in the main program in order to

execute the subroutine stored under that function.

Example: Calling a subroutine via an M function

.

X127 Y150 Z32 F2500

N20

M10

N30

N40

.

[20,2.3]

X110 Y120 Z0

Subroutine call with M function

with parameter transfer

Example: Calling a subroutine via any auxiliary function

.

X127 Y150 Z32 F2000

N20

B10

N30

N40

.

[20,2.3]

X110 Y120 Z0

Subroutine call by means of auxiliary

function with parameter transfer

CPL program execution parallel to machining time

The programs defined in machine parameter P4011 can be activated in the ,

, , modes and in the W.O.P . (workbench−oriented programming)

programming graphics by depressing the softkeys "PARAMETER IN DIALOG",

"CPL/DIALOG CALL", or "CYCLE". In turn, these programs can call other subrou

tines. Since the CPL programs started from the operating modes named above are

also executed simultaneously to a part program running in

possible to use any NC blocks in this case.

3 − 2

mode, it is not

Page 32

Flexible Automation

3. Subroutines and Cycles

Calling subroutines via the CALL function

CALL

Since NC blocks are not read when the CPL dialog is called in the above−named

operating modes, the CPL instruction CALL is required in order to call subroutines

in these modes. The CALL instruction must be located in a separate CPL block. The

keyword CALL is followed by the program number: this number may then be fol

lowed by parameters contained between square brackets..

Example: CALL instruction

.

50 IF A% = 1 THEN

5152CALL 999 2.75,X%,0

ENDIF

.

[]

CC 220/320

CPL Programming Instructions

Subroutine call with parameter transfer

The parameters transferred as a result of the subroutine call are initially always

called P1, P2, P3, etc. in accordance with the sequence of parameter transfer.

In subroutine P999, P1 thus has the value 2.75, P2 has the value of variable X% at

the time of parameter transfer, and P3 has the value 0. If P2 is to represent an IN

TEGER value in the subroutine as well, this may be done by appending a % symbol

to P2. This identification of the variable type is also possible analogously for the

other variable types.

Example: Parameter transfer in the subroutine

.

1 FACTOR=P1 : XVALUE%=P2% : COMPTAB%=P3%

11G1 X[XVALUE%*FACTOR]

G22 K[COMPTAB%]

.

3 − 3

Page 33

Flexible Automation

3. Subroutines and Cycles

CC 220/320

CPL Programming Instructions

3 − 4

Page 34

Flexible Automation

4. System functions

General

4. System Functions

CPL offers the possibility of accessing system data of the NC control. For some in

structions, however, the control used must have a bus link with the PC 600.

CPL Programming Instructions

CC 220/320

WAIT

WAIT(READY)

For some functions, it is necessary to stop block preparation and wait until the pre

vious blocks have been executed. This can be done by means of the ”WAIT” or

”WAIT(READY)” instructions. Both instructions have the same meaning. If the

control recognizes ”WAIT” or ”WAIT(READY)”, block preparation (max. 12

blocks) is stopped at this point until all blocks preceding ”WAIT” or

”WAIT(READY)” have been executed. Afterwards, block preparation continues

automatically. ”WAIT” or ”WAIT(READY)” only act in programs which were

started in the

WAIT(ACTIVE)

If, on the other hand, the system is to wait only until the previous NC block has been

prepared and is active − i.e. has not yet been executed − this can be achieved by

programming ”WAIT(ACTIVE)”. ”WAIT(ACTIVE)” also acts only in programs

which were started in the

WAIT([<IC condition>][,[<time>][,<result variable>]])

These parameters can be used in the following way:

If only one of the parameters is programmed, all commas on the left of the parame

ter must be used as dummies for non−programmed parameters. In contrast, there

must be no comma on the right of the last−programmed parameter.

Examples:

.

1 WAIT(,TIME%,E%) Application of parameters <time> and

.

1 WAIT(,TIME%) Application of parameter <time>

or modes. Otherwise, the instruction is skipped.

or modes.

<result variable>

If the parameters <IC condition> and <time> are used together, the following

blocks are not interpreted unless either the <IC condition> has been satisfied or

the <time> has elapsed.

4 − 1

Page 35

Flexible Automation

4. System Functions

CPL Programming Instructions

CC 220/320

The individual parameters are as follows:

The following syntax rule applies within the parameter <IC condition>:

[NOT] [(]IC(<number>)[)][= <status>]

<nummer> designates the bit number of a CNC input signal and can be an arbi

trary arithmetic expression, <status> is a BOOLEAN expression.

If <status> is omitted, the status of IC(<number>) is assumed as being TRUE.

The waiting time is specified in milliseconds in the parameter <time>. <time>

may be a whole−number arithmetic expression (INTEGER).

If the parameter <result variable> is used, the variable contained therein may be

interrogated with respect to the event which has occurred. This parameter can be

programmed only in conjunction with at least one of the other parameters.

The following variable values can be evaluated:

If the <result variable> variable has the value 0, the <IC condition> was already

satisfied when the call occurred.

If the <result variable> has the value 1, the <time> has elapsed.

If the <result variable> has the value 2, the interface signal has changed.

Example: WAIT

:

1 WAIT(IC(2)=TRUE)

:

1 WAIT(IC((A%+B%)*2)=(E1? OR E2?))

:

1 WAIT(NOT (IC(230)),,C%)

1 IF C%=0 THEN

1 DSP(10,10,”Cond. already satisf”)

1 ENDIF

:

1 WAIT(,TIME%,E%)

:

1 WAIT(IC(232)=E7?,250,ERG%)

1 IF ERG%=0 THEN

1 DSP(10,10,”Not waited!”):ENDIF

1 IF ERG%=2 THEN

1 DSP(10,10,”> 250 ms waited!”)

1 ENDIF

!

Wait until interface signal 2 is set.

!

Wait until the interface signal (A%+B%)*2 has

the value of the logic expression (E1? OR

E2?).

Wait until the interface signal 230 has the

!

value FALSE. The result variable C% supplies

either the value 0, if the condition was already

satisfied when the WAIT instruction was

called, or the value 2, if the condition was

satisfied during the wait.

Wait until the time TIME% has elapsed. The

!

result variable E% is assigned the value 1.

!

Wait until the interface signal 232 has the

value of variable E7? or 250 milliseconds

have elapsed. The value of the result variable

depends on the event which has satisfied the

condition.

4 − 2

Page 36

Flexible Automation

4. System Functions

CPL Programming Instructions

CC 220/320

Restrictions:

1. The WAIT function cannot be programmed with active cutter radius compensa

tion. If this restriction is not observed, the error message "TOO MANY BLOCKS

SUPPR." appears.