Bosch C 70 User Manual

Data Logger C 70

Manual

Version 1.1 26/09/2019

Content

Content

1 Onboard Network Concept............................................................................................................................................ 4

2 Communication channels............................................................................................................................................... 5

3 Preparation...................................................................................................................................................................... 6

4 Power Supply .................................................................................................................................................................. 7

5 Analog and Frequency Inputs ....................................................................................................................................... 8

5.1 Analog inputs......................................................................................................................................................................................................... 8

5.2 Configuring inputs ............................................................................................................................................................................................... 9

5.3 Configuring computed sources ...................................................................................................................................................................... 23

5.4 Hysteresis................................................................................................................................................................................................................. 24

6 Online Measurement ...................................................................................................................................................... 28

6.1 Setting up an online measurement............................................................................................................................................................... 28

6.2 Online calibration of measurement channels............................................................................................................................................ 33

6.3 Online calibration of multipoint adjustment channels .......................................................................................................................... 35

7 Error Memory .................................................................................................................................................................. 37

7.1 Error memory representation in RaceCon .................................................................................................................................................. 37

7.2 Information on errors available from the error memory ...................................................................................................................... 39

7.3 Analog Input Diagnosis...................................................................................................................................................................................... 43

8 Technical Data................................................................................................................................................................. 45

9 Disposal............................................................................................................................................................................ 49

10 Mechanical Drawing ....................................................................................................................................................... 50

11 Starting up....................................................................................................................................................................... 51

11.1 Before starting ....................................................................................................................................................................................................... 51

11.2 Feature activation................................................................................................................................................................................................. 55

11.3 First recording (Quick Start) ............................................................................................................................................................................. 57

11.4 Set time and date ................................................................................................................................................................................................. 60

12 CAN Bus ........................................................................................................................................................................... 62

12.1 CAN bus trivia ........................................................................................................................................................................................................ 62

12.2 CAN input................................................................................................................................................................................................................ 63

12.3 CAN output............................................................................................................................................................................................................. 68

12.4 Multiplexer .............................................................................................................................................................................................................. 70

13 Recording......................................................................................................................................................................... 73

13.1 Features.................................................................................................................................................................................................................... 73

13.2 Configuration of recordings............................................................................................................................................................................. 73

13.3 Recording data on USB device........................................................................................................................................................................ 78

14 Lap Trigger ...................................................................................................................................................................... 83

14.1 Lap trigger (timing beacon).............................................................................................................................................................................. 83

14.2 Counting outing/laps/fragments ................................................................................................................................................................... 90

14.3 Lap timing................................................................................................................................................................................................................ 91

14.4 Segment timing..................................................................................................................................................................................................... 93

14.5 Countdown timer ................................................................................................................................................................................................. 94

ii/112 Data Logger C 70 Manual Bosch Motorsport

Content

15 Predated Laptime............................................................................................................................................................ 95

15.1 Setting up the predated laptime.................................................................................................................................................................... 95

15.2 Functionality and channel outputs ................................................................................................................................................................ 95

16 GPS Sensor....................................................................................................................................................................... 96

16.1 GPS (Global Positioning System).................................................................................................................................................................... 96

16.2 Protocol.................................................................................................................................................................................................................... 96

16.3 Sensor recommendation ................................................................................................................................................................................... 96

16.4 Measurement labels ............................................................................................................................................................................................ 99

16.5 GPS troubleshooting........................................................................................................................................................................................... 100

17 Firmware .......................................................................................................................................................................... 102

17.1 Firmware and configuration............................................................................................................................................................................. 102

17.2 Firmware update................................................................................................................................................................................................... 102

18 Cloning the Unit.............................................................................................................................................................. 105

19 Fuel Consumption Calculation ...................................................................................................................................... 107

19.1 Setting up fuel consumption calculation and tank management..................................................................................................... 107

19.2 Fuel consumption diagnosis/counter reset................................................................................................................................................ 108

19.3 Example .................................................................................................................................................................................................................... 109

20 RaceCon Shortcuts.......................................................................................................................................................... 110

Bosch Motorsport Data Logger C 70 Manual iii/112

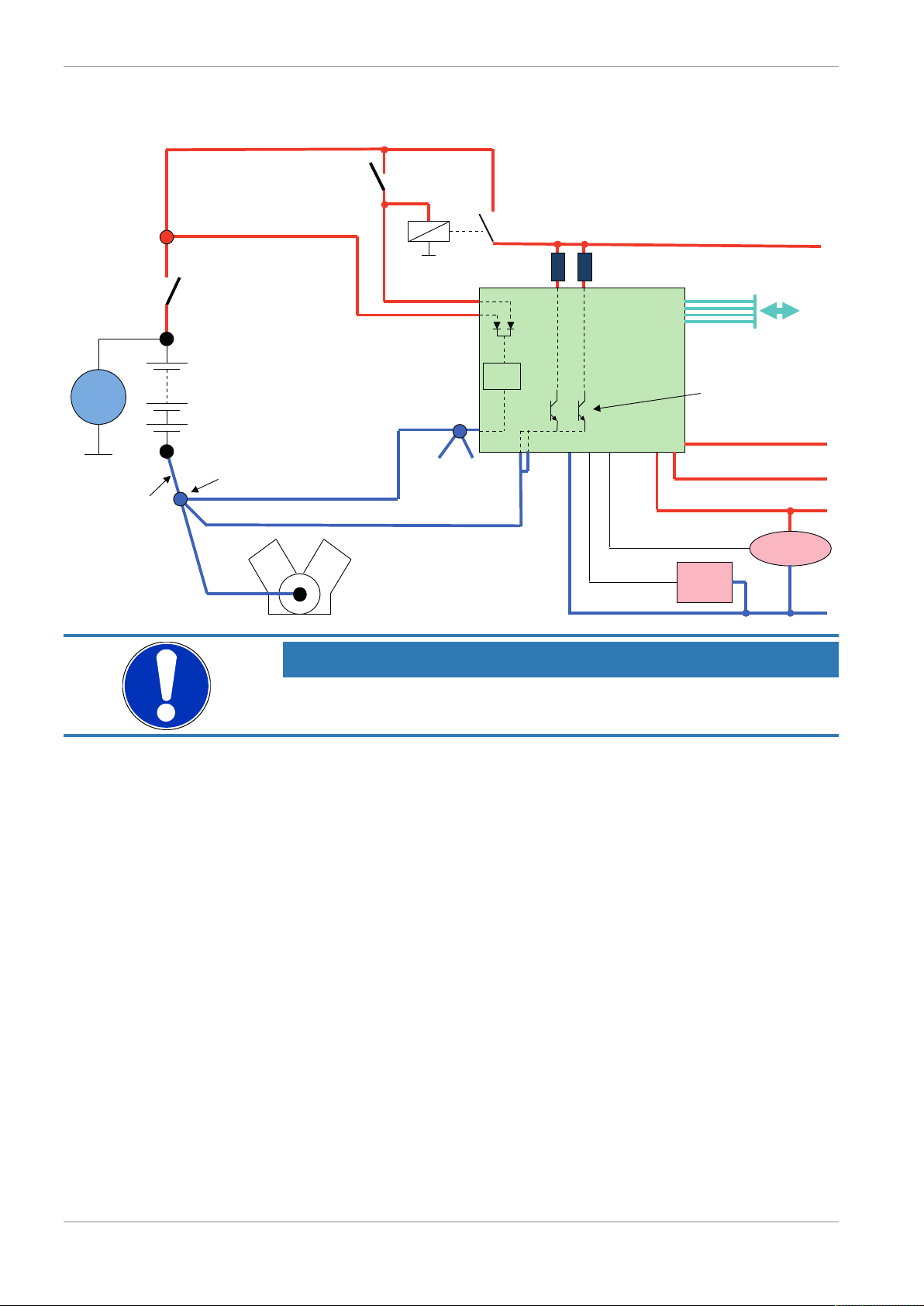

1 | Onboard Network Concept

G

Engine_GND

GND_Starpoint

Chassis

KL31

LS_GND_1

LS_GND_2

Main

Switch

UBAT

Star connection

(term30)

positive terminal

Electric Loads

IGN-

Switch

KL15

SENSPWR5

SENSGND

active

Sensor

ANA_IN(xx)

NTC

Sensor

ANA_IN(xy)

switched pos. terminal

Star connection

dig. sensors

(e.g. wheelspeed)

µC

As short as

possible

SENSPWR10

UBATT_FUSE

KL30

LS_SWITCH1…4

Bosch Motorsport

diagnosis connector

PC

Device

1 Onboard Network Concept

NOTICE

This schematic is not device specific, please see the section “Technical Data for the specifications of your device.

4/112 Data Logger C 70 Manual Bosch Motorsport

Communication channels | 2

2 Communication channels

CAN bus

The C 70 has two CAN buses configurable as input and output. Different baud rates are

selectable. Please note that the C 70 does not contain any CAN termination resistors. Thus

the CAN termination resistors need to be integrated into the wiring loom.

Ethernet channels

The C 70 has one 100 MBit full duplex Ethernet communication ports. The port is internally connected with an Ethernet switch. The Ethernet ports have 'cable auto crossover'

functionality.

RS232 ports

The C 70 has two RS232 serial ports. Baud rate for both ports is programmable. RS232

port 1 is reserved for online telemetry, port 2 can be used for reception of data from a

serial GPS receiver.

Vehicle diagnosis connector

The Bosch Motorsport vehicle diagnosis connector is used as a standard interface to connect the vehicle to a PC e.g. via a MSA-Box II. Loom connector: AS0-12-35SN

Pin Name Description Used for C 70

Pin 1 Terminal 30 Permanent positive +

Pin 2 Terminal 15 Switched positive +

Pin 3 Terminal 31 GND +

Pin 4 CAN High Diagnostic CAN bus

Pin 16 CAN Low Diagnostic CAN bus

Pin 10 K-Line ECU diagnosis

Pin 8 Ethernet RxD + Ethernet interface +

Pin 9 Ethernet RxD - Ethernet interface +

Pin 11 Ethernet TxD + Ethernet interface +

Pin 12 Ethernet TxD - Ethernet interface +

Pin 22 Screen Cable screen +

Bosch Motorsport Data Logger C 70 Manual 5/112

3 | Preparation

3 Preparation

Use the C 70 only as intended in this manual. Any maintenance or repair must be performed by authorized and qualified personnel approved by Bosch Motorsport.

Operation of the C 70 is only certified with the combinations and accessories that are specified in this manual. The use of variant combinations, accessories, and other devices outside the scope of this manual are only permitted when they have been determined to be

compliant from a performance and safety standpoint by a representative from Bosch

Motorsport.

Read the manual carefully and follow the application hints step by step. Do not hesitate to

contact us, contact data can be found on the last page of this document.

Important information on Electromagnetic Conformity

To avoid unwanted interference with the environment (people, animals, electronic devices)

or unwanted harm to the environment, it is mandatory that the user of the C 70 carries

out an appropriate analysis to determine the electromagnetic interaction the C 70 may

have with its individual installation environment.

Disclaimer

Due to continuous enhancements, we reserve the rights to change any illustrations, photos and technical data within this manual.

Please retain this manual for your records.

NOTICE

In this document, all screenshots are created by way of example for a

display. Please consider this and replace the product names with the

name of your device.

6/112 Data Logger C 70 Manual Bosch Motorsport

4 Power Supply

Please ensure that you have a good ground installation. That means:

– A ground that has a solid, low resistance connection to the negative battery terminal

– Connection should be free from dirt, grease, paint, anodizing, etc.

– Use large diameter wire

– More metal-to-metal contact is better!

The following notations for power signals are used:

– KL 15 is a switched battery rail controlled by the IGN-switch

– KL 30 is an unswitched battery positive rail (same as battery positive terminal)

– KL 31 is an unswitched ground rail (same as battery negative terminal)

Be careful to observe current limits of wires and connector pins!

Power Supply | 4

Bosch Motorsport Data Logger C 70 Manual 7/112

5 | Analog and Frequency Inputs

5 Analog and Frequency Inputs

Analog inputs

– 0 to 5 V

– 12 bit A/D converter

– Switchable 3.01 kOhm pull-up resistor

– 10 kHz acquisition rate, up to 1 kHz recording rate

– Linear phase digital filter

Frequency inputs

– 5 V Hall-effect type, 2.5 V trigger level (DF11 input with current interface or 5VHall-

effect input with 2.5 V trigger level)

– 20 kHz max. frequency

– 10 ms measurement window

5.1 Analog inputs

5.1.1 Measurements channels

For each analog channel, several ‘subchannels’ are available.

Measurement labels with the characters ‘raw’ show the exact values in mV.

Measurement labels with the characters ‘_fi’ show filtered values.

The word ‘name’ in the table is a placeholder for the channel’s name.

Measurement label Function

raw_name mV value of sensor

raw_name_fi Filtered mV value of sensor

name Physical value of sensor

name_fi Filtered physical value

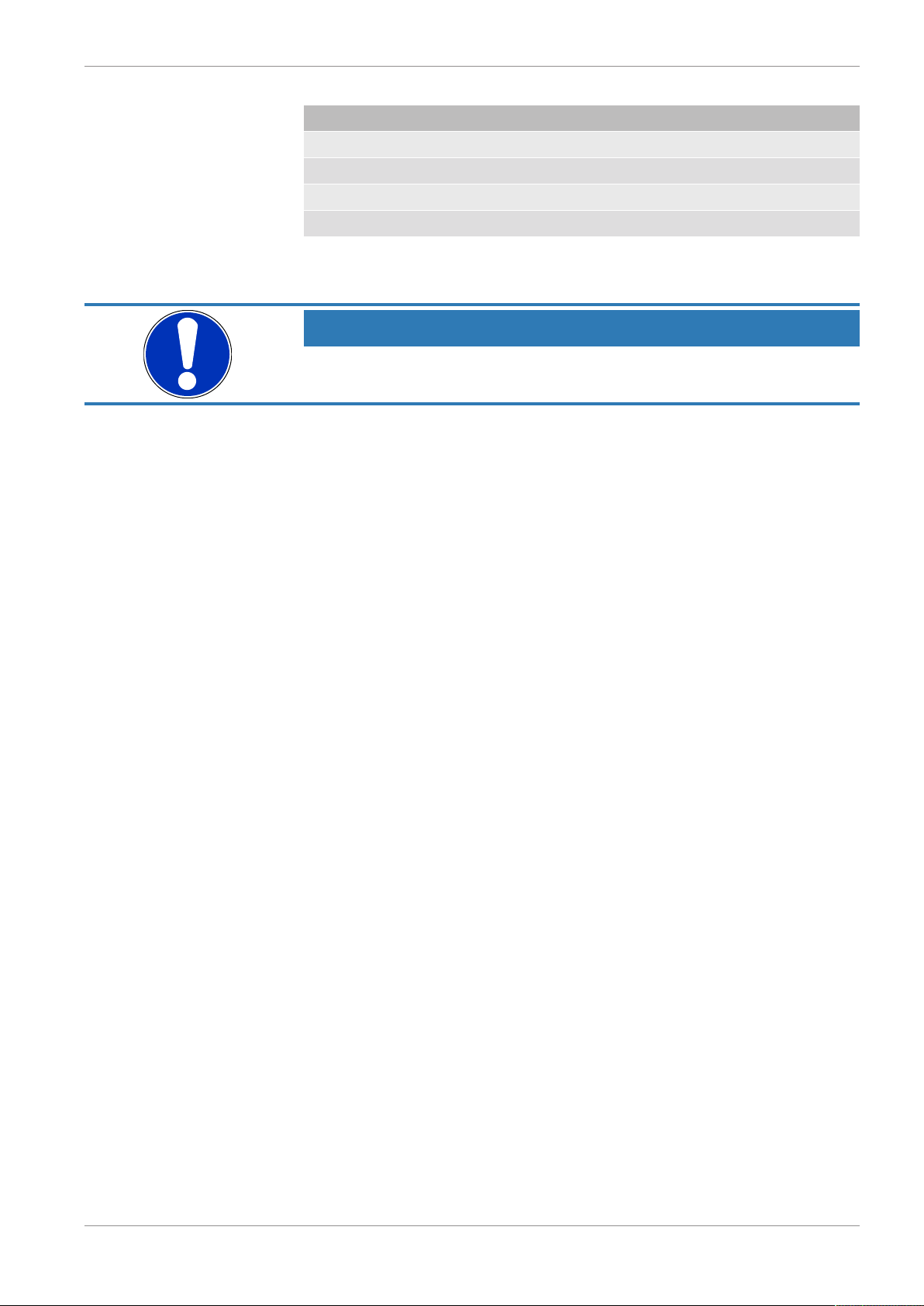

Filtered channels are routed through digital low pass filters:

– C 70 uses A/D converter oversampling and digital filtering to recording rate

– Digital filters eliminate ‘out-of-band’ noise

– Cut-off frequency automatically adjusted to recording rate

– Linear phase – no signal distortion

– Latency compensation – no filter delay in recorded data

8/112 Data Logger C 70 Manual Bosch Motorsport

Analog and Frequency Inputs | 5

Drag + Drop

5.2 Configuring inputs

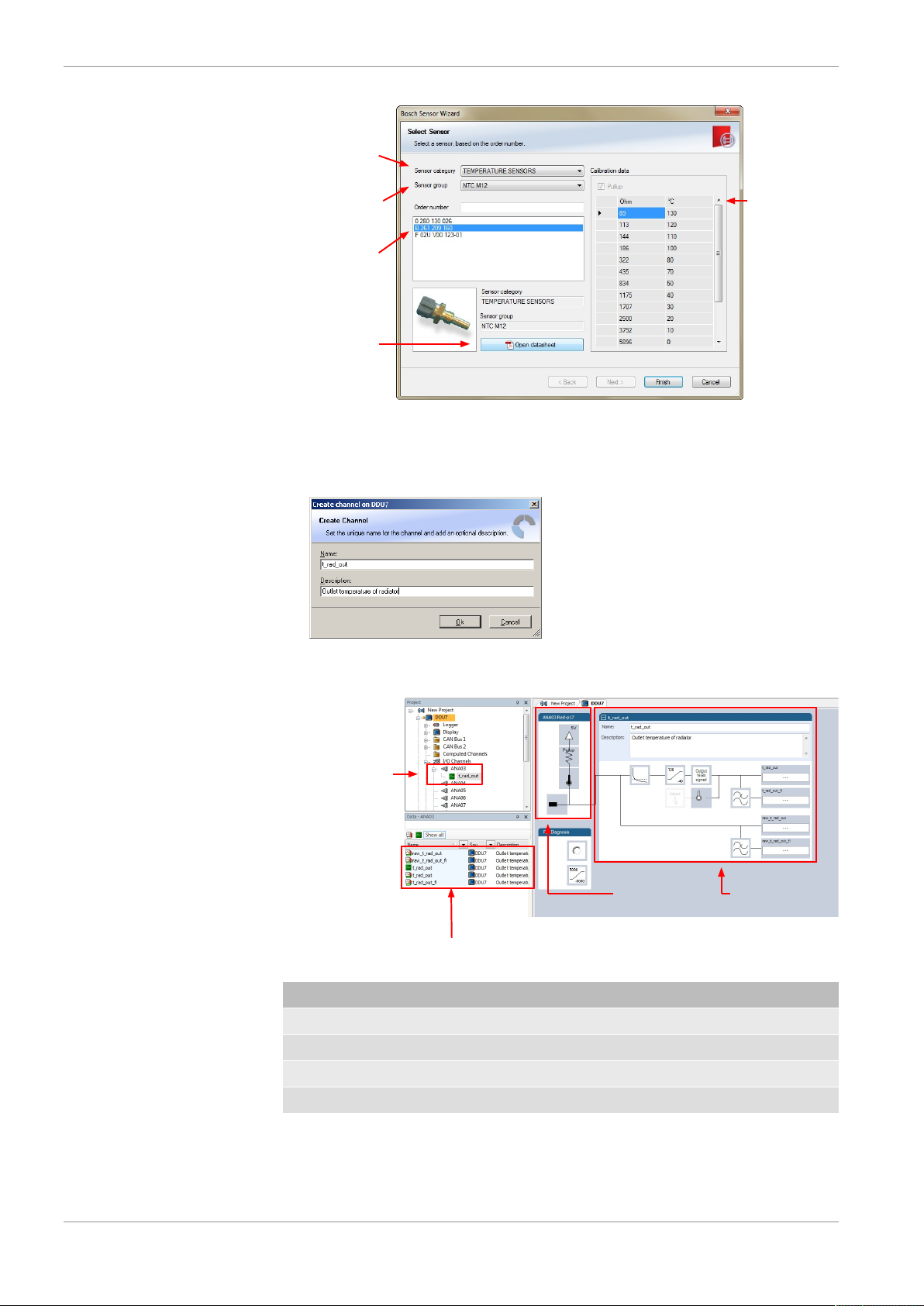

5.2.1 Configuring a predefined Bosch sensor with the 'Bosch Sensor Wizard'

1. Click on ‘Measurement Sources’ in the Toolbox.

2. To expand the list of ‘I/O Channels’, click on ‘+’ in the C 70 Project Tree.

3. Drag the “Bosch Sensor Wizard” from the Toolbox and drop it on the desired analog

input channel in the C 70 Project Tree.

The “Bosch Sensor Wizard” opens.

Bosch Motorsport Data Logger C 70 Manual 9/112

5 | Analog and Frequency Inputs

1st: Choose the

sensor´s category

2nd: To narrow your

choice, choose a

type

3rd: Select the

exact type

Opens sensor´s

datasheet

These calibration

values will be used

Channel is linked

to ANA03

Input pin Pull-up

resistor is activated

Calculation of

physical value with

characteristic curve

4. Click ‘Finish’ when done.

The “Create channel” window opens.

5. Enter the channel name and description.

6. Click ‘Ok’ when done.

The channel is inserted into the C 70 Project Tree.

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi Filtered mV value of sensor

name Physical value of sensor

name_fi Filtered physical value

10/112 Data Logger C 70 Manual Bosch Motorsport

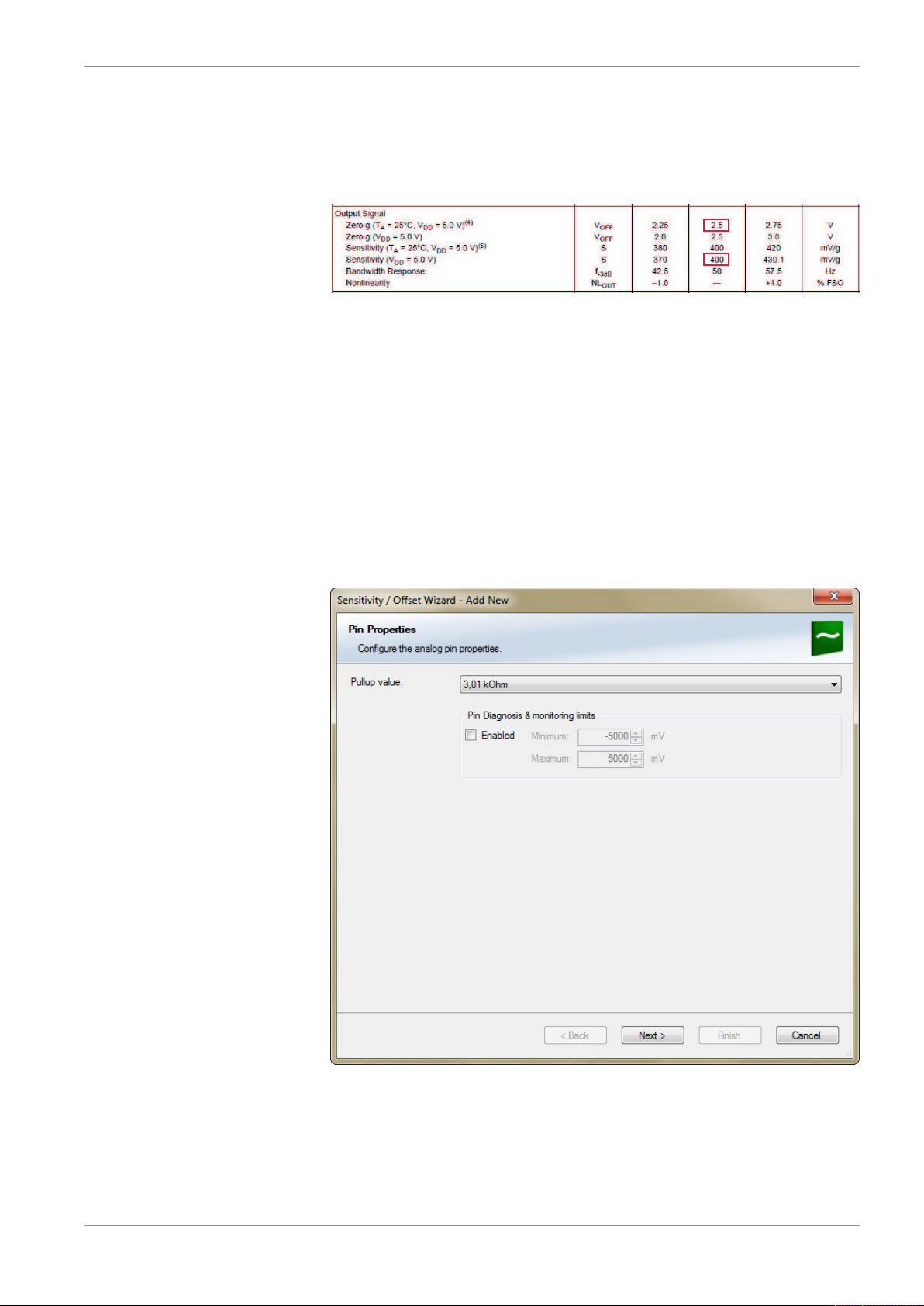

5.2.2 Configuring a generic linear sensor

Example: Acceleration sensor 5 g

– From sensor data sheet - operating characteristics:

– Sensitivity 400 mV/g, Offset 2,500 mV

– The sensor has a linear output signal with sensitivity and offset

1. Click on ‘Measurement Sources’ in the Toolbox.

2. To expand the list of ‘I/O Channels’, click on ‘+’ in the C 70 Project Tree.

3. Drag the “Sensitivity/Offset” analog signal source from the Toolbox and drop it on the

desired analog input channel in the C 70 Project Tree. A “Sensitivity/Offset Wizard”

opens.

Analog and Frequency Inputs | 5

4. To activate the internal pullup-resistor, check the box. The internal pullup-resistor is

used to get a 5 V signal at the analog channel of the C 70. It allows you to use a pushbutton. The fixed value of the internal pullup-resistor is 3,010 Ohm. If using an additional external pullup-resistor, set up the overall resistance.

5. Click ‘Next’ when done.

The second part of the “Sensitivity/Offset Wizard” opens.

Bosch Motorsport Data Logger C 70 Manual 11/112

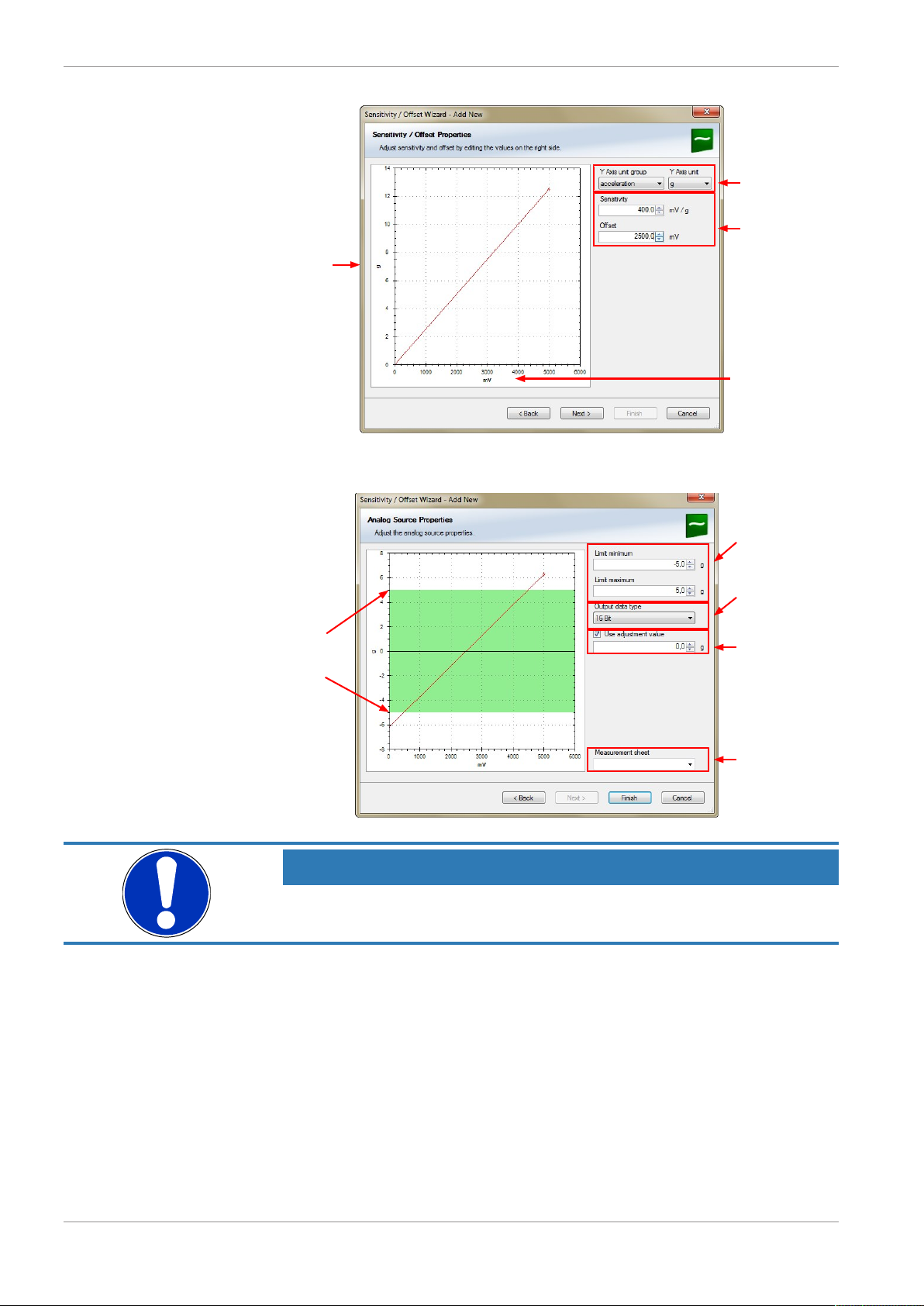

5 | Analog and Frequency Inputs

Physical

(channel)

value

Choose unit

group and unit of

physical value

Enter values from

sensor datasheet

Electrical (pin) value

Physical limits

of channel

Enter physical

limits of the sensor

Choose data type

of the measurement

variable

Check box to enable

online calibration of

offset and enter

desired physical

offset value

Enter name to

automatically create

a new measurement

sheet

6. Click ‘Next’ when done.

The third part of the “Sensitivity/Offset Wizard” opens.

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement [}28]’.

7. Click ‘Finish’ when done.

8. Enter a channel name and a description.

9. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

12/112 Data Logger C 70 Manual Bosch Motorsport

Analog and Frequency Inputs | 5

Input pin Pull-up

resistor is

activated

Sensivity and

Offset value

for sensor

Adjustment

is enabled

Channel is linked

to ANA04

Pin Diagnosis

Name and

Description

editable

Pin

Thermistor

+5V

3 kOhm

Available measurements for channel:

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

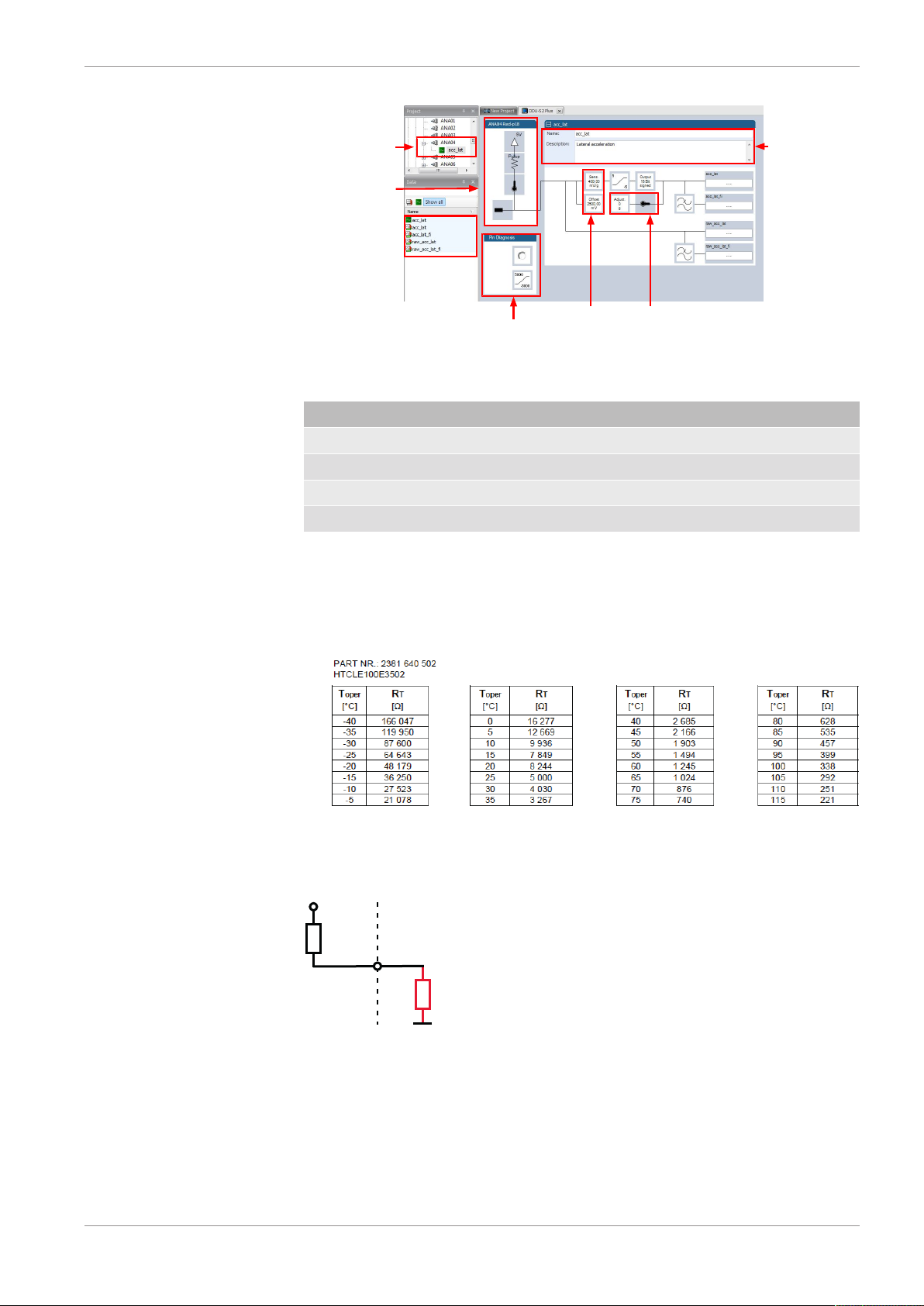

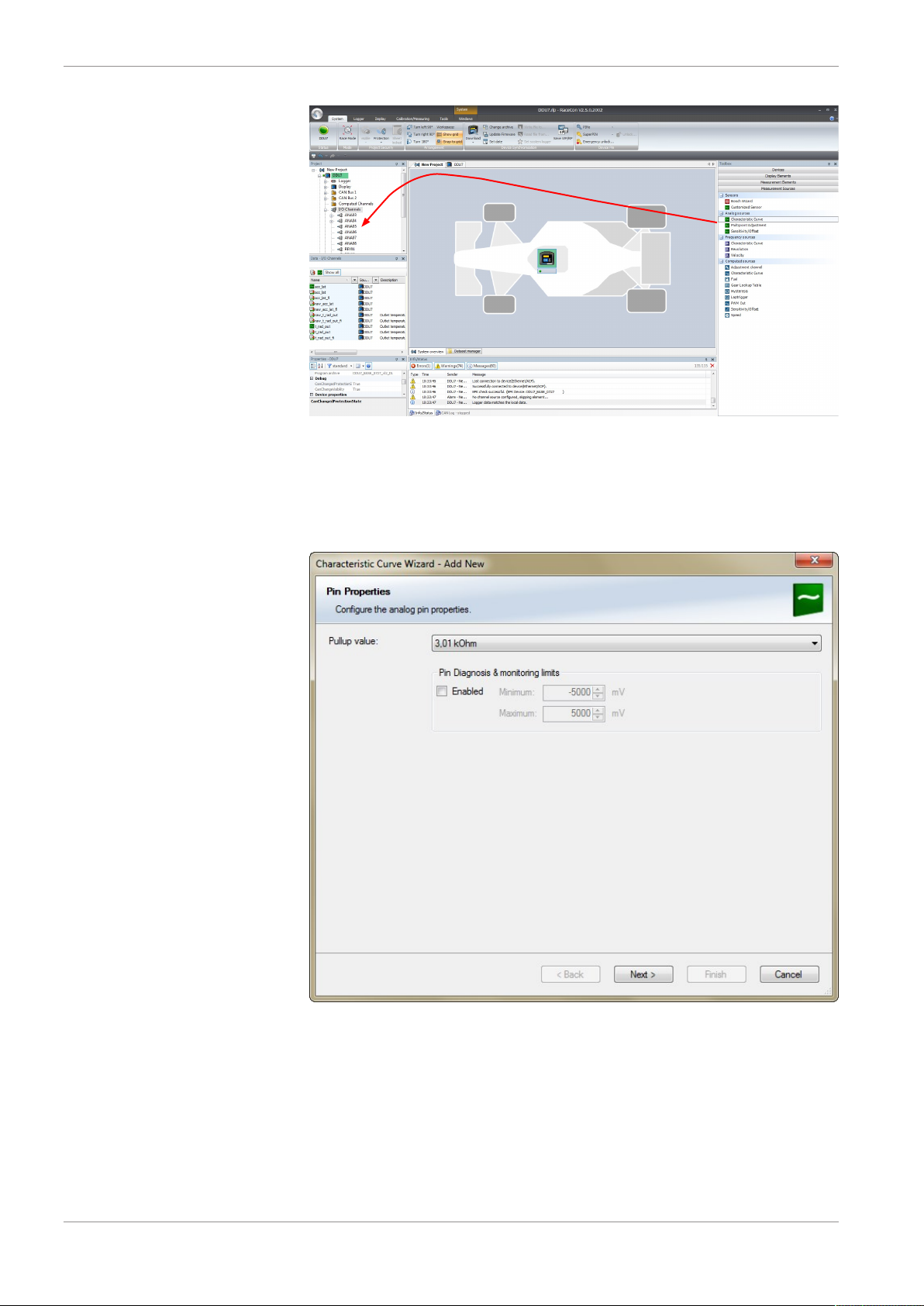

5.2.3 Configuring a generic nonlinear sensor

Example: Thermistor 5 kOhm

– From sensor data sheet - resistance values over temperature:

– The sensor has a nonlinear behavior

– Use characteristic curve for linearization

– Input voltage is the ratio between pull-up resistor and thermistor

1. Click ‘Measurement Sources’ in the Toolbox.

2. To expand the list of ‘I/O Channels’, click on ‘+’ in the C 70 Project Tree.

3. Drag the “Characteristic Curve” analogue signal source from the Toolbox and drop it

on the desired analogue input channel in the C 70 Project Tree.

Bosch Motorsport Data Logger C 70 Manual 13/112

5 | Analog and Frequency Inputs

Drag + Drop

A “Characteristic Curve Wizard” opens.

4. To activate the internal pull up-resistor, check the box. The C 70 pull up-resistor is

used to get a 5 V signal at the analogue channel of the C 70. It allows you, to use a

push-button. The fixed value of the internal pull up-resistor is 3,010 Ohm. If using an

additional external pull up-resistor, set up the overall resistance.

5. Click ‘Next’ when done.

The second part of the “Sensitivity/Offset Wizard” opens.

14/112 Data Logger C 70 Manual Bosch Motorsport

Physical

(channel)

value

Choose 'Ohm' to

enter datasheet

values directly.

Select physical

unit.

Enter resistance/

temperature pairs

from sensor datasheet here (the

3.01 kOhm pullupresistor is automatically taken

into account)

6. Click ‘Next’ when done.

Physical

limits of

channel

Enter physical limits

of the channel

Choose data type of

the measurement

variable

This sensor does not

need offset

calibration

Enter name to automatically create a

new measurement

sheet

Channel is linked

to ANA05

Input pin Pull-up

resistor is activated

Characteristic

curve for sensor

Adjustment

is disabled

The third part of the “Characteristic Curve Wizard” opens.

Analog and Frequency Inputs | 5

7. Click ‘Finish’ when done.

8. Enter channel name and description.

9. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

Available measurements for channel:

Bosch Motorsport Data Logger C 70 Manual 15/112

5 | Analog and Frequency Inputs

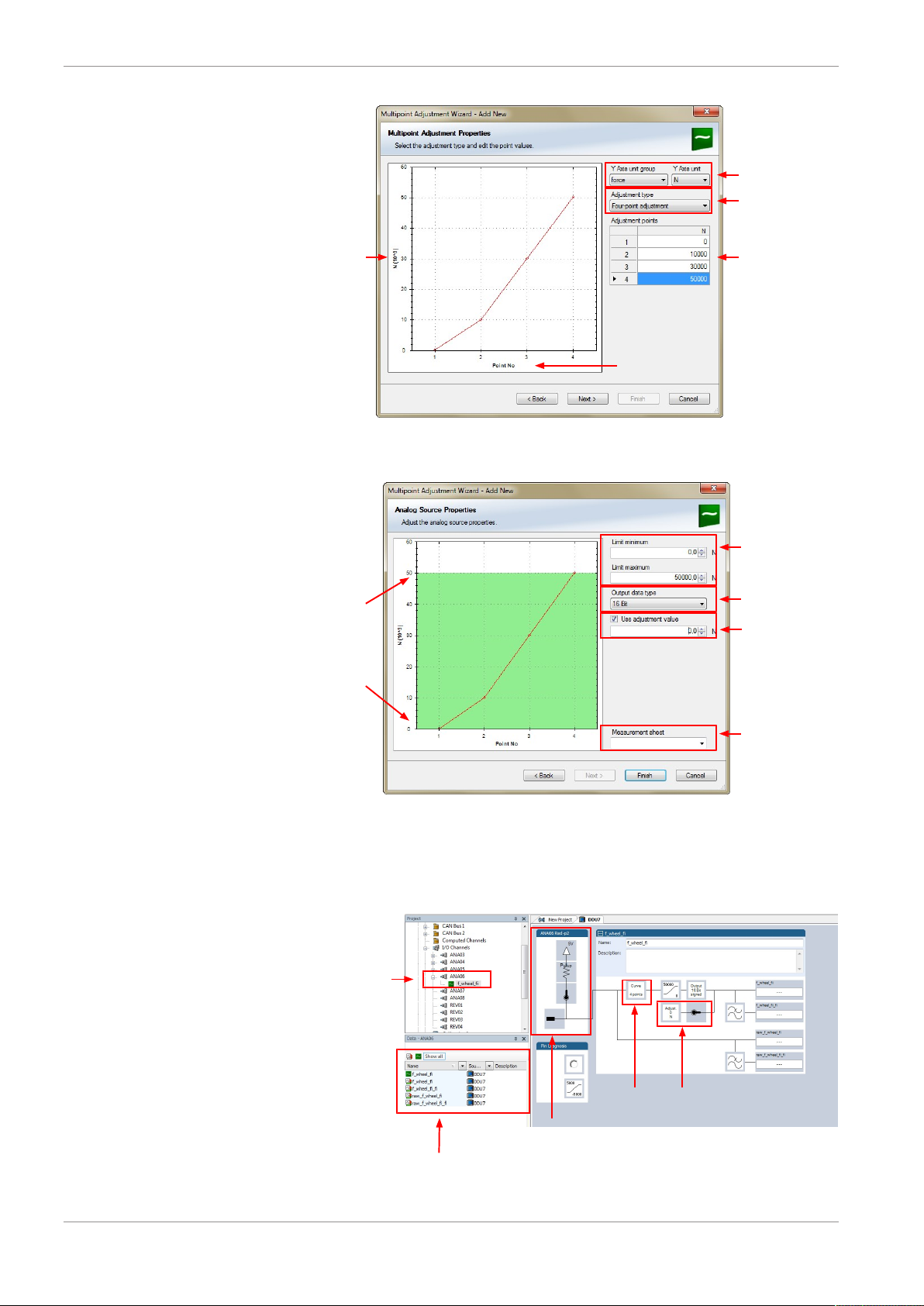

5.2.4 Configuring a multipoint adjustment

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement [}28]’.

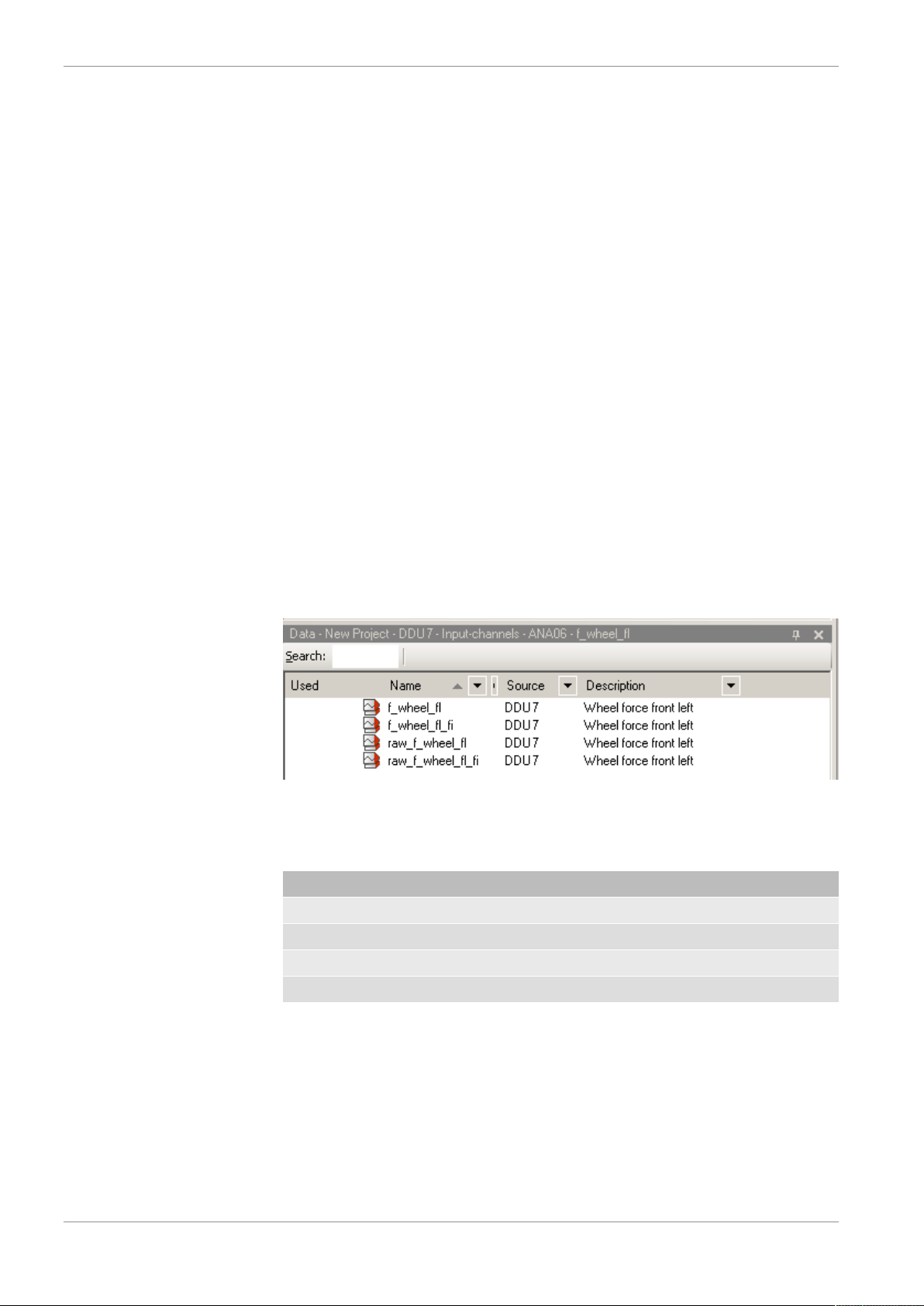

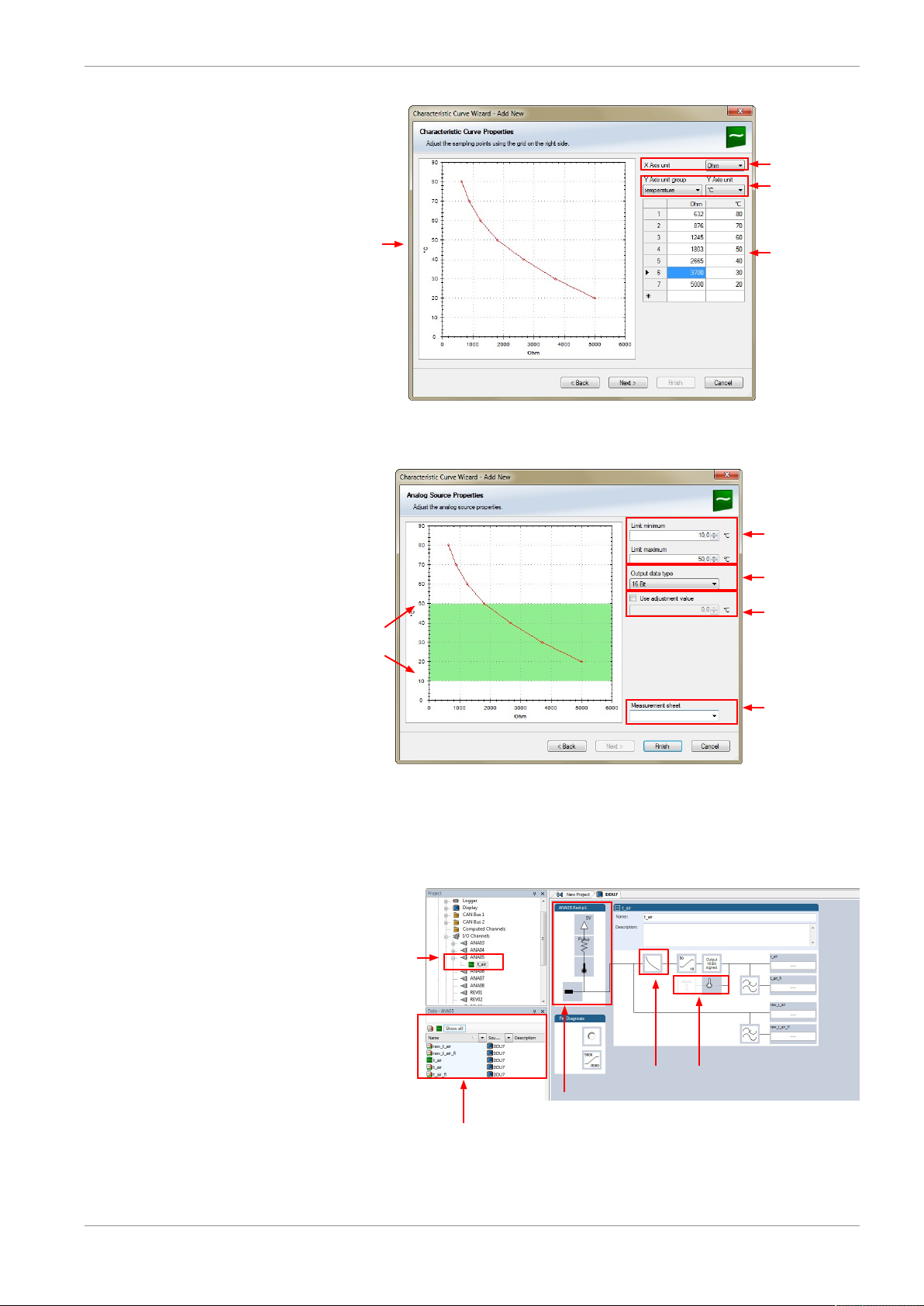

Example: Measurement of wheel force

– Physical property ‘wheel force’ not directly measureable

– Load transfer through suspension kinematics

– Physical value at sensor position defined by vehicle

– Curve definition by online adjustment at vehicle

1. Click on ‘Measurement Sources’ in the Toolbox.

2. Expand the list of ‘I/O Channels’ by clicking on ‘+’ in the C 70 Project Tree.

3. Drag the ‘Multipoint Adjustment’ analog signal source from the Toolbox and drop it

on the desired analog input channel in C 70 Project Tree.

16/112 Data Logger C 70 Manual Bosch Motorsport

Analog and Frequency Inputs | 5

Drag + Drop

A ‘Multipoint Adjustment Wizard’ opens.

4. To activate the internal pullup-resistor, check the box. The internal pullup-resistor is

used to get a 5 V signal at the analog channel of the C 70. It allows you to use a pushbutton. The fixed value of the internal pullup-resistor is 3.01 kOhm. If using an additional external pullup-resistor, set up the overall resistance.

5. Click ‘Next’ when done.

Bosch Motorsport Data Logger C 70 Manual 17/112

The second part of the ‘Multipoint Adjustment Wizard’ opens.

5 | Analog and Frequency Inputs

Physical

(channel)

value

Choose unit group

and unit of physical

value

Select type of curve

Enter physical

adjustment values

her (can still be

edited later)

Electrical (pin) value

Physical limits

of channel

Enter physical limits

of the sensor

Choose data type

of the measurement

variable

Enable additional

online calibration

Enter name to automatically create a

new measurement

sheet

Channel is linked

to ANA06

Input pull-up resistor

is deactivated

Characteristic

curve for sensor

Adjustment

is enabled

6. Click ‘Next’ when done.

The third part of the ‘Multipoint Adjustment Wizard’ opens.

18/112 Data Logger C 70 Manual Bosch Motorsport

7. Click ‘Finish’ when done.

8. Enter channel name and description.

9. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

Available measurements for channel:

Analog and Frequency Inputs | 5

Measurement label Function

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

Online definition of the curve is covered in the chapter ‘Online calibration of measurement

channels [}33]’ of this manual.

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement [}28]’.

Bosch Motorsport Data Logger C 70 Manual 19/112

5 | Analog and Frequency Inputs

0 500 1000 1500 2000 2500 3000

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

Abtastwerte (roh)

Wert

10000Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (gefiltert)

Wert

100Hz Abtastrate

0 5 10 15 20 25 30

-1.5

-1

-0.5

0

0.5

1

1.5

Abtastwerte (dezimiert)

Wert

100Hz Abtastrate

Sensor signal with noise

Recorded signal 100Hz

(unfiltered)

Recorded signal 100Hz

(filtered)

5.2.5 Digital filter details

C 70 uses A/D converter oversampling and digital filtering to recording rate.

Digital filters eliminate ‘out-of-band’ noise

Cut-off frequency automatically adjusted to recording rate

Example:

– 100 Hz recording rate (10 ms)

– <40 Hz pass band (>99 %)

– >50 Hz stop band (<1 %)

Linear phase – no signal distortion

20/112 Data Logger C 70 Manual Bosch Motorsport

Latency compensation – no filter delay in recorded data

– Filtering is (smart) averaging over several samples

– Filtered signal is delayed with respect to real time signal

– C 70 filters have constant, frequency independent delay

Drag + Drop

– Delay (e.g. 22 samples at 10 ms) is corrected during recording

– No delay filtered vs. unfiltered in recorded data

– Correction is (of course) not possible for real time data (display, online, PWM out)

– Use filtered data for recording, use unfiltered data for real-time

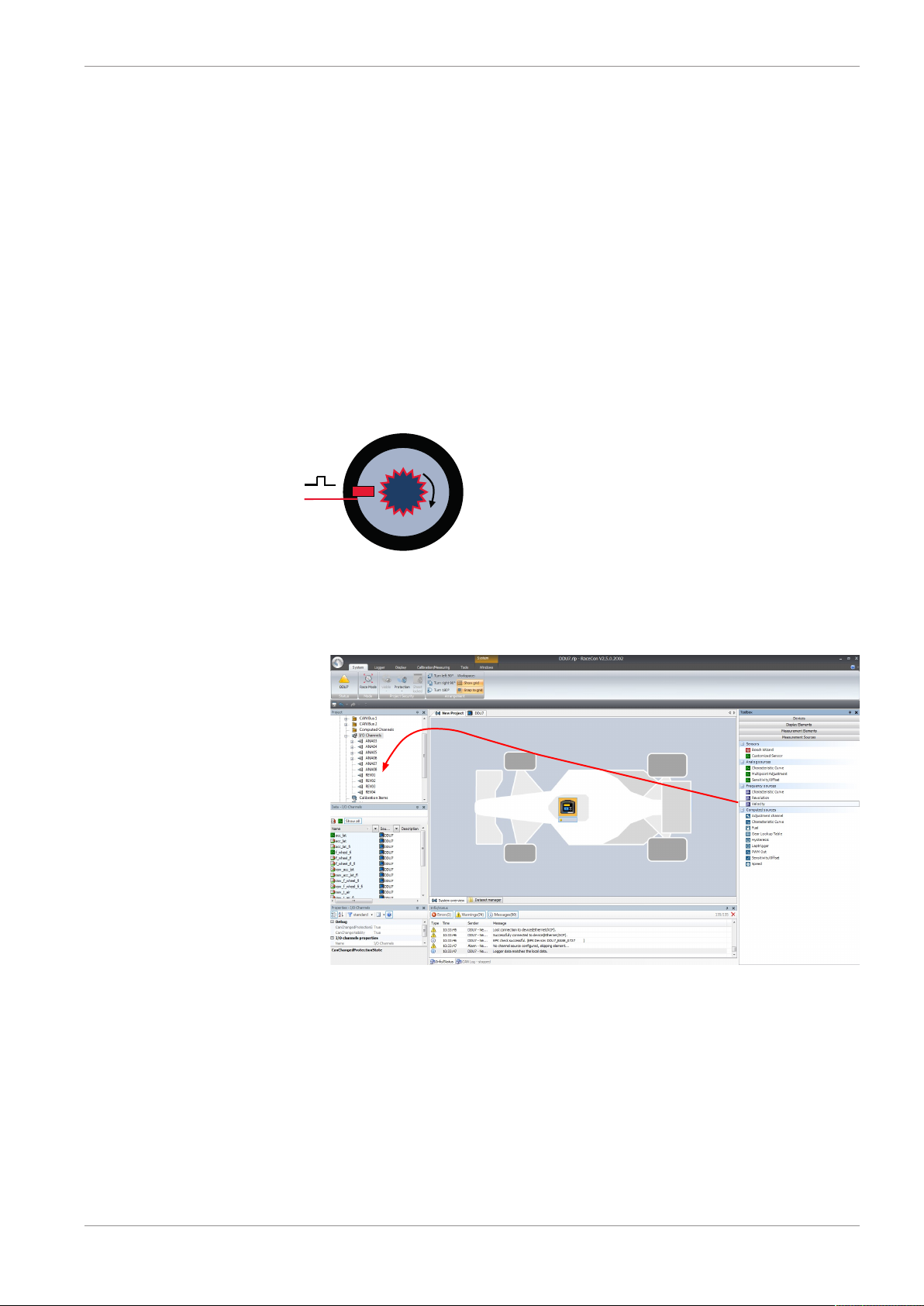

5.2.6 Configuring a frequency input

Example: measurement of wheel speed

– Pulse wheel attached to wheel

– Each passing tooth of pulse wheel triggers hall sensor

– Calculation of wheel speed with wheel circumference

Analog and Frequency Inputs | 5

1. Click on ‘Measurement Sources’ in the Toolbox.

2. To expand the list of ‘I/O Channels’, click on the ‘+’ in the C 70 Project Tree.

3. Drag the ‘Velocity’ digital signal source from the Toolbox and drop it on the desired

‘REV’ input channel in the C 70 Project Tree.

The ‘Velocity Wizard’ opens.

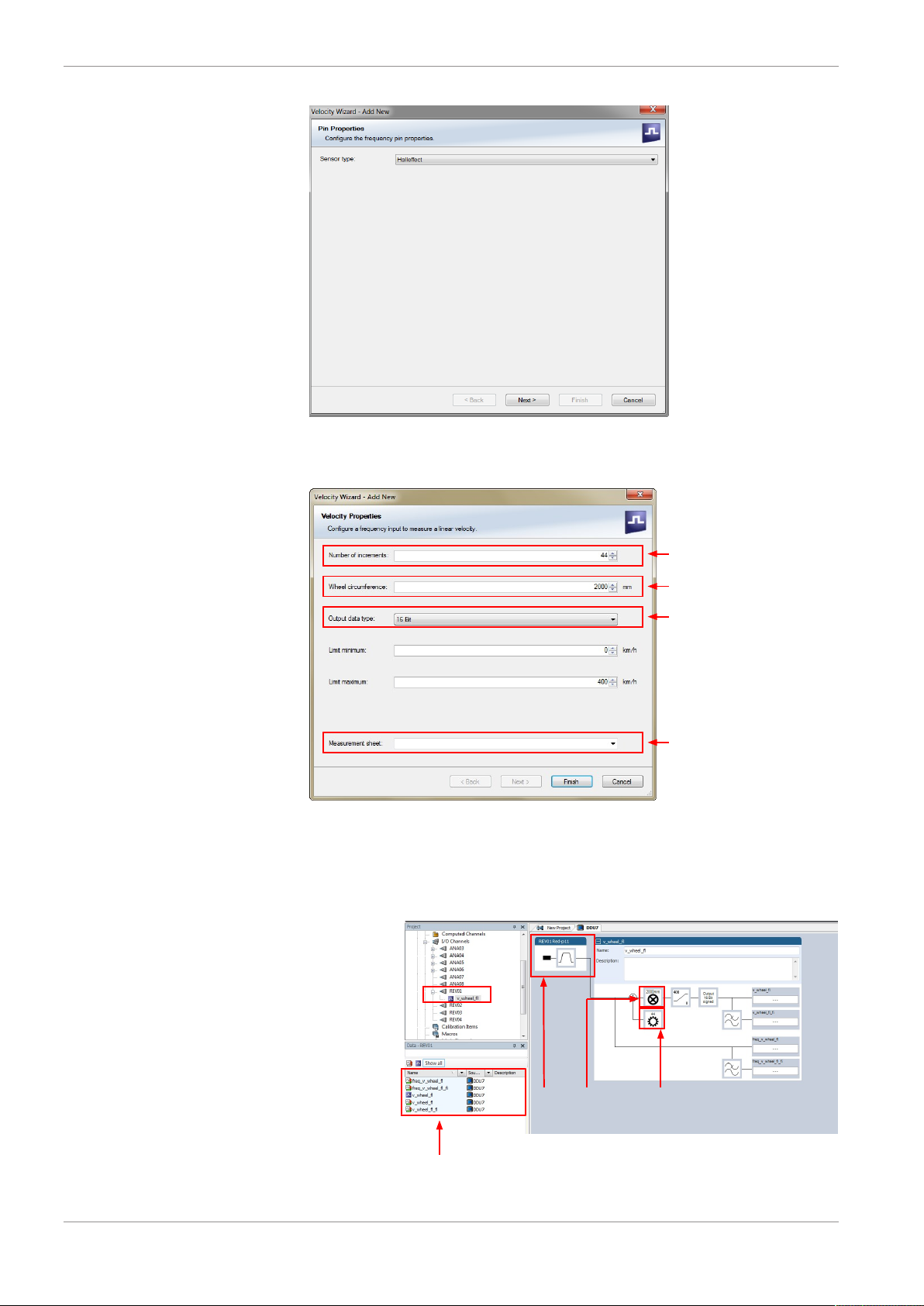

4. Select the sensor type. The DDU10 works with Halleffect and DF11 sensors.

Bosch Motorsport Data Logger C 70 Manual 21/112

5 | Analog and Frequency Inputs

Number of teeth on the

pulse wheel

Circumference of wheel

for speed calculation

Choose data type of the

measurement variable

Enter name to automatically

create a new measurement sheet

Channel is linked

to REV01

Input pin

has hall

interface

Number of

teeth

Wheel

circumference

5. Click ‘Next’.

6. Define the settings for the sensor.

22/112 Data Logger C 70 Manual Bosch Motorsport

7. Click ‘Finish’ when done.

8. Enter the channel name and description.

9. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

Available measurements for channel:

Measurement label Function

Drag + Drop

raw_name mV value of sensor

raw_name_fi filtered mV value of sensor

name physical value of sensor

name_fi filtered physical value

NOTICE

Measurement of ‘Revolution’ is similar.

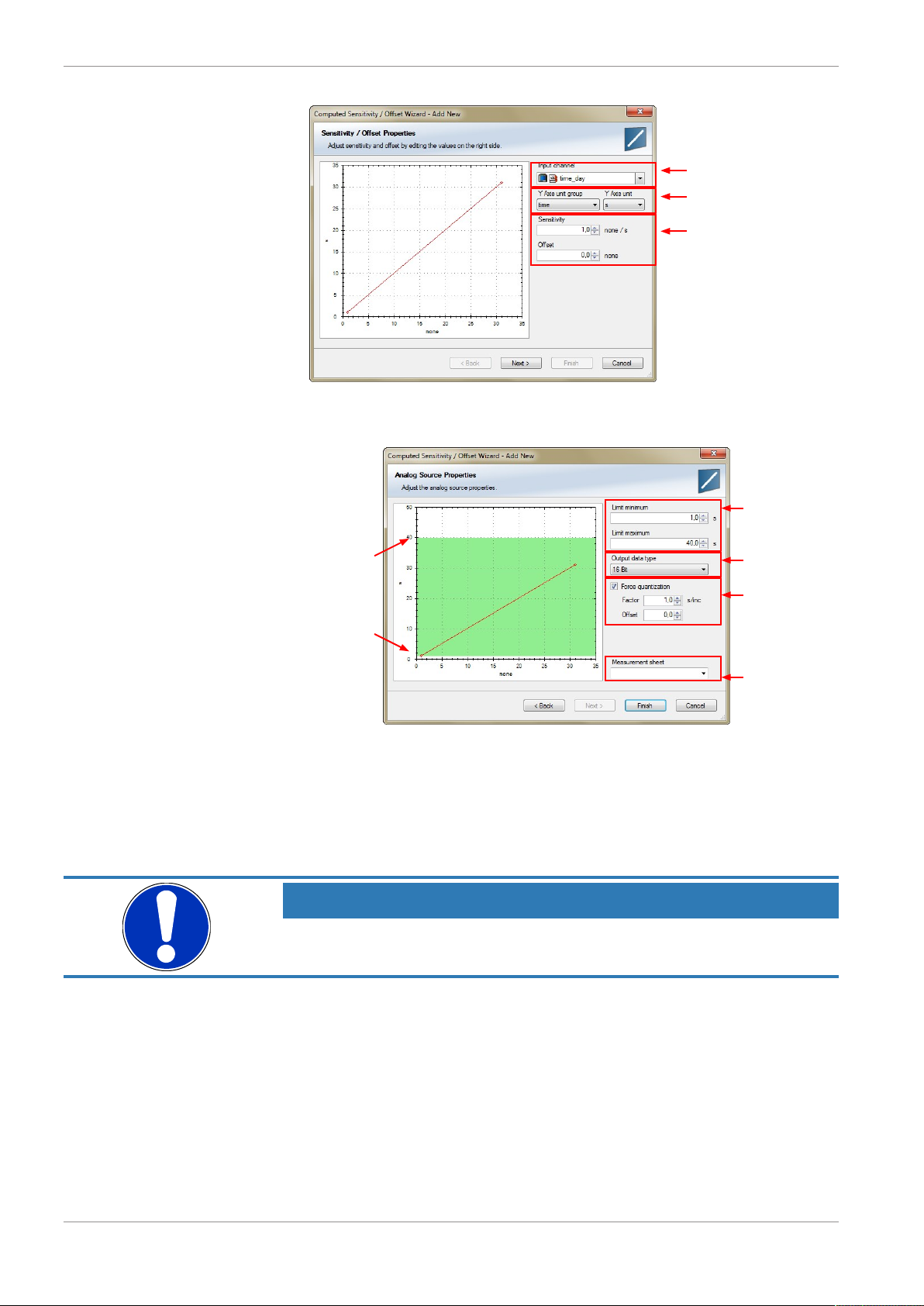

5.3 Configuring computed sources

Computed sources receive data from a measurement channel rather than an input pin.

– Sensitivity/Offset calculation on input channel

– Characteristic curve calculation on input channel

Analog and Frequency Inputs | 5

– Computed vehicle speed

– Lap trigger (covered in a special separate section)

Example: Sensitivity/offset calculation on input channel

1. Click ‘Measurement Sources’ in the Toolbox.

2. Drag the ‘Sensitivity/Offset’ computed source from the Toolbox and drop it on ‘Computed Channels’ in the C 70 Project Tree.

A ‘Computed Sensitivity/Offset Wizard’ opens.

Bosch Motorsport Data Logger C 70 Manual 23/112

5 | Analog and Frequency Inputs

Choose input channel

Choose unit group and

unit of output

Enter sensivity and offset

of conversion formula

Physical limits

of channel

Enter physical limits

of the channel

Choose data type of

the measurement

variable

Check the box to

force the channel's

quantization if the

quantization should

be a fixed value in

the whole CAN

system.

Enter name to automatically create a

new measurement

sheet.

3. Click ‘Next’ when done.

The second part of the ‘Computed Sensitivity/Offset Wizard’ opens.

4. Click ‘Finish’ when done.

5. Enter channel name and description.

6. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

NOTICE

Working with automatically created measurement sheets is explained in chapter ‘Setting up an online measurement’.

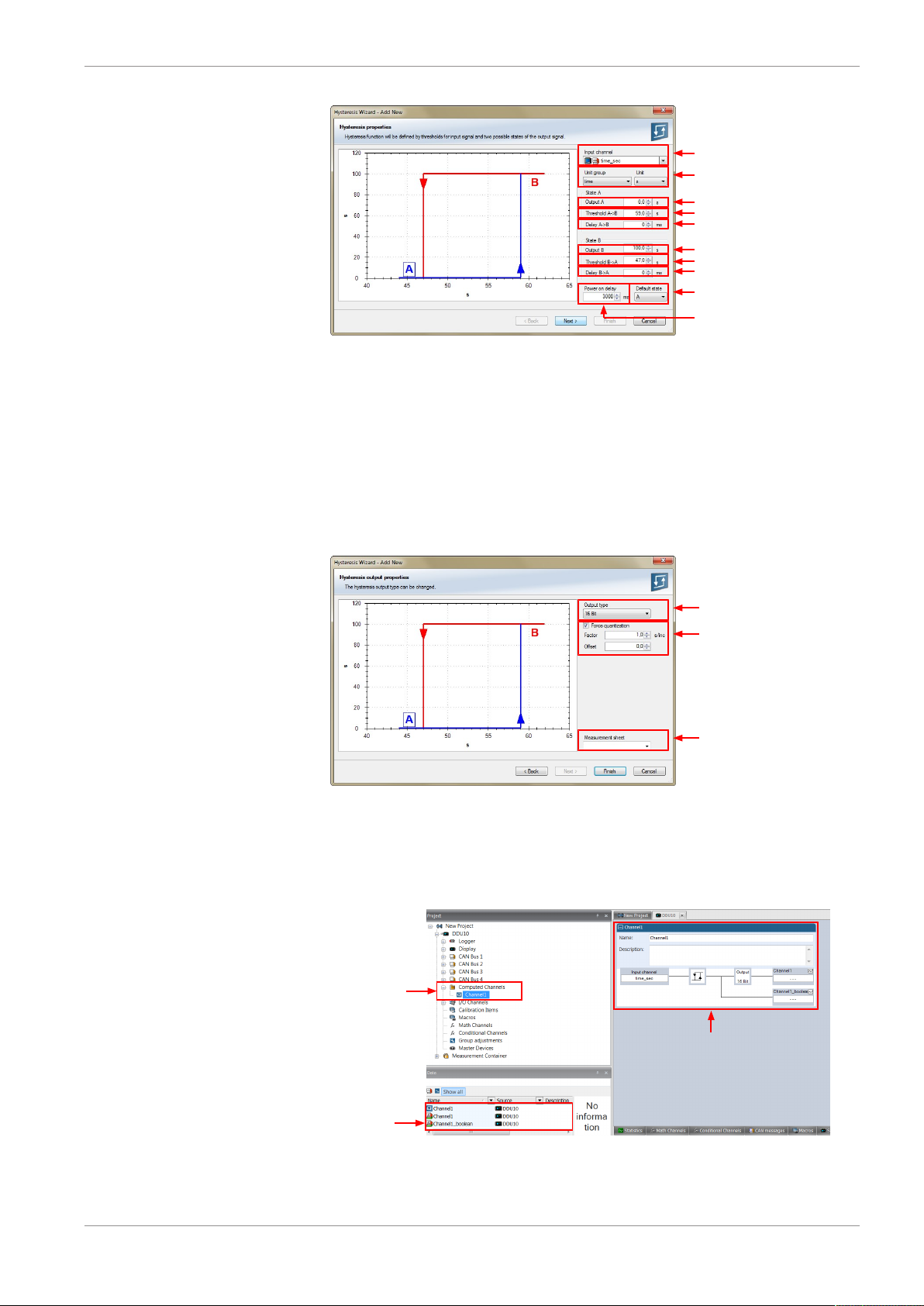

5.4 Hysteresis

The hysteresis function avoids the high-frequent switchover of the measurement channel

value. The hysteresis can be adjusted for each input measurement channel individually

and can be used for further processing.

1. Click ‘Measurement Sources’ in the Toolbox.

2. Drag the ‘Hysteresis’ computed source from the Toolbox and drop it on ‘Computed

Channels’ in the C 70 Project Tree.

A ‘Hysteresis Wizard’ opens.

24/112 Data Logger C 70 Manual Bosch Motorsport

Analog and Frequency Inputs | 5

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

a) Choose input measurement channel.

b) Choose unit group and unit of output.

c) Enter output value of state A in the unit selected in b).

d) Enter threshold value when state changes from A to B.

e) Enter delay time when state changes from A to B.

f) Enter output value of state B in the unit selected in b).

g) Enter threshold value when state changes from B to A.

h) Enter delay time when state changes from B to A.

i) Enter time when the hysteresis function is activated after vehicle´s startup.

j) Enter the channel´s state (A or B) at startup.

Choose data type of

the measurement variable

Check the box to force the

channel's quantization if the

quantization should be a fixed

value in the whole CAN system

Enter name to automatically

create a new measurement sheet

Channels available

in Computed sources

Available

measurements

for channel

Calculation of hysteresis

channel

3. Click ‘Next’ when done.

The second part of the ‘Hysteresis Wizard’ opens.

4. Click ‘Finish’ when done.

5. Enter channel name and description.

6. Click ‘OK’ when done.

The channel is inserted into the C 70 Project Tree.

Bosch Motorsport Data Logger C 70 Manual 25/112

5 | Analog and Frequency Inputs

Drag + Drop

5.4.1 Special functionality: Vehicle speed

This functionality allows:

– high performance vehicle owners to measure wheel spin under acceleration and

wheel slip/lock under braking.

– calculating vehicle ‘speed over ground’.

Vehicle speed calculation function

– Calculating vehicle speed of 2 wheel drive: (Wheel speeds of non-driven axle as input)

Calculated speed is average of both speeds if speed difference between wheels <

limit.

Calculated speed is maximum of both speeds if speed difference between wheels >

limit.

– Calculating vehicle speed of 4 wheel drive: (Wheel speeds of all wheels as input)

Calculated speed is speed of 2nd fastest wheel.

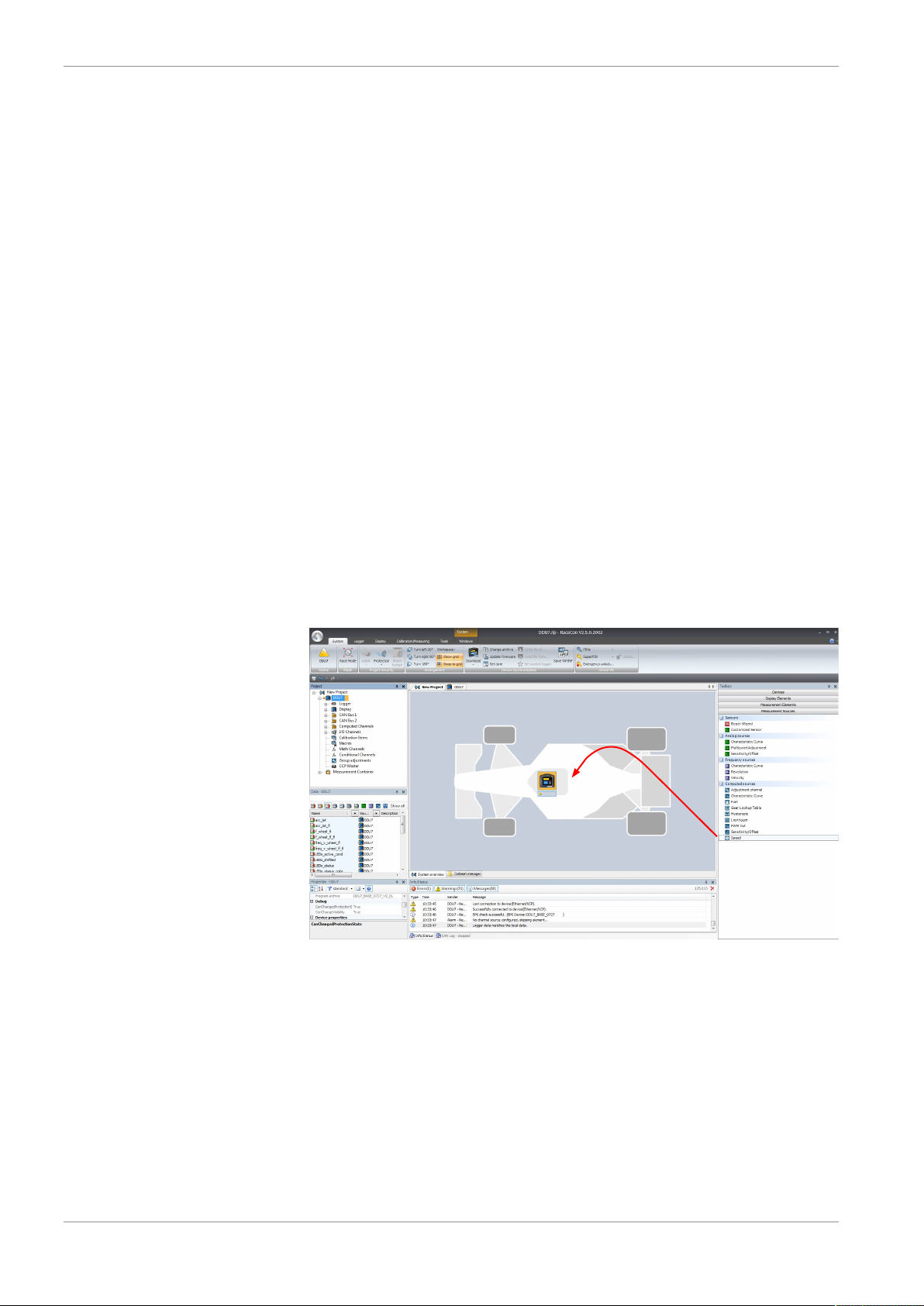

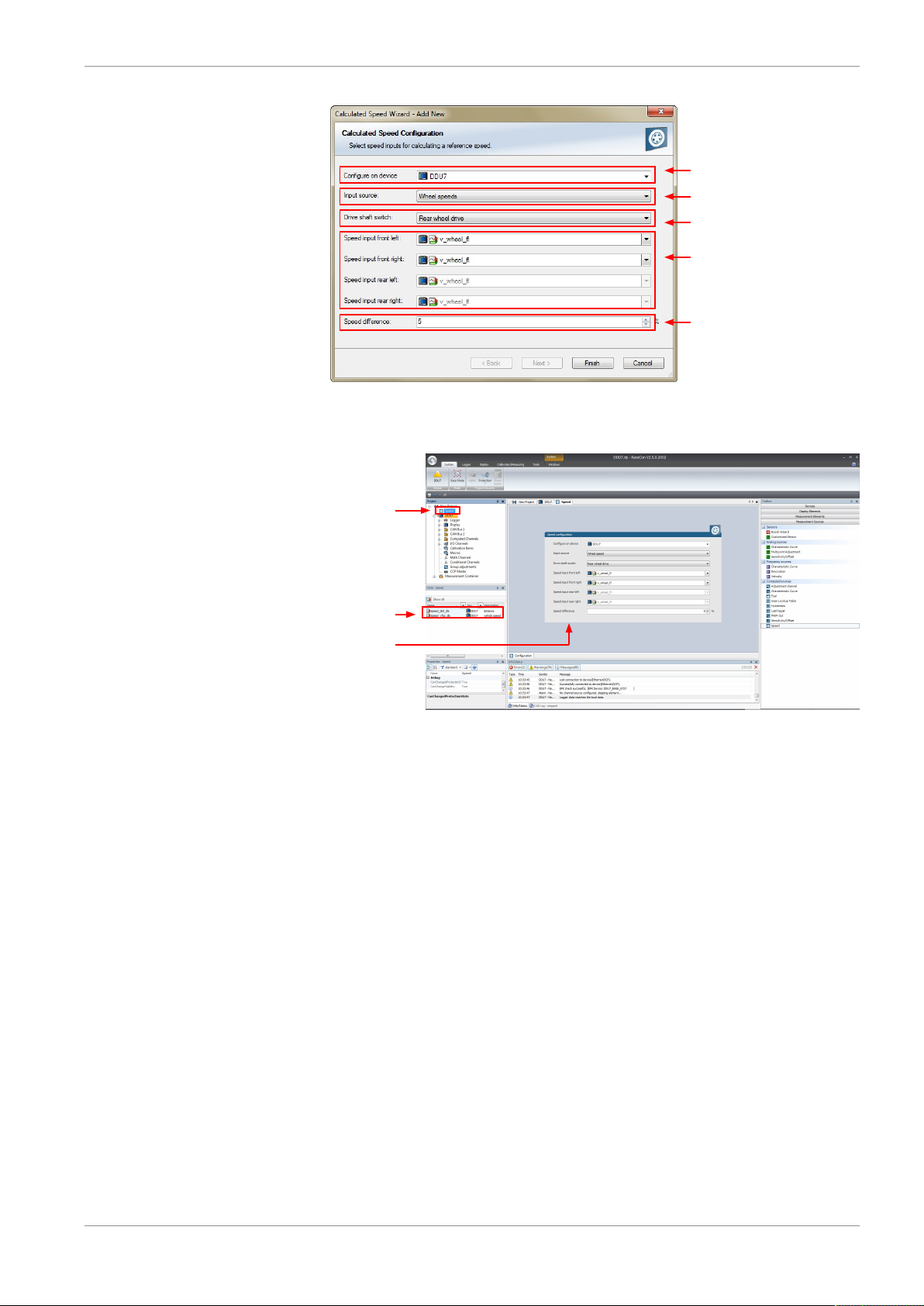

5.4.2 Setting up calculated speed

1. Click on tab ‘System Overview’.

2. Click on ‘Measurement Sources’ in the Toolbox.

3. Drag the ‘Speed’ computed source from the Toolbox and drop it on the project name

in the C 70 Project Tree. Do not drop it on ‘C 70’!

A ‘Calculated Speed Wizard’ opens.

26/112 Data Logger C 70 Manual Bosch Motorsport

Choose device

Choose input source

(internal/external)

Choose driven axle

Choose individual wheel

speed channels

Set limit for speed

difference for calculation

4. Click ‘Finish’ when done.

Speed calculation

in DDU Project

Tree

Measurement

channels

calculated speed

and calculated

distance

Configuration

window

The speed calculation is inserted into the C 70 Project Tree.

Analog and Frequency Inputs | 5

Bosch Motorsport Data Logger C 70 Manual 27/112

6 | Online Measurement

RaceCon changes

automatically

to "Calibration/

Measuring"

6 Online Measurement

C 70 configuration

– System configuration (channel + display configuration, CAN I/O, etc.) is stored in the

C 70

– Use RaceCon to create and download configuration from the PC to C 70 Communica-

tion interface: Ethernet

– Communication protocol: XCP

Online measurement + calibration

– System status and diagnosis

– Check and calibrate sensors in the vehicle

– Live display of sensor values on the PC

– Use RaceCon for diagnosis, online measurement and calibration

– Communication interface: Ethernet

– Communication protocol: XCP

6.1 Setting up an online measurement

C 70 supports online measurement of sensor values and diagnostic variables.

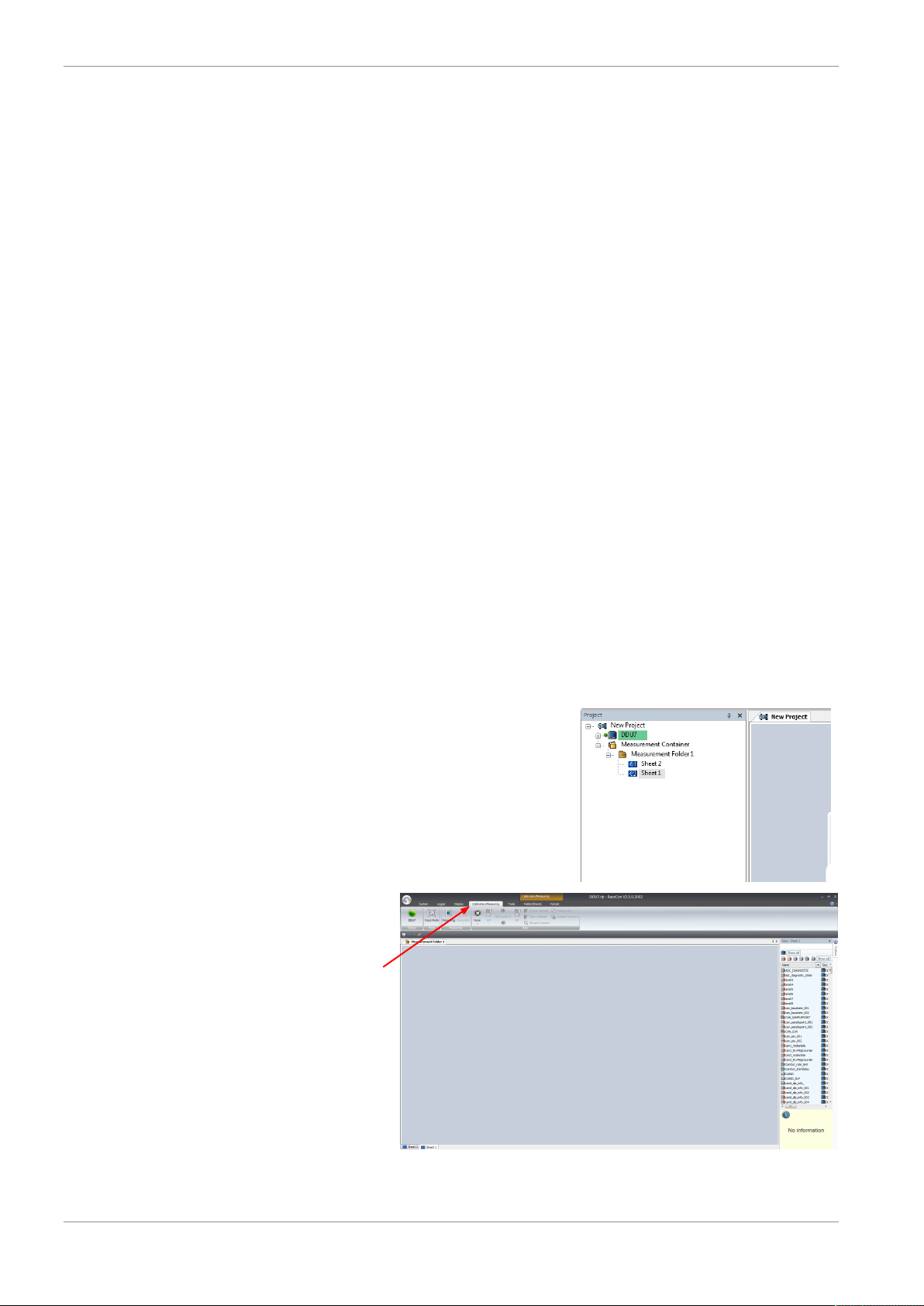

1. Expand ‘Measurement Container’ and ‘Measurement Folder 1’ in the Project Tree and

double-click on ‘Sheet1’. Alternatively, click on the ‘Calibration/Measuring’ tab to

open the window directly.

‘Sheet 1’ opens in a new ‘Calibration/Measuring’ window.

28/112 Data Logger C 70 Manual Bosch Motorsport

2. Click on the ‘Folder/Sheets’ tab, which appears when you are in the ‘Calibration/

Measurement’ window, to create a new measurement folder.

Online Measurement | 6

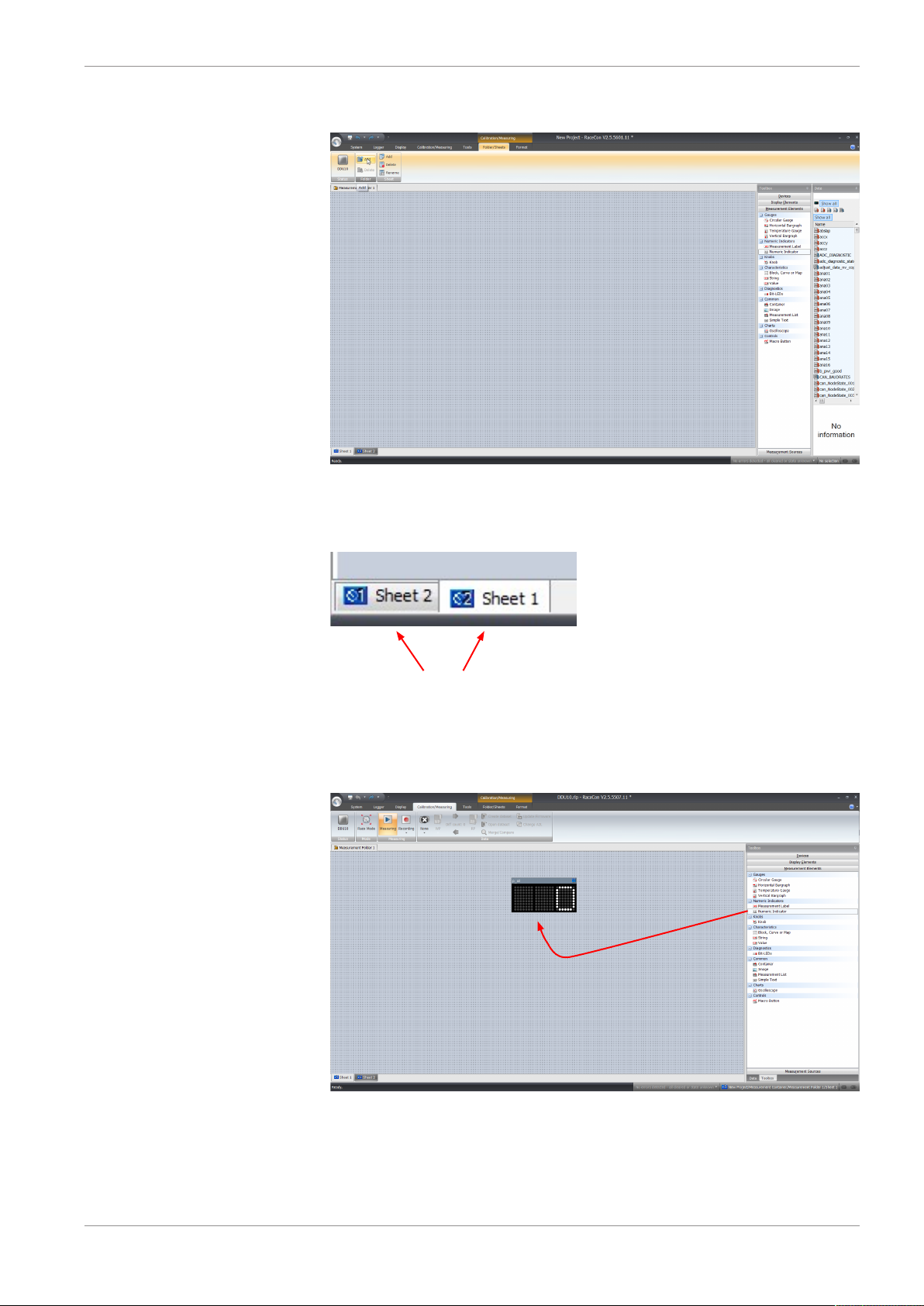

Tabs to switch between sheets

Drag + Drop

3. Click on the ‘Add’ button for folders in the upper left corner.

In the menu for sheets, you will find buttons to add, delete and rename new sheets

4. To change between different sheets, click on the tabs on the bottom of the ‘Calibration/Measuring’ window.

To add an element to a measurement sheet, perform the following steps:

5. Drag a measurement element from the Toolbox and drop it on the measurement

sheet.

Bosch Motorsport Data Logger C 70 Manual 29/112

6. Select the desired measurement channel from the ‘Data’ area and drop it on the

measurement element.

If the C 70 shows the green status, the value is displayed.

6 | Online Measurement

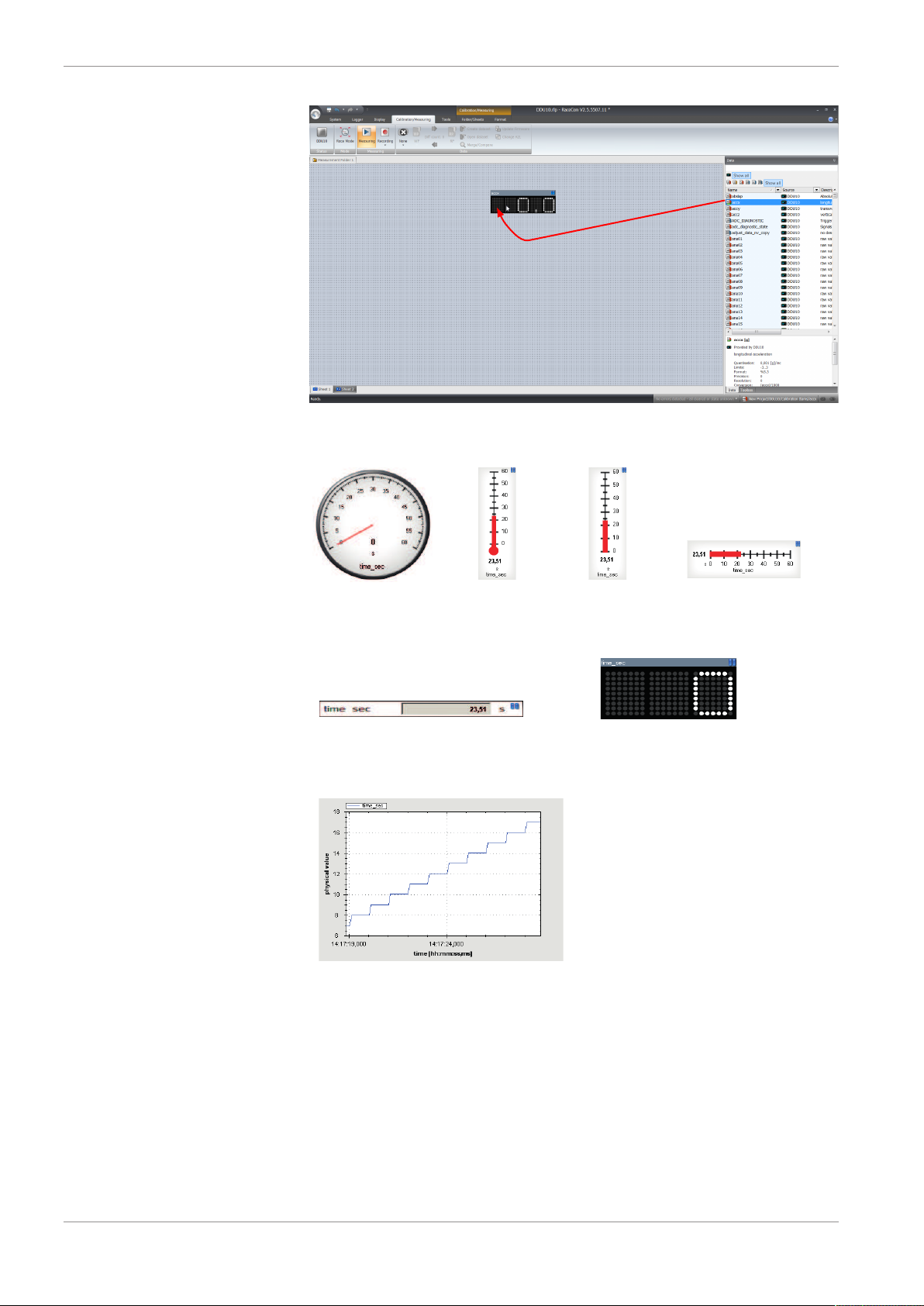

Drag + Drop

Vertical Bar

graph style

Temperature

gauge

Horizontal Bar

graph style

Circular gauge

Numeric indicator

Measurement label

Oscilloscope (Chart)

RaceCon offers different types of measurement elements:

30/112 Data Logger C 70 Manual Bosch Motorsport

6.1.1 Automatic creation of measurement sheets

RaceCon can create measurement sheets automatically.

You can create and use measurement sheets with the C 70 as well as with all other devices

connected to RaceCon.

Loading...

Loading...