Bosch BEA 150, BEA 250, BEA 350 Repair Instructions

Repair Instructions

Bosch Emissions Analysis

BEA 150

BEA 250

BEA 350

In conjunction with Service

software for PC

1

Contents: Page

Contents: Page

1. Important information 4

1.1 Compulsory calibration 4

2. Testing equipment and settings for the

Service software 5

2.1 Testing equipment 5

2.2 Calibrating gases (with manufacturer's certicate) 5

2.3 Settings for the Service software 6

2.3.1 Setting the interface for the Service program 6

2.3.2 Service Software Language Selection 6

2.3.3 Language Selection for RTM 430

Smoke Opacity Module Service Software 7

3. Brief description of unit functions and

Servicing the unit 8

3.1 Exhaust-gas analyzer module 8

3.1.1 Analyzer part (HC, CO and CO2 measurement) 8

3.1.2 System calibration 8

3.1.3 Self-test 8

3.1.4 Adjustment (HC, CO and CO2 measuring channels) 8

3.1.5 O2 measuring channel 8

3.1.6 Compensation of pressure inuence 8

3.1.7 Compensation of temperature inuence 8

3.1.8 Measurement of excess-air factor (lambda) 8

3.1.9 Corrected CO concentration (CO

3.1.10 Parameterization 9

3.1.11 Filtration 9

3.1.12 Principle of ltration 9

3.2 Servicing the unit 9

3.2.1 Half-yearly service 9

3.2.2 Yearly service 9

) 9

vrai

4. Checking the AMM exhaust-gas analyzer

module 11

4.1 Read operating mode 12

4.2 Leakage test 12

4.3 Read measurement values 13

4.4 Read parameters 13

4.5 Write parameters 13

4.5.1 Country-specic settings 14

4.5.2 Lambda calculation On 15

4.5.3 Lambda calculation O 15

4.5.4 CO

4.5.5 CO

4.5.6 O2 sensor available 16

4.5.7 O2 sensor not available 16

4.5.8 Entering lambda coecients OCV and HCV 16

4.6 Identication 17

4.7 Test functions 17

4.7.1 Pump On 18

4.7.2 Pump O 18

4.7.3 Install new O2 sensor 18

4.7.4 O2 measurement 18

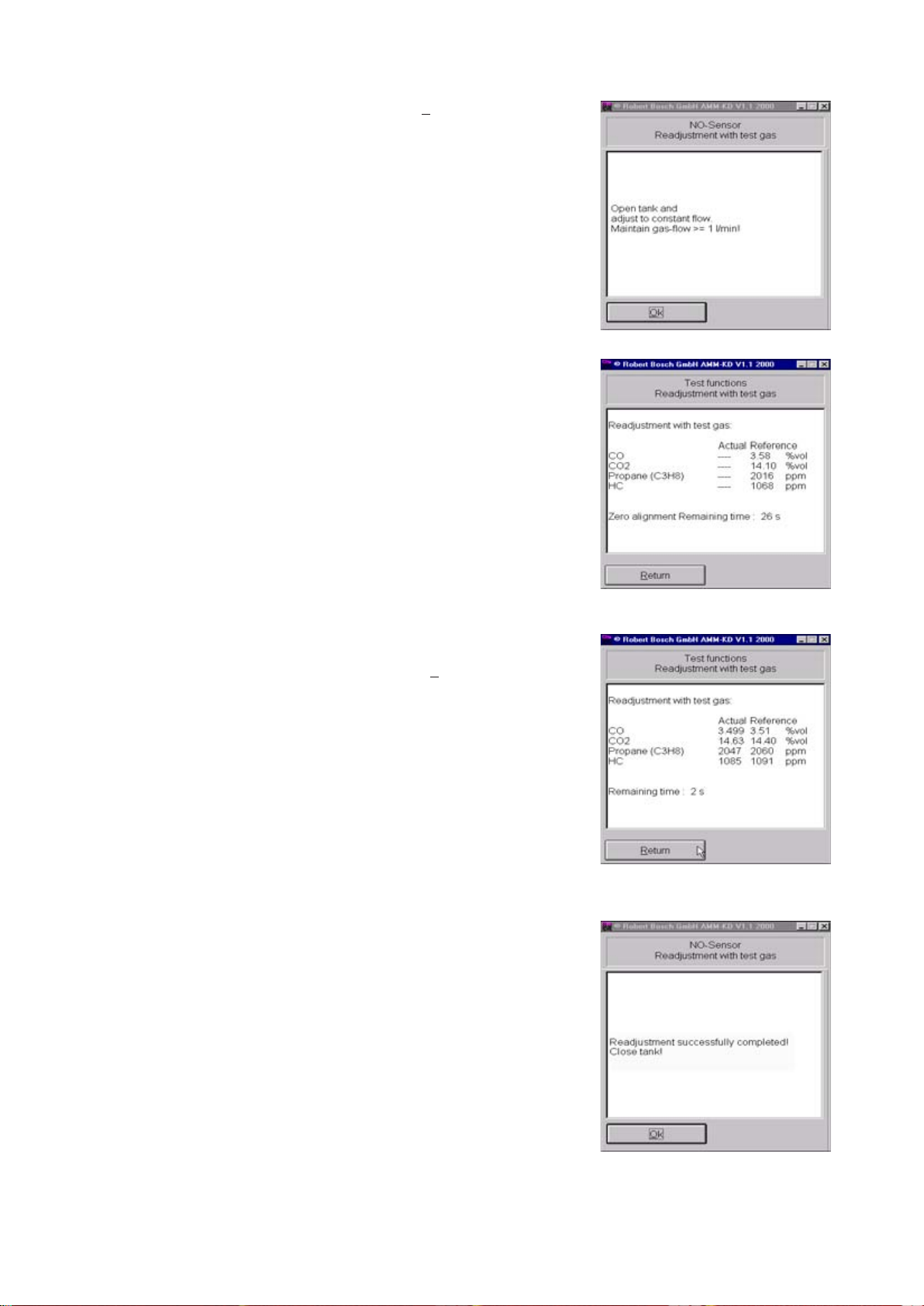

4.7.5 Readjustment with test gas 19

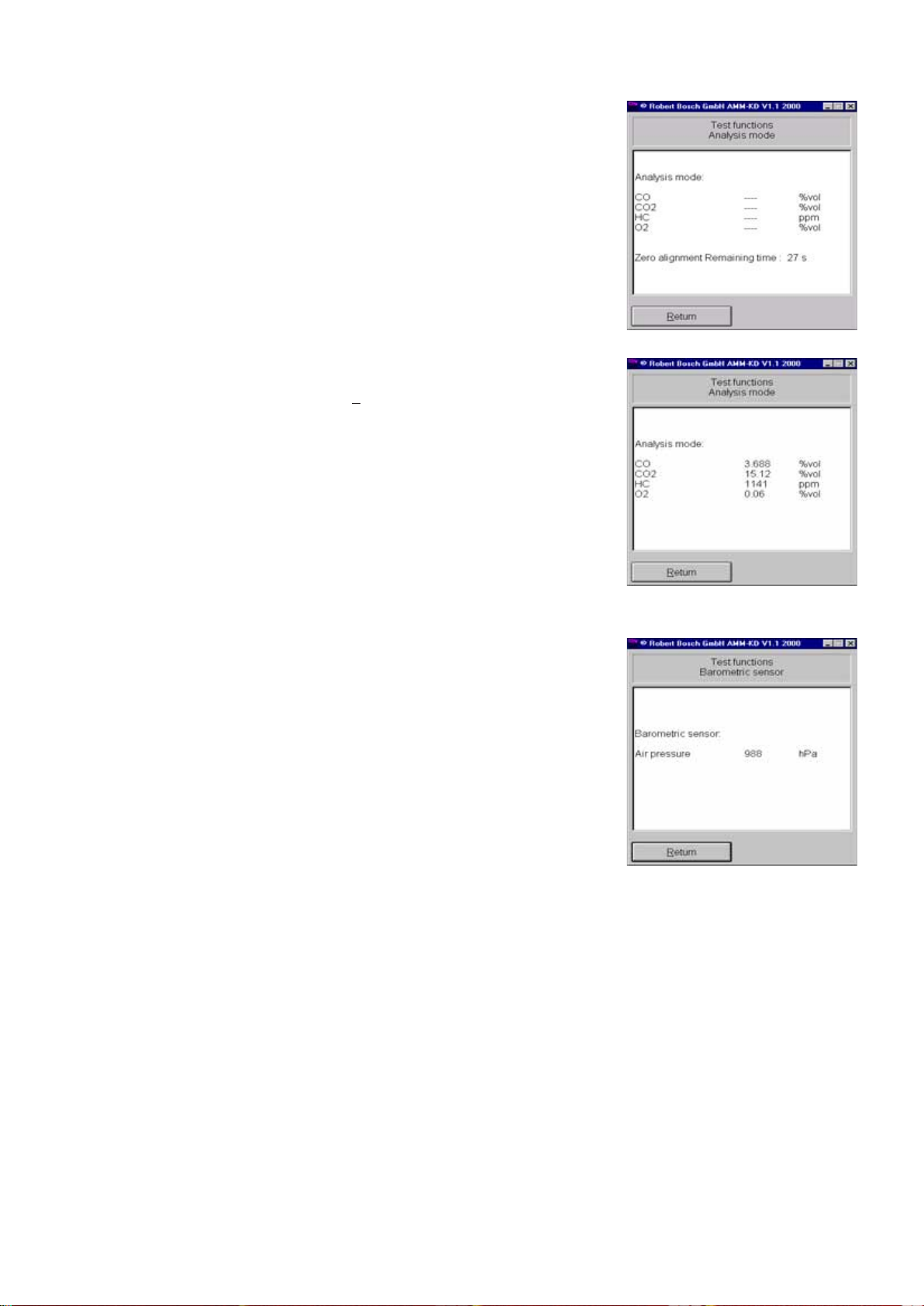

4.7.6 Analysis mode 21

4.7.7 Barometric sensor 21

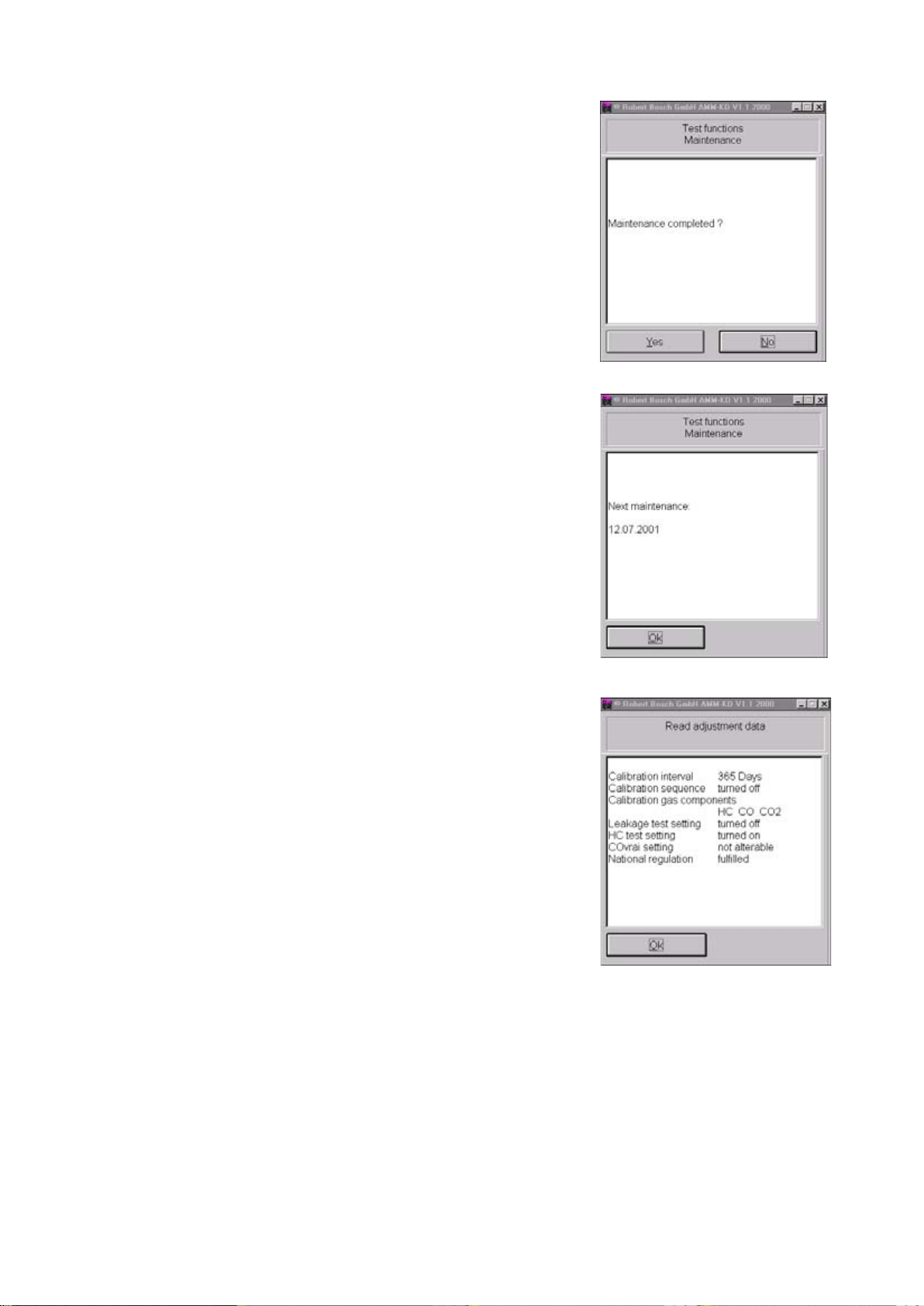

4.7.8 Maintenance (service date) 22

4.8 Read adjustment data 22

4.9 Adjustment functions 23

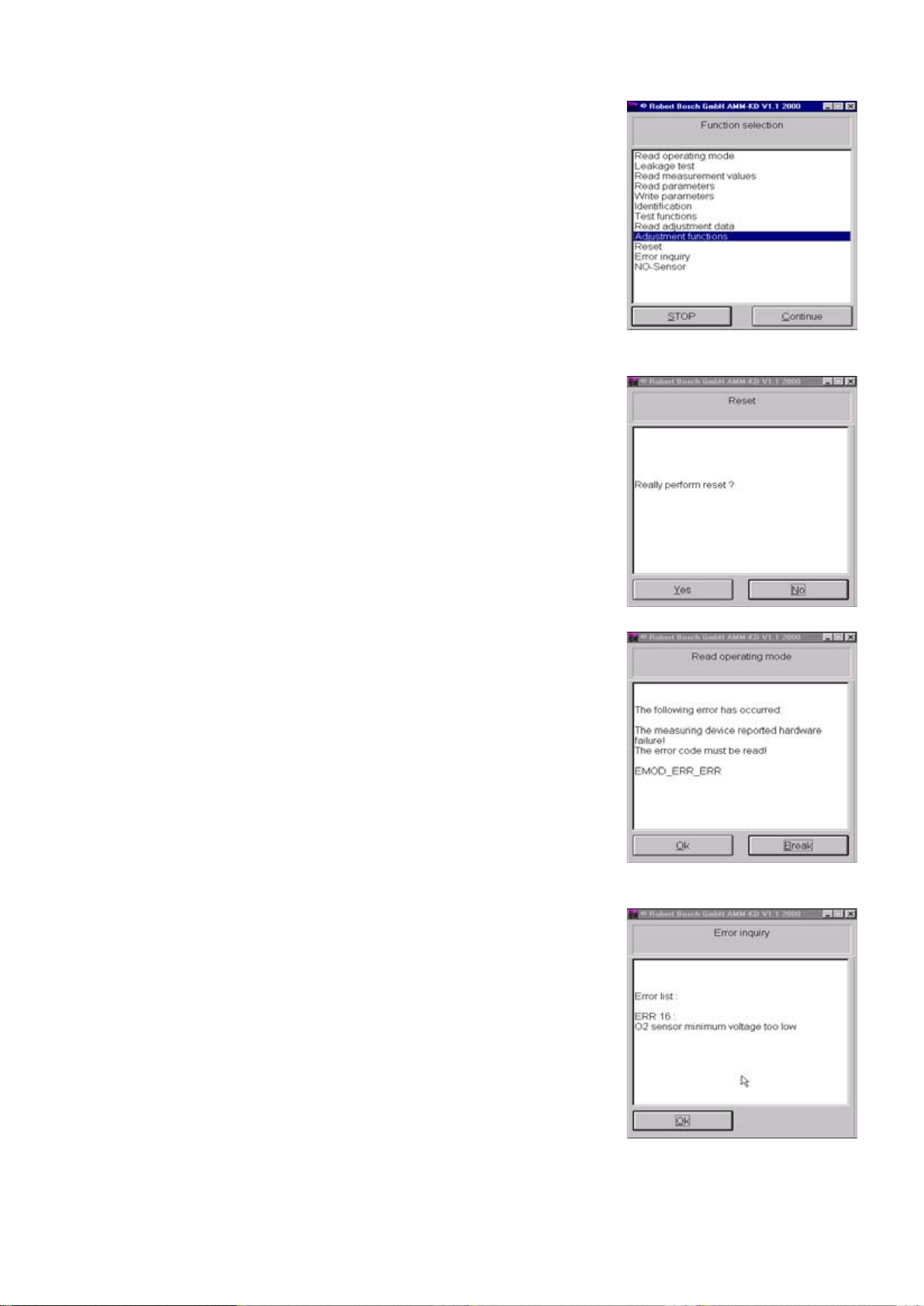

4.10 Reset 23

4.11 Error inquiry 23

4.12 NO-Sensor 24

calculation On 15

vrai

calculation O 15

vrai

4.12.1 Read NO-Sensor 24

4.12.2 Set NO-Sensor 24

4.12.3 NO-Measurement 25

4.12.4 Mounting a new NO-Sensor 25

4.12.5 Readjustment with test gas 28

4.12.6 Read calibration data 30

4.12.7 Calibration interval setting 30

4.12.8 Calibration sequence setting 30

4.13 Checking opacimeter RTM 430 31

5. Checking the PCB and periphery of the

BEA control module 32

5.1 Checking the interface for DTM 32

5.2 Checking the interface for RTM 33

5.3 Checking the interface for AMM 33

5.4 Checking the interface for OBD 34

5.5 Checking the interface for OBD extern

(without CAN-protocol) 34

5.5.1 Loop test 35

5.5.2 OBD error messages 36

5.6 Testing 26-pin interface for OBD external

(with CAN protocol) 37

5.7 Checking the interface for the data terminal

(not for BEA-Euro) 38

5.8 Checking the hard disk 38

5.9 Checking the Floppy disk drive 39

5.10 Checking the internal printer 39

5.11 Checking the external printer 39

5.12 Setting the date and time 40

5.13 Video RAM test 40

5.14 Display test 41

5.15 Display test geometry image 41

5.16 Display test full screen all white 41

5.17 Display test full screen all black 42

5.18 Checking the Foil keypad 42

5.19 Checking the PC keyboard 42

5.20 Checking the remote control 43

5.21 Checking the Test calibration switch for Customer

Service 43

5.22 Reading out the Error list 43

5.23 Download SystemSoft 43

6. Checking the engine-speed and

temperature measuring module (DTM) 45

6.1 Checking oil temperature and engine speed in

Diesel Diagnosis 45

6.1.1 Terminal diagram of connection cable for

clamp-on pickup 46

6.1.2 Terminal diagram of temperature sensor 46

6.2 Checking oil temperature and engine speed in

Petrol Diagnosis 47

6.2.1 Terminal diagram of inductive clip-on trigger sensor 48

6.3 Checking V-lambda 48

6.3.1 Terminal diagram of V-lambda cable 49

6.4 Checking the ignition point and dwell angle 49

6.5 Checking the dwell angle 50

6.5.1 Terminal diagram of timing light 51

6.5.2 Terminal diagram of TD/TN connection cable 51

2

Contents: Page

Contents: Page

7. Technical information (measuring ranges,

resolution and tolerances) 52

7.1 Exhaust-gas analysis in petrol-driven vehicles 52

7.2 Opacity measurement 52

7.3 Engine measurement system TDM+ 52

7.3.1 Temperature measurement 52

7.3.2 RPM measurement, petrol-driven vehicles 52

7.3.3 RPM measurement, diesel vehicles 52

7.3.4 Multiple measurements 53

7.3.5 Ignition point/timing 53

7.3.6 Dwell angle 53

7.3.7 Start of delivery/Injection timing 53

8. Trouble-shooting by message number 54

8.1 Explanations on reference numbers 54

8.2 General messages 54

8.3 Messages about boot test functions 55

8.4 Messages about software installation functions 56

8.5 Messages about printing functions 57

8.6 Messages about hardware test functions 57

8.7 Messages about opacimeter RTM 430 58

8.9 Messages about EAM exhaust-gas analyzer module 59

8.10 Reference numbers when downloading DTM rmware 60

8.11 Reference messages on OBD printed circuit board 61

8.11.1 Reference numbers for errors in "Fatal" group 61

8.11.2 Reference numbers for errors in "Status error" group 61

8.11.3 Reference numbers for errors in "Download" group 61

8.11.4 Reference numbers for errors in „Communication

error“ group 62

8.12 Reference numbers in combination with AWN.Modul 62

8.13 Malfunction messages for testing OBD printed

circuit board with KTS115PC program 63

8.13.1 Error messages for "SDTEST" 63

8.13.2 Error messages for "DLCTEST" 63

8.13.3 Error messages for "LBCTEST" 64

8.13.4 Error messages for "CANTEST" 64

9. Adjustment functions 65

9.1 Setting the Maintenance interval 65

9.2 Setting the calibration interval 66

9.3 Setting the calibration gas components 66

9.4 Setting the calibration sequenz 66

9.5 Setting the leakage test interval 67

9.6 Setting the HC test 67

9.7 Setting CO

9.8 National regulation settings 68

9.9 Download 68

67

vrai

10.13 Checking the pump suction power 78

10.14 Replacing the pump 79

10.15 Checking the pressure sensor 79

10.16 Checking the response time of the pressure sensor 79

10.17 Replacing the pressure sensor 80

10.18 Replacing the water separator 80

10.19 Replacing the solenoid valve 81

10.20 Replacing the NO sensor 81

10.21 Replacing the internal printer 82

10.21.1 Replacing the printing mechanism 82

10.21.2 Replacing the controller PCB 82

10.22 Replacing the disk drive 83

10.23 Replacing the TFT display 83

10.24 Replacing the membrane keypad 84

10.25 Replacing the receiver diode for the remote control 84

10.26 Replacing the control module PCB 85

10.27 Replacing the temperature and RPM PCB 85

10.28 Replacing the control-power transformer 85

10.29 Replacing the OBD circuit board 86

10.30 Replacing AWN printed circuit board 87

10.31 Replacing the power switch 88

10.32 Replacing the battery 88

10.33 Replacing hard disc 88

11. BEA test software OS9 89

11.1 Hard disk 89

11.1.1 Identication 89

11.1.2 Testing 89

11.1.3 Formatting 90

11.2 Flash 90

11.3 Floppy disk 91

11.4 Language 91

12. Overview 92

12.1 Electrical wiring (Siemens analysis chamber) 92

12.2 Circuit diagram (Siemens analysis chamber) 93

12.3 Wiring diagram (Siemens analysis chamber) 94

12.4 Hosing (Siemens analysis chamber) 95

12.5 Gas circuit diagram (Siemens analysis chamber) 96

12.6 Electrical wiring (Andros analysis chamber) 97

12.7 Circuit diagram (Andros analysis chamber) 98

12.8 Wiring diagram (Andros analysis chamber) 99

12.9 Hosing (Andros analysis chamber) 100

12.10 Gas circuit diagram (Andros analysis chamber) 101

12.11 Overview of components 102

10. Repairs 69

10.1 Adjusting mains voltage for toroidal mains transformer 69

10.2 AC / DC voltage supply to control module PCB 69

10.3 Block circuit diagram of voltage supply 71

10.4 View of equipment side of control module PCB 72

10.5 Visual inspection of measuring bank of exhaust-gas

analyzer module 73

10.6 Electrical test of measuring bank of exhaust-gas

analyzer module 73

10.7 Leak test of measuring bank 73

10.8 Cleaning the lamp reector 74

10.9 Cleaning the analysis chambers and windows 75

10.10 Replacing the measuring bank 76

10.11 Install new O2 sensor 76

10.12 Checking cross sensitivity 78

3

1. Important information

1.1 Compulsory calibration

Installation and/or repair may only be performed by trained and

instructed service staff at Robert Bosch GmbH or by an organization nominated by Robert Bosch GmbH. All warranty claims are

rendered null and void in the event that any devices are opened

or modified by a non-authorized person.

Electrical systems and equipment may only be operated in proper

working condition (see also Test Equipment Information

0108_084). This requirement is met if it is ensured following a

modification or repair (initial test) that the applicable electrical

engineering standards have been complied with. To this end,

tests based on the type and scope of measures specified in the

electrical engineering standards (e.g. in Germany BGV A2) are to

be carried out. The type and scope of tests to be carried out is

specified for Germany in VDE 0701/0702 Part 1. Compliance

with the corresponding national standards for countries outside

Germany must be ensured.

When the BEA is used in systems for which calibration is required

by law, legal provisions in the country of use regarding operation,

maintenance and calibration must be observed.

The BEA carries dangerous contact voltage. Unsatisfactory or insufficient maintenance and repair work may

lead to a risk of accident through electric shock.

The regulations governing the calibration of exhaust-gas analyzers in the specific country of use must be complied with.

At half-yearly intervals

the BEA must be serviced by expert, instructed persons.

If an official test seal is broken during such work, proper and

expert repair must be performed and confirmed by the authorized

Service Agent and a new calibration undertaken by the responsible calibration authorities.

Service work

must be recorded in writing, including the following information:

z Time of service

z Type of service work undertaken

z Name of person or company performing the work

These records must be preserved for the duration of five years.

The Operating Instructions must be kept with the BEA so that they

are available at all times.

The owner of the BEA is responsible for compliance

with calibration laws and for regular service and

maintenance.

The BEA must not be used to measure explosive gases.

The exhaust-gas analyzer must not be operated in

rooms where there is a risk of explosion.

During work with toxic gases, care must be taken to

ensure that a concentration which is hazardous to

health cannot arise in the workplace.

Improperly conducted maintenance and repair work

may lead to a risk of intoxication when working with toxic

gases.

The printed circuit boards contain electrostatic sensitive devices.

Observe ESD regulations!

4

2. Testing equipment and settings for the Service software

2.1 Testing equipment

2.2 Calibrating gases (with manufacturer's certificate)

In order to save on calibrating-gas bottles, we recommend a

calibrating-gas bottle filled with mixed gases:

z 1 laptop or PC

z P100

z P140

z Service software for BEA

z ESA module system software to test Engine test functions

z KTS module system software to test OBD functions

i The system software versions for Emissions System Analysis

and the KTS module must be installed on your laptop or PC,

otherwise the Service software will not be fully functional!

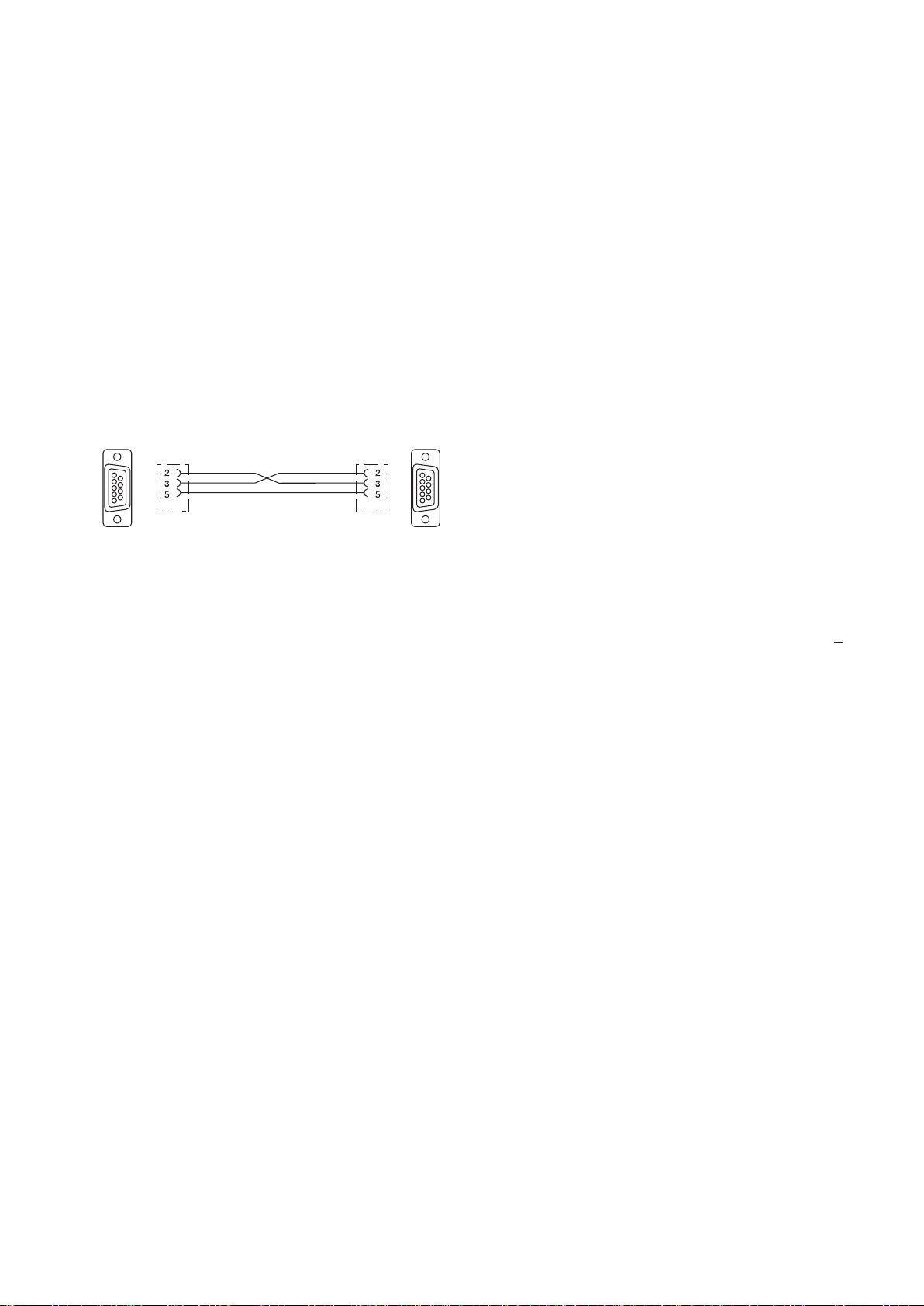

z BEA - PC or laptop, COM1 connecting lead.

As an alternative to the lead shown, the connecting lead for

the data terminal (DTL) 1 684 465 320, can be used.

1

6

9

5

455901-7

1

6

9

5

z Adaptor cable AL350 to check OBD connecting line to

control device.

z Test connector KS350 to check OBD interface in BEA

z 1 flow meter (rotameter), measuring range 1.5 to 2 l/min or

10 l/min, test medium air, 20 °C, 1 bar absolute

z 1 absolute-pressure gauge (barometer) or adjusting barometer

set to absolute pressure. Measuring accuracy 5 hPa (5 mbar)

z 1 gas wash bottle (pearl bottle)

z 1 digital multimeter (DMM)

z 1 DC calibrator, 0 to 15 mV

z 1 stabilizer DC U = 0Volts - 30Volts

z Viton hose for calibrating-gas connection (do not use hoses

of different material)

z 1 U-tube, water gauge 100 cm, inside diameter max. 8 mm

z Compressed air for cleaning exhaust-sample probe and hose

z Torque screwdriver 0.2 - 4 Nm

Insert for inner TORX screws size T15

No. 4 5 % CO + 7.5 % CO

+ 2.000 ppm C3H8 (propane)*,

2

accuracy of analysis ± 1%

In some countries (e.g. Germany), calibrating gases to OIML

Directive R99 A and B are used for calibration. In this case, gas

no. 4 can be dispensed with.

A 2000 ppm vol. C3H8 (propane)*, accuracy of analysis ± 1%

3.5 % vol. CO, accuracy of analysis ± 1%

14 % vol. CO2, accuracy of analysis ± 1%

B 200 ppm vol. C3H8 (propane)*, accuracy of analysis ± 2%

0.5 % vol. CO, accuracy of analysis ± 1%

6 % vol. CO

, accuracy of analysis ± 1%

2

* For practical reasons, the exhaust-gas analyzer module is

calibrated regularly with propane instead of hexane.

When the exhaust-gas analyzer module is calibrated in the

menu Readjustment with test gas in the Test functions

menu, the module is informed of the concentration of the

calibrating gas in ppm propane. The exhaust-gas analyzer

automatically takes account of the required "propane factor".

Additional test equipment and calibrating gas for optional NO

measuring sensor

z NO calibrating-gas bottle: From 1000 to 5000 ppm NO

+ 2 %

z Shutoff valve

z Stopwatch

z 0 - 12 V DC stabilizer

5

2.3 Settings for the Service software

i The Service software contains the functions for AMM

(opacimeter) and the BEA (Bosch Emissions Analysis) control module.

RTM

Your laptop or PC must also have the system software for the emission system

analysis and KTS module installed.

(exhaust-gas analyzer module),

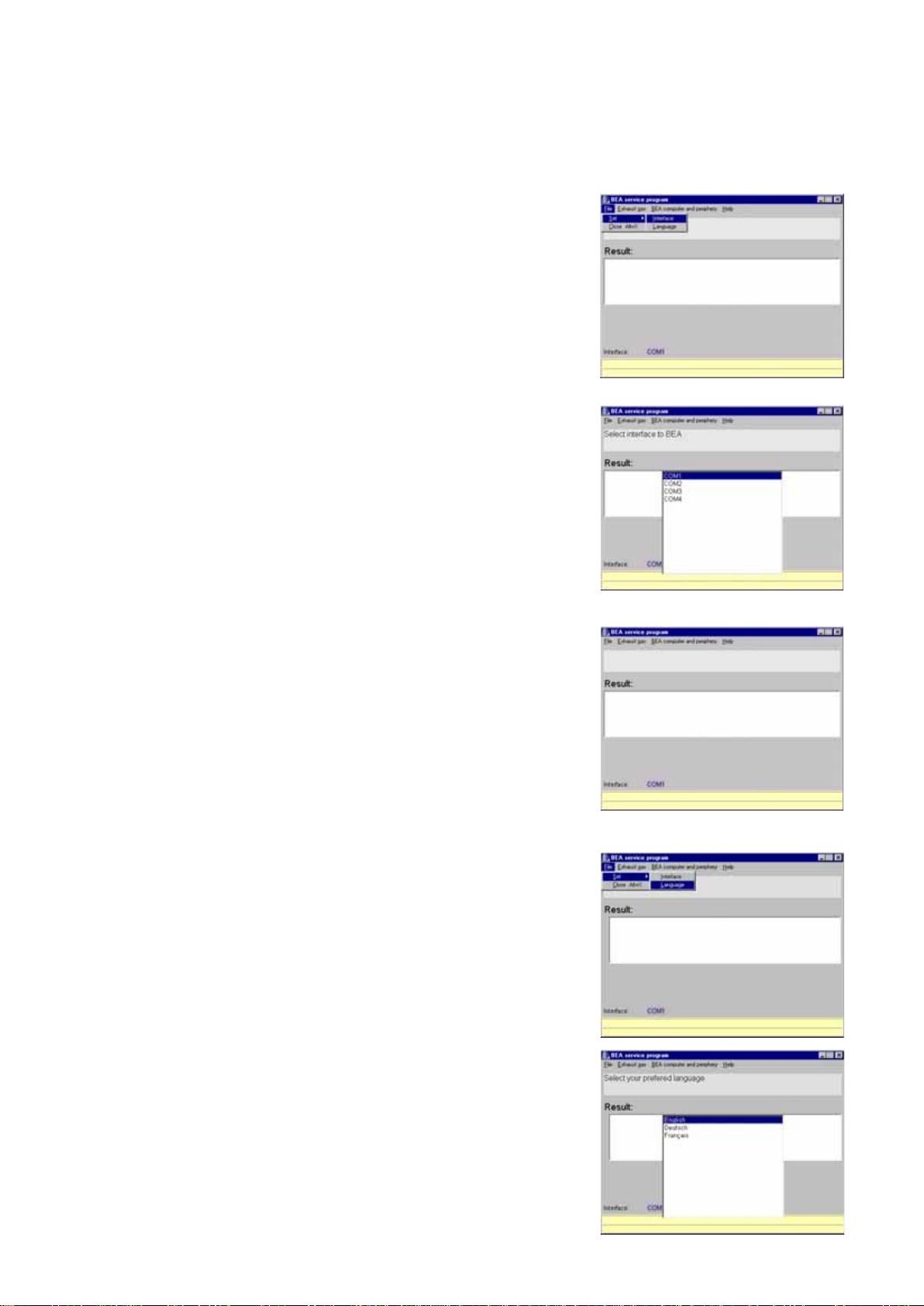

2.3.1 Setting the interface for the Service program

Start the Service program BEAKD.

Open the File menu.

Select Set

Select the appropriate interface and confirm by double-clicking the left-hand

mouse button or by pressing E Enter .

The interface you have selected is displayed below the results window.

and then Interface.

2.3.2 Service Software Language Selection

6

Start the service program BEAKD.

Open the File menu.

Go to Settings and select the Language

menu.

Use the mouse or the o and u keys to

select the laguage for the service program.

Confirm by double clicking the mouse

button or pressing the Enter E key.

The following languages are available:

English

German

French

2.3.3 Language Selection for RTM 430 Smoke Opacity Module Service Software

Open the Exhaust Gas menu and select

the RTM menu.

Open the Swap Languages menu.

A DOS window is opened with a language-selection capability.

Choose the language, by pressing

the appropriate number in front of the

language on your keyboard.

After entering the corresponding number,

the language is automatically changed to.

7

3. Brief description of unit functions and Servicing the unit

3.1 Exhaust-gas analyzer module

The exhaust-gas analyzer module is designed for the following

measuring ranges:

z Carbon monoxide (CO) 0...10.00 % vol.

z Hydrocarbons (HC) 0...9999 ppm

z Carbon dioxide (CO

z Oxygen (O

) 0...22 % vol.

2

z Excess-air factor (lambda) 0.500...9.999

z Nitrogen monoxide (NO) 0...5000 ppm vol. NO

3.1.1 Analyzer part (HC, CO and CO

) 0...18 % vol.

2

measurement)

2

3.1.3 Self-test

The BEA performs a self-test during which it checks all its most

important functions. Any malfunctions detected result in an error

message (Section 8).

3.1.4 Adjustment (HC, CO and CO

measuring channels)

2

During 1-point adjustment (recalibration) with calibrating gas, the

measurement effect (difference from zero) is measured. The

analyzer module is informed by means of a nominal value as to

which concentration of calibrating gas corresponds to this

measurement effect.

You may preselect different adjustment options which vary in type

and frequency, to suit your application.

The measuring channels for HC, CO and CO

infrared pulsating-light method.

function using the

2

This technique makes use of the ability of different gases to

absorb infrared rays of a certain wavelength.

An infrared ray is produced by a lamp and interrupted in cycles by

a chopper wheel, then it passes through analysis systems for CO,

HC and CO

sensitive to infrared light of different wavelengths and can there-

in succession. The individual analysis systems are

2

fore be mechanically arranged one behind the other.

Each of these systems consists of an analysis chamber through

which test gas flows, and a receiving chamber filled with a suitable

gas mixture.

The systems are constructed in such a way that when zero gas

(air) flows through the analysis chamber, a maximum electric

alternating-voltage signal – the measured-value signal – is generated in the receiving chambers.

The signal is amplified by the appropriate channel amplifier,

rectified and conveyed on the motherboard to an analog-to-digital

converter (ADC). The digitalized signal is read and stored by the

MPU.

When test gas containing the component to be measured flows

through the analysis chambers, component-specific wavelengths

of the infrared ray are attenuated accordingly. A smaller measured-value signal is generated in the receiving chambers (see gas

circuit diagram, Section 12.5).

3.1.2 System calibration

System calibration is always started automatically when the

system switches to a measuring mode and the infrared measured

values at this moment differ from zero.

During system calibration, a solenoid valve switches the zero-gas

inlet (with carbon canister) into the test-gas duct for the duration

of calibration. During this process, zero gas (air) is used to

determine the actual system sensitivity of the HC, CO and CO

measuring channels. This value is then stored as the zero point.

If the exhaust-gas analyzer module is still in analysis mode after

15 minutes, system calibration is repeated. Here, the analyzer

module automatically checks whether analysis is currently taking

place and, if it is, delays system calibration until all measured

values have fallen to zero.

3.1.5 O

measuring channel

2

The sensitivity of this measuring channel is adjusted automatically

during each system calibration. During this process, the measured oxygen content is set against the compensating air = 20.9 %

and the condition of the O

zero point of the O

cally.

2

measuring sensor is monitored. The

2

measuring channel is recognised automati-

The oxygen measurement function can be deactivated

(Section 4.5, Write parameters

menu).

3.1.6 Compensation of pressure influence

Different levels of atmospheric pressure mean that different

concentrations are measured in the analysis system. In order for

the exhaust-gas analyzer module to achieve a correct measurement, the atmospheric pressure to be taken into consideration is

determined by means of an integral pressure sensor. The exhaustgas analyzer module can then calculate the correct displayed

value itself.

3.1.7 Compensation of temperature influence

Temperature sensors are situated on the receiving chambers and

on the infrared lamp. The operating temperatures measured there

are automatically taken into account during the adjustment of the

exhaust-gas analyzer module and the conversion of the measured

value to the displayed value.

3.1.8 Measurement of excess-air factor (lambda)

The exhaust-gas analyzer module calculates the excess-air factor

(lambda λ) from the measured concentrations of CO, HC, CO

2

and O2. The lambda value is indicated on the display if the

measured CO

content exceeds 2 % and both the oxygen

2

measurement and excess-air measurement functions are activated. The oxygen measurement is extremely important for calculating the excess-air factor. An imprecise oxygen measurement

leads to the incorrect calculation of the excess-air factor. The

lambda measurement function can be deactivated (Section 4.5,

Write parameters menu).

2

8

3.1.9 Corrected CO concentration (CO

vrai

)

3.2 Servicing the unit

The exhaust-gas analyzer module calculates the true CO concentration (CO

process also takes , for example, factors such as leaks in the

) from the concentrations of CO and CO2. This

vrai

exhaust system into consideration.

This function can be deactivated (Section 4.5, Write parameters

menu).

3.1.10 Parameterization

The exhaust-gas analyzer module can be parameterized for its

specific intended tasks in the Set parameters menu (Section 4.5).

Additional possibilities for parameterization are contained in the

Adjustment functions

menu (Section 9). However, these - like

the adjustment functions themselves - can only be accessed if a

test seal has been broken.

3.1.11 Filtration

Particles and aerosols are removed from the test gas by a

cascade of filters.

Particles constitute solid bodies such as dust and soot, while

aerosols are tiny droplets of fluid which condense in the gas duct

and analysis chambers. There they form a coating which may give

rise to error messages.

For this reason, it is imperative to ensure the correct manner of

filtration.

The service work listed below must be performed irrespective of

legal requirements in the country of operation.

3.2.1 Half-yearly service

i At this interval, only work for testing and maintaining opera-

tional readiness must be performed.

1. Replace GF1 filter (Item 1)

2. Replace inlet filter GF2 (Item 2)

3. Check that both PVC hoses are connected to the gas outlet

(Items 3, 4)

4. Visual inspection of exhaust-sample probe (Item 6)

In the case of major contamination, blow out with compressed air against the direction of suction

5. Perform leak test (Sec. 4.2)

6. Update service date (Sec. 4.7.8)

3.1.12 Principle of filtration

The first filter, GF1, filters the majority of particles and aerosols out

of the gas flow. This filter clogs most rapidly and must therefore

be replaced most frequently: about once a week.

The inlet filter, GF2, at second place in the cascade, filters out a

further part of particles and aerosols. The more clogged the filter

is, the smaller the mesh size and thus the better the filtering action.

The filter becomes wet very quickly from water in the exhaust gas.

This moisture washes the aerosols out of the flow of gas and filters

the particles better. A wet filter is therefore desirable!

This filter should be replaced from around once a month to once

a year.

Filters GF3 and GF4 have the task of protecting the internal

pumps. When the filtration system as a whole is being used

correctly, these filters must only be replaced once a year, at the

most.

Filter GF4, in particular, also has a better filtering action when wet

than dry.

459715/8Ha

4

2

3.2.2 Yearly service

3

6

This service work must be performed by expert maintenance

personnel. It consists of the work included in the half-yearly

service plus the additional items:

1

! It is essential to read Sections 3.1.11 (Filtration) and 3.1.12

before replacing the filters!

1. Replace pump protection filters GF 3 and GF4.

i The pump protection filter GF4 is situated in the interior of the

unit.

! When the GF4 filter is replaced annually, the internal piping

should also always be replaced. Use the parts set 1 687 010

125 for this purpose. Be very careful to consult the gas flow

plan in chapter 12.5.

GF4

459715/9Ha

AF1

GF3

9

Procedure:

Using a non-soluble felt pen, write the current date on the

adhesive label 1 689 980 296 and confirm with your signature

(see illustration).

aktuelles Datum

Datum/Date

Unterschrift/Sign

Unterschrift

459558/23 Ha

Stick the completed adhesive labels onto the new GF3 and

GF4 coarse filters.

Install the new GF3 and GF4 coarse filters.

2. Replace the carbon canister AF1 in the zero gas pipe.

3. Check the measuring accuracy of the exhaust-gas analyzer

with calibrating gas.

i Always ensure a flow rate of > 1 l/min when letting gas flow

through the calibrating-gas inlet. Allow a sufficient warm-up

time (min: 5 minutes).

Click on Test functions (Sec. 4.7) and open the menu item

Analysis mode (Sec. 4.7.6).

Automatic zero calibration takes place.

Let test gas no. 4 (sensitivity test) or single gases of the

appropriate concentration in succession flow through the

exhaust-gas analyzer via the calibrating-gas inlet. Note down

the displayed values.

Next, use test gases no. 5 and no. 1 (gas mixture for sag test)

to check linearity, and note down the displayed values.

If the display deviates from the certified calibrating-gas value

during a measurement (sensitivity or linearity) by more than 5

%, replace the measuring bank (Section 10.10).

! If regular calibration is required due to special regulations,

execute the menu Readjustment with test gas (4.7.5) in the

Test functions menu (4.7). This will reset the monitoring

clock.

10

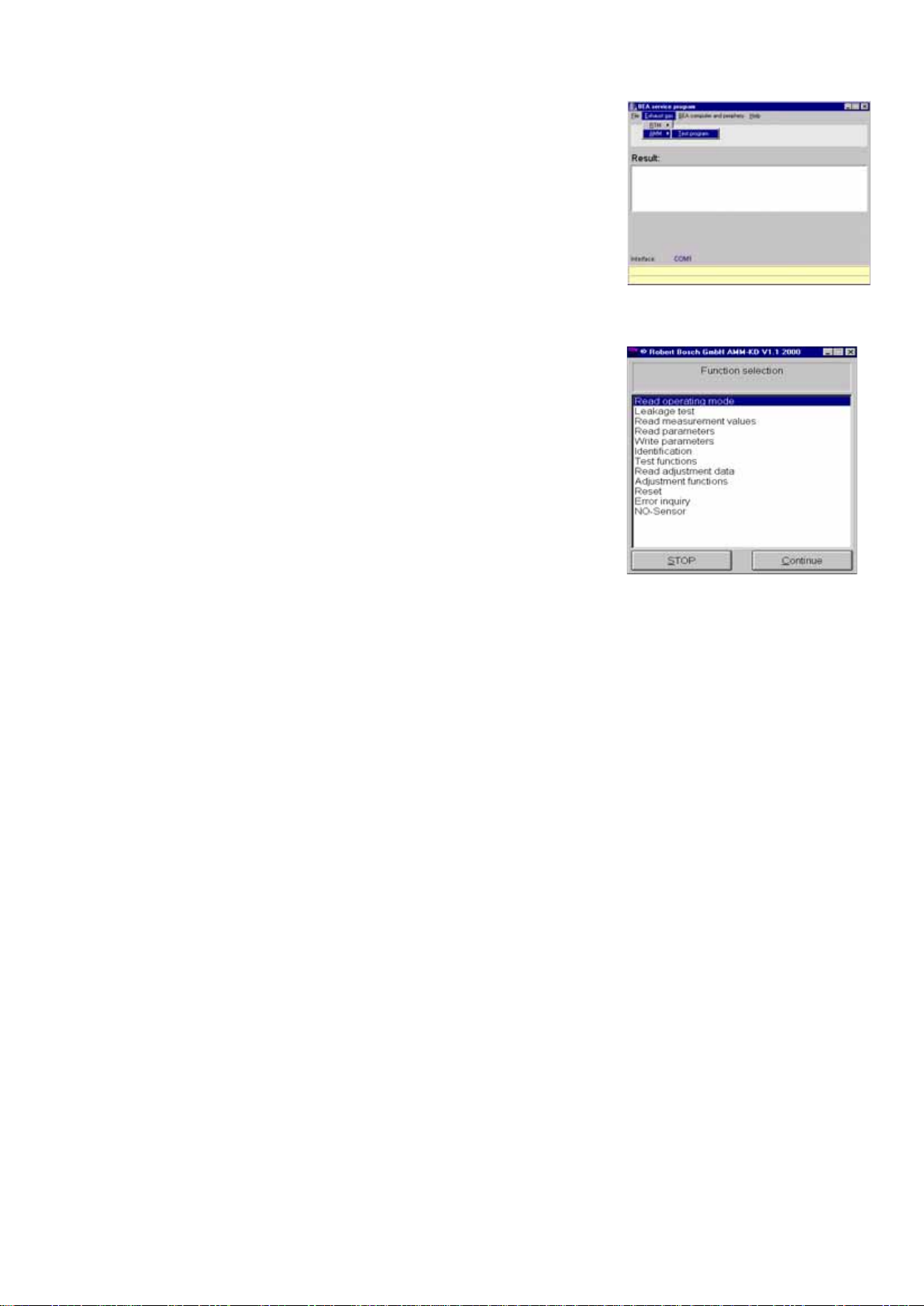

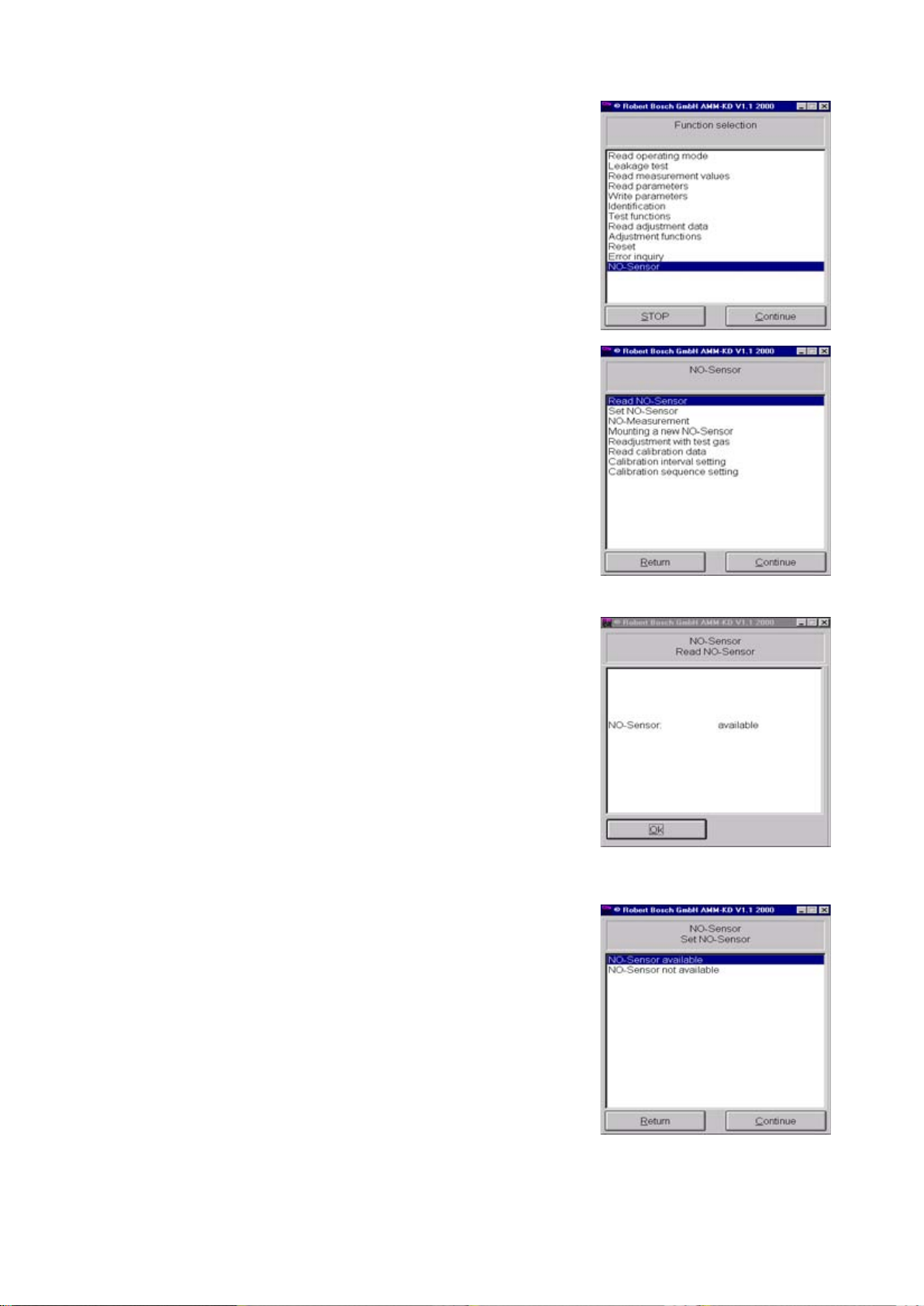

4. Checking the AMM

exhaust-gas analyzer

module

Open the Exhaust gas menu and select

AMM.

Then choose the Test program

Function selection menu (main

The

menu.

menu) opens.

The Function selection menu contains the

following items:

Read operating mode Display the current status (mode) of the exhaust-gas

analyzer module.

Leakage test Perform a manual leak test.

Read measurment values Display current measured values of HC, CO, CO

, lambda CO

O

2

and air pressure.

cor

Read parameters Read out set parameters.

Write parameters Enter parameters which are important for the opera-

tion of the exhaust-gas analyzer module (countryspecific stipulations).

Identification Read out software version and checksum.

Test functions Check unit functions.

Read adjustment data Display setting data important for operation of the

exhaust-gas analyzer module (country-specific stipulations).

Adjustment functions Settings for the exhaust-gas analyzer module.

Reset Restart the exhaust-gas analyzer module. (When this

option is selected, the exhaust-gas analyzer module

is disabled for approx. 15 s).

,

2

Error inquiry Read out the internal fault memory.

NO - Sensor Menu for operating the NO - Sensor.

11

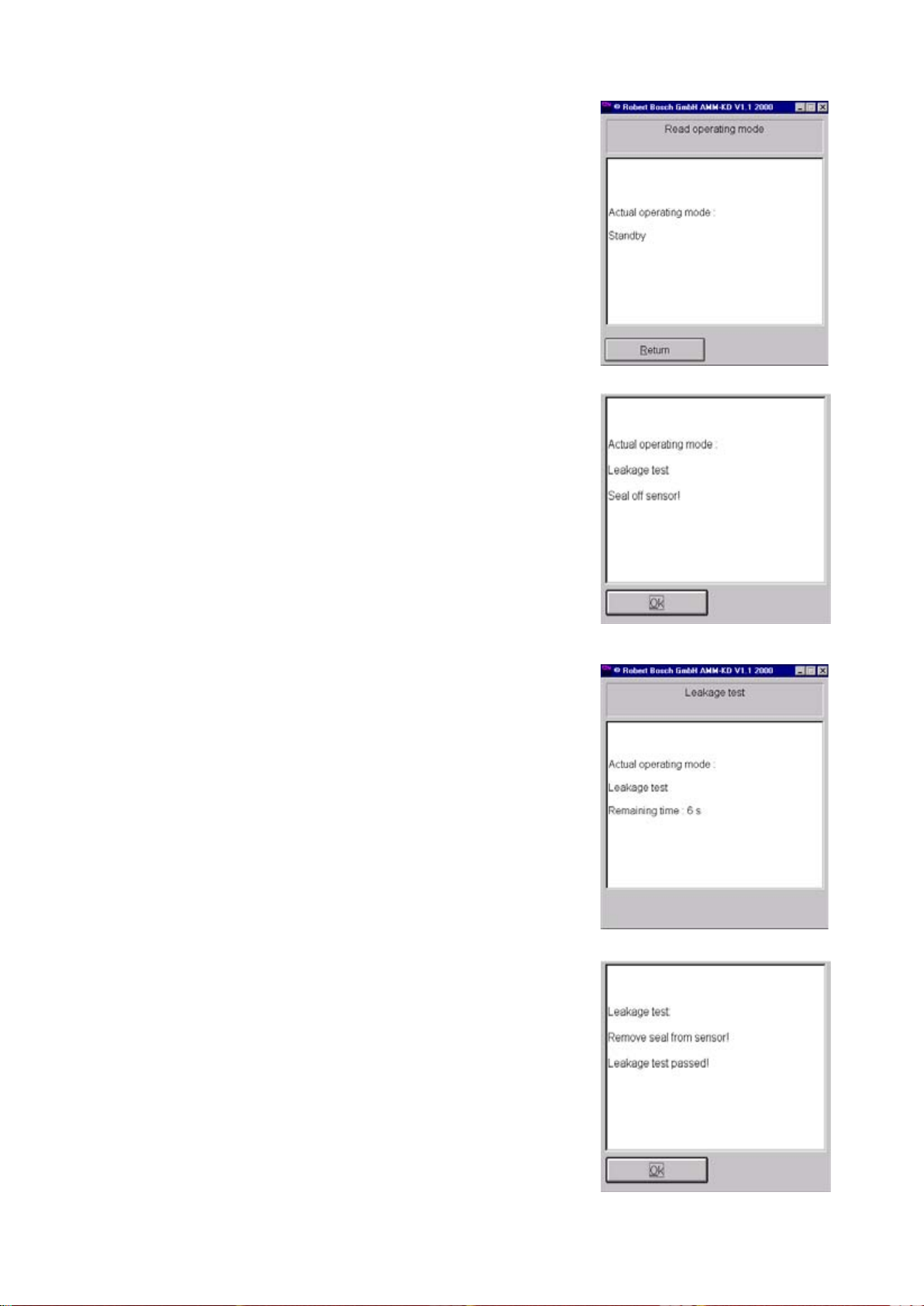

4.1 Read operating mode

The current status (mode) of the exhaustgas analyzer module is displayed.

Depending on when this menu is started,

the following modes may be displayed:

z Leakage test

z Warm-up phase

z Standby

z Error message

4.2 Leakage test

This menu allows you to perform a leakage

test manually to check the tightness of the

exhaust-gas analyzer module.

Seal off the exhaust-sample probe with

the plastic hose or the test bush and

confirm by pressing E or clicking OK.

Follow the instructions on screen.

The pump is then switched on and off in

cycles over a period of approx. 3 sec. until

a certain level of vacuum is reached. After

this, the exhaust-gas analyzer module

measures the drop in pressure over a

period of 15 s. The time is counted backwards from 15 s to 0.

12

Remove the seal from the exhaust-sample

probe and confirm by pressing E or

clicking OK.

If the leakage test is failed, perform trouble-shooting as described in Section 8.

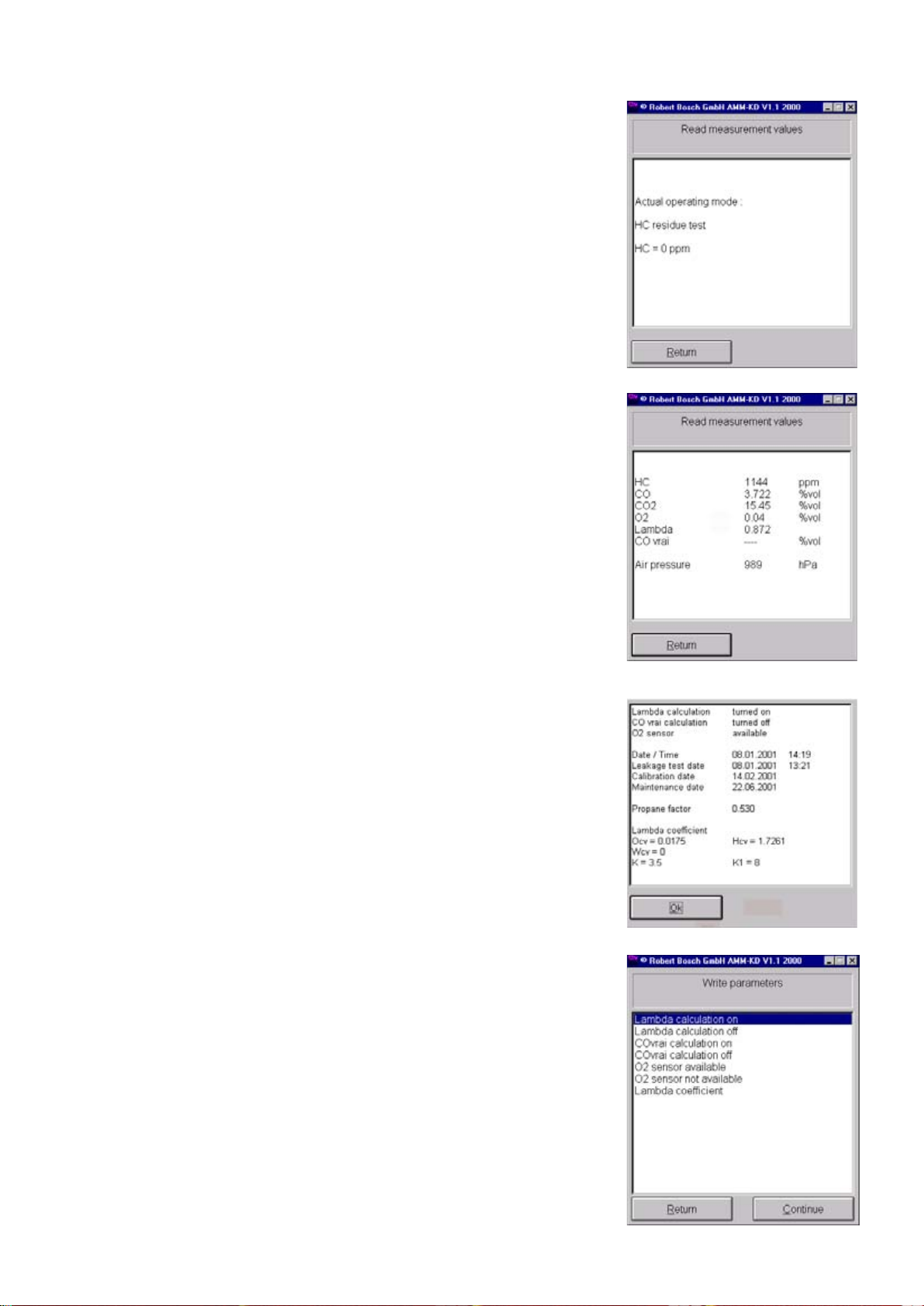

4.3 Read measurement values

After zero calibration, an HC residue test

takes place.

Next, the current measured values for HC,

CO, CO

pressure are displayed.

, O2, lambda, CO

2

and air

cor

4.4 Read parameters

4.5 Write parameters

The parameters set in the Set parameters

mode (Section 4.5) are displayed. For

example:

Parameters specific to the country of use

or required by law are set in this menu.

13

4.5.1 Country-specific settings

Parameter settings

Parameter Germany Standard EU Denmark Switz. France Holland Italy

Lambda calculation ON ON ON O N ON ON ON

CO

calculation OFF OFF ON OFF ON OFF OFF

cor

measurement ON ON ON ON ON ON ON

O

2

Adjustment data settings

Setting Germany Standard EU Denmark Switz. France Holland Italy

Recalibration interval 365 days 365 days 365 days 365 days 365 days 365 days 365 days

Gases for recalibration HC, CO, HC, CO, HC, CO, HC, CO, HC, CO, No setting HC, CO,

CO

2

CO

2

CO

2

CO

2

CO

2

CO

2

Reaction when recalibration Disable No setting No setting Disable No setting Message No setting

due

Leak test configuration Days Days NO Days NO Days Days

Leak test interval 1 day 1 day NO 1 day NO 1 day 1 day

HC residue test YES YES YES YES YES YES YES

National regul. complied with YES NO YES YES NO YES YES

Change CO

setting Disabled Enabled Disabled Disabled Enabled Disabled Enabled

cor

Service interval 183 days 183 days 183 days 183 days 183 days 183 days 183 days

14

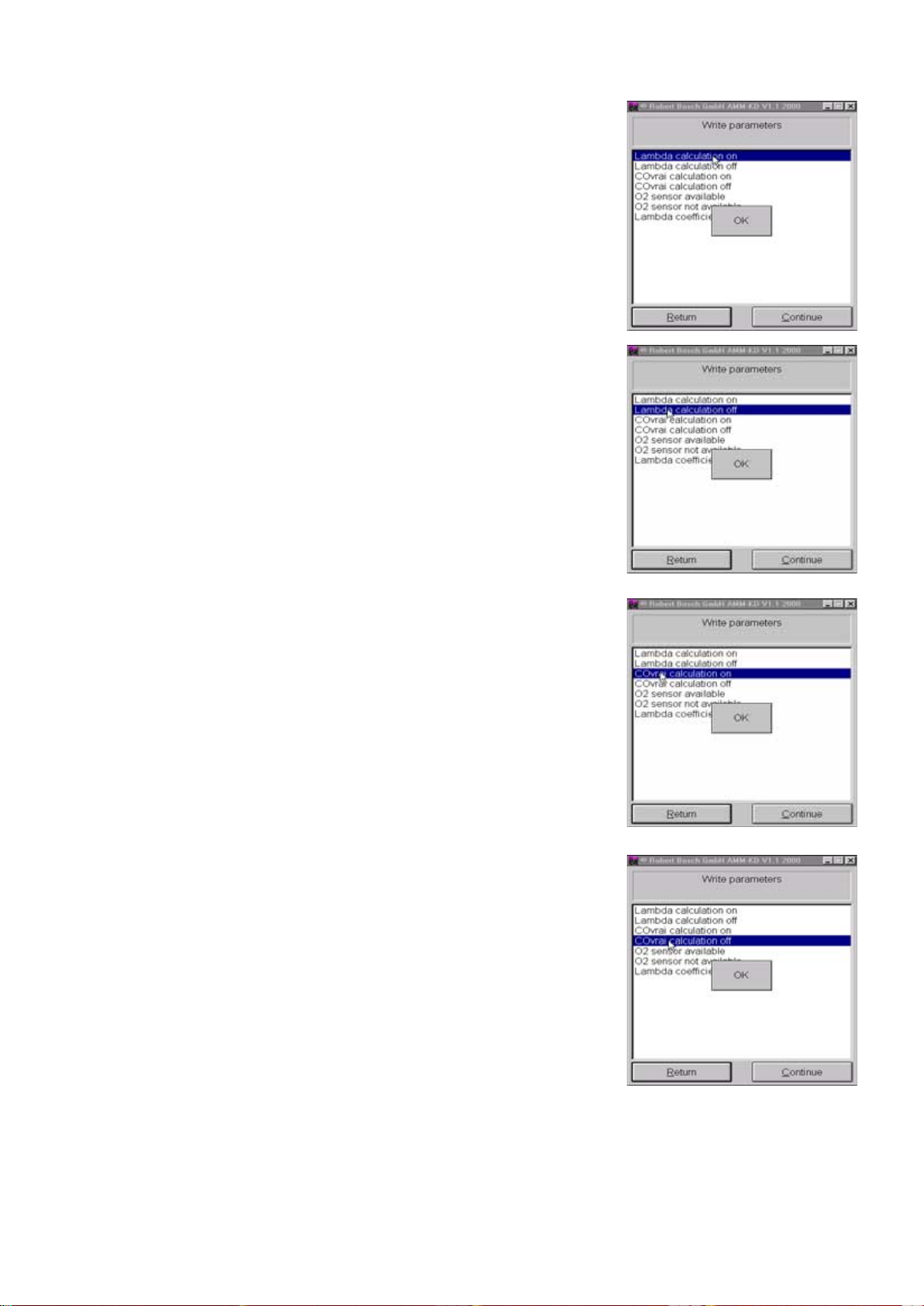

4.5.2 Lambda calculation On

Open the Lambda calculation on menu

using the o u keys and confirm with E or

by double-clicking the mouse.

The OK box is displayed for approx. 1 s.

Lambda calculation is now activated.

4.5.3 Lambda calculation Off

4.5.4 CO

calculation On

vrai

Open the Lambda calculation off

menu using the o u keys and confirm

with E or by double-clicking the mouse.

The OK box is displayed for approx. 1 s.

Lambda calculation is now deactivated.

Open the CO

calculation on menu

vrai

using the o u keys and confirm with E or

by double-clicking the mouse.

The OK box is displayed for approx. 1 s.

calculation is now activated.

CO

cor

4.5.5 CO

calculation Off

vrai

Open the CO

calculation Off menu

vrai

using the o u keys and confirm with E or

by double-clicking the mouse.

The OK box is displayed for approx. 1 s.

calculation is now deactivated.

CO

cor

15

4.5.6 O

sensor available

2

Open the O2 sensor available menu using

the oukeys and confirm with E or by

double-clicking the mouse.

4.5.7 O

sensor not available

2

After confirmation that the O

sensor is not

2

available, the measuring chamber's

measuring computer (SI BENCH) is restarted. After this it jumps back to the Set

parameters sub menu.

i The exhaust-gas analyzer is then once

more in the warm-up phase. Further

measurement with the Service software is disabled for 60 seconds. A

message appears on screen.

Open the O

sensor not available menu

2

using the ou keys and confirm with E or

by double-clicking the mouse.

After confirmation that the O

available, the measuring chamber's

sensor is not

2

measuring computer (SI BENCH) is restarted. After this it jumps back to the Set

parameters sub menu.

i The exhaust-gas analyzer is then once

more in the warm-up phase. Further

measurement with the Service software is disabled for 60 seconds. A

message appears on screen.

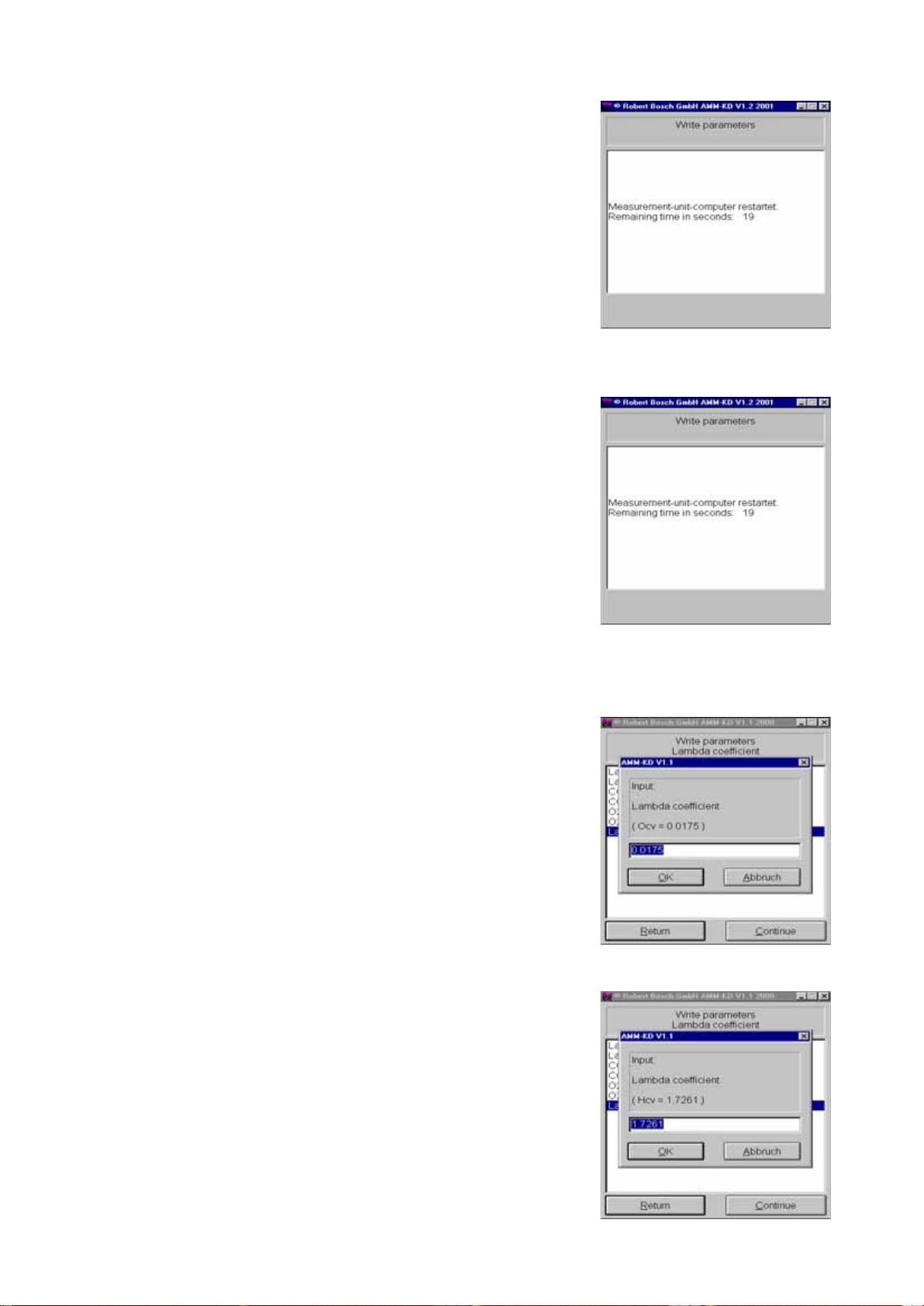

4.5.8 Entering lambda coefficients

OCV and HC

V

i Lambda coefficients must also be set

in accordance with regulations specific to the country of use and must be

stipulated by the law of that country.

Lambda coefficients OC

and HC

V

are fuel-specific values and are required to calculate the lambda value.

Enter the values for OC

on the keyboard

V

and confirm by clicking OK or by pressing E.

e.g.: 0.0175.

Enter the values for HC

on the keyboard

V

and confirm by clicking OK or by pressing E.

e.g.: 1.7261.

V

16

4.5.8 Entering lambda coefficients

HC

and OC

V

V

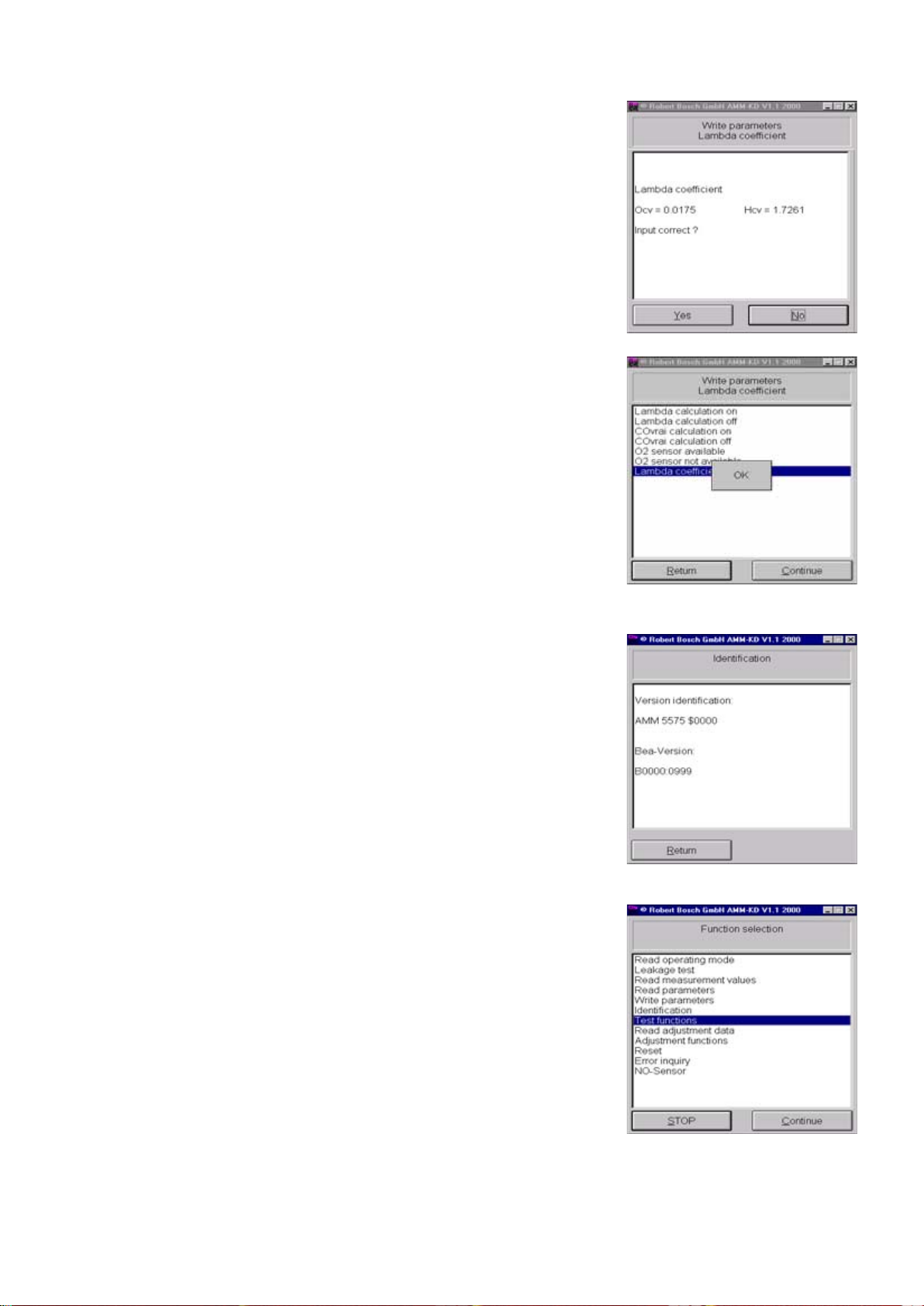

You are now asked if your entry is correct.

Confirm your entry by clicking Yes or by

selecting Yes with the v z buttons and

pressing E.

The OK box is displayed for approx. 1 s.

The HC

and OCV values are stored in the

V

exhaust-gas analyzer.

If you have entered the values incorrectly,

click No or cancel your entry with E.

Enter the lambda coefficient values again.

4.6 Identification

4.7 Test functions

The software version and checksum of the

exhaust-gas analyzer module are displayed. For example (see screenshot):

You can test various functions of the

exhaust-gas analyzer module in the Test

functions menu.

17

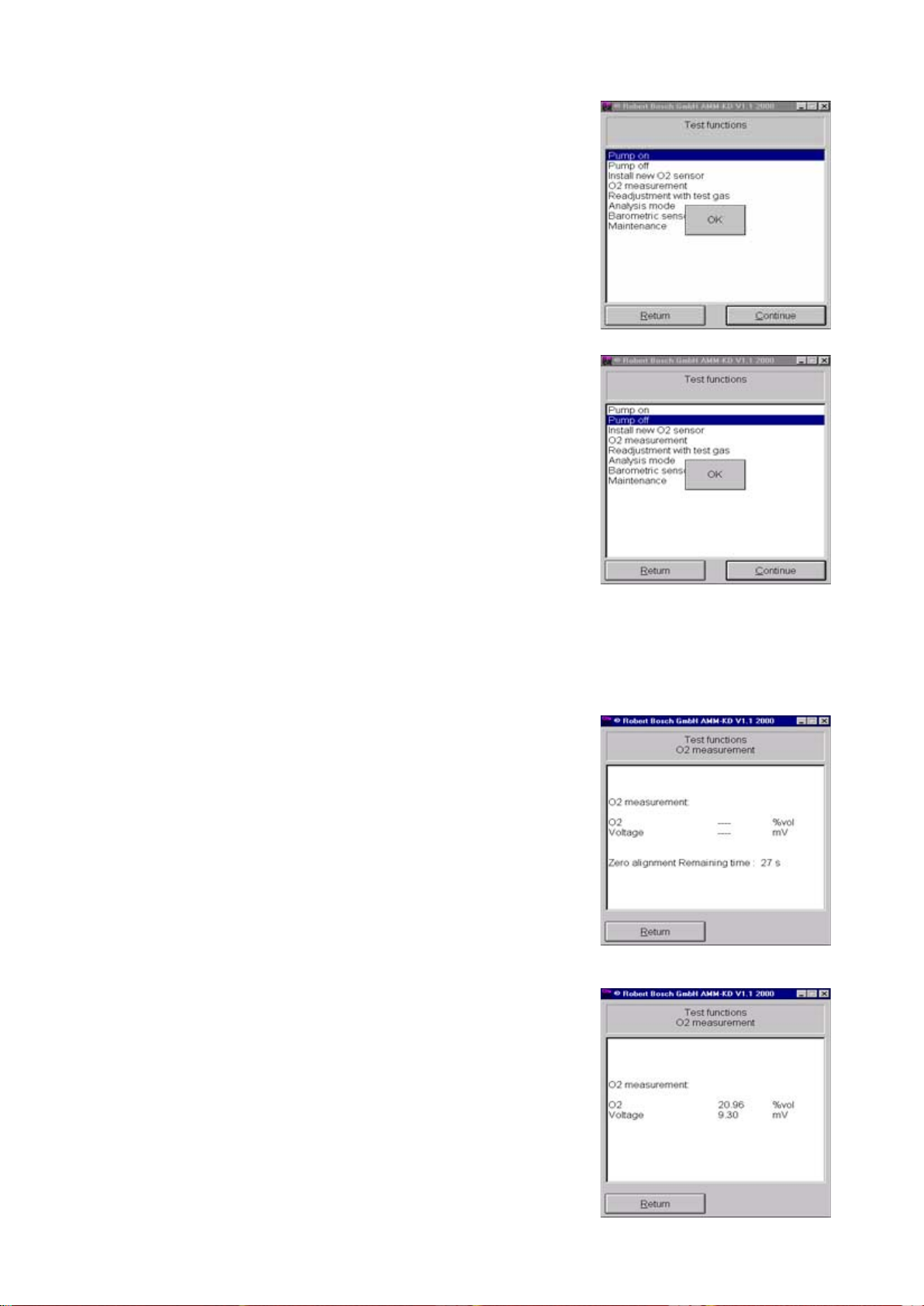

4.7.1 Pump On

Select this menu by double-clicking the

mouse or with the o u keys and confirm

with E.

The pump is switched on and the OK box

is displayed for 1 s.

This function can be used, for example, to

purge the exhaust-gas analyzer module if

it has been contaminated with HC.

4.7.2 Pump Off

4.7.3 Install new O2 sensor

4.7.4 O2 measurement

Select this menu by double-clicking the

mouse or with the o u keys and confirm

with E.

The pump is switched off and the OK box

is displayed for 1 s.

See Section 10.11.

Start the menu by double-clicking the

mouse or with E.

The pump is switched on and zero calibration takes place. During this process, the

measuring channel is recalibrated to

O

2

20.9% O

(this same calibration is also

2

performed automatically during each

system calibration with zero gas/air).

18

After zero calibration, the pump is switched off.

The exhaust-gas analyzer module displays

the concentration of oxygen with the current ADC voltage value below it.

If the current ADC voltage lies at the lower

threshold of 7 mV, you must replace the

measuring sensor (Section 10.11).

O

2

Nominal voltage: 7 mV - 11 mV

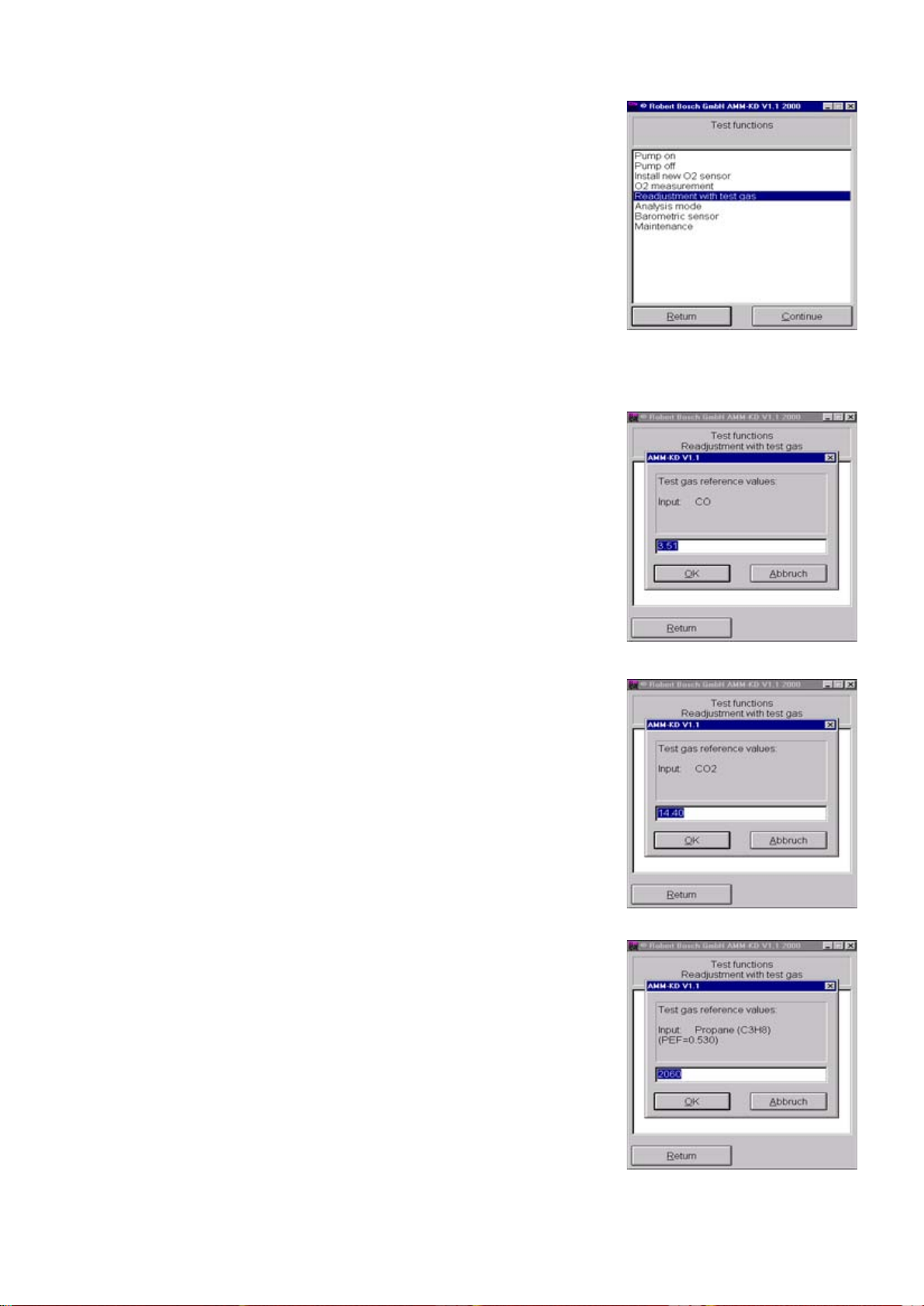

4.7.5 Readjustment with test gas i A distinguishing feature of the exhau-

st-gas analyzer module is the excellent long-time stability of its measuring accuracy. Despite this, the exhaust-gas analyzer may be required

by law or by the regulations of approval authorities to be recalibrated with

calibrating gas at given intervals.

To recalibrate the exhaust-gas analyzer,

you will need a calibrating-gas mixture

with the following concentrations (depending on requirements):

HC: 400 to 2000 ppm vol C3H8,

in propane

entry

CO: 1% to 10% vol CO

CO2: 5% to 18% vol CO

2

Using the keyboard, enter the calibratinggas values for CO as stated on the certificate.

Confirm your entry of these values by

clicking OK or by pressing E.

Using the keyboard, enter the calibratinggas values for CO

as stated on the certifi-

2

cate.

Confirm your entry of these values by

clicking OK or by pressing E.

Using the keyboard, enter the calibratinggas values for HC as stated on the certificate.

Confirm your entry of these values by

clicking OK or by pressing E.

19

4.7.5 Readjustment with test gas Set the flow to

i Only push the calibrating-gas hose

onto the calibrating-gas inlet following successful zero calibration.

The calibrating-gas mixture must be fed

into the calibrating-gas inlet.

The exhaust-gas analyzer module performs zero calibration.

> 1 l/min.

After zero calibration, push the calibratinggas hose onto the calibrating-gas inlet.

Start the flow at

The calibrating-gas values are displayed.

Over a period of 30 seconds, the software

of the exhaust-gas analyzer module compares the measured values with the

entered nominal values.

If readjustment with test gas has been

successful, quit the menu by clicking on

OK or with E.

The screen now returns to the Test

functions menu.

i If recalibration was unsuccessful, the

fault is stated in plain text. Repeat the

recalibration process.

> 1 l/min.

20

4.7.6 Analysis mode

In this mode, measured values are analyzed

whilst the pump is switched off. This saves

on calibrating gas.

i Drift correction is ineffectual in this

mode, as the warm-up phase has

been bypassed. The zero points therefore drift and may lead to errors.

Once you have started this menu, zero

calibration takes place.

Push the calibrating-gas hose onto the

calibrating-gas inlet and start the flow at

> 1 l/min.

Compare the measured values with the

calibrating-gas values.

In the event of deviations, perform troubleshooting as described in Section 10,

Repairs.

4.7.7 Barometric sensor

The current air pressure is displayed in hPa.

Return to the Test functions menu by

clicking Back

or by pressing E .

21

4.7.8 Maintenance (service date)

i In the case of service intervals stipula-

ted by law, confirm completed service

on the exhaust-gas analyzer. This sets

the internal clock to the next service

date.

Select Yes by clicking on it or using the

tab key .

Confirm that service

by clicking Yes or by pressing E.

Confirm the new service date by clicking

OK or with E. The screen now returns to

the Test functions menu.

has been performed

4.8 Read adjustment data

Here, the parameters set in the Adjustment functions menu are read out.

Quit the Read adjustment data menu

by clicking OK or with E.

22

4.9 Adjustment functions

i Make sure that the Service switch is

set to On

functions menu.

For details on how to adjust the exhaustgas analyzer module and undertake

country-specific settings, please refer to

Section 4.5.1 (country-specific settings).

Return to the function menu by clicking

Back or by pressing keys Alt + B.

before you open the Setting

4.10 Reset

A reset must be performed when entries

have been modified in the Setting

functions menu. These modified

settings will only be stored in the

flashprom of the exhaust-gas analyzer

module after a reset.

Select Yes by clicking it or with the tab

key . Confirm that you wish to perform

a reset with E or by double-clicking the

mouse.

The fault memory is deleted and the

exhaust-gas analyzer module is restarted.

i For approx. 15 s, the exhaust-gas

analyzer module has no connection to

the laptop or PC.

The following message therefore appears:

The measuring device reported hardware

failure!

The error code must be read!

After 15 s, restart the Service program

with E or by clicking OK.

4.11 Error inquiry

Any current faults in the exhaust-gas

analyzer module are displayed in plain

text.

Confirm the readout of the fault memory

with E or by clicking OK. The fault

memory is deleted and the screen returns

to the Function menu.

i If a fault still remains in the exhaust-

gas analyzer, this will be displayed

again.

23

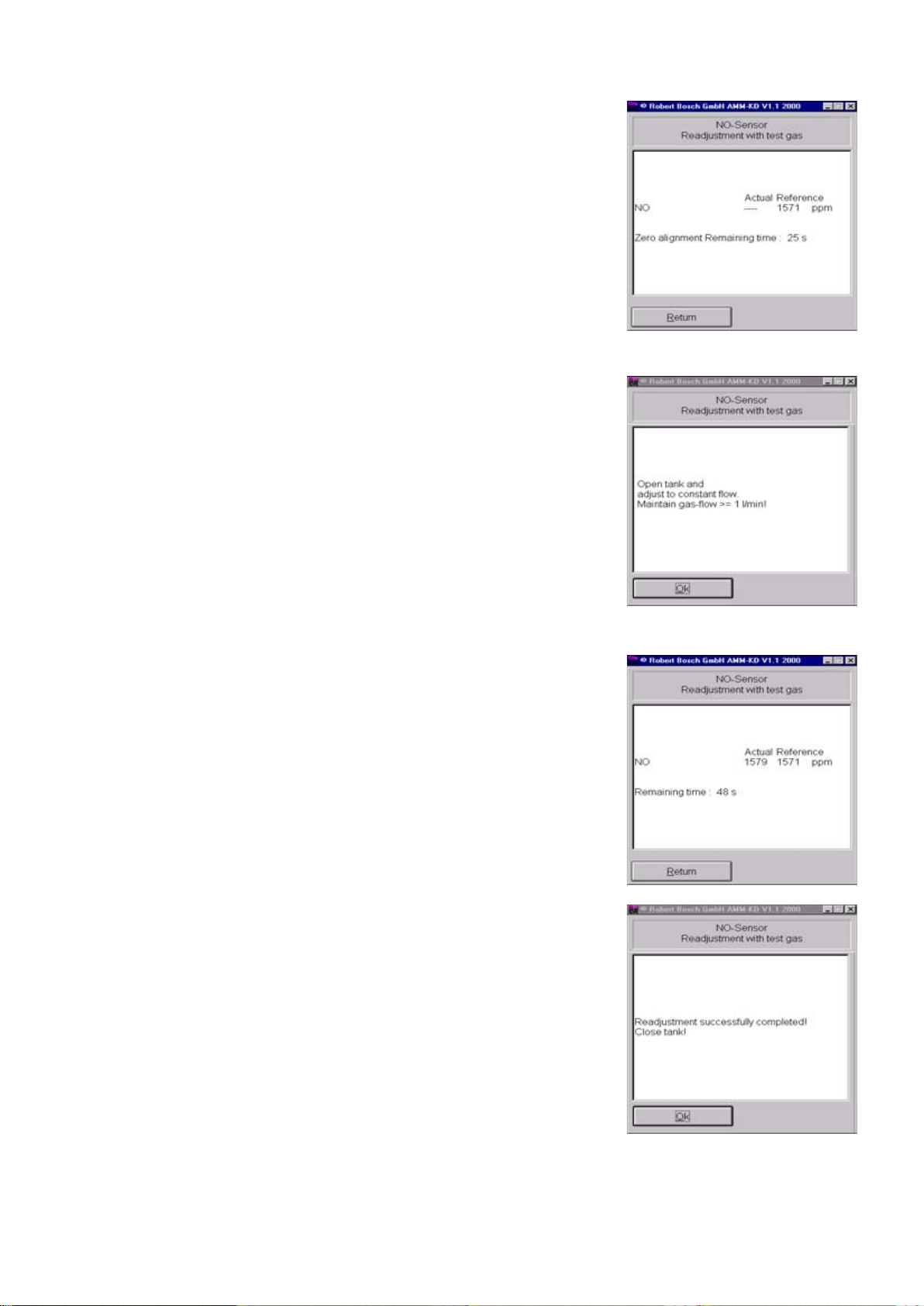

4.12 NO-Sensor

i This menu is only for BEA's equipped

with a retrofit NO measuring sensor!

This menu is used for monitoring, installing and checking the NO measuring sensor.

Start the menu with E or by doubleclicking the mouse.

The following menus can be executed:

z Read NO-Sensor

z Set NO-Sensor

z NO-Measurement

z Mounting an new NO-Sensor

z Readjustment with test gas

z Calibration interval setting

z Calibration sequence setting

4.12.1 Read NO-Sensor

4.12.2 Set NO-Sensor

The status of the NO measuring sensor is

displayed in this menu.

In this menu, the BEA is informed as to

whether or not an NO measuring sensor is

installed.

Confirm your selection of this menu with

E or by double-clicking the mouse.

The OK box appears for 1 s.

24

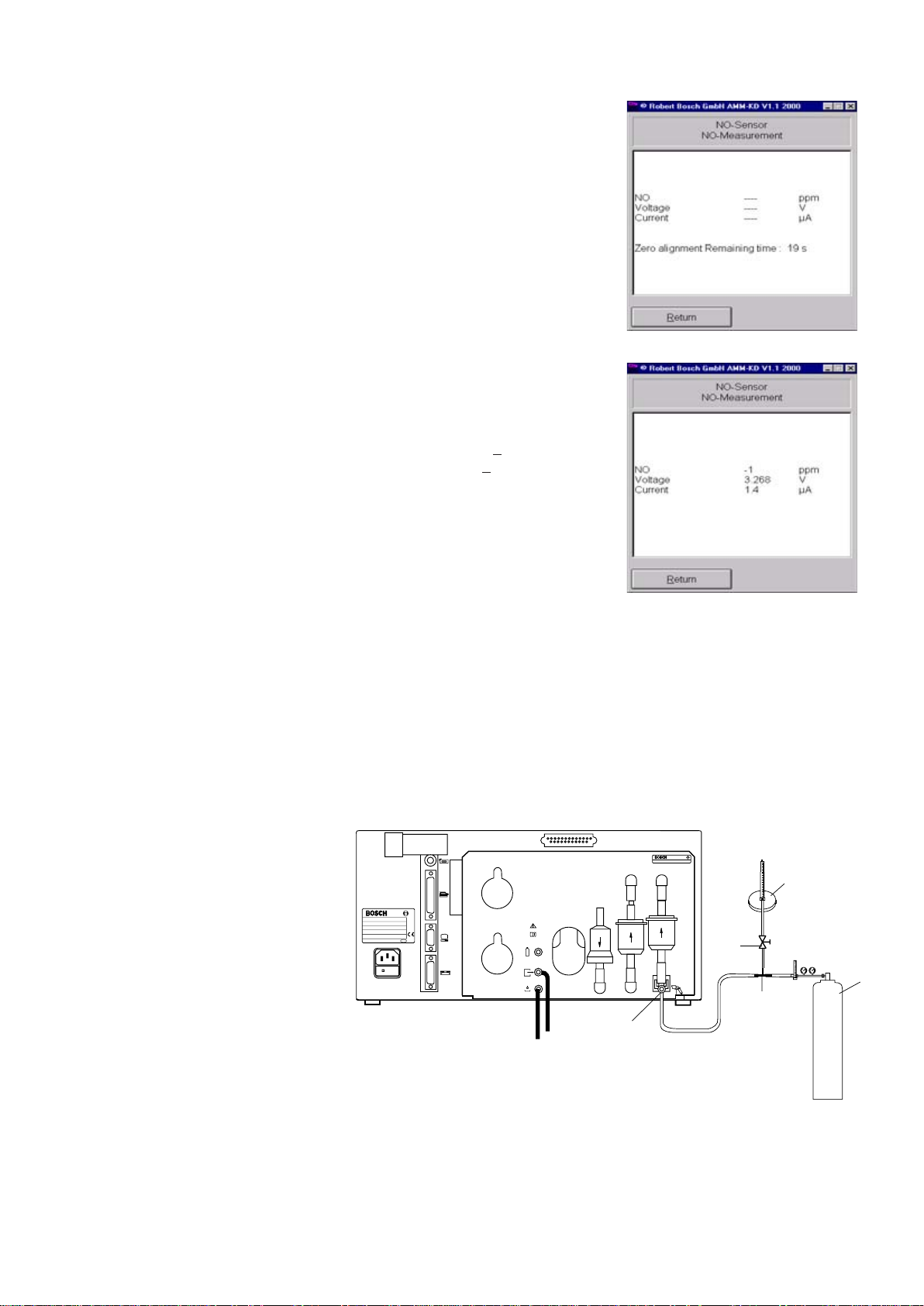

4.12.3 NO-Measurement

This menu is used to check the NO

measuring sensor.

Start the NO test by pressing E or by

double-clicking the mouse.

Zero calibration now takes place.

After zero calibration, the data of the NO

measuring sensor are displayed.

Limit values with air:

NO < 20ppm NO

Voltage 3.290 V

Current 10 µA

+ 0.040 V

+ 10µA

If the limit values are not complied with,

perform trouble-shooting as described in

Section 10.20.

4.12.4 Mounting a new NO-Sensor

Return to the NO menu by clicking Back

or by pressing Alt + B.

i See Section 10.20 for sensor

installation

After the NO measuring sensor has been installed, it must be calibrated. The date of

calibration is written in the flashprom, enabling the age of the NO measuring sensor to be

determined subsequently at any time.

The same calibrating gas is used for calibrating the NO measuring sensor as for

recalibration.

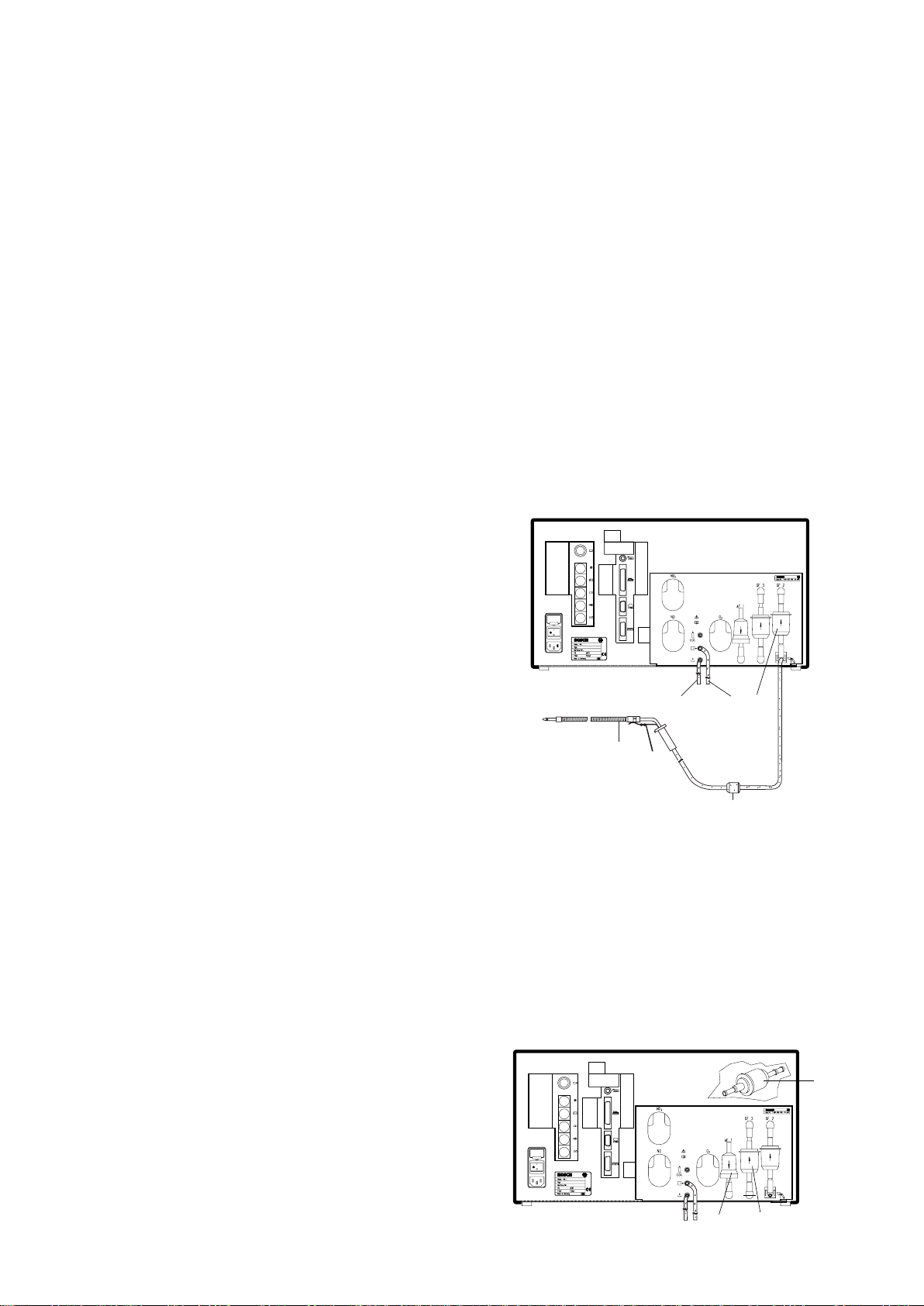

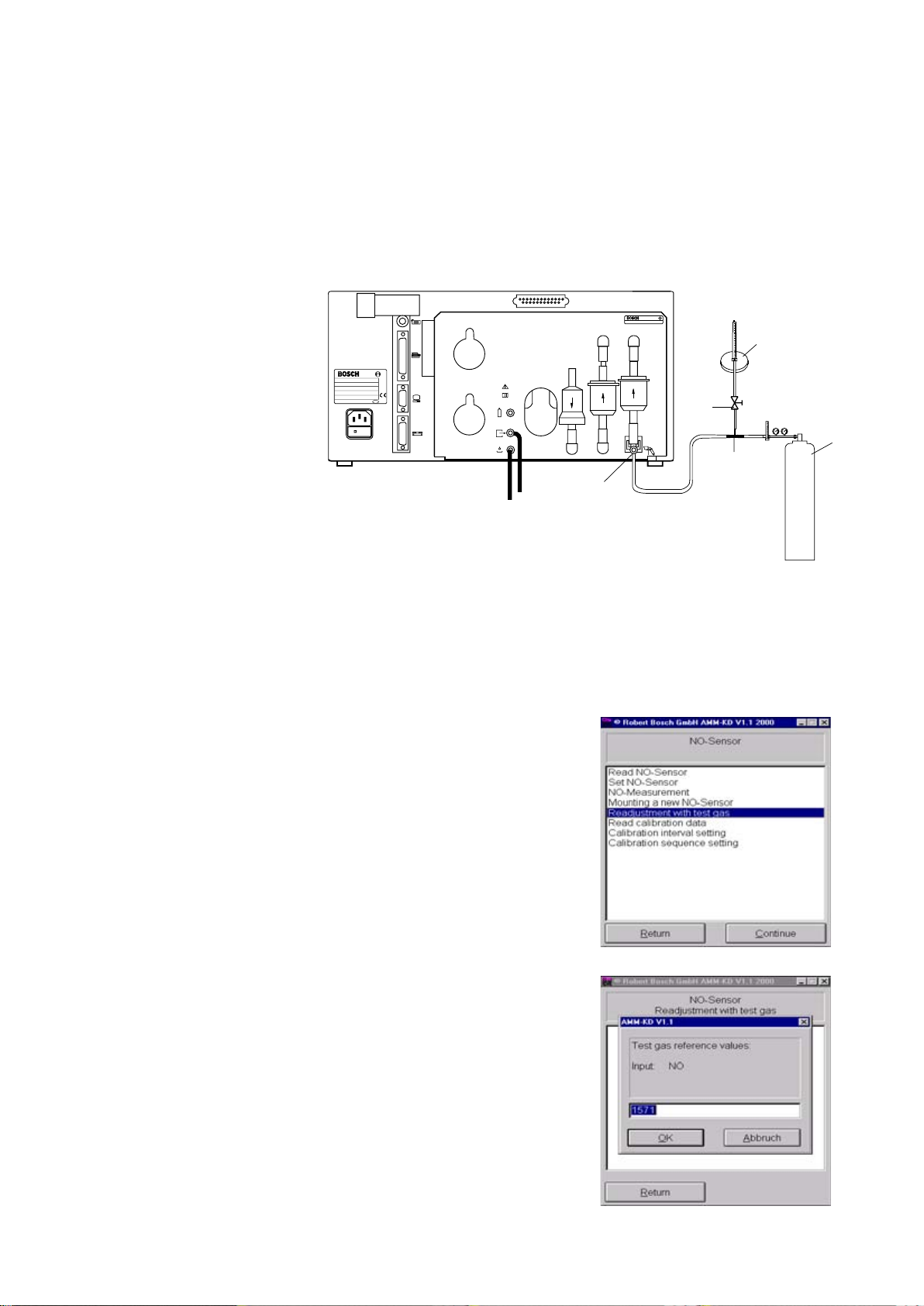

Before commencing calibration, connect the BEA to the calibrating-gas bottle as shown

in the illustration below.

Best. Nr. 1687 022 768 FD xxx

Best.- Nr.

Typ

Geräte - Nr.

FD U ( V )

P ( W ) F ( Hz )

Made in Germany

GF 3 GF 2

AF 1

O

2

088

cal

459737/25Ha

3

5

2

4

NO

1

1 Calibrating-gas bottle

2 Flow meter (rotameter)

3 Shutoff valve

4 Tee

5 Test-gas inlet

25

4.12.4 Mounting a new NO-Sensor

! For initial calibration, it is imperative that the hoses (1) are of the same length and are

connected to the gas outlets of the exhaust-gas analyzer in the same manner as will

actually be the case during subsequent operation by the user.

Best. Nr. 1687 022 768 FD xxx

GF 3 GF 2

AF 1

Best.- Nr.

Typ

Geräte - Nr.

FD U ( V )

P ( W ) F ( Hz )

Made in Germany

088

O

2

cal

459737/26Ha

1

i If the outlet hoses are shortened or lengthened, calibration must be performed again.

The signal from the NO measuring sensor is very sensitive to vibrations from the

pump. The strength of these vibrations depends upon the length of the outlet hoses.

Following successful calibration, the timer for monitoring the set recalibration interval

is started.

- Start evaluation by clicking on Yes or

selecting this button with the z key and

confirming with E.

26

Using the keyboard, enter the calibratinggas value in ppm NO.

i If the calibrating-gas value is stated

on the certificate in mg/m

3

you must

convert this value to ppm.

The formula required for conversion

is:

Test gas value x 0.737.

Example:

2179 mg/m

3

= 1606 ppm NO

Confirm your entry with E or by clicking

OK.

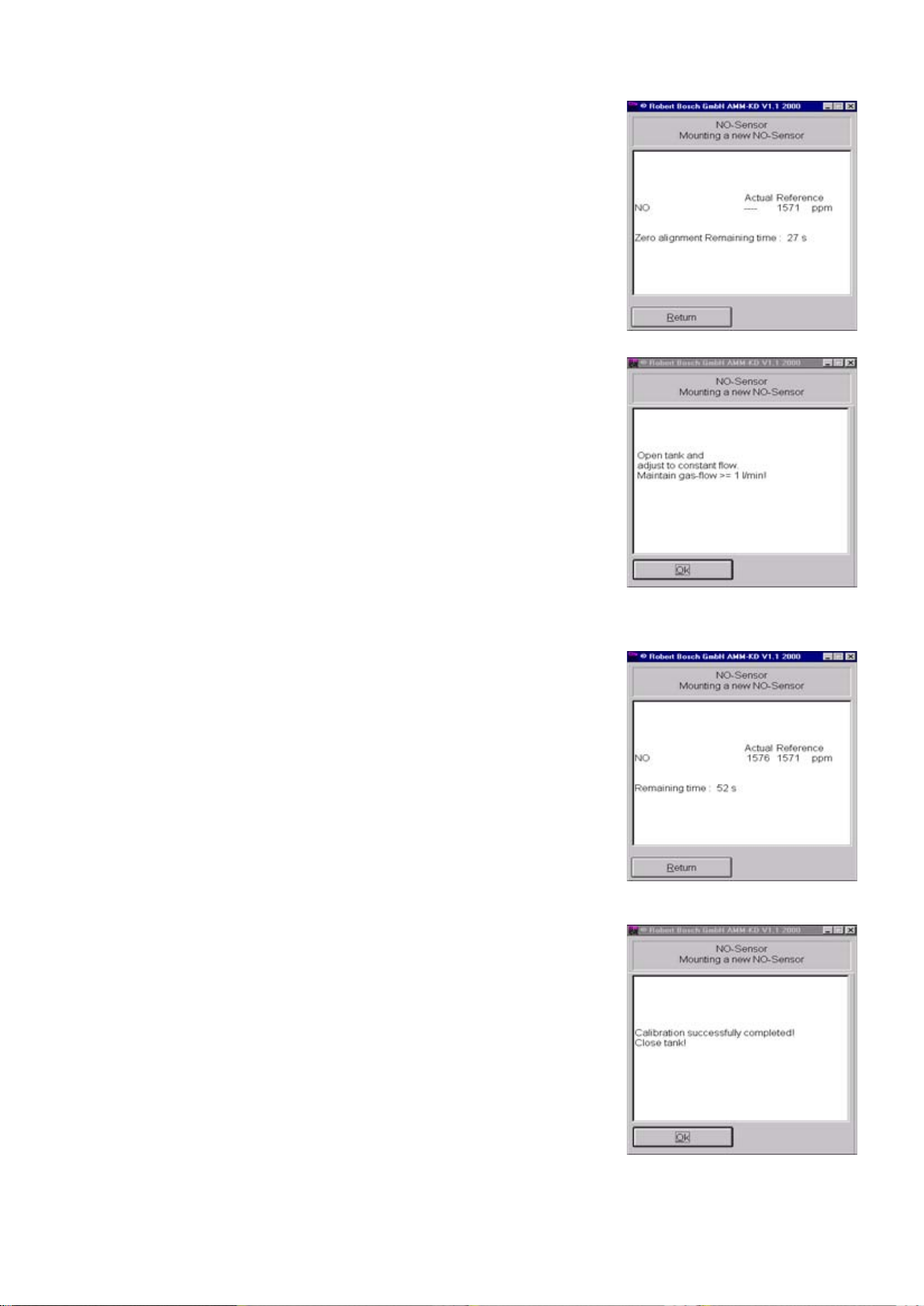

4.12.4 Mounting a new NO-Sensor Zero calibration is performed.

Allow calibrating gas to flow through the

BEA in line with the instructions on

screen.

Open the Test-gas bottle sufficiently to

allow some Test gas to continually flow

out through the rotameter, even with the

pump running (pressure-less calibration).

i The NO measuring sensor is very

sluggish. An "advance flow" through

the NO measuring sensor is therefore

necessary.

After this flow, confirm with E or by

clicking OK.

Assessment is performed. The remaining

flow time is displayed.

After calibrating gas has flown through

the BEA, the measured NO value, the

corresponding test current and the date

calibration are displayed.

To end calibration of the NO measuring

sensor, confirm No by pressing E or

clicking on No.

of

You will now return to the NO-Sensor

menu, and the timer for the adjustment

interval is started.

27

4.12.5 Readjustment with test gas i To calibrate the NO measuring sensor you will require a calibrating gas with the following composition:

From 1000 to 5000 ppm NO in nitrogen (N).

The electrochemical measuring sensor must be recalibrated at regular intervals. Only in

this way can measuring accuracy be reliably maintained. The recalibration process also

allows faulty NO measuring sensors to be detected.

Before commencing recalibration, connect the calibrating-gas bottle as shown in the

illustration below. Connect the calibrating-gas connection to the test-gas inlet.

Best. Nr. 1687 022 768 FD xxx

Best.- Nr.

Typ

Geräte - Nr.

FD U ( V )

P ( W ) F ( Hz )

Made in Germany

GF 3 GF 2

AF 1

O

2

088

cal

459737/25Ha

3

5

2

4

NO

1

1 Calibrating-gas bottle

2 Flow meter (rotameter)

3 Shutoff valve

4 Tee

5 Test-gas inlet

Start recalibration with E or by doubleclicking the mouse.

Using the keyboard, enter the calibratinggas value in ppm NO.

i If the calibrating-gas value is stated

3

on the certificate in mg/m

you must

convert this value to ppm.

The formula required for conversion

is:

Calibrating-gas value x 0.737.

Example:

3

2179 mg/m

= 1606 ppm NO

28

Confirm your entry with E or by clicking

OK.

4.12.5 Readjustment with test gas ! Do not yet open the gas bottle!

The BEA performs zero calibration.

Allow calibrating gas to flow through the

BEA in line with the instructions on

screen.

Open the calibrating-gas bottle sufficiently to allow some calibrating gas to continually flow out through the rotameter, even

with the pump running (pressure-less calibration).

i The NO measuring sensor is very

sluggish. An "advance flow" through

the NO measuring sensor is therefore

necessary.

After this flow, confirm with E or by

clicking OK.

The remaining flow time is displayed.

Once recalibration has successfully been

completed, close the calibrating-gas bottle.

End recalibration by pressing E or by

clicking OK.

! If you have recalibrated the NO

measuring sensor because you have

just installed a new one, you must

also proceed according to the

instructions in Section 4.12.4,

Calibration of a new NO measuring

sensor.

29

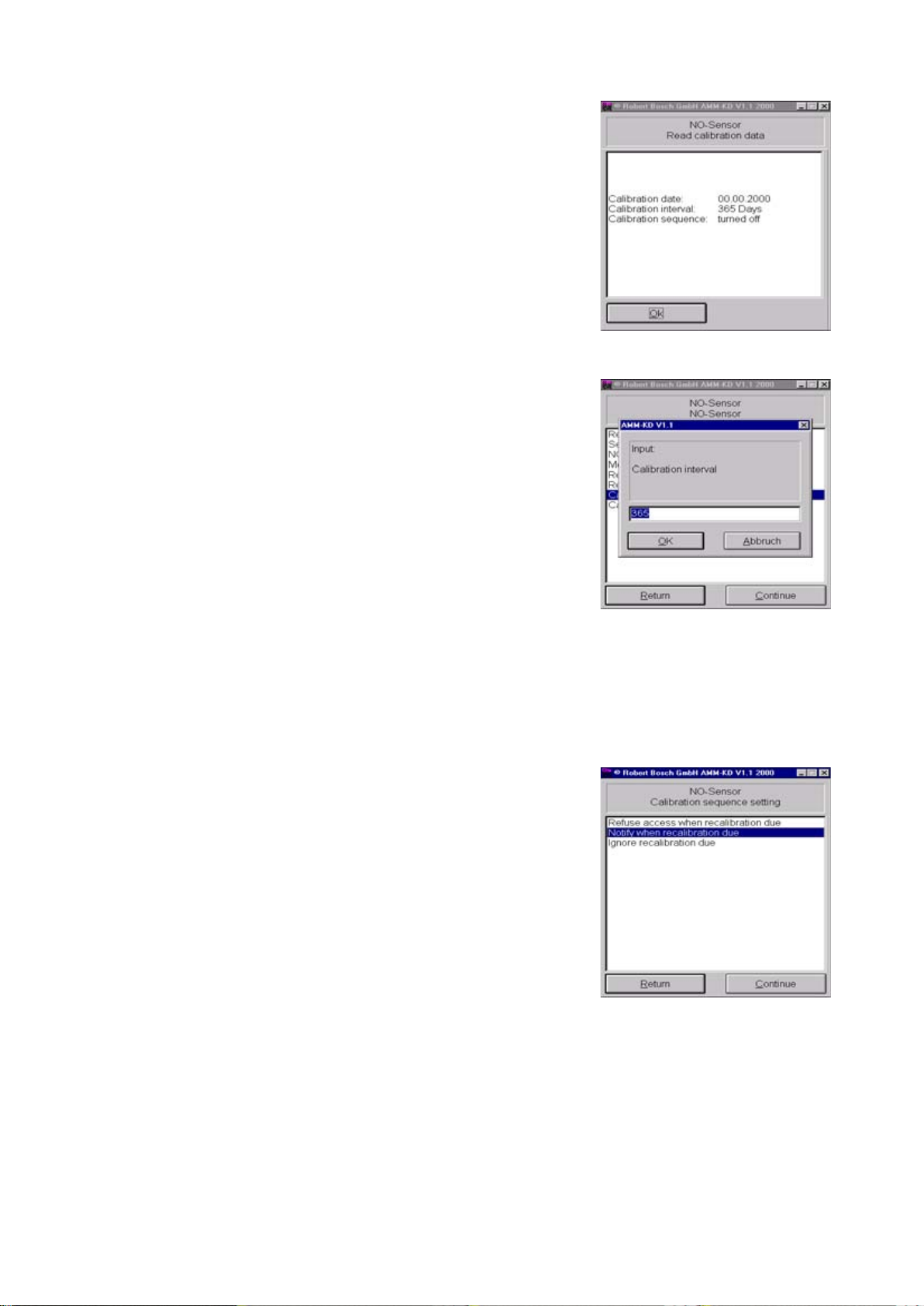

4.12.6 Read calibration data

The following data are read out in this

menu:

Calibration date

Date of next calibration.

Calibration interval

Interval before recalibration in days.

Calibration sequence

Reaction after the calibration interval has

elapsed (Sec. 4.12.8).

4.12.7 Calibration interval setting

4.12.8 Calibration sequence setting

i To access the Set calibration interval

menu, set the Service switch on the

test computer PCB to On.

In this menu, enter the number of days

after which the NO measuring sensor

must be recalibrated.

Enter the number of days using the keyboard.

Confirm your entry with E or by clicking

OK.

The OK window is displayed for 1 s.

This menu enables you to define how the

BEA should react once the calibration

interval has elapsed.

You can choose between the following

options:

Refuse access when recalibration

due:

Once the calibration interval has elapsed,

the BEA is disabled and displays a

message.

The BEA is only ready for measurement

once more after the NO measuring sensor

has been successfully recalibrated.

30

Notify when recalibration due:

Once the calibration interval has elapsed,

the BEA displays a message but remains

ready for measurement.

Ignore recalibration due

No message appears and the BEA

remains ready for measurement.

Loading...

Loading...