Page 1

For English ¿Habla español? Parlez-vous français?

See page 2 Ver página 36 Voir page 70

4412

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Page 2

General Safety Rules

For Bench Top Tools

Work Area

● Keep work area clean and well lit. Cluttered

benches and dark areas invite accidents.

● Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or

fumes.

● Keep bystanders, children and visitors away

while operating a power tool. Distractions

can cause you to lose control.

● Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in the hands of untrained users.

● Do not leave tool running unattended, turn

power off. Do not leave tool until it comes to a

complete stop.

● MAKE WORKSHOP CHILDPROOF with pad

lock, master switches, or by removing starter

keys.

Electrical Safety

● Before plugging in the tool, be certain the

outlet voltage supplied is compatible with

the voltage marked on the nameplate within

10%. An outlet voltage incompatible with that

specified on the nameplate can result in serious

hazards and damage to the tool.

● Double insulated tools are equipped with a

polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install a polarized outlet. Do not change the

plug in any way. Double insulation eliminates

the need for the three wire grounded power cord

and grounded power supply.

● Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is grounded.

● Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

● Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

● When operating a power tool outside, use an

outdoor extension cord marked “W-A” or

“W”. These cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

● Stay alert, watch what you are doing and use

common sense when operating a power

tool. A moment of inattention or use of drugs,

alcohol or medication while operating power

tools can be dangerous.

● Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be

caught in moving parts. Roll long sleeves

above elbows. Rubber gloves and non-skid

footwear are recommended when working outdoors.

● Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

● Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool will

be thrown.

● Do not overreach, keep proper footing and

balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

● Do not stand on tool or its stand. Serious

injury may occur if the tool is tipped or if the cutting tool is accidentally contacted. Do not store

materials on or near the tool such that it is necessary to stand on the tool or its stand to reach

them.

2.

Safety

“READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (●) symbol listed BELOW and other safety precautions, may result in serious person-

al injury.

“SAVE THESE INSTRUCTIONS”

WARNING

!

Page 3

3.

“SAVE THESE INSTRUCTIONS”

● Use safety equipment. Always wear safety

goggles. Dust mask, safety shoes, hard hat or

hearing protection must be used for appropriate

conditions. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety

glasses.

Tool Use and Care

● Use clamps or other practical way to secure

and support the workpiece to a stable platform. Holding the work by hand or against your

body is unstable. It allows for work to shift,

causes binding of the tool and loss of control.

● Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed. Do not use the tool for purpose not

intended - for example; do not use the miter saw

for slicing meats.

● Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be controlled with the switch is dangerous.

● Disconnect the plug from the power source

before making any adjustments or changing

accessories. Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

● Keep cutting tools sharp and clean. Properly

maintained tools, with sharp cutting edges, are

less likely to bind and easier to control. When

mounting saw blades be certain that the arrow

on the blade matches the direction of the arrow

marked on the tool and that the teeth are also

pointing in the same direction.

● Inspect guards before using a tool. Keep

guards in place. Check moving parts for

binding or any other condition that may

affect the normal operation or safety features of the tool. If damaged, have tool serviced before using the tool. Many accidents

are caused by poorly maintained tools.

● Do not alter or misuse tool. Any alteration or

modification is a misuse and may result in serious personal injury.

● The use of any other accessories not speci-

fied in this manual may create a hazard.

Accessories that may be suitable for one type of

tool, may become hazardous when used on an

inappropriate tool.

Service

● Tool service must be performed only by

qualified repair personnel. Service or maintenance performed by unqualified personnel may

result in misplacing internal wires and components which could cause serious hazard.

● When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorized parts or failure to follow

Maintenance Instructions may create a hazard.

Safety Rules

For Miter Saws

● Use clamps to support workpiece whenever

possible. If supporting the workpiece by

hand, you must always keep hand outside of

“No Hand” area as marked with a symbol on

the base. Do not use this saw to cut pieces

that are too small to be securely clamped.

Your hand if placed inside the “No Hands”

region can easily slip or be pulled into the blade.

● Do not reach in back of the saw blade

behind the fence with either hand to hold

down or support the workpiece, remove

wood scraps, or for any other reason. The

proximity of the spinning saw blade to your hand

may not be obvious and you may be seriously

injured.

● Never cross your hand over intended line of

cutting. Supporting the workpiece “cross handed” i.e. holding the left side of the workpiece

with your right hand is very dangerous.

● Always disconnect the power cord from the

power source before making any adjustments or attaching any accessories. You

may unintentionally start the saw, leading to

serious personal injury.

● Miter saws are intended to cut wood or

woodlike products, they cannot be used with

abrasive cutoff wheels for cutting ferrous

material such as bars, rods, studs, etc.

However, if cutting materials like aluminum

or other non-ferrous metals, use only saw

blades specifically recommended for nonferrous metal cutting. Cutting ferrous materi-

als causes excessive sparking and will damage

the lower guard and will overload the motor.

(NOTE: S-B Power Tool Company does not

offer 12” metal cutting blades.)

Safety

“READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (

●) symbol listed BELOW and other safety precautions, may result in serious person-

al injury.

WARNING

!

Page 4

“SAVE THESE INSTRUCTIONS”

4.

● Inspect your workpiece before cutting. If

workpiece is bowed or warped, clamp it with

the outside bowed face toward the fence.

Always make certain that there is no gap between the workpiece, fence and table along

the line of the cut. Bent or warped workpieces

can twist or rock and may cause binding on the

spinning saw blade while cutting. Also, make

sure there are no nails or foreign objects in the

workpiece.

● Do not use the saw until the table is clear of

all tools, wood scraps, etc., except the workpiece. Small debris or loose pieces of wood or

other objects that contact the revolving blade

can be thrown with high speed at the operator.

● Do not feed workpiece into the blade or cut

“freehand” in any way. Workpiece must be

stationary and clamped or braced by your

hand. Saw must be fed through the workpiece

smoothly and at a rate which will not overload

the saw’s motor.

● Cut only one workpiece at a time. Multiple

workpieces cannot be adequately clamped or

braced and may bind on the blade or shift during cutting.

● Be certain the miter saw is mounted or

placed on a level, firm work surface before

using. A level and firm work surface reduces

the risk of the miter saw becoming unstable.

● Plan your work. Provide adequate support

accessories such as tables, saw horses,

table extension, etc. for workpieces wider or

longer than the table top (see page 20).

Workpieces longer or wider than the miter saw

table can tip if not securely supported. If the

cutoff piece or workpiece tips it can lift the lower

guard or be thrown by the spinning blade.

● Do not use another person as a substitute

for a table extension or as additional support. Unstable support for the workpiece can

cause the blade to bind or the workpiece to shift

during the cutting operation pulling you and the

helper into the spinning blade.

● The cutoff piece must not be jammed

against or pressured by any other means

against the spinning saw blade. If confined,

i.e. using length stops, it could get wedged

against the blade and thrown violently.

● Always use a clamp or a fixture designed to

properly support round material such as

dowel rods, or tubing. Rods have a tendency

to roll while being cut, causing the blade to “bite”

and pull the work with your hand into the blade.

● When cutting irregularly shaped work-

pieces, plan your work so it will not slip and

pinch the blade and be torn from your hand.

A piece of molding, for example, must lie flat or

be held by a fixture or jig that will not let it twist,

rock or slip while being cut.

● Let the blade reach full speed before con-

tacting the workpiece. This will help avoid

thrown workpieces.

● If the workpiece or blade becomes jammed

or bogged down, turn miter saw “OFF” by

releasing switch. Wait for all moving parts

to stop and unplug the miter saw, then work

to free the jammed material. Continued saw-

ing with jammed workpiece could cause loss of

control or damage to miter saw.

● Braking action of the saw causes the saw

head to jerk downward. Be ready for this

reaction when making an incomplete cut or

when releasing the switch before the head is

completely in the down position.

● After finishing the cut, release the switch,

hold the saw arm down and wait for blade to

stop before removing work or cutoff piece.

If blade does not stop within five (5) seconds, unplug the saw and follow the instructions in the Troubleshooting section.

REACHING WITH YOUR HAND UNDER A

COASTING BLADE IS DANGEROUS!

● There are additional safety instructions

for particular operations of the saw in the

operating section. Read the rest of the manual for safe operation.

● For slide action cutting, first PULL saw head

assembly away from the fence, until blade

clears the workpiece or to its maximum

extension if blade cannot clear the workpiece. Make certain the clamp does not interfere with the guard and head assembly.

Second, turn saw “ON” and lower the saw to

the table. Then PUSH saw through the workpiece. Release the switch and wait for the

blade to completely stop before raising the

head assembly and removing the workpiece.

Never “pullcut” since blade may climb the workpiece causing KICKBACK.

● For chop action cutting, slide the head

assembly to the rear as far as it will go and

tighten slide lock knob. Then turn the saw

“ON” and lower the head assembly to make

the cut. Release the switch and wait for the

blade to completely stop before raising the

head assembly and removing the workpiece.

Failure to tighten the slide lock knob can cause

the blade to suddenly climb up on the top of the

workpiece and force itself toward you.

Safety

“READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (

●) symbol listed BELOW and other safety precautions, may result in serious person-

al injury.

WARNING

!

Page 5

5.

● Do not allow familiarity gained from frequent

use of your miter saw to become commonplace. Always remember that a careless frac-

tion of a second is sufficient to inflict severe

injury.

● THINK SAFETY! SAFETY IS A COMBINATION

OF OPERATOR’S COMMON SENSE, KNOWLEDGE OF THE SAFETY AND OPERATING

INSTRUCTIONS AND ALERTNESS AT ALL

TIMES WHEN THE MITER SAW IS BEING

USED.

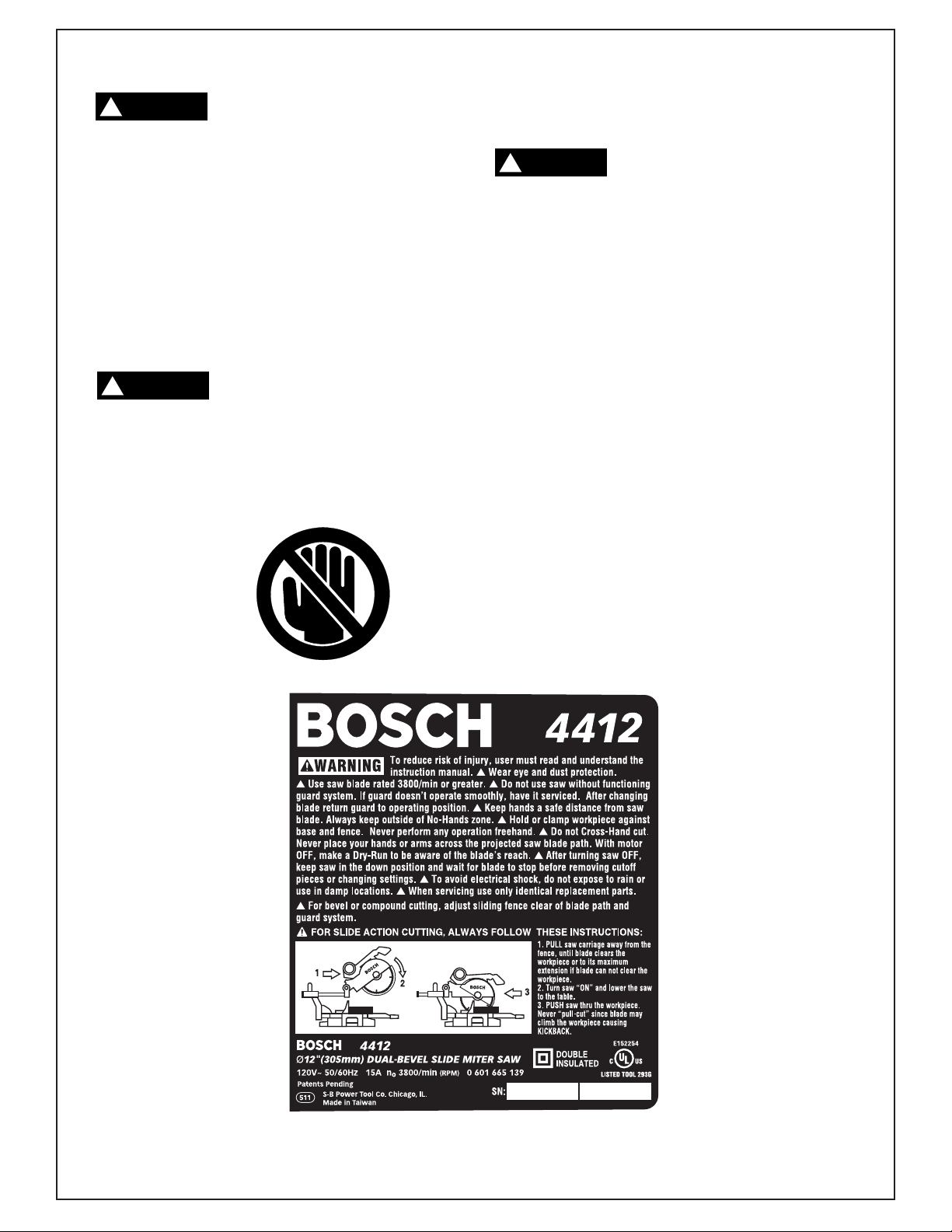

THE WARNINGS SHOWN

BELOW CAN BE FOUND ON

YOUR TOOL. THESE WARNINGS ARE ONLY A

CONDENSED FORM OF THE MORE DETAILED

SAFETY RULES AND PRECAUTIONS THAT

APPEAR IN YOUR OWNER'S MANUAL. THEY

SERVE AS A REMINDER OF ALL SAFETY RULES

NEEDED FOR SAFE OPERATION OF THIS MITER

SAW.

Some dust created by power

sanding, sawing, grinding,

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment,

such as those dust masks that are specially designed

to filter out microscopic particles.

Safety

“READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal

injury.

“SAVE THESE INSTRUCTIONS”

WARNING

!

WARNING

!

WARNING

!

DESIGNATED DANGER ZONE.

AVOID POSITIONING HANDS,

FINGERS OR ARMS IN THE

AREA DESIGNATED BY THIS

SYMBOL.

Page 6

6.

Double Insulated Tools

Double insulation is a design concept used in

electric power tools which eliminates the need for the

three wire grounded power cord and grounded power

supply system. It is a recognized and approved system by Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

● Servicing of a tool with double insulation requires

care and knowledge of the system and should be

performed only by a qualified service technician.

● WHEN SERVICING, USE ONLY IDENTICAL

REPLACEMENT PARTS.

● POLARIZED PLUGS. Your tool is equipped with

a polarized plug (one blade is wider than the

other), this plug will fit in a polarized outlet only

one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper outlet.

To reduce the risk of electrical shock, do not

change the plug in any way.

Extension Cords

● Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

● If an extension cord is necessary, a cord with

adequate size conductors should be used to prevent excessive voltage drop, loss of power or

overheating. The table shows the correct size to

use, depending on cord length and nameplate

amperage rating of tool. If in doubt, use the next

heavier gauge. Always use U.L. and CSA listed

extension cords.

RECOMMENDED SIZES OF EXTENSION CORDS

Tools 120 Volt A.C. Tools

Ampere Cord Length in Feet

Rating Cord Size in A.W.G.

25 50 100 150

3-6 18 16 16 14

6-8 18 16 14 12

8-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12 N/A N/A

NOTE: The smaller the gauge number, the heavier

the cord.

Safety

“READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (

●) symbol listed BELOW and other safety precautions, may result in serious personal

injury.

“SAVE THESE INSTRUCTIONS”

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

General Safety Rules For Bench Top Tools. . . . 2

Safety Rules For Miter Saws . . . . . . . . . . . . . 3-6

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Requirements. . . . . . . . . . . . . . . . . . . 7

Getting To Know Your Miter Saw . . . . . . . . . . 8-9

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Tools Needed for Assembly and Alignment . . . 10

Unpacking and Checking Contents . . . . . . . . . 10

Installation and Removal of the Blade . . . . 11-12

Assembling Dust Elbow and Dust Bag . . . . . . 12

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Checking 0° Bevel Adjustment . . . . . . . . . . . . 13

Adjusting Bevel Lock Lever Tension . . . . . . . . 13

Blade 45° To The Table . . . . . . . . . . . . . . . . . 14

Blade Square To Fence . . . . . . . . . . . . . . . . . 15

Miter Scale Indicator Adjustment. . . . . . . . . . . 15

Kerf Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Depth Adjustment. . . . . . . . . . . . . . . . . . . . . . 16

Transporting, Placement and Mounting . . 17-18

Mounting Applications. . . . . . . . . . . . . . . . . . . 17

Mounting the saw . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Four Position Switch Handle . . . 18

Basic Saw Operations. . . . . . . . . . . . . . . . . 19-22

Body and Hand Position . . . . . . . . . . . . . . . . . 19

Workpiece Support . . . . . . . . . . . . . . . . . . 20-21

Switch Activation . . . . . . . . . . . . . . . . . . . . . . 21

Detent Override . . . . . . . . . . . . . . . . . . . . . . . 22

Sliding Base/Fence Extension . . . . . . . . . . . . 22

Saw Operations . . . . . . . . . . . . . . . . . . . . . . 23-30

Chop Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Slide Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Miter Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bevel Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Compound Cuts . . . . . . . . . . . . . . . . . . . . . . . 26

Cutting Grooves . . . . . . . . . . . . . . . . . . . . . . 27

Cutting Base Molding . . . . . . . . . . . . . . . . . . . 28

Cutting Crown Molding . . . . . . . . . . . . . . . 28-30

Special Cuts. . . . . . . . . . . . . . . . . . . . . . . . . . 31

Maintenance and Lubrication . . . . . . . . . . . 32-33

Belt Changes . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 33-34

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table of Contents

WARNING

!

Page 7

Electrical Requirements

1. Connect this saw to a 120V, 15-amp branch circuit with a 15-amp time delay fuse or circuit

breaker. Using the wrong size fuse can damage

the motor.

2. Fuses may “blow” or circuit breakers may trip

frequently if motor is overloaded. Overloading

can occur if you feed the blade into the workpiece too rapidly or start and stop too often in

a short time.

3. Most motor troubles may be traced to loose or

incorrect connections, overload, low voltage

(such as small size wire in the supply circuit or

too overly long supply circuit wire). Always

check the connections, the load and the supply

circuit whenever motor does not work well.

Electric Brake

Your saw is equipped with an automatic electric

brake which is designed to stop the blade from spinning in about five (5) seconds after you release the

trigger switch. It is useful when making certain cuts

in wood where a coasting blade would result in a

wide, imprecise cut.

When electrical power is lost due to

blown fuse or other causes, the

motor will gradually slow down and the braking action

is initiated ONLY by the release of the trigger switch.

The electric blade brake of your miter saw has been

designed for highest degree of reliability, but unexpected circumstances such as contamination on the

commutator and brushes or failure of motor’s components can cause the brake not to activate. If this condition occurs, turn the saw “ON” and “OFF” four to

five times without contacting the workpiece. If the

tool operates but the brake does not consistently stop

the blade in about five (5) seconds, DO NOT use saw

and have it serviced immediately.

The brake action of this saw is not

intended as a safety feature.

Remember to let the saw blade come to a complete

stop before raising the blade from the workpiece. As

always the guard system is your best protection

against unintentional contact with a spinning saw

blade. NEVER wedge open or defeat the closing

action of the lower guard.

7.

WARNING

!

WARNING

!

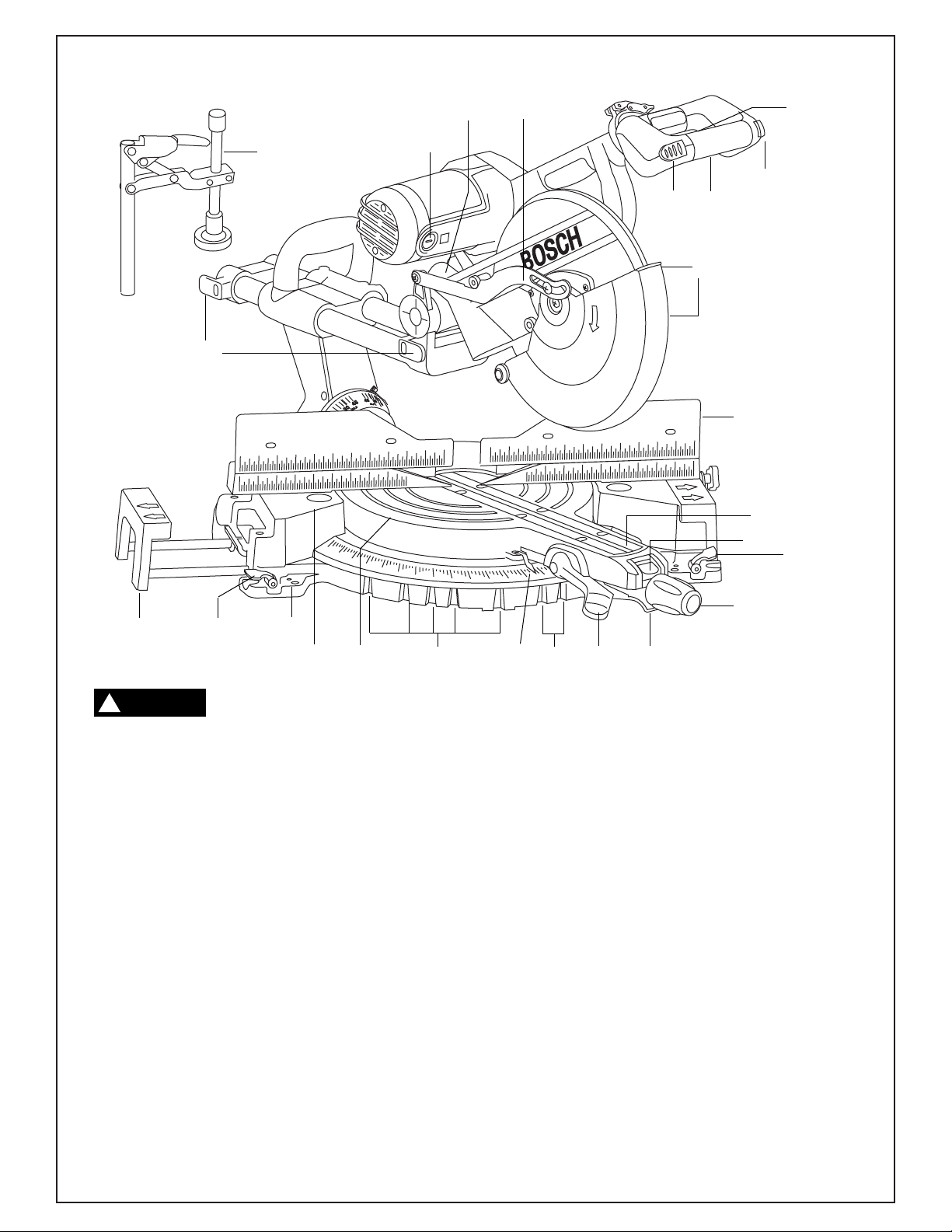

Page 8

To avoid injury from accidental starting, remove plug from power source

outlet before making any adjustments.

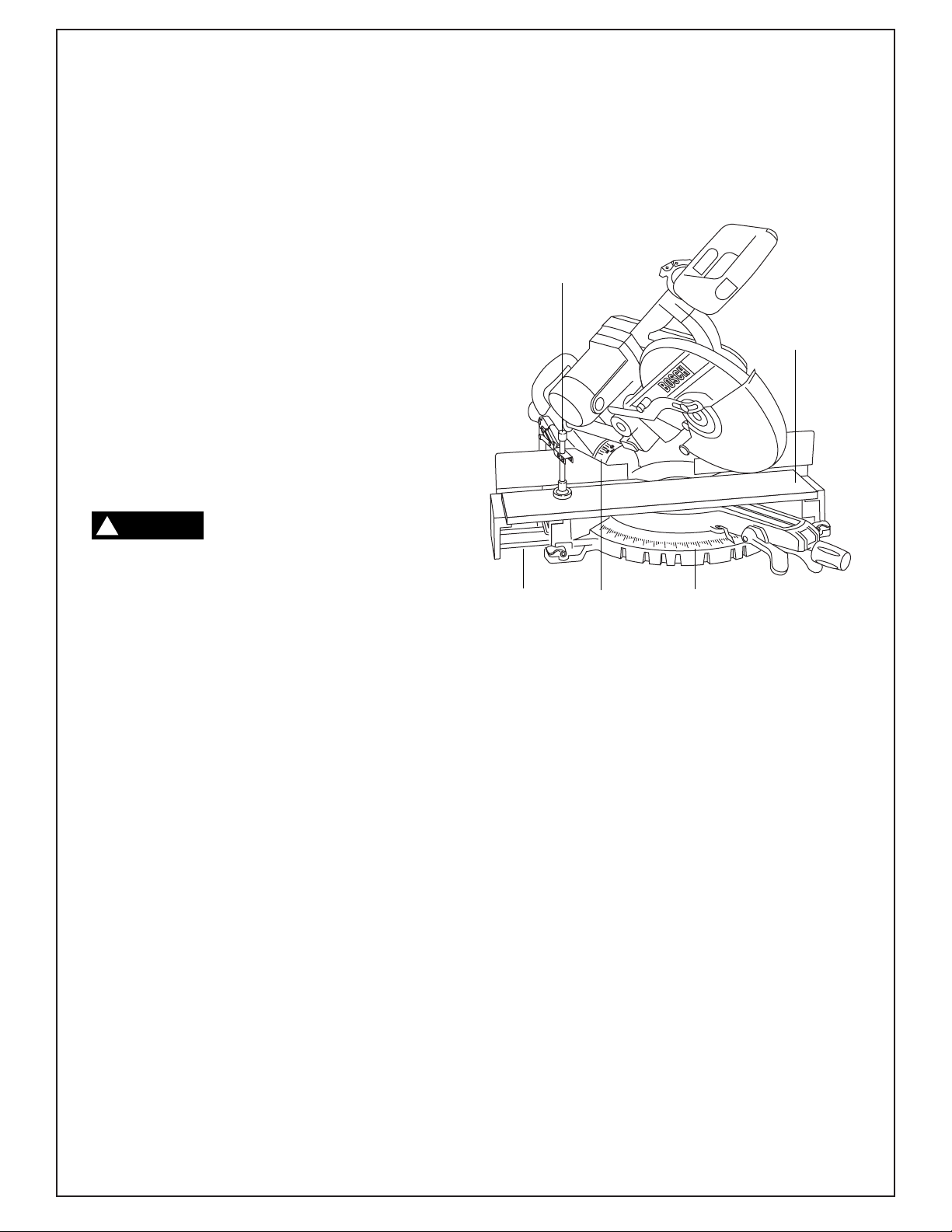

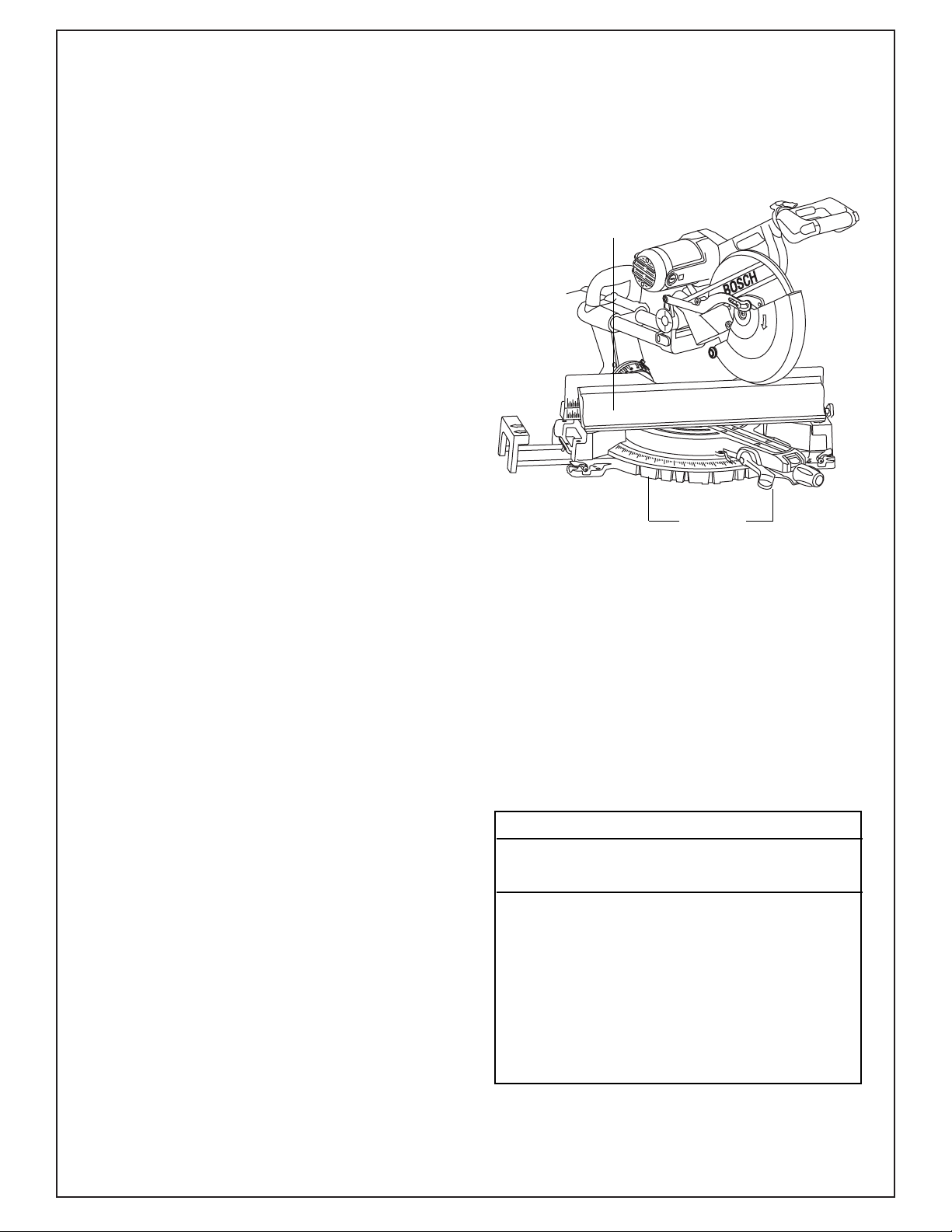

1. Switch Lock-Off Release Button – One of these

two buttons must be pressed before the power

switch can be pressed.

2. Power Switch – The power switch used with the

“Lock-OFF” button energizes the unit.

3. Main Handle – This handle contains the power

switch. Pulling this handle down lowers the blade

into the workpiece.

4. Brush Caps – These caps keep the motor brushes in position and provide easy access for inspecting and replacing brushes.

5. Lower Blade Guard/Lower Guard Lip – The

lower blade guard helps protect your hands from

the spinning blade. It retracts as the blade is lowered. Lip can be used to raise the lower guard

when guard becomes jammed on a workpiece.

6. Blade – Use only 12" blades with 1" arbor hole.

7. Sliding Fence – Supports the workpiece. The

fence has a cast in scale to make repetitive cuts

easy. The fence also has holes to secure an auxiliary fence if desired.

8. Kerf Inserts – Kerf inserts can be adjusted to different blade widths to minimize workpiece tearout.

9. Miter Detent Override – Allows detent action to

be locked out allowing for micro adjustments to

any miter angle.

10. Miter Scale/Miter Angle Indicator – This scale

is cast in on the base of the saw. Indicator is fastened to the table.

11. Miter Detents – There are ten (10) miter detent

slots for fast and accurate miter cuts of common

miter angles.

12. Miter Detent Lever – The lever releases the

table from the detent.

13. Miter Lock Knob – The miter lock knob locks the

miter saw table at any desired miter angle.

14. Table – Sits in base, provides workpiece support,

rotates for desired miter cuts and rotates the

head assembly. The front extended part of the

table is called the miter arm.

15. Base – Provides working surface to support

workpiece.

16. Tool Mounting Pads – The four corners of the

saw provide areas to clamp, bolt or nail the saw

to a flat work surface.

17. Sliding Base Extensions – These extensions

provide extra workpiece support and are especially useful when cutting long workpieces.

8.

Getting To Know Your Miter Saw

WARNING

!

1

2

3

5

7

8

9

10

11

11

12

13

14

15

16

17

18

18

28

21

25

26

4

20

1

Page 9

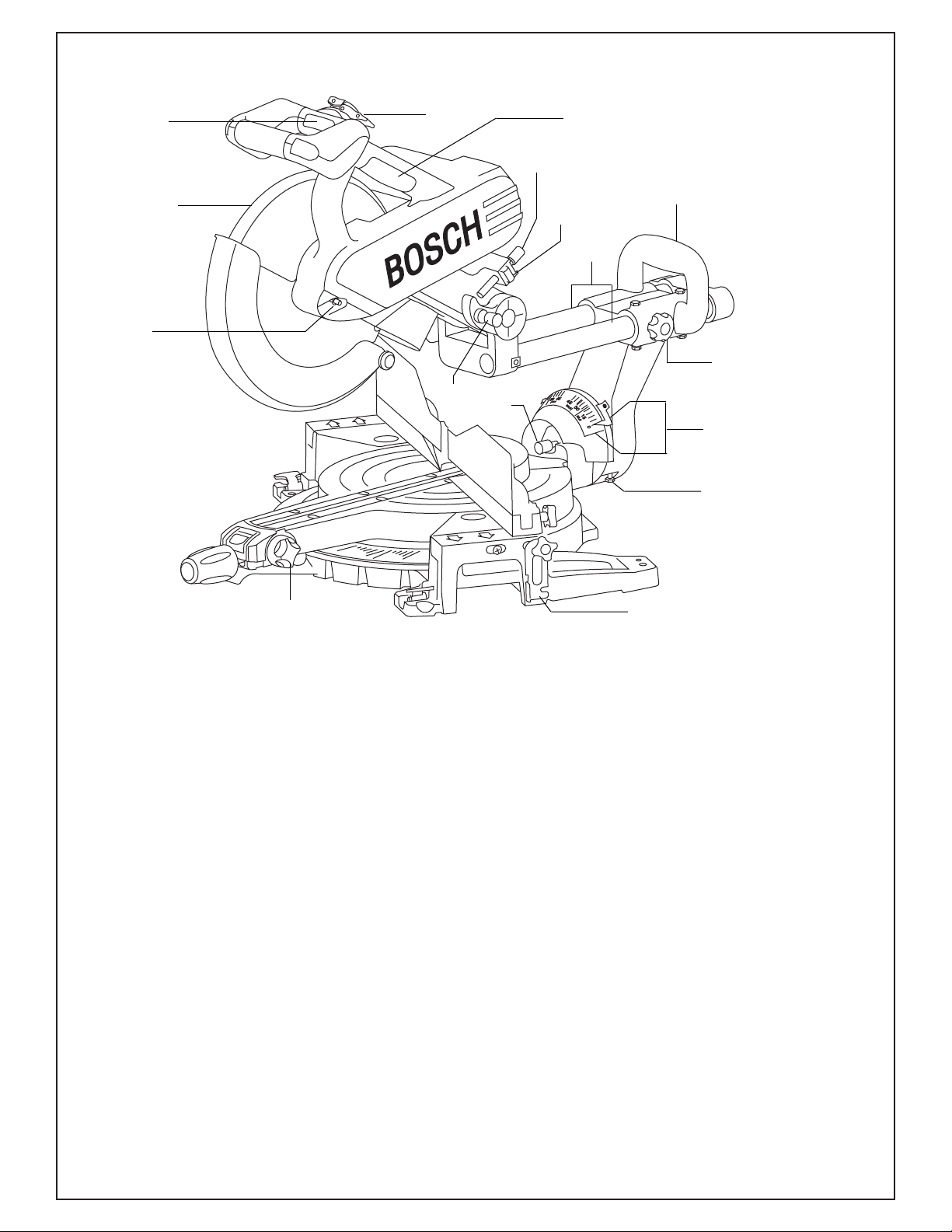

Getting To Know Your Miter Saw

18. Base Extension Clamping Levers – These

levers lock the base extensions at the desired

positions.

19. Length Stop – For repetitive cuts of the same

length. Can be moved to left side, if desired.

20. Dust Port – The dust port can accommodate the

dust chute and dust bag or a 1-1/4" vacuum hose

hookup.

21. Bevel Lock Lever – The front-positioned bevel

lock lever locks the head assembly at the desired

bevel angle.

22. Bevel Range Selector Knob – Allows selection

of the bevel range, 0° to 45° left, 0° to 45° right,

and complete range of 47° left to 47° right.

23. Slide Rail Lock Knob – The slide rail lock knob

locks the slide rails when you are not making

slide cuts and when you are transporting the saw.

24. Slide Rails – Guide the head assembly when

making slide cuts.

25. Quick-Action Clamp Position Holes – There

are two (2) holes (not shown) behind the fence for

placing the quick action clamp.

26. Lower Guard Actuation Link – Allows for

smooth movement of the lower guard.

27. Upper Blade Guard – Covers upper portion of

the blade.

28. Cord Wrap – Allows you to easily wrap up the

cord so it’s out of the way when transporting or

storing.

29. Power Cord – Supplies power to motor.

30. Hex Wrench – Used for loosening/tightening the

blade and for fence adjustments.

31. Bevel Detent Pin (Crown Molding Setting) –

Allows you to easily lock the head assembly to

the bevel angle of 33.9° to the left or right.

32. Bevel Scale – This scale is large and angled to

allow you to easily read bevel angles.

33. Head Assembly Lock Pin – The saw is

equipped with a lock pin used to lock the head

assembly in the lower position for transporting.

34. Quick Release Depth Stop Button – Allows you

to quickly release the depth stop.

35. Depth Stop Fine Adjustment Knob–Allows you

to adjust the depth of the blade for cutting

grooves in the workpiece (Figure 13, page 16).

36. Handle Rotation Release Lever – Pulling this

lever allows the handle to be rotated. Release the

lever into one of four operating positions.

37. Rear Carrying Handle – Used for lifting of the

tool.

38. Handle Clamp – Locks handle in the selected

position.

39. Arbor Lock—Allows the user to keep the blade

from rotating while tightening or loosening arbor

screw during blade replacement or removal.

40. Front Carrying Handle – Used for lifting the tool.

9.

36

38

39

31

19

23

22

24

33

35

34

27

31

32

37

40

Page 10

10.

Disconnect plug from power source before performing any assembly, adjustment or repair to

avoid possible injury.

Assembly

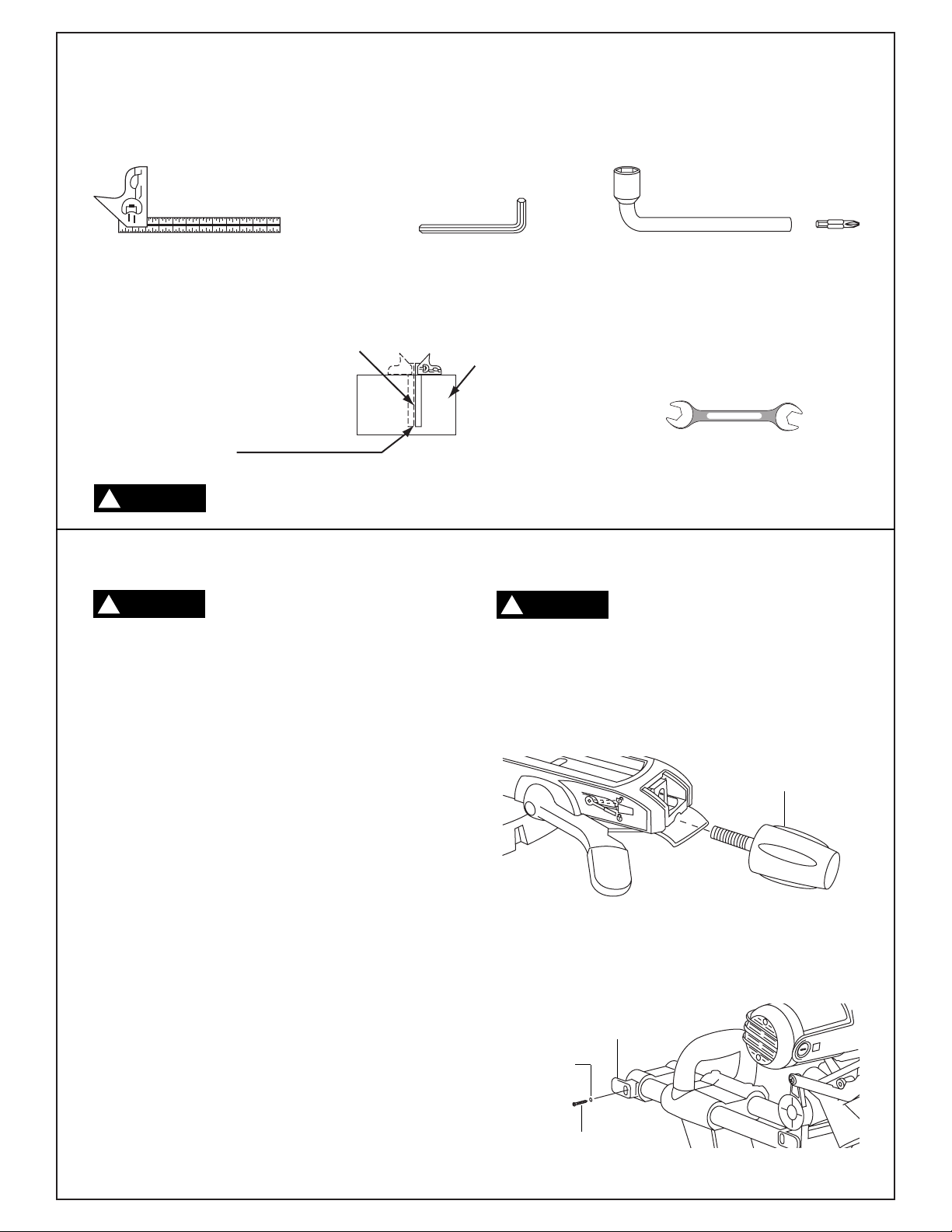

Tools Needed For Assembly And Alignment

Should be no Gap or Overlap

when Square is Flipped Over in

Dotted Position

Draw Light

Line on Board

Along this Edge

Hex “L” Wrench

(supplied) 1.5mm

Straight Edge of

Board 3/4" Thick

This Edge Must be

Perfectly Straight

Multi Purpose Tool

(supplied)

Combination Square Must be True

Combination Square

10mm/17mm Combination

Open End Wrench

Before moving the saw: Lock the

miter lock knob in 45° position. Lock

bevel lock handle. Pull the head assembly completely toward you and tighten the slide rail lock knob.

Lock head assembly in the down position.

Never carry the tool by the slide rails, this may

cause blade damage.

Never carry the tool by the cord or head assembly

power switch handle. Damage to insulation could

cause an electric shock. Damage to wire connections

could cause a fire.

Model 4412 Miter Saw is shipped complete in one

box.

1. Separate all parts from packing materials and

check each one with the “Table of Loose Parts” to

make sure all items are accounted for before discarding any packing material.

2. Table of Loose Parts:

Quick- Action Clamp - Used to clamp workpieces.

Dust Elbow/Dust Bag - Used to collect saw dust.

Multi Purpose Tool - Should be stored on the right

rear base.

Rear Cord Wrap, washer and Screw - Used for

wrapping the cord

Miter Lock Knob - Used to lock the table at desired

miter angle.

If any parts are missing, do not plug

in power cord or turn the switch on

until the missing parts are obtained and are installed

correctly.

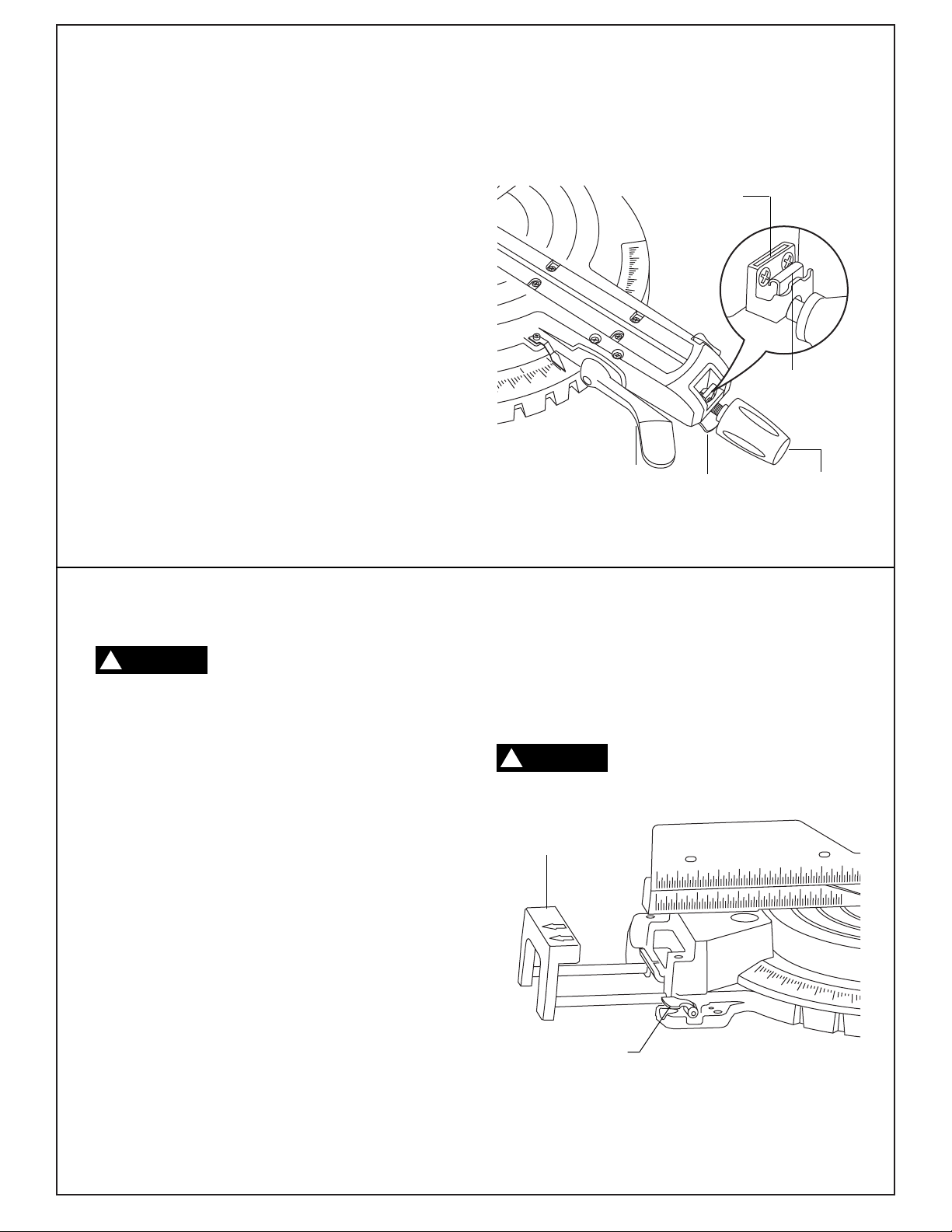

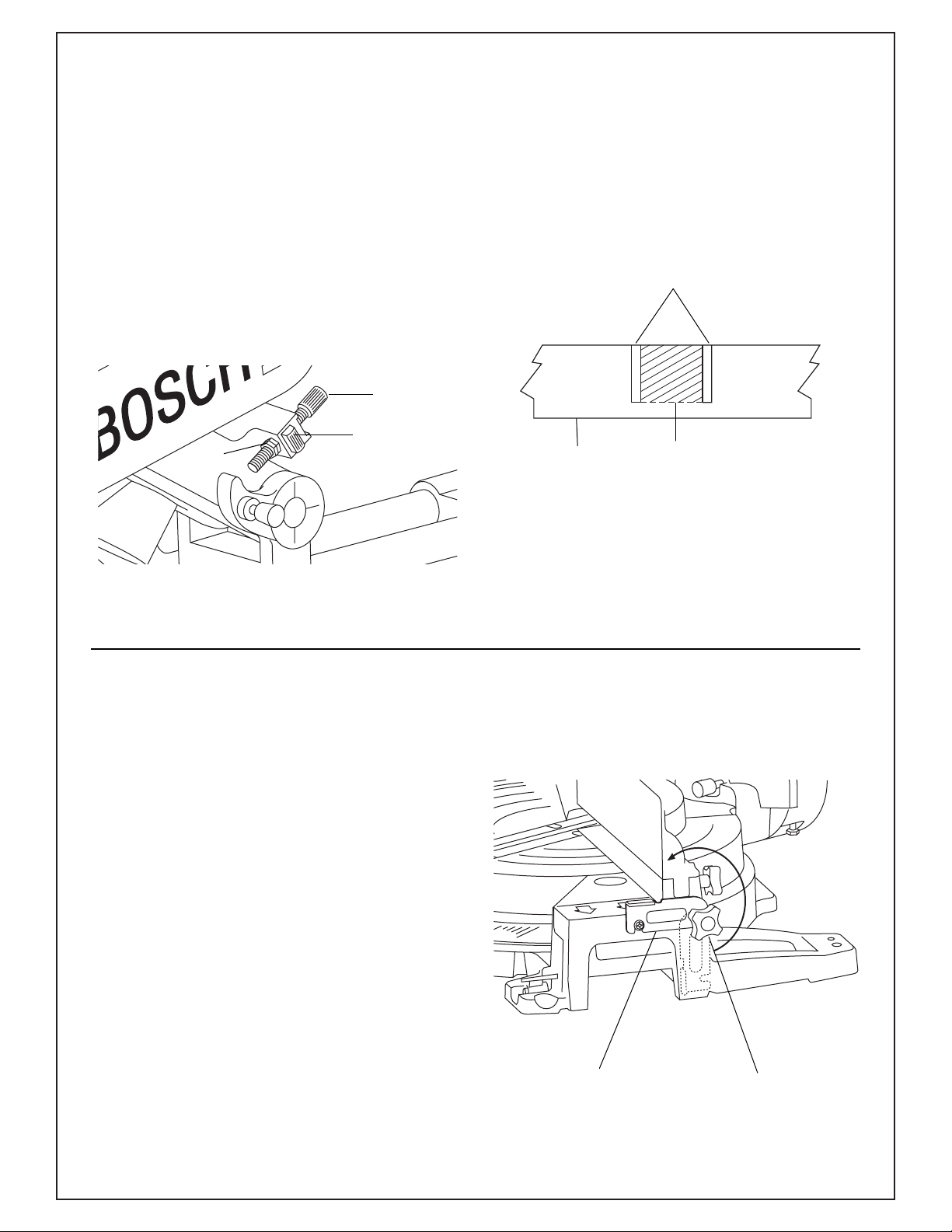

Attaching Miter Lock Knob

Locate the miter gauge lock knob from among the

loose parts, and thread shaft on lock knob into hole

provided.

Attaching Rear Cord Wrap

Locate the rear cord wrap from among the loose parts,

position rear cord wrap as shown and secure with

washer and phillips screw provided.

WARNING

!

WARNING

!

WARNING

!

Unpacking And Checking Contents

Rear Cord Wrap

Phillips Screw

Washer

Miter Gauge

Lock Knob

UNLOCK

LOCK

Page 11

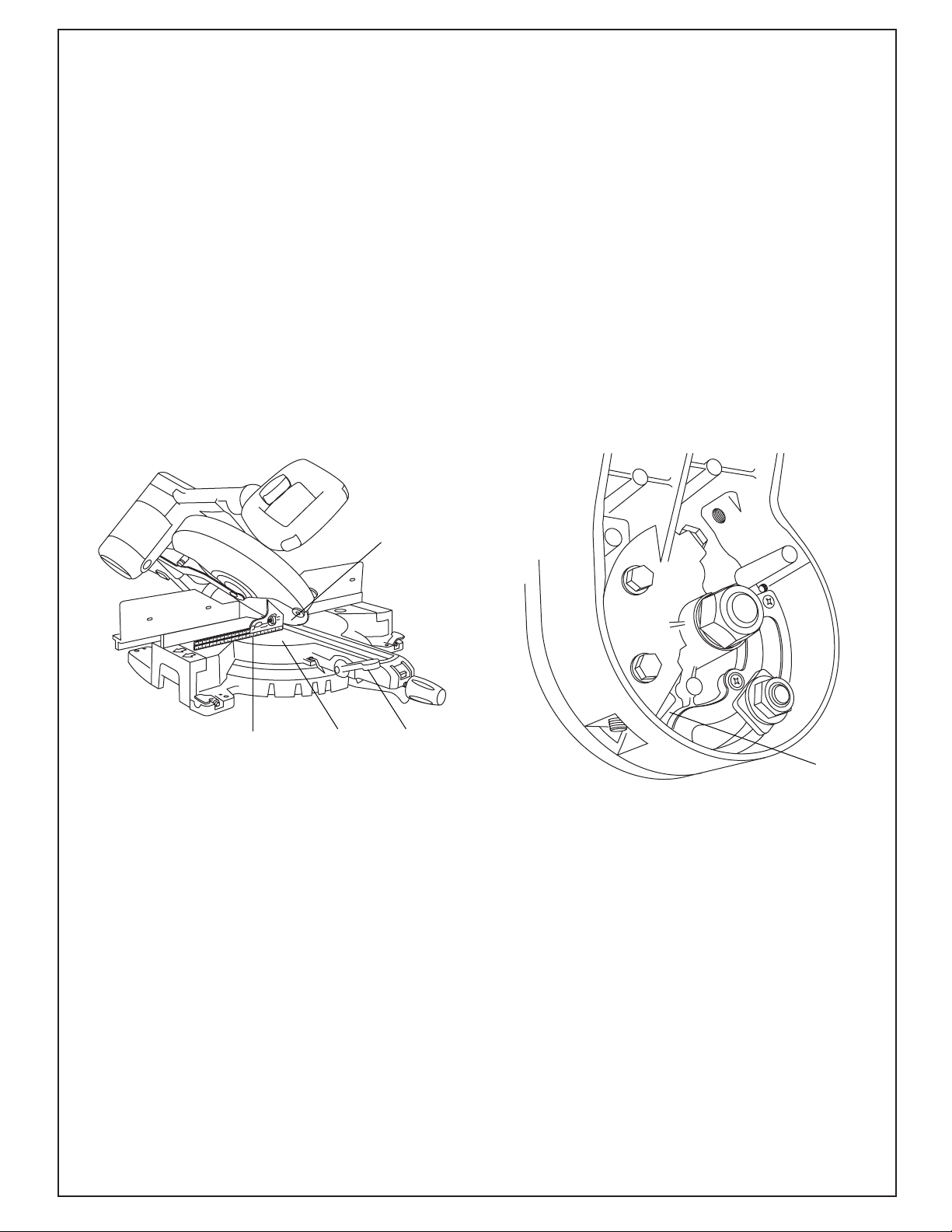

Assembly

11.

Disconnect plug from power source

before performing any assembly,

adjustment or repair to avoid possible injury.

1. The miter saw is equipped with a lock pin used to

lock the miter saw in the lower position. To release,

push the handle down slightly and pull the lock pin

to its full out position and rotate 90°.

NOTE:If the lock pin is stuck and will not pull out

when the handle is pushed down slightly, you may

have to adjust the depth stop bolt (see Depth

Adjustment, page 16) slightly so the handle can be

pushed down and the lock pin can be pulled out.

2. Rotate the lower guard by hand. Loosen front

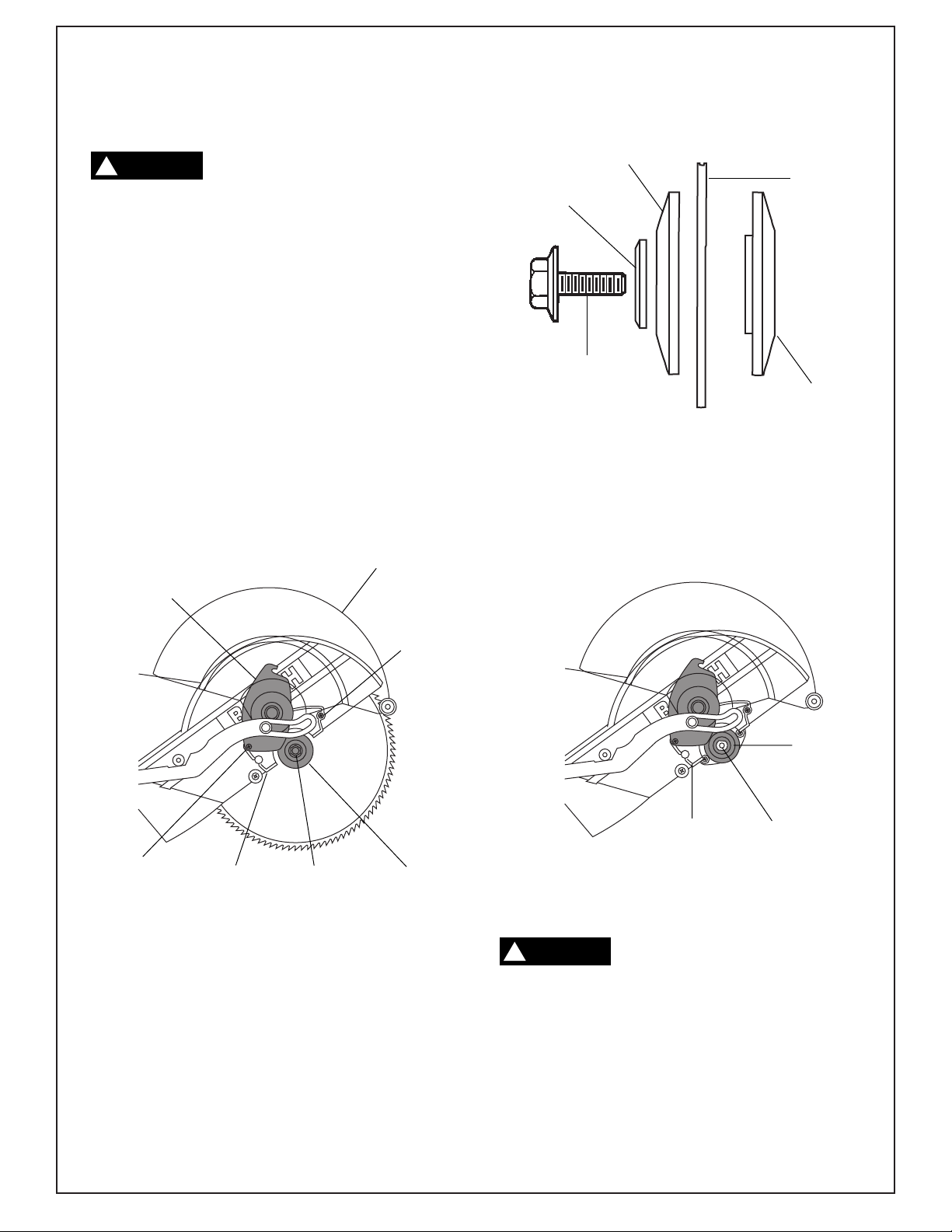

cover screw to a point that cover plate can be lifted (Figure 1).

3. Rotate the cover plate counterclockwise so the

blade bolt is exposed (Figure 1).

4. Press and hold the arbor lock (See figure on page

page 9). Use the multi purpose tool to remove the

blade bolt by turning wrench clockwise. NOTE:

The blade bolt has left hand threading.

Figure 1. Blade Removal

5. Remove the blade bolt, arbor washer, outer washer and the blade. Inner washer does not need to

be removed (Figure 2).

Figure 2. Blade Hardware

6. To install the 12" blade, fit blade between the chip

deflectors and onto the arbor shaft, and onto 1"

support ring on the inner washer (Figure 3).

NOTE: Make sure the rotation arrow on the blade

matches the clockwise rotation arrow on the lower

guard.

Figure 3. Blade Installation

To avoid injury, do not use a blade

larger or smaller than 12" diameter

and 1" arbor.

7. Replace the outer washer in the proper orientation,

insert the arbor washer, and tighten blade bolt

finger tight. Press the arbor lock and tighten blade

bolt securely using multi purpose tool, but do not

overtighten.

8. Rotate cover plate clockwise to original position.

Tighten the front cover plate screw.

Installation And Removal Of The Blade

WARNING

!

WARNING

!

Outer Washer

Inner Washer

Arbor Washer

Sawblade

Blade Bolt

(Left Hand Thread)

Inner

Washer

Arbor

Shaft

Chip

Deflector

Lower Guard

Outer

Washer

Rear Cover

Plate Screw

Cover Plate

Front

Cover

Plate

Screw

Blade

Bolt

Chip

Deflector

Page 12

Tighten the cover plate screw.

Loose cover plate screw may interfere with and hang-up lower blade guard. Never use

saw without cover plate securely in place. Lower

guard will not function properly.

9. Be sure the arbor lock is released so the blade

turns freely.

After installing a new blade,

make sure the blade does not

interfere with the table insert at the 0° and 45°

bevel positions. Lower the blade into the table slot

and check for any contact with the base or turn table

structure. If blade contacts base or table, seek authorized service.

10. Place multi purpose tool in rubber grommet in right

rear of tool.

Assembly

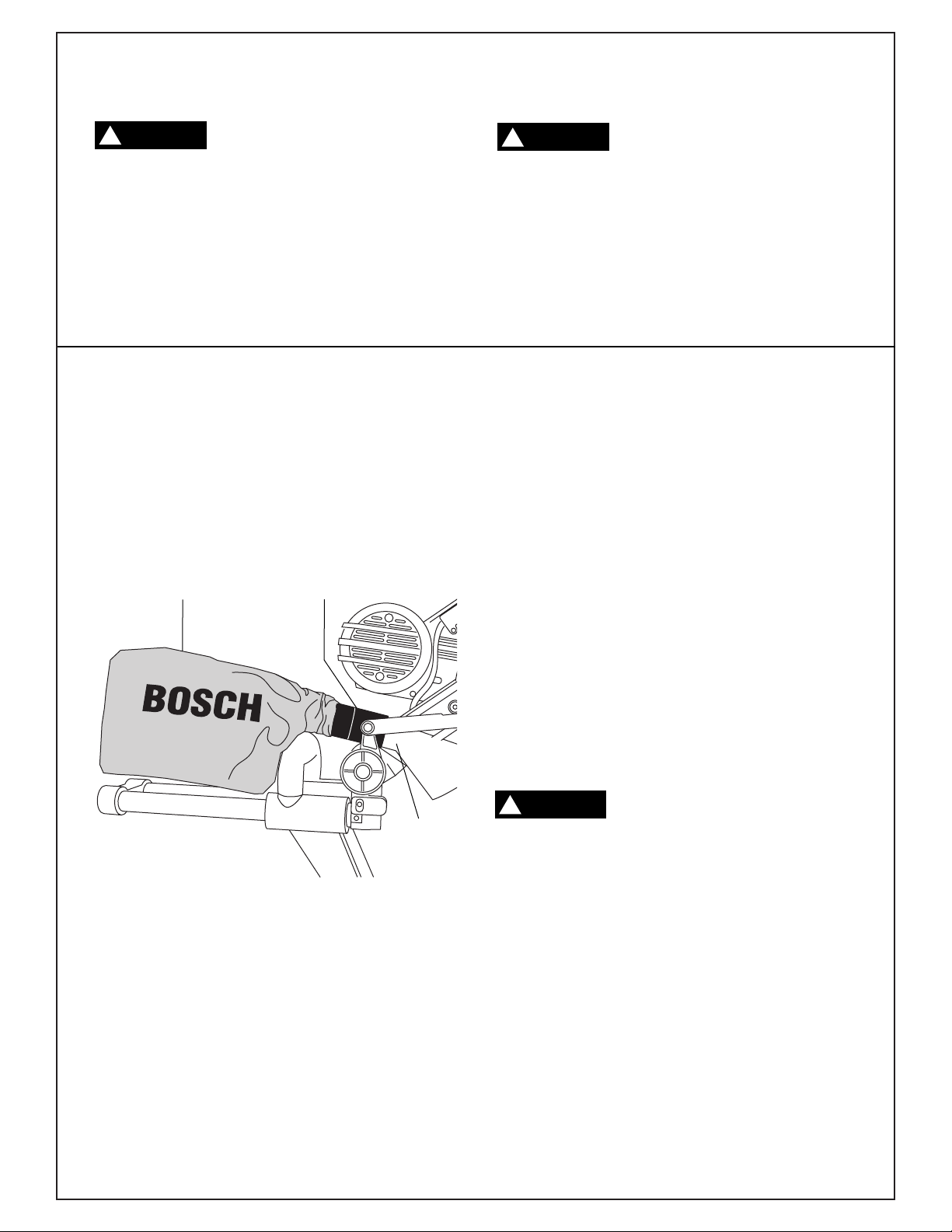

1. With the miter arm locked in the down position,

push the dust elbow onto the dust port. Push the

dust bag onto the elbow and rotate both to desired

position. (Figure 4).

Figure 4. Dust Elbow and Dust Bag

2. Position dust chute/bag so that it does not interfere

with the tool during the cutting operation for all

miter/bevel settings. Make sure dust bag does not

interfere with the slide rails during slide cutting.

3. The dust bag requires emptying when full of

sawdust. Empty it frequently and after completion

of sawing. Carefully remove dust bag from dust

elbow. Empty dust bag in proper trash

bin by unzipping the bag. Be extremely careful of

dust disposed, materials in fine particle form may

be explosive. Do not throw sawdust on an open

fire. Spontaneous combustion, may in time,

result from mixture of oil or water with dust

particles.

Note: The dust port also accepts a standard 1-1/4"

vacuum tube for dust collection.

When sawing chemically pressure

treated lumber, paint that may be

lead based, or any other materials that may contain

carcinogens, use special precautions. A suitable respirator must be worn by all personnel entering the

work area. Work area should be sealed by plastic

sheeting and persons not protected should be kept

out until work area is thoroughly cleaned.

Assembling Dust Elbow And Dust Bag

12.

WARNING

!

WARNING

!

WARNING

!

Dust ElbowDust Bag

Dust

Port

Page 13

13.

Adjustments

Disconnect plug from power source

before performing any assembly,

adjustment or repair to avoid possible injury.

NOTE: Your miter saw was completely adjusted at

the factory. However, during shipment, slight misalignment may have occurred. Check the following

settings and adjust if necessary prior to using this

miter saw.

Checking 0° Bevel

Adjustment

1. Push head assembly down and push head assembly lock pin to hold down head assembly.

2. Slide head assembly completely to the back and

tighten the rail lock knob.

3. Rotate table to 0° miter position

4. Pull up bevel lock lever to loosen.

5. Check position of bevel range selector knob, it

should be at the 0°-45° position.

6. Tilt the saw assembly to the left counterclockwise.

Then rotate saw assembly to the right (clockwise).

Until you feel the stop in the vertical position – This

is where the saw is currently set for the 0° bevel

cut.

Lower the blade and engage the lock pin. Use a

combination square to check blade squareness to

the table. Place the square on the table and press

it against the blade. If the blade does not contact

the full length of the square, (figure 5), follow the

alignment procedure.

Figure 5. Blade Square to Table

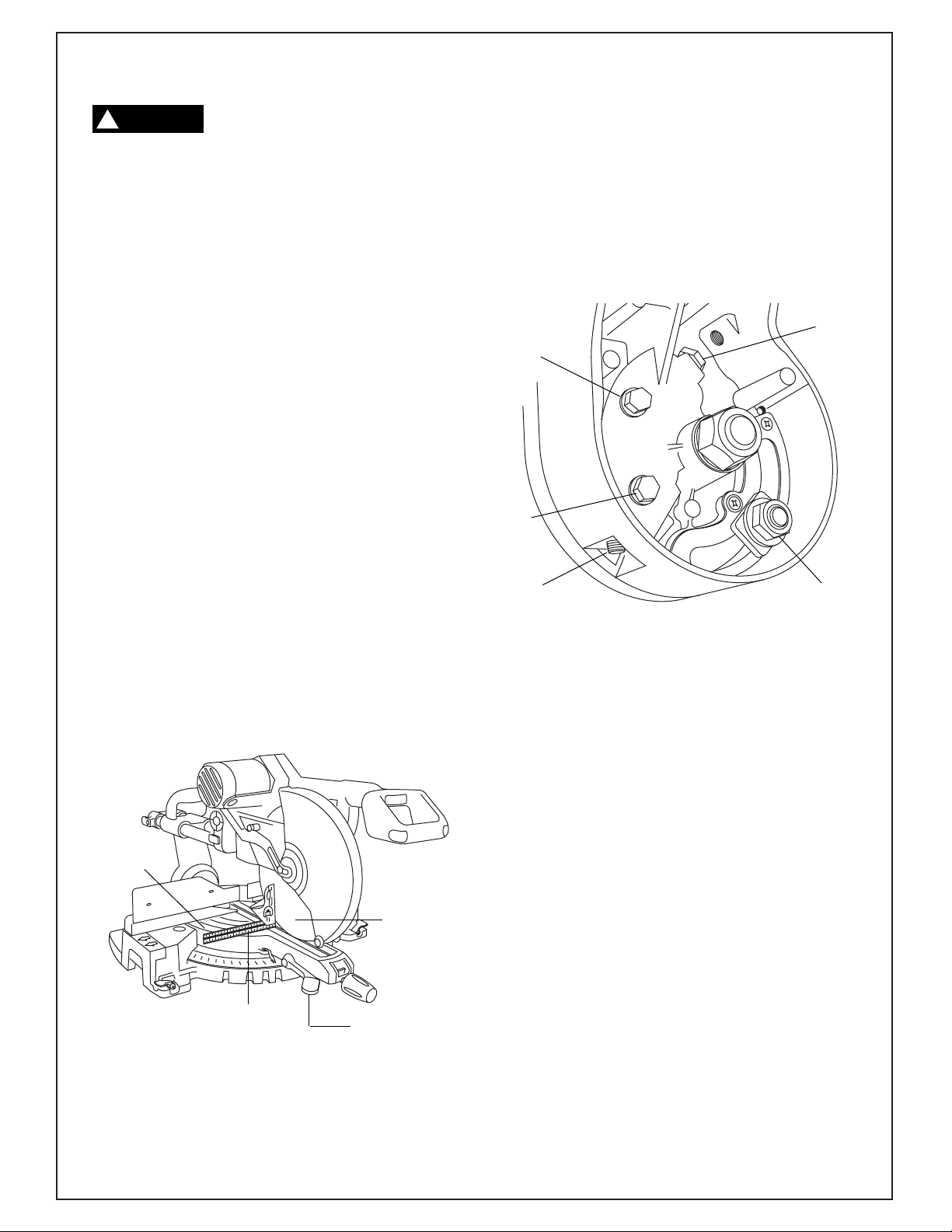

Calibrating Blade at 0 degrees

(90° to the table)

1. Lift bevel lock lever to release bevel lock.

2. Loosen bolt heads “A” and “B” with 10 mm openend wrench at least one full turn (Figure 6).

3. Place 4 mm Allen wrench bit onto multi purpose

tool and into setscrew “D” (Figure 6).

4. Loosen setscrew “D” with 4 mm Allen wrench - at

least 3 full turns.

Figure 6. Calibrating Blade at 0 degrees

(90 to the table)

5. Place combination square on table and against

fence. (See figure 5)

6. While rotating bolt head “C”, watch the saw blade

tilt until it is aligned with the combination square.

When aligned, remove the Allen wrench.

7. Tighten setscrew “D”.

8. Tighten 10 mm bolt heads “A” & “B”

9. Check and adjust bevel pointers to 0 degrees on

each side of bevel scale.

10. Push down bevel lock lever before cutting.

Adjusting Bevel Lock Lever Tension

1. Lift bevel lock lever to release bevel lock.

2. Place 17-mm open-end flat wrench on bolt head

“E” (Figure 6).

3. Turn nut “E” clockwise 1/8 turn to tighten bevel

lock tension or turn counter-clockwise to 1/8 turn

to loosen bevel lock tension.

4. Push down bevel lock lever.

5. Verify that bevel lock tension holds the bevel position secure and also allows bevel lock lever to lock

down to the point that a solid stop is felt.

6. If necessary, repeat steps 1 – 5 to adjust the

tension.

Table

Blade

Combination

Square

D

C

A

B

E

WARNING

!

Bevel Lock

Lever

Page 14

14.

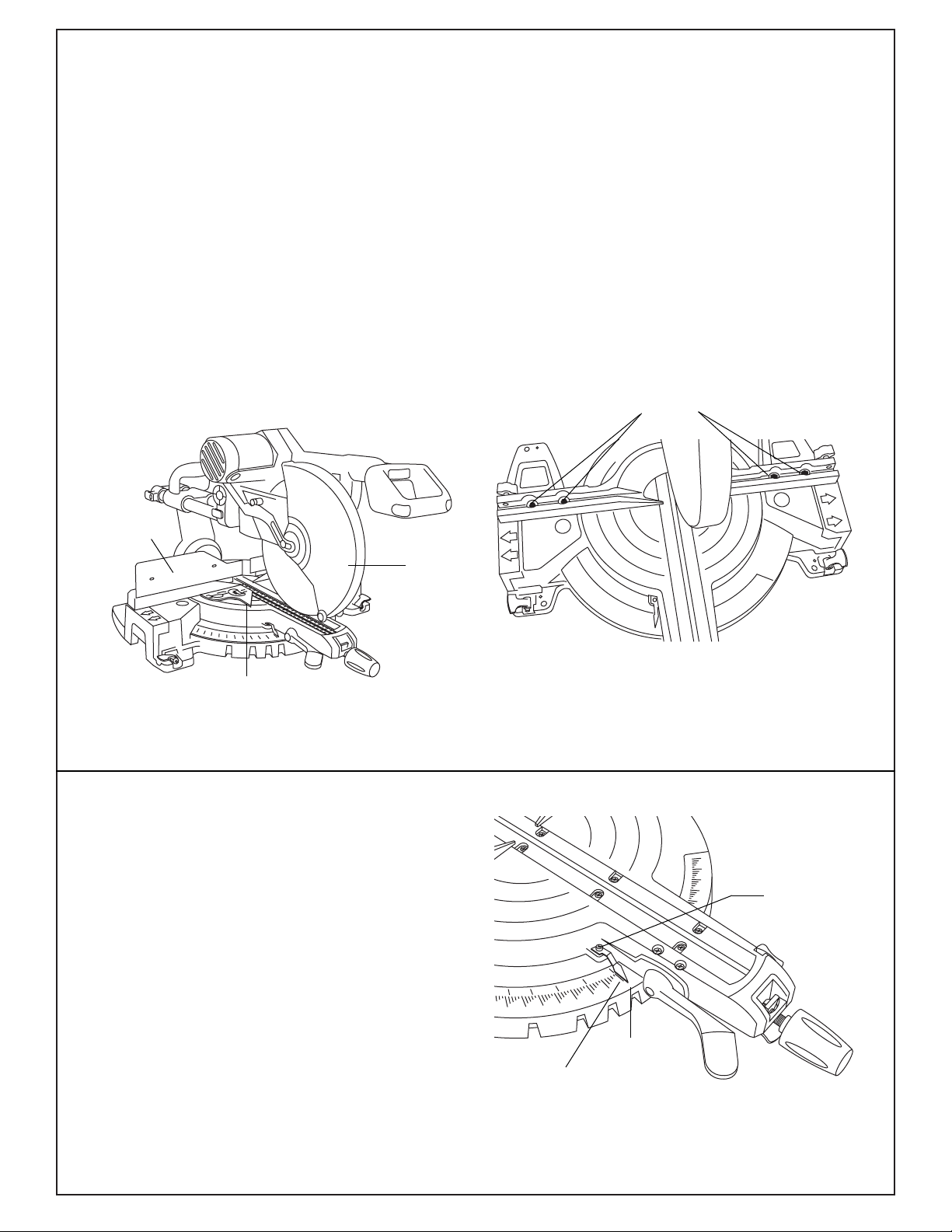

Blade 45° To The Table

Adjustments

Checking 45° Bevel Adjustment

1. Push head assembly down and push head assembly lock pin to hold down head assembly.

2. Slide head assembly completely to the back and

tighten the rail lock knob

3. Rotate table to the 0° miter position

4. Pull up bevel lock lever to loosen.

5. Check position of bevel range selector knob, it

should be at the 0°- 45° position.

6. Tilt the saw assembly to the left counterclockwise.

Then rotate saw assembly to the right (clockwise).

Until you feel the stop in the 45° left position – This

is where the saw is currently set for the 45° left

bevel cut.

Figure 7. Blade 45° To The Table

Use a head of combination square to check blade at

the 45° stop. Place the combination square head on

the table and press it’s 45° surface against the blade.

If the blade does not contact the full length of the

square, (figure 5), follow the alignment procedure.

Calibrating Blade at 45 degrees to the table

1. Lift bevel lock lever to release bevel lock.

2. Tilt saw head to 45 degree stop on left side.

3. Place combination square frame (remove ruler)

with 45 side against the blade. (See figure 7)

4. Place 10 mm open-end wrench on bolt head “F”

(Figure 8).

5. While rotating bolt “F”, watch blade tilt movement

until it is aligned with the 45 degree surface on

combination square frame.

6. Check and adjust bevel pointers to 45 degrees on

each side of bevel scale.

7. Push down bevel lock lever before cutting.

Figure 8. Calibrating Blade at 45 degrees

to the table

Table

Blade

Combination

Square

F

Bevel Lock

Lever

Page 15

15.

Adjustments

Blade Square to Fence

1. Make sure head assembly is pushed forward

near the center of the table and slide rail lock

knob is tightened.

2. Lower the head assembly, pull the lock pin out and

rotate it 90°, rotate to lock the head assembly in the

down position. Make sure table is in 0°

detent and tighten miter lock knob. Place a combination square against the fence and next to the

blade as illustrated. Locate the square properly

so it does not contact the tooth of saw blade.

The saw blade should contact the full length of

the square (Figure 9).

3. If blade does not contact the square, follow the

fence alignment procedure.

Figure 9. Blade Square to Fence

Fence alignment

a. Remove sliding fence extensions.

b. The head assembly should remain in lowered

position.

c. Use multi purpose wrench (supplied) and

loosen four (4) hex bolts behind fence

(Figure 10).

d. Adjust fence until blade and the fence has full

contact with the square.

e. Tighten hex bolts.

f. Re-attach sliding fence.

Figure 10. Fence Adjustment

Miter Scale

Indicator Adjustment

1. Rotate table to 0° position and lock in place.

2. Raise the head assembly to the full-up position.

3. Loosen the Phillips screw that holds the indicator

in place (Figure 11).

4. Position the indicator to align with the 0° miter

mark. Tighten the screw.

Figure 11. Miter Scale Adjustment

Fence

Blade

Combination Square

Hex Bolts

2

Miter Scale

Indicator

0° Mark

Indicator

Adjustment

Screw

12

8

35

4

12

12

6

20

25

30

2

15

12

10

0

0

5

60

55

50

45

40

Page 16

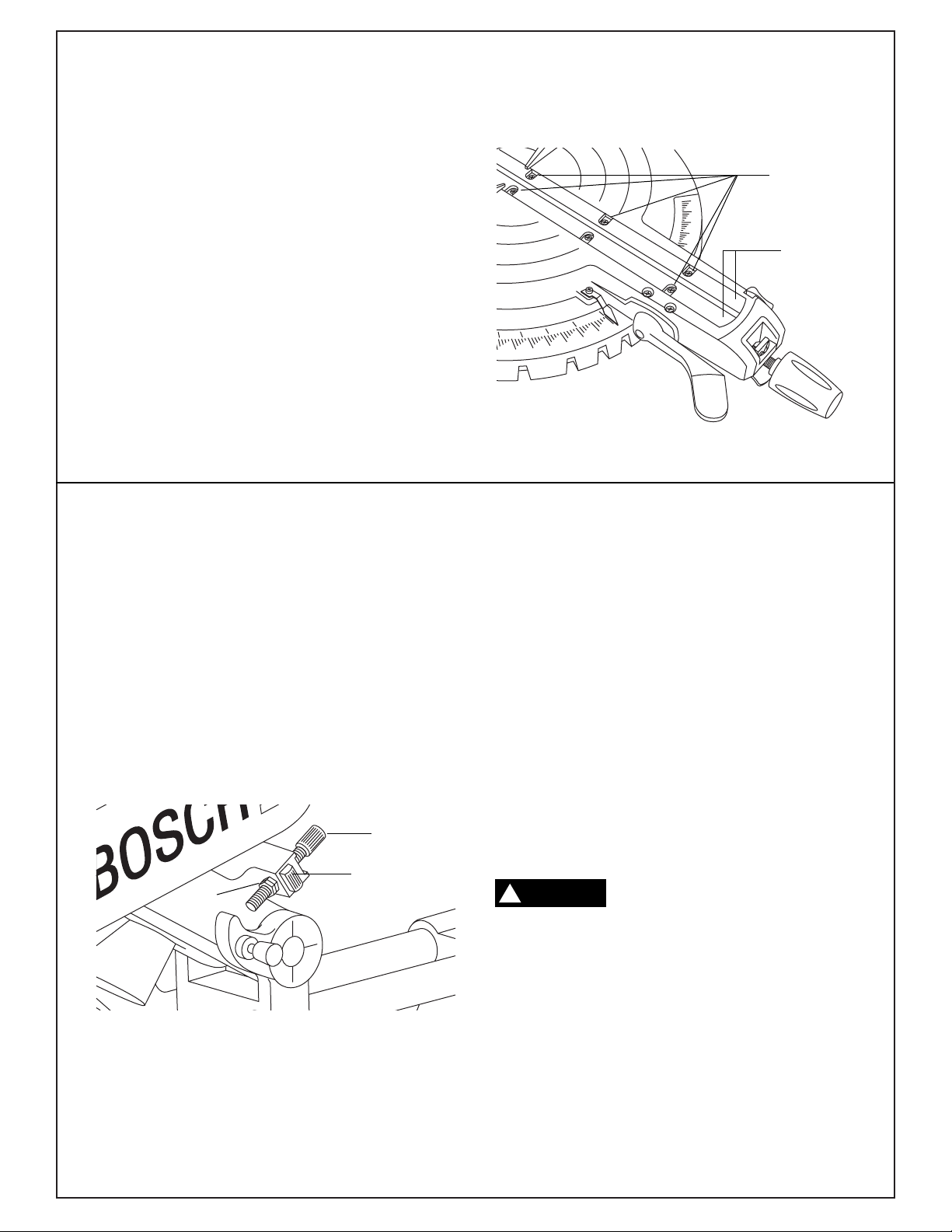

— When the diameter of the blade has been reduced

due to sharpening, it may be necessary to adjust

the depth stop. When a new blade is installed, it

is necessary to check the clearance of the blade

to the turn table structure.

Setting Blade Depth for

Normal Full Cuts

— The depth stop adjustment is a feature used when

cutting grooves in the workpiece. (See page 27 for

cutting grooves.)

1. Loosen and turn both Jam Nuts to just above the

threaded end of the Depth Stop Bolt (Figure 13).

Figure 13. Depth Adjustment

2. Press Depth Stop Release Button and pull up

Depth Stop Bolt until nuts hit the bottom of its

support frame (Figure 13).

3. Set the table to the 0° miter position. Push down

and slide back saw head to the full back position.

4. While looking at both the blade and the corner

where the fence meets the table, turn the Depth

Stop Bolt to set the blade depth to about 1/4 inch

below the table’s surface.

5. Release the saw head to the up position.

6. Turn both Jam Nuts to be tight against the bottom

of the support frame. Tighten nuts against each

other.

7. Practice slide cutting (with tool unplugged) to verify that the blade does not touch table. If it clears

the table, make a practice cut (with tool plugged)

on scrap wood to verify that the cut goes completely through the lower front edge of the workpiece

Do not start the miter saw without

checking for interference between

the blade and the turn table structure. The blade

could be ruined if it cuts into the table structure.

Setting Blade Depth for Cutting Grooves

The depth stop can be easily adjusted to limit the

cutting depth, such as when creating a rough slot.

(See page 27 for instructions)

The kerf insert should be adjusted close to the blade,

but without touching the blade, to avoid tear-out on

the bottom of the workpiece.

1. Lower the head assembly and lock into position.

2. Loosen the six (6) kerf screws using the multi purpose tool (Figure 12).

3. Adjust the kerf inserts as close to the blade (teeth)

as possible without touching the blade.

4. Tighten the kerf screws.

NOTE: At extreme bevel angles the saw blade may

slightly cut into kerf insert.

Figure 12. Kerf Insert

16.

Adjustments

Kerf Insert

Depth Adjustment

Kerf

Inserts

Kerf

Screws

Depth Stop

Bolt

Depth Stop

Release Button

CAUTION

!

Jam Nuts

60

55

50

45

40

0

12

2

12

4

12

12

6

5

30

15

20

25

0

5

10

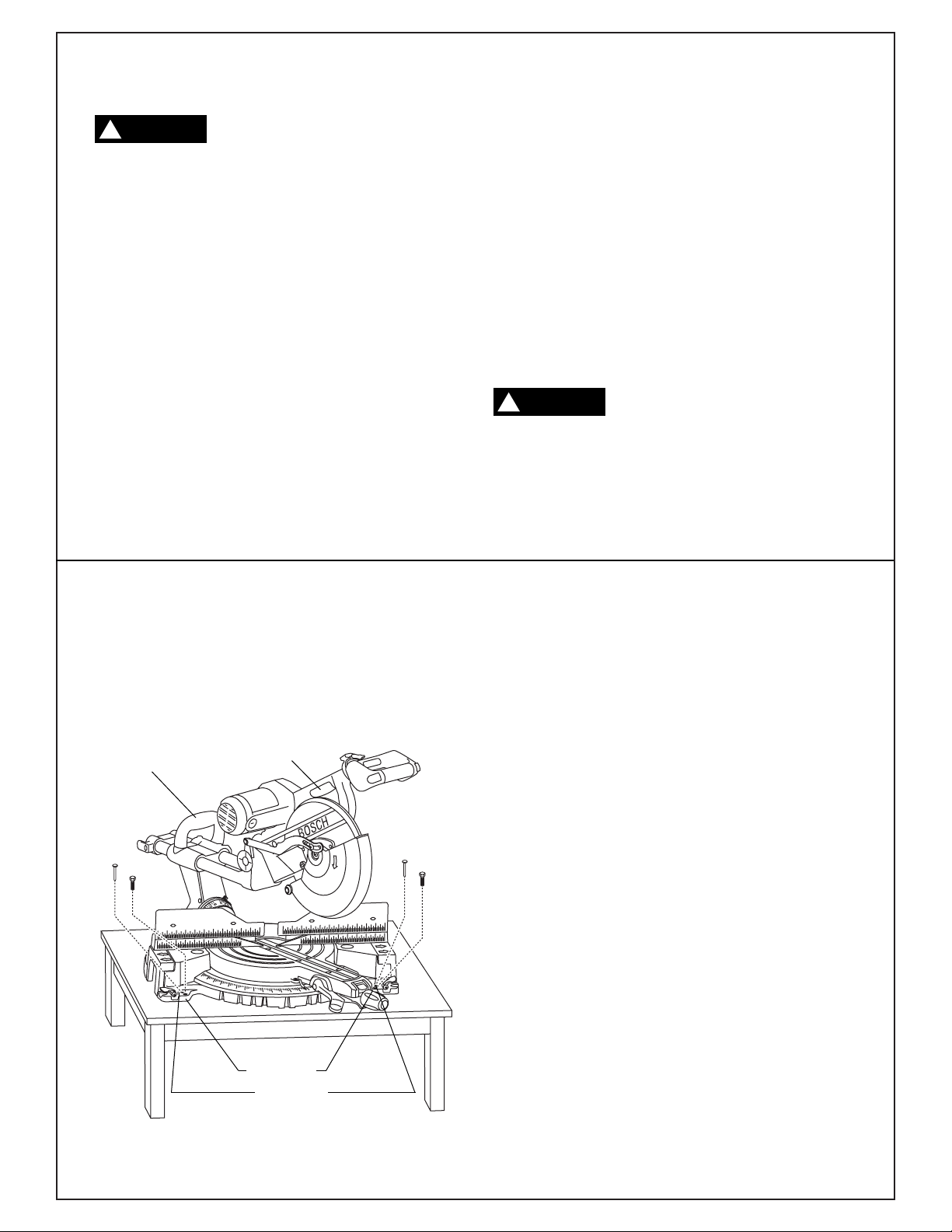

Page 17

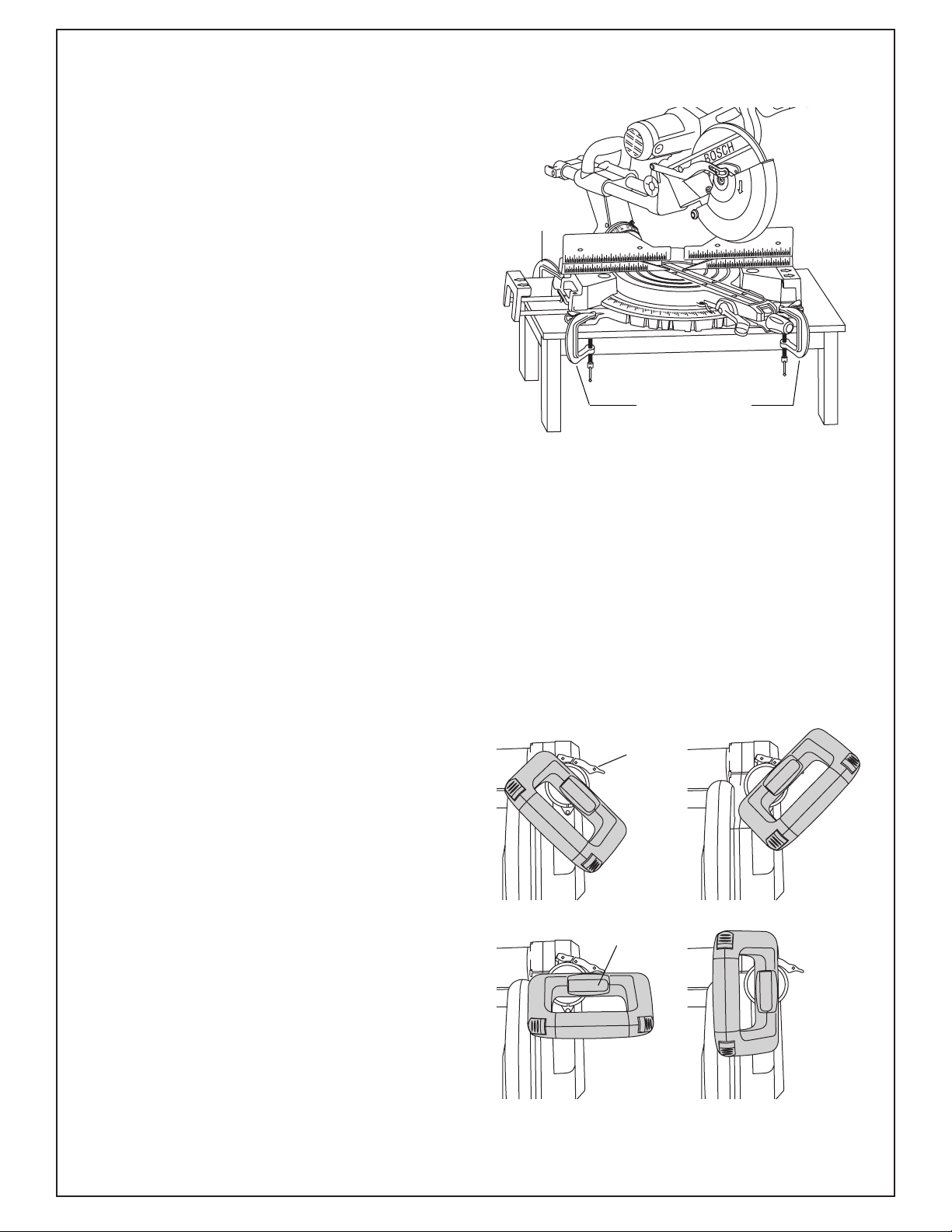

Workbench

Mount the saw using either the four bolt holes (5/16")

or the four nail holes to the workbench (Figure 14).

Check for clearance to the left and right of the saw.

Figure 14. Workbench Mounting

1. Each of the four mounting holes should be bolted

securely using 5/16" bolts, lock washers, and hex

nuts (not included).

2. Locate and mark where the saw is to be mounted.

3. Drill four (4) 5/16" diameter holes through workbench.

4. Place the miter saw on the workbench aligning

holes in base with holes drilled in workbench.

Install bolts, lock washers and hex nuts. As an

alternative, you can mount the saw using drywall

screws in the four nail holes.

Supporting surface where saw is to be mounted

should be examined carefully after mounting to

ensure that no movement can occur during use. If

any tipping or walking is noted, secure the workbench or stand before operating the slide compound miter saw.

17.

Transporting, Placement and Mounting

Mounting Applications

Bolt Hole

Nail Hole

Rear Carrying

Handle

Front Carrying

Handle

To avoid injury always observe the

following:

— Unplug electric cord. Before transporting the saw,

rotate head and lock assembly to 60° right miter,

lock into detent, slide head assembly to the middle of it’s rail, tighten the slide rail lock knob and

lock the head assembly in the lowered position.

Lifting Saw

— To avoid back injury, hold the tool close to your

body when lifting. Bend your knees so you can lift

with your legs, not your back.

— Lift by using the cast-in carry handles at each

side of the bottom of the base.

— Alternate lifting method: When picking tool up

from ground, use rear carrying handle and front

carrying handle (above guard).

— Never carry the tool by the slide rails, this

may cause blade damage.

— Never lift tool by holding switch handle. This

may cause serious damage.

— Never carry the miter saw by the power cord or

the operational handle. Attempting to lift or carry

the tool by the power cord will damage the insulation and the wire connections resulting in electric

shock or fire.

— Observe the position of the saw. People standing

behind it could be injured by thrown debris.

— Place the saw on a firm, level surface where there

is plenty of room for handling and properly supporting the workpiece.

— Bolt, nail or clamp the saw to its support.

Be careful not to over-drive nail

or over-torque the bolt. This could

crack foot or damage base.

WARNING

!

CAUTION

!

Page 18

18.

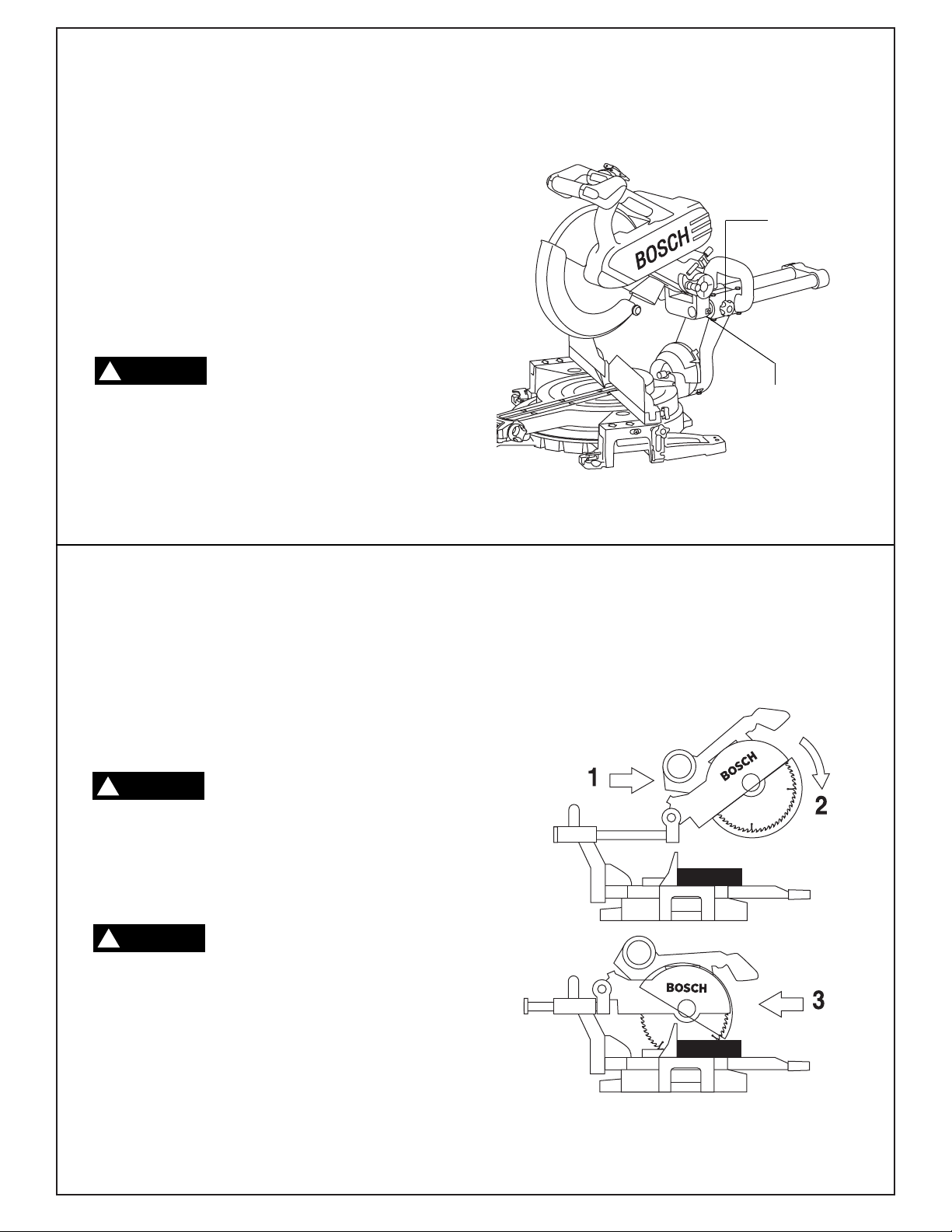

Mounting the Saw

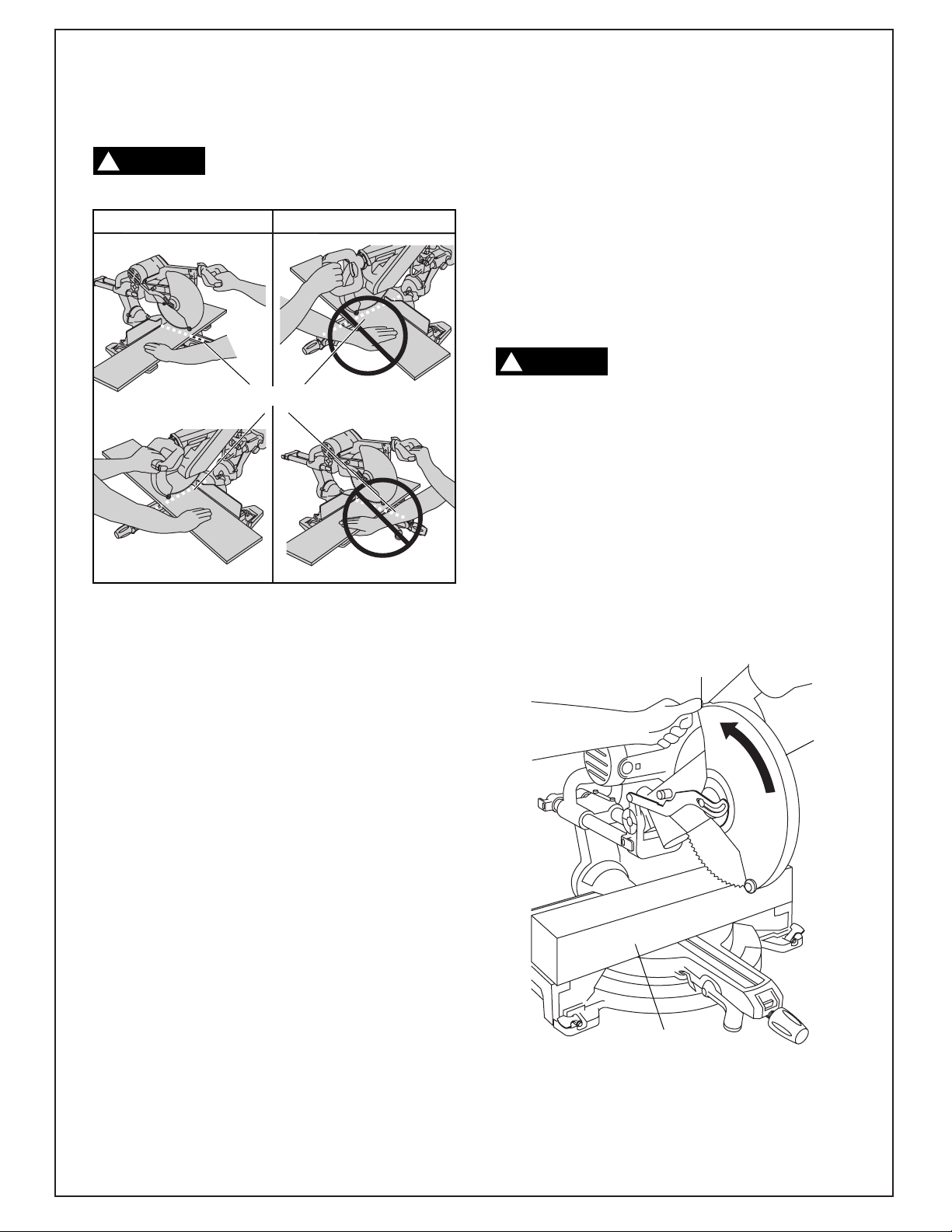

Setting Main Handle in Desired Position

The switch handle can be positioned in any of four

different orientations, depending on the cutting

situation and user preference.

● vertical

● horizontal

● 45° Left

● 45° Right

To reposition the main handle:

1. Release handle clamp (Figure 16).

2. Pull and hold handle rotation release lever

(Figure 16).

3. Rotate handle to desired location.

4. Let go over release lever to set handle into

place. Release lever will retract down only in

one of the four (4) positions

Note: Power switch can not be actuated unless

release lever is retracted down. Do not attempt to

switch tool on between handle position, damage may

occur.

5. Lock the handle clamp.

Adjusting the Four-Position Handle

Clamp Tension

1. Open handle clamp.

2. Using 1.5 mm Allen wrench, increase tension by

turning both setscrews 1/4 turn to the left, tighten

by turning to the right. Always adjust both

setscrews by the same amount.

3. Close handle clamp.

4. Check the tension.

Figure 16. Setting Main Handle Position

Adjusting the Four Position

Switch Handle

Portable Mounting Using Clamps

— If necessary, clamp the miter saw to a workbench

or table top.

— Place two (2) or more “C” clamps on the clamping

areas and secure (Figure 15).

— Be careful not to place clamps over the base

extension clamping levers (Figure 15).

— Mounting with clamps will prevent access to some

wide miter angles.

Figure 15. Portable Mounting Using Clamps

Clamping Areas

Clamping

Areas

Handle

Clamp

Handle Rotation

Release Lever

Pull to Rotate Handle

Pull to Rotate Handle

Pull to Rotate Handle

Pull to Rotate Handle

Page 19

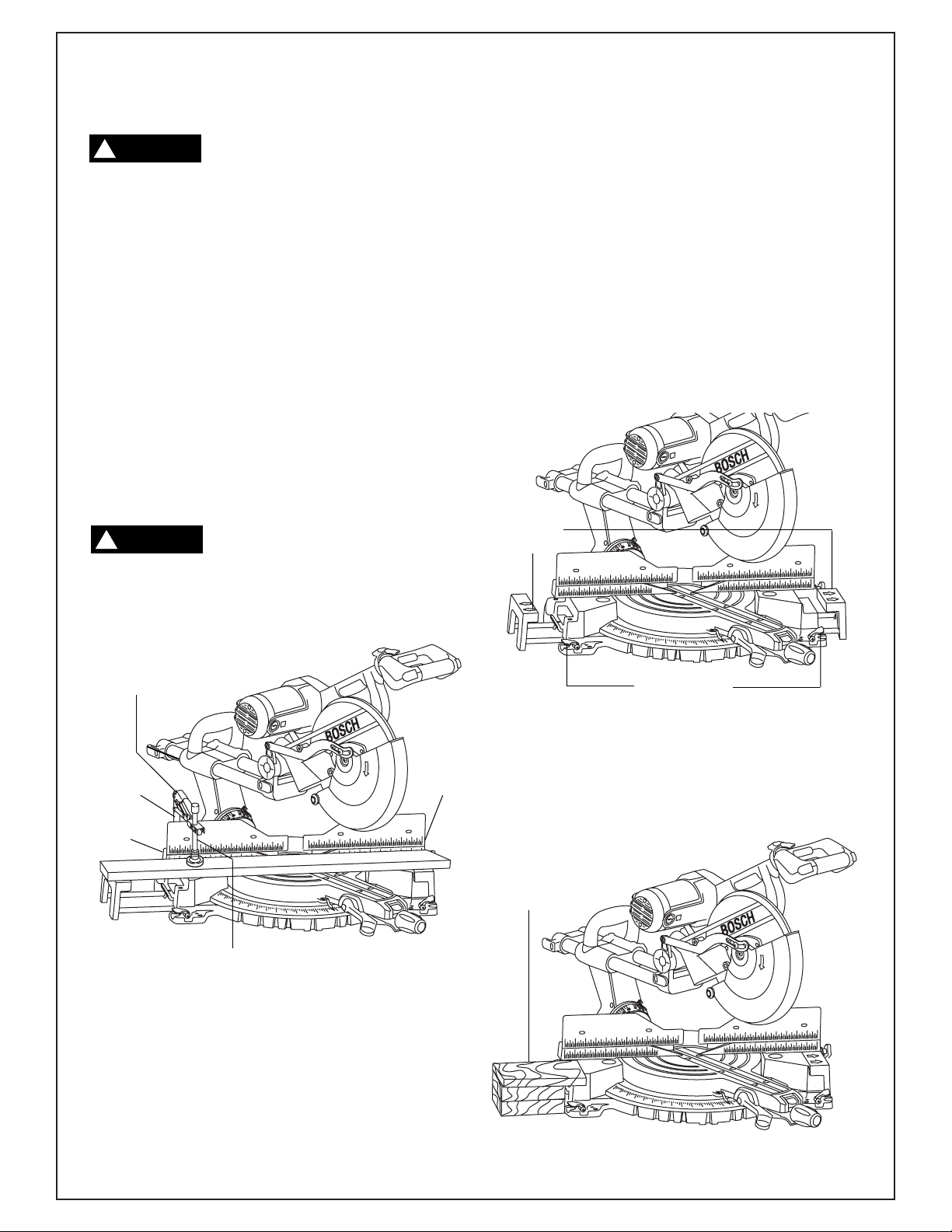

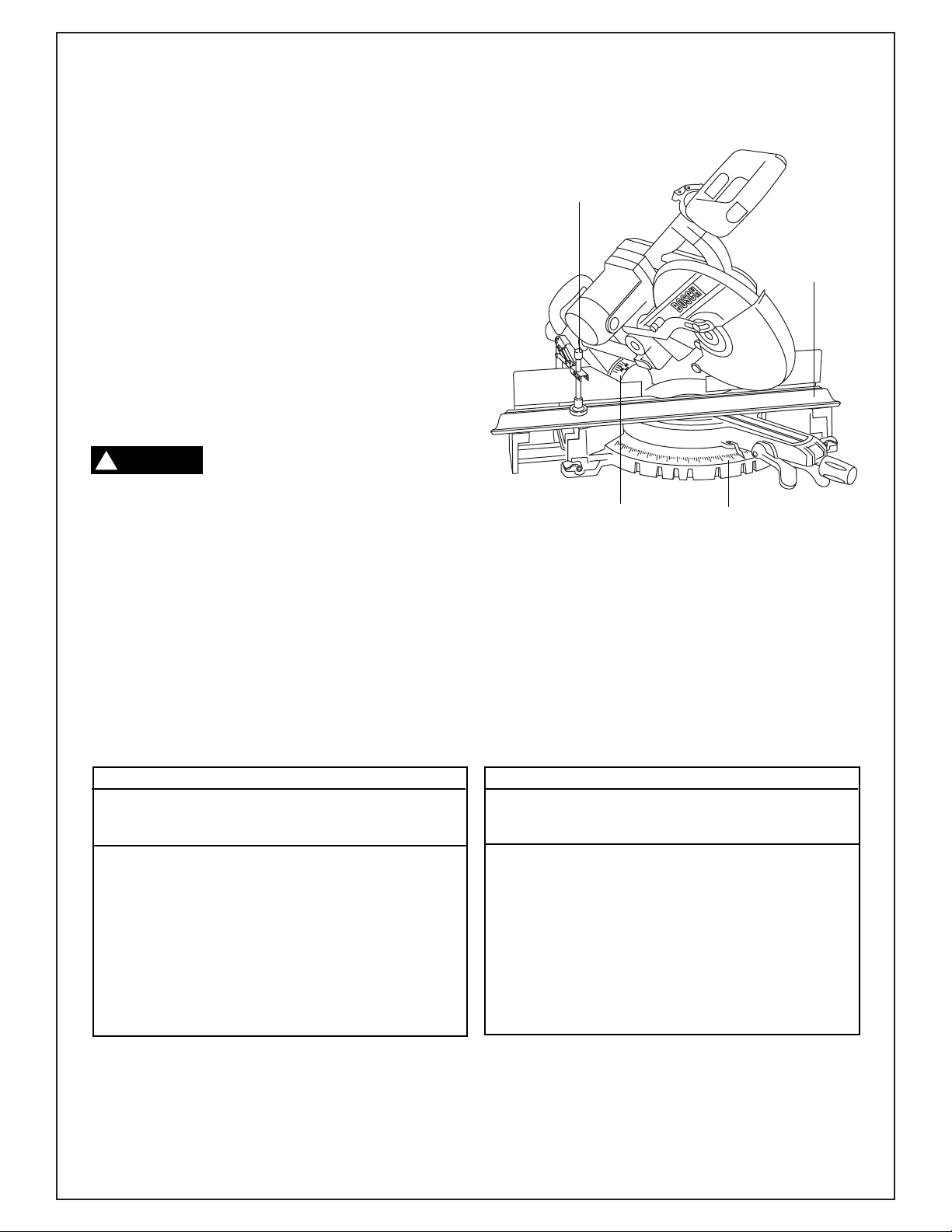

Position your body and hands properly to make cutting easier and

safer. Observe the following instructions (Figure 17).

Figure 17. Hand Positions

● Never place hands near cutting area. Keep hands

and arms outside the “No Hands” zone.

● The “No Hands Zone” is defined as the entire Table

plus the fixed portion of the Base on the right and

left side of the Table and portions of the Fence

within this boundry. This zone is labeled by “No

Hands” symbols placed on the fixed Base.

● Be aware of the path of the sawblade. Make a dry

run with the saw OFF by conducting a simulated

cutting cycle, and observe the projected path of the

sawblade. Keep hands out of the path of sawblade.

DRY RUN—It is important to know where the blade

will intersect with the workpiece during cutting operations. Always perform the simulated cutting

sequence with the power tool switched OFF to gain

an understanding of the projected path of the sawblade. Mentally note where the path of sawblade

will fall and set up your work to keep your hands

and arms out of the path of the spinning blade.

Adjust your clamps and fences so that the smooth

lower guard and cutting action is not interfered with

during cutting operation.

● Hold workpiece firmly against table and fence to

prevent movement.

● Keep hands in position until trigger has been

released and blade has stopped completely.

● Never place hands on slide rails.

● Keep feet firmly on the floor and maintain proper

balance.

● Follow the miter arm when mitering left or right.

Stand slightly to the side of the saw blade.

The lower guard may not automati-

cally open under certain cutting

conditions. For example, when trying to cut workpieces that are near the maximum cutting height

capacity. Under these conditions, the workpiece can

stop the lower guard movement before the downward

motion of the arm could pre-open the lower guard.

If this occurs:

● Workpiece must be securely clamped. This frees a

hand to raise the guard by the lip just

enough to clear the workpiece (Figure 18).

● Start the saw and begin your cut.

● Once you have cleared the position where the

lower guard may bind, release the guard and it will

continue to operate automatically as you cut.

Figure 18. Raising Lower Guard

19.

Basic Saw Operations

Body and Hand Position

WARNING

!

WARNING

!

Lip

Lower

Guard

Workpiece

Correct

Incorrect Use

Projected Line Of Cut

O

P

E

N

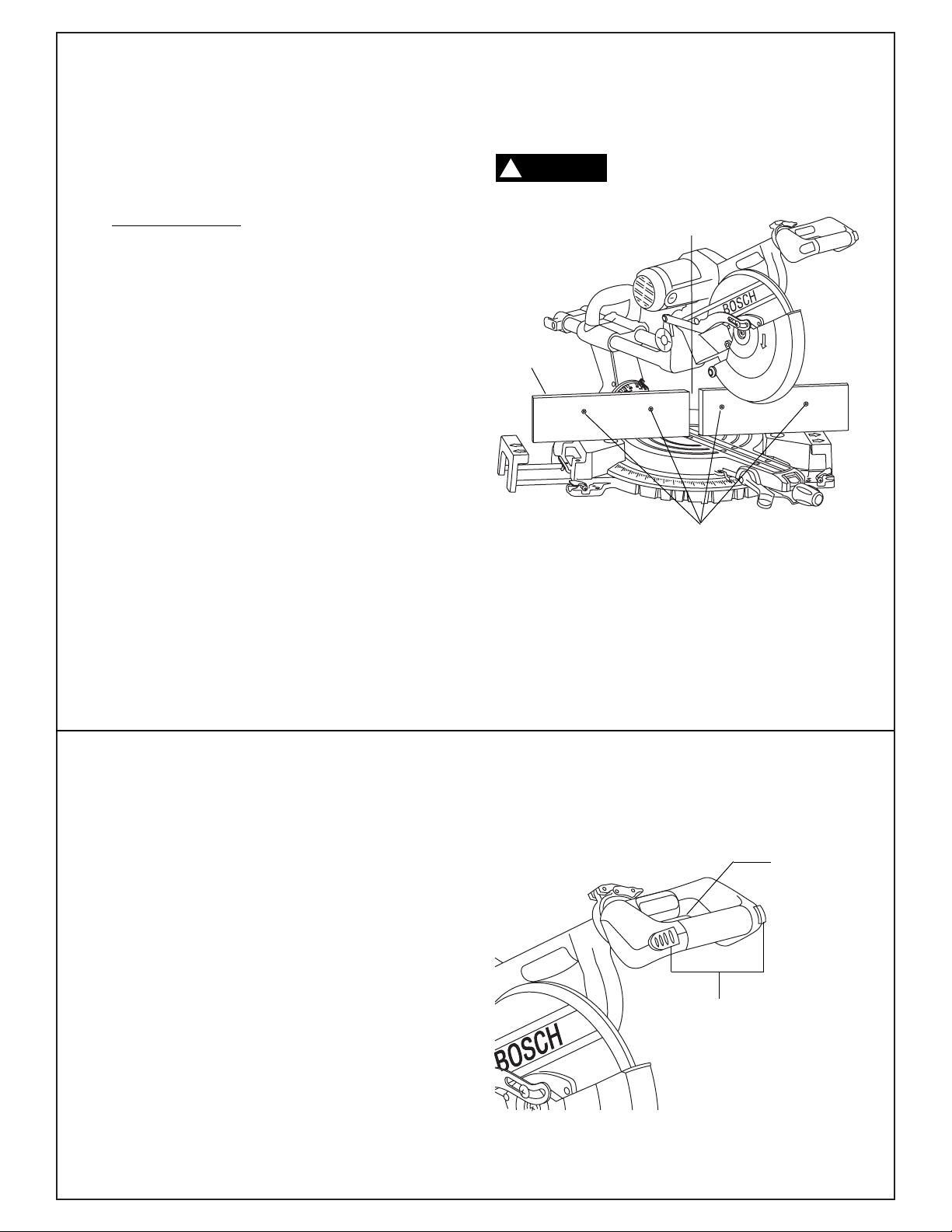

Page 20

Long workpieces have a tendency to

tip over unless clamped down and

properly supported from underneath.

Clamps

Quick-Action Clamp - This clamp easily secures a

workpiece in either of two (2) clamp holes behind the

fence (Figure 19).

— Minimum of 1/2" of knurl must engage clamp post

to be effective.

— Adjust screw if necessary to clear fence or for

large differences in wood heights.

— With clamp in open (lever raised) position, insert

clamp into clamp post until rubber foot comes into

contact with material.

— Press down on lever to tighten clamp.

— Move the head assembly to check clearance with

clamp.

— Pull up on lever to release clamp.

There may be extreme compound

cuts where clamp cannot be used.

Support workpiece with hand outside No Hands

Zone. Do not try to cut short pieces that cannot be

clamped and cause your hand to be in the No Hands

Zone.

Figure 19. Quick-Action Clamp

Horizontal Clamp – The optional MS1221 Horizontal

Clamp and crown stop can be mounted on either side

of the tool and holds the workpiece firmly against the

fence.

Conventional Clamps – and other hold down

devices can be used to hold the workpiece firmly

against the table and the fence.

Long workpiece support

Sliding Base Extensions – These extensions pro-

vide extra workpiece support and are especially useful when cutting long workpieces. To reposition the

extensions, simply unlock the Base Extension

Clamping Levers, reposition the extensions, and relock the levers (Figure 20). (See also Length Stop on

page 27.)

Extra-Long Base Extension Rods – The optional

MS1222 Base Extension Kit allow the 4412’s base

extensions to extend out to 60”. Even after these

longer rods are installed on the 4412, the base extensions can be fully retracted for transportation and

storage.

Figure 20. Sliding Base Extensions

Blocks - Long pieces need extra support. The base

height (3-3/4") is designed to match the standard

lumber of two 2x’s and one 1x. Boards of these thicknesses can be used to create auxiliary support extensions for long workpieces (Figure 21).

Figure 21. Block Support

20.

Basic Saw Operations

Workpiece Support

WARNING

!

WARNING

!

Quick-Action

Clamp

Clamp

Post

Clamp

Hole

Clamp

Hole

Screw Rod

Two 2x’s

and One 1x’s

Sliding

Base

Extensions

Clamp Levers

Page 21

For safety, the switch lever is designed to prevent

accidental starts. To operate safety switch, press the

switch “Lock-OFF” button with either thumb to disengage the lock, then pull the power switch lever and

release the switch “Lock-OFF” release button

(Figure 23). When the power switch lever is released,

the switch “Lock-OFF” button will engage the safety

switch automatically, and the lever will no longer

operate until either “Lock-Off” button is pressed

again.

NOTE: Switch lever can accommodate a padlock

with a long shackle of up to 1/4" in diameter (not

provided with miter saw to prevent unauthorized use.

Figure 23. Switch Activation

Auxiliary Fence

Certain types of molding need a fence face extension

because of the size and position of the workpiece.

Holes are provided in the fence to attach an auxiliary

fence. The auxiliary fence is used with the saw in the

0° bevel position only

.

1. Place a piece of wood against the miter saw fence

(Figure 22). (Wood can have a maximum height of 4-1/2". Check that auxiliary

fence assembly does not interfere with head

assembly.

For splinter-free cuts of molding, attach a one piece

wood auxiliary fence and then cut openings with

miter saw.

2. Mark the locations of the support holes on the

wood from the back side of the fence.

3. Drill and countersink the holes on the front of the

support board.

4. Attach (each) auxiliary fence using two (2)

3/16" flat head machine screws. With 3/4" auxiliary

fence use 1-1/2" long screws. Secure behind

metal fence with washer and machine nuts.

Alternate: With 3/4" auxiliary fence, use 1/4" round

head screws wood screws (3/4" long). Drill four (4)

smaller (then 1/4

" pilot holes through auxiliary

fence and run screws through rear of metal fence.

5. Make a full depth cut to create the blade slot.

Check for interference between the auxiliary fence

and the lower blade guard. Make adjustments as

necessary.

Check for interference from any

components.

Figure 22. Auxiliary Fence

21.

Basic Saw Operations

Switch Activation

Flat Head

Machine Screws

WARNING

!

Power

Switch Lever

Switch

“Lock-Off”

Release Button

Auxiliary

Fence

Blade Slot

Page 22

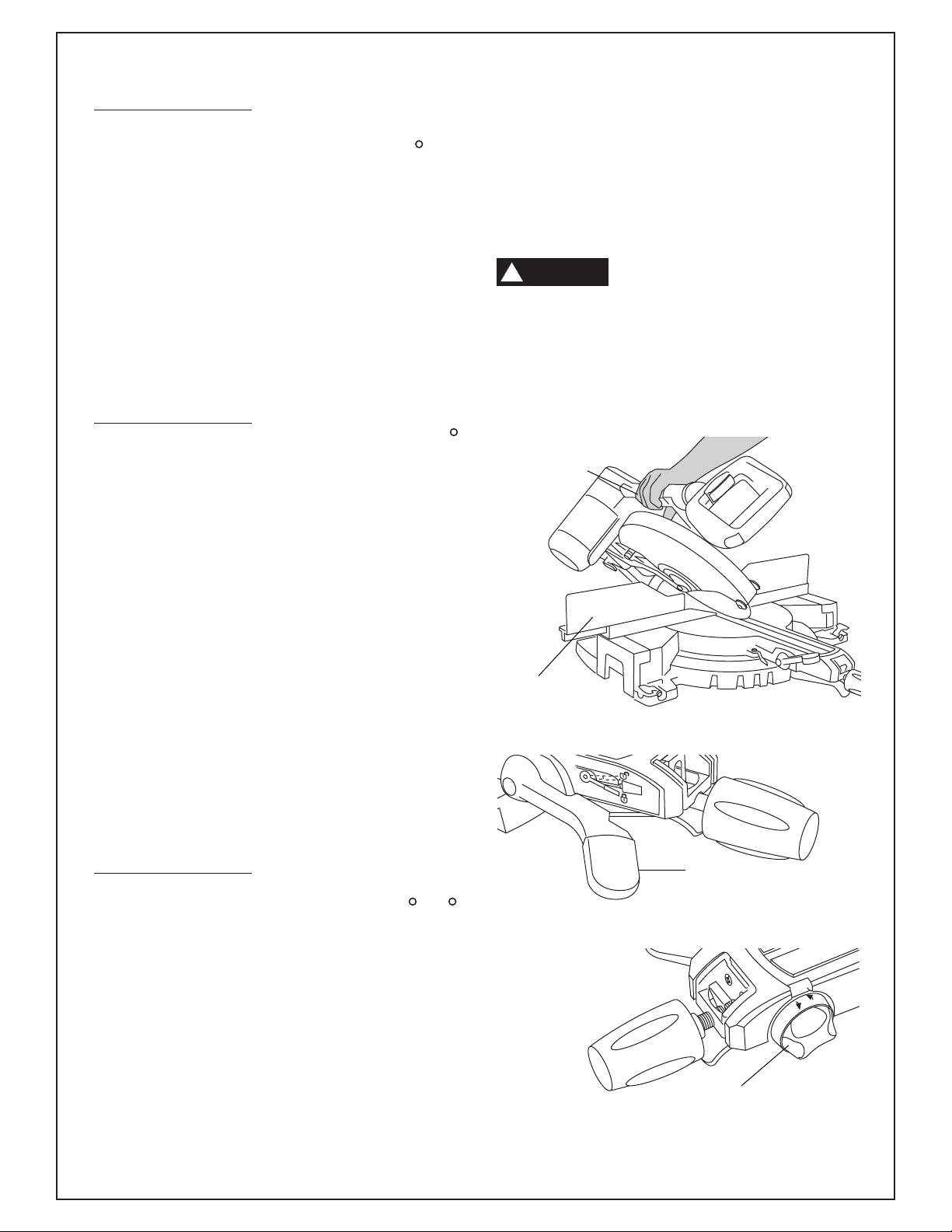

So as to provide sufficient (mini-

mum 6”) spacing from hand to saw

blade, extend the sliding fences and base extensions

when making extreme bevel, miter or compound

cuts.

The base extensions can also be used to provide

extra support for long workpieces.

Sliding Base:

1. Loosen the base extension clamping levers

(Figure 25).

2. Extend sliding base extensions to the desired

position.

3. Press the levers down to clamp the extensions

into place.

Sliding Fence:

1. Loosen the fence locking knobs (behind fence).

2. Slide fence to proper position.

3. Tighten knobs to lock fence into place.

To Temporarily Remove Sliding Fence:

Some extreme compound angles make it necessary

to remove one of the sliding fences.

1. Unscrew fence knob until at least 1/2” of thread

shows.

2. Slide fence to its centermost position.

3. Lift fence to remove.

4. Tighten knob

After the cut is complete, reinstall the sliding fence.

To reinstall the sliding fence, reverse this procedure.

During transportation, sliding base

extensions and fences should

always be secured in the fully closed position.

Figure 25. Sliding Fences and Base Extensions

See page 20 for information about other types of

workpiece support.

22.

Basic Saw Operations

Miter Detent Override

Sliding Fences and Base Extensions

The miter detent override feature allows the detent

action to be locked out, allowing for micro adjustments at any miter angle. When the desired miter

angle is to close to a standard mitering angle that has

a detent slot, this feature prevents the wedge on the

miter arm from slipping into the detent slot on the

base.

1. Lift and hold the miter detent lever (under base

arm).

2. Push the detent override clip forward and latch in

place over edge. Release miter detent lever

(Figure 24).

3. Move miter arm to any position on the miter scale.

4. Lock the miter lock knob to retain miter position.

To Disengage:

5. Loosen miter lock knob and lift the miter detent

lever to release the detent override clip. The clip

should automatically disengage and the table

should lock into any desired miter detent.

Figure 24. Detent Override

2

Detent

Override Clip

Clip Edge

Miter

Detent Lever

WARNING

!

CAUTION

!

Sliding Fences

and Base

Extensions

Base Extensions

Clamping levers

Miter

Lock Knob

60

55

50

45

40

0

12

2

2

15

0

0

5

10

Page 23

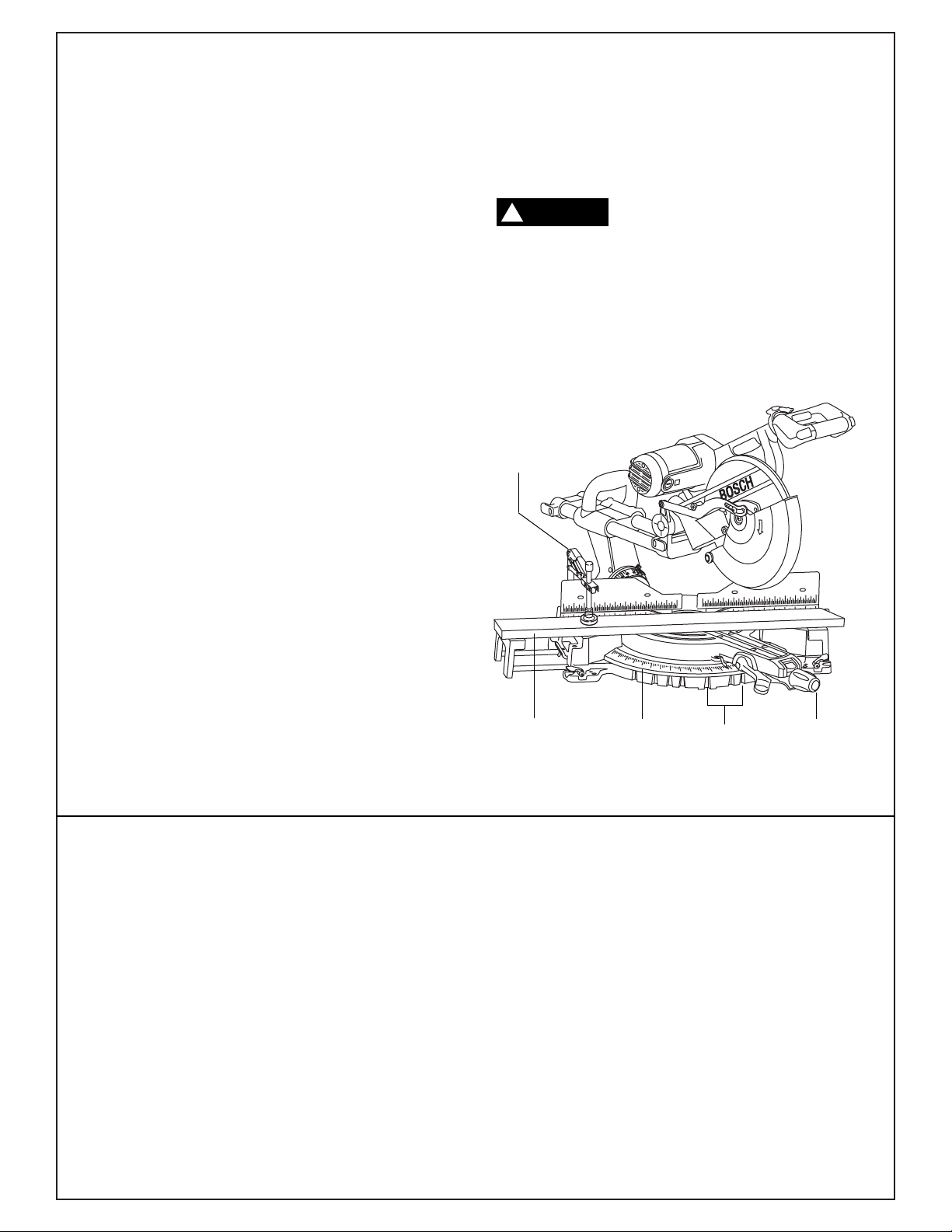

—

The slide rail lock knob is tightened and the head

assembly is lowered to cut through the workpiece.

—

This type of cut is used mainly for narrow pieces.

Follow these instructions for making

your chop cut:

1. Slide the head assembly to the rear as far as it will

go (Figure 26).

2. Tighten the slide rail lock knob (Figure 26).

3. Properly position workpiece. Make sure workpiece

is clamped firmly against the table and the fence.

Use clamping position that does not

interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

4. Activate the switch. Lower the head assembly and

make your cut.

5. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Figure 26. Chop Cut

Saw Operations

Slide Cut

Chop Cut

WARNING

!

23.

Slide completely

Against Rest

Slide Rail

Lock Knob

—

The slide rail lock knob is loose, the head assembly

is pulled towards the operator, the head assembly

is lowered to the workpiece and then pushed to the

rear of the saw to make the cut.

—

This type of cut is used mainly for wide pieces.

—

A positive blade hook of 10 degrees or more is

recommended for best performance when making aggressive cuts or cutting thicker materials.

NEVER pull the saw toward you dur-

ing a cut. The blade can suddenly

climb up on top of the workpiece and force itself toward

you.

Follow these instructions for

making your slide cut:

1. Properly position workpiece. Make sure workpiece is

clamped firmly against the table and the fence.

Use clamping position that does not

interfere with operation. Before

switching on, lower head assembly to make sure clamp

clears guard and head assembly.

2. Loosen the slide rail lock knob.

3. Grasp the switch handle and pull the head assembly

away from the fence, until the blade clears the workpiece or to its maximum extension if blade cannot

clear the workpiece (Figure 27).

4. Activate the switch. Lower the assembly all the way

down and cut through the edge of the workpiece.

5. Push (but do not force) the head assembly towards

the fence to the full rear position to complete the cut.

6. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Figure 27. Slide Cut

WARNING

!

WARNING

!

Page 24

24.

— A “miter cut” is a cross-cut made with the blade

vertical (non-tilted) at a horizontal angle relative to

the fence.

—

A miter cut is made at 0° bevel and any miter

angle in the range from 52° left to 60° right.

—

The miter scale shows the angle of the blade

relative to the fence angle is cast-in on the table

for easy reading.

—

Positive detents have been provided for fast and

accurate mitering at 0°, 15°, 22.5°, 31.6°

and 45° left and right and 60° right.

—

The crown molding detents (left and right) are at

31.6° (See Cutting Crown Molding for more information page 29).

—

For precision settings at angles next to the

detents, use the detent override to lock out the

detent. This prevents the wedge on the detent

lever from slipping back into the detent.

—

A miter cut can be made as either a chop cut or a

slide cut, depending on the width of the workpiece.

—

The kerf inserts should be as close to the blade as

possible without touching the blade (see Kerf

Inserts for adjustment procedures).

Follow these instructions for making

your miter cut:

1. Loosen miter lock knob. Lift miter detent lever and

move the saw to the desired angle, using either

the detents or the miter scale. Tighten miter lock

knob (Figure 28).

2. Extend the base extensions and fence on the side

on which the cut will be made. (See Sliding Fence

and Base Extension on page 22).

3. Properly position workpiece. Make sure workpiece is clamped firmly against the table or the

fence.

Use clamping position that does not

interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

4. Follow procedures for either chop cut or slide cut

(see page 23).

5. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Figure 28. Miter Cut

Saw Operations

Miter Cut

Bevel Cut

WARNING

!

Workpiece

Miter Lock

Knob

Miter

Scale

Detents

Quick

Action

Clamp

— A “bevel cut” is a cross-cut made with the blade

perpendicular to the fence but tilted away from the

vertical position.

— A bevel cut is made at 0° miter and any bevel

angle in the range of -47° to 47°.

— The bevel scale is sized and positioned for easy

reading.

— The front-positioned bevel range selector knob

provides three bevel range choices.

— There are factory set bevel stops at 0° and 45° on

both the left and right. (See

Adjustment section if adjustments are required.)

— There are also positive crown molding bevel

stops at 33.9° on both the left and right.

Disengage this stop unless using the 33.9°

angle (See Cutting Crown Molding for details.)

— A bevel cut can be made as either a chop cut or a

slide cut depending on the width of the workpiece.

— The front-positioned bevel lock lever locks the

head assembly at the desired bevel angle.

1. Lift the bevel lock lever to unlock. Choose the

desired bevel range using the bevel range selector

knob. If in the 0° position and moving to the 0°-to45° right range or 47°-to-47° range, it may be necessary to move the head assembly slightly to the

left before the bevel range selector knob can be

turned. Applying pressure to the cutting assembly

may not allow you to move the bevel range selector Knob.

Page 25

Bevel Range 1 = 45° Left to 0°

This left side bevel range is the default setting

T

o operate in range 1:

1. Move the left sliding fence to clear saw

assembly and re-lock (Figure 29).

2. Lift bevel lock lever to the table height

with the left hand (Figure 30).

3. Grasp the front carry handle with the

right hand and tilt saw head to angle

desired.

4. Once in the desired bevel position, fully press

down bevel lock lever below table height

(Figure 29)..

Without turning the saw on, practice the cutting

action to make sure the fence clears the guards and

adjust as necessary.

Bevel Range 2 = 0° to 45° Right

T

o operate in range 2:

1. Move right sliding fence to clear saw

assembly and re-lock (Figure 29).

2. Lift bevel lock lever to the table height

with the left hand (Figure 30).

3. Grasp the front carry handle with the left hand and

tilt saw head slightly to the left while rotating the

spring-loaded bevel range selector knob with the

right hand so the symbol “ 45-0° “ lines up with the

arrow on the table (Figure 31). The saw assembly

may now be tilted to a right bevel angle up to the

45° stop.

4. Once in the desired bevel position press down

bevel lock lever below table height.

NOTE: When the saw assembly is tilted back left

past 0°, the bevel control knob will snap back to the

default bevel range 1. This is designed to regain the

pre-set bevel stop at the important 0° position.

Bevel Range 3 = 47° Left to 47° Right

This full capacity bevel range setting overrides all

preset stops and allows for cutting at bevel angles

beyond the normal 45° on either side.

T

o operate in range 3:

1. Move left and right-sliding fences to

clear saw assembly and re-lock

(Figure 29).

2. Lift bevel lock lever to the table height

with the left hand (Figure 30).

3. Grasp the front carry handle with the left hand and

tilt saw head slightly to the left while rotating the

spring-loaded bevel range selector knob with the

right hand so the symbol “ 47-47° “ lines up with

the arrow on the table (Figure 31). The saw

assembly may now be tilted to any angle from 47°

left to 47°right.

4. Once in the desired bevel position, fully press

down bevel lock lever below table height.

Follow these instructions for

making your bevel cut:

5. Extend the base extensions and fence on the side

on which the cut will be made. (See Sliding Fence

and Base Extension on page 22).

6. Properly position workpiece. Make sure work

piece is clamped firmly against the table and the

fence.

Use clamping position that does not

interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

7. Follow the procedures for either a chop cut or slide

cut (see page 23).

8. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and/or removing workpiece.

Figure 29.

Figure 30.

Figure 31.

25.

WARNING

!

0

Bevel Lock

Lever

Bevel Range Selector Knob

Sliding

Fence

Front Carry

Handle

4 -5

Left

004- 5

Right

44-7 47

Max

0

UNLOCK

LOCK

0-45º

0-45º

Page 26

26.

— A “compound cut” is a cross-cut made with the

blade both at a horizontal angle relative to the

fence (at a miter angle) and tilted away from the

vertical position (at a bevel angle).

— A compound cut can be made as either a chop cut

or a slide cut depending on the width of the workpiece.

— Because it may take several tries to obtain the

desired compound angle, perform test cuts on

scrap material before making your cut.

Follow these instructions for

making your compound cut:

1. Extend the base extensions and fences on the

side on which the cut will be made. (See Sliding

Fences and Base Extensions on page 22.)

2. Properly position workpiece. Make sure workpiece is clamped firmly against the table or the

fence.

Use clamping position that does not

interfere with operation. Before

switching on, lower head assembly to make sure

clamp clears guard and head assembly.

3. Set miter and bevel angles according to the

instructions on page 24 and 25 for miter and bevel

cuts.

4. Follow the procedures for either chop cut or slide

cut (see page 23).

5. Wait until blade comes to a complete stop before

returning head assembly to the raised position

and / or removing workpiece.

Figure 32. Compound Cut

Saw Operations

Compound Cuts

WARNING

!

Sliding

Base

Miter

Angle

Workpiece

Quick-Action

Clamp

Bevel Angle

Scale

Page 27

—

The depth stop adjustment is a feature used when

cutting grooves in the workpiece.

—

The depth adjustment is used to limit blade depth

to cut grooves.

—

A groove should be cut as a slide cut.

1. For major adjustments, press the depth stop

release button and slide the depth stop bolt to

the desired location (Figure 33).

2. For minor adjustments, simply rotate the depth

stop bolt to the desired location.

Figure 33. Cutting Grooves

3. Cut the two outside grooves.

4. Use a wood chisel or make multiple passes by

sliding the wood over to one side to remove the

material between the outside grooves (Figure 33a).

Figure 33a. Rough Cut Groove

The unit’s flip up length stop can be used when

making repetitive cuts of the same length.

To set the stop, simply unscrew the knob, flip the stop

into position and tighten the knob (Figure 34).

1. To set the cut length, unlock the base extension

clamping lever, reposition the base extension and

length stop, and relock the levers.

2. The maximum length that can be cut using the

length stop is approximately 20".

If desired, the length stop and knob can be moved to

the left base extension. The optional MS1223 Length

Stop Kit can also be installed on the left side to provide stops on either side of the saw.

To increase the length that can be cut using the

length stop, replace the tool’s base extension rods

with the optional MS1222 Extra-Long Base Rod Kit ,

which increases the maximum length that can be cut

using the length stop to approximately 30” on either

side of the tool.

Figure 34. Length Stop

27.

Saw Operations

Cutting Grooves

Length Stop

Outside Grooves

Chisel Cut

Workpiece

Depth Stop

Bolt

Depth Stop

Release Button

Jam Nuts

Knob

Length Stop

Page 28

28.

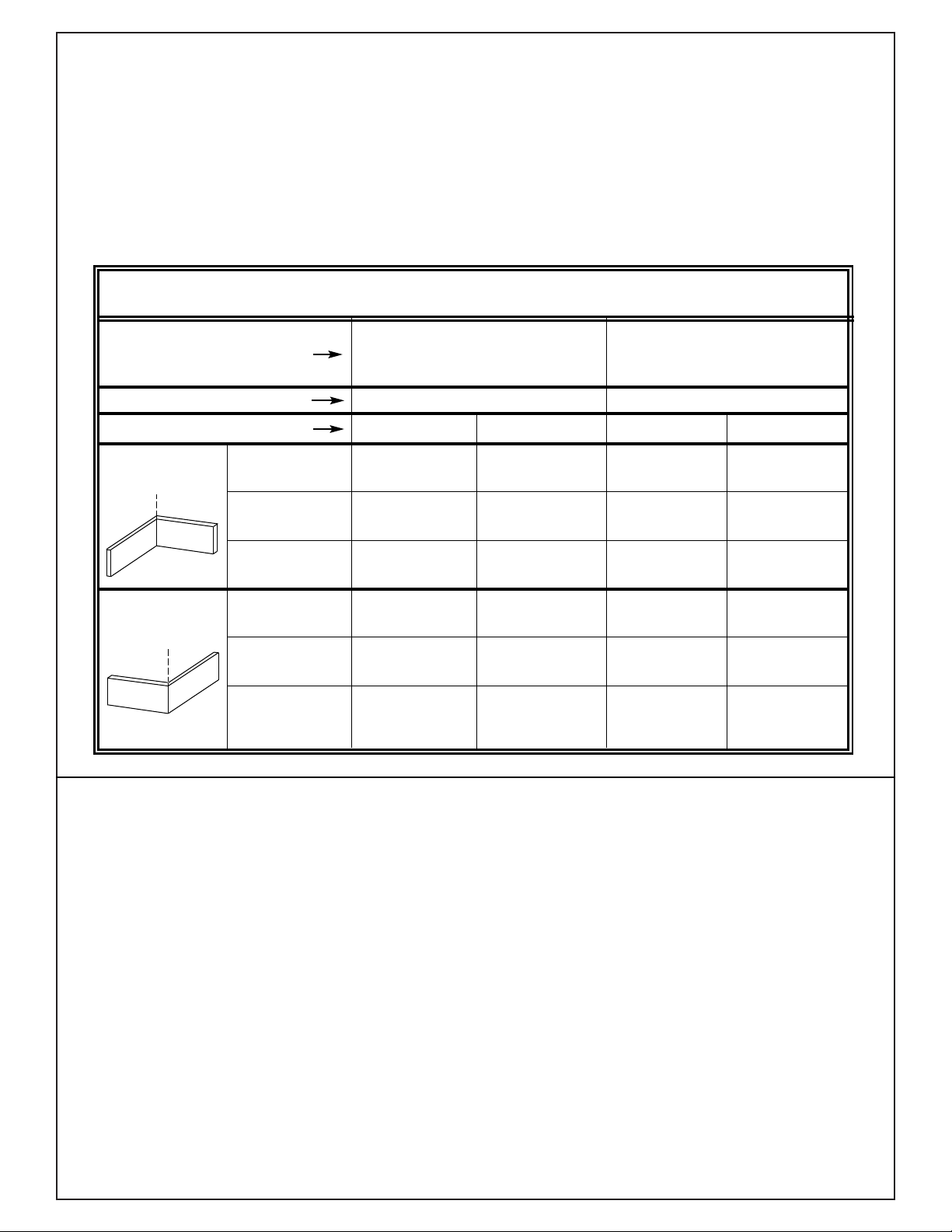

BASE MOLDING CUTTING INSTRUCTIONS

LOCATION OF Molding in Vertical Position: Molding in Horizontal Position:

MOLDING Back of molding is Back of molding is flat

ON SAW against the fence on the table

Bevel Angle Bevel = 0° Bevel = 45°

Molding Piece Being Cut To left of corner To right of corner To left of corner To right of corner

Inside Miter Angle Left at 45° Right at 45° 0° 0°

corner of wall

Position of Bottom Bottom Top against Bottom

molding on Saw against table against table fence against fence

Finished Keep left Keep right Keep left Keep left

side side of cut side of cut side of cut side of cut

Outside Miter Angle Right at 45° Left at 45° 0° 0°

corner of wall

Position of Bottom Bottom Bottom against Top against

molding on Saw against table against table fence fence

Finished Keep left Keep right Keep right Keep right

side side of cut side of cut side of cut side of cut

Saw Operations

Cutting Base Molding

Cutting Crown Molding

Left

Right

Left

Right

— Base molding can be cut vertical against fence or

flat on the table. The maximum size that can be

vertical on the fence is 4-1/4", flat on table is

10-1/4".

— Follow the table for helpful hints on cutting base

molding for corners that have 90° angles.

— Cutting base molding can be done either as a

chop cut or a slide cut depending on the size of

the workpiece.

— Crown molding must be cuts must be positioned

properly to fit exactly.

— There are two ways to cut crown molding: flat on

table or angled to table and fence.

— Crown molding’s “spring angle” is the angle

between the back of the molding and the bottom

flat surface that fits against the wall.

— This miter saw has special miter detents at

31.6° and bevel detents at 33.9°. These

detents allow you to easily position most crown

moldings flat on the table and make precise cuts

for 90° corners. (These detents are only for use

with crown moldings that have a 38°“spring

angle”.) NOTE: These detents cannot be

used with 45° crown molding.

— See also pages 29 & 30 for miter and bevel angle

charts for cutting crown moldings that have

38° and 45° spring angles (and the material is

laid flat on the miter saw base). Each chart lists

the exact miter and bevel settings required for a

wide range of corner angles.

— Even though these angles are standards, most