Page 1

FOR MODELS:

SHI

BOSCH

SHU

4302 4306

6802 6805

6806

3002 3006

3012 3016

4002 4006

4016 4022

4026 4036

4302 4306

4312 4316

5302 5304

5305 5306

5312 5314

5315 5316

6802 6805

6806

Dishwasher Repair Manual

Effective: December 1, 1998 1st Edition/Rev. 0

SHV

4303 4803

BSH Home Appliances

2800 South 25th Avenue

Broadview, Illinois 60153

Page 2

Introduction

This Repair Manual is designed to assist you in the evaluation, diagnosis and repair of

the current SHI, SHU and SHV model dishwasher series. To better understand these

appliances, their operation and construction we suggest that you read this manual

thoroughly before attempting any repairs.

All information is current at the time of printing.

Page 3

H

Table of Contents

Description Page

Section 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warranty / Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model / Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 7

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation, SHU 3002 / 3006 / 3012 / 3016 / 4002 / 4006 / 4016 / 4022 / 4026 / 4036 . 10

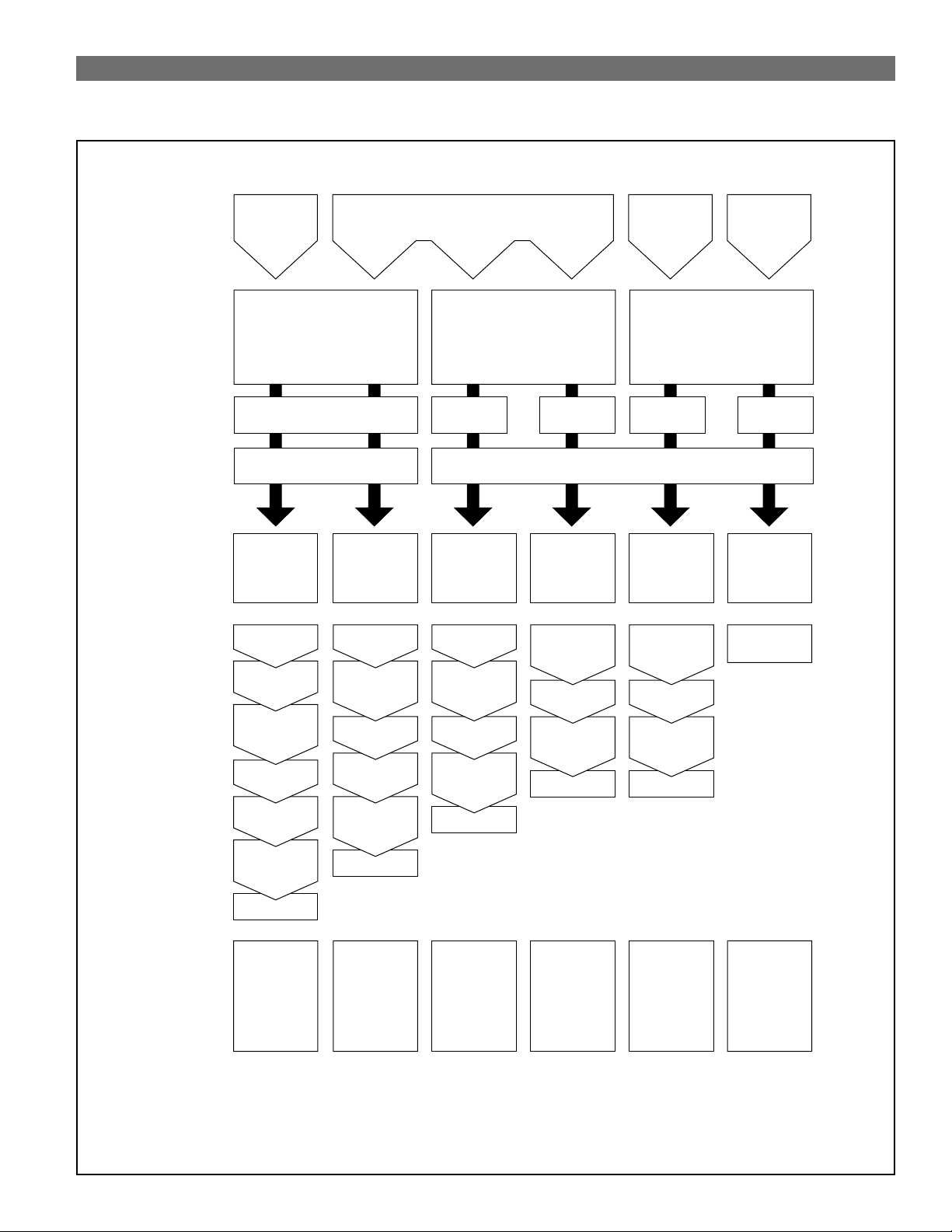

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation, SHI 4302 / 4306 — SHU 4302 / 4306 / 4312 / 4316 . . . . . . . . . . . . . . . . . . . . . . 12

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation, SHU 5302 / 5304 / 5305 / 5306 / 5312 / 5314 / 5315 / 5316 . . . . . . . . . . . . . . 14

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation, SHI / SHU 6802 / 6805 / 6806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1

Section 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rack System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 – 21

Interior Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 – 25

Detergent / Rinse-Agent Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Washability / Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SERVICE REMINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Section 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Outer Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Door Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dispenser Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispenser Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Facia Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 – 35

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Section 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Base Components – Front Accessible: Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . 38

Circulation Motor Capacitor . . . . . . . . . . . . . . . . . . . . 38

Leveling Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Water Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drain Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 — 41

Page 4

2

H

Table of Contents

SERVICE REMINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Description Page

Section 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Left Side Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Left Side Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Water Inlet / Discharge System – Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46 – 47

Water Inlet / Discharge System – Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Section 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Right Side Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Right Side Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

NTC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

NTC Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 – 57

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Section 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 – 62

Base Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Circulation Pump / Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Circulation Pump / Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Heater Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Aqua Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Door Spring Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Section 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Wiring Diagrams / Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72 – 84

Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagram 1

SHI 4302 / 4306 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 1, 8, 9

SHI 6802 / 6805 / 6806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 1, 8, 11

SHU 3002 / 3006 / 3012 / 3016 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 2, 3, 4

SHU 4002 / 4006 / 4016 / 4022 / 4026 / 4036 . . . . . . . . . . . . . . . . . . . . . . Diagrams 5, 6, 7

SHU 4302 / 4306 / 4312 / 4316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 1, 8, 9

SHU 5302 / 5304 / 5305 / 5306 / 5312 / 5314 / 5315 / 5316 . . . . . . . . . Diagrams 1, 8, 10

SHU 6802 / 6805 / 6806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 1, 8, 11

SHV 4303 / 4803 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diagrams 12, 13

Page 5

H

Section 1

Description Page

Warranty / Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model / Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 7

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3

Page 6

4

H

Warranty / Technical Specifications

Warranty

st

1

Year Parts & Labor.

2nd Year Parts only.

3rd – 5th Year Electronic Boards, parts only.

3rd – 5th Year Racks, parts only.

This does not include rack wheels; silverware baskets or plastic shelving.

Lifetime Stainless Steel.

Must receive a special authorization before attempting any repairs or replacement.

Cosmetic items, Facia and Door Panels are only warranted against manufacturing defects. In the event of a scratch or

dent have the customer contact the Customer Service Department.

CUSTOMER SERVICE 800-944-2904

TECHNICAL SERVICE 888-522-6724

Technical Specifications

Electrical Requirements

Rating 120V / 60Hz

Dedicated Circuit 15 Amp

Total Amps (load rated) 11 Amp

Water Supply

Suggested Incoming Temp. 140° f

PSI Min / Max 20 / 60

Water Connection 3/8” Copper or Flexible Stainless Steel

Component Values

Component Ohms* Amperage Other

Water Valve 1K ——

Drain Motor 16 .75 —

Circulation Motor 10 1.25 —

NTC 55K at room temp.

(75° f)

PTC (actuator) 200 ——

Heater 10.5 9.75 1200 watts

— Resistance decreases as

temperature increases

*always disconnect both component leads before measuring for resistance.

Electrical Warning:

To avoid personal injury and/or property damage it is important that safe servicing practices and procedures are observed at

all times. Disconnect the electrical service before attempting any repairs, and live tests are to be performed by experienced

and qualified service personnel only.

Page 7

H

5

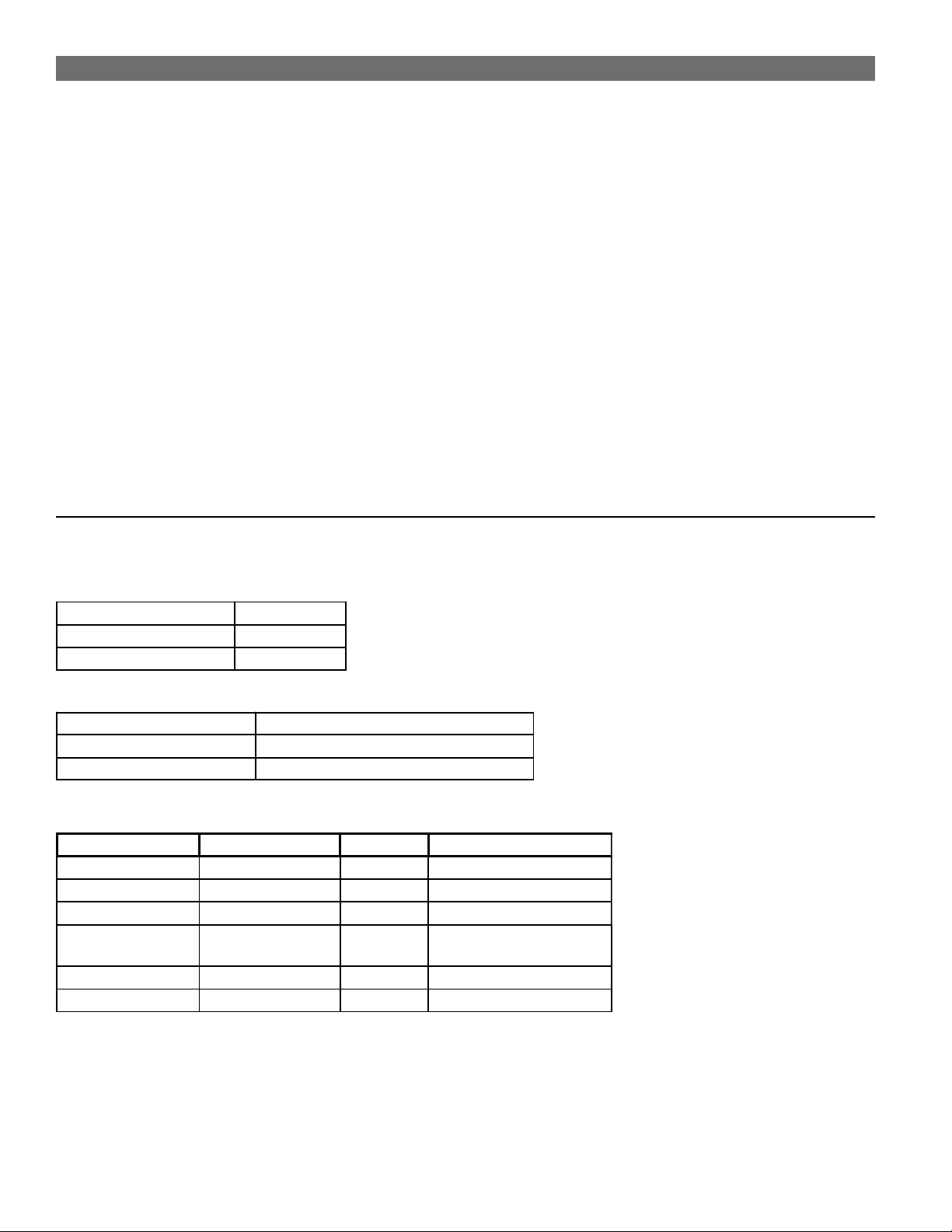

Model / Serial Number Location

Fig. 1-1 Fig. 1-2

Located on the right hand side of the Inner Door is the Model and Serial number tag, Fig. 1-1.

The Model and Serial numbers can be found on the left side of the tag within the black outline box, Fig. 1-2.

The Model Number for this unit is SHU 5312 UC/U06.

Located just under the Model Number is the ten-digit Serial Number.

The Serial Number for this unit is FD 7801 123456.

Service note: A second Model and Serial number tag is located on the Base, see Section 5, Fig. 10-1.

Page 8

6

H

Product Overview

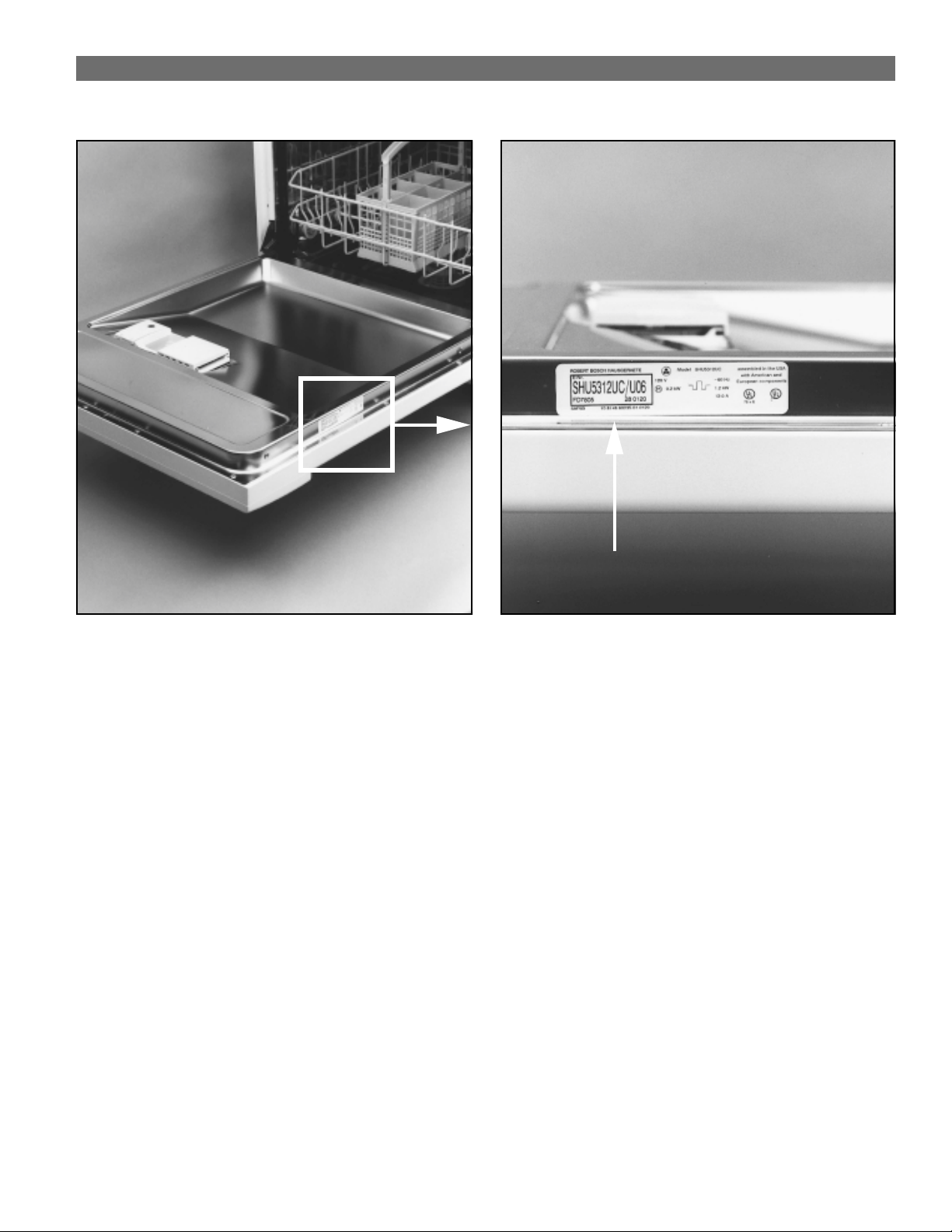

The Bosch dishwasher utilizes a two motor system with separate Circulation and Drain Motors, and a

Flow Through Heater controlled by a Flow Switch and NTC Thermistor. With some models also having

the advanced logic feature of an Aqua Sensor turbidity measuring devise, Fig. 2-1.

• A two motor system allows each motor to be designed for a single function, thus reducing overall

size and energy consumption. While also reducing operating noise.

• The Flow-Through Heater allows a shorter heating cycle since all water must pass through the

Heater, increasing water temperature by approximately two degrees a minute. To protect the

heater from dry fire, the Flow Switch will not allow the Heater to activate unless water is flowing.

• Water temperature is controlled by the NTC (negative temperature coefficient). As water

temperature increases the NTC records the decrease in resistance. The Control Unit Logic Board

measures this resistance change and allows the program to advance once the correct

temperature (resistance level) is reached.

• The Aqua Sensor turbidity measuring device, which is available only on select models, evaluates

the pre-wash water using a beam of light and a pick-up sensor. If the beam passes easily through

the pre-wash water then no additional wash water is added. If the beam cannot pass through,

then the pre-wash water is drained and a fresh fill is added for the main wash cycle.

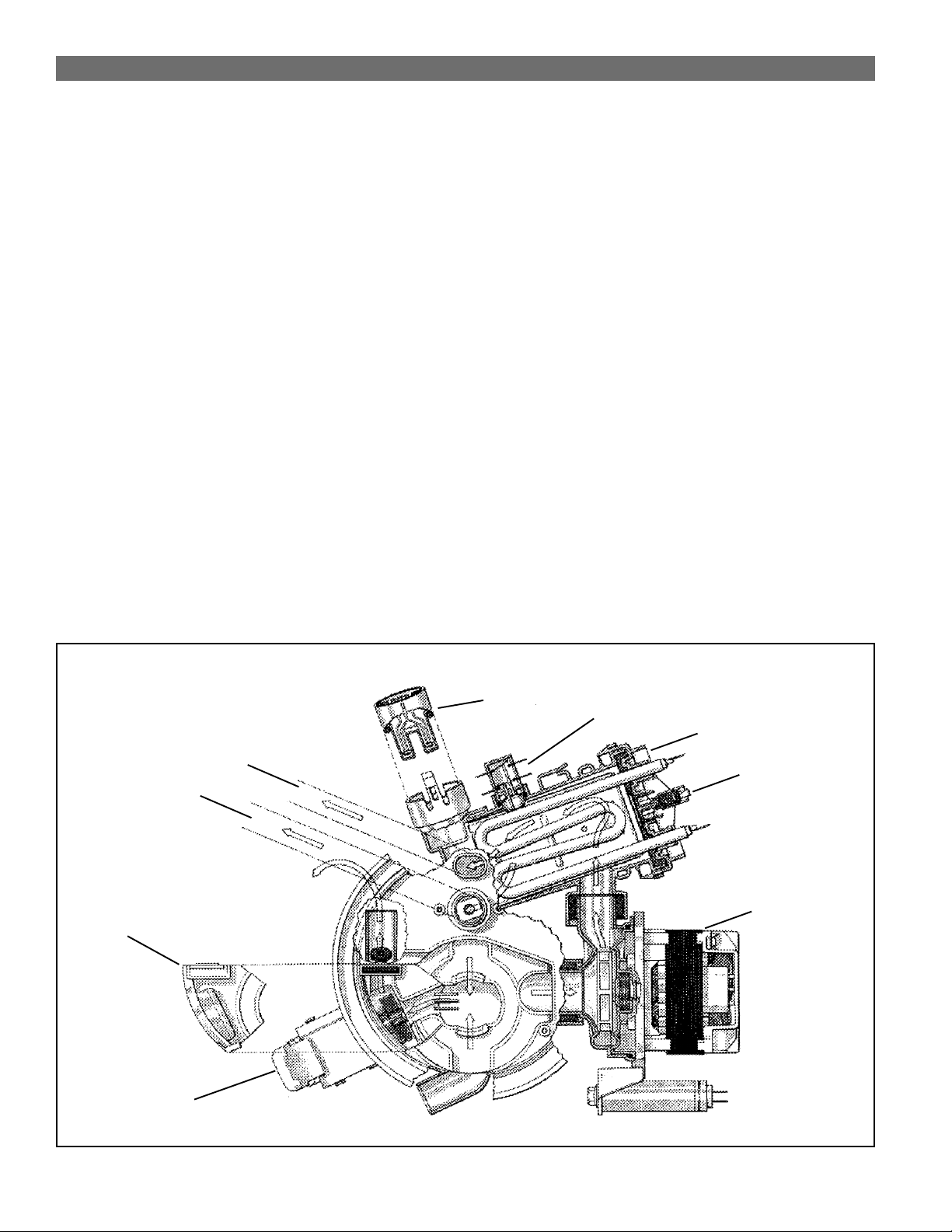

The heated water then advances through the system via a four level wash system that uses both an

upper and lower spray arm as well as an overhead sprayer, Fig. 2-2.

Aqua Sensor

NTC

Flow Through Heater

Upper Spray Arm

Lower Spray Arm

Circulation Motor / Pump

Impeller Cover

Flow Switch

Fig. 2-1

Drain Motor

Page 9

H

7

Product Overview

Overhead Spray

Upper Spray Arm

Lower Spray Arm

Coupling

Feed Tube

Fig. 2-2

Sump

Aqua Sensor

Flow Through

Heater

Page 10

8

H

Notes

Page 11

H

Section 2

Description Page

Operation, SHU 3002 / 3006 / 3012 / 3016 / 4002 / 4006 / 4016 / 4022 / 4026 / 4036 . 10

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation, SHI 4302 / 4306

SHU 4302 / 4306 / 4312 / 4316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation, SHU 5302 / 5304 / 5305 / 5306 / 5312 / 5314 / 5315 / 5316 . . . . . . . . . . . . . . 14

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation, SHI & SHU 6802 / 6805 / 6806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cycle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 12

10

Operation

SHU 3002/3006/3012/3016/4002/4006/4016/4022/4026/4036

H

Fig. 3-1 Fig. 3-2

The SHU 30** and 40** are both mechanical units that operate using a basic Timer and Selector Switch.

TO OPERATE EITHER MODEL, (a SHU 4006 is shown):

Fig. 3-2.

First select a cycle by pushing the corresponding Cycle Button in. The Cycle Button remains in

the indented position until another cycle is chosen.

Now, depress the On/Off Button until it locks in place and the On LED illuminates.

Note: The On lamp will remain illuminated until the On/Off Button is depressed a second time

turning the unit off.

If the door is opened during the cycle, the On/Off Button will be reset to off and must

again be depressed to re-active the unit.

Fig. 3-1.

Then, turn the Timer Knob slowly clockwise to the start position and release. You will hear the

Drain Motor activate.

The Timer Knob will continue to advance clockwise back to the twelve O’clock position until the

cycle is complete.

Please note: During the Rinse & Hold Cycle the Timer Knob will only advance to the two O’clock

position and then stop, indicating the end of the Rinse & Hold cycle.

Page 13

H

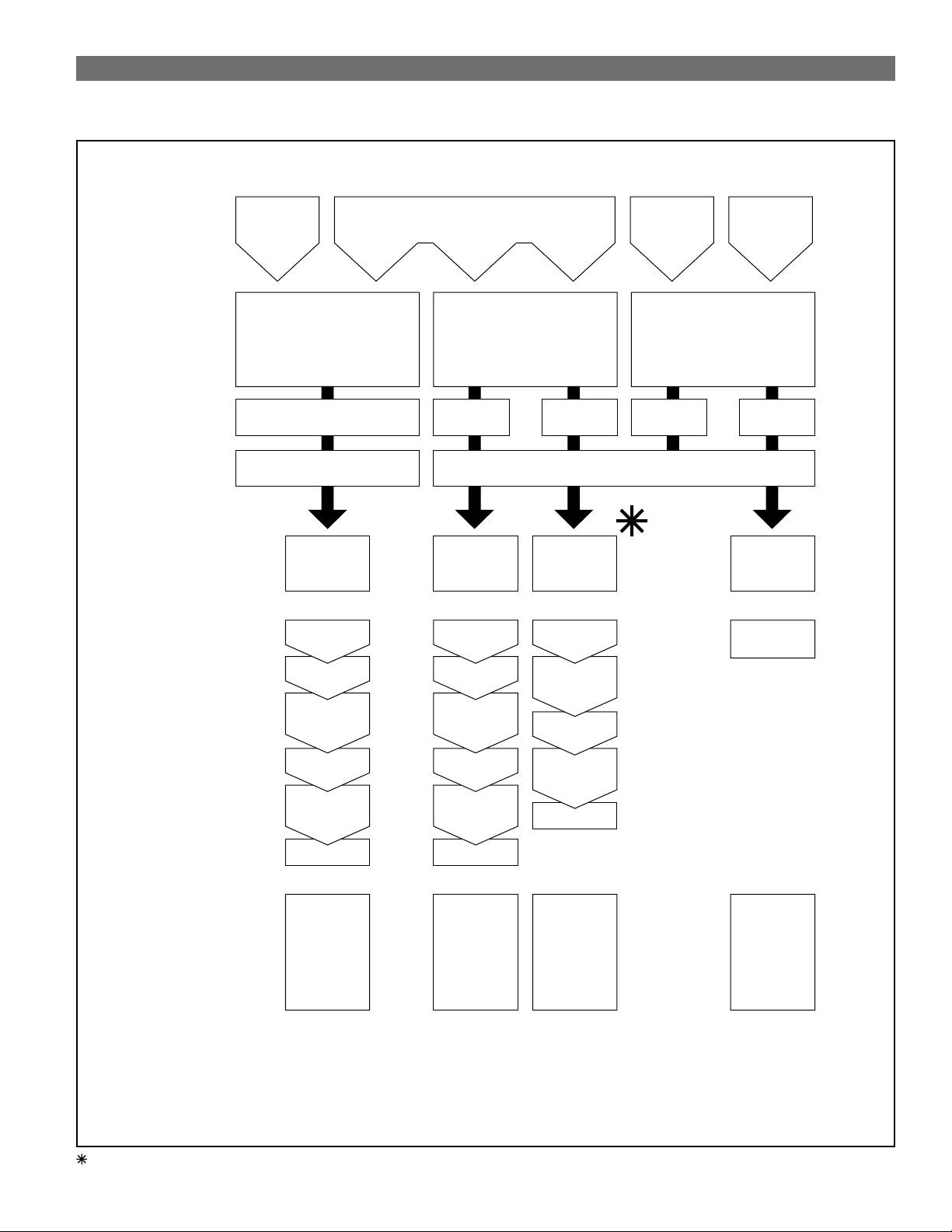

Drying

85

6.55

24.75

78

6.55

24.75

10

1.19

4.5

Rinse-aid

161˚F

Rinse

Wash

161˚F

Pre-wash

70

5.36

20.25

Type of dishware

e.g. china,

pots/pans,

cutlery,

glasses,

etc.

Wash

cycle

Cycle

sequence

Cycle

details

Duration in

minutes

Water consumption

in gallons

Water consumption

in liters

Type of food

remains

Amount of

food remains

Condition of

food remains

Shown above are the range of values that may be obtained while running the dishwasher under normal

conditions. Actual values may vary. The actual cycle duration, water and energy usage are dependent upon

inlet water temperature.

Non-deli-

cate

Soups, casseroles,

sauces, potatoes,

pasta, rice, eggs,

roast or fried food

a lot

stuck on hard

a lot a little a little very little

Power

Scrub

Regular

Wash

Pre-rinse

Drying

Rinse-aid

161˚F

Rinse

Wash

140˚F

Pre-wash

Pre-rinse Pre-rinse

Rinse

& Hold

Soups, potatoes,

pasta, rice, eggs,

roast or fried food

Coffee, cakes, milk,

salami, cold drinks,

salads

Mixed MixedDelicate

loosely attached

Delicate

Wash

Drying

Rinse-aid

161˚F

Rinse

Wash

140˚F

Pre-rinse

11

Cycle Chart

SHU 3002/3006/3012/3016/4002/4006/4016/4022/4026/4036

Delicate cycle not used on SHU 3002/3006/3012/3016

Page 14

12

Operation

SHI 4302/4306 SHU 4302/4306/4312/4316

H

Fig. 3-3 Fig. 3-4

The SHI or SHU 43** series operates using an electronic Control Unit.

TO OPERATE:

Fig. 3-3.

First depress the On/Off Button until it locks in place.

Fig. 3-4.

Once the On/Off Button is depressed the LED above the previously used cycle will illuminate.

To change the cycle, simply press the desired Cycle Button twice. The LED above that cycle will

then illuminate.

As the program advances the Cycle Progress LED’s will illuminate (wash, rinse / dry). When the

cycle is complete the Clean LED will be illuminated.

TO CANCEL A CYCLE:

Press the Power Scrub Plus and Regular Wash Buttons both in at the same time. The unit will

then drain and the Clean LED will illuminate.

Please note: If the door is opened during the cycle, the On/Off Button will be reset to off and must

be depressed again to re-active the cycle. The cycle will resume from where it left off.

Page 15

H

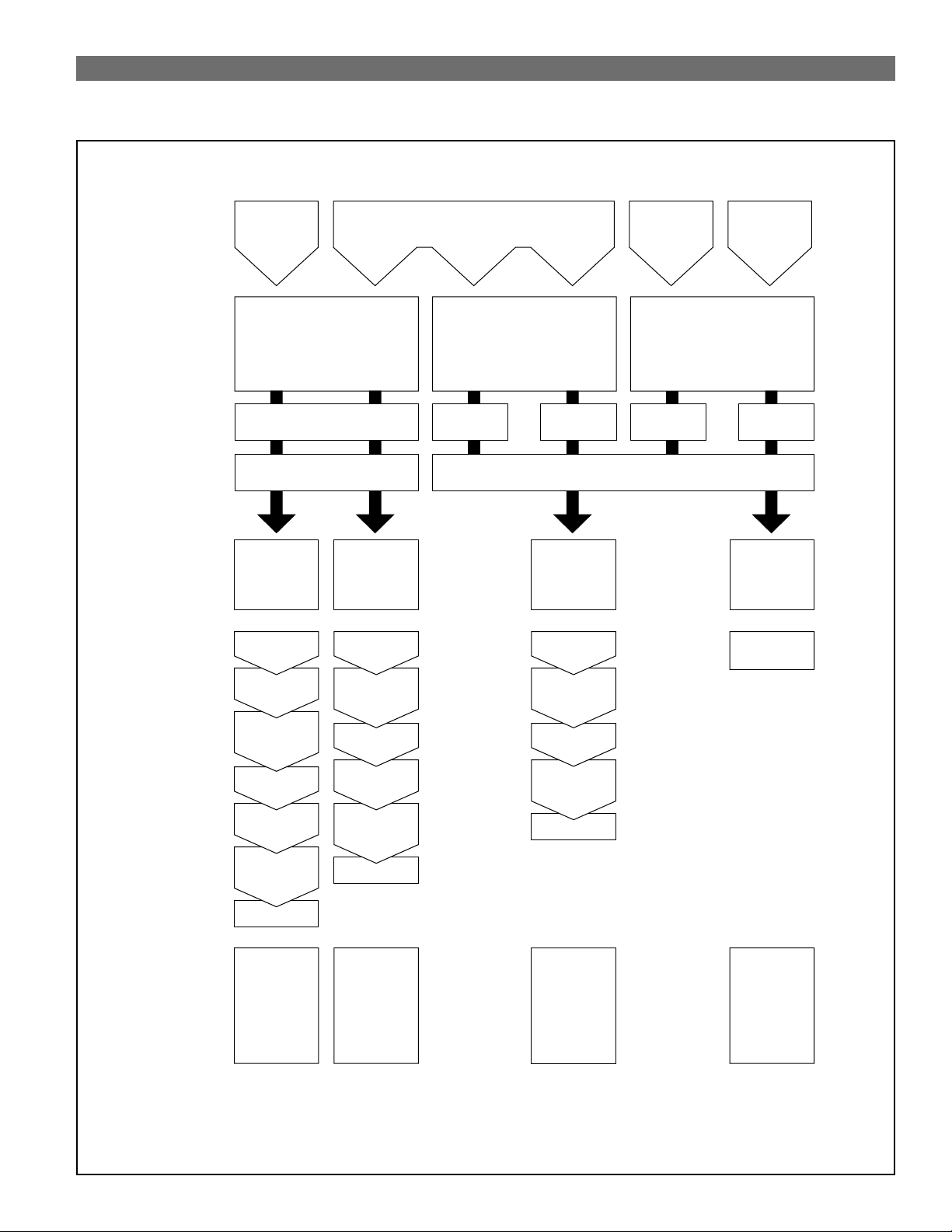

Type of dishware

e.g. china,

pots/pans,

cutlery,

glasses,

etc.

Non-deli-

cate

13

Cycle Chart

SHI 4302/4306 SHU 4302/4306/4312/4316

Mixed MixedDelicate

Type of food

remains

Amount of

food remains

Condition of

food remains

Wash

cycle

Cycle

sequence

Soups, casseroles,

sauces, potatoes,

pasta, rice, eggs,

roast or fried food

a lot

stuck on hard

Power

Scrub

Scrub

Plus

Pre-rinse

Pre-wash

125˚F

Wash

161˚F

First Rinse

Second

Rinse

Rinse-aid

161˚F

Pre-rinse

Wash

150˚F

First Rinse

Second

Rinse-aid

161˚F

Drying

Wash

Rinse

Soups, potatoes,

pasta, rice, eggs,

roast or fried food

Coffee, cakes, milk,

salami, cold drinks,

salads

a lot a little a little very little

loosely attached

Regular

Wash

Rinse

& Hold

Pre-rinse Pre-rinse

Wash

140˚F

Rinse

Rinse-aid

161˚F

Drying

Cycle

Drying

details

Duration in

minutes

Water consumption

in gallons

Water consumption

in liters

Shown above are the range of values that may be obtained while running the dishwasher under normal

conditions. Actual values may vary. The actual cycle duration, water and energy usage are dependent upon

inlet water temperature.

99

7.1 5.4 1.26

26.9

85

22.7

80

20.4

10

4.5

Page 16

14

Operation

SHU 5302/5304/5305/5306/5312/5314/5315/5316

Fig. 3-5 Fig. 3-6

The SHU 53** series operates using an electronic Control Unit.

TO OPERATE:

Fig. 3-5.

H

First depress the On/Off Button until it locks in place.

Fig. 3-6.

Once the On/Off Button is depressed the LED above the previously used cycle will illuminate. To change the cycle, simply press

the desired Cycle Button twice. The LED above that cycle will then illuminate.

The Cycle Countdown will display an approximate run time for the cycle chosen. This run time will depend on incoming water

temperature and the turbidity of the pre-wash water.

Note: It is normal for the Countdown Display to remain at a time increment for more than one minute, or skip a time increment

depending on the calculations of the Control Unit.

Also, with continued use the Control Unit will learn the wash and temperature patterns for the most commonly used

programs and will then reduce the overall start and running times.

At the end of the cycle the display will show a CL, indicating that the cycle is complete.

TO CANCEL A CYCLE:

Press the Scrub Wash and Delicate / Econo Buttons both in at the same time. The unit will then drain and the figure CL will

appear in the display.

DELAY START:

The Delay Start feature allows the unit to be delayed for up to nine hours. To program, start the unit as described above, but

after selecting a cycle push the Delay Start button. The display will show a 1h, or one-hour delay. Continue to depress the

Delay Start Button until the desired delay time is reached (up to nine hours, 9h).

The unit will begin automatically once the delay time has elapsed. To reset the delay, press the Delay Start Button until it reaches 0h.

REFILL RINSE AGENT LED:

The Refill Rinse Agent LED is activated via a Reed Switch on the Detergent Dispenser, Section 4, Fig. 8-3. The LED will

illuminate when the Rinse Agent Dispenser is empty.

Service note: The Refill Rinse Agent LED will also illuminate when the dishwasher door is opened and then

closed even if the Dispenser is full, but will only remain lit for a few seconds.

“F” CODE:

An “F” in the display window indicates a filling fault, see Section 6, Fig. 12-1 through Fig.12-6.

Please note: If the door is opened during the cycle, the On/Off Button will be reset to off and must be depressed again

to re-active the cycle. The cycle will resume from where it left off.

Page 17

H

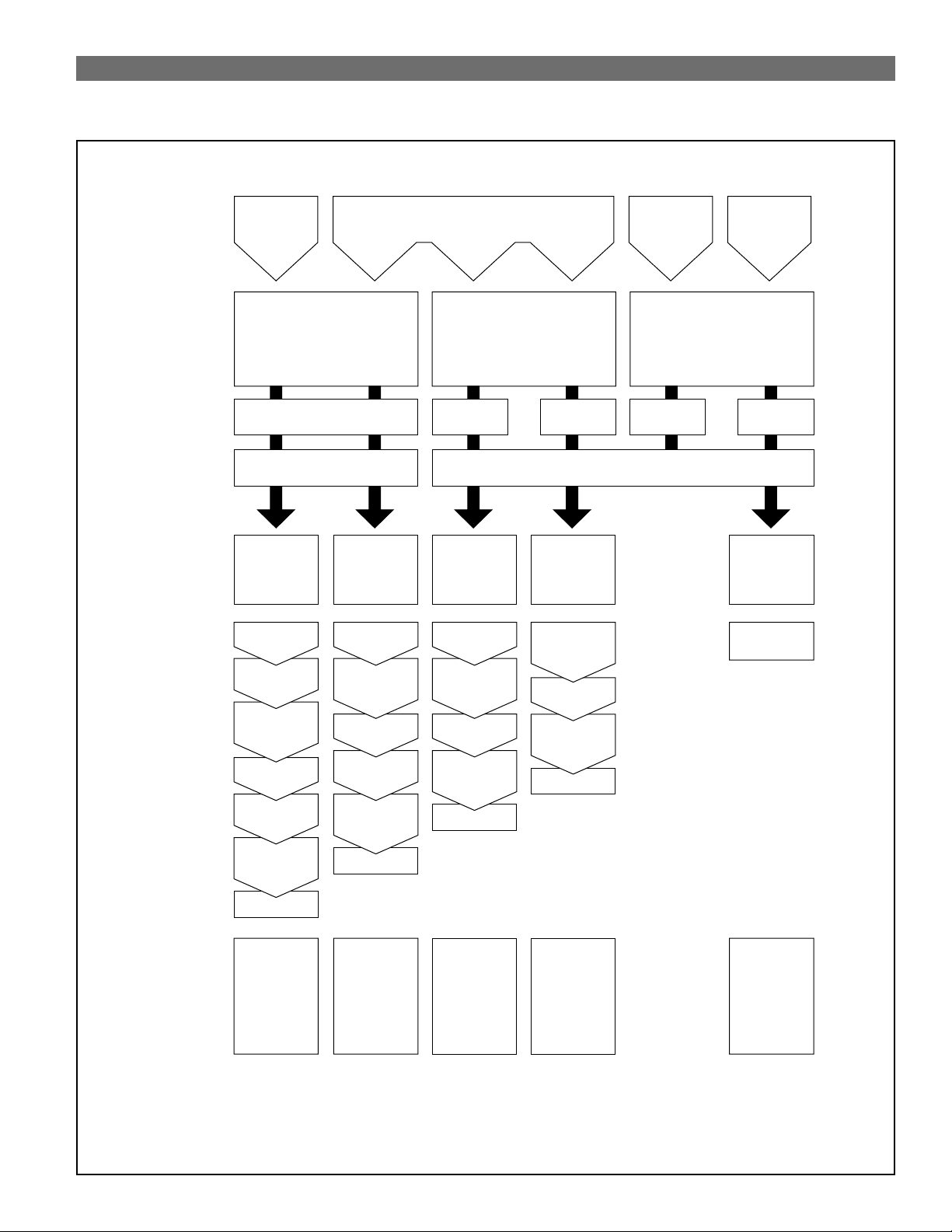

Type of dishware

e.g. china,

pots/pans,

cutlery,

glasses,

etc.

Non-deli-

cate

15

Cycle Chart

SHU 5302/5304/5305/5306/5312/5314/5315/5316

Mixed MixedDelicate

Type of food

remains

Amount of

food remains

Condition of

food remains

Wash

cycle

Cycle

sequence

Soups, casseroles,

sauces, potatoes,

pasta, rice, eggs,

roast or fried food

a lot

stuck on hard

Power

Scrub

Scrub

Wash

Plus

Pre-rinse

Pre-wash

125˚F

Wash

161˚F

First Rinse

Second

Rinse

Rinse-aid

161˚F

Pre-rinse

Wash

150˚F

First Rinse

Second

Rinse

Rinse-aid

161˚F

Drying

Soups, potatoes,

pasta, rice, eggs,

roast or fried food

Coffee, cakes, milk,

salami, cold drinks,

salads

a lot a little a little very little

loosely attached

Regular

Wash

Pre-rinse

Delicate/

Economy

Wash

Rinse

& Hold

Pre-rinse

140˚F

Wash

140˚F

Rinse

Rinse

Rinse-aid

155˚F

Rinse-aid

161˚F

Drying

Drying

Cycle

Drying

details

Duration in

minutes

Water consumption

in gallons

Water consumption

in liters

The Bosch Sensotronic™ will reduce water consumption by approximately 20%, in the case of lightly soiled

dishes. When Top Rack Only™ feature is used the water consumption is reduced approximately 30%.

Shown above are the range of values that may be obtained while running the dishwasher under normal

conditions. Actual values may vary. The actual cycle duration, water and energy usage are dependent upon

inlet water temperature and amount of soil on dishware.

99

7.1/5

26.9/18.9

85

6/4.2

22.7/15.9

80

5.4/3.8

20.4/14.4

70

3.6/2.5

13.5/9.5

10

1.2/0.8

4.5/3.2

Page 18

16

Operation

SHI/SHU 6802/6805/6806

H

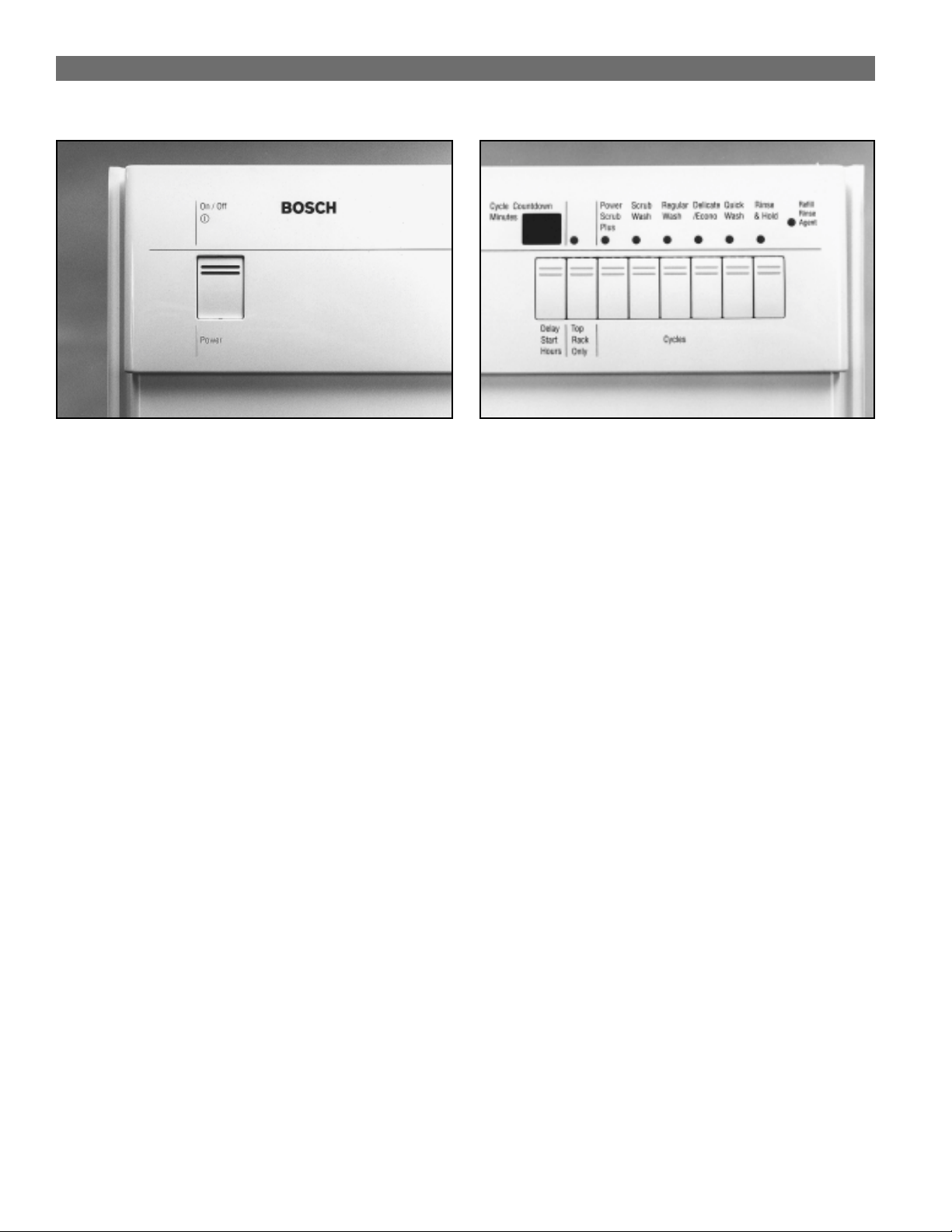

Fig. 3-7

The SHI / SHU 68** series operates using an electronic Control Unit.

TO OPERATE:

Fig. 3-7.

First depress the On/Off Button until it locks in place.

Fig. 3-8.

Once the On/Off Button is depressed the LED above the previously used cycle will illuminate. To change the cycle, simply press

the desired Cycle Button twice. The LED above that cycle will then illuminate.

The Cycle Countdown will display an approximate run time for the cycle chosen. This run time will depend on incoming water

temperature and the turbidity of the pre-wash water.

Note: It is normal for the Countdown Display to remain at a time increment for more than one minute, or skip a time increment

depending on the calculations of the Control Unit.

Also, with continued use the Control Unit will learn the wash and temperature patterns for the most commonly used

programs and will then reduce the overall start and running times.

At the end of the cycle the display will show a CL, indicating that the cycle is complete.

TO CANCEL A CYCLE:

Press the Scrub Wash and Delicate / Econo Buttons both in at the same time. The unit will then drain and the figure CL will

appear in the display.

DELAY START:

The Delay Start feature allows the unit to be delayed for up to nine hours. To program, start the unit as described above, but

after selecting a cycle push the Delay Start button. The display will show a 1h, or one-hour delay. Continue to depress the

Delay Start Button until the desired delay time is reached (up to nine hours, 9h).

The unit will begin automatically once the delay time has elapsed. To reset the delay, press the Delay Start Button until it reaches 0h.

Fig. 3-8

TOP RACK ONLY:

The Top Rack Only feature can be used in conjunction with any cycle. To active, press the Top Rack Only Button after selecting a

cycle, the Top Rack Only LED will illuminate and all water will be diverted to the upper wash arm for the complete cycle.

REFILL RINSE AGENT LED:

The Refill Rinse Agent LED is activated via a Reed Switch on the Detergent Dispenser, Section 4, Fig. 8-3. The LED will

illuminate when the Rinse Agent Dispenser is empty.

Service note: The Refill Rinse Agent LED will also illuminate when the dishwasher door is opened and then

closed even if the Dispenser is full, but will only remain lit for a few seconds.

“F” CODE:

An “F” in the display window indicates a filling fault, see Section 6, Fig. 12-1 through Fig.12-6.

Please note: If the door is opened during the cycle, the On/Off Button will be reset to off and must be depressed again

to re-active the cycle. The cycle will resume from where it left off.

Page 19

H

Type of dishware

e.g. china,

pots/pans,

cutlery,

glasses,

etc.

Non-deli-

cate

17

Cycle Chart

SHI/SHU 6802/6805/6806

Mixed MixedDelicate

Type of food

remains

Amount of

food remains

Condition of

food remains

Wash

cycle

Cycle

sequence

Soups, casseroles,

sauces, potatoes,

pasta, rice, eggs,

roast or fried food

a lot

stuck on hard

Power

Scrub

Scrub

Wash

Plus

Pre-rinse

Pre-wash

125˚F

Wash

161˚F

First Rinse

Second

Rinse

Rinse-aid

161˚F

Pre-rinse

Wash

150˚F

First Rinse

Second

Rinse

Rinse-aid

161˚F

Drying

Soups, potatoes,

pasta, rice, eggs,

roast or fried food

Coffee, cakes, milk,

salami, cold drinks,

salads

a lot a little a little very little

loosely attached

Regular

Wash

Pre-rinse

Delicate/

Economy

Wash

140˚F

Quick

Wash

Wash

104˚F

Rinse

& Hold

Pre-rinse

Wash

140˚F

Rinse

Rinse

Rinse-aid

155˚F

Rinse

Rinse-aid

140˚F

Rinse-aid

161˚F

Drying

Drying

Drying

Cycle

Drying

details

Duration in

minutes

Water consumption

in gallons

Water consumption

in liters

The Bosch Sensotronic™ will reduce water consumption by approximately 20%, in the case of lightly soiled

dishes. When Top Rack Only™ feature is used the water consumption is reduced approximately 30%.

Shown above are the range of values that may be obtained while running the dishwasher under normal

conditions. Actual values may vary. The actual cycle duration, water and energy usage are dependent upon

inlet water temperature and amount of soil on dishware.

99

7.1/5

26.9/18.9

85

6/4.2

22.7/15.9

80

5.4/3.8

20.4/14.4

70

3.6/2.5

13.5/9.5

30

2.7/1.9

10.5/7.4

10

1.2/0.8

4.5/3.2

Page 20

18

H

Notes

Page 21

H

Section 3

Description Page

Rack System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 – 21

Interior Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 – 25

Detergent / Rinse-Agent Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Washability / Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

19

Page 22

20

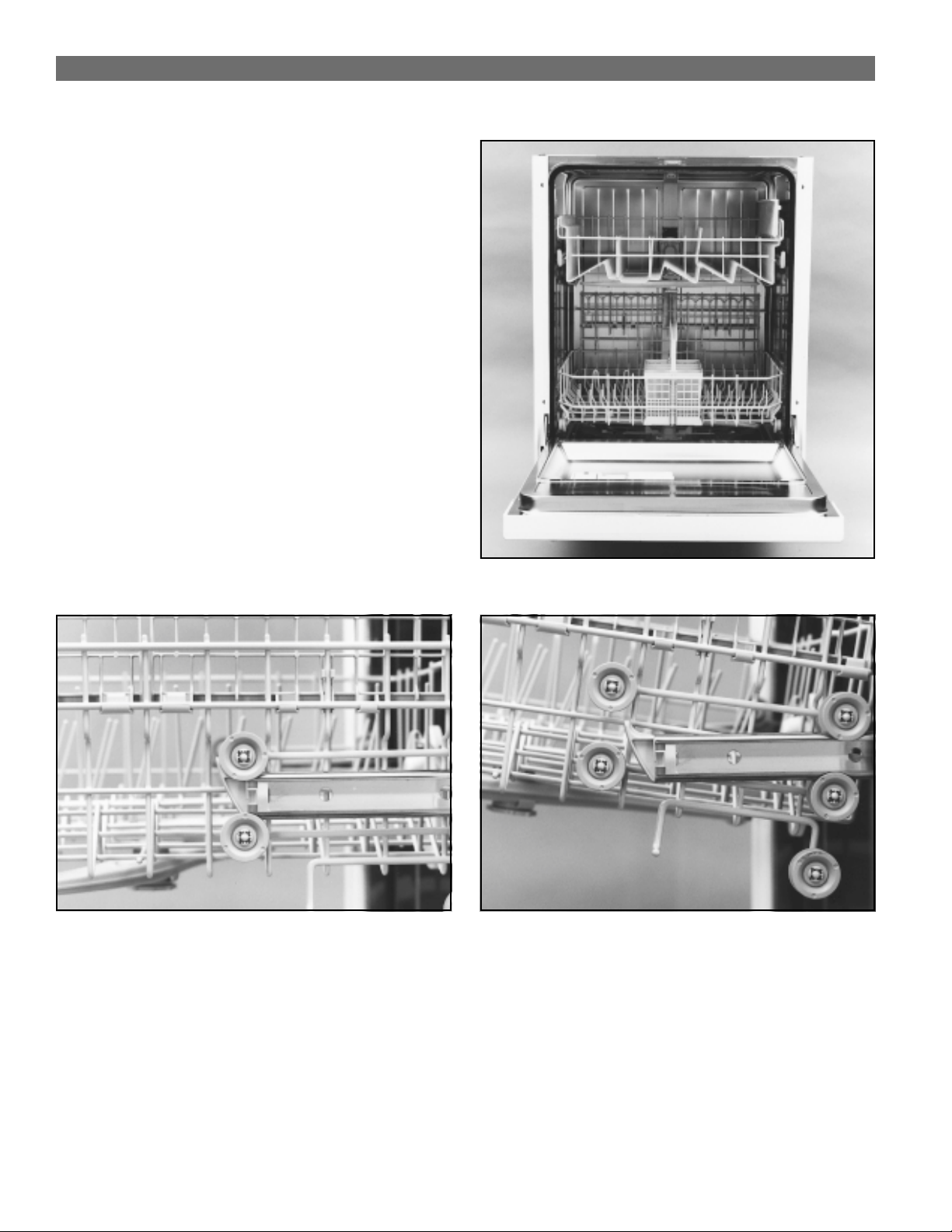

Rack System

Rack configurations for individual dishwasher

models will vary. However, all Racks are

constructed from a steel wire grid with a gray

nylon outer covering.

Note: Racks may discolor due to the water

supply or types of food remaining on

the dishes. We recommend that a

vinegar wash be used to assist in

removing these stains.

Start the unit, and let run approximately

ten minutes, then pour in two cups of

white vinegar and let the unit complete

the cycle, repeat if necessary.

H

Fig. 4-1

Fig. 4-2 Fig. 4-3

On select models the Upper Rack is height

adjustable. To adjust rack height, or to remove the

Rack from the unit.

Fully extend the Rack as shown in Fig. 4-2

With the Rack fully extended. Lift up on the Rack

until the Front Rollers disengage from the Rail.

Now bring the Rack out further and allow the

Rear Wheels to disengage.

Note how the Rack Rollers are designed to ride

on the outside of the Rails for a smoother

operation.

Rollers: Rack Rollers are a press fit making

for easy removal and replacement.

Page 23

H

21

Rack System

Fig. 4-4 Fig. 4-5

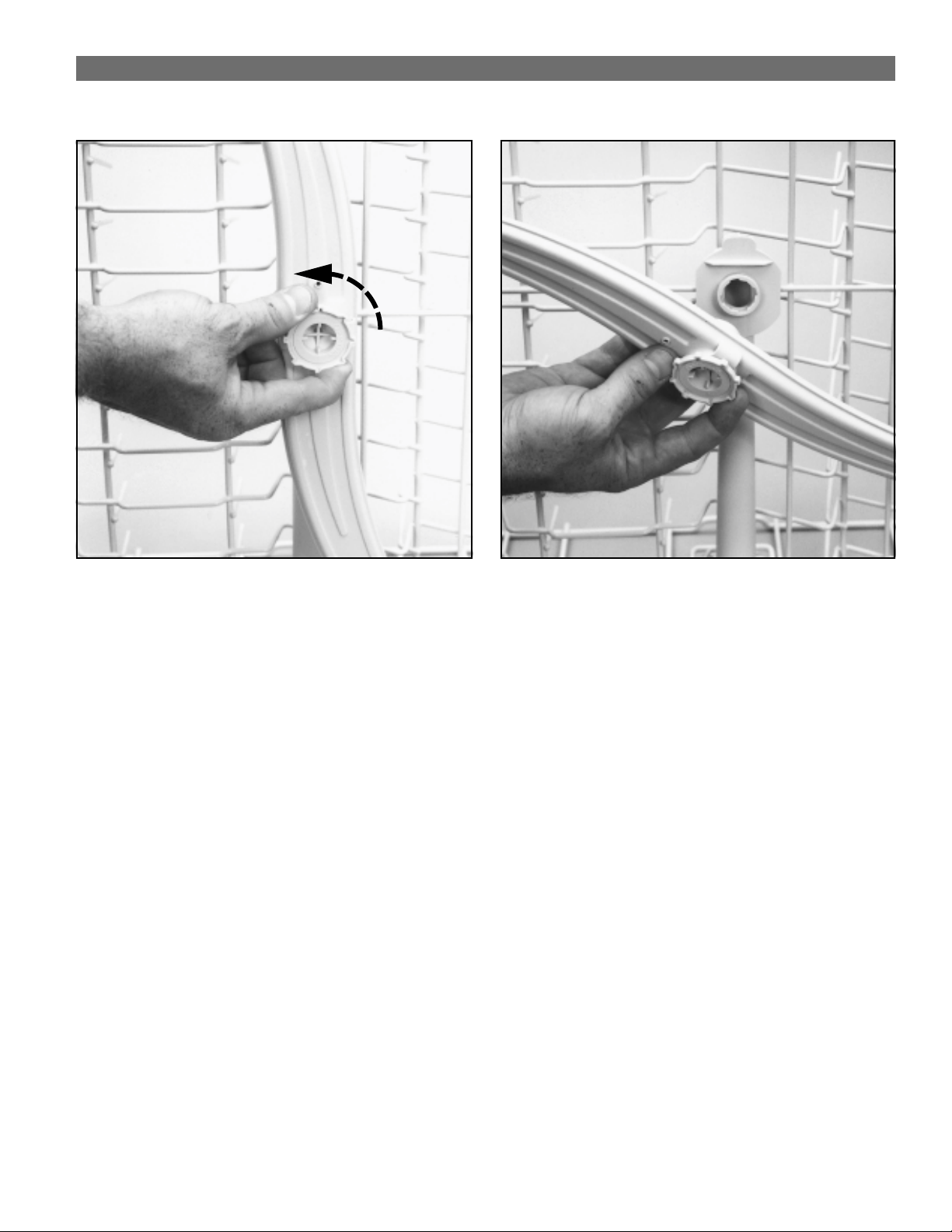

Attached to the Upper Rack is the Upper Spray Arm Assembly.

The Upper Spray Arm can be removed from the Upper Spray Arm Assembly for cleaning or

replacement by turning the Arm Nut counter-clockwise, Fig. 4-4.

And then bringing the Arm down and off the Arm Assembly, Fig. 4-5.

Page 24

22

Interior Features

H

1

5

2

3

4

2

7

6

Fig. 5-1

Interior features for all model dishwasher covered in this repair manual are identical. Those

features include:

1. Strike Plate. The Strike Plate is in a fixed position and cannot be adjusted.

2. Upper Rack Rails and Guide Rollers.

3. Door Gasket

4. Lower Spray Arm

5. Filter Basket

6. Filter Screen

7. Feeder Tube Assembly

Page 25

H

23

Interior Features

Fig. 5-2 Fig. 5-3

The Upper Rack Rails are made

of stainless steel with a plastic

end cap.

To remove the Rail, disengage

the End Cap by applying

outward pressure to the Cap’s

top tab, unclipping it from the

Rail. Then slide the Rail out from

the Guide Rollers.

Fig. 5-4

The Upper Rack Guide Rollers

are permanently attached to the

Tank and cannot be removed or

repaired.

Fig. 5-5 Fig. 5-6

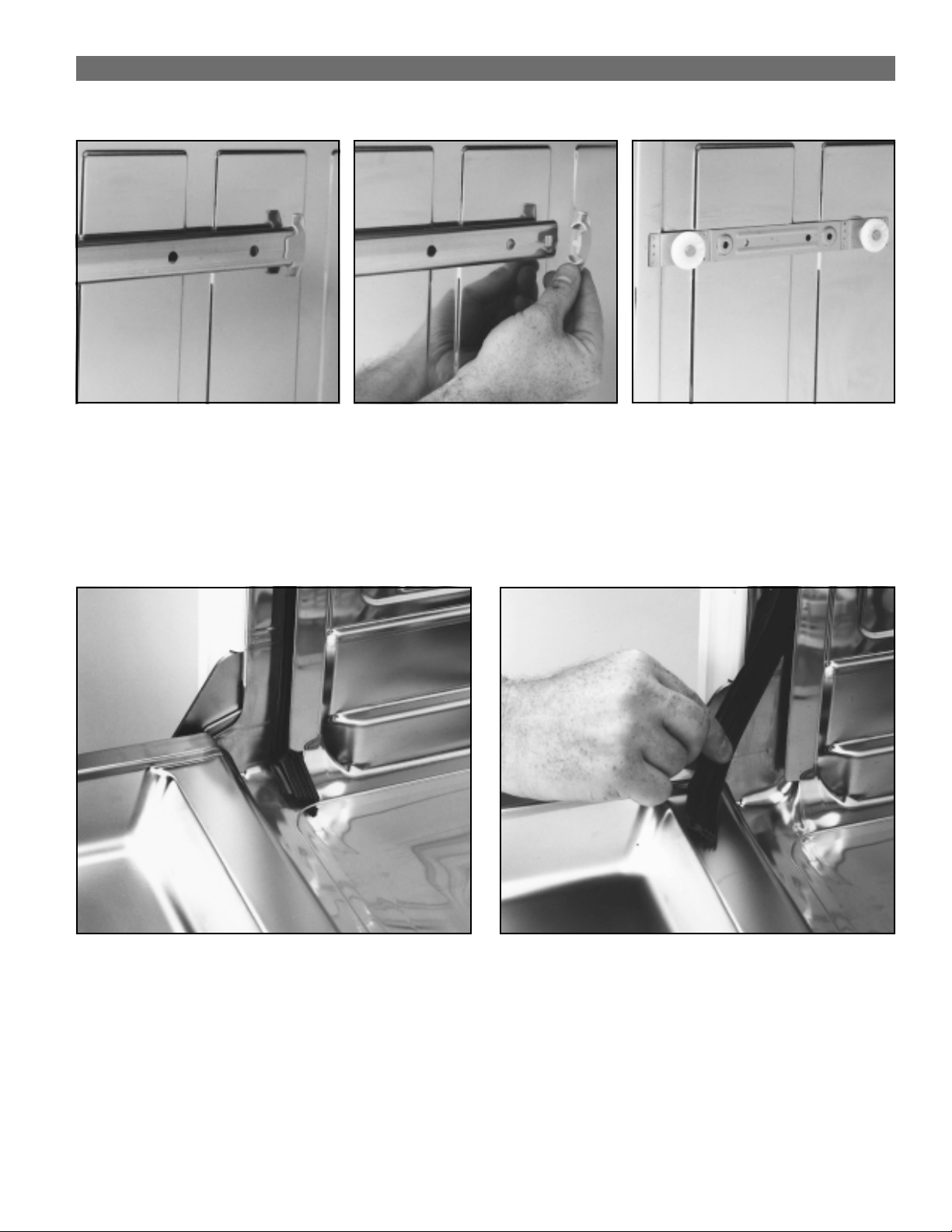

The Door Gasket is press fit into a channel

molded around the Tank.

Note: Two inches of overlap are left at each end

of the Gasket to insure a proper seal.

Service tip: To test for a bad Door Gasket, open the dishwasher door and insert a dollar bill, then

close the door and pull the bill out. If the bill is snug the Gasket is good, if the bill slides

out easily the Door Gasket may need to be replaced.

To remove the Gasket, simply pull it away from the

Tank Channel.

To replace, press the ribbed end firmly into the

channel until secure. No sealant or glue is required.

Page 26

24

Interior Features

Water

Level

Fig. 5-7 Fig. 5-8

H

Fig. 5-9 Fig. 5-10

2 2

1

Fig. 5-11 Fig. 5-12

Page 27

H

25

Interior Features

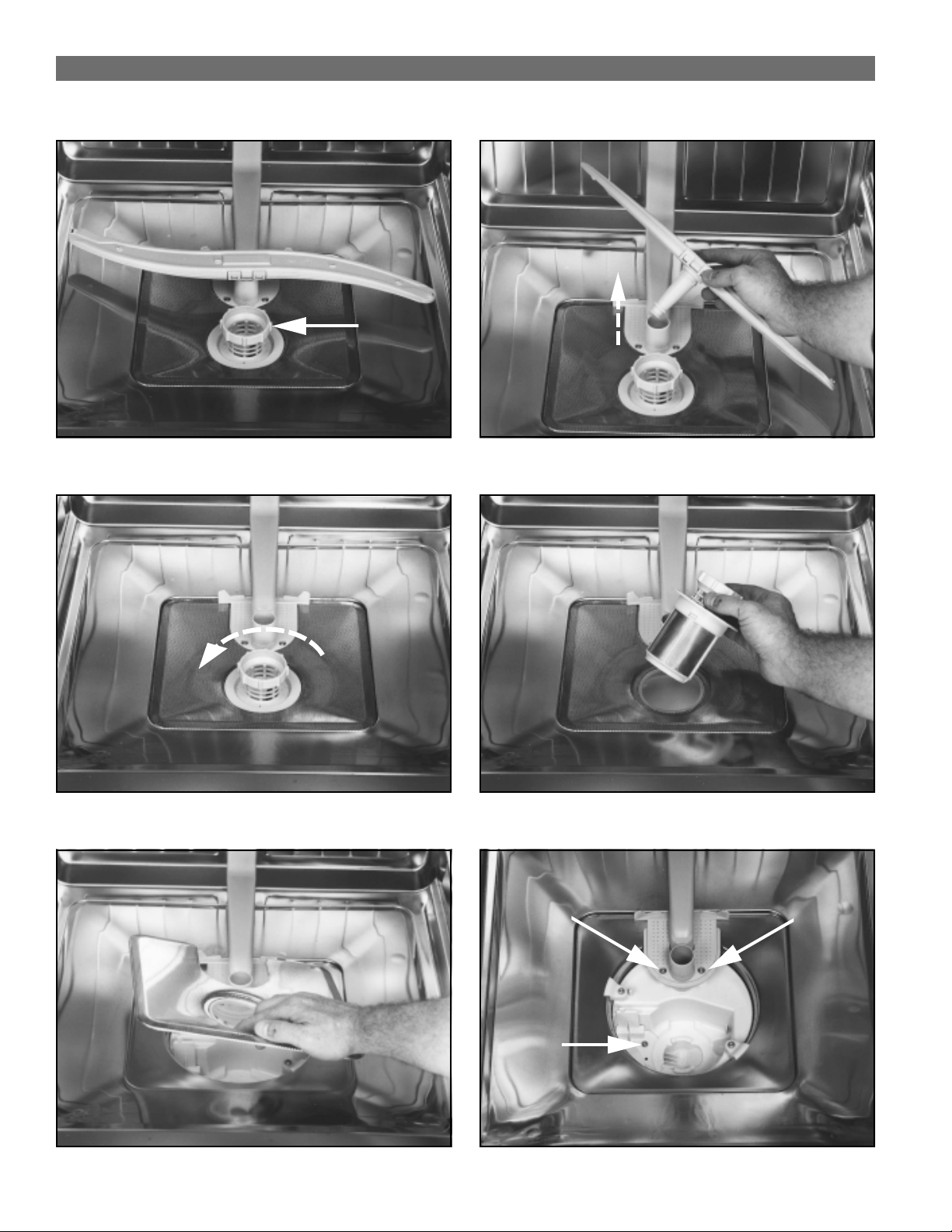

Fig. 5-7 The operating water level of the dishwasher is at approximately the upper edge of the filter basket.

Fig. 5-8 The Lower Spray Arm is press fit into the Feeder Tube Socket.

To remove the Arm, grasp the Arm Hub and pull up until the Arm disengages from the Socket.

The Arm or Arm Socket can now be checked for debris.

Fig. 5-9 The Filter Basket is removed by turning it ninety degrees counter-clockwise.

Fig. 5-10 Then lift it out for cleaning.

The Filter is a fine mesh of stainless steel and should be inspected and cleaned at least

once a month.

Fig. 5-11 With the Filter Basket removed, the filter screen can then be lifted out.

The Filter Screen is also made of stainless steel, and was designed with rolled ends to

eliminate sharp edges. It too should be inspected and cleaned at least once a month.

Fig. 5-12 With the Filter Screens removed you now have access to the sump area.

The Sump has a Drain Intake on the left, and the Circulation Pump Intake on the right.

A removable cover, item 1, hides the Drain Impeller. To remove the cover, remove the single

T-20 Torx screw and then lift the cover off. You may now examine the Impeller for any

obstructions.

The Feeder Tube Assembly allows water to flow to the Lower, then Upper Spray Arms and

then to the Top Sprayer Head. It is replaced as a complete assembly by first removing the

two T-20 Torx screws, item 2, at its base.

Then bring the tube up and off the Sump Housing, and remove it from the retaining clip

located on the rear wall.

Page 28

26

Detergent / Rinse-Agent Dispenser

Fig. 6-1

2

H

Located on the Inner Door is the Detergent / Rinse

Agent Dispenser, Fig. 6-1.

The Dispenser Housing is one assembly containing

three individual components.

Rinse Agent Dispenser.

Detergent Cup.

Steam Vent.

Note: Mechanical operation and removal of the

Dispenser is shown in Section 4.

To fill or adjust the Rinse Agent Dispenser, open

the Rinse Agent Door by pulling up on the Door

Latch.

The Dosage Meter, item 1, is now visible. The

Dosage Meter allows you to adjust the amount of

Rinse Agent dispensed into the rinse stage of the

cycle. The factory setting is three.

1

Fig. 6-2

Fig. 6-3

Fig. 6-4

1

1

1

2

2

There is also an eyepiece, item 2, that provides a

visual indication as to the amount of Rinse Agent

remaining in the Dispenser.

To the right of the Rinse Agent Dispenser is the

Detergent Cup, item 1.

Once detergent has been loaded into the cup, slide

the Detergent Door, item 2, closed.

When the door is fully closed press down on the

door end to lock it.

A white Locking Lever, item 1, will then extend.

Once closed, the detergent door may be released

by pressing in on the Locking Lever.

With the Detergent Door closed the Steam Vent is

now visible, item 2.

During the drying stage of the cycle, steam is

drawn through the vent and collects in a

Condensation Tube.

2

Page 29

H

27

Washability / Drying

WASHABILITY

There are four factors that play a critical role in Washability: Time, Temperature, Water and Detergent. It

is important when attempting to determine the cause of a Washability complaint that all four factors be

considered and tested.

Time: The duration of the program is accurate (see cycle chart).

Temperature: The wash and rinse temperatures are within the desired range (see cycle chart).

Water: The unit is filling with the correct amount of water (Section 3, Fig.5-7)

Detergent: The detergent is fresh, and not being used in excessive amounts.

Please note: Other factors such as clean filters, a properly routed drain hose, water hardness and

quality, as well as loading of items will also effect Washability.

DRYING

As part of an energy saving design Bosch Dishwashers do not activate the Heating Element during the

Drying cycle. Instead, the dishwasher utilizes a rinse temperature of up to 161° Fahrenheit, and the

addition of Rinse Agent to achieve a quality drying result.

HOW THIS SYSTEM FUNCTIONS:

During the rinse cycle water is heated to 161° Fahrenheit, this heat is transferred to the items in

the dishwasher where it is absorb and stored.

During the drying portion of the cycle all dishwasher items will then radiate the stored heat, thus

evaporating any water that has collected on the items surface, burning it off and converting the

liquid into steam.

This process of “flash drying” is assisted by the release of Rinse Agent into the rinse water. Rinse

Agent is a water softener that inhibits water from collecting or pooling, allowing it to be easily

evaporated.

The remaining steam is vented from the interior through the Steam Vent (Fig. 6-4, item 2) where it

is then collected by, and drained from the Condensation Tube (Section 4, Fig. 7-5, item 2).

Service note: When confronted with a drying complaint, make sure the Rinse Agent Dispenser is full,

and the rinse water temperature is within the desired range. Please remember that the

unit will not dry without Rinse Agent.

Page 30

28

H

Service Reminder

From this point in the manual only the technical features and components of the

SHU 5312 will be demonstrated.

However, due to the overwhelming similarities between the model SHU 5312 and the

remaining Bosch Dishwasher line, you will be able to easily diagnose and repair all

current Bosch model SHU, SHI and SHV Dishwashers.

Page 31

H

Section 4

Description Page

Outer Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Door Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dispenser Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispenser Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Facia Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 – 35

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

29

Page 32

30

Outer Door Removal

H

Fig. 7-1 Fig. 7-2

To remove the Outer Door, open the door and remove the

six T-20 Torx screws located three on each side of the Inner

Stainless Door, Fig. 7-1.

Return the door back to its upright position, and bring the

bottom of the Door Panel out toward you, then slide the top of

the panel down and out from under the Facia Panel, Fig. 7-2.

As the Outer Door is being removed, the left or right Door

Guards may shift or fall out of place, Fig. 7-3.

To reposition them, slide them back in over the hinge, Fig. 7-4,

lining up the door guard square tab with the hinge lever

square notch.

Please note: Door Guards must be in place before

reinstalling the Door Panel. Door Guards are

not used on SHI or SHV models.

Fig. 7-3

Fig. 7-4

Page 33

H

31

Door Compoments

7

2

1

6

3

5

4

9

Fig. 7-5

Once the Outer Door has been removed the following components become visible.

1. Dispenser Assembly

2. Condensation Tube

3. Upper Wiring Harness

4. Door Guards

5. Door Seal

6. Bituminious Insulation

7. Cloth Fiber Insulation

8

4

9

Also note the Toe Kick, item 8, and the Toe Kick Mounting Screws, item 9.

Page 34

32

Dispenser Operation

2

1

Fig. 8-1 Fig. 8-2

The Dispenser Assembly operates via a PTC

Actuator (wax motor), item 1.

When voltage is applied to the Actuator it

advances a Combination Lever, item 2.

…and bring the Actuator out from the Dispenser.

Please note: The Combination Lever cannot be

H

replaced individually, but only as

part of a new Dispenser Assembly.

The Combination Lever allows the Soap Door to open,

and later in the cycle dispenses the Rinse Agent.

To remove the Actuator, first disconnect the

Wiring Connector. Then, using a small

screwdriver, release the locking tab….

1

2

Fig. 8-3 Fig. 8-4

When the Dispenser requires Rinse Agent a Magnetic Float, Fig. 8-3, item 1, will lower and draw the

contacts of a Reed Switch, Fig. 8-3, item 2, together. This completes the circuit, and activates the Refill

Rinse Agent LED located on the Facia Panel.

To remove the Reed Switch, first disconnect the Wiring Connector. Now, using a small screwdriver

push in on the Reed Switch Mounting Tab, Fig. 8-3.

As you push in on the mounting tab, use a needle-nose pliers to bring the switch down and out from the

Dispenser, Fig. 8-4.

Page 35

H

Fig. 8-5 Fig. 8-6

33

Dispenser Removal

If required, the Dispenser Assembly can be replaced as a complete unit.

TO REMOVE:

First remove the:

Upper Rack (Section 3, Fig. 4-3).

Wiring Connectors for the PTC Actuator, Reed Switch and Condensation Tube.

The Condensation Tube is inserted into the right side of the Dispenser with a gasket

seal, and press fit along the right side of the Inner Stainless Steel Door.

To remove, first remove any securing tape or wire ties for both the Condensation Tube

and Upper Wiring Harness. Then, disengage the tube from the door by pulling it toward

you, and sliding the tube out from the Dispenser.

Now, using a broad tipped regular screwdriver spread the top and bottom metal positioning

strips away from the Dispenser, Fig. 8-5.

Then apply light pressure to the Dispenser, and break the seal between it and the Inner

Stainless Steel Door, Fig. 8-6.

TO INSTALL:

Clean the inner portion of the stainless steel door where the Dispenser Gasket will seat. Then

bend the positioning strips back into place, straightening them if necessary.

Now, insert the new Dispenser making sure the positioning strips fit snugly against the Dispenser

Body. The Dispenser Gasket will make a watertight seal so caulk or sealant is not required.

Replace the Condensation Tube, Wiring Connectors and Upper Rack.

Page 36

34

Facia Assembly

IMPORTANT SERVICE NOTE:

The Facia Assembly cannot be

removed unless the Outer Door is

removed first.

See section 4, Fig. 7-1.

FACIA ASSEMBLY REMOVAL:

After removing the Outer Door, remove

the six T-20 Torx screws securing the

Facia Assembly to the Inner Stainless

door, Fig. 9-1.

H

Fig. 9-1

Fig. 9-2 Fig. 9-3

With the screws removed, bring the Facia

Assembly down cradling it so as not to scratch

the Facia Console.

Now remove the Wiring Connectors by pressing in

on the locking tabs of each connector, then sliding

the connector up and off from the Control Unit.

Page 37

H

Fig. 9-4

35

Facia Assembly

With the Facia Assembly removed from

the unit, it can be further separated into

two assemblies.

To separate, release the four locking

tabs and bring the Facia Frame up from

the Facia Console, Fig. 9-4.

The Facia Frame houses three

components:

1

Fig. 9-5

1

Fig. 9-6

2

2

3

Item 1,On/Off Switch.

Item 2,Door Latch Assembly.

Item 3,Control Unit.

Note: The Facia Console or Program

Buttons can be replaced at this

time.

ON/OFF SWITCH REMOVAL:

Bend the single tab up, item 1.

Then slide the switch up and out from

the frame, and remove the Locking

Lever, item 2.

Note: The Locking Lever, item 2,

switches the unit off when the

door is opened during operation.

Fig. 9-7

DOOR LATCH ASSEMBLY REMOVAL:

Bend the two tabs up and slide the

Latch down.

CONTROL UNIT REMOVAL:

Press in on the three locking tabs and

bring the Control Unit out from the

Console Frame.

Note: Always reset the new Control Unit

by pressing the appropriate

cancellation buttons, see Section 2.

Page 38

36

H

Notes

Page 39

H

Section 5

Description Page

Base Components – Front Accessible: Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . 38

Circulation Motor Capacitor . . . . . . . . . . . . . . . . . . . 38

Leveling Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Water Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drain Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 — 41

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

37

Page 40

38

Base Components – Front Accessible

H

=

6

7

8

5

33

Fig. 10-1

Service note: To gain access to the Front Accessible Lower

Components remove the Toe Kick. Also, for

better visibility it is strongly recommended that

the Outer Door be removed as well.

The Front Accessible Lower Components consist of the following items.

1. Electrical Connection.

2. Circulation Motor Capacitor.

3. Front Leveling Legs.

4. Model and Serial number tag.

5. Rear Leveling Leg adjustment screw.

6. Water Solenoid Valve.

7. Access Panel.

8. Drain Motor.

9. Circulation Motor.

The Circulation Motor cannot be replaced from the

front, but is accessible for voltage or wiring testing.

10. Door Spring Adjustment Screws.

The adjustment can only be made when an accessory

door panel is added to the unit. Turning the screw

clockwise will balance the additional weight of the

added panel.

2

4

9

1

=

2

1

Fig. 10-2

The electrical connection, item 1, is a three

wire hook-up that is secured with wire-nuts.

The color code is as follows:

Black = Hot

White = Neutral

Green = Ground

The Circulation Motor Capacitor, item 2, is

a 10uf-Start/Run Capacitor held to the

Circulation Motor with a single 13mm nut.

The Capacitor can be replaced as a

separate component without removing the

Circulation Motor.

Page 41

H

Base Components – Front Accessible

Fig. 10-3 Fig. 10-4

The front Leveling Legs can be adjusted by inserting a

regular tipped screwdriver into the foot slot and

turning the leg in the desired direction.

The Rear Leg Adjustment Screw, item 1, allows the

single Rear Leveling Leg to be adjusted from the front

of the unit. Turning the screw clockwise will extend

the leg, and counter-clockwise retracts it.

39

1

2

For convenience an additional Serial Number Tag,

item 2, is located on the Base.

Fig. 10-5 Fig. 10-6

To replace the Water Solenoid Valve, first remove the

two T-20 Torx valve mounting screws.

Then bring the Water Valve out from the Base, and

disconnect the water line by loosening the Water Line

Clamp (arrow) and removing the wiring leads.

Page 42

40

Base Components – Front Accessible

Service note: To provide the required

access that will allow the

Drain Motor to be replaced,

the Lower Access Panel

must be removed, and as

previously mentioned the

Outer Door Panel should

also be removed.

H

1

To remove the Lower Access Panel, Fig.

10-7, item 1, remove the two T-20 Torx

screws located in the left and right

corners of the panel.

As demonstrated in Figs. 10-7 and 10-8,

with the Lower Access Panel removed

you gain all the space required to replace

the Drain Motor, Fig. 10-8, item 1, as well

as allowing better visibility to the

Circulation Motor Wiring, Fig.10-8, item 2,

rear components, wiring and hoses.

Fig. 10-7

1

2

Fig. 10-8

Page 43

H

41

Base Components – Front Accessible

1

Fig. 10-9 Fig. 10-10

To remove the Drain Motor, item 1, first remove the

Sump Fill Hose, item 2, by pulling it out from the

Sump and side inlet connections (see Fig. 10-10)

2

B

Cut Away View

This cut away view shows:

1

2

3

A

Item 1, Drain Motor.

Item 2, Drain Motor Locking Tab.

Item 3, the Sump Fill Hose and its two

connection points A and B.

Fig. 10-11 Fig. 10-12

Next, remove the wiring

connectors and then while

pulling back on the Locking Tab,

turn the Drain Motor clockwise.

Continue turning the Drain Motor

clockwise until it reaches the two

O’clock stop position. Then

bring the motor out from the

Sump.

Fig. 10-13

The Drain Motor is mounted to

the Sump using a slot and tab fit.

To install the Drain Motor, insert it

back into the Sump at the two

O’clock position making sure that

all three slots and tabs line up,

then turn counter-clockwise until

secure and the Locking Tab locks.

Page 44

42

H

Service Reminder

From this point forward, all service procedures demonstrated in the remainder of this

repair manual, will require the dishwasher to be disconnected and removed from the

cabinet for servicing.

Page 45

H

Section 6

Description Page

Left Side Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Left Side Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Water Inlet / Discharge System – Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46 – 47

Water Inlet / Discharge System – Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

43

Page 46

44

Left Side Access

LEFT SIDE PANEL REMOVAL:

Remove the two T-20 Torx screws located

on the top and bottom of the Left Trim Strip,

Fig. 11-1, and then slide the Trim Strip up

and off the unit.

Figs. 11-2 and 11-3

The Side Panel is press fit onto the Front

and Rear Corner Blocks of the dishwasher.

To remove the panel, gently lift up on the

front corner disengaging it from the Front

Corner Block, arrow A. Then bring the

panels back corner off the rear block while

moving the panel toward the rear of the

dishwasher, arrow B.

H

Bring the panel out from the side of the unit

about forty-five degrees, and then lift it out

from the Base Lip.

Fig. 11-1

B

A

Fig. 11-2 Fig. 11-3

Page 47

H

45

Left Side Components

11

2

4

3

7

6

5

8

Fig. 11-4

With the Left Side Panel removed you now have access to the following components:

1. Corner Blocks.

2. Cloth Fiber Insulation Panel.

3. Drain Hoses.

4. Water Chamber.

5. Inlet Water Line.

6. Water Level Housing Assembly.

7. Sump Fill Hose.

8. Left Hinge.

Page 48

46

Water Inlet / Discharge System – Operation

H

4

123

Fig. 12-1

Normal Fill Over Fill Base Float

5

6

8

7

9

Fig. 12-2 Fig. 12-3 Fig. 12-4

Page 49

H

Water Inlet / Discharge System – Operation

WATER SYSTEM OPERATION: Fig. 12-1 is a close up view of the complete Water Systems.

FILLING

NORMAL OPERATION (Fig. 12-2)

Fresh water is brought in by the Water Valve and through the Inlet Water Line, item 3. The

incoming water is then directed into the Water Level Housing Assembly, item 4, and then on to the

Sump via the Sump Fill Hose, item 8.

As the unit fills with water the Diaphragm on the Water Level Housing Assembly expands due to

the pressure of air forced up by the incoming water. When the correct water level is reached the

Diaphragm moves the Switch Lever, which in turn closes the Water Level Switch.

When the Water Level Switch closes the Water Valve shuts and the Circulation Motor is activated,

and the program advances.

Note: Once the Circulation Motor is activated the water level will drop slightly, the unit then

calls for a small amount of additional water to be added.

OVER FILL (Fig. 12-3)

47

As a safety feature, if the Diaphragm were to malfunction the water level would rise and activate

the Safety Float, item 5. As the Safety Float rises it in turn closes the Float Switch, item 6. When

the Float Switch closes it activates the Drain Motor.

Service tip: If the dishwasher repeatedly fills and drains the cause is most likely a faulty

Diaphragm.

BASE FLOAT (Fig. 12-4)

As an additional safety feature, if the Base were to fill with water due to a hose or pump leak the

Base Float, item 9, will rise and via a Float Lever and Pushrod, item 8, would close the Float

Switch, which in turn activates the Drain Motor.

Service tip: If there is water in the base the Drain Motor will run continually, but will not drain

water from the base.

“F” CODE

Dishwashers with a Countdown Display will show an “F” in the display window when a filling fault

occurs. Filling faults can be: Water in the base; overfill; and under or no fill.

Live Dealer Display Models with “F” codes:

Since display models are hand filled, achieving the correct water level is difficult, (see Section 3,

Fig. 5-7) so the unit will perceive a filling fault and display the “F” code. This is normal, do not

attempt a repair.

DRAINING

When the Drain Motor is activated gray water flows from the Sump through the Sump Drain Hose,

item 2, around the Water Chamber and out through the Main Drain Line, item 1.

Page 50

48

Water Inlet / Discharge System – Removal

H

1

Fig. 12-7 Fig. 12-8

The Water Level Switch and Diaphragm are

replace as one assembly. To replace, bend the

small retaining tab out away from the assembly.

Then remove the wiring connector and slide the

assembly up and out from the Water Level Housing.

The Float Switch, item 1, is a press fit and easily

removed as an individual component.

Fig. 12-9 Fig. 12-10

To replace either Drain Hose, first remove the

Drain Hose retaining clip.

Then bring the hose down and out from the Water

Chamber. When re-installing make sure the hose is

snug, and the retaining clip is back in place.

Page 51

H

Section 7

Description Page

Right Side Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Right Side Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

NTC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

NTC Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 – 57

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

49

Page 52

50

Right Side Access

H

Fig. 13-1 Fig. 13-2

RIGHT SIDE PANEL REMOVAL:

Remove the two T-20 Torx screws located on the top and bottom of the Left Trim Strip, Fig. 13-1,

and then slide the Trim Strip up and off the unit.

To remove the panel, refer to Section 6, Figs. 11-2 and 11-3.

Page 53

H

51

Right Side Components

5

3

4

1

2

Fig. 13-3

With the Right Side Panel removed, you now have access to the following components.

1. Circulation Pump / Motor.

2. Base Wiring Connectors.

3. Flow Switch.

4. Heater Assembly.

5. NTC.

COMPONENT EXPLANATION:

Circulation Pump / Motor.

The Circulation Pump / Motor can be replaced from the right side by following the same access

procedures for removal of the NTC outlined in the remainder of this section, and then by following

the steps in Section 8, Figs. 16-2 through 16-7, for the Circulation Pump / Motor removal.

Service Note: Section 8, also gives and alternative removal method for the Circulation Pump / Motor.

Base Wiring Connectors.

The Base Wiring Connectors allow the Upper Wiring Harness to mate with the Base Wiring Harness.

Flow Switch.

Located between the two heater terminals is the Flow Switch. In the event that water does not flow

across the Heating Element, the Flow Switch disables the element. To remove the Flow Switch,

bring the bottom of the switch out from its base, unhook the side tabs, and then lift the switch out.

Heater Assembly.

The Heater Assembly cannot be replaced from the side, but is accessible for continuity testing.

Replacement of the Heater Assembly is outlined in Section 8, Figs. 16-8 through 16-12.

Page 54

52

NTC Operation

H

Fig. 14-1

Located on top of the Heater Assembly is the NTC (Negative Temperature Coefficient), Fig. 14-1. The

NTC uses resistance to control wash and rinse water temperature and is connected with two green leads.

As water temperature increases, the NTC records the decrease in resistance. The Control Unit Logic

Board measures this resistance change and allows the program to advance once the correct

temperature (resistance level) is reached.

Service note: The SHU 30** and SHU 40** models do not use an NTC, but utilize a standard, normally

open thermostat (bi-metal).

Also combined within the NTC (or standard thermostat) is a High Limit Safety Thermostat, connected

with red leads. The normally closed high limit is set to 185° Fahrenheit and is self-resetting.

Service tip: The NTC can be checked without removing the dishwasher by measuring its resistance at

the Control Unit. Using the appropriate wiring diagram, locate the two NTC leads. The

resistance at room temperature should be approximately 55k Ohms.

An extremely high, low or no Ohm reading will usually indicate a faulty NTC.

Page 55

H

53

NTC Removal

To replace the NTC, first remove the Right Side

Panel, Outer Door and Toe Kick, Fig. 14-2.

Then, remove the two Front Base Mounting

Screws, Fig. 14-3.

And the single Rear Base Mounting Screw,

Fig. 14-4.

Fig. 14-2

Fig. 14-3 Fig. 14-4

Page 56

54

NTC Removal

Next, remove the Hinge Cover…

and, unhook the Pulley Arm from the Hinge by

lifting it up…

H

Fig. 14-5

and then off the Hinge.

Fig. 14-6

Fig. 14-7

Page 57

H

Fig. 14-8

1

55

NTC Removal

Now, from inside the dishwasher remove the

Lower Spray Arm, Filter Basket and Screen, then

remove the two screws that attach the Feeder

Tube to the Sump, item 1. And the two Sump

Clamps, item 2.

2

With all steps complete, bring the Tank up from

the Base and insert a block in the rear of the unit

between the Tank and the Base.

Fig. 14-9

Fig. 14-10

With the block in place you now have the required

access to replace the NTC.

Service note: The Circulation Pump / Motor can

also be replaced at this time, see

Section 8.

Page 58

56

NTC Removal

H

Fig. 14-11 Fig. 14-12

As demonstrated in Figs. 14-11 and 14-12, raising the Tank provides the necessary access space

required to remove either the NTC or the Circulation Pump / Motor.

Service note: When re-seating the Tank make sure to check that it is inserted squarely back into the

pump and seated properly.

Page 59

H

Fig. 14-13

2

57

NTC Removal

The NTC is held in place by two locking tabs,

items 1 and 2.

1

To remove the NTC from the Heater Assembly,

unhook the front tab, item 1, and lift the NTC up

slightly on that side, holding the tab open as you lift.

Fig. 14-14

1

2

Cut Away View

Then unhook the rear tab, item 2, holding it open,

while you slide the NTC up and out from the

Heater Assembly.

Once the NTC has been removed make sure to

retrieve the NTC O-ring from the Heater Assembly

if it is not on the NTC when it’s removed.

Service tip: When installing the NTC, apply water

to the O-ring so it will seat easier.

Fig. 14-15

To avoid leaks, always make sure

the NTC is secure and inserted

completely into the Heater

Assembly.

Page 60

58

H

Notes

Page 61

H

Section 8

Description Page

Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 – 62

Base Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Circulation Pump / Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Circulation Pump / Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Heater Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Aqua Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Door Spring Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

59

Page 62

60

Tank Removal

H

Fig. 15-1 Fig. 15-2

In order to gain full access to the Circulation

Pump / Motor, Heater Assembly and Aqua

Sensor the Tank must be removed.

To remove the Tank, start by removing the Outer

Door, Left and Right Side Panels, and Toe Kick,

leaving the unit as shown in Fig. 15-1.

Next, disconnect the Upper Wiring Harness from

the Control Unit and On/Off Switch, and then

bring the harness off its mounting point on the

Condensation Tube, Fig. 15-2.

Now from inside the dishwasher remove the

Lower Spray Arm, Filter Basket and Screen, then

remove the two screws that attach the Feeder

Tube to the Sump, item 1. And the two Sump

Clamps, item 2.

1

2

Fig. 15-3

Page 63

H

Fig. 15-4

61

Tank Removal

Then on both the left and right sides, remove the

Hinge Covers…

and unhook the Pulley Arms from both Hinges by

lifting them up…

Fig. 15-5

Fig. 15-6

and then off the Hinges.

Page 64

62

Tank Removal

1

H

2

Fig. 15-7 Fig. 15-8

Fig. 15-7

Now on both the left and right sides remove

the T-20 Torx Tank Mounting Screws, item 1,

and the Door Hinge Pivot tab, item 2.

Fig. 15-8

To remove the Door Hinge Pivot Tab, insert

your T-20 Torx bit into the Tab and bring the

screwdriver down releasing the tab.

Service note: The tab is a press fit, and will simply

snap into position when replaced.

Fig. 15-9

With both Tank Mounting Screws and Door

Hinge Pivot Tabs removed bring the Inner

Door up and off the unit. The Lower Door

Seal, item 1, will pull away as you remove

the door.

Set the door aside.

1

Service note: The Door Seal is a press fit along

the bottom lip of the tank. To avoid

leaking, make sure the Door Seal is

correctly inserted back along the

tank lip when replaced.

Fig. 15-9

Page 65

H

63

Base Components

3

4

2

Fig. 16-1

The Tank can now be removed from the Base.

Service note: Once removed, lay the Tank on its back so as not to damage the tank bottom. When re-

seating the Tank make sure to check that it’s inserted squarely back into the Sump and

seated properly.

With the Tank removed you now have access to the following components:

1. Circulation Motor

2. Circulation Pump

3. Heater Assembly

4. Aqua Sensor

1

Service reminder: As previously mentioned in Section 7, the Circulation Pump / Motor can also be

replaced from the right side without removing the Tank. However, the additional

visibility and access the Tank removal method allows can be a greater benefit for

this repair.

Page 66

64

Circulation Pump / Motor Removal

H

2

1

Fig. 16-2 Fig. 16-3

1

Fig. 16-4

3

Fig. 16-5

4

2

Page 67

H

65

Circulation Pump / Motor Assembly

Fig. 16-6 Fig. 16-7

CIRCULATION PUMP / MOTOR REMOVAL:

Disconnect the four wire leads, then grasp the Circulation Motor and turn clockwise a quarter turn until

the Motor stops, Fig. 16-2. Now, remove the Motor / Rear Pump Assembly from the Front Pump

Housing, Fig. 16-3.

Note: The Front Pump Housing remains in place when the Motor is removed, Fig.16-3, item 1.

With the Motor / Rear Pump Assembly removed from the unit, separate the Motor from the Rear Pump

Assembly. To do so, first remove the Impeller by placing a block in the rear of the Motor and then turning

the Impeller counter-clockwise, then Fig 16-4.

The Rear Pump Assembly consists of four components, Fig. 16-5:

1. Rear Pump Housing. 3. Impeller.

2. Main Pump Seal. 4. Impeller Seal.

Each component can be replaced as an individual item.

TO I NSTALL:

First, locate the Key Square on the Front Pump Housing, Fig. 16-6. Next, locate the Key Square Cut

Out on the Rear Pump Housing, Fig. 16-3, item 2.

When replacing the Pump / Motor make sure to line up the Key Square with the Key Square Cut Out.

Then bring the two pump halves together in the position shown in Fig. 16-2, and turn the Motor

clockwise until it stops, see Fig. 16-7.

Service note: The Impeller Seal Spring is compressed when the two halves of the Pump Assembly are

brought together. This will take a little force, so make sure to have a good grip on the

Sump as you compress the spring.

Now, reattach the wiring leads, test and check for leaks.

Page 68

66

Heater Assembly Removal

H

3

Fig. 16-8 Fig. 16-9

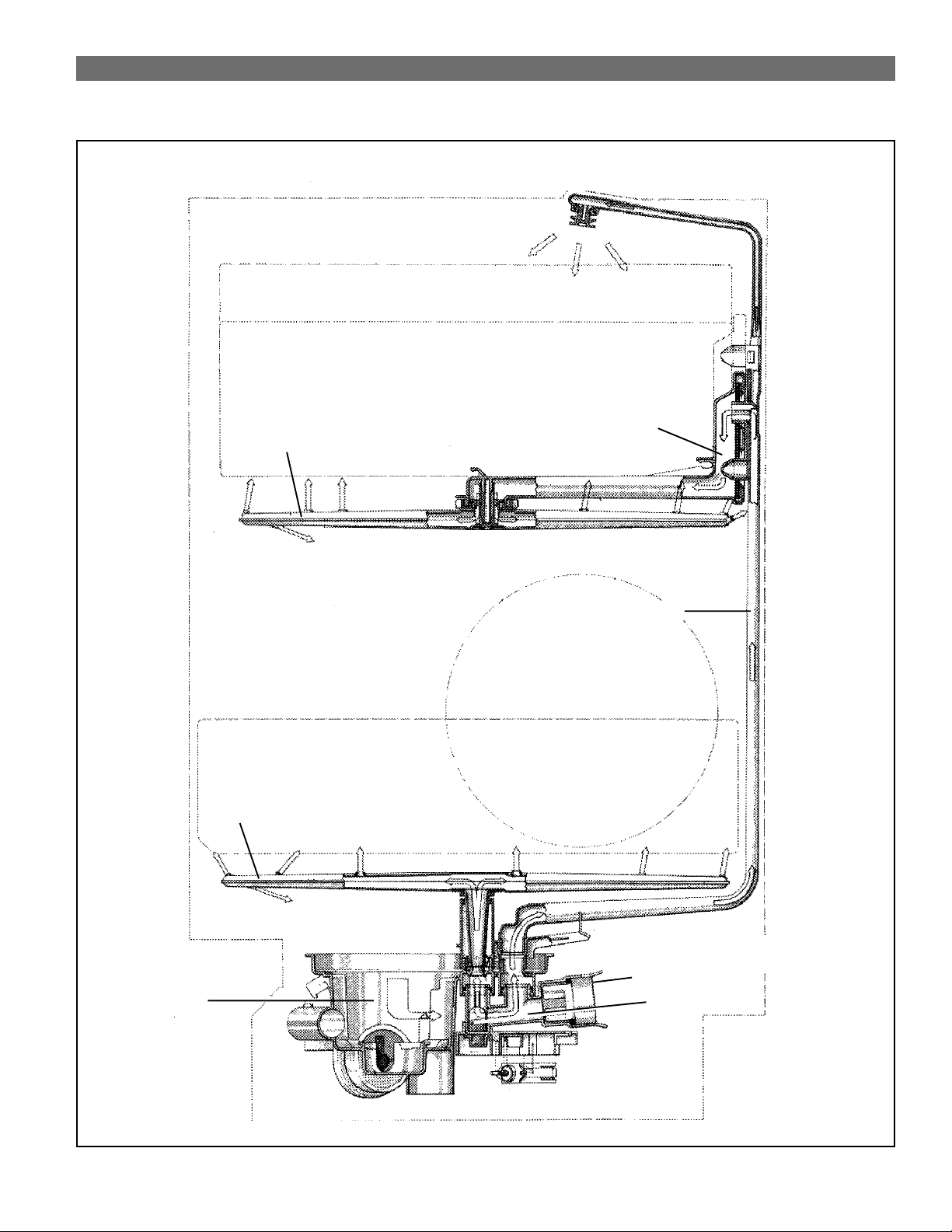

Aqua Sensor

Upper Spray Arm

Lower Spray Arm

Impeller Cover

NTC

1

2

Flow Through Heater

Flow Switch

Circulation Motor / Pump

4

Drain Motor

Fig. 16-10

Page 69

H

67

Heater Assembly

1

2

3

4

5

6

7

Fig. 16-11 Fig. 16-12

The Heater Assembly, Fig. 16-8 is a flow through design, taking water in from the Circulation Pump and

then sending it out the two discharge outlets to the Upper and Lower Spray Arms, Fig. 16-10.

HEATER ASSEMBLY REMOVAL:

See Fig. 16-9, first remove all wiring leads and the two securing screws, item 1.

Now, release the Heater Assembly Locking Tab, item 2, and while holding the tab open bring the Heater

Assembly up on the left side, disengaging the heaters two discharge outlets from the Sump, item 3, and

then out from the Circulation Pump Connection, item 4.

Heater Assembly Components, Fig. 16-11.

1. Intake from Circulation Pump. 5. Locking Tab

2. Discharge to Lower Spray Arm. 6. NTC Socket

3. Discharge to Upper Spray Arm. 7. Flow Switch

4. Aqua Sensor (if equipped).

TO I NSTALL:

Slide the Heater Assembly into the Circulation Pump Connection first, then bring the Heater down

and seat the two outlet gaskets back into the Sump. Make sure all three gaskets are secure and

the locking tab is in place. Then replace the two screws and wiring connections.

Top Rack Actuator, Fig. 16-12.

Top Rack Actuator is used to activate the Top Rack Only wash on models equipped with this

feature. When activated, the Top Rack Actuator diverts all water flow to the Upper Spray Arm.

To remove the Actuator, remove the wire connector, and then pry the Actuator out from its housing.

When installing, make sure the Actuator’s arm is properly inserted back into the Control Gate.

Page 70

68

Aqua Sensor

H

Fig. 16-13 Fig. 16-14

The Aqua Sensor turbidity measuring device, Fig. 16-13, which is available only on select models,

evaluates the pre-wash water using a beam of light and a pick-up sensor.

If the beam passes easily through the pre-wash water then no additional wash water is added. If the

beam cannot pass through, then the pre-wash water is drained and a fresh fill is added for the main

wash cycle.

To replace the sensor, Fig. 16-14, slide it out from its housing located on the Heater Assembly.

Service note: Since the Aqua Sensor has no effect on washability, it should never be replaced. Only if a

leak were to occur should service be performed on this component.

Page 71

H

69

Door Spring Removal

The Door Springs are located on the

bottom of the Base, Fig. 16-15, and

operate via a Spring Cable and Reel

that counter balances the weight of

the Outer Door, Fig. 16-16.

If a Door Panel Kit is applied to the

dishwasher, the factory springs must be

replaced with the heavy duty version

that is provided with the panel kit.

Fig. 16-15

Fig. 16-16

TO REPLACE THE SPRINGS:

Lay the dishwasher on its back,

being careful not to damage the

Drain Hose. Then using a small

screwdriver, remove the Door

Springs by prying the Spring Plate

out from the Base, Fig. 16-17.

Then remove the Spring Cable

by unhooking it from the Spring,

Fig. 16-18.

Fig. 16-17

Fig. 16-18

Page 72

70

H

Notes

Page 73

H

Section 9

Description Page

Wiring Diagrams / Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 72 — 84

Description Diagrams

Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SHI 4302

SHI 4306 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1, 8, 9

SHI 6802

SHI 6805

SHI 6806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1, 8, 11

SHU 3002

SHU 3006

SHU 3012

SHU 3016 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 3, 4

71

SHU 4002

SHU 4006

SHU 4016

SHU 4022

SHU 4026

SHU 4036 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 6, 7

SHU 4302

SHU 4306

SHU 4312

SHU 4316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1, 8, 9

SHU 5302

SHU 5304

SHU 5305

SHU 5306

SHU 5312

SHU 5314

SHU 5315

SHU 5316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1, 8, 10

SHU 6802

SHU 6805