Bosch 3931 Operating/safety Instructions Manual

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento

y seguridad

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 14 Ver página 26

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-BOSCH99 (1-877-267-2499) http://www.boschtools.com

3931

BM 2610919254 12/02 12/18/02 10:52 AM Page 1

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

-2-

Work Area

Keep your work area clean and well lit.

Cluttered and dark areas invite accidents.

Do not operate vacuums in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust.

Appliances create sparks, which may ignite

the dust or fumes.

Keep bystanders, children, and visitors

away while operating the vacuum. Do not

allow to be used as a toy. Close attention is

necessary when used by or near children.

Electrical Safety

This vacuum cleaner intended only for

use indoor and for dry or wet pick-up.

The power tool outlet is grounded and the

vacuum must be plugged into an outlet

properly installed and grounded in

accordance with all codes and

ordinances. Never remove the grounding

prong or modify the plug in any way. Do

not use any adapter plugs. Check with a

qualified electrician if you are in doubt as

to whether the outlet is properly

grounded. If the vacuums should electrically

malfunction or break down, grounding

provides a low resistance path to carry

electricity away from the user.

Do not insert objects like paper clips or

screwdrivers into power tool outlet. The

outlet is live when the vacuum is plugged

into power source and switch is set to power

tool activation mode or filter cleaning mode.

Electric shock may occur.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is grounded. If

operating the vacuum in damp locations is

unavoidable; a Ground Fault Circuit

Interrupter must be used to supply the

power to your vacuum. Electrician’s rubber

gloves and footwear will further enhance

your personal safety.

Don’t expose vacuum to rain or wet

conditions. This vacuum can be used for

picking up non-flammable liquids but it is not

intended to be immersed or submerged in a

fluid. Electric shock may occur.

Do not handle plug or appliance with wet

hands. Electric shock may occur.

Do not abuse the cord. Never use the

cord to carry the vacuum, pull the vacuum

or yank the plug from an outlet. Keep

cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords

immediately. Don’t drive over it or close a

door on it. Damaged cords increase the risk

of electric shock.

When operating a vacuum outside, use an

outdoor extension cord marked “W-A” or

“W”. These cords are rated for outdoor use

and reduce the risk of electric shock. Refer

to Recommended sizes of Extension Cords

in the Accessory section of this manual.

Personal Safety and Vacuum Use

Stay alert, watch what you are doing and

use common sense when operating a

vacuum. Do not use vacuum while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating vacuum may result in serious

personal injury.

Avoid accidental starting. Be sure vacuum

and tool switches are OFF before

plugging in or putting vacuum switch into

power tool activation mode or filter

cleaning mode. Do not keep power tool

plugged into the vacuum cleaner’s power

tool outlet during normal vacuuming.

Plugging in vacuums or tools that have the

switch ON invites accidents.

Do not overreach. Keep proper footing

and balance both for you and the vacuum

at all times. Use extra care when cleaning

on stairs. Proper footing and balance

enables better control of the vacuum in

unexpected situations.

Do not vacuum burning, smoking or

smoldering things like cigarettes,

matches or hot ashes. Fire inside the

vacuum tank may occur.

Do not use to vacuum flammable liquids,

alcohol, gases, or explosive dusts, like

!

WARNING

General Safety Rules

BM 2610919254 12/02 12/18/02 10:52 AM Page 2

-3-

gasoline or other fuels, lighter fluid,

varnish, polyurethane coatings, cleaners,

oil-based paints, natural gas, hydrogen,

coal dust, magnesium dust, grain dust, or

gun powder. Electric motors create sparks

which may ignite the dust or fumes.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts,

hose, and suction nozzles. Keep handles

dry, clean and free from oil and grease.

Do not hold the hose against any body

parts during operation.

Use safety equipment. Always wear eye

and hearing protection. Dust mask, non-

skid safety shoes, hard hat, or hearing

protection must be used for appropriate

conditions.

This product contains

chemicals, including lead,

known to the State of California to cause

cancer, and birth defects or other

reproductive harm. Wash hands after

handling.

Not suitable to vacuum hazardous or

toxic substances or dusts e.g. asbestos.

The filters will not be able to capture all

particles and may exhaust them back into

the environment.

!

WARNING

Vacuum Cleaner Safety Rules

Vacuum Care

Do not use vacuum if switch does not

turn it ON or OFF. Any vacuum that cannot

be controlled with the switch is dangerous

and must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the

vacuum. Such preventive safety measures

reduce the risk of starting the vacuum

accidentally.

Never connect a tool with a rating greater

than the maximum amperes listed on the

receptacle. This vacuum has a power tool

outlet for use in conjunction with other

appliances such as sanders, jigsaws and

planers; tools with greater ratings may cause

a fire.

Do not vacuum dust when liquid/fluid is

contained in the vacuum tank. Do not

vacuum liquids/fluids when dust is in the

tank. In either case empty the tank and/or

remove dust bag before use so that dust

does not cake and harden inside the tank.

Dry filters completely after wet

vacuuming or use a second dry filter set

for dust vacuuming. Damp or wet filters will

cake with dust or develop mold or mildew.

Store idle vacuum out of reach of children

and other untrained persons. Vacuums are

dangerous in the hands of untrained users.

Maintain vacuum with care. Properly

maintain vacuum to keep hose

unobstructed. Do not put any object into

openings. Do not use with any opening

blocked; keep free of dust, lint, hair and

anything that may reduce air flow. Any

alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the

vacuums operation. If damaged, have the

vacuum serviced before using. Poorly

maintained vacuums cause many accidents.

Develop a periodic maintenance schedule

for your vacuum.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one vacuum may become

hazardous when used on another vacuum.

Service

Only qualified repair personnel must

perform vacuum service. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a vacuum, use only

identical replacement parts. Follow

instructions in the Maintenance section of

this manual. Use of unauthorized parts or

failure to follow the Maintenance Instructions

may create a risk of electric shock or injury.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

BM 2610919254 12/02 12/18/02 10:52 AM Page 3

-4-

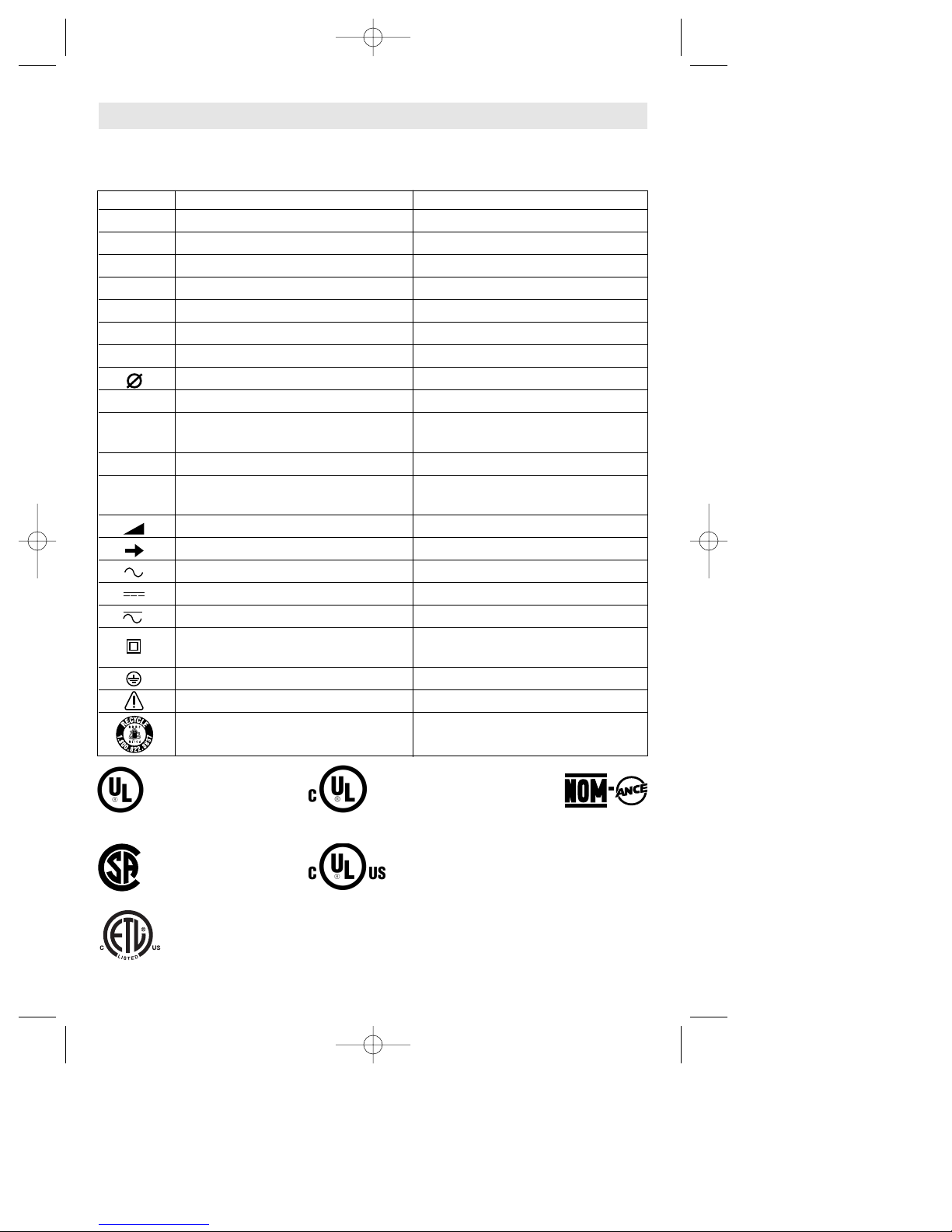

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Symbols

0

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

T

his symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

This symbol designates that this tool is listed by

Intertek Testing Services.

BM 2610919254 12/02 12/18/02 10:52 AM Page 4

-5-

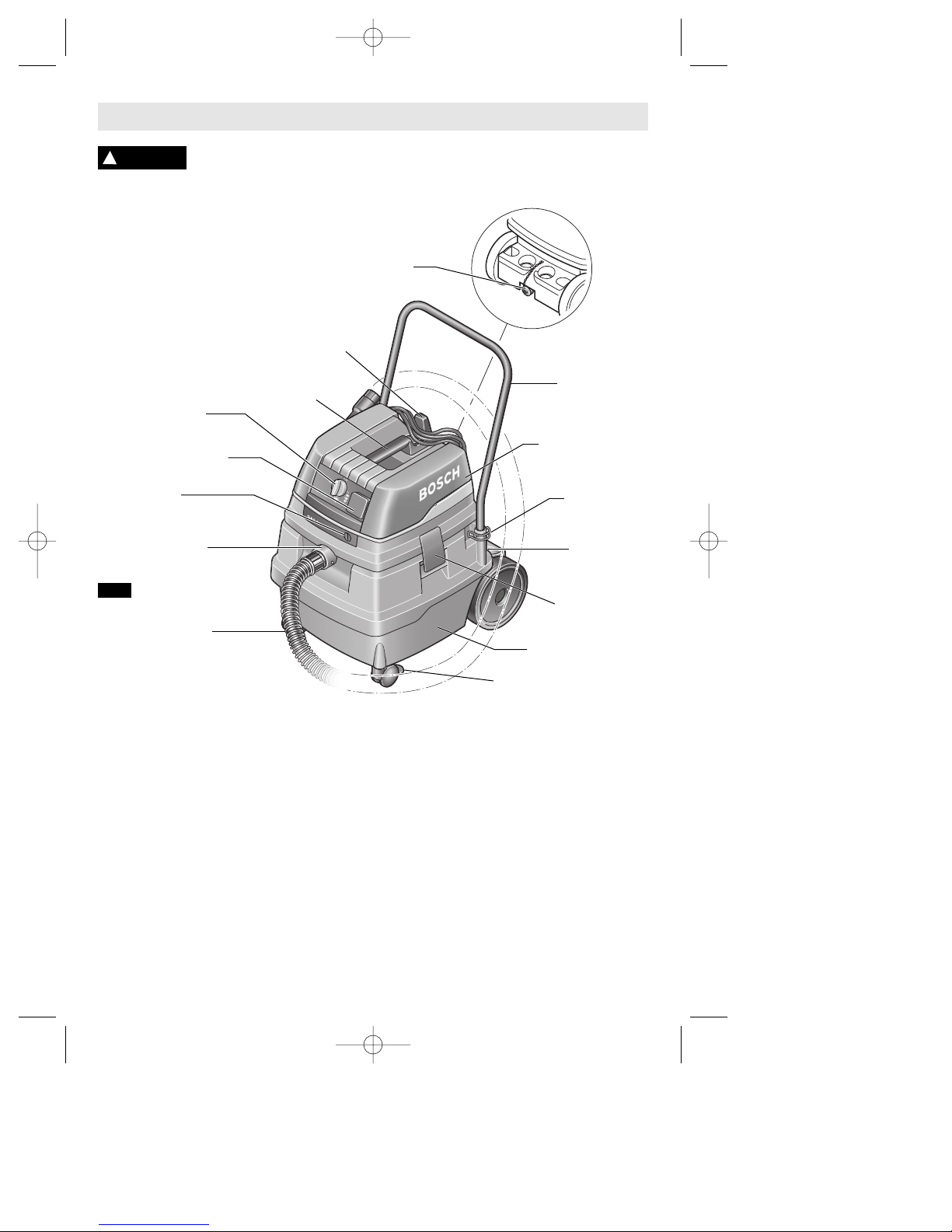

Functional Description and Specifications

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

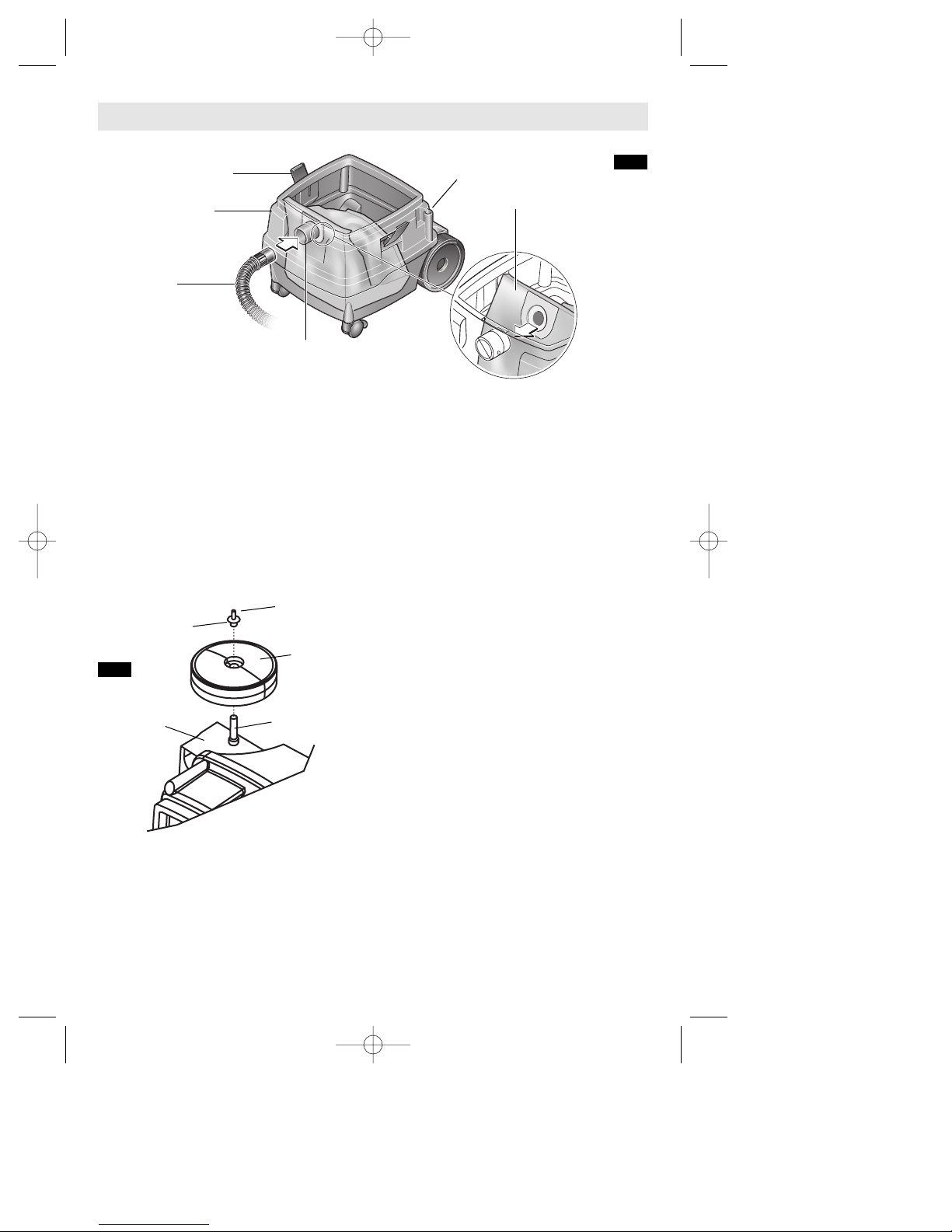

MAIN HANDLE

HANDLE

CLAMPS

WAND

STORAGE

CANISTER

LATCH

RUST PROOF

CANISTER

VACUUM

HOSE

HOSE PORT

FILTER

COMPARTMENT

LOCK

POWER TOOL

SOCKET

MODE

SELECTOR

SWITCH

CARRYING

HANDLE

CORD

WRAP

CANISTER

DRAIN

All-Purpose Vacuum Cleaner

CONTROL UNIT

FIG. 1

Specifications:

Part number ........................................... 0 601 989 139

Voltage.................................................... 120V

Frequency................................................ 60 Hz

Rated Power of Vacuum Cleaner

No Power Tool Connected ...................... 11.1 Amps

Power Tool Connected ............................ 11.1 to 4.8 Amps

Max. Rating of Connected Power Tool .... 7.2 Amps

Canister Volume (gross) ........................ 13.3 gal. (50 ltr.)

Canister Volume wet (net) ...................... 11.35 gal. (45 ltr.)

Canister Volume dry (net) ...................... 11.35 gal. (45 ltr.)

Dust Bag Volume (net)............................ 5.5 gal. (21 ltr.)

Air Flow* ........................................ 130 CFM (61 ltr./sec.)

Static Water Lift*............................. 100 in.

Vacuum Suction Pressure* .................... 248 millibars

Filter Cartridge Type ............................... (BIA) M

Filter Cartridge Surface Area (Ea.)........... 4300 cm2

Number of Filter Cartridges..................... 2

Total Filter Surface Area .......................... 8600 cm2

Dust Retention ........................................ 99.93%

Sound Pressure Level ............................. 69 dB (A)**

Weight w/o Main Handle ......................... 39 lbs. (17.7 kg)

Weight w/ Main Handle .......................... 42.2 lbs. (19.2 kg)

Cord Length ............................................ 26 feet

Hose Length............................................ 9.84’ (3 meter)

Standard Equipment:

1 35 mm Vacuum Hose (stored in canister)

1 Main Handle and 2 Handle Clamps

1 Dust Bag, 2 Filter Cartridges

2 Motor Protection Filters

2 Rear Wheels, 1 Axle

2 Axle Cap-and-Pin Assemblies

2 Front Casters

*Measured at the blower.

**The typical A-weighted sound pressure level of the product is 69 dB (A), which is determined at 1.60 m height and 1 m

distance according to IEC 704-1.

CASTER BRAKE

BM 2610919254 12/02 12/18/02 10:52 AM Page 5

-6-

When unpacking, make sure that all of the

standard equipment is present and that

there is no transportation damage.

Before preforming any work on the

machine itself, disconnect the power

plug.

CASTERS

1. The front casters are equipped with

brakes.

2. To actuate the castor brake, press the

lever downwards.

3. To deactivate, lift up.

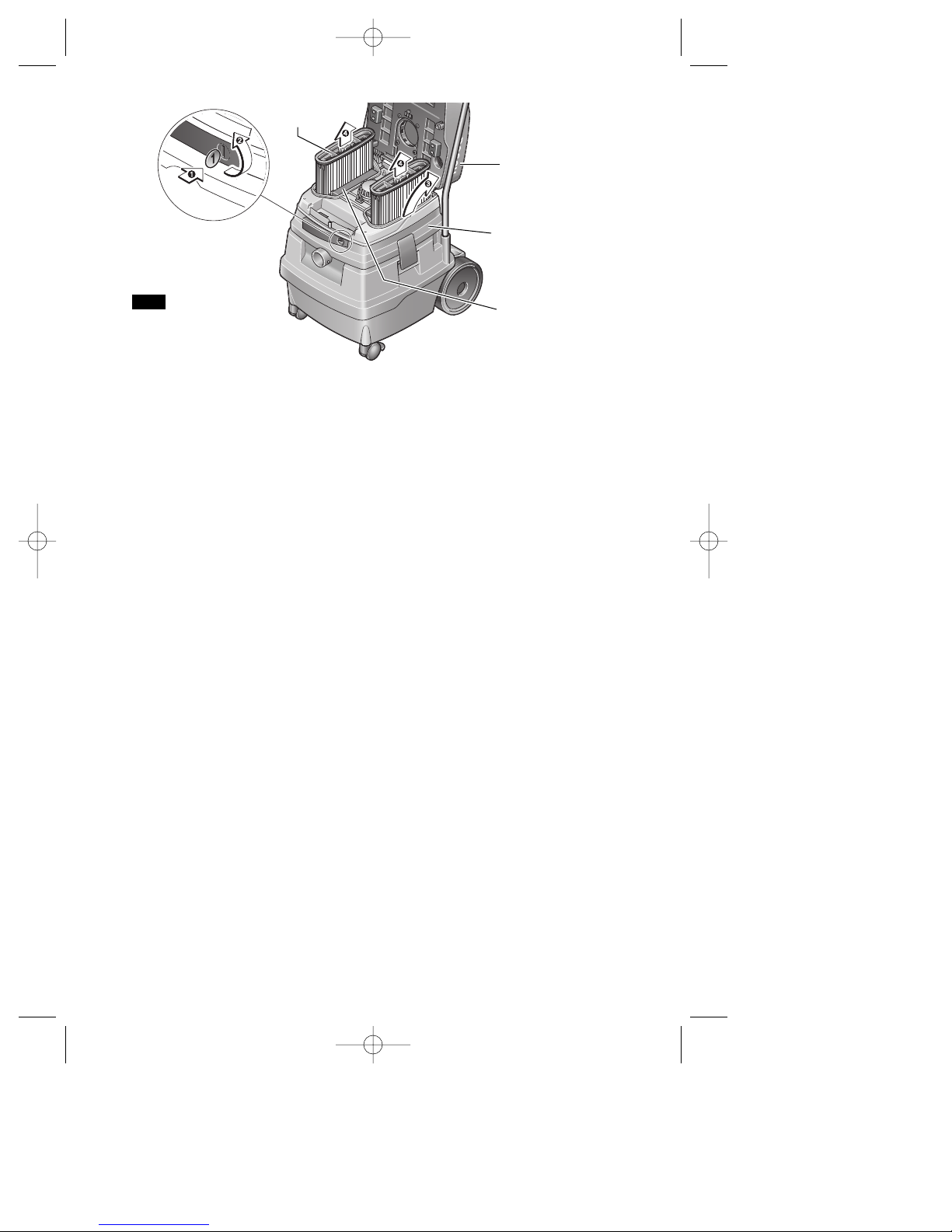

ATTACHING THE REAR WHEELS

1.Place one axle cap-and-pin assembly

onto end of axle.

2. Hammer pin into cap until the top of the

pin is flush with the top of the cap.

3. Slide one wheel onto the axle, slide axle

through the canister, then slide second

wheel onto axle as shown in figure 2.

4. Turn canister on its side. So as to provide

support during step 5, place small block

of wood or stack of quarters under the

already-capped end of the axle

5. Place second axle cap-and-pin assembly

onto end open of axle.

6. Hammer pin into cap until the top of the

pin is flush with the top of the cap.

ASSEMBLING THE MAIN HANDLE

The vacuum cleaner can be moved easily

with the main handle. Always move the unit

using both hands. Insert the handle into the

two openings and fasten with the two handle

clamps.

ATTACHING THE VACUUM HOSE

Connect the 35-mm vacuum hose (standard

equipment) onto the 3931’s hose port by

sliding the wider end of the hose onto the

port then turning it to the right slightly to lock

it in place.

The 35-mm hose can be connected to

optional accessories, including the Bosch

VAC011 wand kit and the dust extraction

hoods on various power tools, including

Bosch routers, planers and grinder hoods.

The 3931’s universal hose port also accept

many other vacuum hoses, including most

1-1/4” hoses, 1-1/2” hoses, 2-1/2” hoses

and other Bosch hoses. (See Accessories,

page 13)

Assembly & Preparation

CANISTER LATCH

CANISTER

HANDLE OPENING

HOSE PORT

VACUUM

HOSE

DUST BAG

FIG. 3

AXLE CAP

WHEEL

AXLE

CANISTER

PIN

FIG. 2

BM 2610919254 12/02 12/18/02 10:52 AM Page 6

INSTALLING THE DUST BAG

When dry-vacuuming such materials as dust

from drywall, plaster, cement, soot, and

flour, a dust bag should be inserted.

Even when vacuuming other dry materials,

using a dust bag extends the amount of time

the unit operates at high performance and

extends the amount of time it takes for the

filter cartridge to become clogged. It also

makes the disposal of dust easier.

Notes:

• Bags should not be used when wetvacuuming.

• The filter cartridges must be installed,

even when using a bag.

To install the bag:

1. Unlock the canister latches and remove

the control unit.

2. Grasp a new dust bag at the flange. Push

it over the bottom of the connection piece

first and then over the catch on the top of

the connection piece. Make sure that the

full length of the dust bag faces against

the inner wall of the canister.

3. Re-attach the control unit.

4. Lock the canister latches.

REMOVING THE DUST BAG

1. Unlock the canister latches and remove

the control unit.

2. Pull the dust bag away from and off of the

connection piece.

3.Close the opening in the dust bag by

folding down the lid

4. Remove bag and dispose of properly.

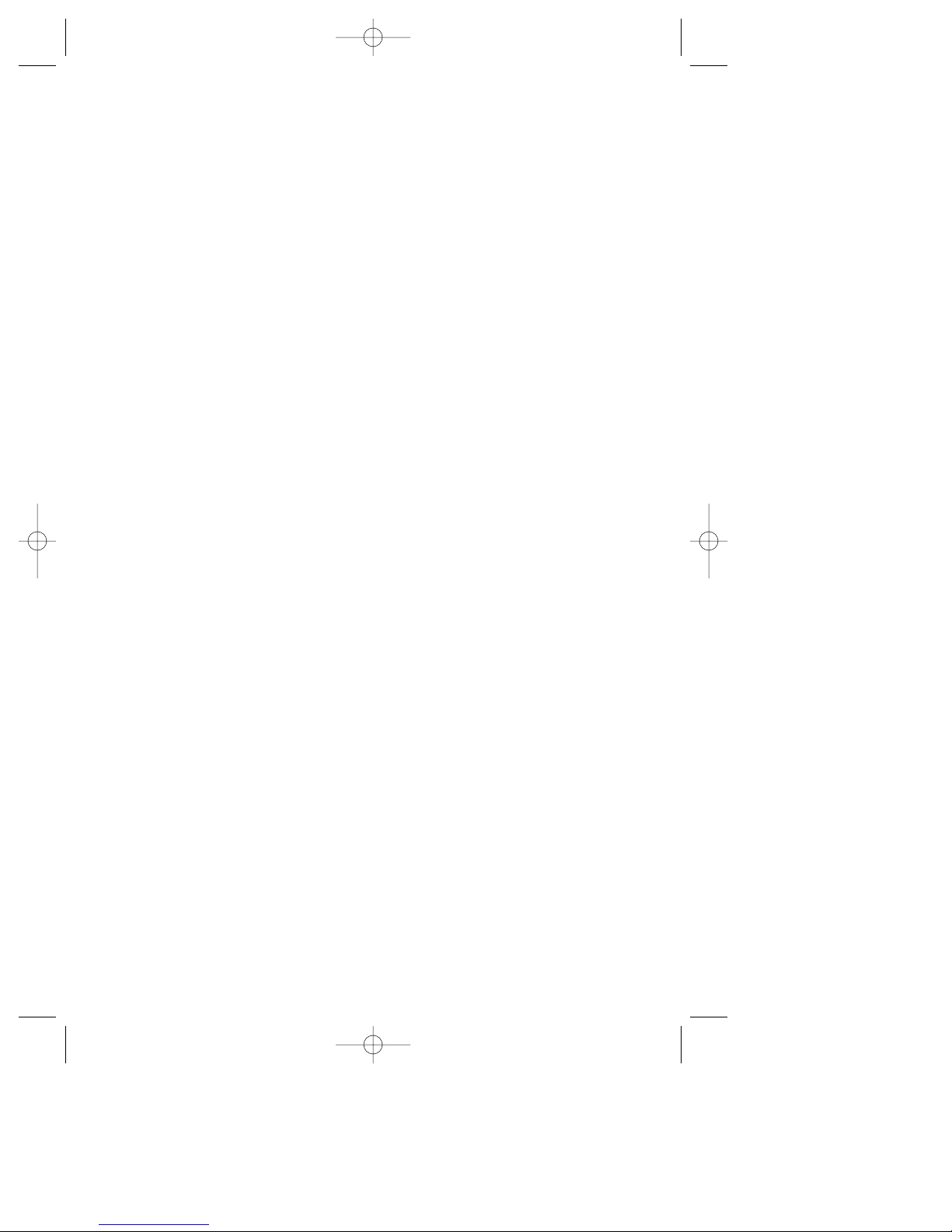

REMOVING THE FILTER CARTRIDGES

1. First, clean the filters by setting the mode

selector switch to the PULSE-CLEAN™

mode, which takes only 10 seconds.

2. To open the filter access compartment,

use a coin to rotate the filter compartment

lock by 1/4 turn in the direction of the

arrow and push the lock in.

3. Lift up the top section of the control unit.

4. Grasp the filter cartridge by the fins, pull

up and remove.

Replace a damaged filter cartridge

immediately.

THOROUGH CLEANING OF THE

FILTER CARTRIDGES

If necessary, the filter cartridges can also be

cleaned with a soft brush and can also be

washed with water.

REPLACING THE FILTER CARTRIDGES

1. Insert new or cleaned filter cartridge and

ensure firm seating.

2. Lower the top section down again.

3. With slight pressure from the top of the

control unit, the filter compartment lock

will snap back again.

CLEANING THE MOTOR

PROTECTION FILTERS

The motor protection filters are basically

maintenance-free. Take out the motor

protection filters from time to time and wash

them. Allow them to dry thoroughly before

reinserting.

-7-

FILTER

CARTRIDGE

CONTROL UNIT

TOP SECTION

CONTROL UNIT

BOTTOM SECTION

MOTOR PROTECTION

FILTER

FILTER

COMPARTMENT

LOCK

FIG. 4

BM 2610919254 12/02 12/18/02 10:52 AM Page 7

-8-

REMOVING THE MOTOR

PROTECTION FILTERS

1. To open the filter access compartment,

use a coin to rotate the lock by 1/4 turn in

the direction of the arrow and push the

lock in.

2. Lift up the top section.

3. Grasp the filter, pull up and remove.

REPLACING THE MOTOR

PROTECTION FILTERS

See Figure 4.

1. Insert clean motor protection filters and

ensure firm seating.

2. Lower the top section.

3. With slight pressure from the top of the

control unit, the filter compartment lock

will snap back again.

WAND STORAGE

The wands from the optional VAC011 wand

kit can be stored in the recesses at the

bottom of the rear of the container. See

Figure 1.

BM 2610919254 12/02 12/18/02 10:52 AM Page 8

-9-

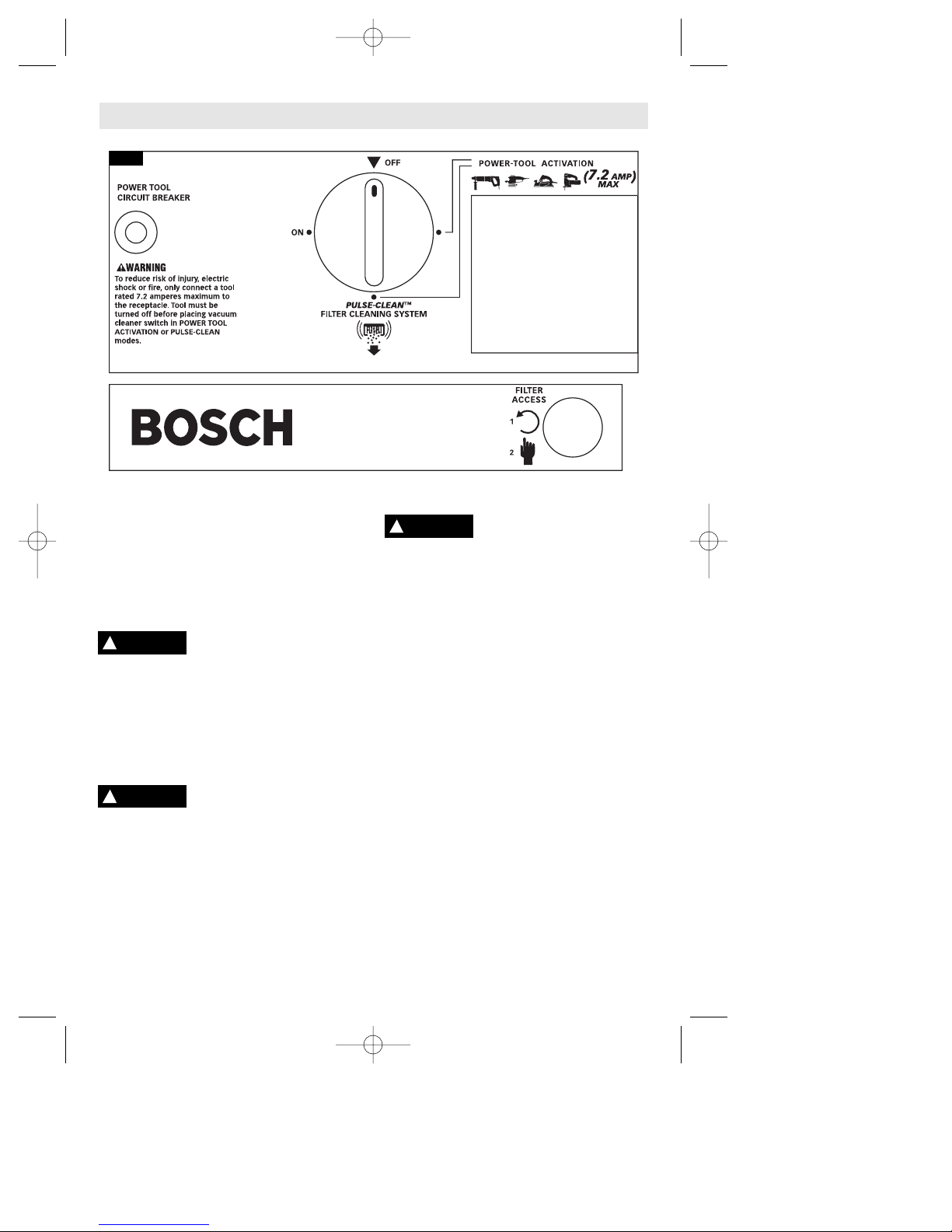

Operating Instructions

The vacuum cleaner has four operating

modes:

• Normal Vacuuming Mode

• Power Tool Activation Mode

• Pulse-Clean Filter Cleaning Mode

• Pulse-Clean Filter Cleaning Combined

with Power Tool Activation Mode

Avoid accidental starting.

Be sure vacuum and tool

switches are OFF before plugging in or

putting vacuum switch into power tool

activation mode or filter cleaning mode.

Do not keep power tool plugged into the

vacuum cleaner’s power tool outlet

during normal vacuuming. Plugging in

vacuums or tools that have the switch ON

invites accidents.

Not suitable to vacuum

hazardous or toxic

substances or dusts e.g. asbestos. The

filters will not be able to capture all particles

and may exhaust them back into the

environment.

NORMAL VACUUMING MODE

Switching the Unit On: Set mode selector

switch to ON.

Switching the Unit Off: Set mode selector

switch to OFF.

POWER-TOOL ACTIVATION MODE

Never connect a tool with

a rating greater than the

amperes listed on the receptacle. This

vacuum has a power tool outlet for use in

conjunction with other appliances such as

sanders, jigsaws and planers; tools with

ratings greater ratings may cause a fire.

1. Check power tool nameplate for

acceptable amperage rating. Only tools

with rated at 7.2 amps or less should be

connected to the vacuum cleaner.

2. Make sure the power tool is switched off,

and then plug it in.

3. Set the mode selector switch to POWER

TOOL ACTIVATION position.

4. When the power tool is switched on, the

power tool automatically switches on the

vacuum cleaner.

Switching The Vacuum Cleaner ON: When

the power tool is switched on, the vacuum

cleaner automatically switches on.

In the Power Tool Activation Mode or

Pulse-Clean Mode combined with Power

Tool Activation, the vacuum cleaner power is

set at 4.8 amps. In the normal vacuuming

and normal PULSE-CLEAN mode, the power

is 11.1 amps.

!

WARNING

!

WARNING

!

WARNING

FIG. 5

GROUNDED OUTLET

(OUTLET COVER)

BM 2610919254 12/02 12/18/02 10:52 AM Page 9

-10-

Switching The Vacuum Cleaner OFF:

When the power tool is switched off, the

vacuum cleaner is switched off. In order to

empty the hose, the vacuum cleaner

switches off after a 6 second delay.

BUILT-IN CIRCUIT BREAKER

If a power tool is connected to the vacuum

cleaner and draws more than 12 amps, the

circuit breaker will trip and shut down the

power supply to the outlet. This will stop

operation of the power tool and stop the

operation of the vacuum cleaner in the

following modes:

• Power Tool Activation

• Pulse-Clean Filter Cleaning Combined

with Power Tool Activation

(The circuit breaker has no affect on the

Normal Vacuuming mode or the regular

PULSE-CLEAN™ Filter Cleaning mode.)

PULSE-CLEAN™ FILTER CLEANING

The vacuum cleaner is equipped with the

electromagnetic PULSE-CLEAN™ filter

cartridge cleaning system, which in 10

seconds allows the unit to self-remove dust

that is adhering to the filter cartridge.

Before using the PULSE-CLEAN™ mode,

we suggest to advise those in hearing

range about the sound of this feature.

PULSE-CLEAN™ MODE

(when no power tool is plugged in)

1.Turn vacuum cleaner dial to PULSECLEAN™ setting.

2. The filter cleaning process will be

automatically completed within about 10

seconds.

3. After PULSE-CLEAN™ cycle completes

itself, the vacuum cleaner will become

idle.

4. Switch the vacuum cleaner to the OFF or

ON position, as desired.

See PULSE-CLEAN™ notes below.

PULSE-CLEAN™ MODE COMBINED

WITH POWER TOOL ACTIVATION

The PULSE-CLEAN™ system can also be

used when a power tool is connected and

used with the “POWER TOOL

ACTIVATION MODE”. This is very handy

when the location of vacuum cleaner is

separated from the connected power tool,

such as when the tool is being used up on a

scaffold.

1.Plug the power tool into the vacuum

cleaner’s power tool outlet.

2. Turn the vacuum cleaner dial to PULSECLEAN™ setting.

3. The vacuum cleaner goes into the PULSECLEAN™ mode for 10 seconds.

4. After PULSE-CLEAN™ mode is

completed, switch on the power tool, and

the vacuum cleaner will operate until the

power tool is switched off or disconnected

from the vacuum cleaner.

5. At the time the tool is switched off, the

vacuum cleaner will automatically

determine if the filter needs to be cleaned.

If it determines that cleaning is necessary,

the PULSE-CLEAN™ system

automatically activates, the cleaning

process will be completed within about 10

seconds.

6. After PULSE-CLEAN™ cycle completes

itself, the vacuum cleaner will become

idle.

7. Switch the vacuum cleaner OFF, or to

continue working, switch the power tool

on again.

8. If power tool is switched on before the

PULSE-CLEAN™ cycle is complete,

PULSE-CLEAN™ automatically stops and

vacuum cleaner starts to vacuum.

PULSE-CLEAN™ Notes:

• The sound of the PULSE-CLEAN™

system may surprise those near the work

area. Before using PULSE-CLEAN™, alert

those in the vicinity of the vacuum cleaner

of this feature and the associated sound it

makes.

• Any power tool plugged into the vacuum

cleaner’s power tool outlet will receive

power during the PULSE-CLEAN™

modes, as well as the power-tool

activation mode. Don’t keep power tool

plugged into the vacuum cleaner’s power

tool outlet during normal vacuuming.

• The PULSE-CLEAN™ system must be

activated when the suction power

decreases to the point of being

insufficient.

• The PULSE-CLEAN™ system should be

activated regularly to keep the filter

cartridges clean. The proper frequency for

activating the PULSE-CLEAN™ system

depends on the type and amount of dust.

With regular usage, the maximum

vacuuming performance is maintained

longer.

BM 2610919254 12/02 12/18/02 10:52 AM Page 10

-11-

RESETTING THE CIRCUIT BREAKER

1. Switch off the power tool

2. Press the circuit breaker button.

3. Restart the vacuum cleaner in the desired

mode.

WET VACUUMING

Your 3931 can also be used for wet

vacuuming.

Do not use to vacuum

flammable liquids, gases,

or explosive dusts, like gasoline or other

fuels, lighter fluid, varnish, polyurethane

coatings, cleaners, oil-based paints,

natural gas, hydrogen, coal dust,

magnesium dust, grain dust, or gun

powder. Electric motors create sparks,

which may ignite the dust or fumes.

1. Before wet vacuuming, run the vacuum in

the PULSE-CLEAN™ mode.

2. Empty the canister to prevent encrustation

when wet vacuuming. If bag is in canister,

remove it as well.

Notes:

• Empty the canister before wet vacuuming.

• Do not use a dust bag when wet

vacuuming

• The filter cartridge must be used when

wet vacuuming.

• Do not activate the PULSE-CLEAN™

mode when the contents of the vacuum

cleaner are wet.

• The unit is equipped with water level

sensors. The unit switches off when the

maximum filling height is reached. The

unit still has power, but will not operate.

The unit must be first switched off before

it can be switched on again.

• When the unit is shut off, some water may

flow out of the hose.

• To prevent siphoning or spillage, lift the

suction hose out of the liquid before

draining the vacuum cleaner.

• Before opening and emptying, move the

switch to the OFF position.

• Always disconnect the vacuum cleaner

cord from the power supply.

• In order to avoid mildew, after wet

vacuuming, remove both filter cartridges

and allow them to dry thoroughly, Dry the

filter and canister thoroughly so that dust

cannot adhere to moist parts. Also remove

the control unit and allow it to dry, too.

• Use a dry filter for subsequent dry

vacuuming. We suggest purchasing extra

filter cartridges when frequently

alternating between wet and dry

vacuuming and swap them out as

appropriate.

Clean the canister and accessories with

water. Wipe the top section with a moist

cloth.

WATER-LEVEL SENSOR MAINTENANCE

Clean the water level sensors occasionally:

See Figure 6.

1. Unlock the canister latches and remove

the control unit.

2. Clean the water level sensors with a soft

cloth.

3. Reattach the control unit again

4. Lock the canister latches.

EMPTYING THE CANISTER

1. Switch the unit off.

2. Disconnect from the power supply.

3. Open the canister latches.

4. Remove control unit.

5. Remove the paper filter bag; dump out the

canister, or drain out the canister as

appropriate.

CANISTER MAINTENANCE

Wipe out the canister from time to time with

a commercially available, non-scouring

cleaning agent and allow to dry.

LEVEL

SENSOR

FIG. 6

!

WARNING

BM 2610919254 12/02 12/18/02 10:52 AM Page 11

-12-

Service

Preventive maintenance

performed by unauthorized personnel may result in misplacing

of internal wires and components which

could cause serious hazard. We

recommend that all tool service be

performed by a Bosch Factory Service

Center or Authorized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly

lubricated and is ready to use.

Cleaning

To avoid accidents always

disconnect the tool from

the power supply before cleaning or

performing any maintenance. The tool may

be cleaned most effectively with

compressed dry air. Always wear safety

goggles when cleaning tools with

compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

Certain cleaning agents

and solvents damage

plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household

detergents that contain ammonia.

!

WARNING

!

WARNING

Maintenance

!

CAUTION

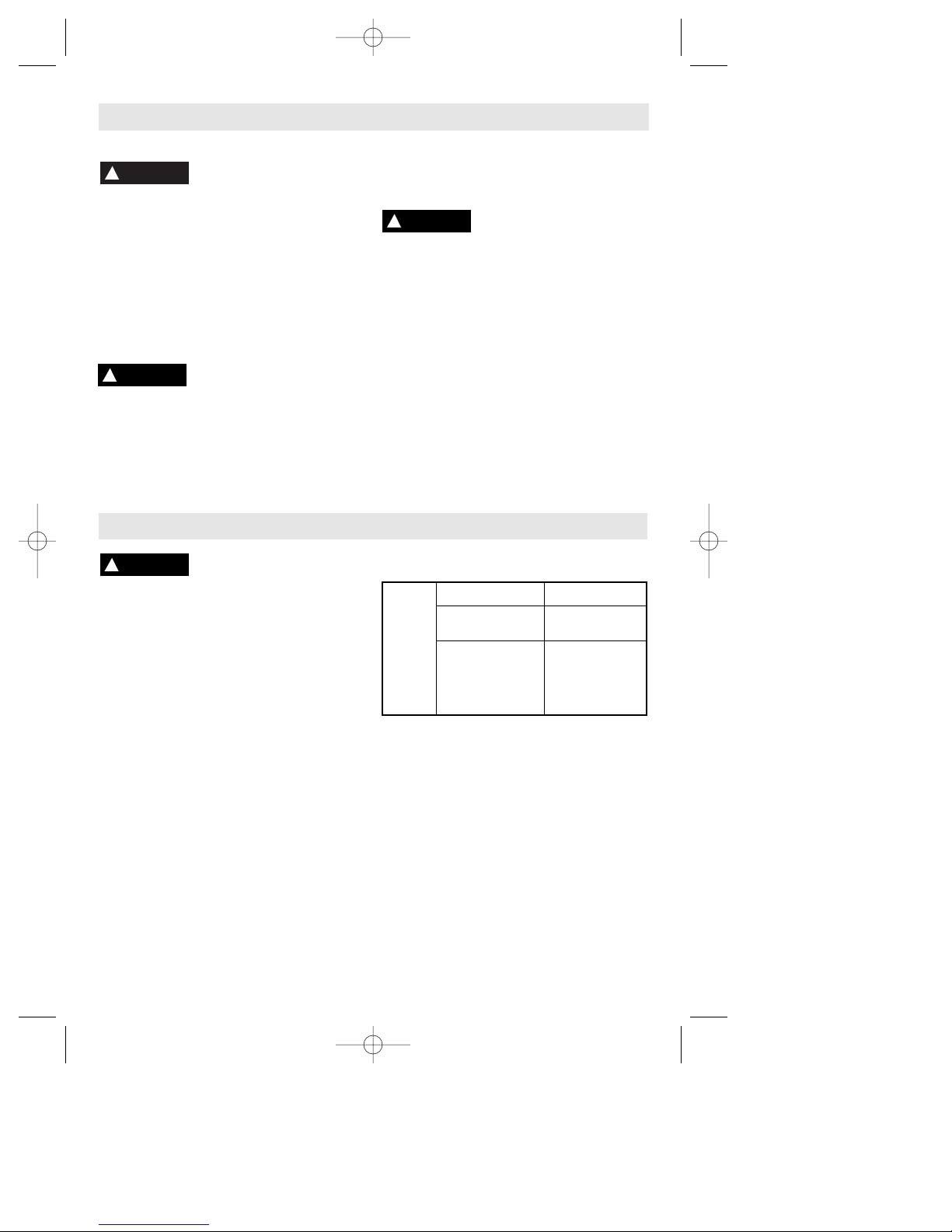

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3wire extension cords that have 3-prong

plugs and receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

The length of the vacuum cleaner cord must

be included in calculating the total length of

cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

!

WARNING

Accessories

BM 2610919254 12/02 12/18/02 10:52 AM Page 12

Loading...

Loading...