Page 1

BM 1619929572 11-06 11/8/06 8:51 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1944LCD

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

For English Version Version française Versión en español

See page 2

Voir page 12

Ver la página 22

Page 2

BM 1619929572 11-06 11/8/06 8:51 AM Page 2

Important Safety Instructions for Heat Guns

WARNING

!

Hidden areas such as behind walls, ceilings, floors, soffit boards and other panels may

contain flammable materials (dust, cob webs, mice nests, etc.) that could be ignited by

the heat gun when working in these locations.

readily apparent and could result in property damage and injury to persons.

When working in locations that may have hidden areas, keep the heat gun moving in a

back-and-forth motion.

material behind it.

Paint Stripping Safety Instructions

WARNING

!

paint.

The peelings, residue and vapors of

paint may contain lead, which is poisonous.

Any pre-1977 paint may contain lead and

paint applied to homes prior to 1950 is likely

to contain lead. Once deposited on surfaces,

hand to mouth contact can result in the

ingestion of lead. Exposure to even low

levels of lead can cause irreversible brain

and nervous system damage; young and

unborn children are particularly vulnerable.

Before beginning any paint removal process

you should determine whether the paint you

are removing contains lead. This can be

done by your local health department or by a

professional who uses a paint analyzer to

check the lead content of the paint to be

removed. LEAD-BASED PAINT SHOULD

ONLY BE REMOVED BY A PROFESSIONAL

AND MUST NOT BE REMOVED USING A

HEAT GUN.

Persons removing paint should follow

these guidelines:

1) Move the work piece outdoors. If this is

not possible, keep the work area well

ventilated. Open the windows and put an

exhaust fan in one of them. Be sure the fan

is moving the air from inside to outside.

2) Remove or cover any household items

in the area such as carpets, rugs,

furniture, and clothing, cooking utensils

and air ducts.

3) Place drop cloths in the work area to

catch any paint chips or peelings.

protective clothing such as extra work shirts,

overalls and hats.

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

The ignition of these materials may not be

Lingering or pausing in one spot could ignite the panel or the

4) Work in one room at a time. Furnishings

Extreme care should be

taken when stripping

Wear

should be removed or placed in the center of

the room and covered. Work areas should be

sealed off from the rest of the dwelling by

sealing doorways with drop cloths.

5) Children, pregnant or potentially

pregnant women and nursing mothers

should not be present in the work area

until the work is done and all clean up is

complete.

6) Wear a dust respirator mask or a dual

filter (dust and fume) respirator mask,

which has been approved by the

Occupational Safety and Health

Administration (OSHA), the National

Institute of Safety and Health (NIOSH), or

the United States Bureau of Mines.

masks and replaceable filters are readily

available at major hardware stores. Be sure

the mask fits. Beards and facial hair may

keep masks from sealing properly. Change

filters often. DISPOSABLE PAPER MASKS

ARE NOT ADEQUATE.

7) Use caution when operating the heat

Keep the heat gun moving, as

gun.

excessive heat will generate fumes that can

be inhaled by the operator.

8) Keep food and drink out of the work

Wash hands, arms and face and rinse

area.

mouth before eating or drinking. Do not

smoke or chew gum or tobacco in the work

area.

9) Clean up all removed paint and dust by

wet mopping the floors.

clean all walls, sills and any other surface

where paint or dust is clinging. DO NOT

SWEEP, DRY DUST OR VACUUM. Use a

high phosphate detergent or trisodium

phosphate (TSP) to wash and mop areas.

Use a wet cloth to

These

-2-

Page 3

BM 1619929572 11-06 11/8/06 8:51 AM Page 3

10) At the end of each work session put

the paint chips and debris in a double

plastic bag, close it with tape or twist ties

and dispose of properly.

11) Remove protective clothing and work

shoes in the work area to avoid carrying

dust into the rest of the dwelling.

work clothes separately. Wipe shoes off with

a wet rag that is then washed with the work

clothes. Wash hair and body thoroughly with

soap and water.

!

WARNING

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

Some dust created by

power sanding, sawing,

SAVE THESE INSTRUCTIONS

Wash

General Safety Rules for Heat Guns

DANGER

!

seriously injured.

Avoid contact with nozzle of heat gun

during use.

temperatures as high as 1200 degrees

Fahrenheit. You may be seriously burned.

Do not use heat guns in the rain, moisture

or immerse in water.

gun element to water or other liquids may

cause electrical shock hazard.

Do not use heat guns in areas where

flammable liquids or gases may be stored

or are present.

high temperatures and may ignite these

materials.

Keep your work area clean and well lit.

Cluttered and dark areas invite accidents.

Do not operate heating appliance in

explosive atmospheres, such as in the

presence of flammable liquids, gases or

dust, dry grass, leaves and paper.

appliances generate high temperatures

which may ignite the dust or fumes.

Combustible materials like dry grass, leaves

and paper will scorch and may catch fire.

Never use heat guns as

hairdryers!

This heat gun generates

The heat gun generates

You will be

Exposing the heat

Work Area

Heating

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

Keep bystanders, children and visitors

away while operating a heating appliance.

Distractions can cause you to lose control.

Electrical Safety

Before plugging in the heating appliance,

be certain the outlet voltage supplied is

compatible with the voltage marked on

the nameplate within 10%.

voltage incompatible with that specified on

the nameplate can result in serious hazards

and damage to the heating appliance.

When operating a heating appliance use

Ground Fault Circuit Interrupter (GFCI) on

the circuit or outlet.

appliance to rain or wet conditions. Water

entering a heating appliance will create an

electric shock hazard.

Do not abuse the cord. Never use the

cord to carry the heating appliance or pull

the plug from an outlet. Keep cord away

from heat, oil, sharp edges or moving

parts. Replace damaged cords

immediately.

shock hazard.

Damaged cords create electric

Don’t expose heating

An outlet

-3-

Page 4

BM 1619929572 11-06 11/8/06 8:51 AM Page 4

When operating a heating appliance with an

extension cord while outdoors, use only

extension cords marked W–A or W.

cords are rated for outdoor use and

reduce the risk of electric shock.

These

Personal Safety

Stay alert, watch what you are doing and

use COMMON SENSE when operating a

heating appliance.

or use of drugs, alcohol or medication while

operating a heating appliance can be

dangerous.

Use safety equipment. Always wear safety

goggles.

safety shoes or non-skid shoes, must be

used for appropriate conditions.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in.

heating appliance with your finger on the

switch or plugging in the heating appliance

that has switch “ON” invites accidents.

Do not direct hot tip or nozzle toward

clothing, hands or other body parts.

Intense heat from tip or nozzle can cause

serious burns or cause clothing to ignite.

Do not touch nozzle or shield until

completely cool.

temperatures are generated in these areas.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, body, clothing and gloves

away from nozzle or shield.

could ignite from extreme heat.

Do not overreach, keep proper footing

and balance at all times.

Dust mask, protective gloves,

A moment of inattention

Carrying the

During use very high

Clothing or hair

Proper footing and

balance enables better control of the heating

appliance in unexpected situations.

Tool Use and Care

D

o not use heating appliance if switch

does not turn it “ON” or “OFF”.

which cannot be controlled by the switch is

dangerous.

Disconnect the plug from the power

source before making any adjustments or

changing accessories.

safety measures reduce the risk of starting

the heating appliance accidentally.

Store idle heating appliance only after

adequate cooling period, indoors in high,

dry place out of the reach of children and

untrained persons.

dangerous in the hands of untrained

persons.

Do not leave heating appliance

unattended while it is running or cooling

down.

Always set tool on a flat, level surface

so that nozzle tip is directed upwards, away

from supporting surface while running or

cooling down.

Keep a fully charged fire extinguisher

close at hand for emergency use.

Such preventative

Heating appliances are

Any tool

Service

Heating appliance service must be

performed only by qualified repair

personnel.

performed by unqualified personnel may

result in misplacing internal wiring and

components which could cause serious

hazard.

Service or maintenance

Double Insulated Tools

Double Insulation is a design concept used

in electric power tools which eliminates the

for the three wire grounded power cord

need

and grounded power supply system. It is a

recognized and approved system by

Underwriter’s Laboratories, CSA and Federal

OSHA authorities.

IMPORTANT: Servicing of a tool with double

insulation requires care and knowledge of the

system and should be performed only by a

qualified service technician.

WHEN SERVICING, USE ONLY IDENTICAL

REPLACEMENT PARTS.

Double Insulated heating appliances are equip

ped with a polarized plug (one blade is wider

than the other.) This plug will fit in a polarized

outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any

way.

-4-

-

Page 5

BM 1619929572 11-06 11/8/06 8:51 AM Page 5

Functional Description and Specifications

WARNING

!

m

easures reduce the risk of starting the tool accidentally.

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories.

Heat Gun

STAND LEGS

AIR VENTS

STORE

BUTTON

OFF/COOL/HOT

SELECTOR SWITCH

AIR VENT

COVER

DISPLAY

BUTTON FOR SETTING AIR FLOW

Such preventive safety

PROGRAM

SELECTION

BUTTON

BUTTON FOR SETTING

THE TEMPERATURE

FIG. 1

NOZZLE

Model number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEAT

PROTECTOR

1944LCD

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8"L x 5-1/4"W x 9-1/2"H

Nozzle opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3/16" dia.

Avg. air volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6-17.6 cfm

Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 Ibs.

Voltage rating . . . . . . . . . . . . . . . . . . . . . . . . . . . .

120 V 60 Hz

Amperage rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13A

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . 120 °F-1200 °F

-5-

OFF/COOL/HOT

SELECTOR SWITCH

STAND LEG

Page 6

BM 1619929572 11-06 11/8/06 8:51 AM Page 6

FIG. 2

FIG. 3

-6-

Page 7

BM 1619929572 11-06 11/8/06 8:51 AM Page 7

Operating Instructions

Your Bosch Heat Gun is a heavy-duty,

industrial-quality, general-purpose heat gun.

You can do more heating jobs faster with this

heat gun because of its high power and air

flow ratings.

This product provides a fast flow of heated air

for applications such as activating adhesives,

bending and forming plastics, curing epoxies,

deburring plastics, defrosting frozen coils,

drying negatives and parts, heating solids and

liquids, loosening nuts and bolts, removing

floor tiles and putty, repairing vinyl, shrinking

tubing and packaging, softening materials

and stripping paint.

The proper amount of heat for each

application is dependent upon, the distance of

the nozzle opening from the work surface and

length of time that heat is applied to the work

surface.

Before performing an application, we

recommend that you experiment with a piece

of scrap material. Use care in approaching

the work until you find the proper combination

of shutter adjustment, distance from the work

surface and heat application time.

Use a gentle back and forth motion when

applying heat unless it is found that a

concentrated heat is desired.

OFF/COOL/HOT SELECTOR SWITCH

To turn unit on, slide the selector switch to the

position (cool air setting) or (hot air setting.)

In both positions, the unit starts with the air flow

and temperature values that were set before

the last switch-off.

To turn unit off, slide the selector switch to the

O stop position.

When working for long periods of time with high

temperatures, allow the unit to cool down by

running the unit in the cool air setting before

turn the unit off (Fig. 1).

When heat gun is used in an enclosed

container, such as a shrink tunnel or special

enclosure, ambient air must be allowed to

pass into the heat gun and there must be an

outlet of equal size for the heated air to pass

out of the enclosure also. Total enclosure will

cause damage or possible failure to the heat

gun due to the extreme heat generated.

COOL AIR SETTING

The air flow can be regulated, but

the temperature is fixed at 120 °F

(cannot be regulated), and no

programmed operation is possible.

The cool air setting is suitable for cooling a

warmed workpiece, or for drying of paint. It is

also used for cooling the unit before placing

down or the changing of nozzles.

When changing from the hot air setting with

high temperatures to the cool air setting , a

short period of cooling period is required until

the unit cools down to 120 °C. During this

cooling period, the actual temperature of the

nozzle outlet is shown in the display (Fig. 1) .

When changing from the hot air setting to the

cool air setting , the current air flow setting is

used.

HOT AIR SETTING

The air flow and temperature can

be regulated, normal and

programmed operation is possible.

For applications, see Typical

Applications. When changing from the cold air

setting to the hot air setting , air flow,

temperature, operating mode and program

revert back to the settings that were in use

when the hot air setting was last used.

SETTING THE TEMPERATURE

The temperature in the hot air setting can be

adjusted (Fig. 2).

To change to another temperature, the unit

needs a short time to warm or cool the air

stream to the target temperature. The target

temperature is shown in the display during this

time with blinking arrows .

After reaching the required temperature, the

arrows are eliminated and the display

shows the actual temperature.

The target temperature can be increased in

steps of 10°F by pressing the “+” side of the

temperature button or reduced by pressing the

“–” side of the button. Brief pressing of the

button increases or decreases the target

temperature one time by 10°F. Longer pressing

of the button increases or decreases the

temperature continuously by 10°F steps until

the button is released or the minimum or

maximum temperature is reached.

-7-

Page 8

BM 1619929572 11-06 11/8/06 8:51 AM Page 8

The air flow can be regulated with the air flow

button (Fig. 1).

The CFM at each of the 10 airflow settings

depends on the temperature setting. For

example, at the lowest temperature (120

degrees) the lowest airflow setting delivers 3.6

cfm, whereas at the highest temperature (1200

degrees) the lowest airflow setting delivers 8.8 cfm

The air flow can be increased by pressing the

“+” side of the air flow button or decreased by

pushing the “–” side of the button. Brief

pressing of the button increases or decreases

the air flow by one step. Longer pressing of the

button increases or decreases the air flow

continuously until the maximum or minimum air

flow is reached.

Decrease the air flow when, for example:

The surroundings of the workpiece should not

be heated more than necessary. A light

workpiece could be blown away by the air

stream.

In programmed operation, air flow and

temperature settings can be stored in four

programs. In each program, any air flow and

temperature combination are possible.

Also in programmed operation, air flow and

temperature can be changed at any time. If the

changes are not stored through

reprogramming, they are lost when switching

the unit off or when changing to another

program.

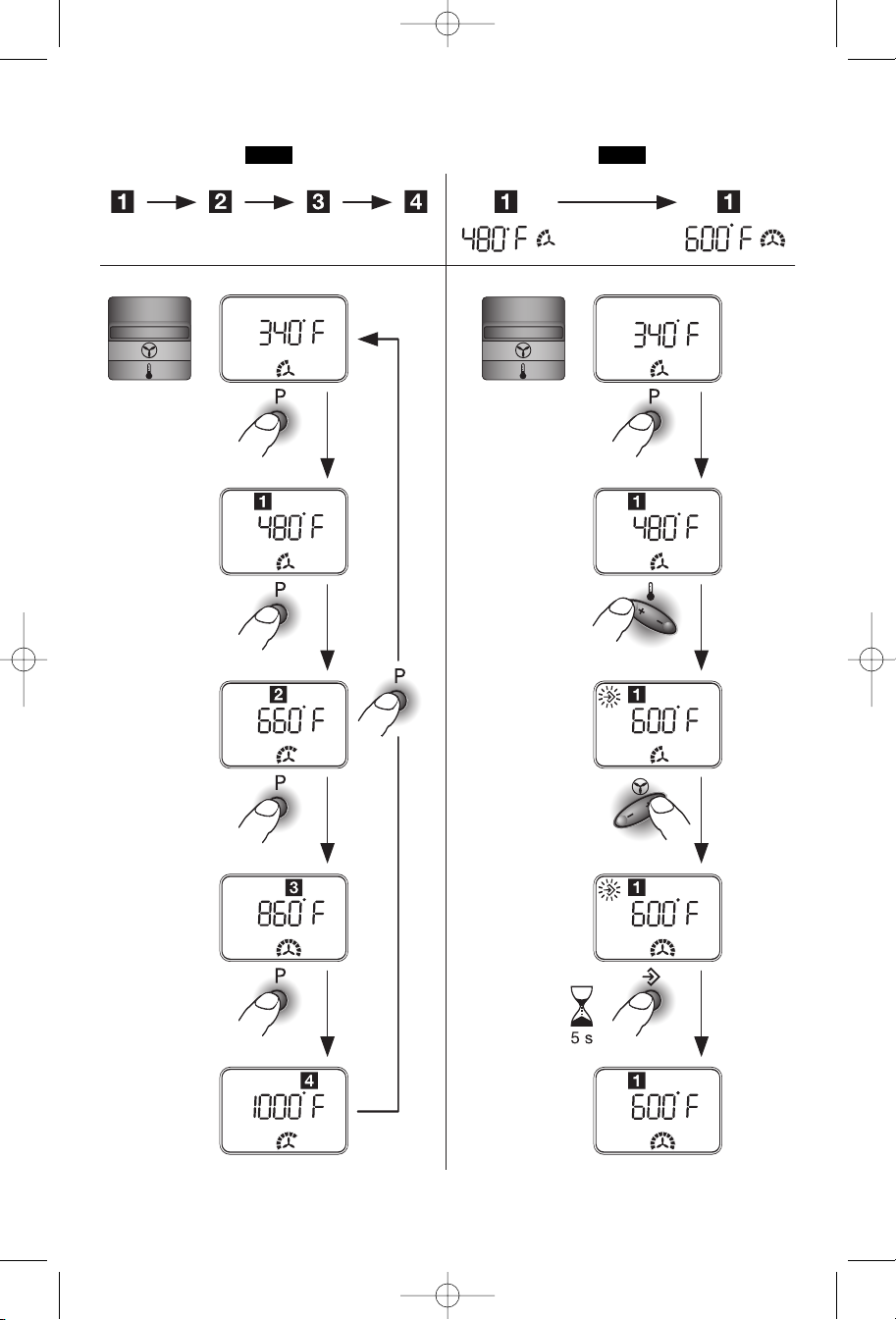

To use one of the pre-stored modes, press the

program selection button

of the required program ( , , or ) as

shown in the display (Fig. 2).

The unit is equipped with the following four prestored programs:

Program

SETTING THE AIR FLOW

Minimum air flow (approx. 3.6-8.8 CFM,

depending on temperature setting)

Maximum air flow (approx. 17.6 CFM)

PROGRAMMED OPERATION

“P” until the number

PRE-STORED PROGRAMS

Application

1 Shaping of plastic 480 °F

tubing (e.g. LDPE)

2 Welding of plastic 660 °F

(e.g. PVC)

3 Removing paint/ 860 °F

softening adhesives

4 Soldering 1000 °F

Temperature

Air

Flow

Press the program selection button “P” until

the number of the program to be

reprogrammed is shown in the display. Set the

required temperature and air flow (see figure 3).

As soon as the values of the program are

altered, the symbol blinks in the upper left of

t

he display.

After setting the required air flow and

temperature, press the store button (for about

5 seconds) until the symbol in the display

disappears. The values set are now stored

under the program number shown in the

display.

To change to normal operation, press the

program selection button

there is no longer a program number shown

over the temperature in the display.

The air flow and temperature can be changed

at any time.

The last set unprogramed values for the air flow

and temperature remain stored under the

following conditions:

– Move to program operation

– Move to the cool setting

– Switch-off the unit

REMOVING THE HEAT PROTECTOR

For working in especially narrow places, the

heat protector can be removed.

!

exists when working without the heat protector.

To remove or mount the heat protector, the unit

must be turned off and have cooled. To cool

unit down, run unit briefly in the cool air setting,

if necessary.

Turn the heat protector counter-clockwise to

remove, and clockwise to mount again.

For cooling of the heated unit or to have both

hands free for working, the unit can be set

down in the upright position on the stand legs

on the rear of the tool (Fig. 6).

!

There is danger of burning by the hot nozzle

and the hot air stream.

REPROGRAMMING

NORMAL OPERATION

WARNING

WARNING

Be careful of the hot nozzle!

Increased danger of burning

USING THE UNIT IN

STATIONARY POSITION

Be especially careful when

working with the upright unit!

“P” repeatedly until

-8-

Page 9

860 ˚F

860˚ ˚F

HDPE 560˚ F

PVC (hard) 560˚ F

PVC (soft) 740˚ F

PP 500˚ F

LDPE 480˚ F

ABS 660˚ F

BM 1619929572 11-06 11/8/06 8:51 AM Page 9

Typical Applications

Temperature settings given in the application

examples are suggested values that,

depending on the material characteristics, can

deviate. The distance between the nozzle and

workpiece is dependent on the material to be

processed.

The ideal temperature should first be

ascertained by performing a test. Therefore,

begin with a lower temperature setting.

All application examples (except figure 5) can

be performed without accessories. However,

the use of the recommended accessories

simplify the work and significantly improve the

quality of the results.

WARNING

!

Be careful when changing the

nozzle, danger of burning! Do

not touch the hot nozzle. Allow the unit to cool.

Wear protective gloves.

Bosch stocks a range of accessories (see

Bosch catalog) which facilitate a wide range of

other applications.

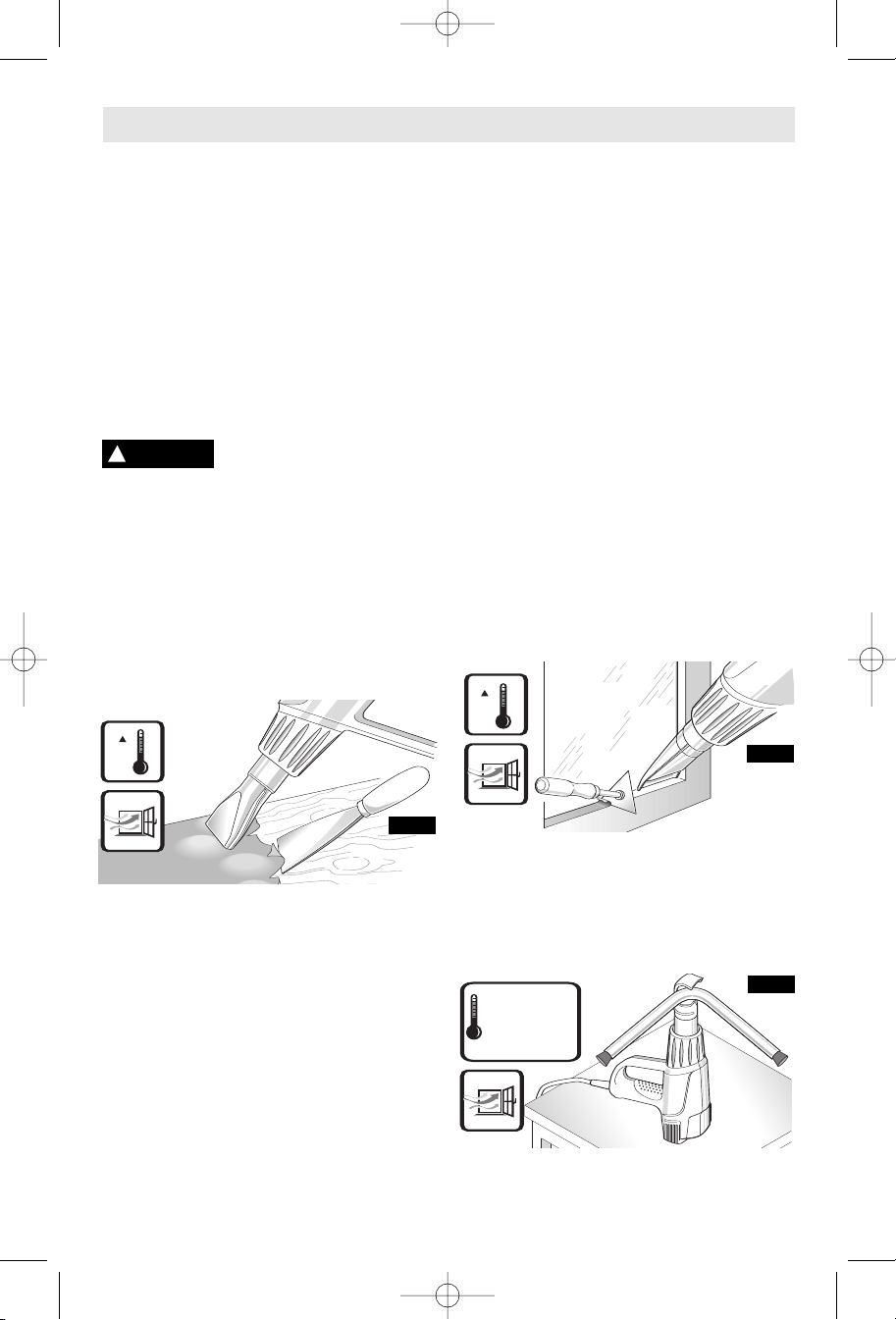

STRIPPING PAINT/SOFTENING ADHESIVES

Attach the optional HG010 spreader nozzle.

Soften the paint using hot air and remove

evenly using a spatula. Do not heat the paint for

too long since this will burn the paint, making it

more difficult to remove (Fig. 4).

2. As paint begins to blister and bubble, move

gun slowly in a steady progression across

the surface. Follow closely with a scraping

knife (a 2-inch wall scraper works best) to

scrape the loosened paint. Preheat scraper

as you are heating the paint surface. This

increases the speed of paint stripping.

a. Removal of paint by using heat is based

on the fact that all organic paints soften

at elevated temperatures. When soft, the

paint can be easily lifted off without

damage to the surface.

b. When stripping paint from grooves in

moldings, you can devise your own

scraping tools. Old screwdrivers with

ground-down blades and linoleum

knives are often used.

REMOVING PAINT FROM WINDOW

FRAMES

Danger

of glass breaking!

Use of the optional HG030 deflector nozzle is

essential.

On profiled surfaces, paint can be removed

using a spatula and brushed off using a soft

wire brush (Fig. 5).

FIG. 4

Many adhesives (e.g. stickers) become softer

when heated allowing adhesive bonds to be

separated or superfluous adhesive to be

removed.

1. To strip paint, turn unit on and hold it about

1 inch from the surface being stripped.

Proper distance and speed of stripping

should be determined by experience. It is

an advantage to hold the gun further from

the surface and to move forward slowly.

Slower speed is compensated by the wider

softened areas. Heat will also penetrate

deeper.

FIG. 5

SHAPING PLASTIC TUBING

Attach the optional HG040 reflector nozzle. To

avoid kinking the tubing, fill the tubing with sand

and seal at both ends (Fig. 6).

Heat the tubing evenly by moving it from side to

side.

FIG. 6

-9-

Page 10

FE 1000 ˚F

P

VC (hard) 560 ˚F

1000 ˚F

560˚ ˚F

BM 1619929572 11-06 11/8/06 8:51 AM Page 10

Attach the optional HG020 concentrator or

SHRINK TUBING

H

G040 reflector nozzle. Select the diameter of

t

he heat-shrink tubing according to the

workpiece, for example, a cable lug (Fig. 7).

Use stand to free both hands. Slide tubing

over area to be insulated. Place in air stream

and move with a side to side motion until

tubing has shrunk. Remove from air stream.

Heat the heat-shrinkable tubing evenly.

FIG. 7

DEFROSTING WATER PIPES

Water lines often do not differ in appearance

from gas lines. Gas lines are not to be heated

under any circumstances.

Attach the optional HG040 reflector nozzle.

Direct hot air stream at end of frozen part and

wave back and forth until part is defrosted or

thawed. Heat the frozen zone always from the

outside to the middle.

When warming plastic pipes or connections

between pipe pieces, be especially carefully to

p

revent damage (Fig. 8).

FIG. 8

SOFT SOLDERING

For point soldering, attach the optional HG020

concentrator nozzle. For soldering of pipes,

attach optional the reflector nozzle.

If solder without flux, apply soldering grease or

paste to the location to be soldered. Warm the

location to be soldered for 50–120 seconds on

the material. Apply the solder. Heat the

workpiece and allow it to melt the solder. Do

not heat the solder directly. After the soldered

location has cooled, remove the flux (Fig. 9).

FIG. 9

-10-

Page 11

BM 1619929572 11-06 11/8/06 8:51 AM Page 11

Maintenance

Service

WARNING

!

o

rized personnel may result in misplacing

of internal wires and components which

could cause serious hazard.

recommend that all tool service be performed

by a Bosch Factory Service Center or Authorized Bosch Service Station.

Preventive maintenance

p

erformed by unauth-

We

Cleaning

WARNING

!

the power supply before cleaning or

performing any maintenance.

be cleaned most effectively with compressed

dry air.

Always wear safety goggles when

cleaning tools with compressed air.

To avoid accidents always

disconnect the tool from

The tool may

Extension Cords

WARNING

!

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used.

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

If an extension cord is

necessary, a cord with

This will prevent

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

CLEANING THE AIR VENTS

Slide the covers containing the air vents to the

rear out of the housing. Blow out the air vents

(with compressed air for example) or clean with

a soft brush. Replace the covers.

CAUTION

!

plastic parts.

Certain cleaning agents

and solvents damage

Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household

detergents that contain ammonia.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet

50 100 150 15

25

18 16 16 14 0.75 0.75 1.5 2.5

16 14 12 0.75 1.0 2.5 4.0

18

18 16 14 12 0.75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

Wire Sizes in mm

Cord Length in Meters

30

2

60 120

(*= standard equipment)

(**= optional accessories)

* Case

Accessories

** Reflector

Concentrator

**

** Spreader

** Deflector

-

11

-

Page 12

BM 1619929572 11-06 11/8/06 8:51 AM Page 12

Important consignes de sécurité pour pistolets chauffants

!

VERTISSEMENT

A

et/ou de blessures graves.

Les murs, plafonds, planchers, cache-moineaux et autres panneaux peuvent dissimuler des matériaux

combustibles (poussière, toiles d’araignée, nids de souris, etc.) qui risquent de s’enflammer quand on travail

à proximité avec un pistolet thermique. Leur combustion n’est pas nécessairement évidente et risque de causer

des dégâts matériels et des blessures corporelles.

Quand on travail dans des endroits qui peuvent dissimuler des matériaux combustibles, il convient d’imprimer

au pistolet thermique un mouvement alternatif ininterrompu. S’attarder ou pauser sur un point particulier risque

d’enflammer le panneau ou le matériau se trouvant derrière lui.

Consignes de sécurité pour le décapage

!

AVERTISSEMENT

peinture. Les écailles, débris et vapeurs de peinture

peuvent contenir du plomb, lequel est un poison. Toute

peinture datant d’avant 1977 peut contenir du plomb et

toute peinture utilisée dans les habitations avant 1950

en contient probablement. Une fois la peinture déposée

sur des surfaces le contact main-bouche peut résulter

en une ingestion de plomb. L’exposition au plomb,

même en faible quantité, peut causer des lésions

irréversibles du cerveau et du système nerveux. Les

jeunes enfants et les fétus sont plus particulièrement

vulnérables. Avant de commencer tout travail de

décapage de peinture, vous devez déterminer si la

peinture que vous voulez décaper contient du plomb.

Ceci peut être effectué par votre service de santé local

ou par un professionnel muni d’un analyseur de

peinture qui lui permet de mesurer la teneur en plomb

de la peinture à décaper. LES PEINTURES AU PLOMB

DOIVENT ÊTRE DÉCAPÉES PAR DES

PROFESSIONNELS. L’UTILISATION DE PISTOLETS

CHAUFFANTS EST INTERDITE.

Les personnes qui décapent de la peinture doivent

suivre ces instructions :

1) Portez la pièce à décaper à l’extérieur. Si ce n’est

pas possible, ventilez bien la zone de travail. Ouvrez les

fenêtres et placez un ventilateur d’extraction dans l’une

d’elles. Assurez-vous que le ventilateur aspire l’air de la

pièce pour le rejeter à l’extérieur.

2) Enlevez ou couvrez tous les objets domestiques se

trouvant dans la zone, tels que moquettes, tapis,

meubles, vêtements, ustensiles de cuisine et

bouches d’aération.

3) Placez des toiles dans la zone de travail pour

récolter toutes les écailles et éclats de peintures.

Portez des vêtements de protection, par exemple une

chemise supplémentaire, une combinaison et une

casquette.

Vous devez lire et comprendre toutes les instructions. Le non-respect, même

partiel, des instructions ci-après entraîne un risque de choc életrique, d'incendie

4) Travaillez dans une pièce à la fois. Le mobilier doit

de la peinture

Il faut être très prudent

lorsqu’on décape de la

être enlevé ou placé au centre de la pièce et couvert.

Les zones de travail doivent être isolées du reste de

l’habitation en obturant les ouvertures de porte avec

des toiles.

5) Les enfants, les femmes enceintes ou pouvant

l’être et les mères qui allaitent ne doivent pas se

trouver dans la zone de travail tant que le travail

n’est pas terminé et que tout a été complètement

nettoyé.

6) Portez un masque anti-poussière ou un masque à

double filtre (poussière et fumées) homologué par

l’OSHA (Occupational Safety and Health

Administration – Bureau de l’hygiène du travail) ou le

NIOSH (National Institute of Safety and Health –

Institut National de la Santé et de la Sécurité), ou par

le Service des Mines des États-Unis. On peut se

procurer facilement ces masques et filtres

interchangeables dans les grandes quincailleries.

Assurez-vous que le masque est bien ajusté. La barbe

ou les poils peuvent affecter l’étanchéité du masque.

Changez souvent de filtre. LES MASQUES EN PAPIER

JETABLES SONT INSUFFISANTS.

7) Agissez avec prudence quand vous utilisez le

pistolet thermique. Déplacez le pistolet thermique

sans arrêt car la chaleur excessive génère des vapeurs

qui risquent d’être inhalées par l’utilisateur.

8) N’apportez ni aliments, ni boisson dans la zone de

travail. Lavez-vous les mains, les bras et le visage et

rincez-vous la bouche avant de manger ou de boire. Ne

fumez pas, ne mâchez ni gomme, ni tabac dans la zone

de travail.

9) Nettoyez toute la peinture décapée et la poussière

en passant un balai humide sur le sol. Nettoyez tous

les murs, appuis de fenêtre et toute autre surface sur

lesquels colle la peinture ou la poussière à l’aide d’un

chiffon humide. NE BALAYEZ PAS, N’ÉPOUSSETEZ

PAS ET NE PASSEZ PAS L’ASPIRATEUR. Utilisez un

détergent à haute teneur en phosphate ou de

phosphate trisodique pour laver ou nettoyer la zone de

travail.

-12-

Page 13

BM 1619929572 11-06 11/8/06 8:51 AM Page 13

10) À la fin de chaque session de travail, placez les

éclats de peinture et les débris dans un sac en

plastique double, fermez-le avec du ruban adhésif ou

une attache en fil de fer et débarrassez-vous en

correctement.

11) Enlevez vos vêtements de protection et vos

chaussures de travail dans la zone de travail pour

éviter d’emmener de la poussière dans le reste de

l’habitation. Lavez les vêtements de travail

séparément. Essuyez vos chaussures avec un torchon

mouillé qui devra ensuite être lavé avec les vêtements

de travail. Lavez-vous les cheveux et le corps

soigneusement avec de l’eau savonneuse.

AVERTISSEMENT

!

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

Les travaux à la machine

tel que ponçage, sciage,

CONSERVEZ CES INSTRUCTIONS

Consignes générales de sécurité aux pistolets thermiques

DANGER

!

Vous risquez des blessures graves.

Évitez de toucher la buse du pistolet thermique

pendant l’utilisation. Ce pistolet thermique génère des

températures pouvant atteindre 1000 degrés

Fahrenheit. Vous risquez des brûlures graves.

N’utilisez pas le pistolet thermique sous la pluie ou à

l’humidité. Ne l’immergez pas dans l’eau.

L’exposition de l’élément chauffant à l’eau ou à d’autres

liquides peut présenter un risque de choc électrique.

N’utilisez pas de pistolet thermique dans des

endroits où pourraient se trouver ou pourraient être

entreposés des gaz ou liquides inflammables. Le

pistolet thermique produit des températures

importantes qui risquent de les enflammer.

Gardez votre zone de travail propre et bien éclairée.

Les endroits encombrés et sombres facilitent les

accidents.

N’utilisez pas l’appareil chauffant dans des

atmosphères explosives, notamment en présence de

poussière, gaz ou liquides inflammables, herbe

sèche, feuilles et papier. Les appareils chauffants

génèrent des températures élevées susceptibles

d’enflammer la poussière ou les fumées. Les matières

combustibles telles que l’herbe sèche, les feuilles et le

papier roussiront et peuvent s’enflammer.

Tenez les spectateurs, les enfants et les visiteurs à

distance durant l’utilisation d’un appareil chauffant.

Les distractions peuvent vous faire perdre le contrôle.

N’utilisez jamais de pistolet

thermique comme sèche-cheveux !

Zone de travail

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

Sécurité électrique

Avant de brancher l’appareil chauffant, assurez-vous

que la tension à la prise est compatible avec la

tension indiquée sur la plaque signalétique dans une

marge de 10 %. L’incompatibilité de la tension à la

prise avec celle précisée sur la plaque signalétique peut

créer des risques importants et abîmer l’appareil

chauffant.

Lorsque vous faites fonctionner un appareil chauffant,

utilisez un disjoncteur de fuite à la terre sur le circuit

ou la prise. N’exposez pas l’appareil chauffant à la

pluie ou à l’humidité. L’eau pénétrant dans un appareil

chauffant provoquera un risque de secousses

électriques.

Ne faites pas un usage abusif du cordon. N’utilisez

jamais le cordon pour transporter l’appareil chauffant

et ne tirez pas le cordon de la prise. Tenez le cordon à

l’écart de la chaleur, de l’huile, des arêtes vives ou

des pièces en mouvement. Remplacez les cordons

abîmés immédiatement. Les cordons abîmés créent

un risque de secousses électriques.

Lorsque vous faites fonctionner un appareil chauffant

à l’extérieur avec un cordon de rallonge, utilisez

uniquement les cordons de rallonge marqués W-A ou

W. Ces cordons sont prévus pour usage extérieur et

réduisent le risque de secousses électriques.

Sécurité personnelle

Demeurez vigilant, regardez ce que vous faites et

faites preuve de BON SENS lorsque vous utilisez un

appareil chauffant. Un moment d’inattention ou la

consommation de drogues, d’alcool ou de médicaments

-13-

Page 14

BM 1619929572 11-06 11/8/06 8:51 AM Page 14

alors que vous utilisez un appareil chauffant peut être

dangereux.

Utilisez du matériel de sécurité. Portez toujours des

lunettes à coques latérales. Un masque anti-

poussières, des gants protecteurs, des chaussures de

sécurité ou des chaussures antidérapantes doivent être

portés dans les conditions appropriées.

Évitez la mise en marche accidentelle. Assurez-vous

que l’interrupteur est en position d’arrêt « OFF » avant

de brancher l’appareil. Pour éviter les accidents, ne

transportez pas l’appareil chauffant avec votre doigt sur

l’interrupteur et ne branchez pas l’appareil chauffant si

son interrupteur est en position de marche « ON ».

Ne dirigez pas la buse ou l’embout chaud vers les

vêtements, les mains ou autres parties du corps. La

chaleur intense qui se dégage de l’embout ou de la buse

peut provoquer des brûlures graves ou enflammer les

vêtements.

Ne touchez pas la buse ou le protecteur jusqu’à ce

qu’ils aient complètement refroidi. Des températures

très élevées sont produites dans ces parties durant

l’usage.

Habillez-vous adéquatement. Ne portez pas de bijoux

et de vêtements lâches. Contenez les cheveux longs

dans un serre-tête. Gardez vos cheveux, corps,

vêtements et gants à l’écart de la buse et du

protecteur. La chaleur extrême peut enflammer les

vêtements ou les cheveux.

Ne tentez pas d’aller trop loin, tenez-vous bien

d’aplomb et en équilibre à tout moment, ce qui vous

permettra de mieux contrôler l’appareil chauffant dans

des situations imprévues.

Utilisation et entretien de l’outil

N’utilisez pas l’appareil chauffant si l’interrupteur ne

le met pas en marche « ON » ou à l’arrêt « OFF ».

Tout outil qui ne peut être commandé par l’interrupteur

est dangereux.

Débranchez la fiche de la prise de courant avant

d’effectuer tout réglage ou de changer les

accessoires. Ces mesures préventives réduisent le

risque d’une mise en marche accidentelle de l’appareil

chauffant.

Rangez l’appareil chauffant qui n’est plus utilisé,

uniquement après une période adéquate de

refroidissement, à l’intérieur, à un endroit élevé et

sec, hors de la portée des enfants et des personnes

n’ayant pas été formées quant à son usage. Les

appareils chauffants sont dangereux dans les mains des

personnes qui n’ont pas appris à les utiliser.

Ne laissez pas l’appareil chauffant sans surveillance

alors qu’il est en marche ou qu’il refroidit. Posez

toujours l’appareil sur une surface plate et à niveau de

manière à ce que le bout de la buse soit dirigé vers le

haut, à l’écart de la surface d’appui pendant que

l’appareil est en marche ou qu’il refroidit.

Gardez un extincteur pleinement chargé à portée de

la main en cas d’urgence.

Réparations

L’appareil chauffant ne doit être réparé que par des

techniciens de réparation habilités à ce faire. Les

réparations ou la maintenance effectuées par des

personnes non habilitées peuvent entraîner un

positionnement erroné des composants ou des fils

internes, et donc des risques graves.

Pour réparer un appareil chauffant, n’utilisez que des

pièces de rechange identiques. Suivez les consignes

contenues dans la section Entretien de ce manuel.

L’utilisation de pièces non autorisées ou le non-respect

des consignes d’entretien peut présenter un danger.

Double isolation

La double isolation est utilisée dans les outils électriques pour éliminer le besoin de cordon d’alimentation

avec prise de terre et de dispositif d’alimentation à prise

de terre. Elle est homologuée par l’Underwriter’s

Laboratories, l’ACNOR et l’OSHA.

IMPORTANT : L’entretien d’un outil à double isolation

exige la connaisance du système et la compétence d’un

technicien qualifié.

EN CAS D’ENTRETIEN, N’UTILISEZ QUE DES PIÈCES DE

RECHANGE IDENTIQUES.

Les appareils chauffants à double isolation sont équipés

d’une fiche polarisée (une lame est plus large que

l’autre). Cette fiche peut être insérée dans une prise

polarisée d’une seule façon. Si la fiche ne s’insère pas à

fond dans la prise, la fiche doit être inversée. Si elle ne

s’insère toujours pas à fond, mettez-vous en contact

avec un électricien habilité pour faire poser une prise

polarisée. Ne modifiez la fiche d’aucune manière.

-14-

Page 15

BM 1619929572 11-06 11/8/06 8:51 AM Page 15

Description fonctionnelle et spécifications

!

VERTISSEMENT

A

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

Pistolet thermique

PIEDS DE SUPPORT

ÉVENTS DE

CIRCULATION

DE L'AIR

BOUTON DE MISE

EN MÉMOIRE

INTERRUPTEUR/SÉLECTEUR

ARRÊT/FROID-CHAUD

CACHE DE PROTECTION

DES ÉVENTS D'AIR

ÉCRAN D'AFFICHAGE

BOUTON DE RÉGLAGE DU DÉBIT D'AIR

BOUTON DE RÉGLAGE DE LA

TEMPÉRATURE

BOUTON DE

SÉLECTION DE

PROGRAMME

FIG. 1

INTERRUPTEUR/SÉLECTEUR

ARRÊT/FROID-CHAUD

BUSE

Numéro de modèle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions longueur 20 cm x largeur 13 cm x hauteur 24 cm

Diamètre de la buse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Débit moyen (volume) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3,6-17,6 cfm

Poids net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,2lbs)

Tension nominale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V 60 Hz

Intensité nominale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13A

Plage de Températures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120 ºF -1200 ºF

GAINE

CALORIFUGE

(8 po x 5-1/4 po x 9-1/2 po)

PIED DE SUPPORT

1944LCD

3 cm (1-3/16 po)

-15-

Page 16

BM 1619929572 11-06 11/8/06 8:51 AM Page 16

FIG. 2

FIG. 3

-16-

Page 17

BM 1619929572 11-06 11/8/06 8:51 AM Page 17

Consignes de fonctionnement

Votre pistolet thermique Bosch est un pistolet à air chaud

polyvalent de capacité élevée et de qualité industrielle.

Sa puissance et son débit élevés vous permettront

d’accomplir plus rapidement vos travaux à chaud.

Cet appareil émet un flux rapide d’air chaud pouvant

servir à activer les adhésifs, plier et façonner les

matières plastiques, sécher les résines époxydes,

ébavurer les plastiques, dégivrer les bobines gelées,

sécher les négatifs et autres pièces, chauffer les solides

et les liquides, desserrer les écrous et les boulons,

enlever les dalles de carrelage et le mastic de soutien

de vitres, réparer les vinyles, rétrécir les tubes isolants

et les films d’emballage, ramollir les matières dures et

décaper les surfaces peintes.

La quantité adéquate de chaleur pour chaque

application dépend de la distance entre l'orifice de la

buse et la surface de travail, ainsi que de la durée

d'exposition de la surface de travail à la chaleur.

Nous vous recommandons, avant chaque type

d’application, d’essayer l’appareil sur une pièce de

rebut. Approchez prudemment l’appareil de la surface

jusqu’à obtention de la combinaison adéquate

d’ouverture du volet, de distance et de durée

d’expostion.

À moins qu’une concentration de chaleur ne soit

souhaitable, déplacez constamment toujours l’appareil

d’un mouvement de va-et-vient doux.

INTERRUPTEUR/SÉLECTEUR ARRÊT/FROID-CHAUD

Pour mettre le pistolet en service, faites glisser

l'interrupteur/sélecteur en position (réglage d'air

froid) ou (réglage d'air chaud).

Dans chacune de ces positions, le pistolet se

déclenche avec les valeurs de débit d'air et de

température qui avaient été réglées avant la dernière

mise à l'arrêt du pistolet.

Pour mettre le pistolet en position d'arrêt, faites

glisser l'interrupteur/sélecteur en position d'arrêt O.

Lorsque vous avez travaillé pendant une période

prolongée à haute température, laissez le pistolet

refroidir en le faisant fonctionner quelques instants en

position de réglage d'air froid avant de le mettre en

position d'arrêt (Fig. 1).

Quand le pistolet thermique est utilisé dans un espace

clos, comme un tunnel de rétraction ou une enceinte

spéciale, il est nécessaire que de l'air ambiant puisse

être introduit à l'intérieur du pistolet thermique, et il

faut qu'il existe un orifice de taille équivalente pour

permettre à l'air chauffé de sortir de l'espace clos.

L'absence totale de circulation d'air vers l'intérieur et

vers l'extérieur d'un tel espace endommagera le

pistolet thermique et risque même de provoquer sa

défaillance en raison de la chaleur extrême qui s'y

accumulera.

RÉGLAGE D'AIR FROID

Le débit d'air peut être contrôlé, mais la

température est fixée à 120 °F (cette valeur

ne peut pas être changée), et aucune

opération programmée n'est possible.

Le réglage d'air froid est approprié pour refroidir une

pièce en cours d'usinage chauffée ou pour le séchage

de surfaces venant d'être peintes. Il est également

utilisé pour refroidir le pistolet avant de le poser sur

une surface quelconque ou de changer la buse.

Lors du passage du réglage d'air chaud à

température élevée au réglage d'air froid , une courte

période de transition est nécessaire pour refroidir le

pistolet jusqu'à une température de 120 °C. Pendant

cette période de refroidissement, la température réelle à

la sortie de la buse est indiquée sur le tableau

d'affichage (Fig. 1).

Lors du passage du réglage d'air chaud au réglage

d'air froid , le réglage du débit d'air actif à ce moment

est utilisé.

RÉGLAGE D'AIR CHAUD

Le débit d'air et la température peuvent

être contrôlés. Un fonctionnement normal

ou programmé est possible. Pour les

applications, se reporter à la rubrique

Applications types. Lors du passage du réglage d'air

froid au réglage d'air chaud , le débit d'air, la

température, le mode de fonctionnement et le

programme reprennent les valeurs qui étaient

employées la dernière fois que le réglage d'air chaud

avait été utilisé.

RÉGLAGE DE LA TEMPÉRATURE

La température du réglage d'air chaud peut être

modifiée (Fig. 2).

Pour passer à une autre température, il faut laisser le

pistolet réchauffer ou refroidir le flux d'air, suivant le

cas, quelques instants pour atteindre la température

désirée. Celle-ci est indiquée sur l'écran d'affichage

avec des flèches clignotantes pendant ce temps.

Lorsque l'air aura atteint la température requise, les

flèches clignotantes disparaîtront et l'écran

affichera la température réelle.

La température désirée peut être augmentée par

incréments de 10 °F en appuyant sur le côté « + » du

bouton de réglage de la température ou réduite en

appuyant sur le côté « - » du bouton. Si vous appuyez

brièvement sur le bouton, vous augmenterez ou

réduirez ponctuellement la température désirée de 10

°F. Si vous maintenez le bouton enfoncé plus

longtemps, vous augmenterez ou réduirez la

température à multiples reprises par incréments de 10

°F jusqu'à ce que le bouton soit relâché ou jusqu'à ce

que la température minimum ou maximum soit

atteinte.

-17-

Page 18

BM 1619929572 11-06 11/8/06 8:51 AM Page 18

Le débit d'air peut être contrôlé au moyen du bouton de

réglage du débit d'air (Fig. 1).

Le débit d'air à chacun des 10 réglages de débit d'air

dépend du réglage de la température. Par exemple, à la

température la plus basse (120 degrés F), le réglage de

débit d'air le plus bas produit 3,6 pi cu/mn, tandis qu'à

la température la plus élevée (1 200 degrés F), le

réglage de débit d'air le plus bas produit 8,8 pi cu/mn.

Le débit d'air peut être augmenté en appuyant sur le

côté « + » du bouton de réglage du débit d'air ou réduit

en appuyant sur le côté « - » du bouton. Si vous

appuyez brièvement sur le bouton, vous augmenterez

ou réduirez ponctuellement le débit d'air d'un

incrément. Si vous maintenez le bouton enfoncé plus

longtemps, vous augmenterez ou réduirez le débit d’air

à multiples reprises jusqu'à ce que le débit d'air

minimum ou maximum soit atteint.

Réduisez le débit d'air quand, par exemple :

L'air ambiant de la pièce sur laquelle vous travaillez ne

doit pas être chauffé plus que le strict nécessaire. Une

pièce légère risque d'être déplacée par le flux d'air si le

débit est élevé.

Lors d'un fonctionnement programmé, les paramètres

de réglage de la température et du débit d'air peuvent

être mis en mémoire dans quatre programmes. Il est

possible de régler une combinaison quelconque de

débit d'air et de température dans chaque programme.

Également lors d'un fonctionnement programmé, il est

possible de changer à n'importe quel moment le débit

d'air et la température. Si les changements ne sont pas

mis en mémoire par une nouvelle programmation, ils

sont perdus lorsque le pistolet est mis en position

d'arrêt ou lorsque vous passez à un autre programme.

Pour utiliser l'un des modes mis en mémoire, appuyez

sur le bouton de sélection de programme

« P » et continuez à appuyer jusqu'à ce que le numéro

du programme désiré ( ou ) soit affiché sur

l'écran (Fig. 2).

Le pistolet est livré avec les quatre programmes

pré-enregistrés suivants :

Programme

1

2 Soudage de plastique 660 °F

3 Décapage/

4 Brasage 1 000 °F

RÉGLAGE DU DÉBIT D'AIR

Débit d'air minimum (approx. 3,6-8,8 pi cu/mn en

fonction du réglage de température)

Débit d'air maximum (approx. 17,6 pi cu/mn)

FONCTIONNEMENT PROGRAMMÉ

PROGRAMMES PRÉ-ENREGISTRÉS

Application

Façonnage de tubes 480°F

en plastique

(p. ex., PE-BD)

(p. ex., PCV)

ramollissement

de peinture/d'adhésifs

Température

860

Débit

d'air

F

°

-18-

CHANGEMENT DE LA PROGRAMMATION

Appuyez sur le bouton de sélection de programme

« P » jusqu'à ce que le numéro du programme à

changer soit affiché sur l'écran. Réglez la température

et le débit désirés (cf. Fig. 3). Dès que les valeurs du

programme sont modifiées, le symbole clignote

dans le coin supérieur gauche de l'écran.

Après avoir réglé les valeurs désirées pour le débit d'air

et la température, appuyez sur le bouton de mise en

mémoire pendant environ 5 secondes jusqu'à ce que

le symbole disparaisse de l'écran. Les valeurs ainsi

réglées sont désormais mises en mémoire sous le

numéro de programme indiqué sur l'écran.

Pour passer en mode de fonctionnement normal,

appuyez sur le bouton de sélection de programme « P »

à plusieurs reprises, jusqu'à ce qu'il n'y ait plus de

numéro de programme affiché au-dessus de la

température sur l'écran.

Les valeurs de débit d'air et de température peuvent

être changées n'importe quand.

Les dernières valeurs non programmées qui ont été

fixées pour le débit d'air et la température restent en

mémoire dans les conditions suivantes :

- Passage au mode de fonctionnement programmé

- Passage au mode de réglage froid

- Mise du pistolet en position d'arrêt

La gaine calorifuge peut être retirée si vous avez besoin

de travailler dans des espaces particulièrement étroits.

!

brûler est plus élevé si vous travaillez sans la gaine

calorifuge en place.

Pour monter ou démonter la gaine calorifuge, mettez le

pistolet en position d'arrêt et laissez-le refroidir. Pour

accélérer le refroidissement du pistolet, faites-le

fonctionner quelques instants en position de réglage

d'air froid si nécessaire.

Faites tourner la gaine calorifuge dans le sens contraire

des aiguilles d'une montre pour la retirer ou dans le

sens des aiguilles d'une monter pour la mettre en

place.

Il est possible de placer le pistolet à plat en position

verticale sur les pieds de support situés à l'arrière de

l'outil si vous voulez le laissez refroidir ou si vous

désirez avoir les mains libres pour travailler (Fig. 6).

!

travaillez avec le pistolet à plat en position verticale !

Vous risquez de vous brûler en raison de l'air chaud

sortant de la buse, ou en touchant la buse chaude

elle-même.

FONCTIONNEMENT NORMAL

RETRAIT DE LA GAINE CALORIFUGE

AVERTISSEMENT

UTILISATION DU PISTOLET EN POSITION FIXE

AVERTISSEMENT

Ne touchez pas la buse

chaude ! Le risque de se

Faites particulièrement

attention lorsque vous

Page 19

860 ˚F

860˚ ˚F

PE-HD 560˚ F

PCV (dur) 560˚ F

PCV (doux) 740˚ F

PP 500˚ F

PE-BD 480˚ F

ABS 660˚ F

BM 1619929572 11-06 11/8/06 8:51 AM Page 19

Applications types

Les réglages de températures présentés dans les

exemples d'applications ne sont que des suggestions

de valeurs. Les réglages peuvent varier en fonction des

circonstances matérielles. La distance idéale entre la

buse et la pièce à travailler dépend du matériau en

cours d'usinage.

Faites un test pour déterminer la température idéale.

Commencez par conséquent avec un réglage de

température assez bas.

Tous les exemples d'applications (à l'exception de la

Figure 5) peuvent être exécutés sans accessoires.

Toutefois, l'emploi des accessoires recommandés

simplifie le travail et améliore substantiellement la

qualité des résultats.

!

AVERTISSEMENT

Faites attention lorsque vous

changez la buse car vous

risquez de vous brûler ! Ne touchez pas la buse

chaude. Laissez le pistolet refroidir. Portez des gants de

protection.

Bosch offre toute une gamme d'accessoires (cf.

catalogue Bosch) qui facilitent un grand nombre

d'autres applications.

DÉCAPAGE/RAMOLLISSEMENT DE

PEINTURE/D'ADHÉSIFS

Attachez la buse d'épandage en option HG010.

Ramollissez la peinture en utilisant de l'air chaud, et

retirez-la uniformément avec une spatule. Ne chauffez

pas trop longtemps la peinture car cela la calcinerait, ce

qui compliquerait la tâche de décapage (Fig. 4).

2. Lorsque la peinture commence à se boursoufler et à

former des bulles, déplacez lentement et

uniformément le pistolet par-dessus la surface, et

commencez immédiatement à décaper avec un

grattoir (un grattoir de 50 mm (2”) assure les

meilleurs résultats) pour éliminer la peinture décollée.

Préchauffez le grattoir tout en chauffant la surface

peinte pour accélérer le décapage.

a. Le décapage à l’air chaud est rendu possible grâce

au ramolissement des peintures organiques sous

l’effet de températures élevées. Une fois ramollie, la

peinture peut être aisément soulevée, sans abîmer la

surface qu’elle recouvrait..

b. Pour décaper les rainures de moulures, vous pouvez

créer vos propres grattoirs. Les vieux tournevis à

tête émoulue et les couteaux à linoléum sont souvent

utiles.

DÉCAPAGE DE PEINTURE SUR DES

DORMANTS DE FENÊTRE

Danger : risque de cassage de carreaux !

Il est essentiel d'utiliser la buse à déflecteur en option

HG030.

Sur les surfaces profilées, la peinture peut être retirée

en utilisant une spatule et une brosse métallique douce

(Fig. 5).

FIG. 4

De nombreux adhésifs (p. ex., autocollants) se

ramollissent quand ils sont chauffés, ce qui permet de

les détacher de la surface à laquelle ils adhéraient ou

d'amincir la couche d'adhésif si besoin est.

1. Pour décaper une surface peinte, allumez l’appareil

et tenez-le à environ 25 mm (1 po) de la surface à

décaper. L’expérience vous aidera à déterminer la

distance et la vitesse de décapage adéquates. Il est

préférable de maintenir le pistolet à une certaine

distance de la surface et de l’en approcher

lentement. Le ralentissement de la vitesse sera

compensé par la largeur accrue de la surface

ramollie. La chaleur pénétrera également plus en

profondeur.

FIG. 5

FAÇONNAGE DE TUBES EN PLASTIQUE

Attachez la buse à réflecteur en option HG040.

Remplissez le tube de sable et fermez-le aux deux

extrémités pour éviter tout risque de pliure (Fig. 6).

Chauffez uniformément le tube en le déplaçant

latéralement à plusieurs reprises.

FIG. 6

-19-

Page 20

F

E 1000 ˚F

PVC (hard) 560 ˚F

1000 ˚F

5

60˚ ˚F

BM 1619929572 11-06 11/8/06 8:51 AM Page 20

Attachez le concentrateur HG020 ou la buse à réflecteur

TUBES THERMORÉTRÉCISSABLES

en option HG040. Sélectionnez le diamètre de tube

thermorétrécissable désiré en fonction de la pièce sur

laquelle vous travaillez – par exemple, une cosse de

câble de batterie (Fig. 7).

Posez l’appareil sur son support afin de garder les deux

mains libres. Glissez le tube sur la zone à isoler. Placez-le

au-dessus du flux d’air chaud et déplacez-le d’un

mouvement latéral constant jusqu’à ce qu’il se rétracte.

Retirez-le du flux d’air chaud.

Chauffez uniformément le tube thermorétrécissable.

FIG. 7

DÉGIVRAGE DE CONDUITES D'EAU

Les conduites d'eau ressemblent souvent à des

canalisations de gaz. Il ne faut en aucun cas réchauffer

des canalisations de gaz.

Attachez la buse à réflecteur en option HG040. Dirigez

un jet d'air chaud à l'extrémité de la partie givrée et

balayez ce jet d'un mouvement de va et vient sur cette

partie de la conduite jusqu'à ce qu'elle soit dégivrée ou

dégelée. Réchauffez toujours la zone gelée depuis

l'extérieur en direction du milieu.

Faites particulièrement attention de ne pas endommager

des tuyaux ou des raccords en plastique entre deux

conduites d'eau lorsque vous les réchauffez (Fig. 8).

FIG. 8

BRASAGE TENDRE

Pour le brasage par points, attachez la buse à

concentrateur en option HG020. Pour le brasage de

conduites, attachez la buse à réflecteur en option.

Si vous brasez sans flux, appliquez de la graisse ou

pâte à souder à l'endroit désiré. Chauffez pendant 50 à

120 secondes l'endroit à souder sur le matériau.

Appliquez le métal d'apport de brasage. Chauffez la

pièce et attendez que le métal d'apport y adhère. Ne

chauffez pas directement le métal d'apport. Retirez le

flux une fois que la zone soudée aura refroidi (Fig. 9).

FIG. 9

-20-

Page 21

BM 1619929572 11-06 11/8/06 8:51 AM Page 21

Entretien

Service

!

AVERTISSEMENT

personnels non autorisés peut résulter en mauvais

placement de fils internes ou de pièces, ce qui peut

présenter un danger grave. Nous vous conseillons de

faire faire tout l’entretien par un centre de service

d’usine Bosch ou une station service agréée Bosch.

Tout entretien préventif

effectué par des

Nettoyage

!

AVERTISSEMENT

l’outil avant de le nettoyer ou de l’entretenir. Le

meilleur moyen de nettoyer l’outil est d’utiliser de l’air

comprimé sec. Il faut toujours porter des lunettes de

protection quand on utilise de l’air comprimé.

Pour éviter les accidents,

il faut toujours débrancher

Cordons de rallonge

!

AVERTISSEMENT

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

REMARQUE : Plus le calibre est petit, plus le fil est gros.

Si un cordon de rallonge

s'avère nécessaire, vous

Les ouïes de ventilation et les leviers de l’interrupteur

doivent rester propres et exempts de corps étrangers.

Ne tentez pas de les nettoyer en enfonçant des objets

pointus dans les orifices.

NETTOYAGE DES ÉVENTS DE CIRCULATION DE L'AIR

Faites glisser les caches de protection des évents à

l'arrière pour les retirer complètement. Soufflez les

évents de circulation de l'air (avec de l'air comprimé,

par exemple), ou nettoyez-les avec une brosse douce.

Remettez les caches à leur place.

!

MISE EN GARDE

Certains agents de

nettoyages et certains

dissolvants abîment les pièces en plastique. Parmi

ceux-ci se trouvent: l’essence, le tétrachlorure de

carbone, les dissolvants de nettoyage chlorés,

l’ammoniaque ainsi que les détergents domestiques

qui en contiennent.

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

Intensité

nominale

de l’outil

3-6

6-8

8-10

10-12

12-16

Calibre A.W.G.

Longueur en pieds

25 50 100 150 15 30 60 120

18 16 16 14 0,75 0,75 1,5 2,5

18 16

18

16 16 14 12 1,0 2,5 4,0 —

14

14 12 0,75 1,0 2,5 4,0

14 12 0,75 1,0 2,5 4,0

16

—— ————

12

Calibre en mm

Longueur en mètres

2

(* = équipement de série)

(** = accessoires optionnels)

* Étui

** Réflecteur

Accessoires

** Concentrateur

** Épandeur

** Déflecteur

-21-

Page 22

BM 1619929572 11-06 11/8/06 8:51 AM Page 22

Importante instrucciones de seguridad para pistolas de aire caliente

!

DVERTENCIA

A

personales graves.

Las áreas ocultas, por ejemplo detrás de paredes, techos, pisos, tableros de sofito y otros paneles, pueden

contener materiales inflamables (polvo, telarañas, ratoneras, etc.) que podrían ser incendiados por la pistola de

aire caliente al trabajar en estas ubicaciones. Es posible que la ignición de estos materiales no sea claramente

evidente y dicha ignición podría causar daños a la propiedad y lesiones a las personas.

Cuando trabaje en ubicaciones que puedan tener áreas ocultas, mantenga la pistola de aire caliente moviéndose

de manera que describa un movimiento hacia atrás y hacia delante. Quedarse sobre un punto localizado o pausar

sobre él podría incendiar el panel o el material que esté detrás de él.

Instrucciones de seguridad para

!

ADVERTENCIA

descascarillados, los residuos y los vapores de pintura

pueden contener plomo, el cual es venenoso. Todas las

pinturas de antes de 1977 pueden contener plomo y es

probable que la pintura aplicada a las casas antes de

1950 contenga plomo. Una vez que se haya depositado

en las superficies, el contacto de la mano con la boca

puede causar la ingestión de plomo. La exposición a

niveles de plomo incluso más bajos puede causar daños

irreversibles en el cerebro y el sistema nervioso central;

los niños pequeños y que aún no hayan nacido son

especialmente vulnerables. Antes de comenzar cualquier

proceso de remoción de pintura, se debe determinar si la

pintura que se va a quitar contiene plomo. Esto lo puede

hacer el departamento de salud local o un profesional

que use un analizador de pintura para comprobar el

contenido de plomo de la pintura que se vaya a quitar.

LA PINTURA A BASE DE PLOMO DEBE QUITARLA

SOLAMENTE UN PROFESIONAL Y NO SE DEBE QUITAR

USANDO UNA PISTOLA DE AIRE CALIENTE.

Las personas que quiten pintura deben seguir estas

directrices:

1) Lleve la pieza de trabajo a un lugar al aire libre. Si

esto no es posible, mantenga bien ventilada el área de

trabajo. Abra las ventanas y ponga un ventilador de

extracción en una de ellas. Asegúrese de que el

ventilador esté moviendo el aire de dentro a fuera del

área.

2) Quite o cubra todos los objetos domésticos que

estén en el área, como alfombras, alfombrillas,

muebles, ropa, utensilios de cocinar y conductos de

aire.

3) Coloque telas protectoras suspendidas en el área

de trabajo para atrapar todas las virutas o los

descascarillados de pintura. Use ropa protectora, por

ejemplo camisas de trabajo adicionales, overoles y

sombreros.

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

4) Trabaje en un cuarto a la vez. El mobiliario debe

la remoción de pintura

Debe tenerse sumo cuidado al

quitar pintura. Los

retirarse o ponerse en el centro del cuarto y cubrirse. Las

áreas de trabajo deben sellarse del resto de la vivienda

sellando los claros de puerta con telas protectoras

suspendidas.

5) Los niños, las mujeres embarazadas o

potencialmente embarazadas y las madres lactantes

no deben estar presentes en el área de trabajo hasta

que se haya realizado el trabajo y se haya completado

toda la limpieza.

6) Use una máscara respiradora antipolvo o una

máscara respiradora con filtro doble (para polvo y

vapores) que haya sido aprobada por la

Administración de Seguridad y Salud Laboral (OSHA),

el Instituto Nacional de Seguridad y Salud (NIOHS) o

el Departamento de Minas de los Estados Unidos.

Estas máscaras y filtros reemplazables pueden

obtenerse fácilmente en las principales ferreterías.

Asegúrese de que la máscara se ajuste firmemente. Las

barbas y el vello facial pueden impedir que las máscaras

se ajusten adecuadamente. Cambie los filtros con

frecuencia. LAS MÁSCARAS DE PAPEL DESECHABLES

NO SON ADECUADAS.

7) Tenga precaución al utilizar la pistola de aire

caliente. Mantenga en movimiento la pistola de aire

caliente, ya que el calor excesivo generará humos que

pueden ser inhalados por el operador.

8) Mantenga los alimentos y las bebidas fuera del

área de trabajo. Lávese las manos, los brazos y la cara

y enjuáguese la boca antes de comer o beber. No fume

ni mastique chicle o tabaco en el área de trabajo.

9) Recoja toda la pintura y el polvo que se hayan

quitado, utilizando un trapeador mojado para limpiar

los pisos. Use un paño mojado para limpiar todas las

paredes, repisas y cualquier otra superficie en la que

haya pintura o polvo que estén pegados. NO BARRA, NI

QUITE EL POLVO EN SECO NI LIMPIE CON

ASPIRADORA. Use un detergente con alto contenido de

fosfatos o fosfato trisódico (FTS) para lavar y limpiar con

trapeador las áreas.

-22-

Page 23

BM 1619929572 11-06 11/8/06 8:51 AM Page 23

10) Al final de cada sesión de trabajo, ponga las

virutas y los residuos de pintura en una bolsa de

plástico doble, cierre la bolsa con cinta adhesiva o

ataduras de torsión y deshágase de ella

apropiadamente.

11) Quítese la ropa protectora y los zapatos de trabajo

en el área de trabajo para evitar llevar polvo al resto

de la vivienda. Lave la ropa de trabajo por separado.

Limpie los zapatos con un trapo mojado y luego lave

dicho trapo junto con la ropa de trabajo. Lávese muy

bien el pelo y el cuerpo con agua y jabón.

ADVERTENCIA

!

taladrado mecánicos, y por otras actividades de

construcción, contiene agentes químicos que se sabe

que causan cáncer, defectos de nacimiento u otros

Cierto polvo generado por el

lijado, aserrado, amolado y

CONSERVE ESTAS INSTRUCCIONES

Normas generales de seguridad para pistolas de aire caliente

PELIGRO

!

lo hace, sufrirá lesiones graves.

Evite el contacto con la boquilla de la pistola de aire

caliente durante el uso. Esta pistola de aire caliente

genera temperaturas de hasta 1000 grados Fahrenheit.

Usted podría sufrir quemaduras graves.

No utilice pistolas de aire caliente en la lluvia ni en

humedad, ni las sumerja en agua. Al exponer el

elemento de la pistola de aire caliente al agua o a otros

líquidos se puede causar un peligro de descargas

eléctricas.

No utilice pistolas de aire caliente en áreas donde

pueda haber almacenados o se encuentren presentes

líquidos o gases inflamables. La pistola de aire caliente

genera altas temperaturas y puede incendiar estos

materiales.

Mantenga el área de trabajo limpia y bien iluminada.

Las áreas desordenadas y oscuras invitan a que se

produzcan accidentes.

No utilice el aparato de aire caliente en atmósferas

explosivas, como por ejemplo en presencia de

líquidos, gases o polvos inflamables, pasto seco,

hojas secas y papel. Los aparatos de aire caliente

generan altas temperaturas, las cuales pueden inflamar

el polvo o los vapores. Los materiales combustibles

tales como pasto seco, hojas secas y papel se

chamuscarán y podrán incendiarse.

Nunca utilice las pistolas de aire

caliente como secadores de pelo! Si

Area de trabajo

daños sobre la reproducción. Algunos ejemplos de

estos agentes químicos son:

• Plomo de pinturas a base de plomo,

• Sílice cristalina de ladrillos y cemento y otros

productos de mampostería, y

• Arsénico y cromo de madera tratada químicamente.

Su riesgo por causa de estas exposiciones varía,

dependiendo de con cuánta frecuencia realice este tipo

de trabajo. Para reducir su exposición a estos agentes

químicos: trabaje en un área bien ventilada y trabaje con

equipo de seguridad aprobado, como por ejemplo

máscaras antipolvo que estén diseñadas especialmente

para impedir mediante filtración el paso de partículas

microscópicas.

Mantenga alejados a las personas que se encuentren

presentes, a los niños y a los visitantes mientras

utiliza un aparato de aire caliente. Las distracciones

pueden hacer que usted pierda el control del aparato.

Seguridad eléctrica

Antes de enchufar el aparato de aire caliente,

asegúrese de que la tensión de tomacorriente

suministrada es compatible con la tensión marcada

en la placa del fabricante dentro de un margen del

10%. Una tensión de tomacorriente incompatible con la

tensión especificada en la placa del fabricante puede

tener como resultado peligros graves y daños al aparato

de aire caliente.

Al utilizar un aparato de aire caliente, use en el

circuito o en el tomacorriente un interruptor de

circuito accionado por corriente de pérdida a tierra

(GFCI). No exponga el aparato de aire caliente a la

lluvia ni a condiciones húmedas. Si entra agua en el

aparato de aire caliente, se producirá peligro de

sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar

el aparato de aire caliente ni para sacar el enchufe de

un tomacorriente. Mantenga el cordón alejado del

calor, el aceite, los bordes afilados o las piezas

móviles. Cambie los cordones dañados

inmediatamente.

de sacudidas eléctricas.

Al utilizar a la intemperie un aparato de aire caliente

con un cordón de extensión, use únicamente

cordones marcados con las letras W-A o W.

Los cordones dañados crean peligro

Estos

-23-

Page 24

BM 1619929572 11-06 11/8/06 8:51 AM Page 24

cordones tienen capacidad nominal para el uso a la

intemperie y reducen el riesgo de sacudidas eléctricas.

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use EL SENTIDO COMUN al utilizar un aparato de aire