Technical�training.

Product�information.

N57TU�Engine

BMW�Service

General�information

Symbols�used

The�following�symbol�is�used�in�this�document�to�facilitate�better�comprehension�or�to�draw�attention

to�very�important�information:

Contains�important�safety�information�and�information�that�needs�to�be�observed�strictly�in�order�to

guarantee�the�smooth�operation�of�the�system.

Information�status�and�national-market�versions

BMW�Group�vehicles�meet�the�requirements�of�the�highest�safety�and�quality�standards.�Changes

in�requirements�for�environmental�protection,�customer�benefits�and�design�render�necessary

continuous�development�of�systems�and�components.�Consequently,�there�may�be�discrepancies

between�the�contents�of�this�document�and�the�vehicles�available�in�the�training�course.

This�document�basically�relates�to�the�European�version�of�left�hand�drive�vehicles.�Some�operating

elements�or�components�are�arranged�differently�in�right-hand�drive�vehicles�than�shown�in�the

graphics�in�this�document.�Further�differences�may�arise�as�the�result�of�the�equipment�specification�in

specific�markets�or�countries.

Additional�sources�of�information

Further�information�on�the�individual�topics�can�be�found�in�the�following:

• Owner's�Handbook

• Integrated�Service�Technical�Application.

Contact:�conceptinfo@bmw.de

©2010�BMW�AG,�Munich

Reprints�of�this�publication�or�its�parts�require�the�written�approval�of�BMW�AG,�München

The�information�contained�in�this�document�forms�an�integral�part�of�the�technical�training�of�the

BMW�Group�and�is�intended�for�the�trainer�and�participants�in�the�seminar.�Refer�to�the�latest�relevant

information�systems�of�the�BMW�Group�for�any�changes/additions�to�the�technical�data.

Contact

Gernot�Nehmeyer/Udo�Metz

Telephone�+49�(0)�89�382�34059/+49�(0)�89�382�58506

gernot.nehmeyer@bmw.de/udo.metz@bmw.de

Status�of�the�information:�November�2010

BV-72/Technical�Training

N57TU�Engine

Contents

1. Introduction.............................................................................................................................................................................................................................................1

1.1. Technical�data............................................................................................................................................................................................................. 2

1.2. Engine�identification......................................................................................................................................................................................... 3

1.2.1. Engine�designation............................................................................................................................................................3

1.2.2. Engine�identification........................................................................................................................................................5

1.3. Design�features.........................................................................................................................................................................................................6

2. Engine�Mechanical.....................................................................................................................................................................................................................7

2.1. Crankcase...........................................................................................................................................................................................................................7

2.2. Oil�sump............................................................................................................................................................................................................................... 9

2.3. Crankshaft..................................................................................................................................................................................................................... 11

2.4. Piston.................................................................................................................................................................................................................................... 13

2.5. Connecting�rod..................................................................................................................................................................................................... 13

2.6. Cylinder�head...........................................................................................................................................................................................................14

2.7. Cylinder�head�gasket...................................................................................................................................................................................16

2.8. Crankcase�ventilation.................................................................................................................................................................................. 17

2.9. Camshaft�drive�system.............................................................................................................................................................................20

2.10. Camshafts�and�timing................................................................................................................................................................................21

2.10.1. Timing................................................................................................................................................................................................ 23

3. Belt�Drive.................................................................................................................................................................................................................................................24

3.1. N57�engine.................................................................................................................................................................................................................. 24

3.2. N57TU�engine........................................................................................................................................................................................................ 25

4. Oil�Supply...............................................................................................................................................................................................................................................27

4.1. Oil�circuit......................................................................................................................................................................................................................... 27

4.2. Oil�pump.......................................................................................................................................................................................................................... 28

4.2.1. Pressure�limiting�valve............................................................................................................................................. 30

4.3. Oil�filter�module....................................................................................................................................................................................................34

4.3.1. Transmission�oil�cooling....................................................................................................................................... 36

5. Intake�Air,�Exhaust�and�Emission�Sys............................................................................................................................................. 40

5.1. Intake�air�system.................................................................................................................................................................................................42

5.1.1. Intake�manifold.....................................................................................................................................................................44

5.2. Vacuum�system.................................................................................................................................................................................................... 46

5.2.1. Vacuum�pump....................................................................................................................................................................... 47

5.2.2. Electro-pneumatic�changeover�valve�(EUV).......................................................................... 48

5.3. Exhaust�emission�system.....................................................................................................................................................................49

5.3.1. Exhaust�turbocharger�(VNT)...........................................................................................................................50

5.3.2. Exhaust-gas�recirculation....................................................................................................................................55

5.3.3. EGR�valve/actuator.........................................................................................................................................................56

N57TU�Engine

Contents

5.3.4. Exhaust�after-treatment.........................................................................................................................................58

6. Fuel�Preparation.........................................................................................................................................................................................................................60

6.1. High�pressure�pump..................................................................................................................................................................................... 61

6.1.1. Fuel�quantity�control�valve................................................................................................................................66

6.1.2. Volumetric�flow�regulation�functional�description........................................................ 68

6.1.3. Rail�pressure�sensor................................................................................................................................................... 69

6.2. Leakage�oil�line.....................................................................................................................................................................................................69

6.3. Injector................................................................................................................................................................................................................................ 70

6.3.1. Injector�CRI2.5......................................................................................................................................................................71

6.3.2. Injection�volume�calibration.............................................................................................................................74

7. Engine�Electrical�System..........................................................................................................................................................................................76

7.1. Preheating�control�unit............................................................................................................................................................................. 80

7.1.1. Glow�plug......................................................................................................................................................................................81

7.2. Sensors�and�actuators..............................................................................................................................................................................82

7.2.1. Crankshaft�sensor........................................................................................................................................................... 82

7.2.2. Camshaft�sensor...............................................................................................................................................................85

7.2.3. Hot-film�air�mass�meter.........................................................................................................................................85

7.2.4. Rail�pressure�sensor................................................................................................................................................... 86

7.2.5. Boost-pressure�sensor�......................................................................................................................................... 87

7.2.6. Charge-air�temperature�sensor............................................................................................................... 88

7.2.7. Coolant�temperature�sensor.......................................................................................................................... 88

7.2.8. Oxygen�sensor..................................................................................................................................................................... 89

7.2.9. NOx�sensors............................................................................................................................................................................ 90

7.2.10. Particulate�matter�sensor.................................................................................................................................... 90

7.2.11. Exhaust�gas�temperature�sensor............................................................................................................ 92

7.2.12. Fuel�temperature�and�pressure�sensor.......................................................................................92

7.2.13. Exhaust�back-pressure�sensor�upstream�of�exhaust

turbocharger.............................................................................................................................................................................93

7.2.14. Throttle�valve�actuator.............................................................................................................................................94

8. Engine�Control�Functions........................................................................................................................................................................................ 96

8.1. Air�supply....................................................................................................................................................................................................................... 96

8.1.1. Boost-pressure�control...........................................................................................................................................96

8.2. Fuel�supply.................................................................................................................................................................................................................. 97

8.2.1. Fuel�injection...........................................................................................................................................................................97

8.2.2. High-pressure�control............................................................................................................................................... 97

8.2.3. Injector�volume�calibration................................................................................................................................ 97

8.2.4. Volume�calibration�control................................................................................................................................. 98

8.2.5. Zero�volume�calibration..........................................................................................................................................98

N57TU�Engine

Contents

8.2.6. Mean�volume�adaptation..................................................................................................................................... 98

8.3. Exhaust�emission�system.....................................................................................................................................................................99

8.3.1. Oxygen�control.....................................................................................................................................................................99

8.3.2. Lambda�adaptation....................................................................................................................................................... 99

8.3.3. Exhaust�gas�recirculation�(EGR)...........................................................................................................100

N57TU�Engine

1.�Introduction

The�N57TU�engine�is�based�on�the�N57�engine�which�was�not�available�in�the�US�but�has�been

used�in�other�markets�for�some�time.�The�differences�between�the�N57TU�engine�and�N57�engine�are

essentially�the�same�as�the�differences�between�the�N47TU�engine�and�N47�engine.�This�document

deals�exclusively�with�the�adaptations/changes�made�with�regard�to�the�N57TU�engine.�The�N57TU

6�cylinder�engine�replaces�the�(M57D30T2)�6�cylinder�which�was�first�introduced�to�the�US�market�in

2009�with�the�E90�335d�and�the�E70�xDrive35d.

The�N57TU�engine�was�installed�in�the�F10�535d�and�535d�xDrive�2014�models�from�7/2013

start�production�and�was�also�installed�on�the�new�2014�X5�model�xDrive35d�(F15)�introduced�in

September�of�2013.

Model Series Engine Start�of�production

535d F10 N57D30O1 7/13

535d�xDrive F10 N57D30O1 7/13

X5�xDrive35d F15 N57D30O1 9/13

The�N47TU�and�the�N57TU�engine�are�considered�second�generation�BMW�diesel�engines

(in�the�US�market).�The�exhaust�after-treatment�systems�and�components�of�the�N47TU�and

the�N57TU�have�been�especially�design�to�comply�with�current�(ULEV�II)�US�market�emission

regulations�and�thus�differ�from�those�used�with�the�previous�US�diesel�(M57D30T2)�engine.

1

N57TU�Engine

1.�Introduction

1.1.�Technical�data

The�N57TU�engine�technical�data�is�described�in�the�following�table.

Full-load�diagram�of�F10�BMW�535d�with�N57D30O1�engine

Engine�specifications Unit N57D30O1�(F10/535d�xDrive)

Design Inline�6

Displacement [cm³] 2993

Bore/stroke [mm] 84/90

Power�output

at�engine�speed

2

[kW�(HP)]

[rpm]

190�(255)

4000

N57TU�Engine

1.�Introduction

Engine�specifications Unit N57D30O1�(F10/535d�xDrive)

Power�output�per�liter [kW/l] 63.48

Torque

at�engine�speed

Compression�ratio [ε] 16.5�:�1

Valves�per�cylinder 4

Fuel�consumption�complying�with

EU

CO2�emissions [grams�per

Digital�Motor�Electronics DDE7.41

Exhaust�emissions�legislation ULEV�II

Maximum�speed [km/h/mph] 250/155

Acceleration�0�–�60mph [s] 6.0

Vehicle�curb�weight�DIN/EU [kg] 1790/1865

[Nm/ft-lb]

[rpm]

[l/100km] 5.7

kilometer]

560/413

1500�–�3000

150

1.2.�Engine�identification

1.2.1.�Engine�designation

In�the�technical�documentation,�the�engine�designation�is�used�to�ensure�unambiguous�identification

of�the�engine.�Frequently,�however,�only�a�short�designation�is�used.

This�short�form�is�used�so�an�engine�can�be�identified�as�belonging�to�a�specific�engine�family.�The

N57�engine�family�to�which�several�engines,�such�as�the�N57D30T0,�N57D30O0,�N57D30U0�and

N57D30K0,�belong�is�therefore�frequently�mentioned.�The�initial�redesigned�version�is�therefore

referred�to�as�the�N57TU�engine�and�is�currently�the�only�N57�available�in�the�US�market.

Position Meaning Index Explanation

1 Engine�developer M,�N

P

S

W

2 Engine�type 1

2

4

5

6

7

8

3 Change�to�the�basic

engine�concept

0

1�–�9

BMW�Group

BMW�M�Sport

BMW�M�GmbH

Bought-in�engines

4-cylinder�in-line�engine�(e.g.�N18)

4-cylinder�in-line�engine�(e.g.�N20)

4-cylinder�in-line�engine�(e.g.�N47)

6-cylinder�in-line�engine�(e.g.�N57)

V8�engine�(e.g.�N63)

V12�engine�(e.g.�N74)

V10�engine�(e.g.�S85)

Basic�engine

Changes,�e.g.�combustion�process

3

N57TU�Engine

1.�Introduction

Position Meaning Index Explanation

4 Working�method�or

fuel�type�and�possibly

installation�position

5�+�6 Displacement�in

1/10�liter

7 Performance�class K

8 Revision�relevant

to�approval

Breakdown�of�N57D30O1�engine�designation

Index Explanation

N BMW�Group�Development

5 4-cylinder�in-line�engine

7 Direct�fuel�injection�and�exhaust�turbocharger

D Diesel�engine�longitudinal�installation

B

D

H

30 3.0�liters�displacement

U

M

O

T

0

1�–�9

Gasoline�engine�longitudinal�installation

Diesel�engine�longitudinal�installation

Hydrogen�internal�combustion�engine

longitudinal�installation

Lowest

Lower

Middle

Upper

TOP

New�development

Redesign

30 3.0�liters�displacement

O Upper�performance�class

1 1.�Redesign

4

N57TU�Engine

1.�Introduction

1.2.2.�Engine�identification

The�engines�have�an�identification�mark�on�the�crankcase�to�ensure�clear�identification�and

classification.�The�engine�identification�is�also�required�for�approval�by�the�authorities.�The�engine

number�can�be�found�on�the�engine,�above�the�engine�identification.�This�consecutive�number,�in

conjunction�with�the�engine�identification,�permits�clear�and�definite�identification�of�each�individual

engine.�The�first�six�digits�correspond�to�the�engine�designation.

Position Meaning Index Explanation

1 Engine�developer M,�N

P

S

W

2 Engine�type 1

2

4

5

6

7

8

3 Change�to�the�basic

engine�concept

4 Working�method�or

fuel�type�and�possibly

installation�position

5�+�6 Displacement�in

1/10�liter

7 Type�test�concerns

(changes�that�require

a�new�type�test)

0

1�–�9

B

D

H

30 3.0�liters�displacement

A

B�–�Z

BMW�Group

BMW�M�Sport

BMW�M�GmbH

Bought-in�engines

4-cylinder�in-line�engine�(e.g.�N18)

4-cylinder�in-line�engine�(e.g.�N20)

4-cylinder�in-line�engine�(e.g.�N47)

6-cylinder�in-line�engine�(e.g.�N57)

V8�engine�(e.g.�N63)

V12�engine�(e.g.�N74)

V10�engine�(e.g.�S85)

Basic�engine

Changes,�e.g.�combustion�process

Gasoline�engine�longitudinal�installation

Diesel�engine�longitudinal�installation

Hydrogen�internal�combustion�engine

longitudinal�installation

Standard

Acc.�to�requirements,�e.g.�RON87

N57TU�engine,�engine�identification�and�engine�number

5

N57TU�Engine

1.�Introduction

Index Explanation

27117547 Running�engine�number

N BMW�Group�Development

5 6-cylinder�in-line�engine

7 Direct�fuel�injection�and�exhaust�turbocharger

D Diesel�engine�longitudinal�installation

30 3.0�liters�displacement

A Standard

1.3.�Design�features

System Comment

Engine�mechanics

Belt�drive

Oil�supply

Intake�air�system

Exhaust�emission�system

Fuel�preparation

Engine�electrical�system

• Optimized�crankcase

• Modified�cylinder�head

• Weight-optimized�crankshaft

• New�piston

• New�low-friction�belt�drive�with�modified�arrangement

of�components

• New�oil�filter�module�with�integrated�transmission

oil-to-coolant�heat�exchanger

• Adaptation�of�intake�silencer�to�modified�geometry

• Exhaust-gas�recirculation�redesigned

• New�injectors�deliver�a�fuel�pressure�of�up�to�1800�bar

• New�sensors�and�modified�control�unit

6

N57TU�Engine

2.�Engine�Mechanical

2.1.�Crankcase

The�aluminium�crankcase�of�the�N57TU�engine�is�a�new�engineering�design�that�is�based�on�the

crankcase�of�the�N57�engine�(not�available�in�the�US).�This�new�design�was�necessary�as�the�engine

support�required�additional�connection�points.�The�oil�pressure�switch�needed�to�be�repositioned�and

a�new�oil�passages�for�the�oil�module�supply�was�required.�In�addition,�the�crankcase�is�exposed�to

higher�loads�due�to�the�increased�power�of�the�N57TU�engine�family.�This�has�been�taken�into�account

by�making�changes�to�details�and�geometry�to�enhance�its�strength.�The�familiar�oil�filter�module

(from�the�N47TU�engine)�with�integrated�engine�and�transmission�oil�coolers�is�also�used.�For�more

information,�refer�to�“Oil�supply”.

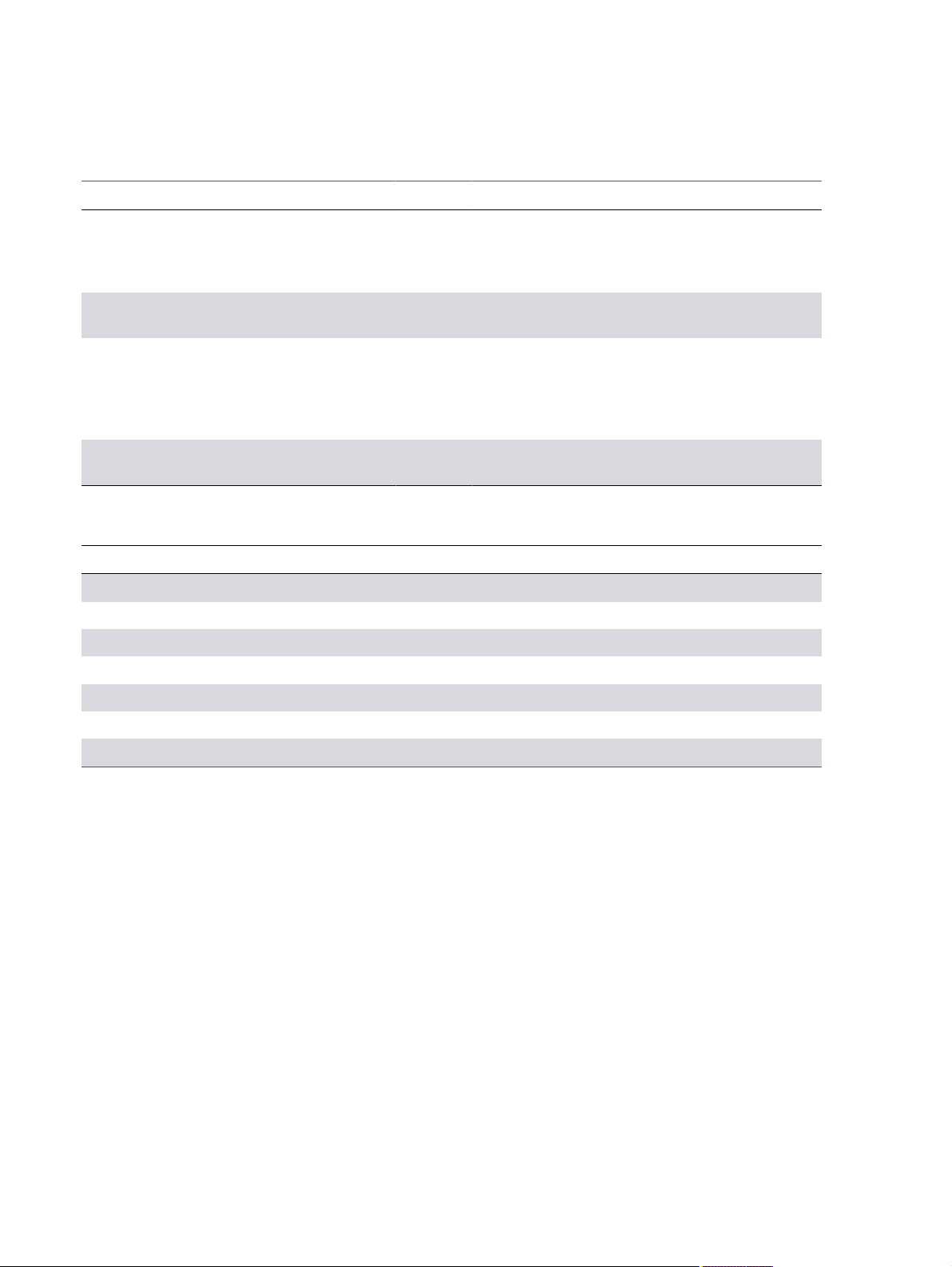

N57TU�engine�block�components

7

N57TU�Engine

2.�Engine�Mechanical

Index Explanation

1 Cylinder�head�cover

2 Camshaft�carrier�plate

3 Cylinder�head

4 Head�gasket

5 Crankcase

6 Timing�case�cover

7 Sump

Loctite�5970�silicone�gasket�is�used�(no�actual�gasket�is�installed)�on�the�sump�and�timing

case�cover�of�the�rear�wheel�drive�535i�models�with�the�N57TU.

The�xDrive�models�with�the�N57TU�use�gaskets�instead�of�the�sealant.

The�special�features�of�the�N57TU�engine�crankcase�are:

• Crankcase�made�of�aluminium.

• Chain�drive�located�on�the�force�transmitting�(flywheel)�side.

• Main�bearing�caps�made�of�sintered�metal.

• Closed-deck�design.

• Main�bearing�pedestal�with�side�walls�that�extend�downwards

and�individual�main�bearing�caps.

• Main�bearing�caps�with�raised-profile�joint�face.

• Dry,�thermally�joined,�cast-iron�cylinder�liners.

Additional�crankcase�rigidity�is�provided�by�a�reinforcing�plate�bolted�to�the�bottom�of�the�crankcase.

That�reinforcing�plate�is�required�to�cope�with�the�lateral�stresses�that�occur�on�the�crankcase

mounting�attachment�points�when�driving�over�a�pothole.�Without�a�reinforcing�plate,�the�crankcase

could�break�at�the�attachment�points�to�the�engine�mounting�bracket�or�at�the�junction�between�the

bearing�pedestal�and�the�side�wall.�The�reinforcing�also�provides�benefits�in�terms�of�noise�reduction.

8

N57TU�Engine

2.�Engine�Mechanical

N57TU�crankcase�with�reinforcing

Index Explanation

1 Crankcase

2 Reinforcing�plate

3 Oil�pump

2.2.�Oil�sump

As�with�the�N47TU�the�engine�oil�sump�gasket�surface�was�converted�to�use�a�silicone�Loctite�gasket

5970.�The�oil�sump�of�the�N57TU�(rear�wheel�drive�model�only)�was�machined�with�chamfer�to

use�the�silicone�gasket.�This�chamfer�is�located�on�the�inside�of�the�flange,�which�serves�as�a�defined

reservoir�for�the�excess�silicone.

9

N57TU�Engine

2.�Engine�Mechanical

Schematic�diagram,�oil�sump�gasket

Index Explanation

A Components�without�silicone�bead

B Components�with�silicone�bead

C Components�bolted�with�silicone�bead

1 Crankcase

2 Silicone�bead

3 Oil�sump�with�chamfer

4 Emergence�of�silicone�through�the�screw�connection�into�the�provided�space

in�the�oil�sump

A�bevel�is�necessary�when�using�a�surface�sealant�to�ensure�that�sealing�compound�that�encroaches�is

deposited�in�a�controlled�manner�in�the�designated�space�where�it�cannot�detach�due�to�splashing�of

oil.

Positioning,�silicone�bead

10

N57TU�Engine

2.�Engine�Mechanical

Index Explanation

1 Oil�sump�sealing�surface

2 Silicone�bead

3 Chamfer�on�inside�of�oil�sump

Loctite�5970�silicone�gasket�is�used�(no�actual�gasket�is�installed)�on�the�sump�and�timing

case�cover�of�the�rear�wheel�drive�535i�models�with�the�N57TU.

The�xDrive�models�with�the�N57TU�use�gaskets�instead�of�the�sealant.

Please�refer�to�the�repair�instructions�for�proper�procedure�and�torque�specifications.

2.3.�Crankshaft

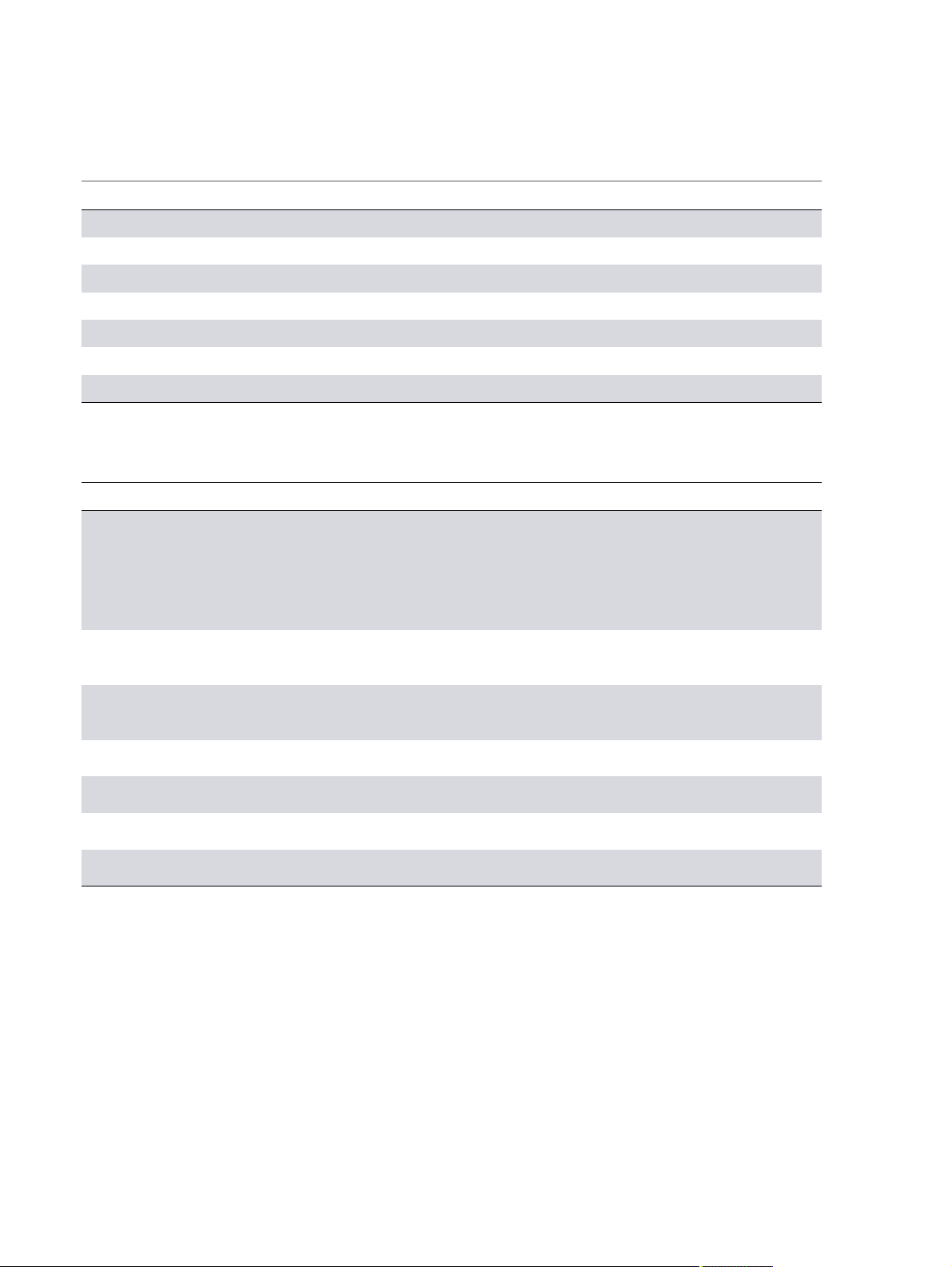

N57TU�crankshaft

11

N57TU�Engine

2.�Engine�Mechanical

Index Explanation

1 Output�flange

2 Rod�bearing�journal�(big-end)

3 Main�bearing�journal

4 Counterweight

5 Axial�bearing�thrust�surface

Counterweights�create�a�balance�of�inertial�forces�around�the�crankshaft�so�as�to�produce�even

rotation�of�the�shaft.�They�are�designed�so�as�to�counterbalance�some�of�the�oscillating�(up-and-down)

inertial�forces�as�well�as�the�rotational�(revolving)�inertial�forces.

The�crankshaft�of�the�N57TU�engine�has�eight�counterweights.

The�N57TU�engine�has�a�forged�crankshaft�made�of�C38modBY.�BY�stands�for�controlled�cooling�from

the�forging�heat�in�the�air�and�makes�for�uniform�joints.�The�material�specifications�are�the�same�as

those�of�the�(M57D30T2)�engine.�In�order�to�achieve�the�required�hardness,�the�crankshaft�is�induction

hardened.�This�forms�an�especially�hard�surface�layer�approximately�1.5�mm�thick.

Advantages�of�forged�crankshafts�compared�to�cast:

• Forged�crankshafts�are�more�rigid�and�have�better�vibrational�properties.

• Especially�when�combined�with�an�aluminium�crankcase,�the�crankshaft�drive�system�must�be

as�rigid�as�possible�because�the�crankcase�itself�is�made�of�material�with�a�lower�rigidity.

• Forged�crankshafts�have�better�wearing�characteristics�at�the�bearing�journals.

In�summary:�the�strength�of�a�forged�crankshaft�is�significantly�greater�than�that�of�a�cast�one.�A�cast

crankshaft�would�not�be�able�to�cope�with�the�loads�to�which�it�is�subjected�in�the�N57TU�engine.

Crankshaft�specifications Unit N57TU

Material C38modBY

Type Forged

Main�bearing�journal

diameter

Rod�bearing�(big-end)

diameter

Crank�pin�off-set [°] 120

Number�of�counterweights 8

Number�of�main�bearings 7

[mm] 55

[mm] 50

Position�of�thrust�bearing 4

Always�refer�to�the�proper�repair�instructions�for�more�information�and�follow�the�special

bearing�classification�procedure�when�servicing�the�crankshaft�and�bearings�on�BMW

engines.

12

N57TU�Engine

2.�Engine�Mechanical

2.4.�Piston

The�pistons�have�been�adapted�to�the�new�requirements�due�to�the�use�of�solenoid�type�injectors.�The

combustion�chamber�and�injector�are�always�harmonized�with�one�another.

2.5.�Connecting�rod

The�shaped�hole�in�the�small�connecting�rod�eye�is�familiar�technology�that�already�features�in�the�N55

and�N47TU�engines.�The�shaped�hole�reduces�edge�load�by�allowing�the�force�acting�on�the�piston�via

the�wrist�pin�to�be�distributed�optimally�across�the�surface�of�the�cylinder�liner.

N57TU�engine,�small�connecting�rod�eye

Index Explanation

1 Bushing

2 Connecting�rod

The�graphic�on�the�following�page�shows�(on�the�left�side)�the�surface�load�for�a�normal�connecting�rod

without�a�shaped�bore.�Due�to�the�pressure�on�the�piston,�most�of�the�force�is�transferred�via�the�wrist

pin�to�the�edges�of�the�small�connecting�rod�eye�bushing.

13

N57TU�Engine

2.�Engine�Mechanical

If�a�shaped�hole�is�introduced�into�the�small�connecting�rod�eye�(graphic�on�the�right)�the�force�is

distributed�across�a�larger�surface�and�the�load�on�the�edge�of�the�bushing�reduces�considerably.�The

force�is�now�transmitted�via�a�larger�surface.

N57TU�engine,�small�connecting�rod�eye

Index Explanation

A Low�surface�load

B High�surface�load

1 Without�shaped�bore

2 With�shaped�bore

2.6.�Cylinder�head

The�distinguishing�technical�features�of�the�N57TU�engine�cylinder�head�are�as�follows:

• Material:�AlSI7MgCu0.5

• Two-piece�cylinder�head�with�camshaft�carrier�plate

• Cross-flow�cooling

• Integral�exhaust�recirculation�channel

• Four�valves�per�cylinder

• Parallel�valve�arrangement�(axes�parallel�with�the�cylinder�axes)

• Tangential�and�swirl�ports

• Reduced�height

14

N57TU�Engine

2.�Engine�Mechanical

N57TU�Cylinder�head�cut�away�with�view�of�the�valvetrain

Index Explanation

1 Camshaft�carrier�plate

2 Hydraulic�valve�clearance�adjuster

3 Glow�plug

4 Exhaust�recirculation�channel

5 Intake�valve

6 Exhaust�valve

7 Valve�guide

8 Valve�spring

9 Roller�cam�follower

10 Exhaust�camshaft

11 Intake�camshaft

The�cylinder�head�of�the�N57TU�engine�largely�matches�the�standards�of�the�current�diesel�engines.�A

special�feature,�however,�is�that�the�cylinder�head�is�comprised�of�two�large�cast�parts.�The�camshafts

are�integrated�inside�their�own�camshaft�carrier.�In�the�case�of�the�N57TU�cylinder�head,�those

two�parts�are�the�main�casting�of�actual�cylinder�head,�and�a�carrier�plate�for�the�camshafts.�Both

camshafts�are�mounted�in�this�camshaft�carrier.�This�design�simplifies�the�manufacturing�process.

15

N57TU�Engine

2.�Engine�Mechanical

2.7.�Cylinder�head�gasket

N57TU�head�gasket

Index Explanation

1 Outer�spring�steel�layer

2 Intermediate�layer�with�welded�sealing�lips

3 Outer�spring�steel�layer

4 Coding�for�identifying�gasket�thickness

The�cylinder�head�gasket�must�be�capable�of�sealing�off�four�zones�from�each�other.

• Combustion�chamber

• Atmosphere

• Engine�oil�passages

• Coolant�passages

A�three-layer�metal�gasket�is�used�on�the�N57TU�engine.

The�cylinder�head�gasket�is�available�to�order�in�three�different�thicknesses,�which�depend�on�the

piston�projection�concerned.�The�thickness�of�the�cylinder�head�gasket�is�indicated�by�holes,�whereby

one�hole�indicates�the�thinnest�and�three�holes�the�thickest�gasket.

16

N57TU�Engine

2.�Engine�Mechanical

2.8.�Crankcase�ventilation

N57TU�crankcase�ventilation

Index Explanation

1 Exhaust�turbocharger

2 Intercooler

3 Pressure�regulation�valve

4 Spring�plates

5 Blow-by�channel

6 Oil�return�channel

7 Air�cleaner

17

N57TU�Engine

2.�Engine�Mechanical

When�the�engine�is�running,�blow-by�gases�escape�from�the�cylinders�into�the�crankshaft�cavity.�Those

blow-by�gases�contain�unburned�fuel�and�all�the�constituents�of�the�exhaust.�In�the�crankshaft�cavity,

they�mix�with�the�engine�oil�that�is�present�in�the�form�of�oil�vapor.

The�extent�of�blow-by�is�dependent�on�load.�Pressure�is�created�inside�the�crankshaft�cavity�and,�due

to�the�motion�of�the�pistons,�is�also�dependent�on�engine�speed.�This�overpressure�is�also�present�in

all�spaces�that�connect�to�the�crankshaft�cavity�(e.g.�oil�return,�chain�cavity,�etc.)�and�if�not�released

would�force�oil�out�through�the�sealed�joints.

The�crankcase�venting�system�prevents�that�from�happening.�It�channels�blow-by�gases�that�are

largely�free�of�engine�oil�into�the�filtered-air�pipe�upstream�of�the�turbocharger.�The�separated�engine

oil�droplets�work�their�way�back�into�the�sump�through�an�oil�return�pipe.�The�crankcase�venting

system�also�ensures�that�excess�pressure�is�not�created�in�the�crankcase.

The�N57�engine�is�equipped�with�a�vacuum�controlled�crankcase�venting�system�with�a�regulated

negative�pressure�of�about�38�mbar�(maintained).

Pre-loaded�metal�spring�plates�(known�as�variable-aperture�separators)�regulate�the�air�mass�flow�rate,

thereby�ensuring�optimum�oil�separation�from�the�blow-by�gas�in�all�engine�operating�situations.

A�negative�pressure�is�created�in�the�purified�air�pipe�due�to�the�suction�of�the�exhaust�turbocharger.

As�a�result�of�the�pressure�difference�relative�to�the�crankcase,�the�blow-by�gas�is�drawn�into�the

cylinder�head.

In�the�cylinder�head,�the�blow-by�gas�first�enters�the�plenum�chamber.�The�purpose�of�the�plenum

chamber�is�to�ensure�that�no�oil�spray,�e.g.�from�the�camshafts,�enters�the�crankcase�venting�system.

Thus,�a�degree�of�initial�separation�already�takes�place�in�the�plenum�chamber.�The�oil�that�deposits�on

the�wall�here�flows�back�into�the�cylinder�head.

The�blow-by�gas�flows�from�the�plenum�chamber�to�the�spring-plate�separators.�The�spring�plates�are

forced�open�by�the�flow�of�blow-by�gas�so�that�the�blow-by�gas�passes�through.�Since�the�aperture

size�is�relatively�small,�the�flow�velocity�of�the�blow-by�gas�is�accelerated.�And�since�the�blow-by�gas

flow�is�then�deflected�by�about�180°,�the�fluid�contained�in�the�blow-by�gas�is�thrown�against�the

surrounding�walls�by�centrifugal�force�and�runs�down�them�into�a�drain�channel�and�back�into�the

sump.�The�spring�plates�are�opened�to�a�greater�(B)�or�lesser�(A)�degree�depending�on�the�quantity

of�blow-by�gas�so�that�optimum�oil�separation�is�achieved�regardless�of�blow-by�gas�flow�rate.�The

spring-plate�separator�has�brought�about�an�improvement�in�the�separation�quality�under�all�operating

conditions�but�especially�at�low�blow-by�gas�flow�rates.�The�cleaned�blow-by�gas�flows�through�the

pressure�regulating�valve�and�into�the�filtered-air�pipe�upstream�of�the�turbocharger.

18

N57TU�Engine

2.�Engine�Mechanical

N57TU�oil�separation�in�the�cylinder�head

index Explanation

A Low�blow-by�gas�flow�rate

B High�blow-by�gas�flow�rate

1 Oil�droplets

2 Air�flow

3 Blow-by�gas�flow

4 Spring�plate

5 Channel�to�pressure�regulating�valve

6 Pressure�regulating�valve

7 Blow-by�gas�feed�into�filtered-air�pipe

8 Oil�return�channel

9 Blow-by�gas�inflow

10 Plenum�chamber

19

N57TU�Engine

2.�Engine�Mechanical

2.9.�Camshaft�drive�system

The�special�features�and�specifications�of�the�chain�drive�system�on�the�N57TU�engine�are�as�follows:

• Chain�drive�system�mounted�on�flywheel�side�of�engine.

• Two-section�system�for�driving�the�high�pressure�pump�and�camshafts.

• Use�of�simplex�sleeve-type�chains.

• Oil/vacuum�pump�driven�by�second�chain.

• Plastic�tensioning�and�guide�rails.

• Hydraulic�chain�tensioners.

As�on�the�N47TU�engine,�the�chain�drive�system�on�the�N57TU�engine�is�mounted�on�the�flywheel

end,�i.e.�the�rear,�of�the�engine.�Due�to�the�fact�that�the�timing�gear�is�mounted�at�the�rear,�the�engine

is�lower�at�the�front.�This�is�of�benefit�for�the�passive�safety�features�for�minimizing�pedestrian�impact

severity.�It�creates�more�space�between�the�engine�and�the�hood.�Thus,�in�the�event�of�a�crash,�there

is�more�room�for�the�hood�to�deform�and�absorb�the�impact�therefore�minimizing�the�injury�to�the

pedestrian.�Another�benefit�is�that�rotational�vibrations�are�significantly�reduced�due�to�the�inertial

mass�of�the�transmission�at�this�end.�This�results�in�an�enormous�relief�of�load�on�the�chain�drive.�One

of�the�consequences�of�this�arrangement�is�that�various�components�are�installed�in�unconventional

locations�or�positions,�e.g.�oil�pump,�camshaft�sensor,�etc.

N57TU�chain�drive

20

N57TU�Engine

2.�Engine�Mechanical

Index Explanation

1 Upper�chain

2 Exhaust�camshaft�gear

3 Upper�chain�tensioner

4 Upper�tensioning�rail

5 Lower�chain�tensioner

6 Lower�tensioning�rail

7 Crankshaft

8 Oil�vacuum/pump�sprocket

9 Oil�vacuum/pump�chain

10 Lower�chain�guide�rail

11 Oil�spray�nozzle

12 High-pressure�pump�sprocket

13 Lower�chain

14 Upper�guide�rail

15 Intake�camshaft�sprocket

2.10.�Camshafts�and�timing

The�N57TU�engine�is�fitted�with�the�now�familiar�composite�camshafts.�They�are�made�using�the

Presta�method�in�common�with�the�camshafts�on�all�BMW�diesel�engines.

N57TU�camshaft

21

N57TU�Engine

2.�Engine�Mechanical

Index Explanation

1 Cam

2 Shaft

3 Gear�and�camshaft�sensor�wheel

The�intake�camshaft�is�driven�by�a�sprocket�which�is�chain-driven�by�the�crankshaft.�The�exhaust

camshaft�is�driven�by�direct�gear-to-gear�transmission�from�the�intake�camshaft.�The�camshaft�gears

are�integral�components�of�the�camshafts�and�are�permanently�attached�to�them.�Markings�on�the

camshaft�gears�facilitate�the�correct�positioning�of�the�camshafts�relative�to�one�another�when�fitting.

The�intake�camshaft�gear�also�has�raised�lugs�so�that�it�serves�simultaneously�as�the�reluctor�ring�for

the�camshaft�sensor.�The�twin-flatted�collar�for�accepting�the�special�tool�for�positioning�the�camshaft

relative�to�the�crankshaft�when�fitting�is�integral�with�the�camshaft.�On�the�N57TU�engine,�the�special

tool�is�only�placed�on�the�exhaust�camshaft.

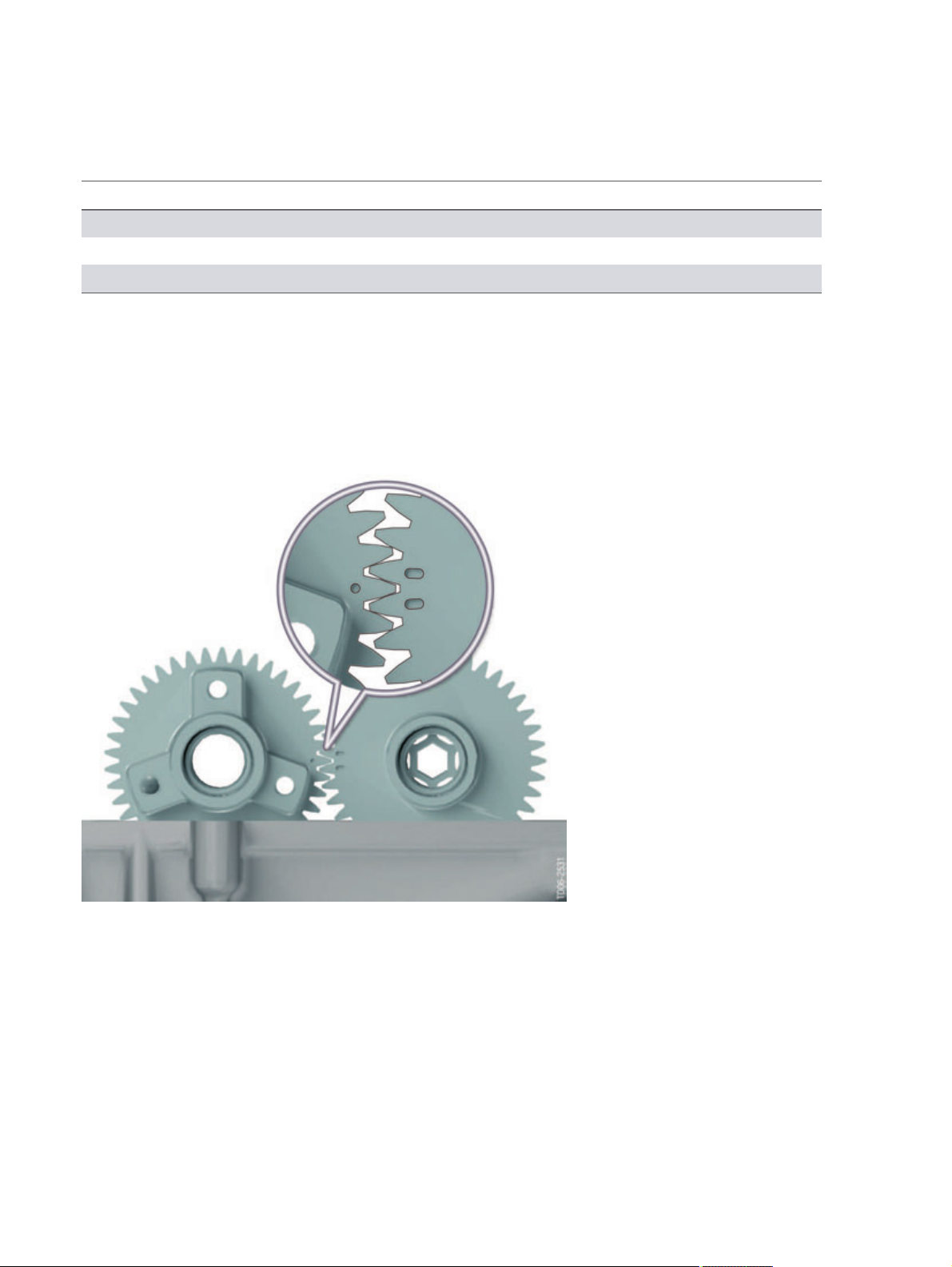

N57TU�timing�gear�alignment

The�camshaft�sprocket�is�bolted�to�the�camshaft�gear�of�the�intake�camshaft.�Slots�are�provided�for

adjusting�the�valve�timing.�A�new�feature�is�that�the�sprocket�can�be�bolted�in�place�without�turning�the

camshaft�out�of�position.�To�that�end,�the�three�bolts�are�not�spaced�evenly�120°�apart�(see�graphic

above).�To�brace�the�camshaft�when�fitting�the�sprocket,�an�Allen-key�socket�in�the�center�of�the

camshaft�gear�on�the�exhaust�camshaft�is�used.

22

N57TU�Engine

2.�Engine�Mechanical

2.10.1.�Timing

The�N57TU�engine�timing�has�remained�the�same�when�compared�to�the�N47TU�engine.

N57TU�engine,�timing�diagram

N57TU�intake N57TU�exhaust

Valve�diameter [mm] 27.2 24.6

Max.�valve�lift [mm] 8.5 8.5

Spread [crankshaft

degrees]

Valve�opens [crankshaft

degrees]

Valve�closes [crankshaft

degrees]

Valve�opening�period [crankshaft

degrees]

100 105

352.4 140.7

567.1 363.9

214.7 223.1

23

N57TU�Engine

3.�Belt�Drive

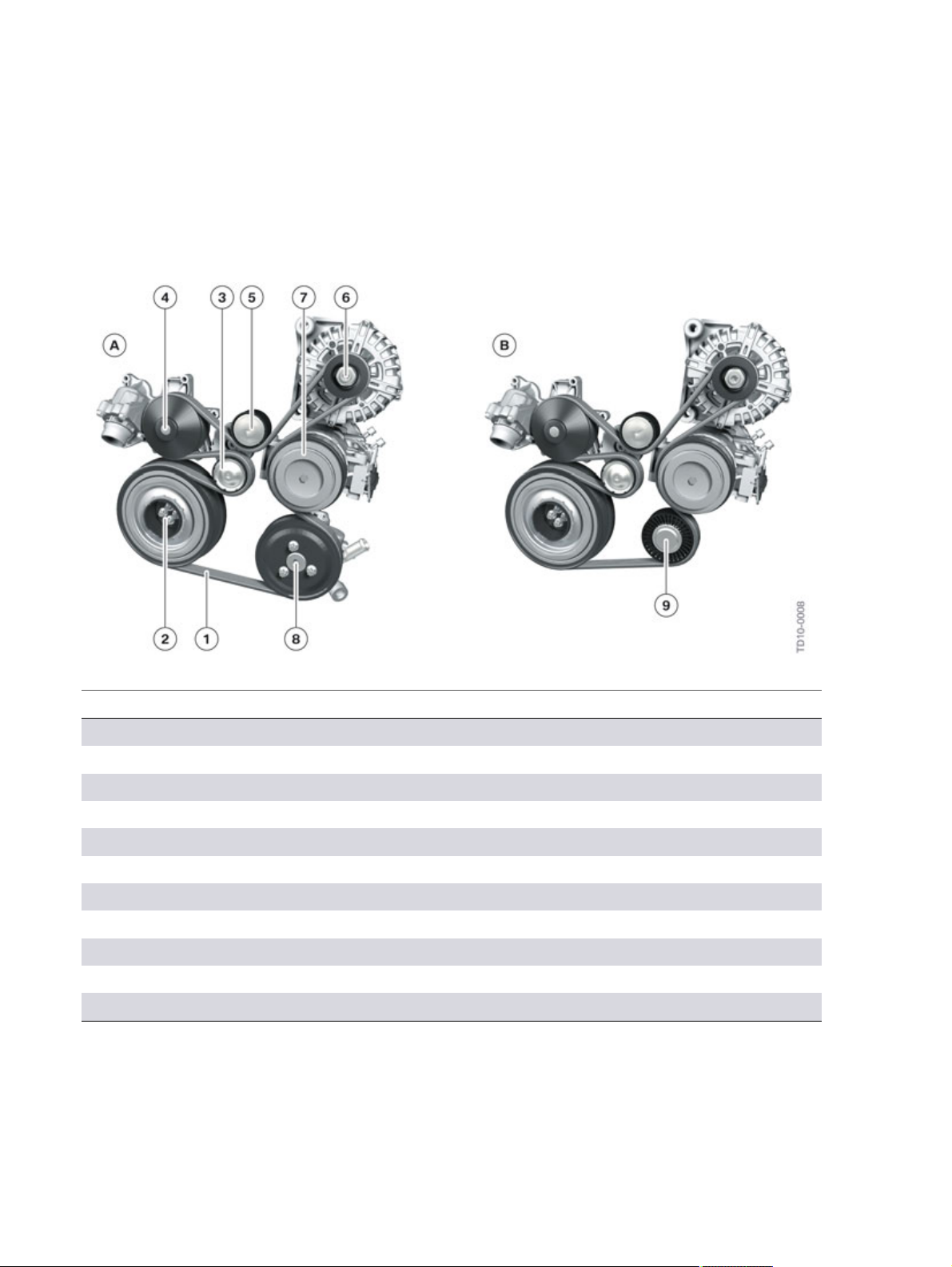

The�layout�of�the�belt�drive�and�assemblies�has�been�redesigned.

3.1.�N57�engine

N57�engine,�belt�drive�variants

Index Explanation

A With�air�conditioning�and�hydraulic�steering

B With�air�conditioning�and�electromechanical�power�steering

1 Drive�belt,�double-sided

2 Torsional�vibration�damper

3 Tensioning�pulley

4 Coolant�pump

5 Deflecting�element

6 Alternator

7 Air�conditioning�compressor

8 Power�steering�pump

9 Deflecting�element

24

Loading...

Loading...