BMW N55 User Manual

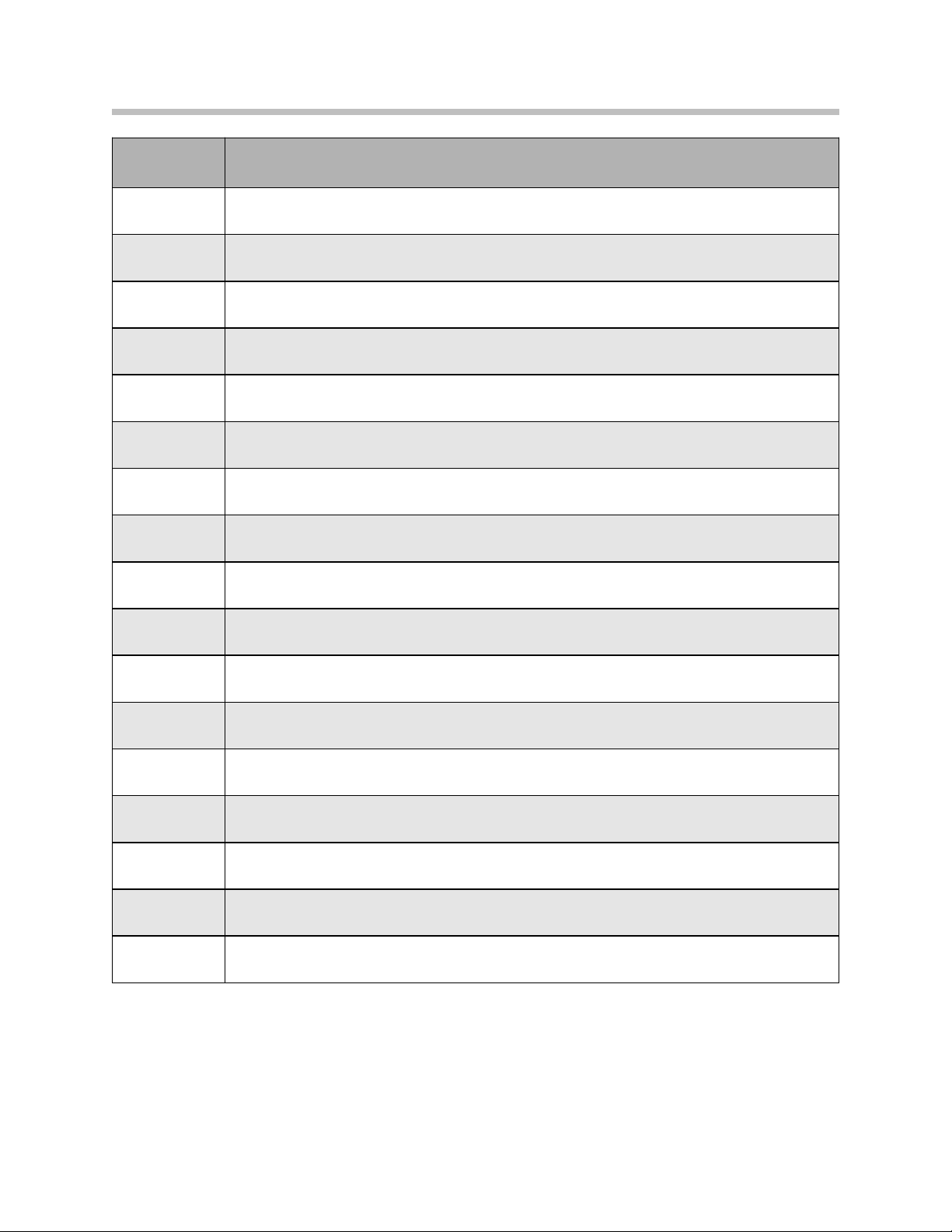

Tab l e of Contents

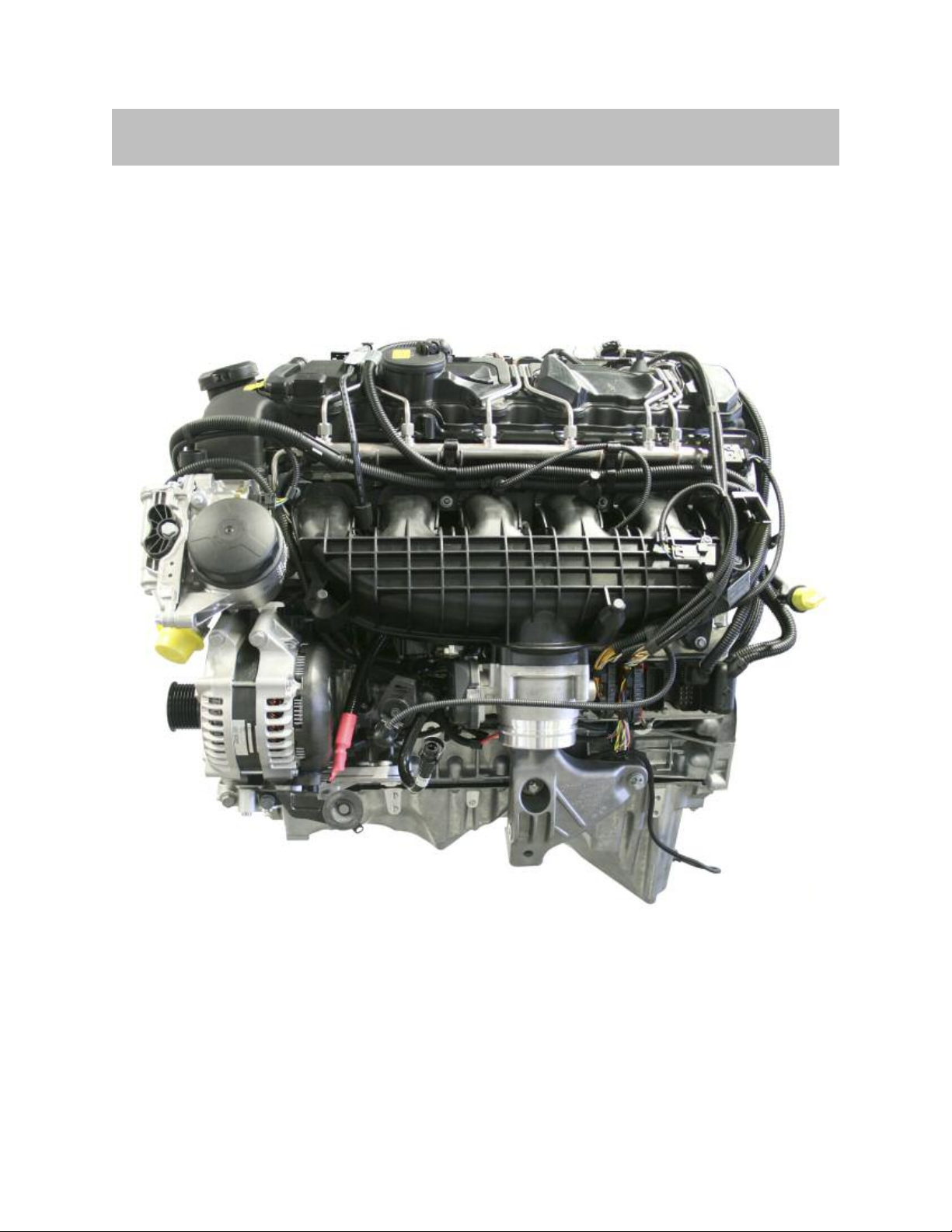

N55 Engine

Subject Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine Components/Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Te ch n i ca l Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Full Load Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Current Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine Designation and Engine Identification . . . . . . . . . . . . . . . . . . . . .11

Engine Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Breakdown of N55 Engine Designation . . . . . . . . . . . . . . . . . . . . . . . .12

Engine Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Crankcase and Bedplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Crankshaft Main Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Pistons and Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Connecting Rod and Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Electrionic Volume-controlled Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . .23

Oil Pump and Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Oil Filtration and Oil Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Oil Spray Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Oil Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Oil Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Cylinder Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Crankcase Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Naturally Aspirated Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Boost Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Valve train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Intake and Exhaust Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Valve Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Initial Print Date: 02/10

Revision Date:

Subject Page

Camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Valve Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

VANOS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

VANOS Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Cam Sensor Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Valve tronic III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Masking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Combustion Chamber Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Valve Lift Adjustment Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Valve tronic Servomotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Belt Drive and Auxiliarly Components . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Vibration Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Air Intake and Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Air Intake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Fuel Ta n k Ventilation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Tu rb oc h ar ge r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Function of the twin scroll turbocharger . . . . . . . . . . . . . . . . . . . .65

Diverter valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Catalytic Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Fuel Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Fuel Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

High Pressure Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Fuel Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

N55, Cooling System Components . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Coolant Passages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Engine Cooling Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Digital Motor Electronics (DME/ECM) . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Digital Motor Electronics Circuit Diagram . . . . . . . . . . . . . . . . . . . . . .88

N55, MEVD17.2 Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Subject Page

Fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Fuel quantity control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Boost pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Engine cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

System Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Crankshaft Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Ignition Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Oil Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Oxygen Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Oxygen sensor before catalytic converter . . . . . . . . . . . . . . . . . . .96

Oxygen sensor after catalytic converter . . . . . . . . . . . . . . . . . . . . .96

Hot-film air mass meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

High Pressure Fuel Injector Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Cylinder Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Fuel Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Ignition Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

N55 Engine

Model: All with N55

Production: From Start of Production

After completion of this module you will be able to:

• Describe the features of the N55B30M0 engine

• Describe the specifications of the N55 engine

• Identify the internal and external components of the N55 engine

• Understand the function of the crankcase ventilation on the N55 engine

• Understand the function of the electronic volume control oil pump

4

N55 Engine

Introduction

The N55 engine is the successor to the N54. Re-engineering and modifications have

made it possible to now use only one exhaust turbocharger. Against the backdrop of

reduced costs and improved quality, the technical data have remained virtually the same.

N55 Engine

N55 Engine

5

Engine Components/Systems Overview

The following provides an overview of the features of the N55 engine:

Crankcase:

• Large longitudinal ventilation holes inter-connect the crankcase lower chambers

and relieve unwanted crankcase pressure between cylinders.

• Modified oil galleries enhance the supply of oil to vacuum pump.

Crankshaft: Is light weight design and has an asymmetric counterweight arrangement.

Pistons and connecting rods:

• A specially formed bushing/bore in small end of the connecting rods evenly

distributes the force of the pistons on the power stroke.

• Lead-free bearing shells are installed on the big-end of the connecting rods.

Cylinder head:

• Specially designed water passages intergraded into the cylinder head enhance

injector cooling.

• The combustion chambers are machined to work in conjuction with the Va lvetronic

III system with regard to promoting air turbulence and mixture formation.

Crankcase ventilation:

• In contrast to the N54, the N55 crankcase ventilation does not use cyclone

separators.

• The cylinder and head cover have integrated blow-by passages that connect the

crankcase ventilation directly to the intake ports.

VANOS:

• The N55 VANOS oil passages are simplified compared to the N54 engine.

• The solenoid valves have integrated non-return valve and 3 screen filters.

• The VANOS units are of a lightweight design for increased adjustment speed

and have a reduced susceptibility to soiling.

Valvetrain:

• The N55 is the first BMW turbo engine to incorporate Valvetronic.

• The valvetrain is a new designed that combines Valvetronic III with Double VANOS.

• With Valvetronic III the 3rd generation brushless servomotor is introduced.

• The position detection sensor of eccentric shaft is now integrated in the servomotor.

6

N55 Engine

Oil supply:

• An enhanced and simplified oil circuit design is used.

• The inlet pipe, oil deflector, and oil collector are combined in one component.

• Oil pump uses a Duroplast slide valve and it is electronically controlled based on

a characteristic map within the engine management.

Forced induction:

• The N55 uses a single twin scroll turbocharger with vacuum operated,

electronically controlled wastegate valve.

• The electric diverter valve is intergraded into the turbocharger compressor housing.

Air intake and exhaust system:

• Air intake system is similar in configuration as the N54 with the exception of the

intake manifold and the use of a single turbo.

• The intercooler is an air to air type mounted in the lower area of the front bumper

cover.

• The exhaust system uses no underbody catalytic converter.

Vacuum system:

• The N55 engine has a two-stage vacuum pump as on the N54.

• The vacuum system has the vacuum reservoir built into the cylinder head cover.

Fuel injection:

• HDE (high pressure fuel injection) system is installed on the N55.

• The HDE system uses solenoid valve fuel injectors instead of the piezoelectric

type used on HPI.

• The high pressure pump and pressure sensors are similar in design and function

in both the HDE and HPI systems.

Digital Motor Electronics (DME):

• The DME is mounted on the intake manifold and cooled by intake air.

• The location of the DME facilitates the installation of the N55 engine in several

current BMW platforms/models.

N55 Engine

7

Te chni c a l Data

Configuration

Cylinder capacity

Bore/stroke

Power output at

engine speed

Power output per liter

Tor qu e at engine speed

Compression ratio

Valves/cylinder

Fuel consumption,

EU combined

CO2 emission

Digital Motor Electronics

Exhaust emission

legislation, US

Unit

[cm³] 2979 2979

[mm] 84.0/89.6 84.0/89.6

[kW/bhp] [rpm] 225/306 5800 - 6250 225/306 5800 - 6400

[kW/l] 75.53 75.53

[Nm] [rpm] 400 1300 - 5000 400 1200 - 5000

[ε]

[l/100 km] 10.9 8.9

g/km 262 209

N54B30O0 (E71/X6

xDrive35i)

6 inline 6 inline

10.2 10.2

4 4

MSD81 MEVD17.2

ULEV ULEV II

N55B30M0

(F07/535i)

Engine oil specification

Top speed

Acceleration

0 - 100 km/h/62mph

Veh icle curb weight DIN/EU

* = Electronically governed

8

N55 Engine

BMW Longlife-01 BMW

Longlife-01 FE BMW

Longlife-04

[km/h] 240 250

[s] 6.7 6.3

[kg] 2070/2145 1940/2015

-

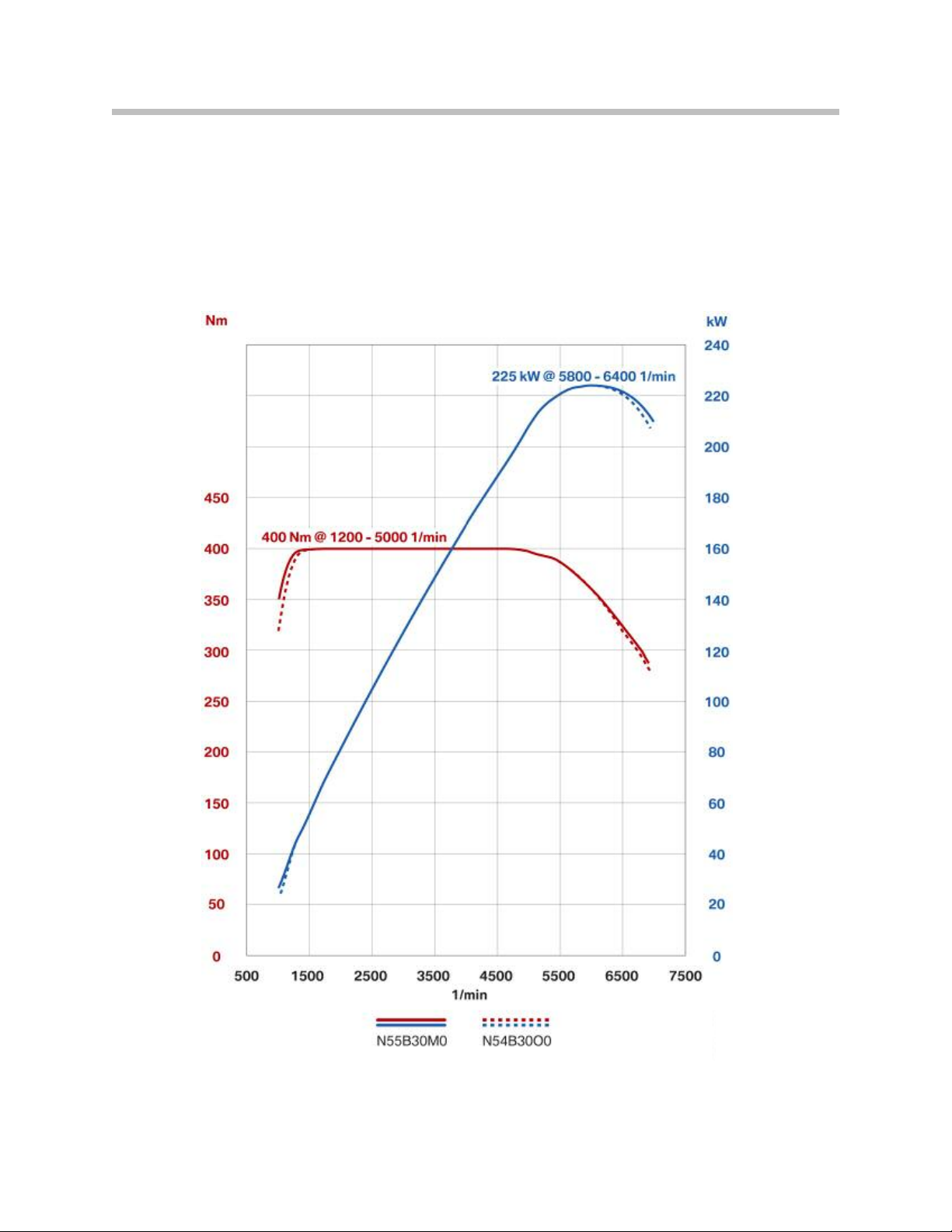

Full Load Diagram

Compared to its predecessor, the N55 engine is characterized by lower fuel consumption

with the same power output and torque data.

Full load diagram E90 335i with N54B30O0 engine

compared to the F07 535i with N55B30M0 engine

N55 Engine

9

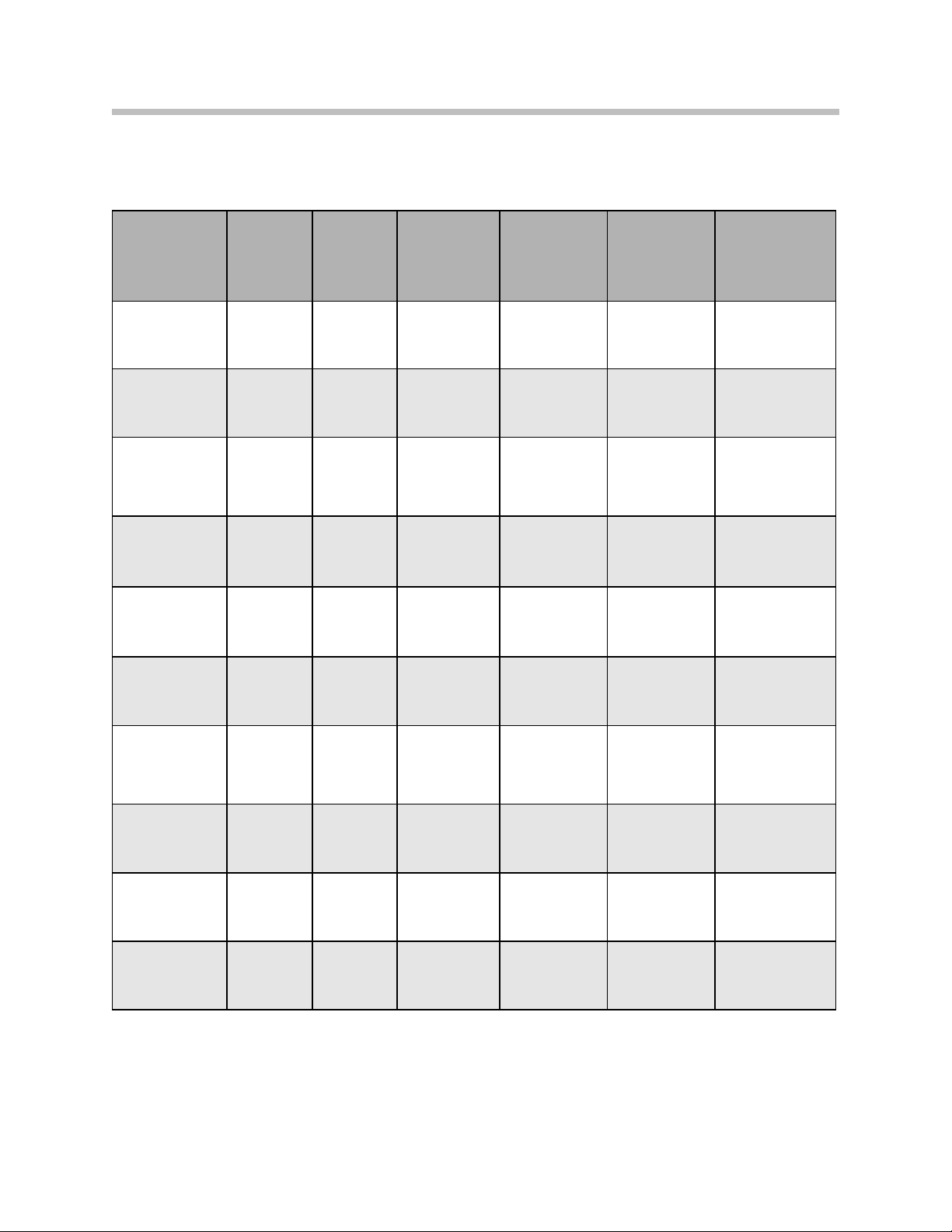

Current Models

N54B30O0 engine variants

Model Vers io n Series

135i

335i

335i xDrive

335is

Z4 sDrive35i

Z4

sDrive35is

US E82, E88 2979 89.6/84.0

US

US E90, E92 2979 89.6/84.0

US E92, E93 2979 89.6/84.0

US E89 2979 89.6/84.0

US E89 2979 89.6/84.0

E90, E92,

E93

Displacement in

cm³

2979 89.6/84.0

Stroke/

bore in

mm

Power

output in

kW/bhp at

rpm

300 SAE hp

5800 - 6250

300 SAE hp

5800 - 6250

300 SAE hp

5800 - 6250

320 SAE hp

5800 - 6250

300 SAE hp

5800 - 6250

335 SAE hp

5800 - 6250

To r q u e i n

Nm at rpm

407

(300 ft-lbs)

1400 - 5000

407

(300 ft-lbs)

1400 - 5000

407

(300 ft-lbs)

1400 - 5000

450

(332 ft-lbs)

1400 - 5000

407

(300 ft-lbs)

1400 - 5000

450

(332/369 ft-lbs)

*1400 - 5000

407

(300 ft-lbs)

1400 - 5000

407

(300 ft-lbs)

1400 - 5000

407

(300 ft-lbs)

1400 - 5000

450

(330 ft-lbs)

1600 - 4500

535i

535i xDrive

X6 xDrive35i

740i

US E60 2979 89.6/84.0

US E60, E61 2979 89.6/84.0

US E71 2979 89.6/84.0

US F01, F02 2979 89.6/84.0

300 SAE hp

5800 - 6250

300 SAE hp

5800 - 6250

300 SAE hp

5800 - 6250

315 SAE hp

5800 - 6250

* The enhanced engine management system of the BMW Z4 sDrive35is and the 335is include

an electronically controlled overboost function to briefly increase torque under full load by

another 37 ft-lbs. This temporary torque peak of 369 ft-lbs gives the car a significant increase

in acceleration for approximately 5 seconds.

10

N55 Engine

Engine Designation and Engine Identification

Engine Designation

This training material describes the N55B30M0 in detail.

In the technical documentation, the engine designation is used for unique identification of

the engine. In the technical documentation you will also find the abbreviated engine designation, i.e. N55, that only indicates the engine type.

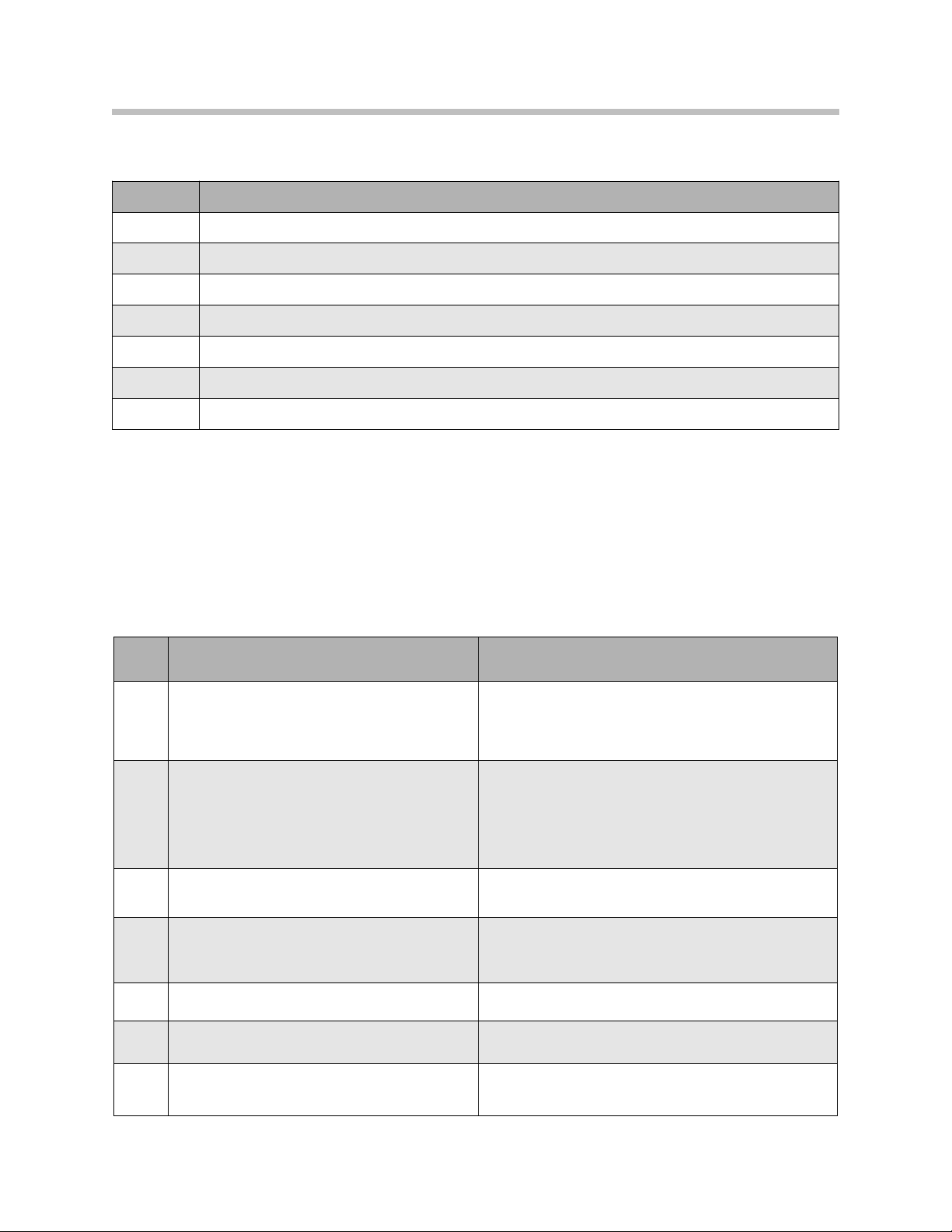

Item Meaning Index / explanation

M, N = BMW Group

1 Engine developer

2 Engine type

P = BMW Motorsport

S = BMW M mbH

W = Non-BMW engines

1 = R4 (e.g. N12)

4 = R4 (e.g. N43)

5 = R6 (e.g. N55)

6 = V8 (e.g. N63)

7 = V12 (e.g. N73)

8 = V10 (e.g. S85)

3 Change to the basic engine concept

4

5 Displacement in liters 1 = 1 liter (whole number of liters)

6 Displacement in 1/10 liter 8 = 0.8 liter (tenth of liter)

7 Performance class

8 Revision relevant to approval

Working method or fuel type and

possibly installation position

0 = basic engine

1 – 9 = changes, e.g. combustion process

B = Gasoline, longitudinal installation

D = Diesel, longitudinal installation

H = Hydrogen

K = Smallest

U = Lower

M = Middle

O = Upper (standard)

T = To p

S = Super

0 = New development

1 – 9 = Revision

11

N55 Engine

Breakdown of N55 Engine Designation

Index Explanation

N

5

5

B

30

M

0

Engine with direct injection, Val vet ron ic and exhaust turbocharger

BMW Group Development

Straight 6 engine

Gasoline engine, longitudinal

3.0-liter capacity

Medium performance class

New development

Engine Identification

The engines are marked on the crankcase with an engine identification code for unique

identification. This engine identifier is also required for approval by the authorities. The

N55 engine further develops this identification system and the code has been reduced

from previously eight to seven characters. The engine serial number can be found under

the engine identifier on the engine. To g e th e r with the engine identifier, this consecutive

number enables unique identification of each individual engine.

Item Meaning Index / explanation

M, N = BMW Group

1

2

3

Change to the basic engine concept

4

5

6

7

Typ e test concerns (changes that

Engine developer

Engine type

Working method or fuel type and

possibly installation position

Displacement in liters 1 = 1 liter (whole number of liters)

Displacement in 1/10 liter 8 = 0.8 liter (tenth of liter)

require a new type test)

P = BMW Motorsport

S = BMW M GmbH

W = Non-BMW engines

1 = R4 (e.g. N12)

4 = R4 (e.g. N43)

5 = R6 (e.g. N55)

6 = V8 (e.g. N63)

7 = V12 (e.g. N73)

8 = V10 (e.g. S85)

0 = basic engine

1 – 9 = changes, e.g. combustion process

B = Gasoline, longitudinal installation

D = diesel, longitudinal installation

H = hydrogen

A = Standard

B – Z = Depending on requirement, e.g. RON 87

12

N55 Engine

N55 engine, engine identification and engine serial number

Index Explanation

08027053

N

5

5

B

30

A

Change to basic engine concept, turbocharging, Valvetronic , direct fuel injection

Operating principle or fuel supply and installation position, petrol engine longitudinal

Individual consecutive engine serial number

Engine developer, BMW Group

Engine type, straight 6

Displacement in 1/10 liter, 3 liter

Typ e approval requirements, standard

13

N55 Engine

Engine Components

Engine Housing

The engine housing consists of the engine block (crankcase and bedplate), cylinder

head, cylinder head cover, oil pan and gaskets.

Engine Block

The engine block is made from an aluminum die-casting and consists of the crankcase

with bedplate.

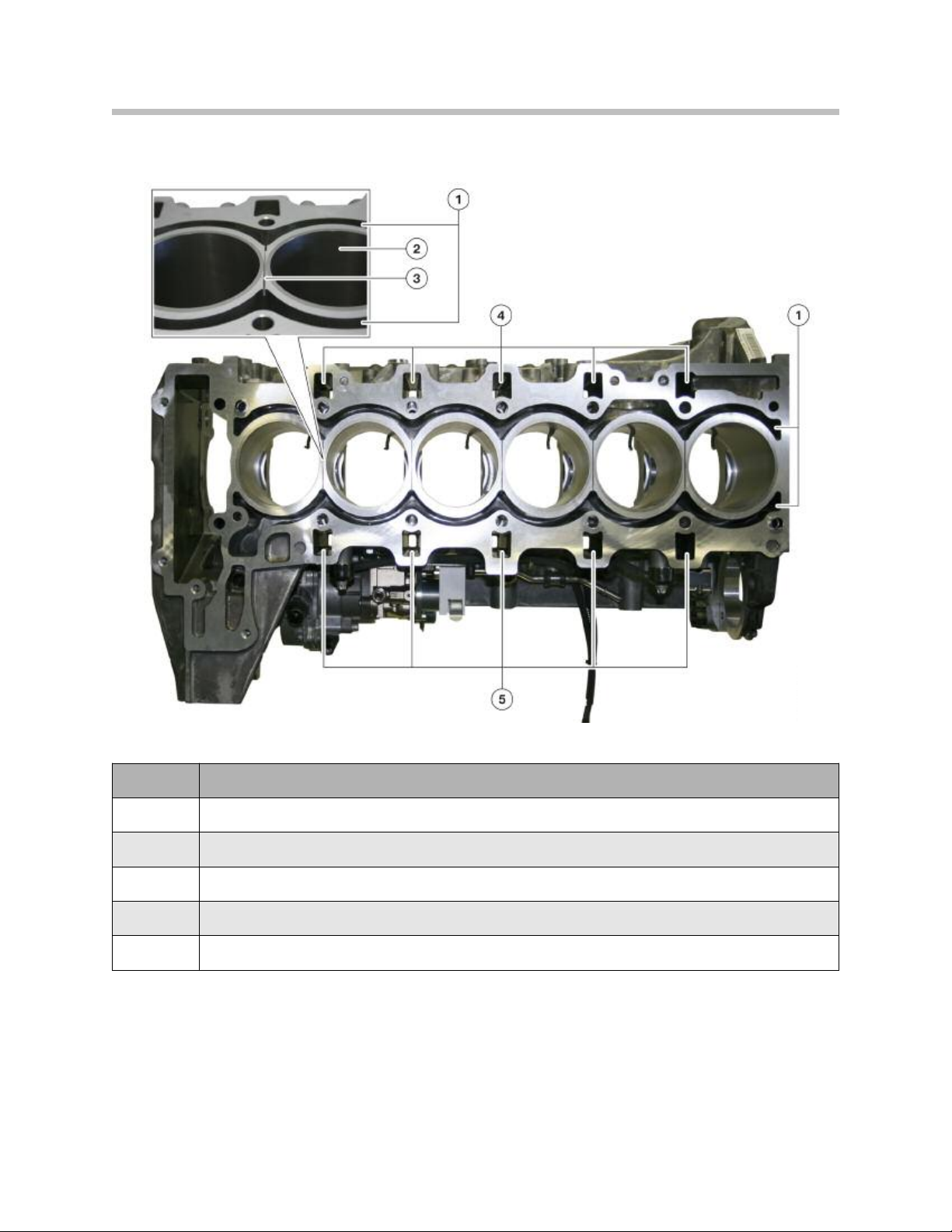

Crankcase and Bedplate

The crankcase features cast iron cylinder liners (2). A new feature is that the webs

between two cylinders on the deck of the block now have a grooved cooling passage

(3). Coolant can flow along these grooves from one side of the crankcase to the other,

thus enhancing cooling of this area.

Five oil return ducts on the exhaust side (4) now permit oil to return from the cylinder

head into the oil pan. These oil return channels extend into the bedplate up to below the

oil deflector. They help reduce churning losses as the returning engine oil can no longer

reach the crankshaft even at high transverse acceleration.

Five oil return channels on the intake side (5) also ensure that the blow-by gasses can

flow unobstructed from the crankshaft area into the cylinder head and to the crankcase

breather in the cylinder head cover.

The cooling duct (1) in the engine block is split and coolant flows directly through it.

14

N55 Engine

N55, crankcase with web cooling

Index Explanation

1

2

3

4

Oil return ducts, exhaust side

5

Cooling duct

Cylinder liner

Grooved cooling passage

Oil return ducts, intake side

15

N55 Engine

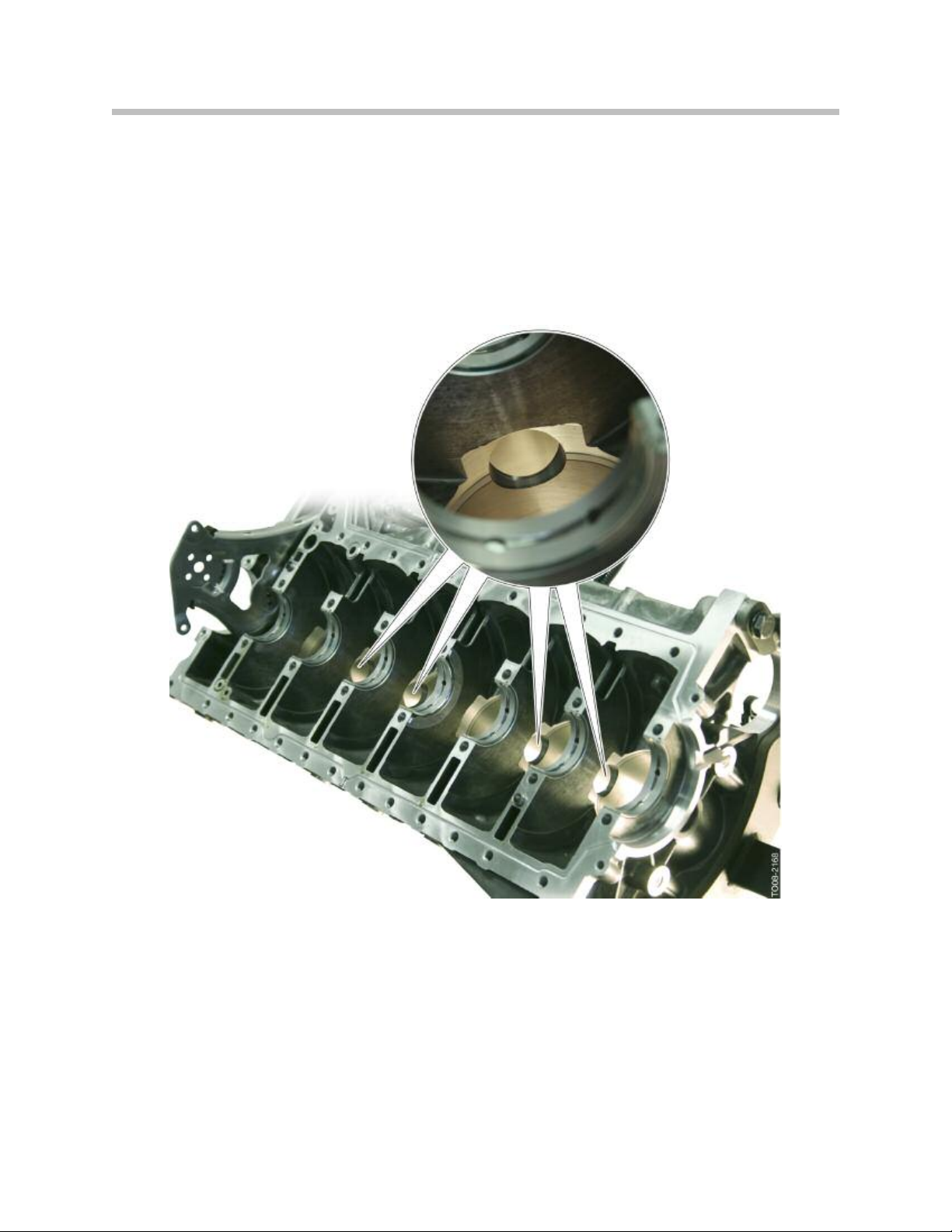

The crankcase has large longitudinal ventilation holes bored between the lower chambers

of the cylinders. The longitudinal ventilation holes improve the pressure equalization,

between the oscillating air columns that are created in the crankcase, by the up and down

movement of the pistons.

This enhances power by relieving the unwanted pressure that acts against the downward

movement of the pistons. It also enhances crankcase ventilation and adds to oil service

life by promoting the movement of blow-by gasses within the engine.

N55, ventilation holes in crankcase

16

N55 Engine

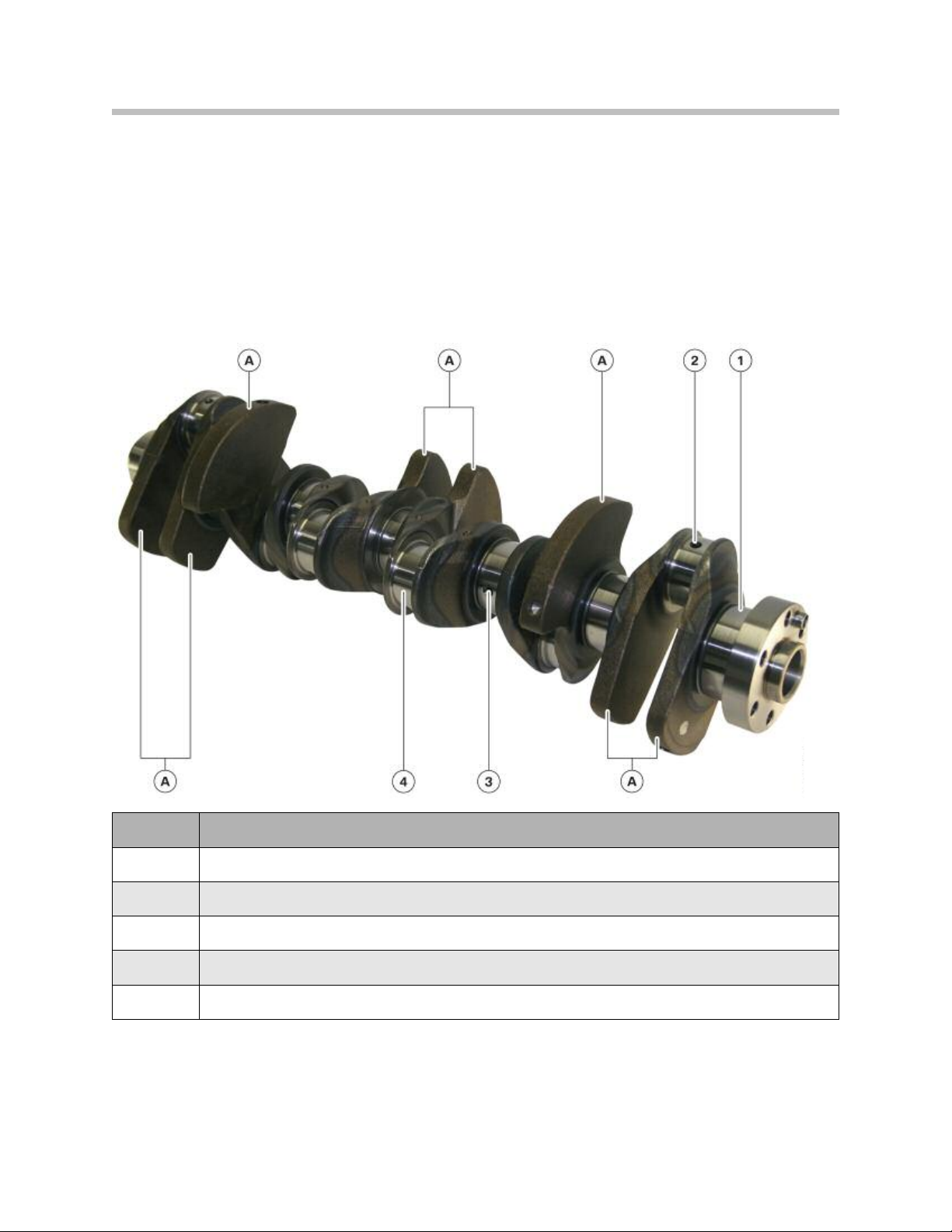

Crankshaft

The crankshaft of the N55 is of lightweight design, at 20.3 kg it’s approximately 3 kg

lighter than the crankshaft in the N54 engine.

The crankshaft is made from cast iron (GGG70). The counterweights are arranged asymmetrically. There is no incremental wheel installed on the crankshaft. The timing chains

are mounted by means of an M18 central bolt.

N55 Crankshaft

Index Explanation

A

1

2

3

4

Oil hole from big-end bearing to main bearing

Oil hole from main bearing to big-end bearing

Big-end bearing journal, cylinder 4

Counterweights

Main bearing journal 7

Crankshaft Main Bearings

As on the N54 engine, the main bearings on the crankshaft are designed as two

component bearings free of lead. The thrust bearing is mounted at the fourth bearing

position.

N55 Engine

17

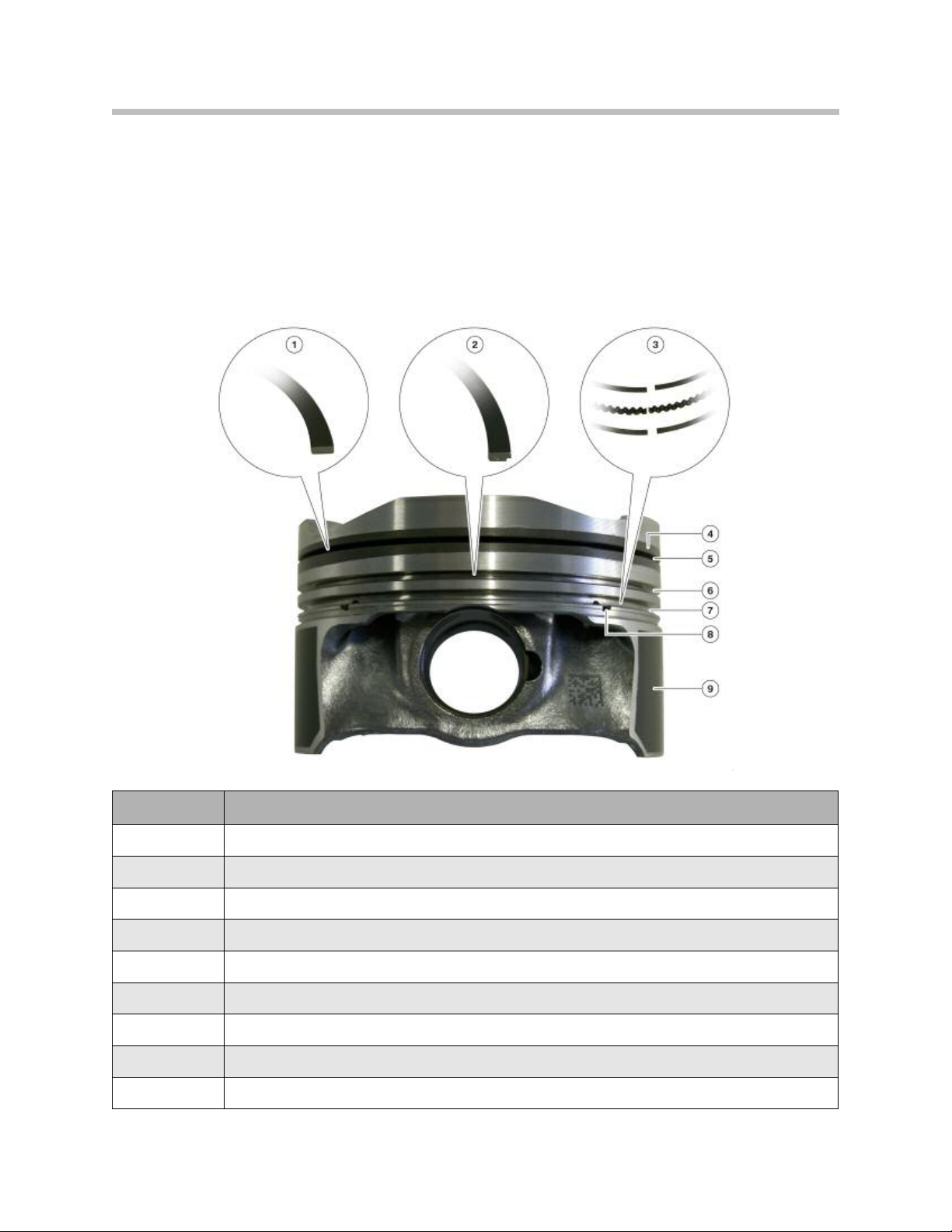

Pistons and Rings

A full slipper skirt type piston with a diameter of 82.5 mm is used. The first piston ring is a

plain rectangular compression ring with a chrome-ceramic coating on the contact surface.

The second piston ring is a tapered faced Napier type ring. The oil scrape ring is

designed as a steel band ring with spring that is also known as VF system.

N55 piston with piston rings

Index Explanation

1

2

3

4

5

6

7

8

9

Plain rectangular compression ring

Ta p er e d faced Napier ring

VF system ring

Steel inlay for first piston ring

Groove for first piston ring

Groove for second piston ring

Groove for oil scraper ring

Hole for lubricating oil drain

Graphite coating

18

N55 Engine

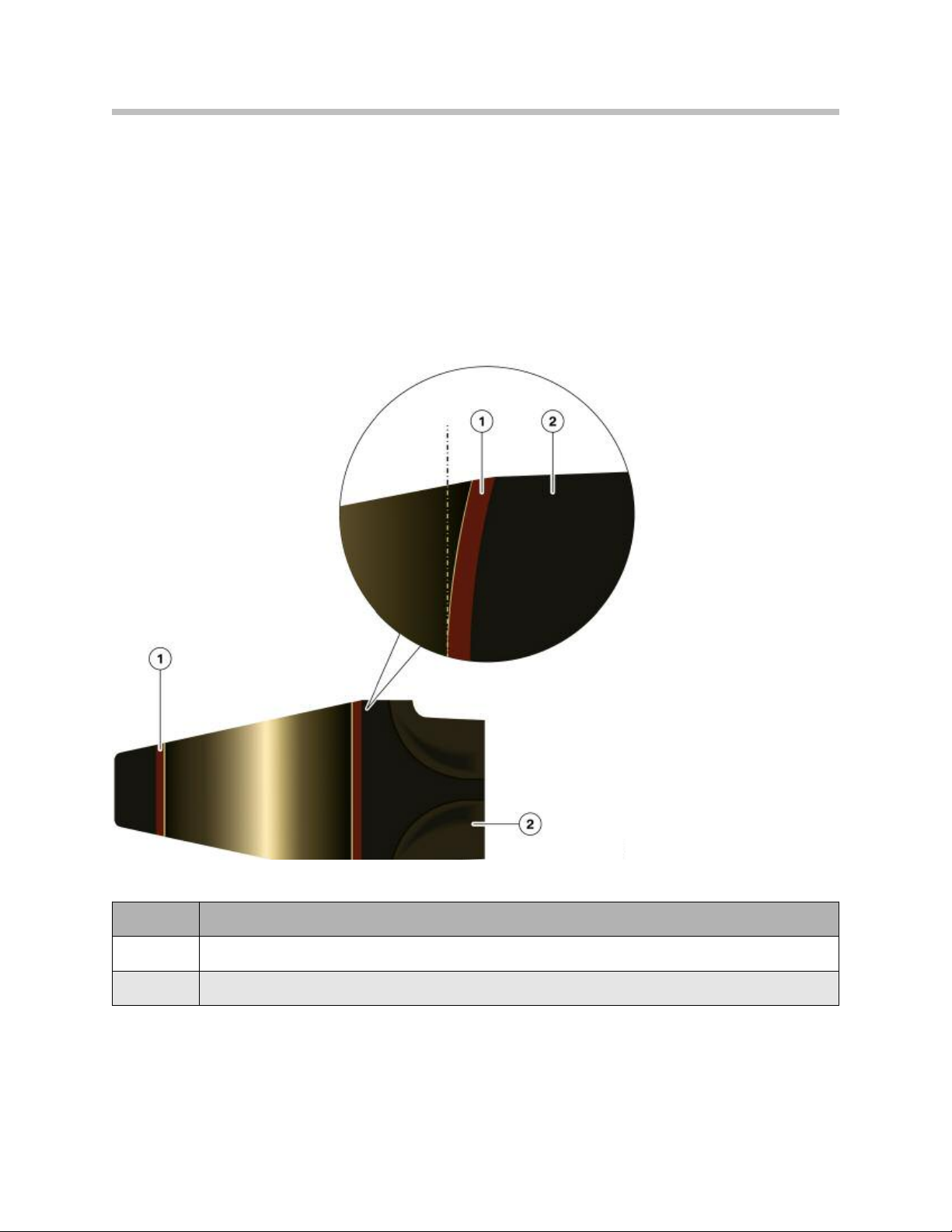

Connecting Rod and Bearings

The size of the connecting rod of the N55 engine is 144.35 mm. A new feature is the

specially formed hole in the small end of the connecting rod. This formed hole is

machined wider on the lower edges of the wrist pin bushing/bore. This design evenly

distributes the force acting on the wrist pin over the entire surface of the rod bushing and

reduces the load at the edges, as the piston is forced downward on the power stroke.

N55, small end of the connecting rod

Index Explanation

1

2

Bushing

Connecting rod

19

N55 Engine

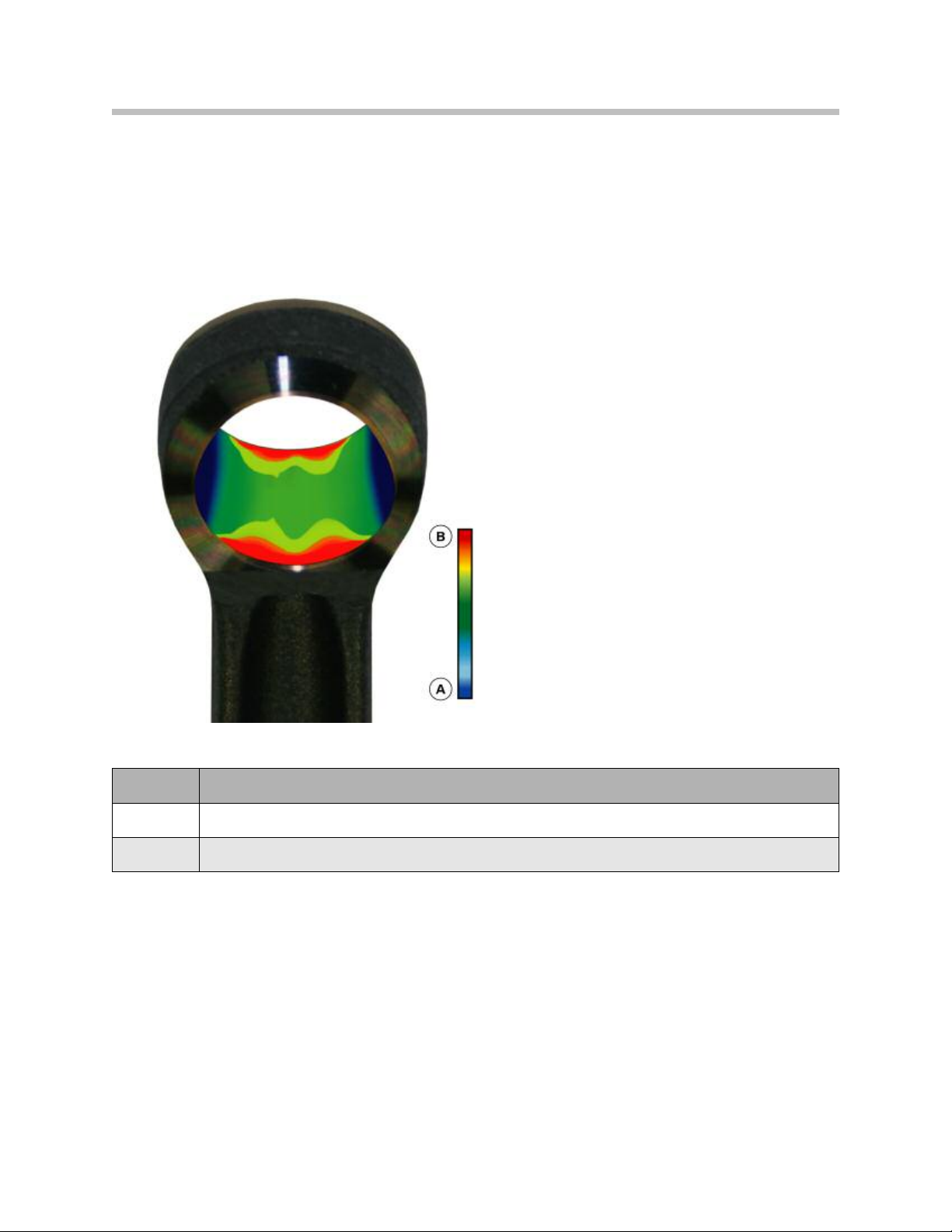

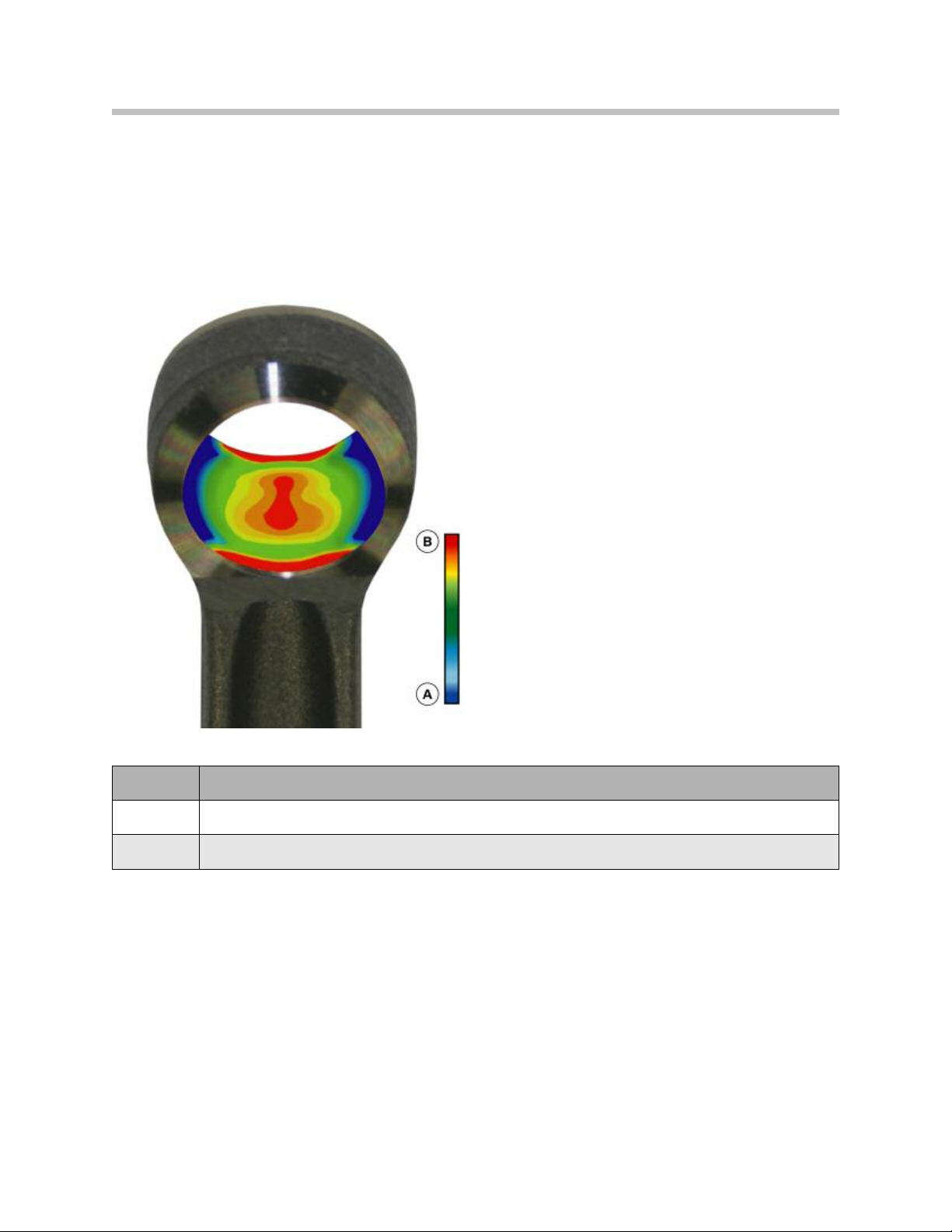

The following graphic shows the surface load on a standard connecting rod without the

formed hole. Due to combustion pressure, the force exerted by the piston via the wrist

pin is mainly transmitted to the edges of the rod bushing.

N54, connecting rod small end without formed hole

Index Explanation

A

B

Low surface load

High surface load

20

N55 Engine

The graphic below illustrates the small end of the connecting rod with a formed hole. The

force is more evenly distributed over a larger area and the load on the edges of the rod

bushing is reduced considerably.

N55, connecting rod small with formed hole

Index Explanation

A

B

Low surface load

High surface load

Lead-free bearing shells are used on the large connecting rod end. The material G-488 is

used on the connecting rod side and the material G-444 on the bearing cap side.

The size M9 x 47 connecting rod bolts are the same on the N55 and N54 connecting

rod.

21

N55 Engine

Oil Pan

The oil pan is made from an aluminum casting. The oil deflector and the intake pipe to

the oil pump are designed as one component. To facilitate attachment to the bedplate,

the oil return ducts are designed so that they extend over the oil deflector. Consequently,

the oil return ducts end in the oil sump.

Ducts are provided for the oil supply to the vacuum pump as it is now lubricated by

filtered oil and not by unfiltered oil as on the N54 engine.

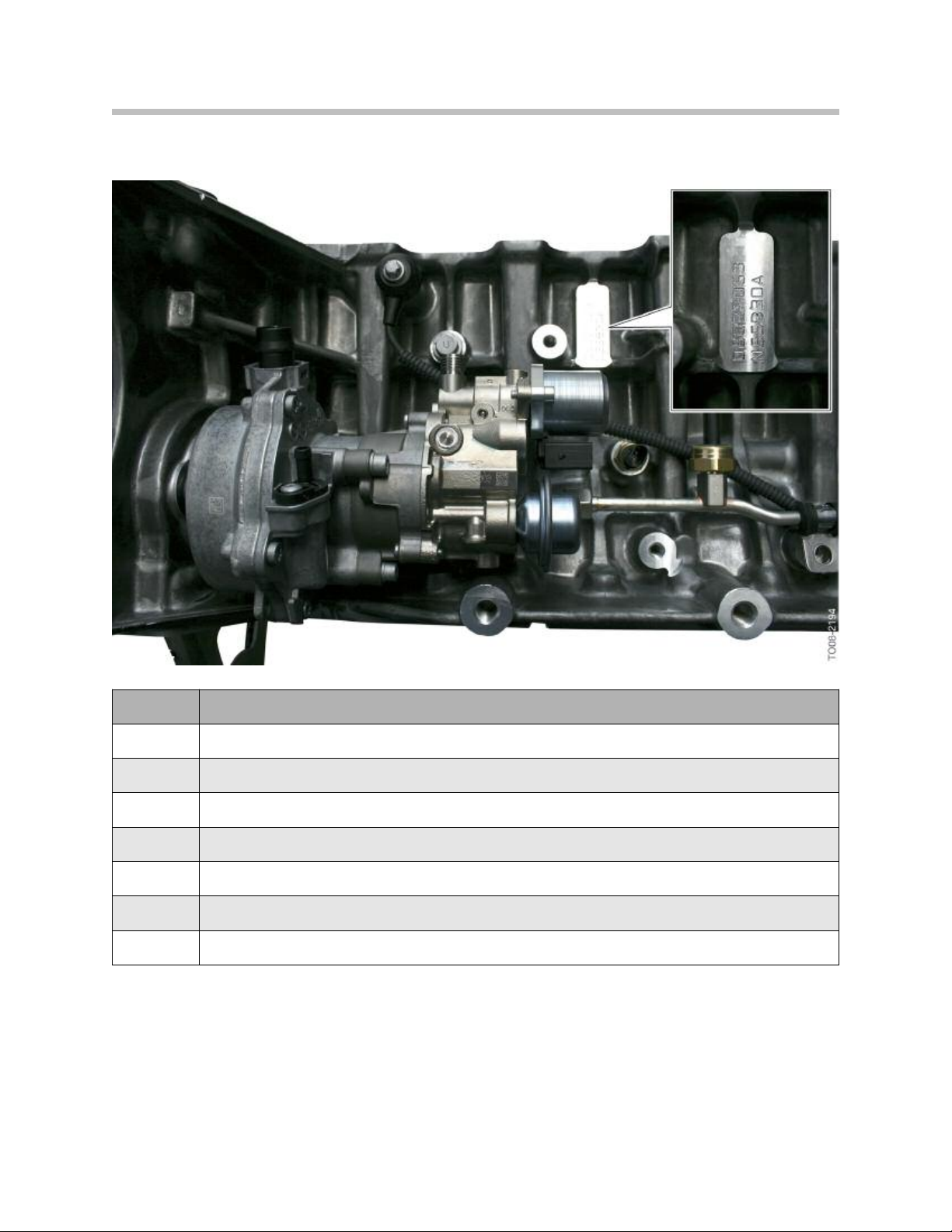

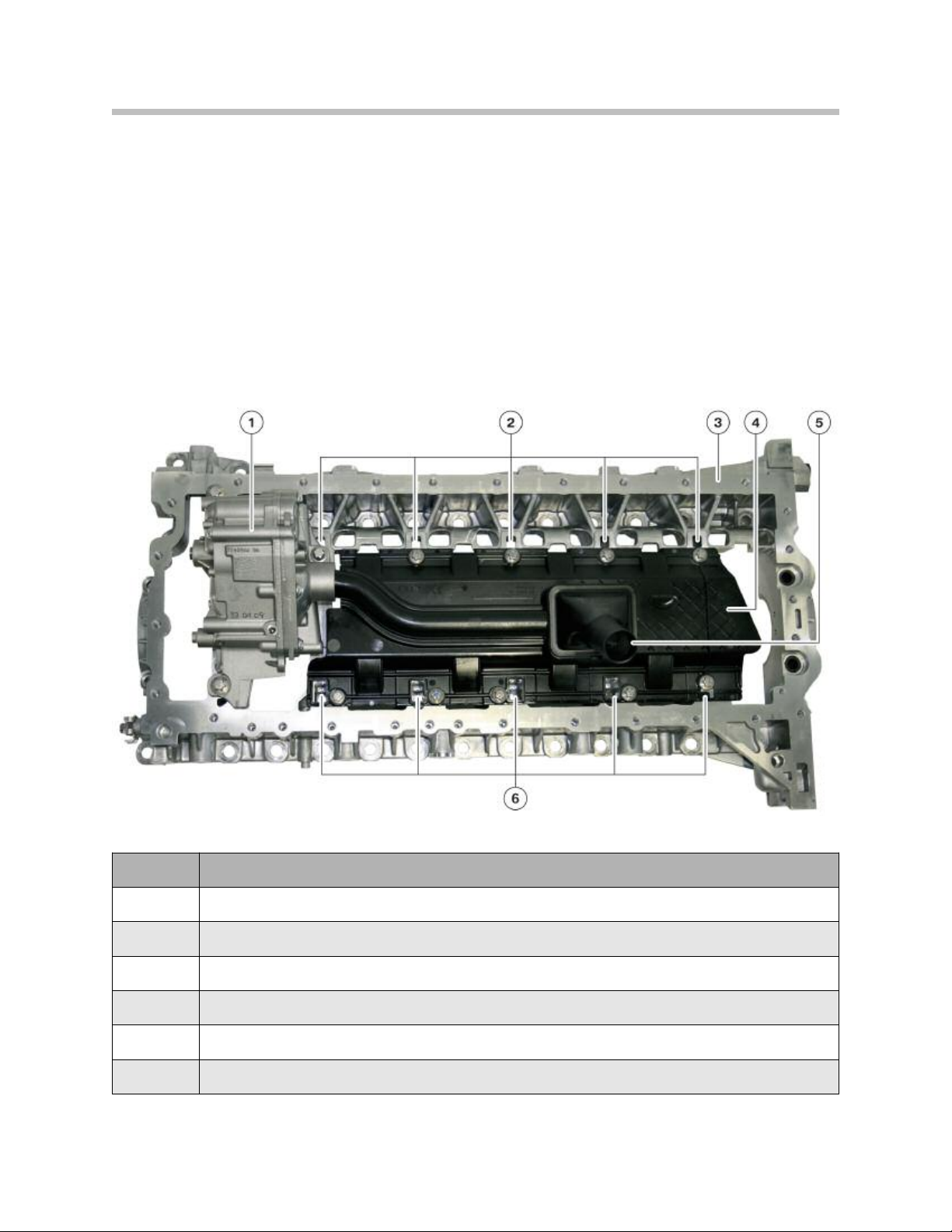

N55, bedplate with oil pump and oil deflector

Index Explanation

1

2

3

4

5

6

Oil return ducts, intake side

Intake manifold with oil screen filter

Oil return ducts, exhaust side

Oil pump

Bedplate

Oil deflector

22

N55 Engine

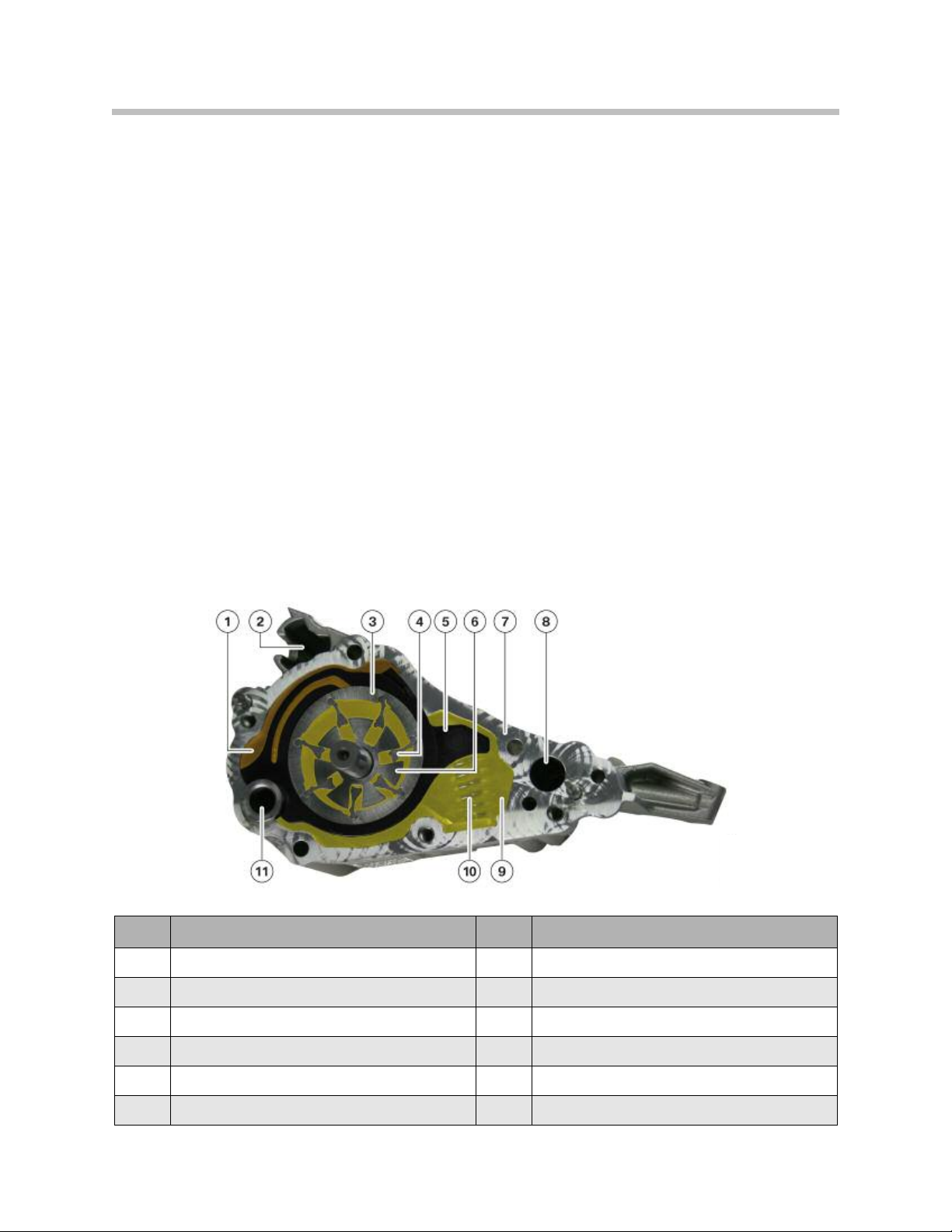

Electrionic Volume-controlled Oil Pump

A modified version of the volume control oil pump of the N54 engine is used. For the first

time a Duroplast reciprocating slide valve is installed. The volumetric flow control system

operating principle of the oil pump is described in the E71 X6 training material under the

”N63 Engine” available on TIS and ICP.

This type of pump delivers only as much oil as is necessary under the respective engine

operating conditions. No surplus quantities of oil are delivered in low-load operating

ranges. This operating mode reduces the pump work and therefore the fuel consumption

of the engine while also slowing down the oil aging process. The pump is designed as a

slide valve-type vane pump. In delivery mode, the pump shaft is positioned off-center in

the housing and the vanes are displaced radially during rotation. As a result, the vanes

form chambers of differing volume. The oil is drawn in as the volume increases and

expelled into the oil galleries as the volume decreases.

The oil pressure in the system (downstream of the oil filter) acts on the slide against the

force of a compression springs in the control oil chamber. The slide element rotates

about a pivot axis.

N55, oil pump

Index Explanation Index Explanation

1

2

3

4

5

6

Control oil chamber

Pressure limiting valve

Rotor

Van e

Duroplast slide valve

Inner rotor

7

8

9

10

11

Hole for pressure control valve

Compression spring (2x)

Housing

Damping oil chamber

Pivot axis of rotation

23

N55 Engine

Oil Pump and Pressure Control

The oil pump has been redesigned with regard to the functionality and durability of the

Duroplast reciprocating slide valve. The oil pump used in the N55 engine is a further

development of the shuttle slide valve volume control oil pump. The activation of the oil

pump is adapted by the engine management and controlled through an oil pressure

control valve.

The delivered oil volume is controlled by means of the oil pressure, based on specific

requirements. The modifications, compared to previous pumps, are primarily in the pump

activation system. The oil pressure no longer acts directly on the control piston but rather

directly on the slide valve. The engine management activates the electrohydraulic

pressure control valve, which affects the oil pressure at the slide valve control mechanism

within the oil pump, altering the pump output. This has the advantage of avoiding power

losses by running the oil pump only when needed.

The electrohydraulic pressure control valve controls the pump output and is bolted to the

front of the engine block. It is operated based on a characteristic map within the DME

(ECM) which in turn is based on feedback from the oil pressure sensor. The N55 uses a

special oil pressure sensor for this purpose which functions in the similar way as the HPI

fuel pressure sensor.

Characteristic map-controlled oil pressure

Index Explanation Index Explanation

A

B

1

2

Oil pressure control, hydraulic/ mechanical

Oil pressure (bar)

Engine speed (rpm)

Characteristic map-controlled

oil pressure, full load

3

4

5

Characteristic map-controlled

oil pressure, no load

Saving potential, full load

Saving potential, no load

24

N55 Engine

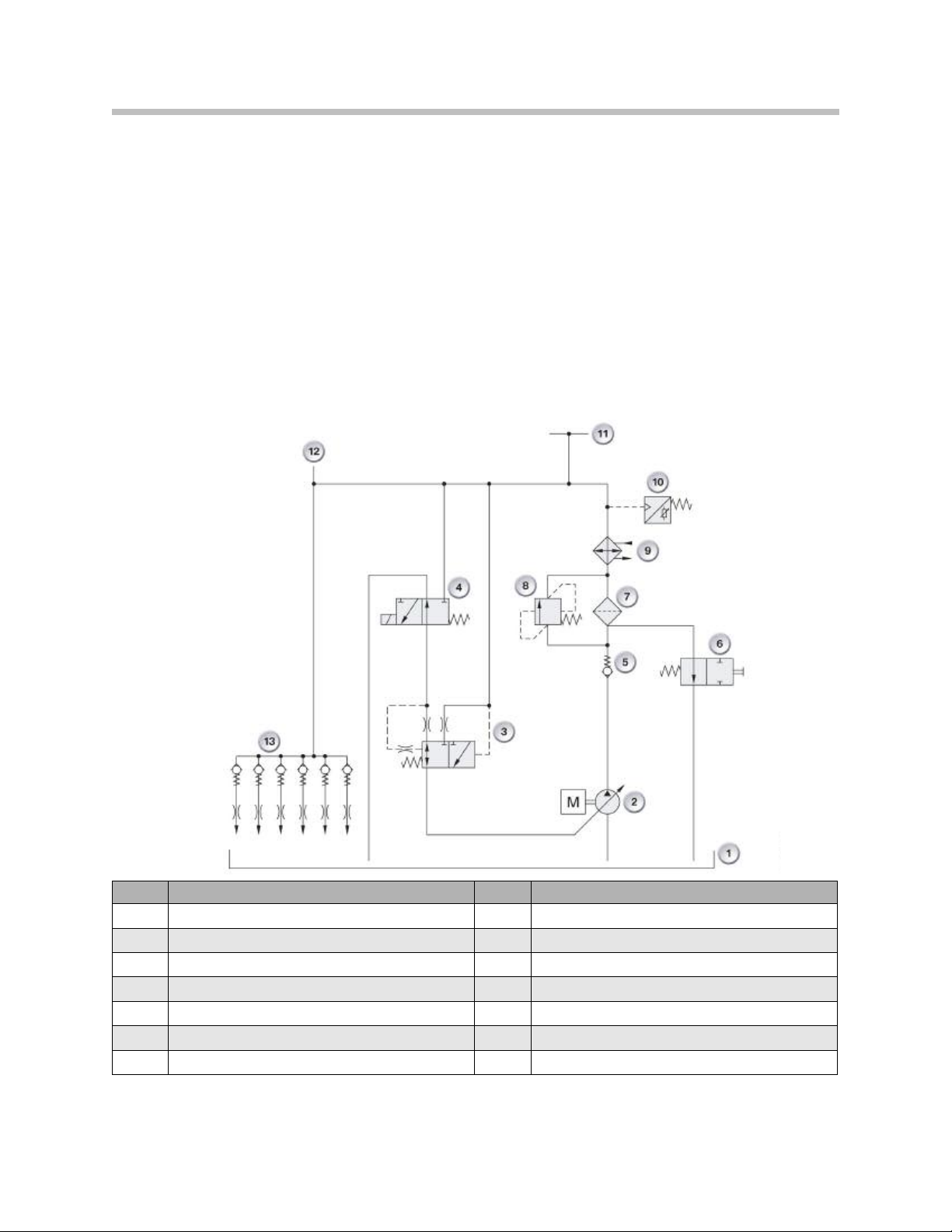

The oil pressure generated by the oil pump (2) is delivered to the engine’s lubricating

points and hydraulic actuators. This system uses oil pressure feed back to control the

desired operating oil pressure. For this purpose, the oil pressure downstream of the oil

filter (7) and engine oil-to-coolant heat exchanger (9) is adjusted by the DME (map-controlled) via the pressure control valve (4) to the pressure control valve (3).

The actual generated oil pressure is registered by the oil pressure sensor (10) and

recognized by the engine management.

In the event of an electrical malfunction, the oil pressure is set to the default control

setting. The pump compression springs are allowed to expand, moving the slide valve to

its maximum oil pressure position.

Hydraulic diagram of the N53 engine oil circuit with electronic pressure control

Index Explanation Index Explanation

1

2

3

4

5

6

7

Vol ume controlled oil pump

Pressure regulating valve

Electro-hydraulic pressure regulating valve

Outlet valve at the filter

Oil Pan

Non-return valve

Oil filter

8

9

10

11

12

13

Engine oil to coolant heat exchanger

Filter By-pass valve

Oil Pressure sensor

Lubricating points, cylinder head

Lubricating points, engine block

Oil spray nozzles, piston crowns

Note: The N53 hydraulic circuit diagram shown is for explanation of the oil

pressure control only, and does not apply directly to the N55 engine.

25

N55 Engine

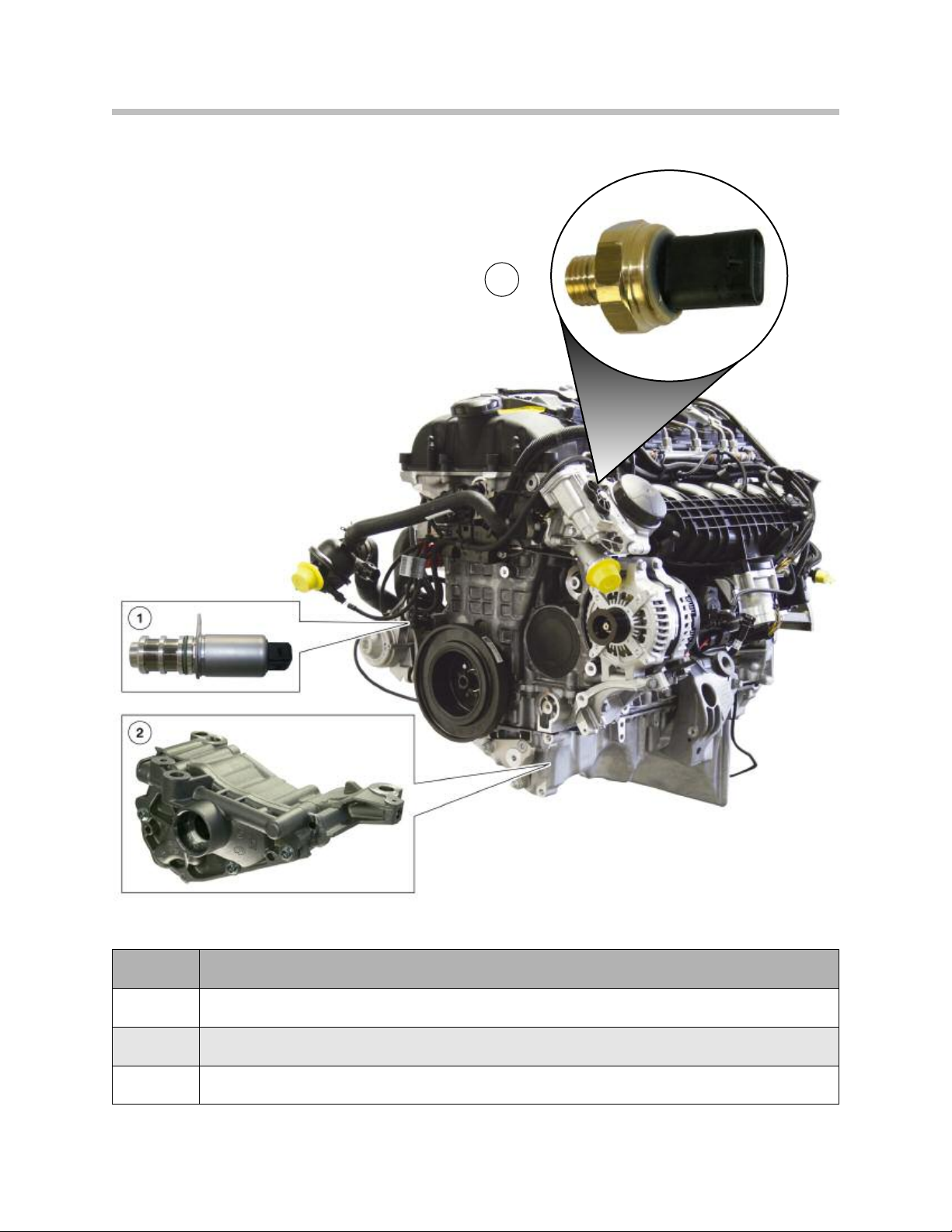

N55, oil pump and pressure control valve

3

Index Explanation

1

2

3

Oil pressure control valve

Oil pump

Oil pressure sensor

26

N55 Engine

Oil Supply

The following graphics show an overview of the oil circuit of the N55. Compared to the

N54 engine, there are considerably fewer oil ducts in the cylinder head. This is mainly due

to the use of the new VANOS solenoid valves.

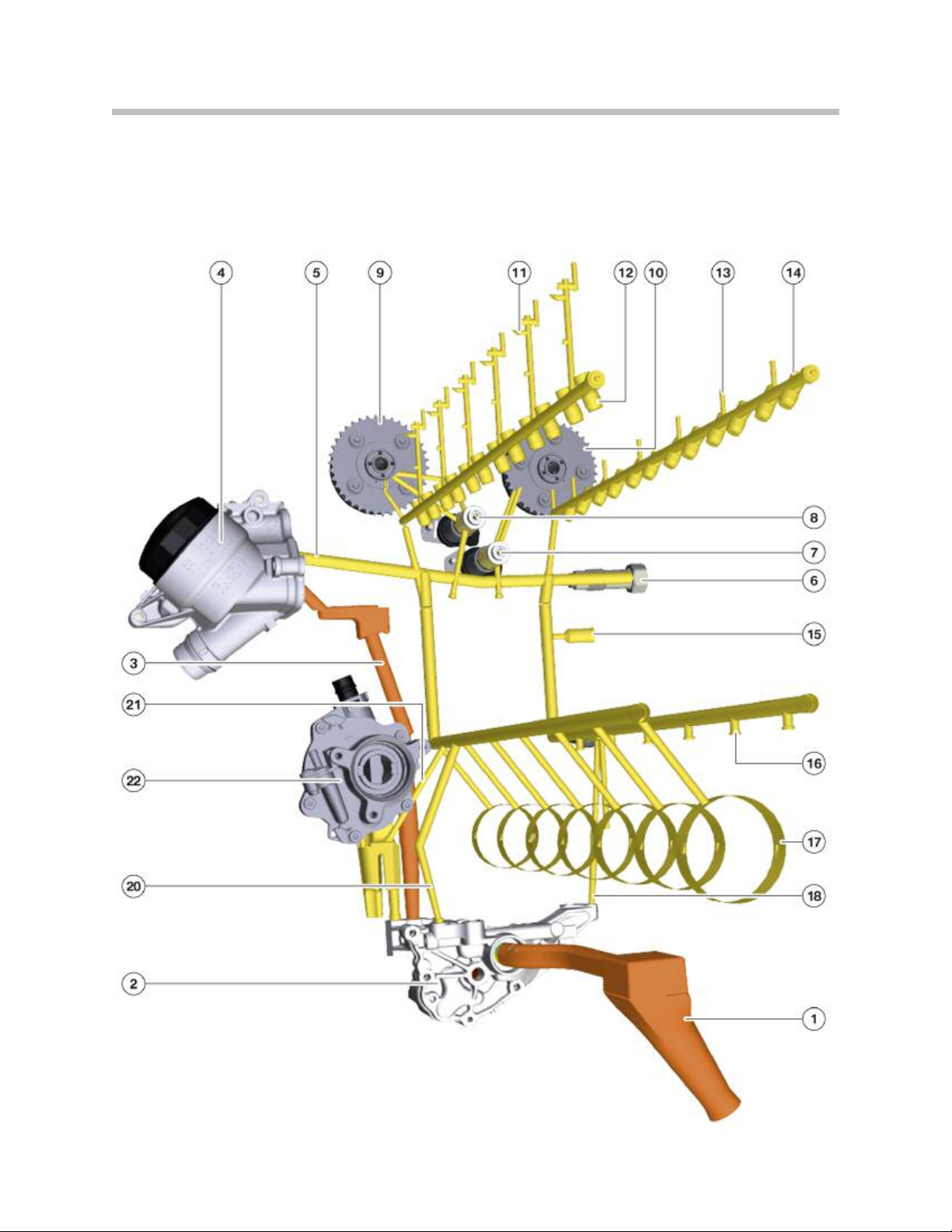

N55, oil passages rear view

27

N55 Engine

Index Explanation

1

2

3

4

5

6

7

8

9

10

11

Intake pipe

Oil pump

Unfiltered oil duct

Oil filter

Main oil duct (filtered oil duct)

Chain tensioner

VAN OS solenoid valve, exhaust side

VAN OS solenoid valve, intake side

VAN OS adjustment unit, intake side

VAN OS adjustment unit, exhaust side

Oil duct for intake camshaft and eccentric shaft lubrication

12

13

14

15

16

17

18

20

21

22

Hydraulic valve lash adjustment

Oil duct for exhaust camshaft lubrication

Hydraulic valve lash adjustment

Connection to exhaust turbocharger lubrication

Connection for oil spray nozzles

Crankshaft bearing

Oil duct for oil pressure control

Oil duct for oil pressure control

Oil duct for vacuum pump lubrication

Vac uum pump

28

N55 Engine

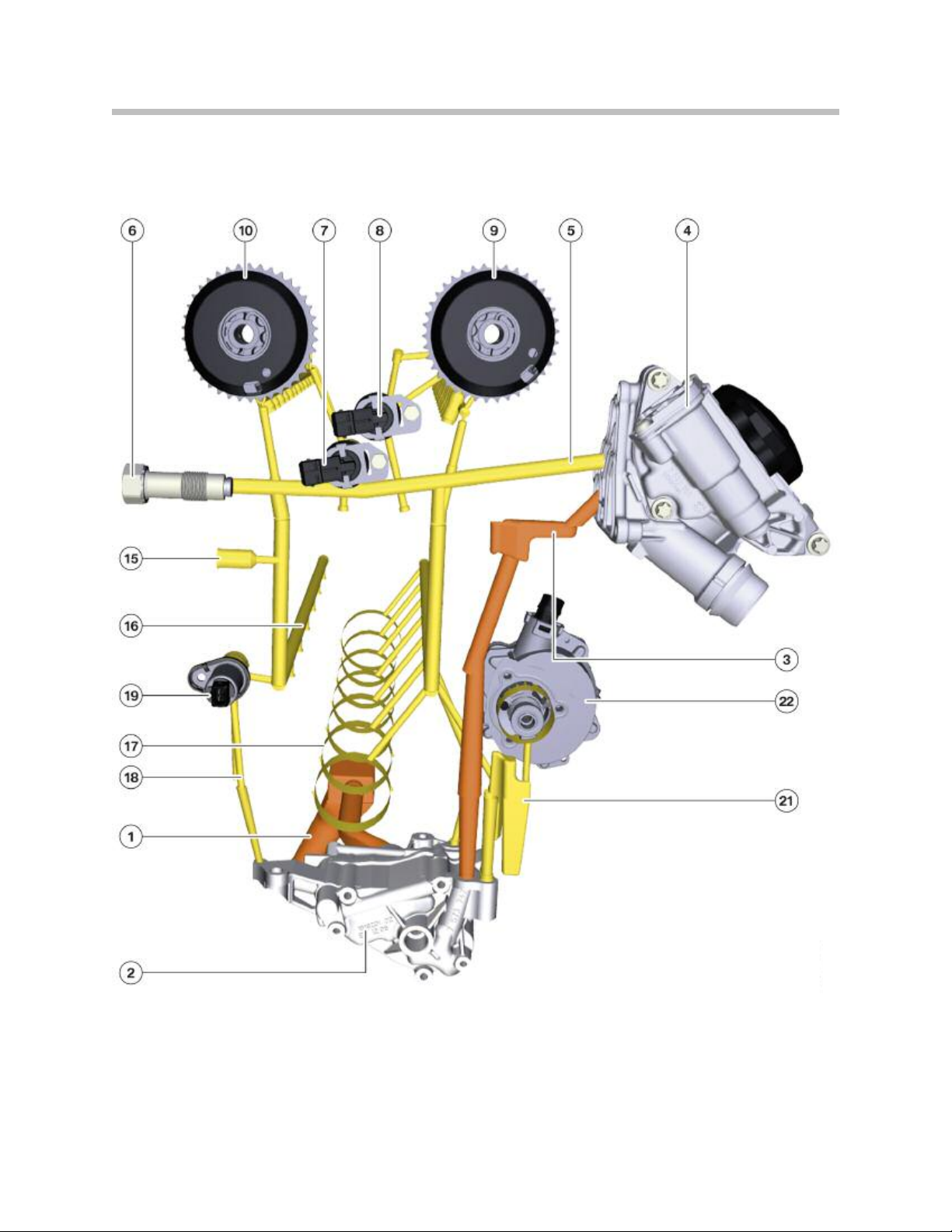

N55, oil passages front view

29

N55 Engine

Index Explanation

1

2

3

4

5

6

7

8

9

10

Intake pipe

Oil pump

Unfiltered oil duct

Oil filter

Main oil duct (filtered oil duct)

Chain tensioner

VAN OS solenoid valve, exhaust side

VAN OS solenoid valve, intake side

VAN OS adjustment unit, intake side

VAN OS adjustment unit, exhaust side

15

16

17

18

19

21

22

Connection to exhaust turbocharger lubrication

Connection for oil spray nozzles

Crankshaft bearing

Oil duct for oil pressure control

Oil pressure control valve

Oil duct for vacuum pump lubrication

Vac uum pump

Oil Filtration and Oil Cooling

The oil filter housing is made from Duroplast. Based on the application, two types of

engine oil coolers may be used. Depending on the oil temperature, a thermostat on the

oil filter housing controls the oil flow through the oil cooler.

30

N55 Engine

Loading...

Loading...