Product Information.

N47 engine.

BMW Service

The information contained in the Product Information and the Workbook form an integral part of

the training literature of Aftersales Training.

Refer to the latest relevant BMW Service information for any changes/supplements to the

technical data.

Information status: November 2006

Contact: conceptinfo@bmw.de

© 2006 BMW AG

München, Germany

Reprints of this publication or its parts require the written approval of

BMW AG, München

VS-12 Aftersales Training

Product Information.

N47 engine.

Rear chain drive

Vacuum pump in the oil sump

Balancing shafts in the crankcase

Notes on this Product Information

Symbols used

The following symbols are used in this Product Information to improve

understanding and to highlight important information:

3 contains information to improve understanding of the systems

described and their function.

1 identifies the end of a note.

Information status and national variants

BMW vehicles satisfy the highest requirements of safety and quality.

Changes in terms of environmental protection, customer benefits and

design render necessary continuous development of systems and

components. Discrepancies may therefore arise between specific details

provided in this Product Information and the vehicles available during the

training course.

This documentation only describes European left-hand-drive variants. In

right-hand-drive vehicles some control elements and components are

arranged differently from what is shown in the graphics in this Product

Information. Further discrepancies may arise from market- or countryspecific equipment specifications.

Additional sources of information

Further information on the individual subjects can be found in the

following:

- in the Owner's Handbook

- in the BMW diagnosis system

- in the Workshop Systems documentation

- in BMW Service Technik.

Contents.

N47 engine.

Objectives

Product Information and reference material for

practical applications

Models 3

Engine variants 3

Introduction 5

System overview 9

Engine identification 9

System components 11

1

1

Overview of engine mechanicals 11

Crankcase 18

Cylinder head and cover 24

Sump 30

Crankcase breather system 31

Crankshaft and bearings 37

Connecting rods and bearings 42

Pistons, piston rings and gudgeon 47

Balancing shafts 54

Rotational vibration damping 57

Camshaft drive system (timing gear) 61

Belt drive and auxiliary equipment 64

Camshafts 67

Lever tappets 72

Hydraulic valve clearance adjustment 74

Valves, valve guides and valve springs 76

Overview of the oil supply 80

From the sump to the oil filter 82

Oil filtration and oil cooling 87

Oil spray nozzles and piston cooling valve 90

Oil monitoring 92

Overview of the intake and exhaust system 106

Intake system 108

Exhaust system 111

Negative pressure system 118

Fuel system 121

Overview of the cooling system 129

Components in the coolant circuit 132

Cooling module 142

Overview of the engine electrical system 143

Functions of the engine electrical system 145

Sensors and actuators 155

Service information 185

System components 185

Test questions 189

Questions 189

Answers to the questions 191

3

Objectives.

N47 engine.

Product Information and reference material for practical applications

This Product Information is intended to

provide you with information on the design

and operation of the N47 engine.

The Product Informationis designed as awork

of reference and supplements the contents of

the BMW Aftersales Training course. The

Product Information is also suitable for private

study.

As preparation for the technical training

course, this Product Information provides an

insight into the new N47 4-cylinder diesel

engine. In conjunction with the practical

exercises carried outin the training course,the

aim of the Product Information is to equip

participants with the skills to carry out

servicing work on the N47 engine.

Existing technical and practical knowledge of

current BMW dieselengineswill make iteasier

to understand the systems and their functions

presented here.

Please remember to work through

the SIP on this topic.

Basic knowledge provides surety in

theory and practice.

1

3

2

4

Models.

N47 engine.

Engine variants

Models with N47 engine for market launch in

March 2007.

3

Model

118d E81 N47D20U0 1995 90/84

120d E81 N47D20O0 1995 90/84

118d E87 N47D20U0 1995 90/84

120d E87 N47D20O0 1995 90/84

320d E92 N47D20O0 1995 90/84

Model series

Engine

Cylinder capacity in cm

Bore/stroke

in mm

Power in

kW/bhp at rpm

105/143

4000

130/177

4000

105/143

4000

130/177

4000

130/177

4000

Torque in

Nm at rpm

300

1750

350

1750

300

1750

350

1750

350

1750

3

4

History

Four-cylinder diesel engines at BMW.

3

Engine

M41D17 318tds E36 1665 66/90 190 DDE2.1 9/94 9/00

M47D20O0 320d E46 1951 100/136 280 DDE3.0 4/98 9/01

M47D20O0 520d E39 1951 100/136 280 DDE3.0 9/99 5/03

M47D20U0 318d E46 1951 85/115 240 DDE3.0 9/01 3/03

M47D20O1 320d E46 1995 110/150 330 DDE5.0 9/01 3/04

M47D20U1 318d E46 1995 85/115 240 DDE5.0 3/03 3/04

M47D20U1 318d E46 1995 85/115 240 DDE506 3/04 3/05

M47D20O1 320d E46 1995 110/150 330 DDE506 3/04 9/06

M47D20U2 118d E87 1995 90/122 280 DDE603 9/04 3/07

M47D20O2 120d E87 1995 120/163 340 DDE604 9/04 3/07

M47D20O2 X3 2.0d E83 1995 110/150 330 DDE506 9/04 9/05

M47D20O2 320d E90 1995 120/163 340 DDE604 3/05 Still

M47D20U2 318d E90 1995 90/122 280 DDE603 9/05 Still

M47D20O2 320d E91 1995 120/163 340 DDE604 9/05 Still

M47D20O2 X3 2.0d E83 1995 110/150 330 DDE604 9/05 Still

Model

Model series

Cylinder

capacity in cm

Power

in kW/bhp

Torque

in Nm

Engine

management

First used

current

current

current

current

Last used

4

Introduction.

N47 engine.

The new generation

5

After eight years, a successful model - yet to

be equalled - is to be replaced. The M47

engine gave the diesel engine at BMW a

respectable pedigree. Offering sporty

acceleration and mighty power coupled with

such low fuel consumption, it soon became

one of the most favourite engines in the BMW

repertoire.

To carry on the baton is the challenge that

faces the successor model, the N47 engine.

Indeed, it is a challenge that it will gladly take

on. With even more power and torque

combined with low fuel consumption and

weight, it is ideally equipped to carry on the

success.

The N47 engine is a completely new

development bestowed with a multitude of

new applications. This has been combined

with the latestdieseltechnology and a number

of tried-and-tested solutions.

An overview of innovations, modifications and special features

Debuting on BMW diesel engines

• Chain driveand high-pressure pump on the

force transmitting side (rear)

• Balancing shafts integrated in the

crankcase with needle bearings

• Common oil/vacuum pump in the oil sump

• Double-sided belt drive

• All auxiliaryequipment on the left-hand side

of the engine

• Rotational vibration damper with freewheel

• Exhaust gas recirculation cooler with

bypass (only upper powerclasswithmanual

transmission)

• Starter on the right-hand side of the engine

• New CP4.1 single-piston high-pressure

pump with 1,800 bar maximum pressure

(lower power class: 1,600 bar)

• Majority of oil ducts cast using a new

casting method

• DDE7 engine management

• Active crankshaft sensor with reverse

rotation detection

• Ceramic glow plugs.

Modifications by comparison with the

predecessor

• Aluminium crankcase with thermally-joined,

grey cast-iron cylinder bushes

• PIEZO injectors (upper power class only)

• More compact roller cam followers

• Two-piece cylinder head

• Reinforcement shell for the crankcase

• Pressure-controlled electric fuel pump

• Fuel filter heating controlled by the DDE

• Crankshaft main bearing caps with indent fit

• Electronic oil level measurement with QLT.

Other key data

• Oil separation in the cylinder head cover

with cyclone filters

• Composite camshafts built in accordance

with the Presta method

• Electric swirl flaps (upper power class only)

• Exhaust turbocharger with electrically

variable turbine geometry (VNT)

• Oxi-cat and DPF in a common, engine-side

housing.

5

5

Technical data

Designation M47D20U2 N47D20U0 M47D20O2 N47D20O0

Engine type 4 inline 4 inline 4 inline 4 inline

Cylinder capacity [cm3] 1,995 1,995 1,995 1,995

Stroke/bore [mm] 90/84 90/84 90/84 90/84

Output

at engine speed

Torque (1st gear)

at engine speed

Torque (remaining)

at engine speed

Cutoff speed [rpm] 4,600 4,600 4,600 4,600

Power output per litre [kW/l] 45.11 52.63 60.15 65.16

Compression ratio ε 17.0 16.0 17.0 16.0

Cylinder gap [mm] 91 91 91 91

Valves/cylinders 4 4 4 4

Inlet valve dia. [mm] 25.9 27.2 25.9 27.2

Exhaust valve dia. [mm] 25.9 24.6 25.9 24.6

Main bearing journal

dia. of crankshaft

Big-end bearing journal

dia. of crankshaft

Engine management DDE603 DDE7.0 DDE604 DDE7.1

Emissions standard EURO 4 EURO 4 EURO 4 EURO 4

[kW/

bhp]

[rpm]

[Nm]

[rpm]

[Nm]

[rpm]

[mm] 60 55 60 55

[mm] 45 50 45 50

90/122

4,000

240

1,750

280

1,750

105/143

4,000

240

1,750

300

1,750

120/163

4,000

280

2,000

340

2,000

130/177

4,000

280

1,750

350

1,750

6

Full-load diagram

The N47 engine is set apart from its

predecessor by an increase in overall

performance and a beefier torque curve.

5

1 - Full load diagram of the N47D20U0 by comparison with its

predecessor

2 - Full load diagram of the N47D20U0 by comparison with its

predecessor

7

5

8

6

System overview.

N47 engine.

Engine identification

Engine designation

The engine designation is used in the

technical documentation for unique

identification of the engine.

The N47 engine has the following variants:

• N47D20U0

• N47D20O0

The technical documentation may also

contain the abbreviated form of the engine

designation, N47, which only makes it

possible to identify the engine model.

This means:

Index Explanation

N BMW Group "New generation"

4 4-cylinder engine

7 Direct diesel injection

D Diesel engine

20 2.0-litre capacity

U/O Lower/upper power class

0 New development

Engine identifier and number

The crankcase ofthe engine ismarked with an

identifier for unique identification and

assignment of the engine. This engine

identifier is also required for approval by the

authorities. The first seven positions are

relevant here.

With the N47 engine, the engine identifier is

now a diesel engine identifier that has been

changed so as to comply with the new

standard wherebythe first sixpositions are the

same as the engine designation.

The engine number is a serial number that

makes it possible to uniquely identify any

individual engine.

The engine identifier and number are located

on the crankcase on the bracket of the highpressure fuel pump.

1 - Engine identifier and number on the N47 engine

9

6

10

7

System components.

N47 engine.

Overview of engine mechanicals

The engine mechanicals can be subdivided

into three major systems:

• Engine casing

• Crankshaft drive system

• Valvegear

Those threesystems are in a stateof constant

interaction with one another. This interaction

has a very significant influence on engine

properties.

Some important interrelationships, such as

firing interval and firing order, will now be

explained in more detail.

Interrelationships

The following table shows the key data for the

N47 inrespect of firing interval and firing order.

N47 engine

Engine configuration/no. of cylinders 4-cylinder in-line engine

Crankshaft crank-pin offset 180°

Firing interval 180° CR

Firing order 1-3-4-2

Firing interval

The firing interval is the angle of crankshaft

rotation between two successive ignitions.

In the course of a complete engine operating

cycle, each cylinder ignites once. The fourstroke cycle (intake, compression, power,

exhaust) of an internal combustion engine

takes two complete revolutions of the

crankshaft, i.e. 720° of rotation.

Having the same firing interval between all

ignition points ensures that the engine runs

evenly at all speeds. Such a firing interval is

calculated as follows:

Firing interval = 720° / Number of cylinders

With a 4-cylinder engine like the N47, this

produces a firing interval of 180° crankshaft.

The firing interval is determined by the

crankshaft's crank-pin offset (the angular

separation of the crank arms), i.e. the angle

between the crank pins for successively firing

cylinders (as determined by the firing order).

Firing order

The firing order is the order in which the

cylinders of an engine are ignited.

The firing order is directly responsible for how

smoothly an engine runs. It is determined on

the basis of the engine configuration, number

of cylinders and firing interval.

The firing order is always quoted starting from

cylinder number 1.

With a 4-cylinder in-line engine, a firing order

of 1-3-4-2 hasprovento be themostideal and

this is also used for the N47 engine.

Cylinder numbering order

Even though the N47 engine has the timing

gear at the rear, the numbering order begins

on the opposite side from which force is

transmitted, like in all BMW engines. The first

cylinder is therefore at the front.

11

7

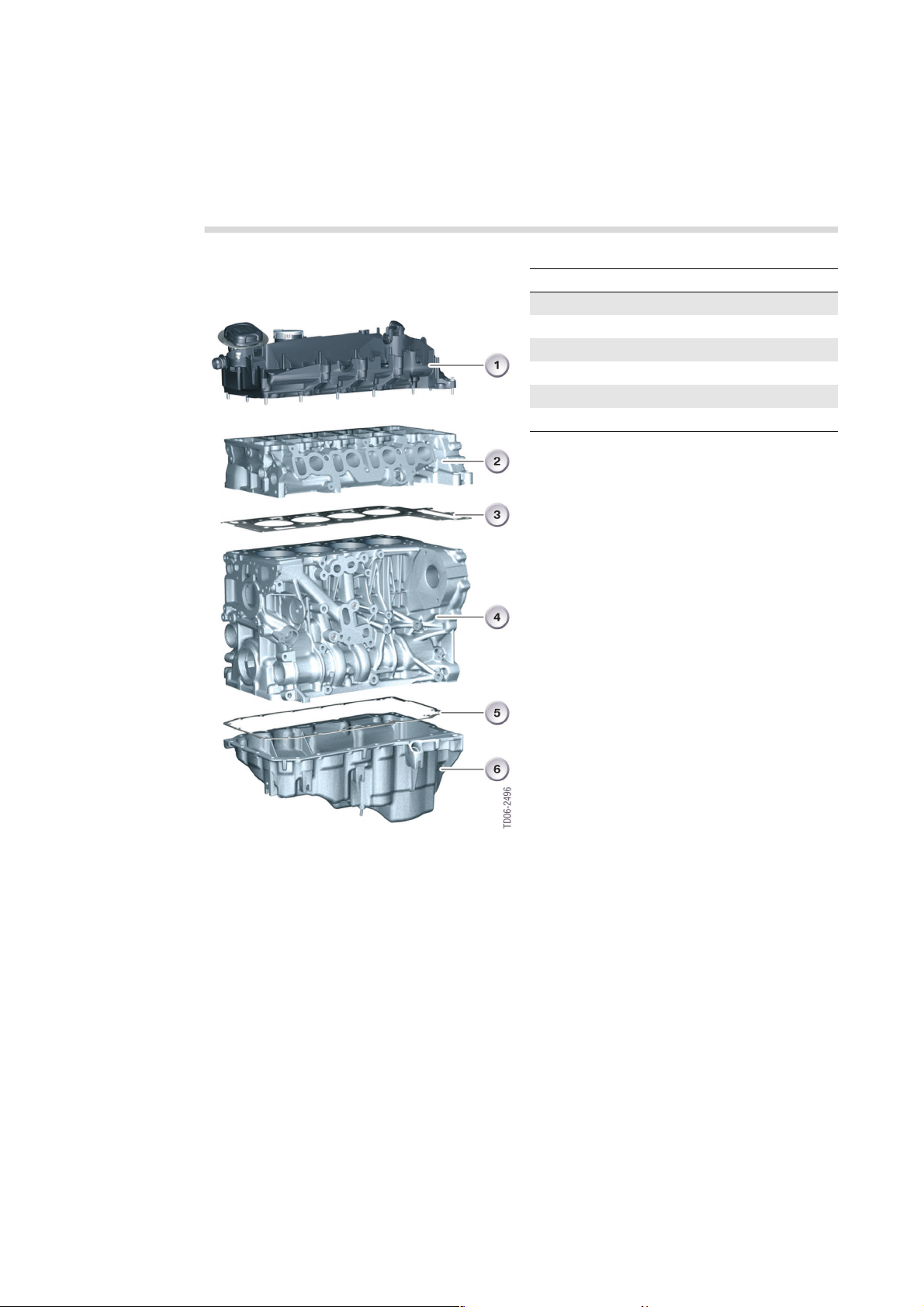

Engine casing

The graphic shows the components of the

engine casing.

Index Explanation

1 Cylinder head cover

2 Cylinder head

3 Cylinder head seal

4 Crankcase

5 Sump gasket

6 Sump

In addition, gaskets and bolts are also part of

this system so that it can perform its job.

That job consists essentially of the following

tasks:

• Containing the forces generated by

operation of the engine

• Sealing functions for the combustion

chamber, engine oil and coolant

• Holding the crankshaft drive system,

valvegear and other components

12

1 - N47 engine casing

7

Crankshaft drive system

The crankshaft drive system, also known as

the power unit, is a function group that

converts the combustion chamber pressure

into kinetic energy. In the process, the

crankshaft converts the linear motion of the

pistons into a rotary motion. The crankshaft

drive systemrepresents the optimumin terms

of work utilization, efficiency and technical

practicability for the task in question.

Index Explanation Index Explanation

1 Connecting rod 3 Crankshaft

2 Piston

Nevertheless, the following technical

limitations and design challenges have to be

dealt with:

• Engine speed limitation due to inertial

forces

• Uneven power delivery over the course of

an operating cycle

• Generation of torsional vibrations that place

stresses on the crankshaft and drive train

• Interaction of the various frictional surfaces

2 - N47 engine crankshaft

drive

13

7

Valvegear

The engine has to be supplied with air in a

regular cycle, while the exhaust gases that it

produces must be expelled. The intake of

fresh air and the ejection of exhaust gas is

referred to as the charge or gas exchange

cycle. Inthe course of the gasexchange cycle,

the inlet and exhaust ducts are periodically

opened and closed by the inlet and exhaust

valves.

The inlet and exhaust valves take the form of

poppet valves. The timing and sequence of

the valve movements are determined by the

camshaft.

The entire mechanism for transferring cam lift

to the valve is known as the valvegear.

In the N47 engine, the crankshaft and

camshaft are mechanically linked by a timing

chain. Timing is therefore fixed.

Design

The valvegear is made up of the following

components:

• Camshafts

• Transmitting elements (roller cam

followers)

• Valves (complete valve assemblies))

• Hydraulic valve clearance adjustment

(HVA).

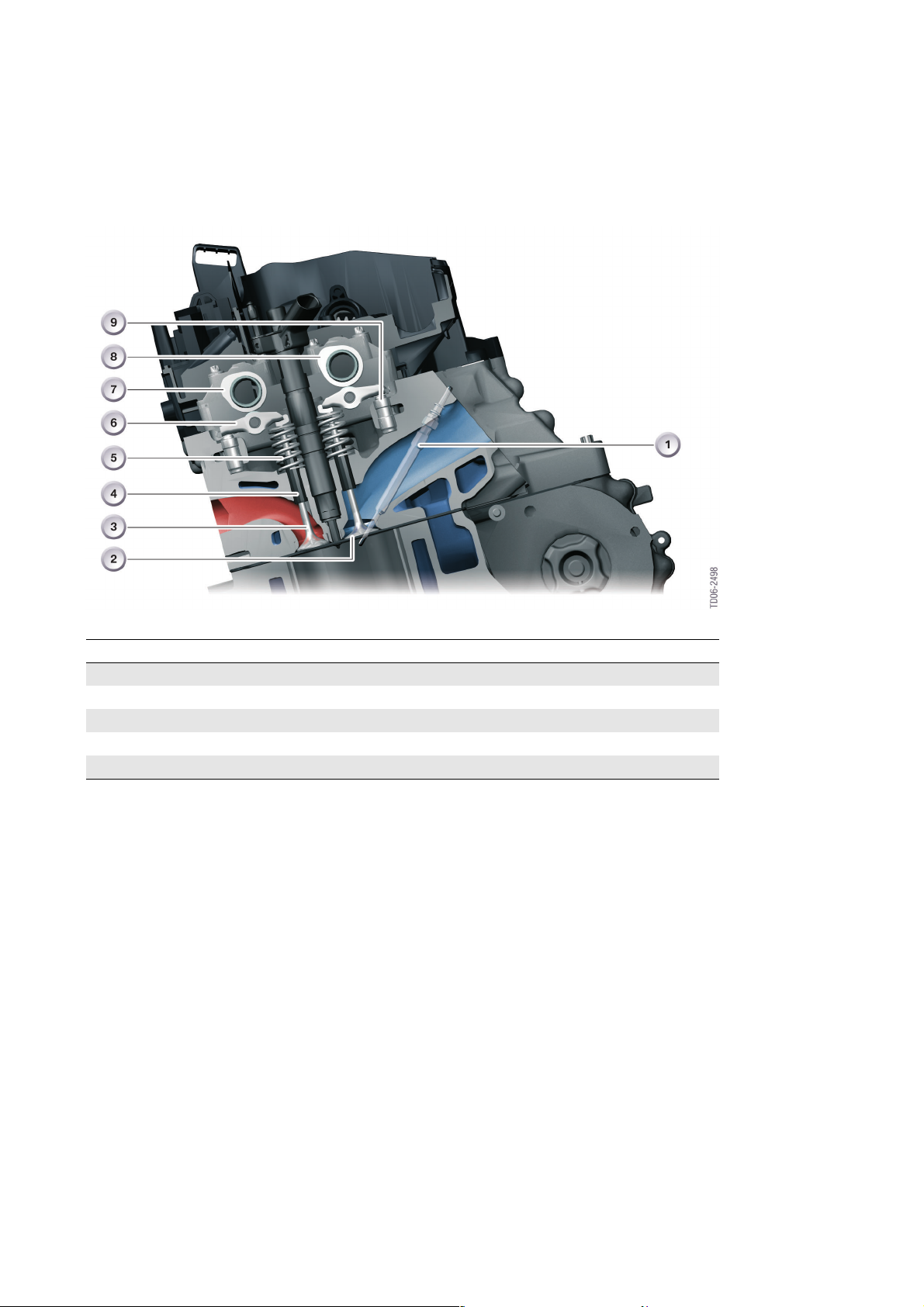

The following graphic shows the design of the

valvegear inthe four-valve cylinderhead of the

N47 engine.

14

7

3 - N47 engine valvegear

Index Explanation Index Explanation

1 Glow plug 6 Roller cam follower

2 Inlet valve 7 Exhaust camshaft

3 Exhaust valve 8 Inlet camshaft

4 Valve guide 9 Hydraulic valve-clearance adjuster

5 Valve spring

Design types

There are a variety of valvegear designs. They

are distinguished according to the following

features:

• Number and position of the valves

• Number and position of the camshafts

• Method of actuation of the valves

• Method of valve clearance adjustment

The designation of the type of valvegear

depends on the first two attributes. The

possible variations are listed below.

Like all current BMW diesel engines, the N47

engine has a DOHC valvegear layout.

This stands for "double overhead camshaft"

and means that the engine has overhead

valves with two camshafts located above the

cylinders. One camshaft is used for the intake

valves, the other for the exhaust valves.

Cam movement on the N47 engine is

transferred from the camshaft to the valve by

roller cam followers in the same way as it is on

all current BMW diesel engines.

The N47 is equipped with valve clearance

adjustment (HVA) to ensure that the correct

amount of playismaintained between the cam

of the camshaft and the roller cam follower.

The following graphic shows the components

of the valvegear on the N47 engine.

15

7

4 - N47 engine valvegear components

Index Explanation Index Explanation

1 Inlet camshaft 7 Valve spring

2 Hydraulic valve-clearance adjuster 8 Lower valve spring retainer

3 Roller cam follower 9 Upper valve spring retainer

4 Valve stem seal 10 Valve guide

5 Valve collets 11 Exhaust valve

6 Inlet valve 12 Exhaust camshaft

Lower valve spring retainer (8) and valve stem

seal (4) form a single component.

16

Timing diagram

7

5 - N47 engine timing diagram

M47TU2

inlet

Valve diameter [mm] 25.9 27.2 25.9 24.6

Max. valve lift [mm] 7.5 7.5 7.5 8.0

Lobe separation [°cranks

haft]

Valve opens [°cranks

haft]

Valve closes [°cranks

haft]

Valve open duration [°cranks

haft]

Inlet valve

The diameter of the inlet valve has been

increased by comparison with the M47TU2.

With no difference in timing, a wider opening

cross section yields improved inflow

characteristics, facilitating the charge cycle.

100 100 108 108

352.0 352.0 142.0 140.7

568.0 568.0 364.0 362.5

216.0 216.0 222.0 221.8

N47

inlet

Exhaust valve

The diameter of the exhaust valve has been

reduced by comparison with the predecessor.

Nevertheless, a greater valve lift produces

better flow characteristicsduringejection.The

opening duration has been marginally

reduced.

M47TU2

exhaust

N47

exhaust

17

7

Crankcase

General information

The crankcase, also known as the cylinder

block or engine block, comprises the

cylinders, the cooling jacket and the

crankshaft housing.

The crankcase of the N47 engine is an entirely

new development.

The special features of the crankcase of the

N47 engine are:

• Crankcase made of aluminium

• Balancing shafts integrated in the

crankcase

• Chain drive located on the force

transmitting side

• Majority of pressurized oil ducts are precast

• Main bearing cap made of sintered metal.

Further technical attributes include:

• Closed-deck design

• Main bearing pedestal with side walls that

extend downwards and individual main

bearing caps

• Main bearing caps with indent fit

• dry, thermally-joined, grey cast-iron cylinder

bushes.

18

7

Design

To provide a better description of the type of

crankcase design, this has been subdivided

into various sections. The types of design can

be classified according to the design of the

following items:

• Deck

• Main bearing pedestals

• Cylinders

Index Explanation Index Explanation

1 Deck 4 Bearing pedestal

2 Crankcase 5 Hole for crankshaft

3 Ventilation window (aperture) 6 Main bearing cap

Deck

The design of the deck affects not only the

choice of casting method but also the rigidity

of the crankcase. A distinction is made

between an open-deck and closed-deck

design.

The N47 engine is equipped with a crankcase

with a closed-deck design.

As the name suggests, a closed deck is, to a

large extent, closed in the area surrounding

the cylinders.

There are holes and openings for oil pressure

and return channels, coolant circulation

channels, crankcase vents and cylinder-head

bolts.

The coolant-channel openings connect the

coolant chamber surrounding the cylinders

with the coolant jacket in the cylinder head.

While this design does have certain

disadvantages in respect of cylinder cooling in

the TDC range, its benefits outweigh those of

the open-deck design what with the greater

rigidity of the deck and thus less deck

deformation, less cylinder twist and better

noise characteristics.

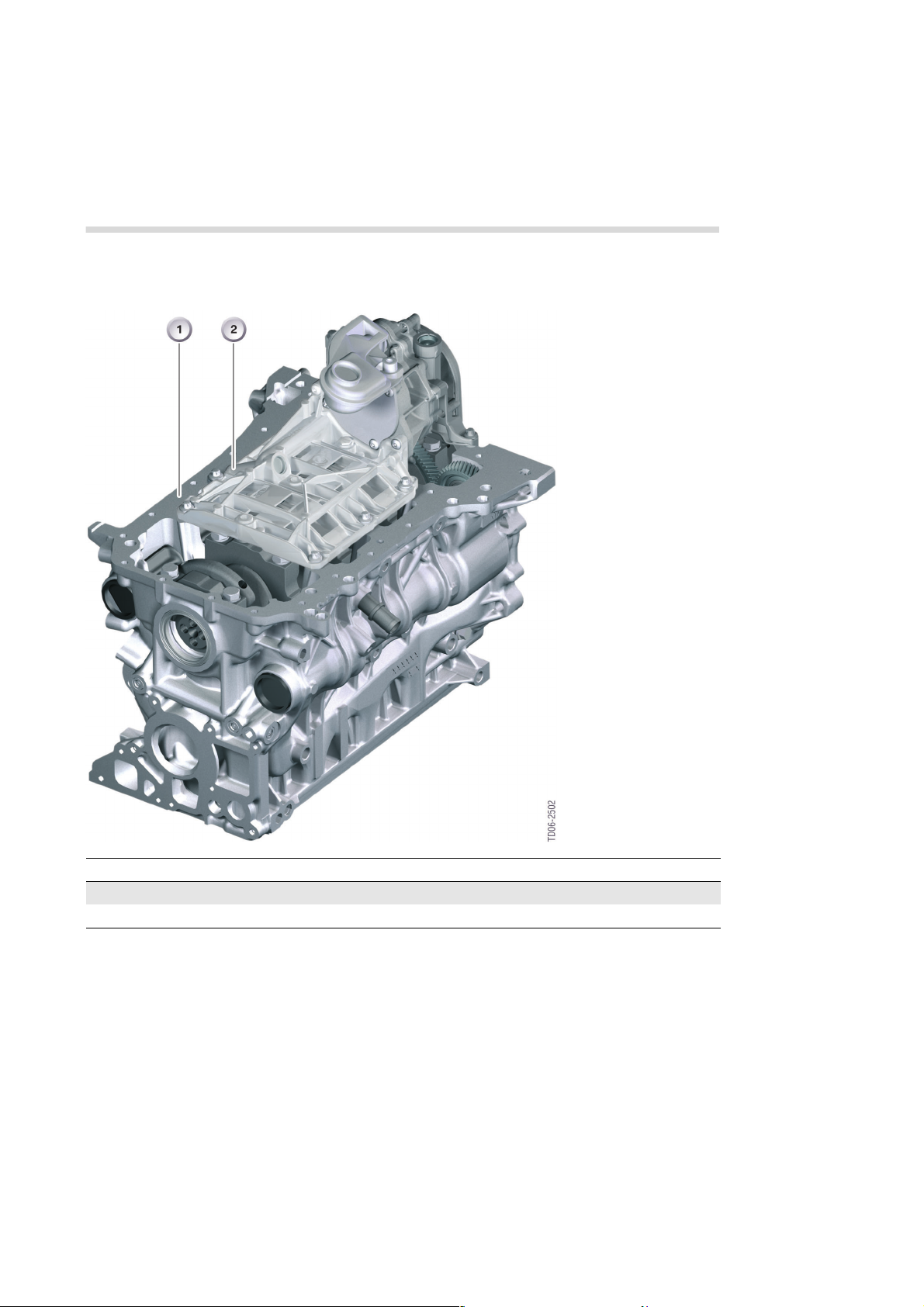

6 - Layout of the N47 engine

crankcase

19

7

Main bearing pedestals

The design of the main bearing pedestal area

is therefore of particular importance because

this is where the forces acting on the

crankshaft bearings are absorbed.

The different types ofdesignaredistinguished

by the partition between the crankcase and

the sump and the design of the main bearing

caps.

In the N47 engine, the partition is below the

centre of the crankshaft; the side walls of the

crankcase extend downwards. Individual main

bearing caps are used.

This design provides high rigidity and is costeffective to manufacture.

Main bearing caps

The main bearing caps form the lower seals

for thebearing pedestals and are rigidlybolted

to them. When the crankcase is

manufactured, the bearingpedestalsand caps

are machinedas one. Therefore, precise fixing

of their relative positions is absolutely

imperative. This is normally done by locating

dowels or cut-away surfaces at the sides of

the bearing pedestals. If the crankcase and

main bearing caps are made of the same

material, the two components may be made

as one and then split by cracking.

In the N47 engine, a relatively new method is

employed to ensure precise positioning. This

involves an indent fit in the contact surface

between the bearing pedestal and the main

bearing cap. This technology was firstused on

the M67TU engine.

This positioning method ensures there is an

absolutely flush surface junction between the

bearing pedestal and main bearing cap in the

bore for the main bearings even after

dismantling and reassembly.

Main bearing caps with an indent fit are

designed with a profile. During the initial

tightening of the main bearing bolts, this

profile is indented into the housing-side

bearing pedestal surface and creates a

positive lock along the transverse and

longitudinal axis of the engine.

Bearing pedestal

The bearing pedestal is the top half of a

crankshaft main bearing in the crankcase.

Bearing pedestals are always integrated into

the cast of the crankcase.

In the N47 engine, there are ventilation

windows in the bearing pedestals above the

crankshaft.

When the engine is running, the air andvapour

inside the crankshaftcavity are continuouslyin

motion. The action of the pistons has a pumplike effect on those gases. The ventilation

windows reduce these losses because they

facilitate pressure compensation in the entire

crankcase.

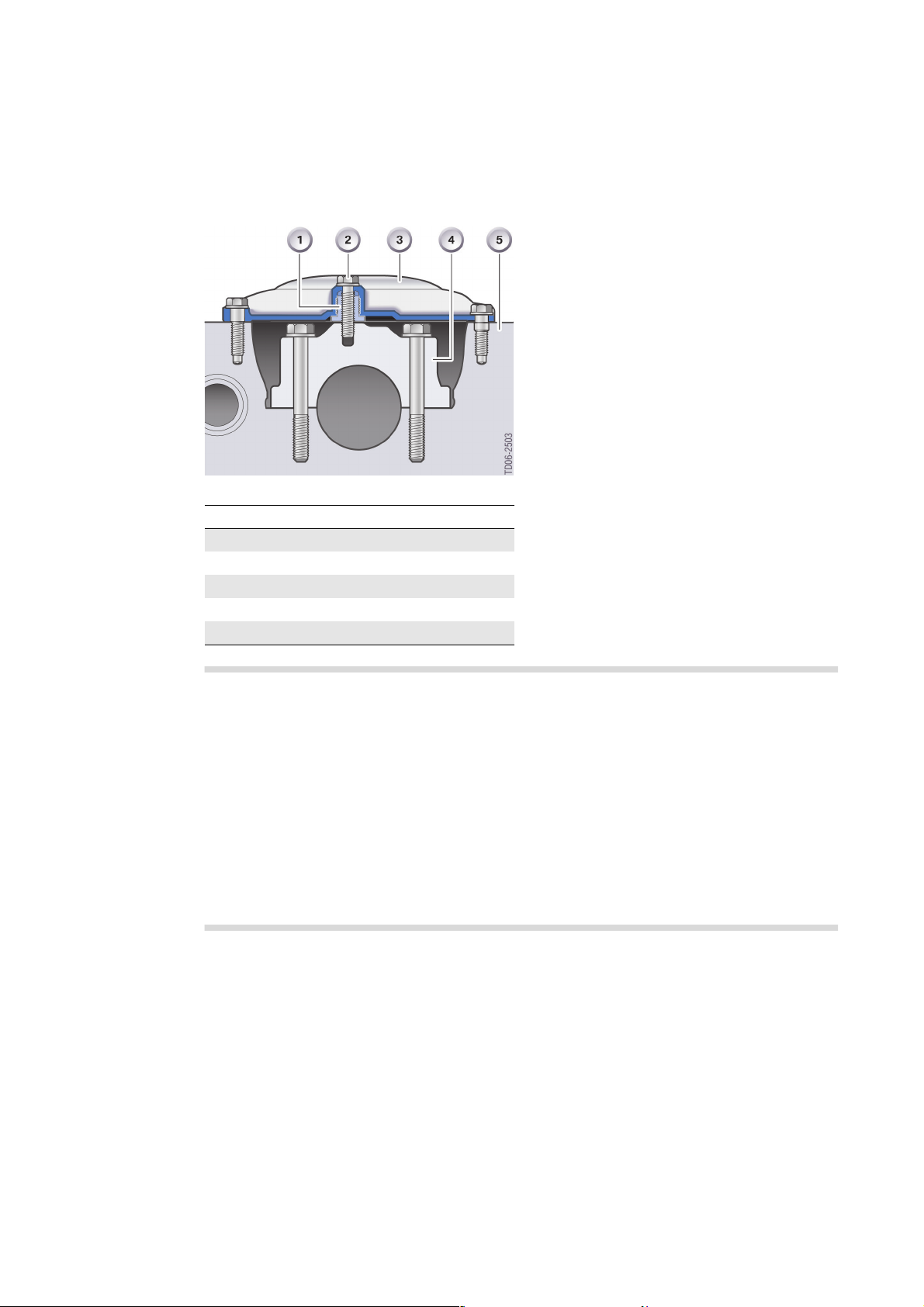

7 - N47 engine main bearing cap with indent fit

Index Explanation

1 Main bearing cap

2 Main bearing pedestal

To provide positive lock along the longitudinal

axis of the engine, the profile must be shorter

than the housing-side contact surface. In this

way, the profile does not protrude but instead

has a limit position. To avoid making the

bearing pedestal any wider than necessary,

the bearing cap is slightly tapered near the

profile.

Unlike the M67TU, only two rather than six

profile elements per contact surface are used.

The main bearing cap is made of an extremely

rigid, sintered iron material.

20

Reinforcement shell

A reinforcement shell bolted onto the

crankcase from underneath provides the

7

crankcase and crankshaft bearings with

additional reinforcement.

Index Explanation

1 Crankcase

2 Reinforcement shell

The reinforcement shellissimilar in function to

the reinforcement on the M67TU engine; the

only difference is that there are no individual

reinforcement brackets used, but a common

reinforcement shell covering the three centre

crankshaft bearings.

8 - Crankcase with

reinforcement shell in the

N47 engine

This reinforcement shell reinforces the

crankcase itself and additionally forms a

connection to the main bearing caps. To this

end, the reinforcement shell is bolted to the

crankcase and the main bearing caps.

21

7

A spacer sleeve is screwed into the

reinforcement shell to exertadefinedpressure

on the main bearing cap. After the

reinforcement shell has been connected to

the crankcase, the spacer sleeve is tightened

to a defined torque against the main bearing

cap. The reinforcement shell is then bolted to

the main bearing cap. This method produces

an extremely rigid system overall.

3 Before the reinforcement shell is fitted, it

is essential that the spacer sleeves be

screwed into the reinforcement shell fully,

otherwise there is a risk of damage. The

procedure in the repair instructions must be

9 - Connection between reinforcement shell and main bearing cap

Index Explanation

1 Spacer sleeve

2 Bolt in the main bearing cap

3 Reinforcement shell

4 Main bearing cap

5 Crankcase

observed. 1

The reinforcement shell has the additional

task of being an oil deflector. It is also

connected to the oil/vacuum pump and

contains the untreated and purified oil ducts.

Cylinder

As part of the combustion chamber, the

cylinder issubjected to high thermal loads and

pressures. With its finely machined surface,

the cylinder liner provides good anti-friction

and sealing characteristics in interaction with

the piston rings. In addition, the cylinder

carries the heat to the crankcase or directly to

the coolant.

Since the aluminium of the crankcase is

unable to meet requirements, the N47 engine

is equipped with cylinder bushes.

Material

The N47 engine has a crankcase made of

aluminium alloy, while the M47 engine has

until recently been manufactured with a grey

cast-iron crankcase. Aluminium crankcases

were introduced on the M67TU and M57TU2

engine.

These are made of grey cast iron and are

thermally joined. Thermally joined means that

the cold cylinder bushes are inserted into the

heated crankcase. As it cools, the crankcase

contracts, therebyensuring firmseating of the

cylinder bushes.

Dry bushes are used in the N47 engine. This

means that the cylinder bush has no direct

contact with thewater jacket. Thewater jacket

is completely enclosed by the crankcase cast.

The crankcase isone of theheaviest individual

components anywhere onthevehicle. It is also

located in a position critical to driving

dynamics, i.e. above the front axle. For this

reason, it makes sense to exploit any potential

for weight reduction to the maximum.

22

7

The density ofaluminiumalloys is about athird

that of grey iron. However, that cannot be

converted one-for-one into a weight

advantage because the lower strength of the

material means the crankcase has to be made

thicker. Nevertheless, its use still sees a

10 - Development of crankcase weight and engine output

Index Explanation Index Explanation

A Weight of the crankcase B Engine output

remarkable advantage in terms of weight.

Indeed, the crankcase of the N47 engine is 38

% lighterthan that ofthe M47TU2 - and thisis

despite the fact that the N47 is able to offer

higher output.

Engine Power

output

M47 100 kW 43 kg

M47TU 110 kW 44 kg

M47TU2 120 kW 45 kg

N47 130 kW 28 kg

Weight of the

crankcase

Other properties of aluminium alloys are:

• good heat conductivity

• good chemical resistance

• positive strength qualities

• good machinability

Pure aluminium is not suitable as a casting

material for crankcases because its strength

properties are inadequate. This is why the

heat-treated alloy AlSi8Cu3, already triedand-tested on many a BMW engine, is used

for the crankcase of the N47 engine.

23

7

Cylinder head and cover

General information

There is hardly an engine assembly more

influential on such operating properties as

output efficiency, fuel consumption, and

torque, exhaust emissions and noise

characteristics than the assembled cylinder

head. The cylinder head accommodates

virtually the entire engine management

system.

The cylinder head of the N47 engine largely

conforms to the standards for current diesel

engines. Aspecial feature, however,is that the

cylinder head comprises two large cast parts.

The camshafts are integrated inside their own

camshaft carrier.

The cylinder head of the N47 engine stands

out for the following technical features:

• Material: AlSI7MgCu0.5

• Two-piece cylinder head with camshaft

carrier

• Crossflow cooling

• Integrated EGR duct

• Four valves per cylinder

• Parallel valve arrangement (axes parallel

with the cylinder axes)

• Tangential duct and swirl duct.

Design

The shaping of the cylinder head is

determined to a very large degree by the

components that it accommodates. The

following factors fundamentally affect the

shape of the cylinder head:

• Number and position of the valves

• Number and position of the camshafts

• Position of the glow plugs

• Position of the injectors and injection

method

• Shape of the inlet and exhaust ducts

One of the requirements of the cylinder head

is that it should be as compact as possible.

Essentially, cylinder heads are classified

according to the following criteria:

• Number of components

• Number of valves

• Cooling method

24

Loading...

Loading...