Page 1

Repair Manual

R 1100 RT

R 1100 RS

R 850/1100 GS

R 850/1100 R

BMW Motorcycle

After Sales

Page 2

Published by: © BMW Motorcycle

After Sales

UX-VS-2

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Produced in Germany 02/00

Page 3

Introduction

This repair manual will help you to perform all the main maintenance and repair work correctly and efficiently. It should be consulted regularly by workshop personnel as an addition to the practical and theoretical

knowledge obtained in Training School courses. It is a contribution towards achieving even higher Service

quality.

All information in both text and illustrations refers to motorcycles in standard condition or with genuine

BMW accessories installed, and not to motorcycles which have been modified in any way to depart from

the manufacturer’s specification.

● The repair manual is structured in the logical sequence of the work to be performed: Removal, Dis-

assembly, Repair, Assembly, Installation.

● The entire contents are divided into individual chapters, corresponding to the Construction Groups.

11 . 10

Chap. Page number within chapter

● Work to be performed during an Inspection is described in Group “00”. The various inspection routines

are numbered I, II, III and IV. This numbering is repeated in the work descriptions which follow, so that

work can take place without interruption.

● Use of the BMW special tools needed for certain tasks is described in the work instructions.

If the need arises, repair instructions are also issued in the form of Service Information. This information is

of course incorporated into the next issue of the repair manual. We also recommend you to consult the

detailed illustrations on the Parts microfiches as an additional source of information.

BMW Motorcycle

After Sales

Published by: BMW Motorrad

Hufelandstr. 6

D - 80937 München

All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written

permission.

Errors and omissions excepted; subject to technical amendment.

Produced in Germany

Page 4

Contents

<< Back

Group / Chapter

00 Maintenance and general instructions

11 Motor

12 Engine electrics

13 Fuel preparation and control

16 Fuel tank and lines

18 Exhaust system

21 Clutch

23 Gearbox

31 Front fork

32 Steering

33 Rear wheel drive

>> Continuation

Page 5

Group / Chapter

34 Brakes

36 Wheels and tyres

46 Frame

51 Equipment

52 Seat

>> Continuation

61 General electrical equipment

62 Instruments

63 Lights

<< Back

Page 6

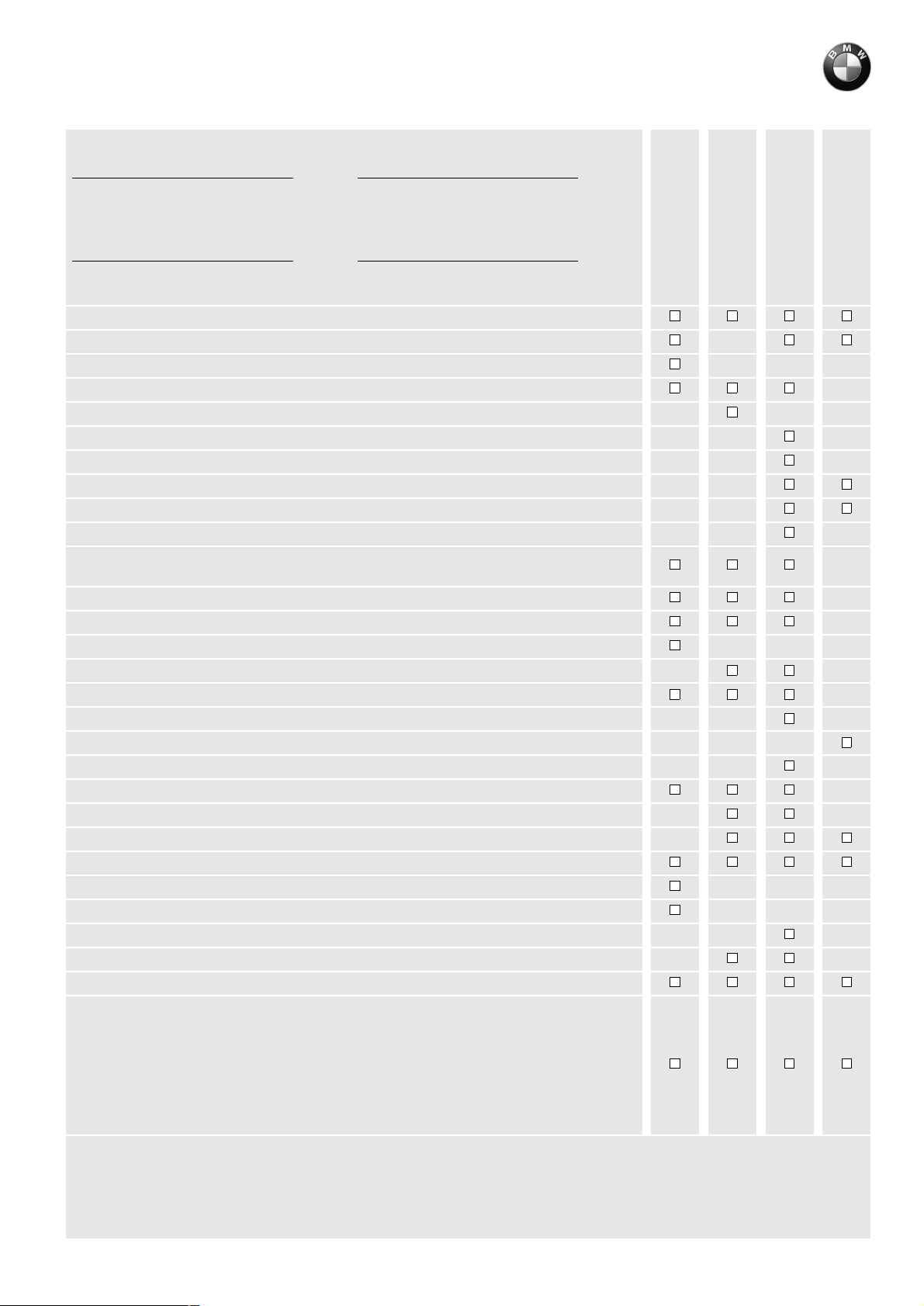

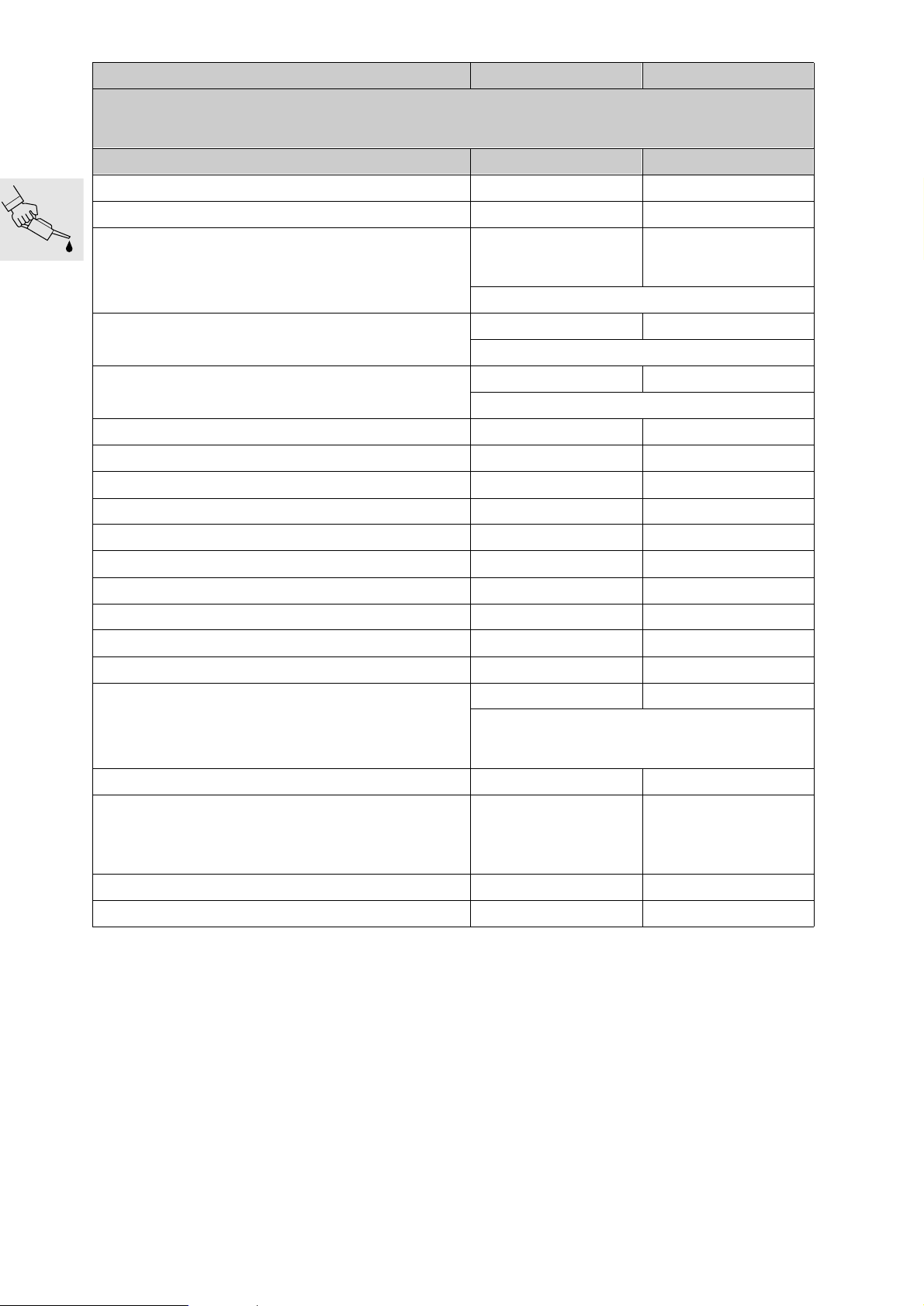

BMW AG Motorcycle Division

Maintenance Schedule

R1100RT/R 1100RS/R850GS/R1100 GS/R 850R/R 1100 R

Customer Registration No.

Order No. Signature of mechanic

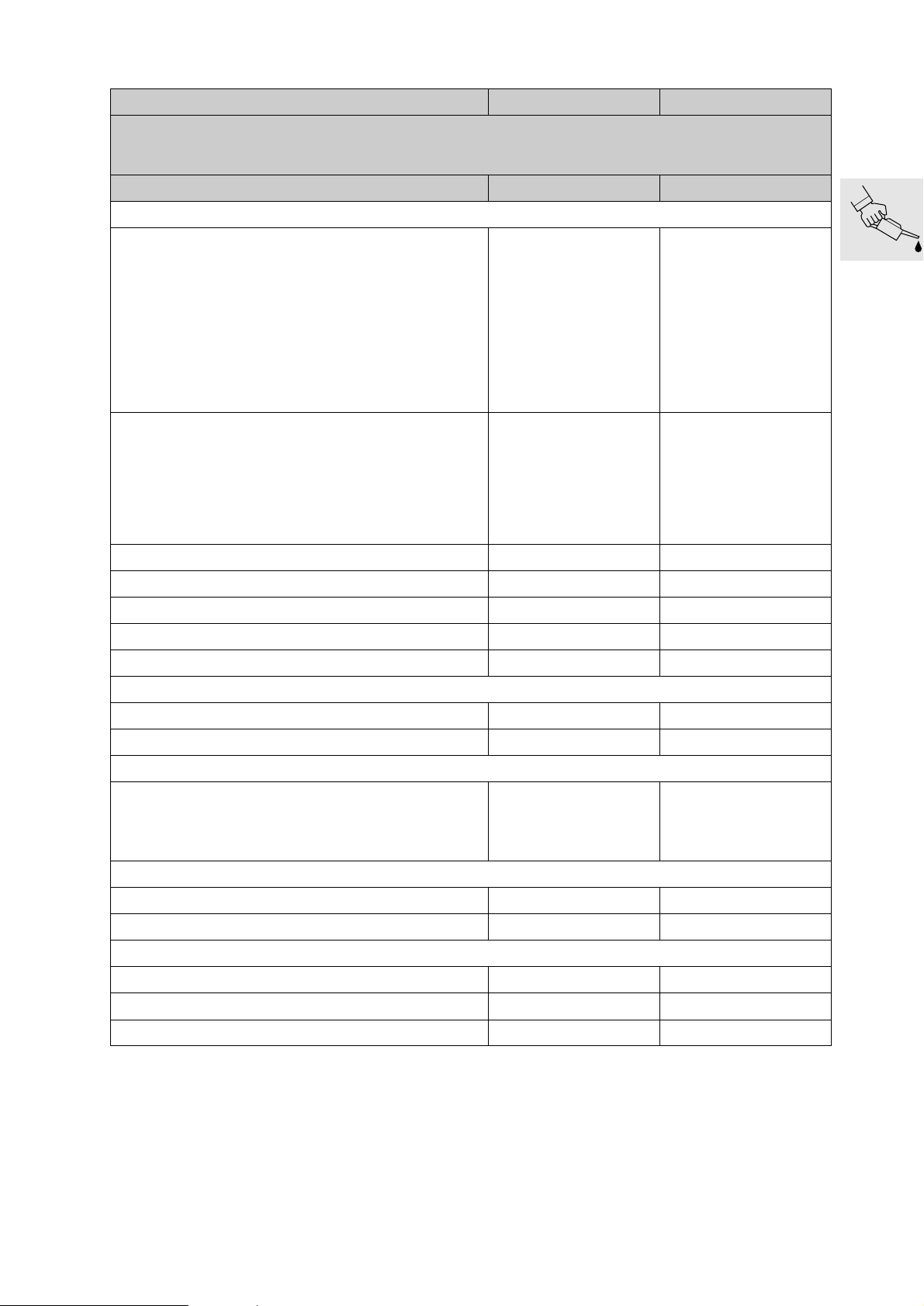

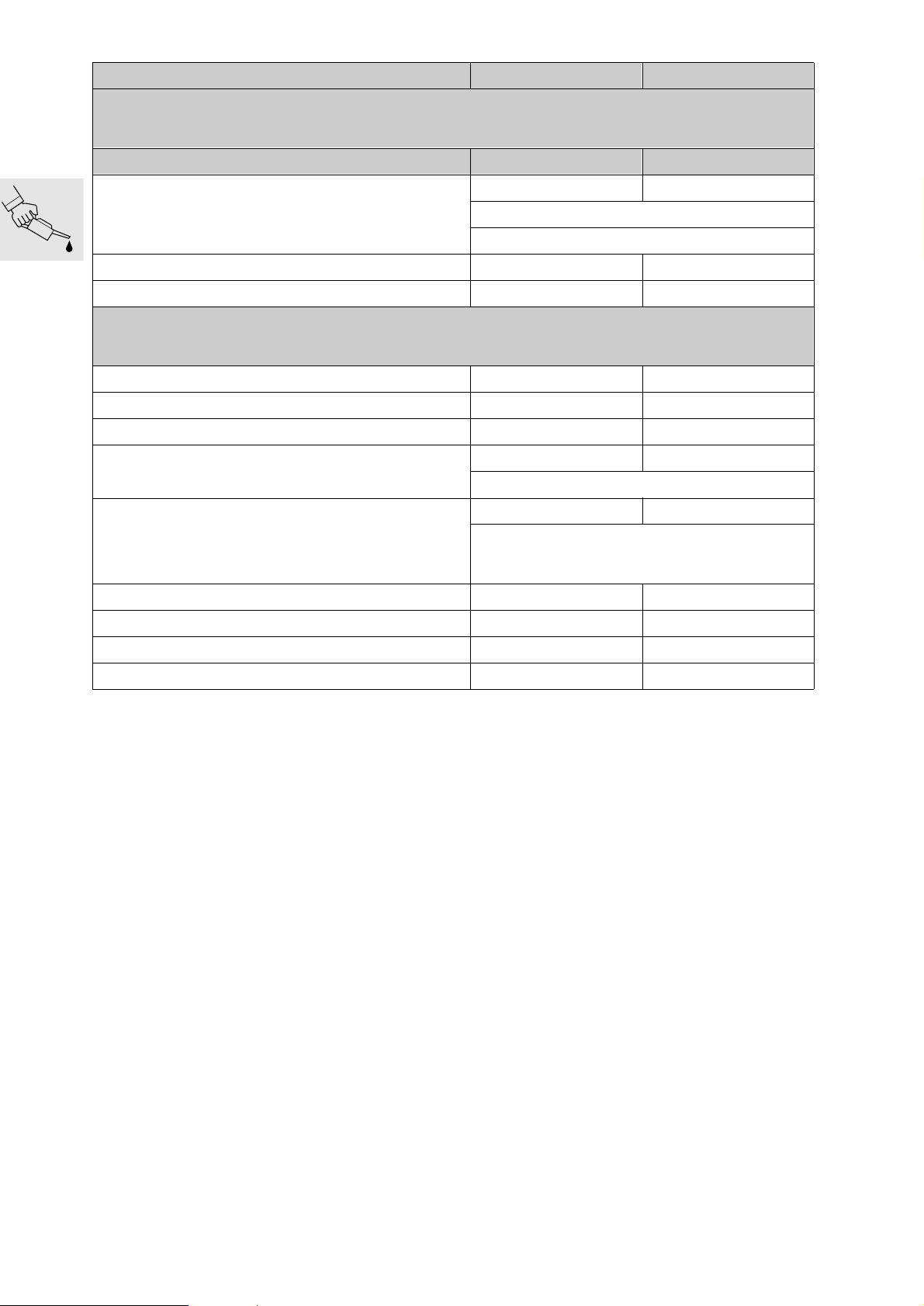

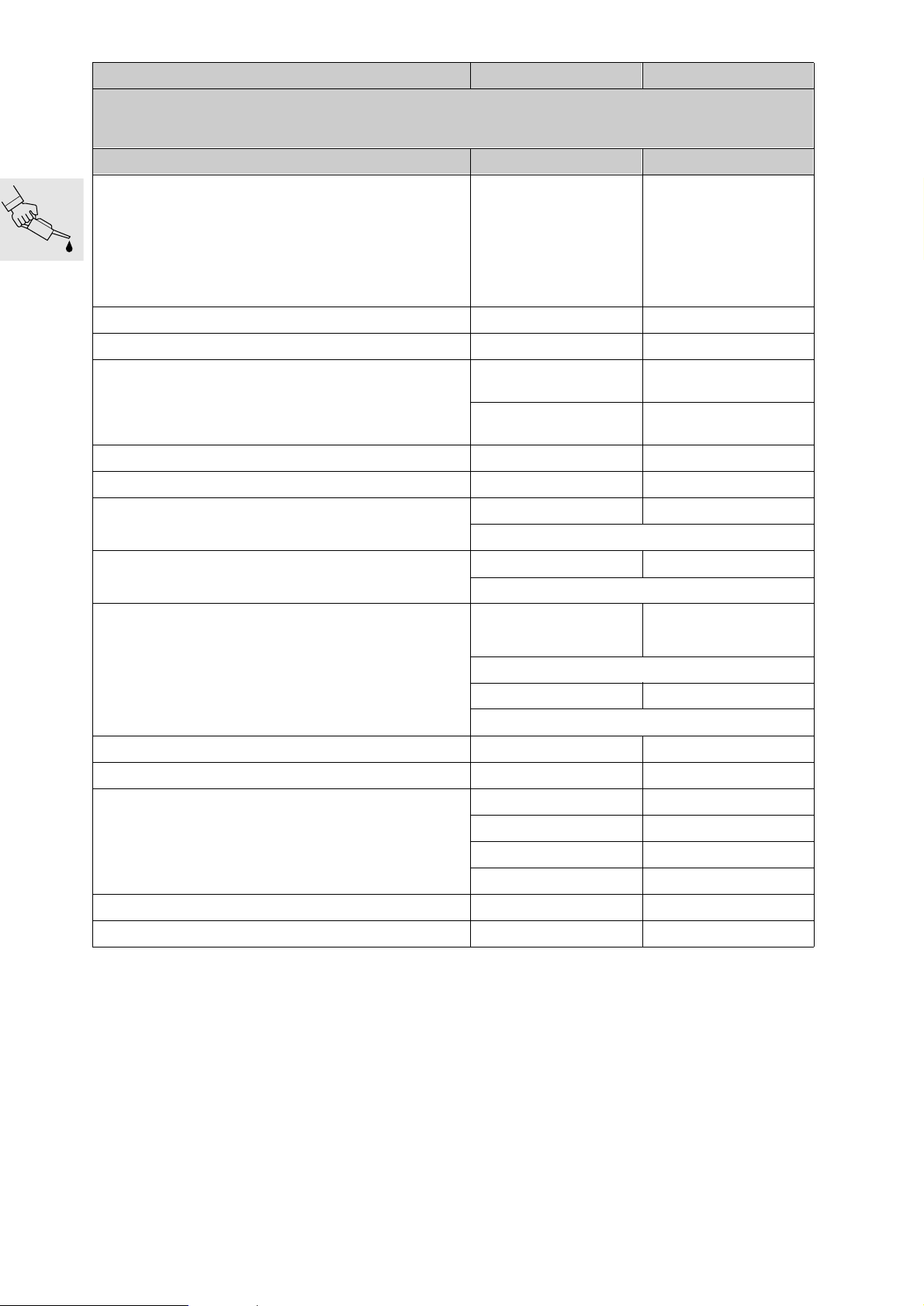

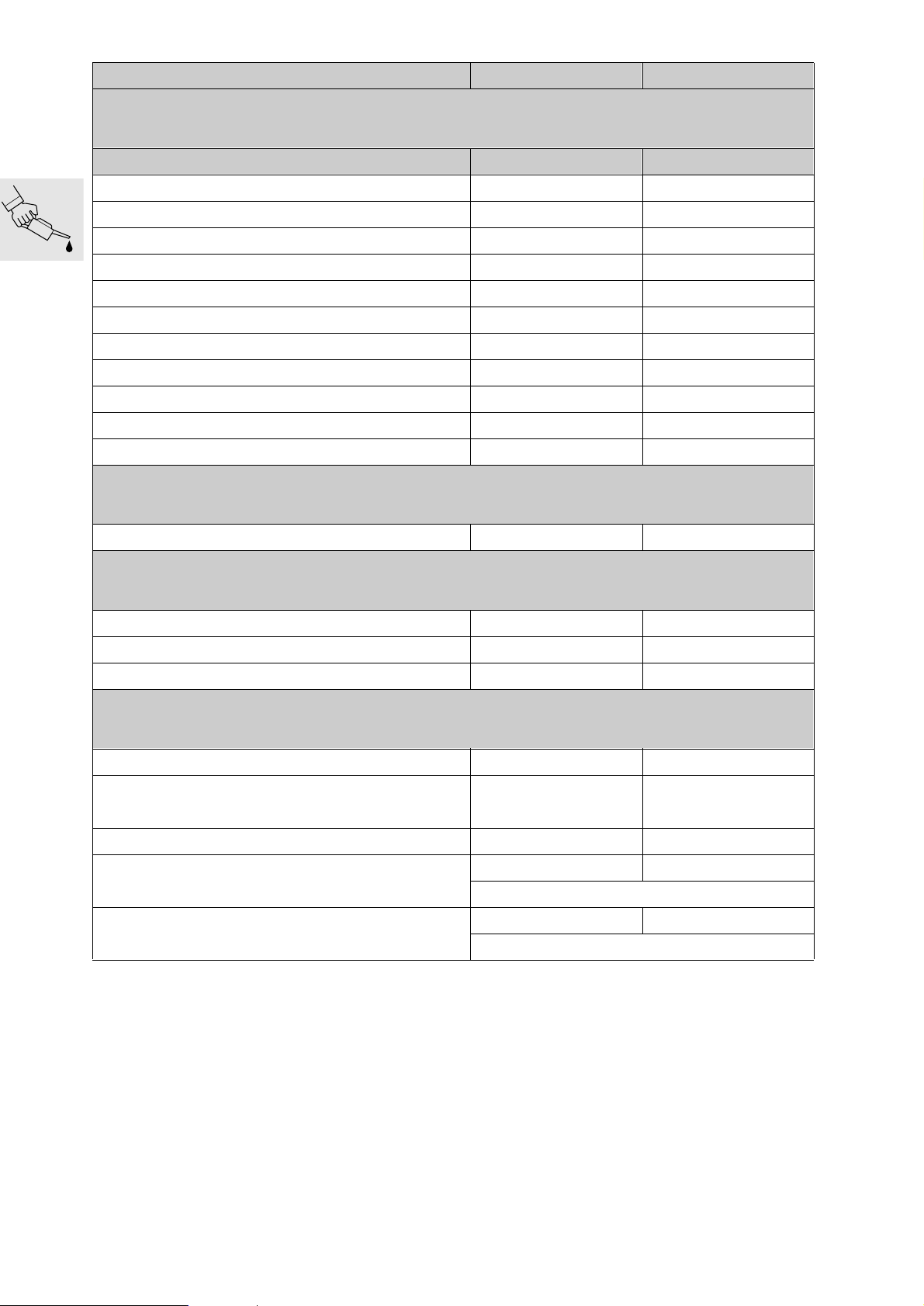

BMW Inspection

1000 km/ 600 mls

BMW Service

10 000 km/6000 mls

BMW Inspection

Change engine oil when engine is warm, renew oil filter cartridge

Change oil in manual transmission and rear wheel drive when at operating temperature

Retighten cylinder head nuts

Adjust valve clearance

Check spark plugs

Renew spark plugs

Renew fuel filter

3) *)

Check battery acid level, if necessary top up with distilled water

Clean and grease battery terminals

Renew intake air cleaner

Check throttle cables for free movement, abrasion and kinking,

renewing if necessary *

2)

)

Check clutch clearance, adjust if necessary

Adjust Poly-V-belt [b SI 12 020 95 (700)] 4)

5)

Retighten hose clips at intake pipe

Check brake pads and discs for wear, renew if necessary *

Check front/rear brake fluid level, top up if necessary *) [b SI 00 027 95 (716)]

Check brake system with regard to function, leaks; repair/renew as required *

Renew brake fluid at least once a year

Check wheel bearings, renew if necessary *

)

Check swinging arm bearing (no play), adjust if necessary *

Check steering damper (R850/1100R)

Lubricate side stands, centre stand (R 1100 RS) and nipple for clutch cable assembly

Check side stand switch for damage and correct operation [b SI 46 033 96 (722)]

Check fit of rear wheel bolts

Check bolts of control arm to specified torque

Clean and grease shaft for windshield adjustment (R 1100 RS)

Grease lower eye of front spring strut (R 1100 RS slide bearing)

Check idle speed, throttle synchronisation and CO value, adjust if necessary

Final inspection with safety/operating check:

– condition of tyres and wheels, rims and spokes, tyre pressures

– lights and signal systems

– telltale and warning lights

– clutch and gear shift

– handbrake and footbrake, steering

– instruments

– test ride, if necessary

1)

for short-distance driving or outside temperatures below 0°C every 3 months, every 3,000 km (1,800 miles) at the latest

2)

in very dirty or dusty conditions, renew the intake air cleaner element every 10,000 km (6,000 miles), or even more frequently if necessary

3)

normally every 40,000 km (24,000 miles), but if fuel is of poor quality every 20,000 km (12,000 miles)

4)

Renew Poly-V-belt every 40,000 km (24,000 miles)

5)

After 60,000 km (36,000 miles), change the maintainance free Poly-V-belt, do not adjust

*)

invoiced as a separate item

1)

)

)

)

20 000 km/12 000 mls

BMW

Annual Service

Order No. 01 71 7 654 296 UX-VS-2, 03.99 Printed in Germany

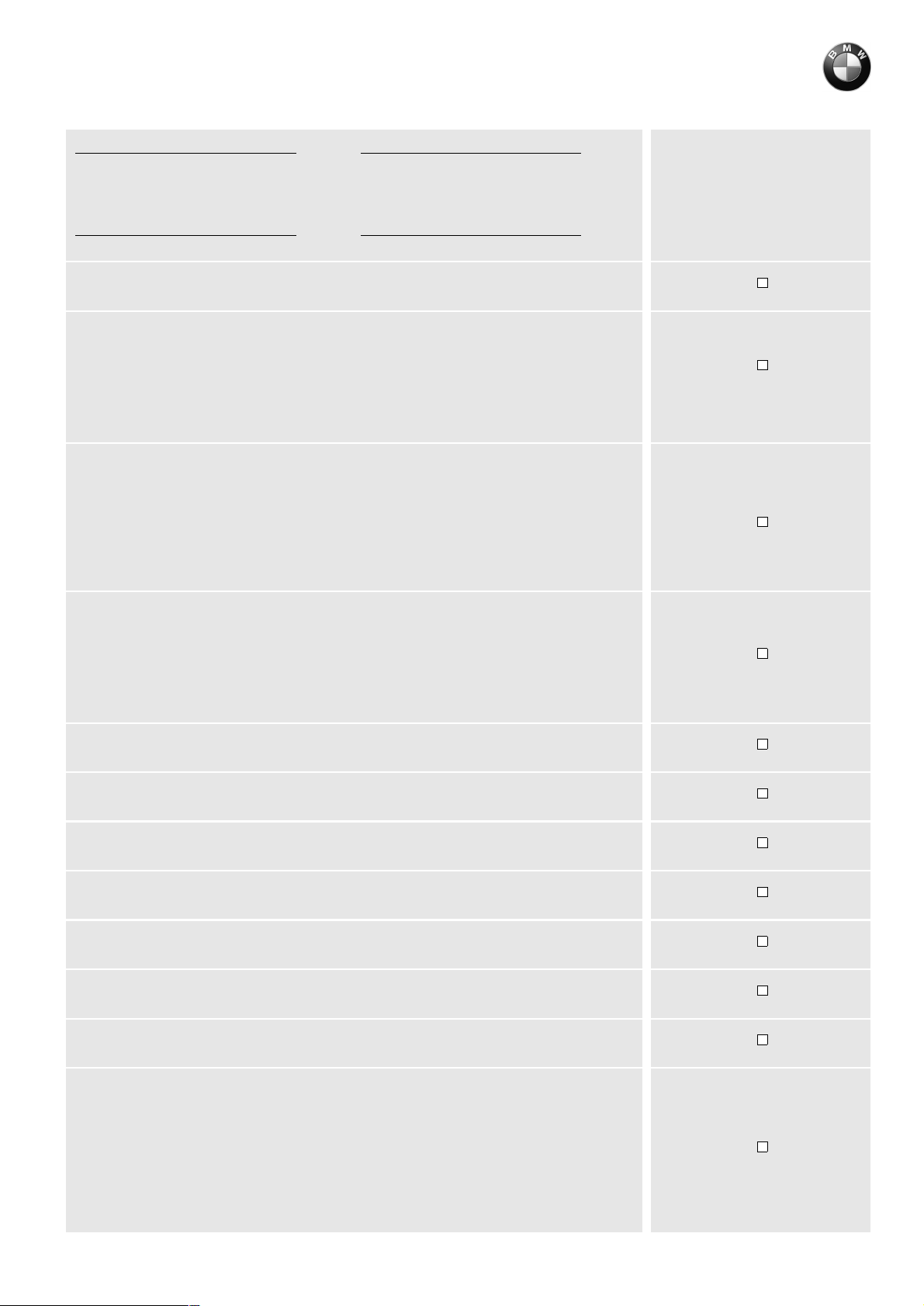

Page 7

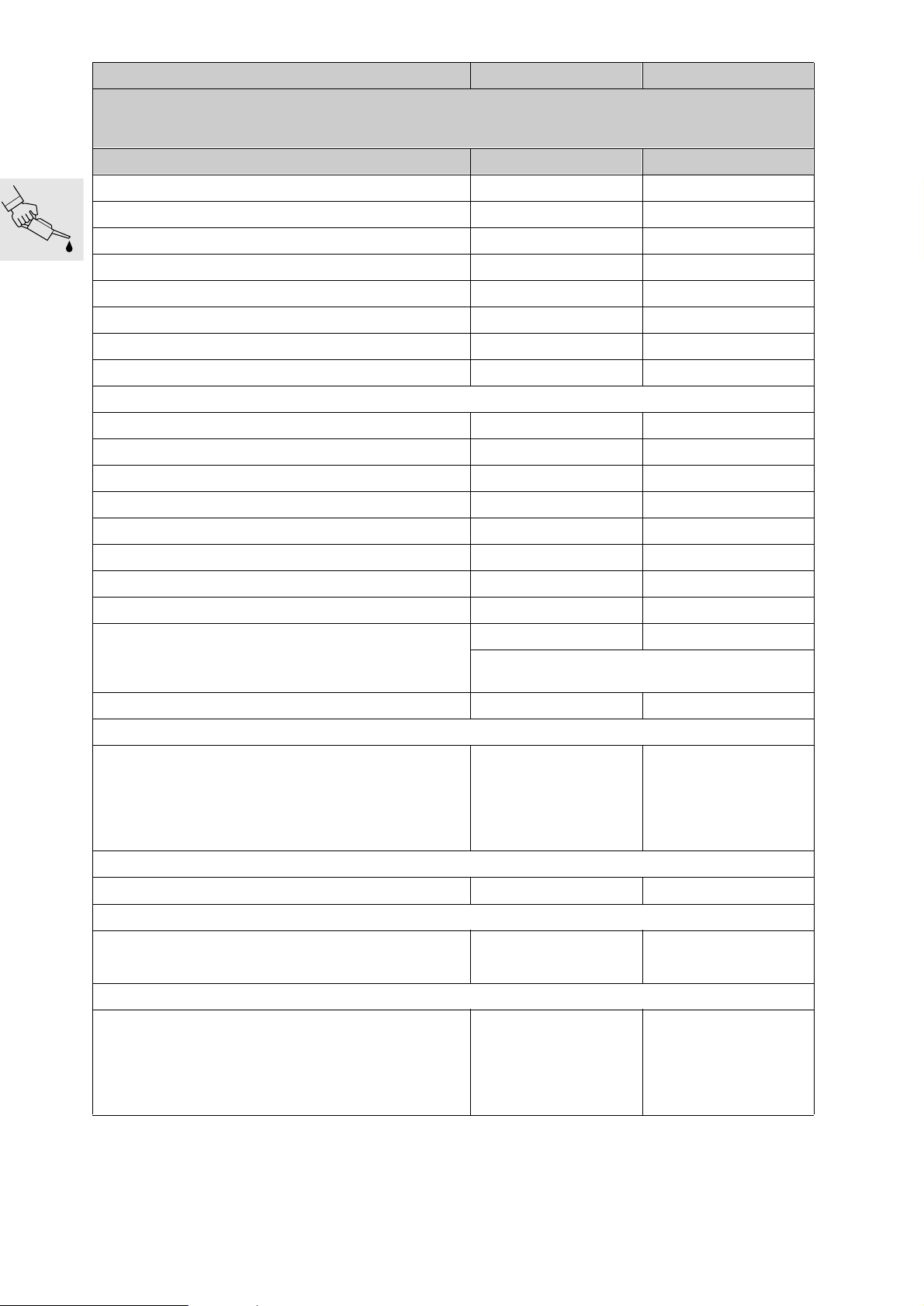

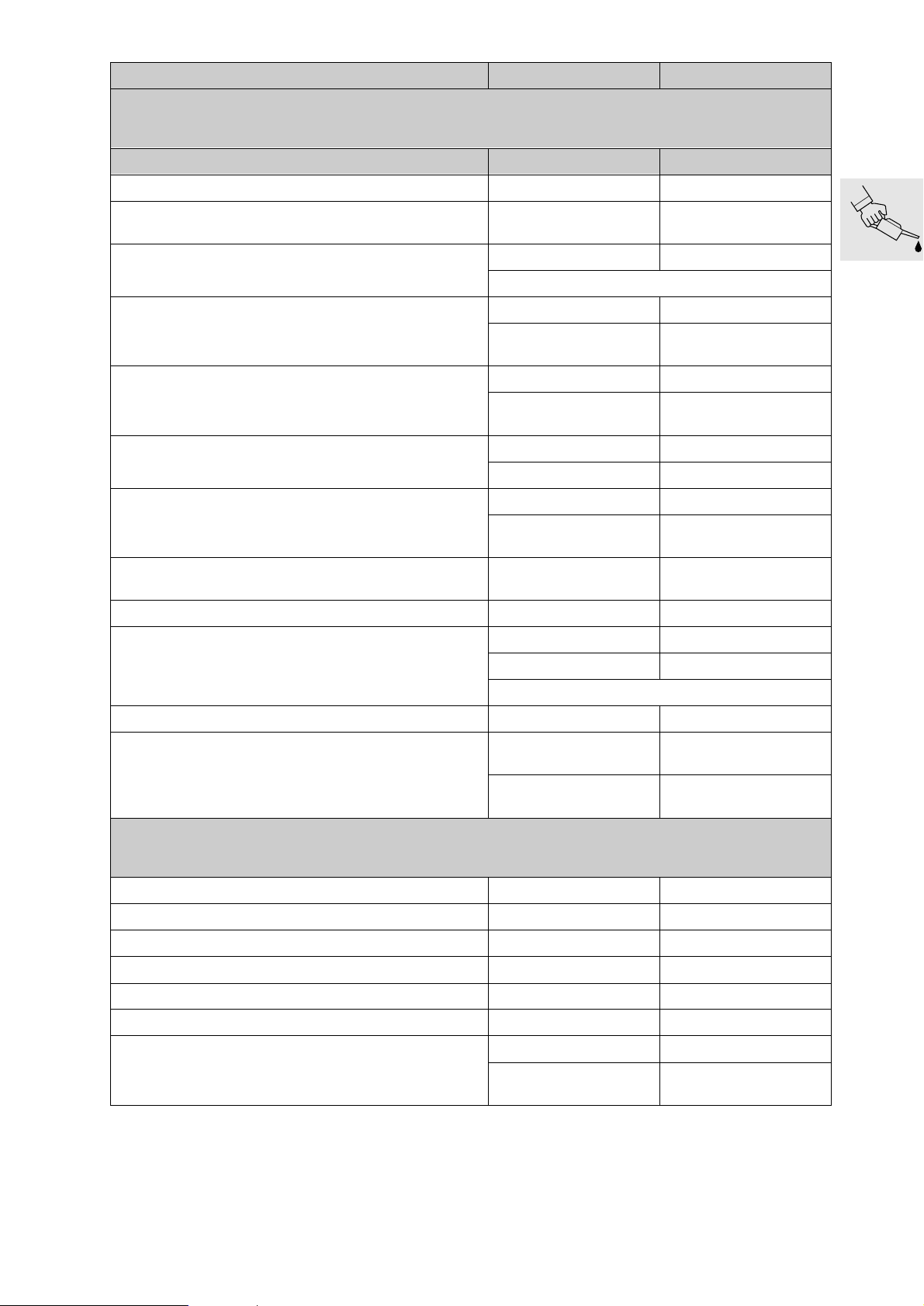

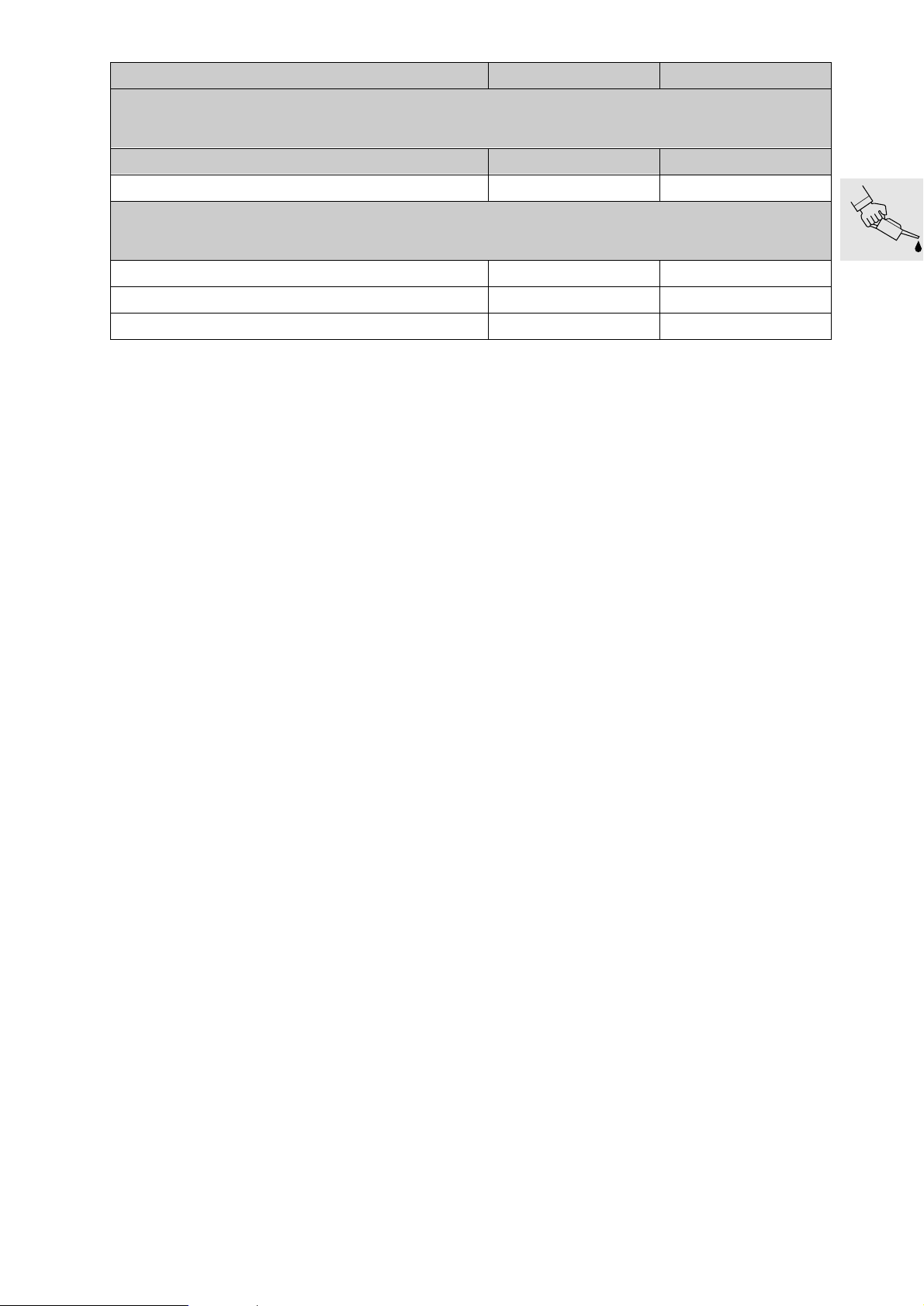

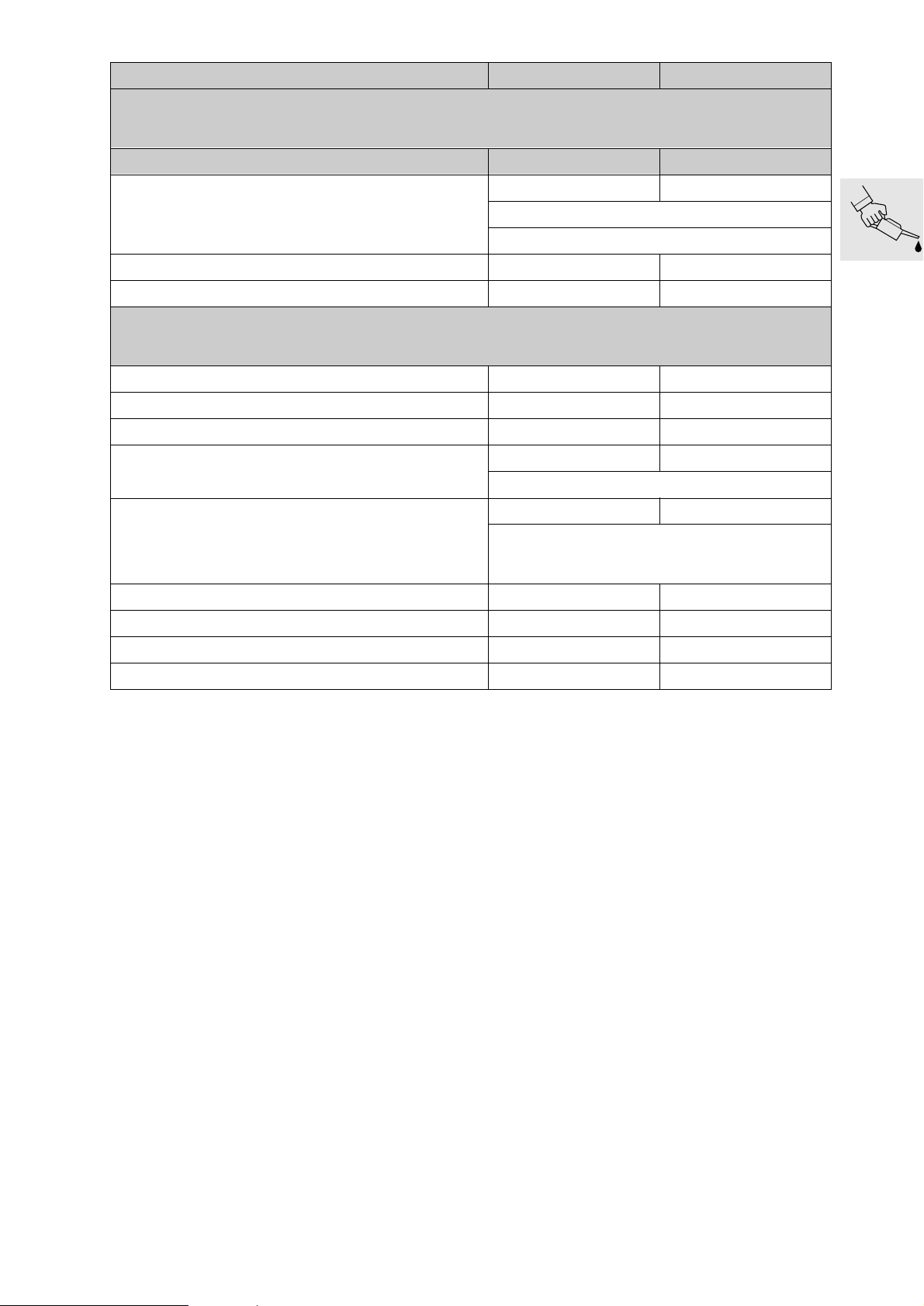

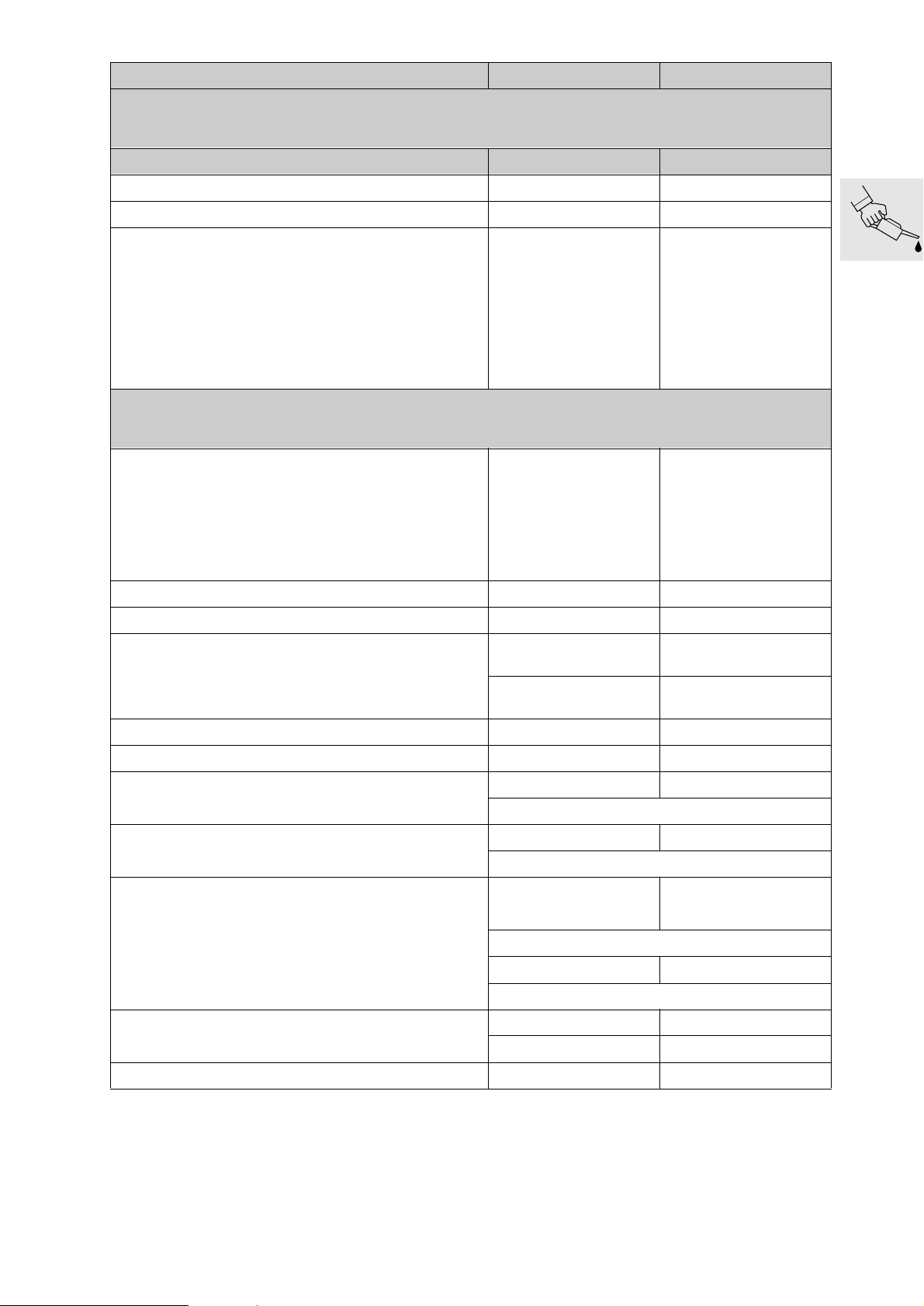

BMW AG Motorcycle Division

Pre-delivery check

R1100 RT/R 1100 RS/R850GS/R1100 GS/R 850R/R1100 R

Customer Registration No.

BMW

Pre-delivery check

Order No. Signature of mechanic

Inspect crates on receipt for signs of damage

Motorcycle:

– unpack

– check scope of delivery

– install/complete

– clean

Battery:

– remove

– add battery acid

– charge

– grease the terminal posts

– re-install (mark date)

Check complete specification delivery:

– tools

– handbooks and documents

– keys

– optional extras

Check headlight (basic setting), adjust if necessary

Check front and rear wheel brake fluid levels

Check torque setting of the rear wheel retaining studs

Check tyre pressure

Check engine oil level, top up if necessary

Fuel the motorcycle

Check basic clutch setting, adjust if necessary

Safety/operating check as final inspection:

– idle speed

– clutch, gear shifting

– steering

– front and rear brakes

– telltale and warning lights, instruments, lighting and signalling equipment

– ABS

– test ride, if necessary

Order No. 01 71 7 654 296 UX-VS-2, 03.99 Printed in Germany

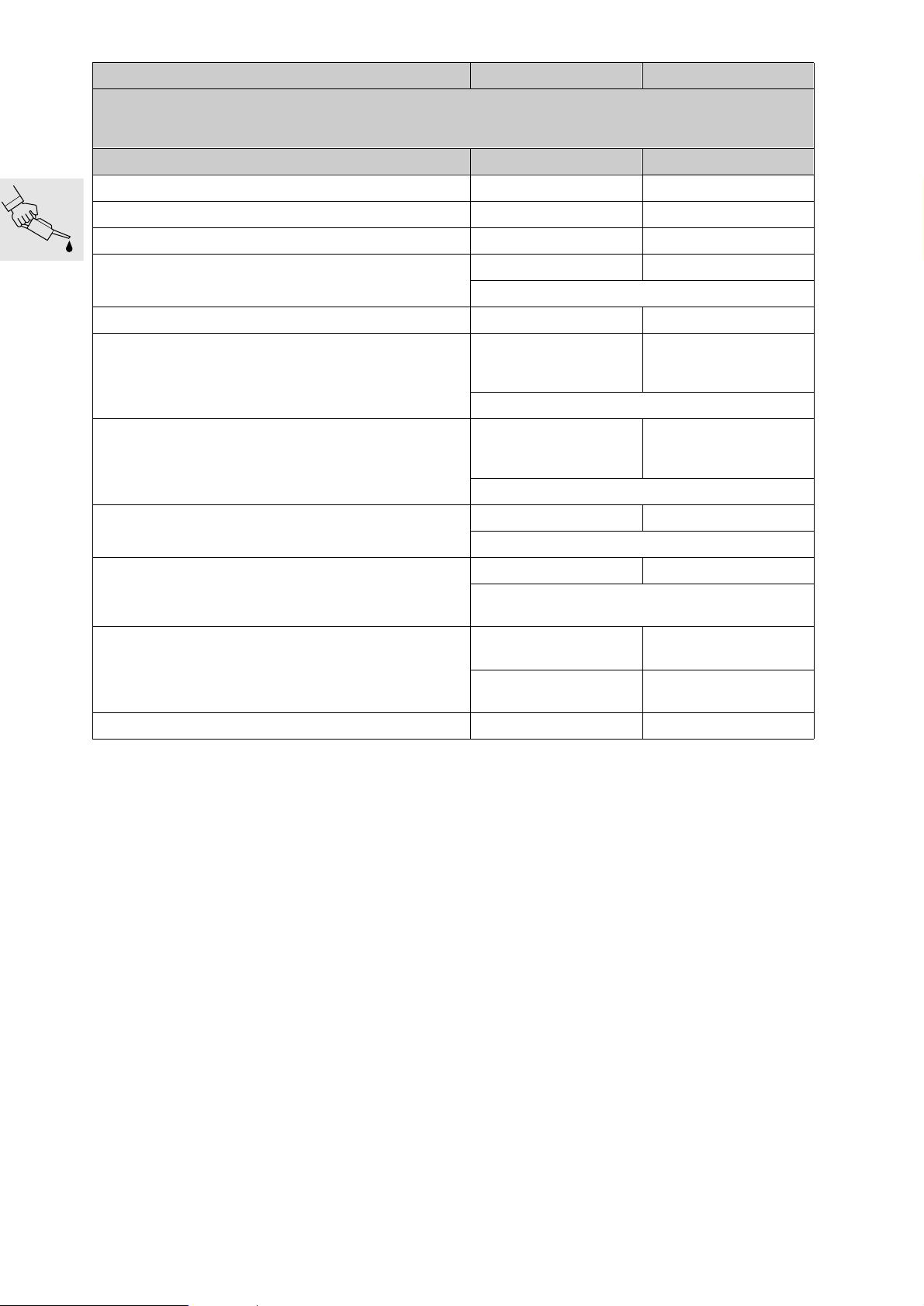

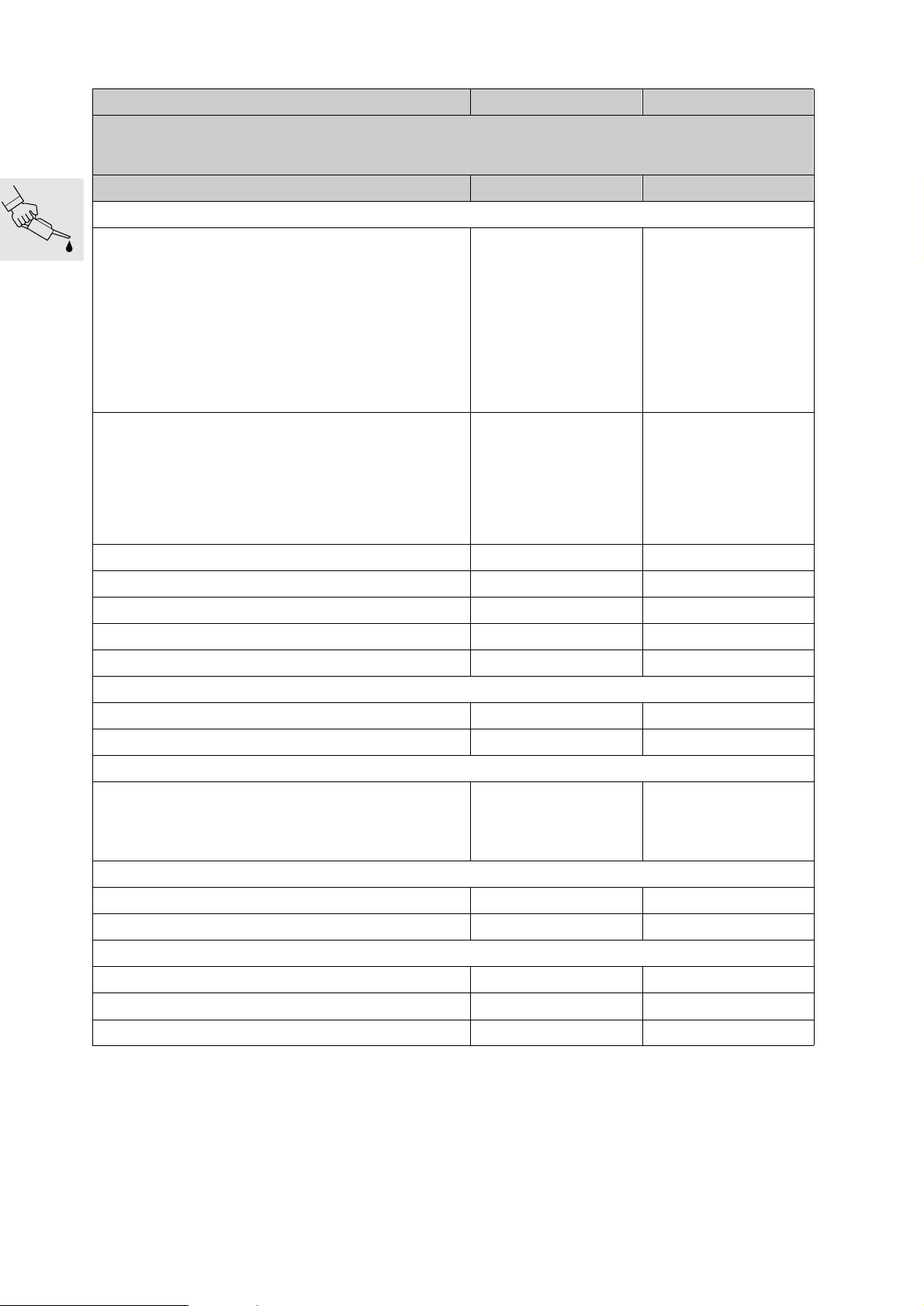

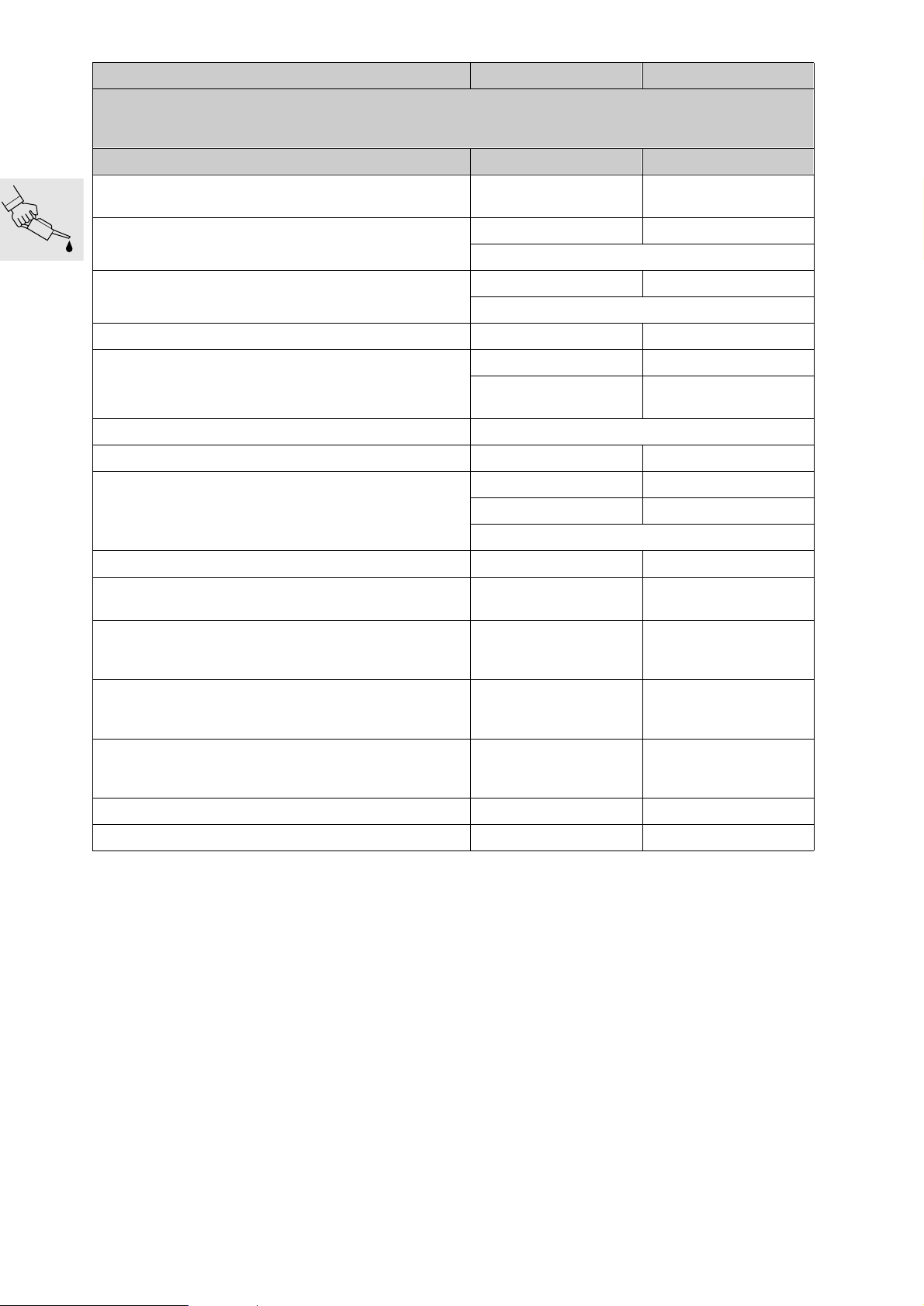

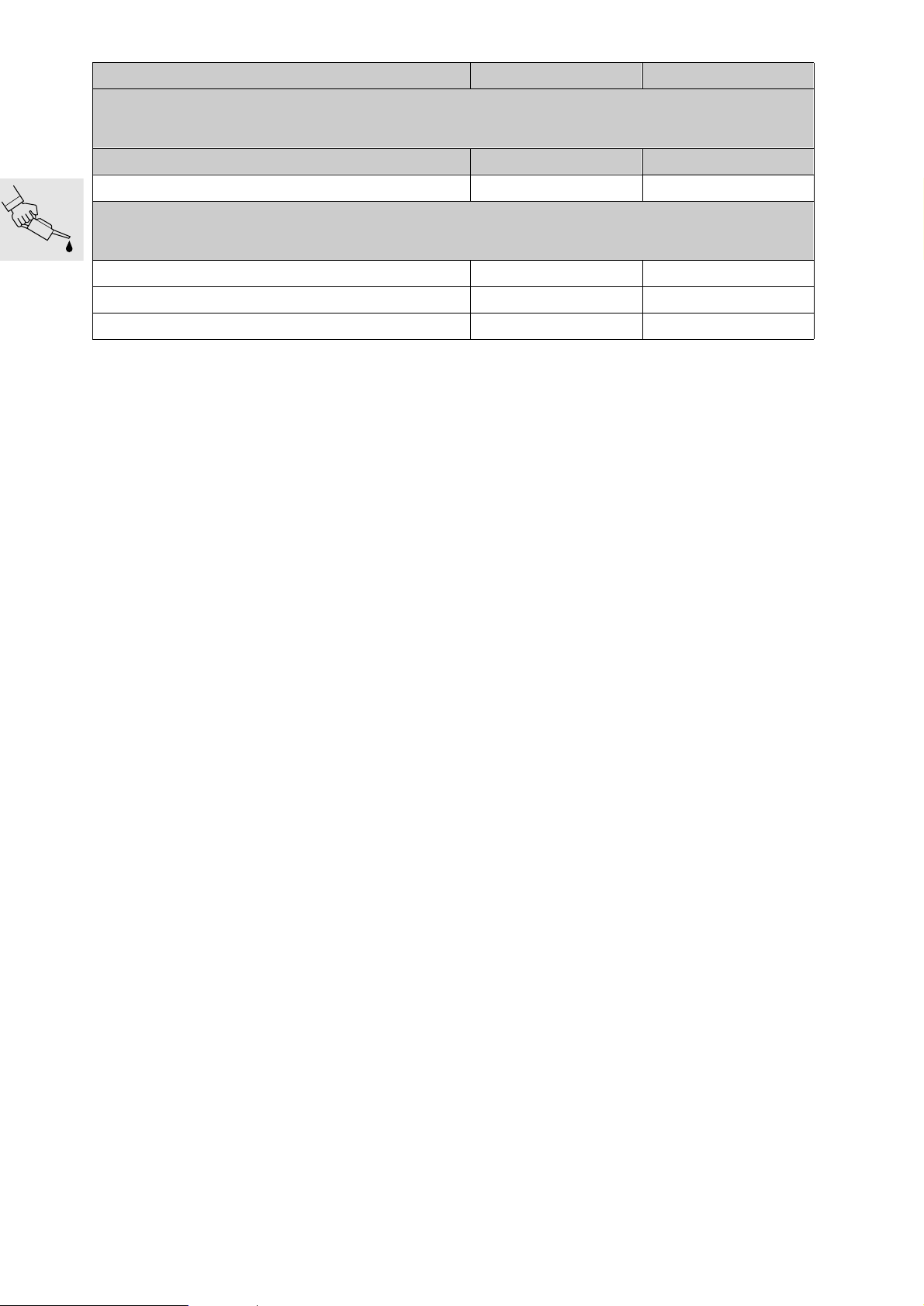

Page 8

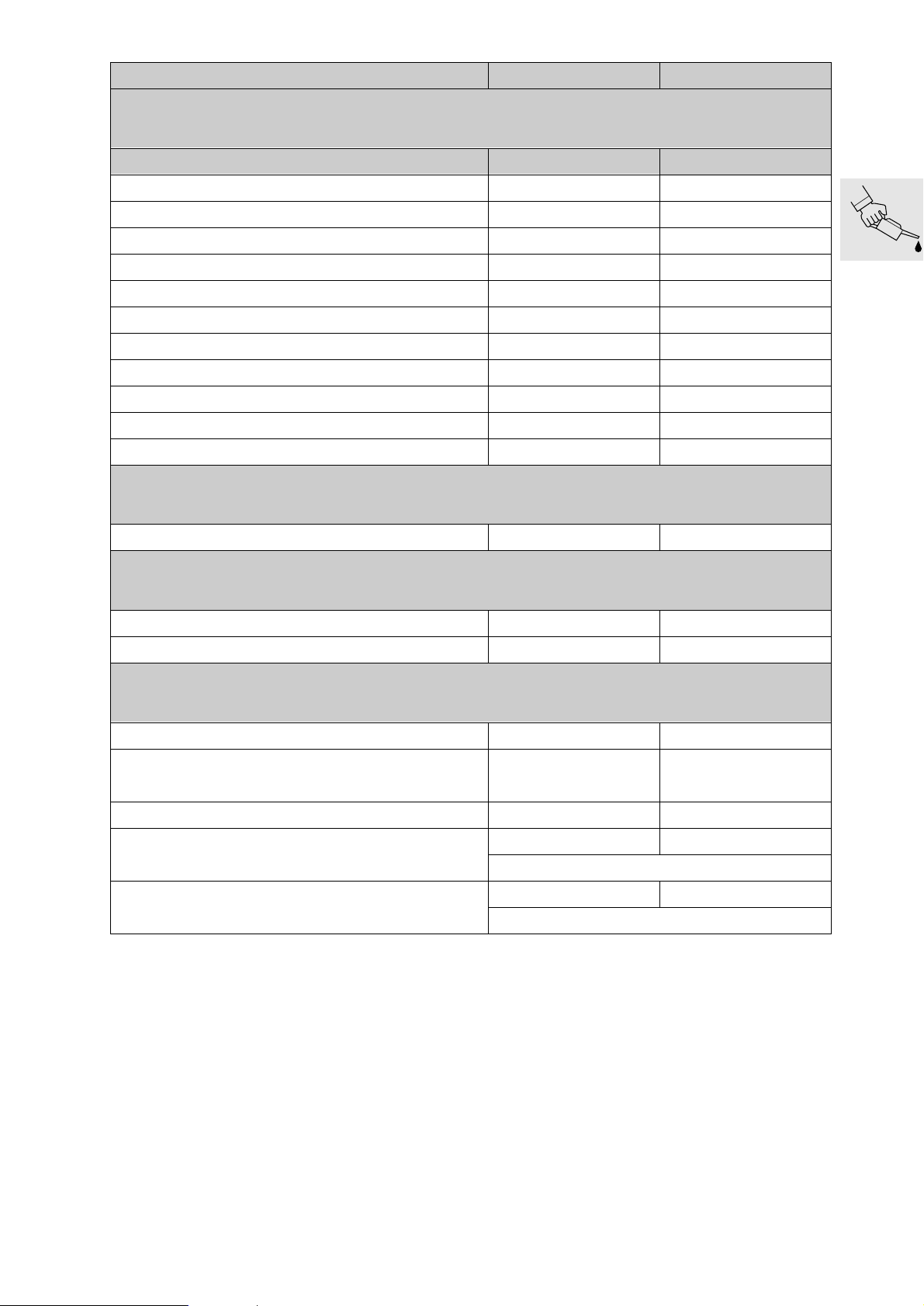

BMW AG Motorcycle Division

Service Data

R 1100 RT/R 1100 RS/R 1100 GS/R 1100 R/R 850 R

Designation Data Measuring unit or

specification

Oilcapacities

Engine (incl. filter)

Engine (without filter renewal)

3.75

5.50

Brand-name HD oil for

petrol engines of API classi-

fication SE, SF, SG;

combination with CC or CD

B

litre

litre

[SI 11 048 90]

specification

Gearbox

Rear wheel drive

Valve clearance

measured cold, i.e. at max. 35 °C

Ignition

Static ignition

Spark plugs

Electrode gap

limit of wear

Engine idle speed 1000 +150 1/min

CO value (without catalytic converter) 1.5 ±0.5 Vol %

Cable adjustment

for increased cold starting speed (without cable junction)

(with cable junction)

throttle (without cable junction)

gas cable (one piece)

connecting cable

throttle (with cable junction)

gas cable (one piece)

junction cable

Clutch cable adjustment

wire cable at handle bar lever

at lever

Tyre pressure

depending on load and speed

Tightening torques:

Oilfilter

Engine oil drain plug

Gearbox oil drain plug

Rear wheel drive oil drain plug

Locknut valve adjustment

Cylinder head cover

Generator to bracket

Tension multiple ripped belt (Poly-V)

Spark plugs

Fuel tank to rear frame

Fuel pump to tank

Adjustable handle bars

Quick release axle thread (axial)

Quick release axle clamp

Brake caliper

Bearing bolt swingarm to gearbox/rear axle

Idler bearing pin on swinging arm on gearbox/rear wheel drive

Locknut

Rear wheel retaining studs

Tube clips to air intake pipe

Screw connect. spring strut on control arm (RS with slide bearing)

Tighten cylinder head

– M 10 screw

Order No. 01 71 9 799 171 UX-VS-1, 7/95 Printed in Germany

fresh fill 1.0

change 0.8

fresh fill 0.25

change 0.23

E 0.15 / A 0.30 mm

disconnect at

6° b TDC

Bosch FR5DTC

0.8

1.0

< 1

no backslash

ca. 0.5

no backslash

ca. 0.5

no backslash

12.0

7.0

front: 2.2 – 2.5

rear: 2.5 – 2.9

11

32

23

23

8

8

20

8

20

22

6

20

30

22

front / rear 40

150 (Loctite 2701)

7 (Loctite 2701)

105 (Loctite 2701)

105

2

43

Thighten 20

180

40

Nm (clean thread)

Nm (clean thread)

Nm (clean thread)

Nm (8.8 screw)

° Torsion angle

litre

litre

litre

litre

mm

mm

mm play

mm play

mm play

mm thread

mm play

bar

bar

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Page 9

00

00 Maintenance and general instructions

Contents Page

Tightening torques R 1100 RS / R 1100 RT ....................................................................3

Tightening torques R 850/1100 GS und R 850/1100 R ...........................................12

Operating materials ...................................................................................................................21

Key to maintenance intervals ...................................................................................................22

Change engine oil, renew oil filter element .................................................................22

(Inspection I, II, III, IV) ........................................................................................................................22

Change the oil in the gearbox and rear wheel drive ...............................................23

(Inspection I, III, IV) ............................................................................................................................23

Changing oil in gearbox .............................................................................................................23

Changing oil in rear wheel drive .............................................................................................23

Checking battery acid level/topping up if necessary, cleaning/greasing

battery posts .................................................................................................................................24

(Inspection III, IV) ...............................................................................................................................24

Renewing air cleaner ...............................................................................................................24

(Inspection III) ....................................................................................................................................24

Renewing fuel filter ...................................................................................................................25

(Inspektion III) ....................................................................................................................................25

Checking/renewing spark plugs ........................................................................................29

(Inspection II, III) ................................................................................................................................29

Taking up slack at cylinder heads ....................................................................................29

(Inspection I) ......................................................................................................................................29

Checking/adjusting valve operating clearances ......................................................30

(Inspection I, II, III) .............................................................................................................................30

Adjusting Poly-V belt ................................................................................................................31

(Inspection I, II, III) .............................................................................................................................31

Renewing Poly-V belt

(40 000 km/24 000miles) ..........................................................................................................31

(renew maintenance-free belts every 60 000 km/36 000 miles) .........................................................31

Checking brake pads and discs for wear/renewing ...............................................32

(Inspection III) ....................................................................................................................................32

(ABS: Inspection II, III) .......................................................................................................................32

00.1

Page 10

Contents Page

Checking brake pads for wear ................................................................................................32

Renewing brake pads – front brake ......................................................................................32

[RS] Renewing brake pads - rear brake ..............................................................................33

[GS/R/RT] Renewing brake pads - rear brake .................................................................33

Checking brake discs for wear ...............................................................................................33

Checking brake fluid level/topping up ............................................................................33

(Inspection III) ....................................................................................................................................33

Bleeding/renewing the brake fluid using the handbrake lever/

brake pedaln .................................................................................................................................34

(Inspection III, IV) ...............................................................................................................................34

Bleeding front brake circuit/renewing fluid ........................................................................34

Bleeding rear brake circuit/renewing brake fluid ............................................................34

Grease the centre stand [RS], side stand and clutch cable nipple ................35

(Inspection II, III, IV) ...........................................................................................................................35

[RS] Cleaning and greasing the windshield adjusting shaft ...............................35

(Inspection III) ....................................................................................................................................35

[RS] Grease front suspension strut at its lower attachment lug

(version with plain bearing only)

(Inspection II, III) ................................................................................................................................35

........................................................................................35

Checking/adjusting clutch operating clearance ......................................................36

(Inspection I, II, III) .............................................................................................................................36

Checking tightness of rear wheel studs ........................................................................37

(Inspection I) ......................................................................................................................................37

[RS] Check tightness of screws at adjustable handlebar ....................................37

(Inspection I) ......................................................................................................................................37

[R] Check steering damper ...................................................................................................37

(Inspection II, III) ................................................................................................................................37

Taking up slack on hose clips at intake stub pipen ................................................37

(Inspection I, III) .................................................................................................................................37

Checking front wheel bearings/

checking tilt play at rear wheel ..........................................................................................37

(Inspection III) ....................................................................................................................................37

Checking swinging arm bearings, adjusting if necessary ...................................37

(Inspection I, II, III) .............................................................................................................................37

Checking/adjusting throttle synchronisation and CO emission value ..........38

(Inspection I, II, III, IV) ........................................................................................................................38

Final inspection with road safety and functional check .......................................42

(Inspection I, II, III, IV) ........................................................................................................................42

00.2

Page 11

00

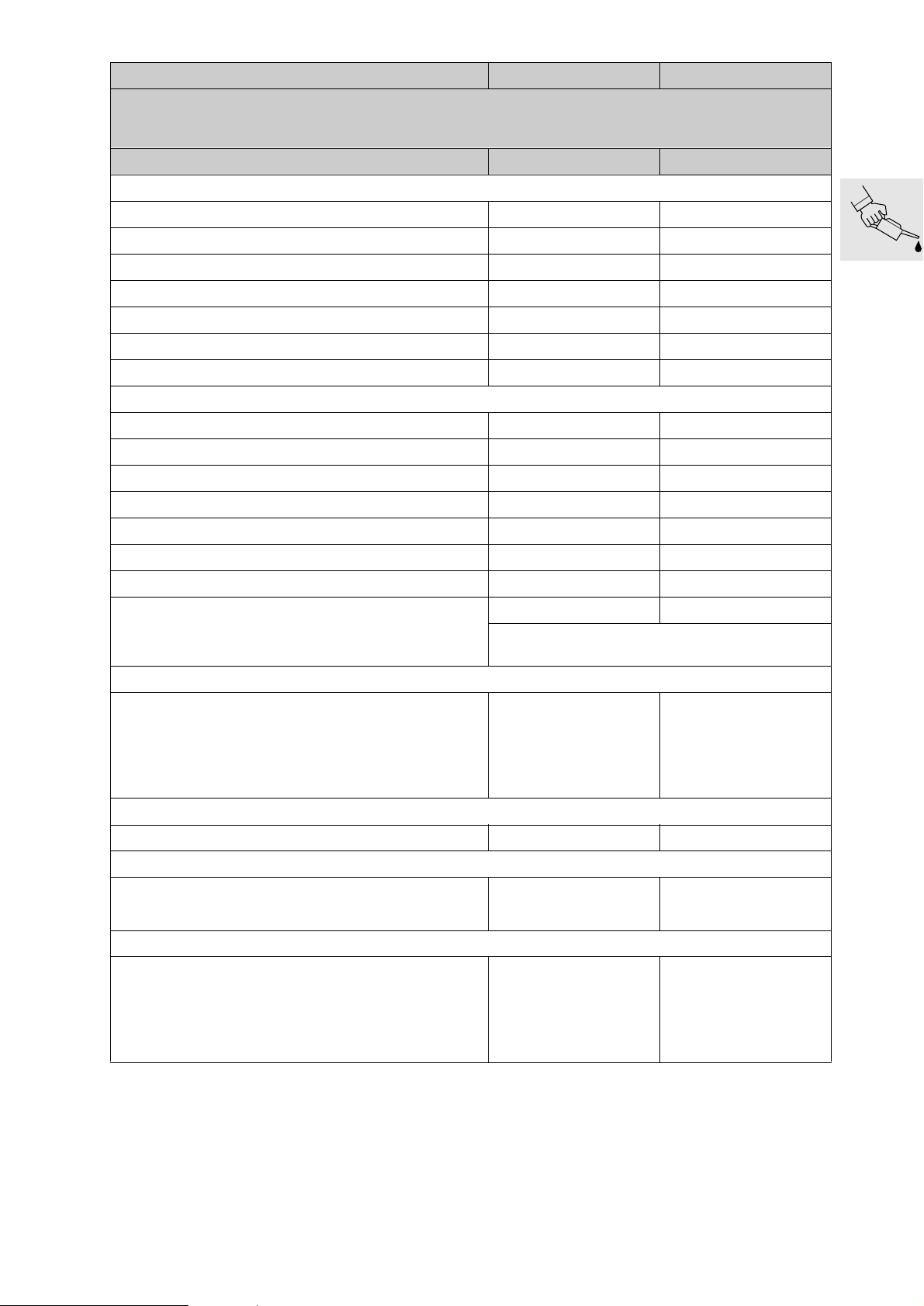

Tightening torques R 1100 RS / R 1100 RT

Model R 1100 RS R 1100 RT

11 Engine

Connection Nm Nm

Cylinder head

Tightening sequence:

1. Tighten cylinder head nuts (oiled) crosswise 20 20

1.1 Tighten all nuts to correct torque for joint

1.2 Tighten all nuts to correct angle 90°

1.3 Tighten all nuts to correct angle 90°

2. M 10 screw 40 40

3. M 6 screw 9 9

After 1000 km, tighten cylinder head nuts crosswise:

1. Unfasten one nut

2. Tighten one nut to initial value 20 20

3. Tighten nut to wrench angle 180°

4. Unfasten/retighten M10 screw 40 40

Bearing cap on rocker shaft 15 15

Locknut on valve clearance adjusting screw 8 8

Cylinder head cover to cylinder head 8 8

Camshaft end cover to cylinder head 9 9

Air intake connection to cylinder head 9 9

Camshaft

Chain sprocket to camshaft 65 65

Camshaft bearing cap 15 15

Rotary breather

Vent line to alternator mount cover

M 8 screw 20 20

Banjo screw 25 25

Alternator mount cover

M 6 screw 9 9

M 8 screw 20 20

Auxiliary shaft

Chain sprocket to crankshaft 10 10

Chainwheel to auxiliary shaft 70 70

Chain tensioner housing to engine block 9 9

00.3

Page 12

Model R 1100 RS R 1100 RT

11 Engine

Connection Nm Nm

Oil filter

Oil filter 11 11

Oil drain plug 32 32

Oil pump

Mesh filter basket to engine block 9 9

Oil pump cover 9 9

Pressure relief valve 35 35

Oil pressure switch 30 30

Oil cooler

Oil cooler pipe to engine block 10 10

Cooling oil line - banjo screw 25 25

Cooling oil line - banjo screw with oil vent valve 25 25

Oil lines to oil cooler 25 –

Oil cooler to holder 9 9

Oil cooler return line to engine block 35 35

Oil cooler feed line to frame 20 20

Oil cooler feed line to engine block 25 25

Screw-in union for oil cooler connection at

engine block

Oil cooler hose at oil thermostat – 40

Cylinders

Tightening sequence

M 8 screw 20 20

M 6 screw 9 9

Chain guide rail pivot screw 18 18

Timing chain

Chain tensioner 32 32

Connecting rod

Big end cap Joint torque 20 20

Additional wrench angle 80°

Crankcase

35 35

Clean threads and apply Loctite 603 to inner and

outer threads and in the contact face area

Tightening sequence:

M 10 screw (oiled) 45 45

M 8 screw (oiled) 20 20

M 6 screw 9 9

00.4

Page 13

Model R 1100 RS R 1100 RT

12 Engine electrical system

Connection Nm Nm

Starter motor to engine 20 20

Starter cover to gearbox housing 7 –

Positive lead to starter motor 10 10

Alternator to alternator support cover 20 20

Tensioning and retaining strap at alternator 20 20

Spacer at alternator 20 20

Positive lead to alternator 15 15

Belt pulley at alternator 50 50

Belt pulley to crankshaft 50 50

Poly-V belt preload 8 8

Spark plug 20 20

13 Fuel preparation and control

Temperature sensor on engine block 25 25

16 Fuel tank and lines

Fuel tank to rear frame 22 22

Fuel pump assembly to tank 6 6

18 Exhaust system

Muffler to footrest 35 35

Manifold to cylinder head (with strap) 22 22

(with jacket pipe) 18 18

Muffler to support plate for center stand 20 20

Clip on muffler 50 50

Grease clamping face with Never Seez

Oxygen sensor (lambda probe) to muffler 55 55

Grease with Never Seez

00.5

Page 14

Model R 1100 RS R 1100 RT

21 Clutch

Connection Nm Nm

Clutch housing Joint torque 40 40

oil screw threads lightly

Additional wrench angle 32°

Housing cover 18 18

Locknut on release lever 22 22

23 Gearbox

Oil filler plug 23 23

Oil drain plug 23 23

Gearbox cover to gearbox housing 9 9

Screw for neutral detent 13 13

clean thread + Loctite 243

Oil guide plate at gearbox housing 9 9

clean thread + Loctite 573, also apply Loctite 573

to sealing face between oil baffle plate and gear-

box housing

Gearbox to engine block 22 22

Clutch lever to gearbox housing 18 18

Selector lever to selector shaft 9 9

Pedal to footrest plate 35 18

00.6

Page 15

Model R 1100 RS R 1100 RT

31 Front fork

Connection Nm Nm

Clamp between fixed tubes and fork bridge 22 –

Screw connection between fixed tube and

fork bridge

Control arm to ball joint 130 130

Fork bridge to ball joint 130 –

– 45 (free from oil and

grease)

clean thread + Loctite 2701

clean threads

+ Loctite 2701

Threaded journal to frame – 130

– clean threads

Ball joint to fork slider tube bridge 230 230

Frame 230 –

Slider tube bridge to slider tube 22 –

clean thread

+ Loctite 243

Screw plug to fixed fork tube 18 pressed fit,

Clamping screws, quick-release axle 22 22

Control arm to engine right 73 73

Screw cap left 42 42

apply light coat of Never Seez to thread

Spring strut to frame 47 47

Spring strut to control arm 43

8.8 screw

–

+ Loctite 243

–

do not release

43

8.8 screw

50

10.9 screw

32 Steering

Handlebar at rubber mount 40 –

Rubber mount at fork bridge 40 –

Handlebar to fork bridge – 21

Twistgrip to handlebar 7 7

Handlebar weight to fixed handlebar 20 –

Handlebar weight to handlebar – 20

Handlebar weight to adjustable handlebar 7 7

clean threads

+ Loctite 2701

50

10.9 screw

–

00.7

Page 16

Model R 1100 RS R 1100 RT

33 Rear wheel drive

Connection Nm Nm

Oil drain plug 23 23

Oil filler plug 23 23

Threaded ring 118 (Hylomar SQ 32 M) 118 (Hylomar SQ 32 M)

Hexagon nut, input bevel gear 200 200

clean thread + Loctite 273

Housing cover 35 35

Fixed bearing journal

Swinging arm to gearbox/

Swinging arm at rear wheel drive

Free bearing journal

Swinging arm to gearbox/

Swinging arm at rear wheel drive

Locknut on free bearing journal 105 105

Strut at rear wheel drive / gearbox 43 43

Spring strut to rear frame / rear swinging

arm

Hydraulic spring adjuster at footrest plate – 22

150 150

clean thread + Loctite 2701

77

clean thread + Loctite 2701

clean thread + Loctite 2701

load motorcycle with approx. 85 kg and tighten

loose strut

43

8.8 screw

50

10.9 screw

43

8.8 screw

50

10.9 screw

00.8

Page 17

Model R 1100 RS R 1100 RT

34 Brakes

Connection Nm Nm

Brake caliper to slider tube 40 40

Brake caliper to rear wheel drive 40 40

Brake disc to front wheel 21 21

Brake disc to rear wheel drive 21 21

clean thread + Loctite 273

Brake hose to brake caliper, front/rear 15 15

Brake hose to fitting 15 15

Brake hose to flow distributor 15 15

Flow distributor to frame 9 9

Flow distributor to slider tube bridge 9 9

Flow distributor to holder/slider tube – 9

Bleed screw on front brake caliper 7 7

Bleed screw on rear brake caliper 7 4

Master cylinder to footrest plate 9 9

Brake pedal to footrest plate 37 37

Handbrake lever pivot pinl 8 8

the Tuflok blue thread retaining agent can be

slackened off and tightened several times if nec-

essary

ABS sensor 4 (handtight) 4 (handtight)

ABS unit to holder

M6 screw 9 9

M6 screw (Torx) 5 5

Brake line to ABS unit 15 15

Bleed screw to ABS unit 9 9

36 Wheels and tyres

Clamping screws, quick-release axle 22 22

Screw connection, quick-release axle 30 30

Screw on wheel nuts handtight, then tighten

crosswise:

Initial tightening 50

50

Final tightening

105

105

00.9

Page 18

Model R 1100 RS R 1100 RT

46 Frame

Connection Nm Nm

Rear frame to gearbox/engine 47 47

Screw connection on right of gearbo

at right of engine

at left of engine

at left of gearbox

Footrest plate to gearbox 22 22

Frame to engine 82 82

Struts to frame 47

8.8 screw

58

10.9 screw

Struts to engine 47 47

Guard hoop to cylinder head 20 20

Side stand to pivot mount 42 42

clean thread + Loctite 2701

Center stand to carrier plate 21 21

clean thread + Loctite 2701

Carrier plate for center stand to engine block

M12 screw 72 72

clean thread + Loctite 2701

M 8 screw (countersunk) 21 21

clean thread + Loctite 2701

Grab handle to rear frame 9 9

Lifting handle to rear frame 10 10

Footrest plate to rear frame

47

8.8 screw

58

10.9 screw

M 6 screw 9 –

M 8 screw 21 21

M 10 screw 42 –

Footrest to footrest plate 42 –

Fairing support bracket to frame 20 20

00.10

Page 19

Model R 1100 RS R 1100 RT

51 Equipment

Connection Nm Nm

Ignition/steering lock to fork bridg 15 15

61 General electrical system

Horn to horn bracket 8 20

Ground (earth) strap to engine block 10 10

Rubber bushing for battery holder at gearbox 4 4

00.11

Page 20

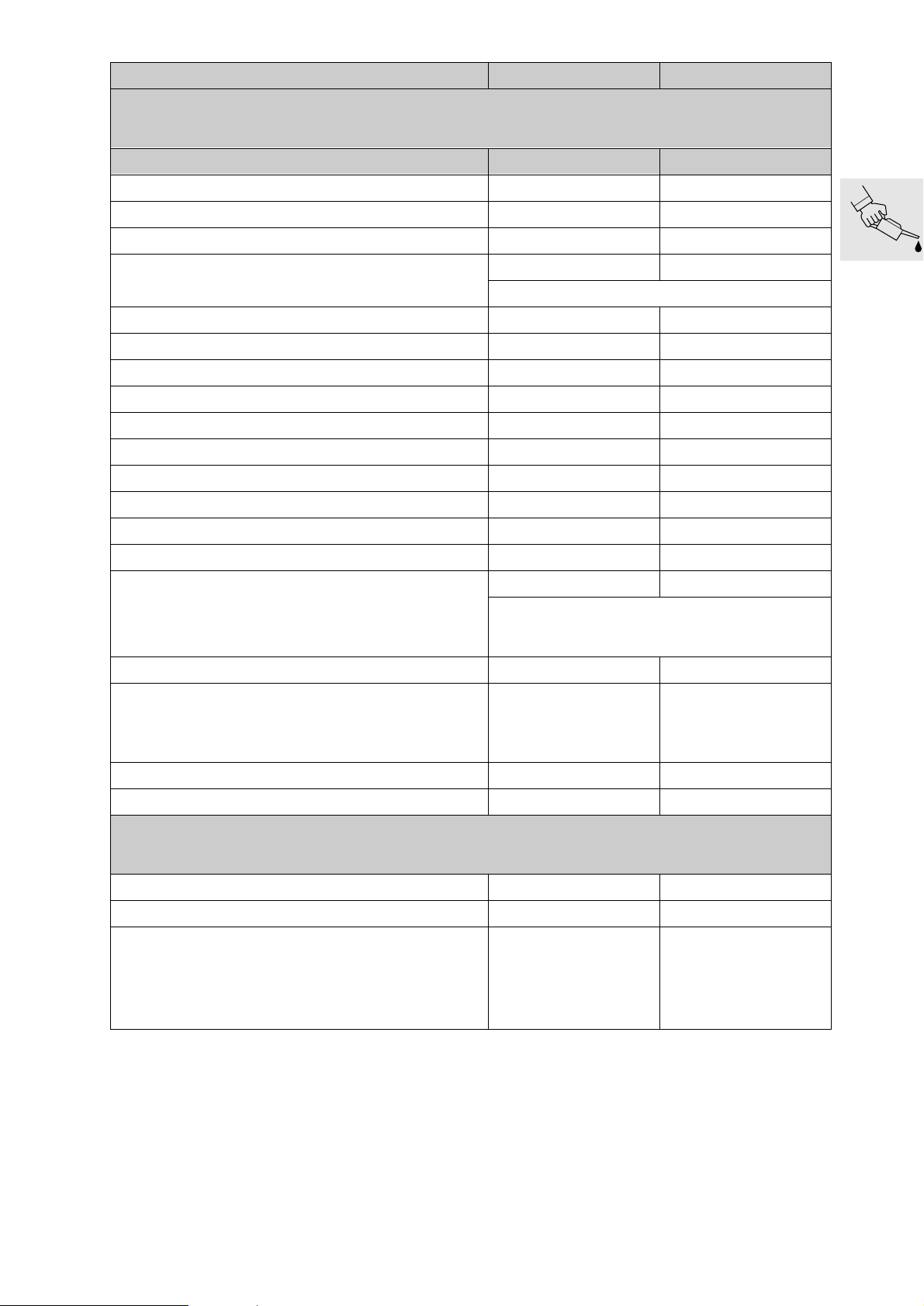

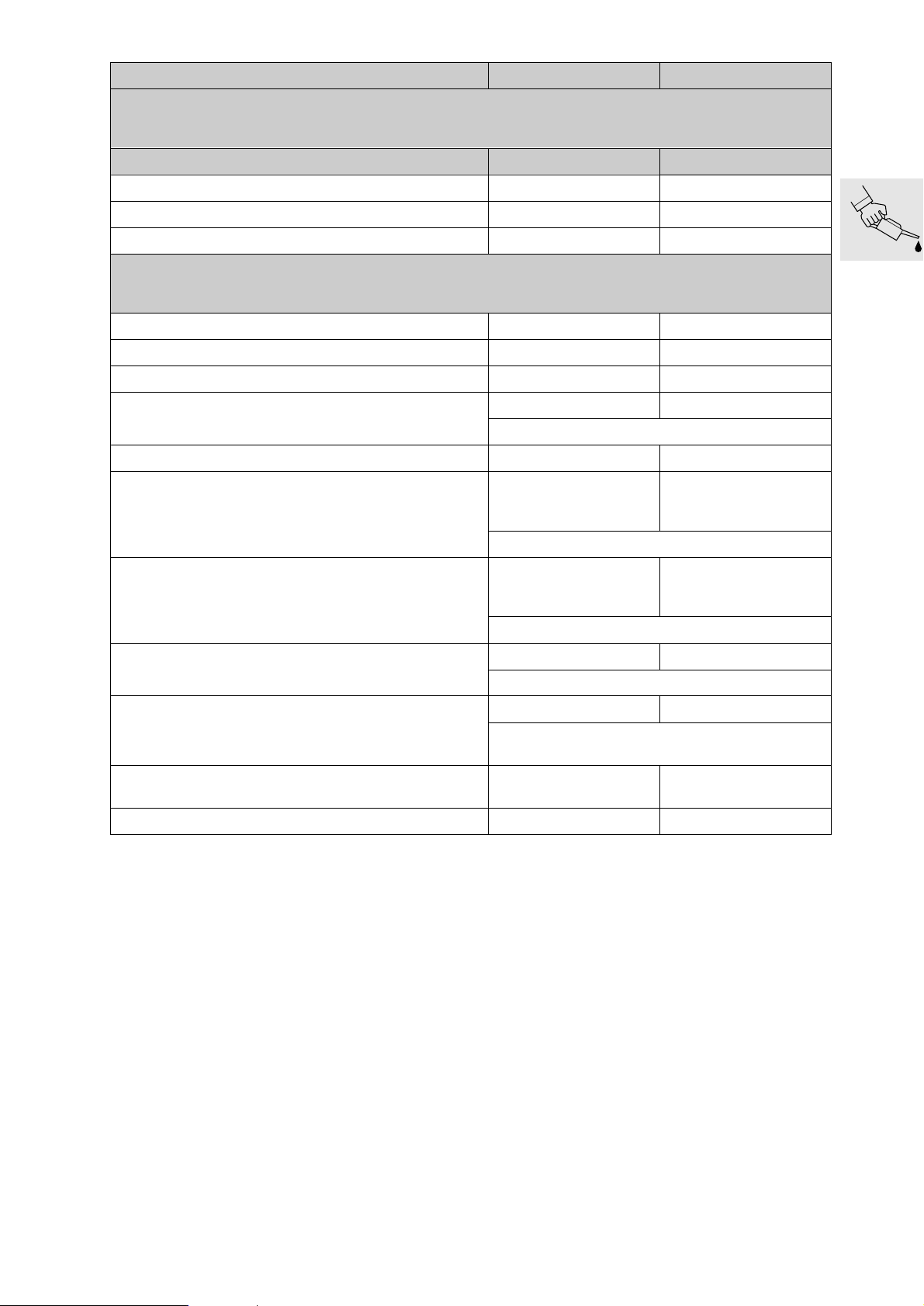

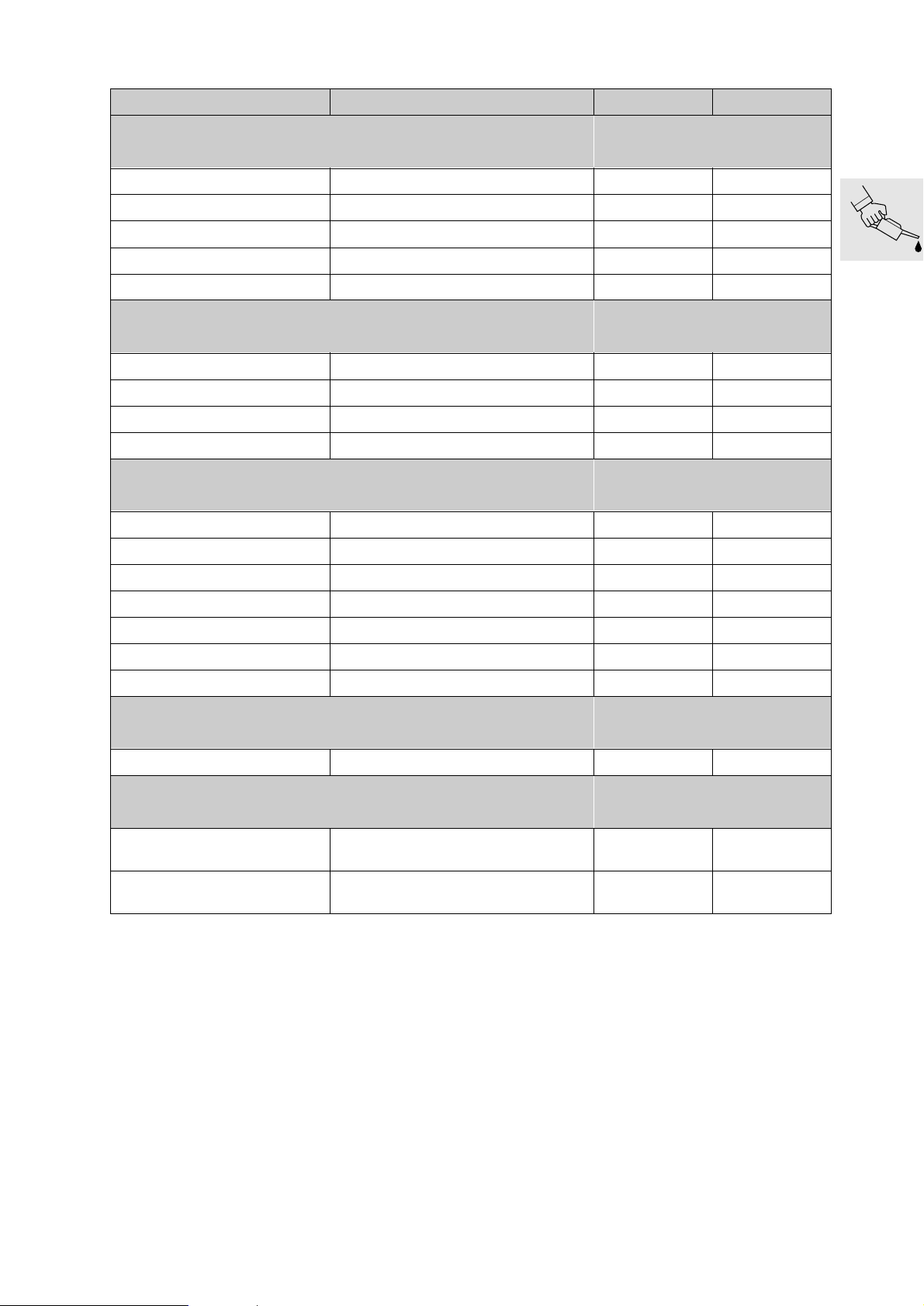

Tightening torques R 850/1100 GS und R 850/1100 R

Model R 850/1100 GS R850/1100R

11 Engine

Connection Nm Nm

Cylinder head

Tightening sequence:

1. Tighten cylinder head nuts (oiled) crosswise 20 20

1.1 Tighten all nuts to correct torque for joint

1.2 Tighten all nuts to correct angle 90°

1.3 Tighten all nuts to correct angle 90°

2. M 10 screw 40 40

3. M 6 screw 9 9

After 1000 km, tighten cylinder head nuts crosswise:

1. Unfasten one nut

2. Tighten one nut to initial value 20 20

3. Tighten nut to wrench angle 180°

4. Unfasten/retighten M10 screw 40 40

Bearing cap on rocker shaft 15 15

Locknut on valve clearance adjusting screw 8 8

Cylinder head cover to cylinder head 8 8

Camshaft end cover to cylinder head 9 9

Air intake connection to cylinder head 9 9

Camshaft

Chain sprocket to camshaft 65 65

Camshaft bearing cap 15 15

Rotary breather

Vent line to alternator mount cover

M 8 screw 20 20

Banjo screw 25 25

Alternator mount cover

M 6 screw 9 9

M 8 screw 20 20

Auxiliary shaft

Chain sprocket to crankshaft 10 10

Chainwheel to auxiliary shaft 70 70

Chain tensioner housing to engine block 9 9

00.12

Page 21

Model R 850/1100 GS R850/1100R

11 Engine

Connection Nm Nm

Oil filter

Oil filter 11 11

Oil drain plug 32 32

Oil pump

Mesh filter basket to engine block 9 9

Oil pump cover 9 9

Pressure relief valve 35 35

Oil pressure switch 30 30

Oil cooler

Oil cooler pipe to engine block 10 10

Cooling oil line - banjo screw 25 25

Cooling oil line - banjo screw with oil vent valve 25 25

Oil lines to oil cooler 25 –

Oil cooler to holder 9 9

Oil cooler return line to engine block 35 35

Oil cooler feed line to engine block 25 25

Screw-in union for oil cooler connection at

engine block

Cylinders

Tightening sequence:

1. M 8 screw 20 20

2. M 6 screw 9 9

3. Chain guide rail pivot screw 18 18

Timing chain

Chain tensioner 32 32

Connecting rod

Big end cap Joint torque 20 20

Additional wrench angle 80°

Crankcase

Tightening sequence:

1. M 10 screw (oiled) 45 45

35 35

Clean threads and apply Loctite 603 to inner and

outer threads and in the contact face area

2. M 8 screw (oiled) 20 20

3. M 6 screw 9 9

00.13

Page 22

Model R 850/1100 GS R850/1100R

12 Engine electrical system

Connection Nm Nm

Starter motor to engine 20 20

Starter cover to gearbox housing 7 7

Positive lead to starter motor 10 10

Alternator to alternator support cover 20 20

Tensioning and retaining strap at alternator 20 20

Spacer at alternator 20 20

Positive lead to alternator 15 15

Belt pulley at alternator 50 50

Belt pulley to crankshaft 50 50

Poly-V belt preload 8 8

Spark plug 20 20

13 Fuel preparation and control

Temperature sensor on engine block 25 25

16 Fuel tank and line

Fuel tank to rear frame 22 22

Fuel pump assembly to tank 6 6

Strut to tank – 15

18 Exhaust system

Muffler to rear frame 24 24

Manifold to cylinder head (with strap) 22 22

(with jacket pipe) 18 18

Muffler to support plate for center stand 20 20

Clip on muffler 50 50

Grease clamping face with Never Seez

Oxygen sensor (lambda probe) to muffler 55 55

Grease with Never Seez

00.14

Page 23

Model R 850/1100 GS R850/1100R

21 Clutch

Connection Nm Nm

Clutch housing Joint torque 40 40

oil screw threads lightly

Additional wrench angle 32°

Housing cover 18 18

Locknut on release lever 22 22

23 Gearbox

Oil filler plug 23 23

Oil drain plug 23 23

Gearbox cover to gearbox housing 9 9

Screw for neutral detent 13 13

clean thread + Loctite 243

Oil guide plate at gearbox housing 9 9

clean thread + Loctite 573, also apply Loctite 573

to sealing face between oil baffle plate and gear-

box housing

Gearbox to engine block 22 22

Clutch lever to gearbox housing 18 18

Selector lever to selector shaft 9 9

Pedal to footrest plate 35 35

00.15

Page 24

Model R 850/1100 GS R850/1100R

31 Front fork

Connection Nm Nm

Screw connection between fixed tube and

fork bridge

Control arm to ball joint 130 130

Threaded journal to frame 130 130

Ball joint to fork slider tube bridge 230 230

Slider tube bridge to slider tube 22 22

Screw plug to fixed fork tube press fit, do not release!

Clamping screws, quick-release axle 22 22

Control arm to engine right 73 73

Screw cap left 42 42

Spring strut to frame 47 47

Spring strut to control arm 50

Steering damper to fork slider bridge mount – 20

Steering damper mount to fork slider bridge – 9

45 (free from oil and

grease)

clean thread + Loctite 2701

clean threads + Loctite 243

clean threads

+ Loctite 243

apply light coat of Never Seez to thread

10.9 screw

45 (free from oil and

grease)

50

10.9 screw

clean thread

+ Loctite 2701

clean thread

+ Loctite 2701

Steering damper to leading link pivot mount – 20

clean thread

+ Loctite 2701

Steering damper pivot mount at leading link – 20

Joint head against locknut – 20

00.16

Page 25

Model R 850/1100 GS R850/1100R

32 Steering

Connection Nm Nm

Handlebar to fork bridge 21 21

Twistgrip to handlebar 7 7

Handlebar weight to fixed handlebar 20 20

33 Rear wheel drive

Oil drain plug 23 23

Oil filler plug 23 23

Threaded ring 118 (Hylomar SQ 32 M) 118 (Hylomar SQ 32 M)

Hexagon nut, input bevel gear 200 200

clean thread + Loctite 273

Housing cover 35 35

Fixed bearing journal

Swinging arm at gearbox

Swinging arm at rear wheel drive

150 150

clean thread + Loctite 2701

Free bearing journal

Swinging arm to gearbox/

Swinging arm to rear wheel drive

Locknut on free bearing journal 105 105

Strut at rear wheel drive / gearbox 43 43

Spring strut to rear frame / rear swinging arm 50

Hydraulic spring adjuster at footrest plat 22 –

77

clean thread + Loctite 2701

clean thread + Loctite 2701

(load motorcycle with approx. 85 kg and tighten

loose strut)

50

10.9 screw

10.9 screw

00.17

Page 26

Model R 850/1100 GS R850/1100R

34 Brakes

Connection Nm Nm

Brake caliper to slider tube 40 40

Brake caliper to rear wheel drive 40 40

Brake disc to front wheel

Cast wheel

Spoked whee

Brake disc to rear wheel drive 21 21

Brake disc to rear wheel 21 21

Brake hose to brake caliper, front/rear 15 15

Brake hose to fitting 15 15

Brake hose to flow distributor 15 15

Flow distributor to frame 9 9

–

24

clean thread + Loctite 243

clean thread + Loctite 273

clean thread + Loctite 243

21

24

Flow distributor to slider tube bridge 9 –

Flow distributor to holder/slider tube – 9

Bleed screw on front brake caliper 7 7

Bleed screw on rear brake caliper 4 4

Master cylinder to footrest plate 9 9

Brake pedal to footrest plate 37 37

Handbrake lever pivot pinl 8 8

(the Tuflok blue thread retaining agent can be

slackened off and tightened several times if nec-

essary)

ABS sensor 4 (handtight) 4 (handtight)

ABS unit to holder

M6 screw 9 9

M6 screw (Torx) 5 5

Brake line to ABS unit 15 15

Bleed screw to ABS unit 9 9

00.18

Page 27

Model R 850/1100 GS R850/1100R

36 Wheels and tyres

Connection Nm Nm

Clamping screws, quick-release axle 22 22

Screw connection, quick-release axle 30 30

Screw on wheel nuts handtight, then tighten

crosswise:

Initial tightening

Final tightening

46 Frame

Rear frame to gearbox/engine 47 47

1. Screw connection on right of gearbox

2. at right of engine

3. at left of engine

4. at left of gearbox

Footrest plate to gearbox 22 22

Frame to engine 82 82

Struts to frame 47

Struts to engine 58 58

50

105

8.8 screw

58

10.9 screw

50

105

47

8.8 screw

58

10.9 screw

Guard hoop to cylinder head 20 20

Side stand to pivot mount 42 42

clean thread + Loctite 2701

Center stand to carrier plate 21 21

clean thread + Loctite 2701

Carrier plate for center stand to engine block

M12 screw 72 72

clean thread + Loctite 2701

M 8 screw (countersunk) 21 21

clean thread + Loctite 2701

Footrest plate to rear frame

M 8 screw 21 21

Fairing support bracket to frame 20 –

00.19

Page 28

Model R 850/1100 GS R850/1100R

51 Equipment

Connection Nm Nm

Ignition/steering lock to fork bridge 15 15

61 General electrical system

Horn to horn bracket 8 8

Ground (earth) strap to engine block 10 10

Rubber bushing for battery holder at gearbox 4 4

00.20

Page 29

Operating materials

Item Use Order number Quantity

Lubricant

Optimoly MP 3 High-performance lubricating paste 07 55 9 062 476 100 g tube

Optimoly TA High-temperature assembly paste 18 21 9 062 599 100 g tube

Silicone grease 300, heavy Damping grease 07 58 9 058 193 10 g tube

Retinax A (Taper) roller bearing grease 81 22 9 407 710 100 g tube

Contact spray Contact spray 81 22 9 400 208 300 ml aerosol

Sealants

3-Bond 1209 Surface sealant 07 58 9 062 376 30 g tube

Loctite 574 Surface sealant 81 22 9 407 301 50 ml tube

Curil K 2 Heat-conductive sealant 81 22 9 400 243 250 g can

Hylomar SQ 32 M Permanently elastic sealant 81 22 9 400 339 100 g tube

Adhesives and retaining

agents

Loctite 648 Structural adhesive, ultra-high speed 07 58 9 067 732 5 g bottle

Loctite 638 Joint connector 07 58 9 056 030 10 ml bottle

Loctite 243 Thread retainer, medium-strength 07 58 9 056 031 10 ml bottle

Loctite 270 Thread retainer, strong 81 22 9 400 086 10 ml bottle

Loctite 2701 Thread retainer 33 17 2 331 095 10 ml bottle

Loctite 454 Cyanacrylate adhesive 07 58 9 062 157 20 g tube

3-Bond 1110 B Joint adhesive 07 58 9 056 998 5 g tube

Cleaner

Brake cleaner Brake cleaner 81 22 9 407 704 600 ml aerosol

Testing agent

Penetrant MR 68 Crack testing agent for alu-

minum housings

Entwickler MR 70 Developer for aluminum housing

crack testing agent

81 22 9 407 494 500 ml spray

81 22 9 407 495 500 ml spray

00.21

Page 30

Key to maintenance intervals

– Inspection at 1000 km (600 miles) I

– BMW Service II

– BMW Inspection III

– Annual Service IV

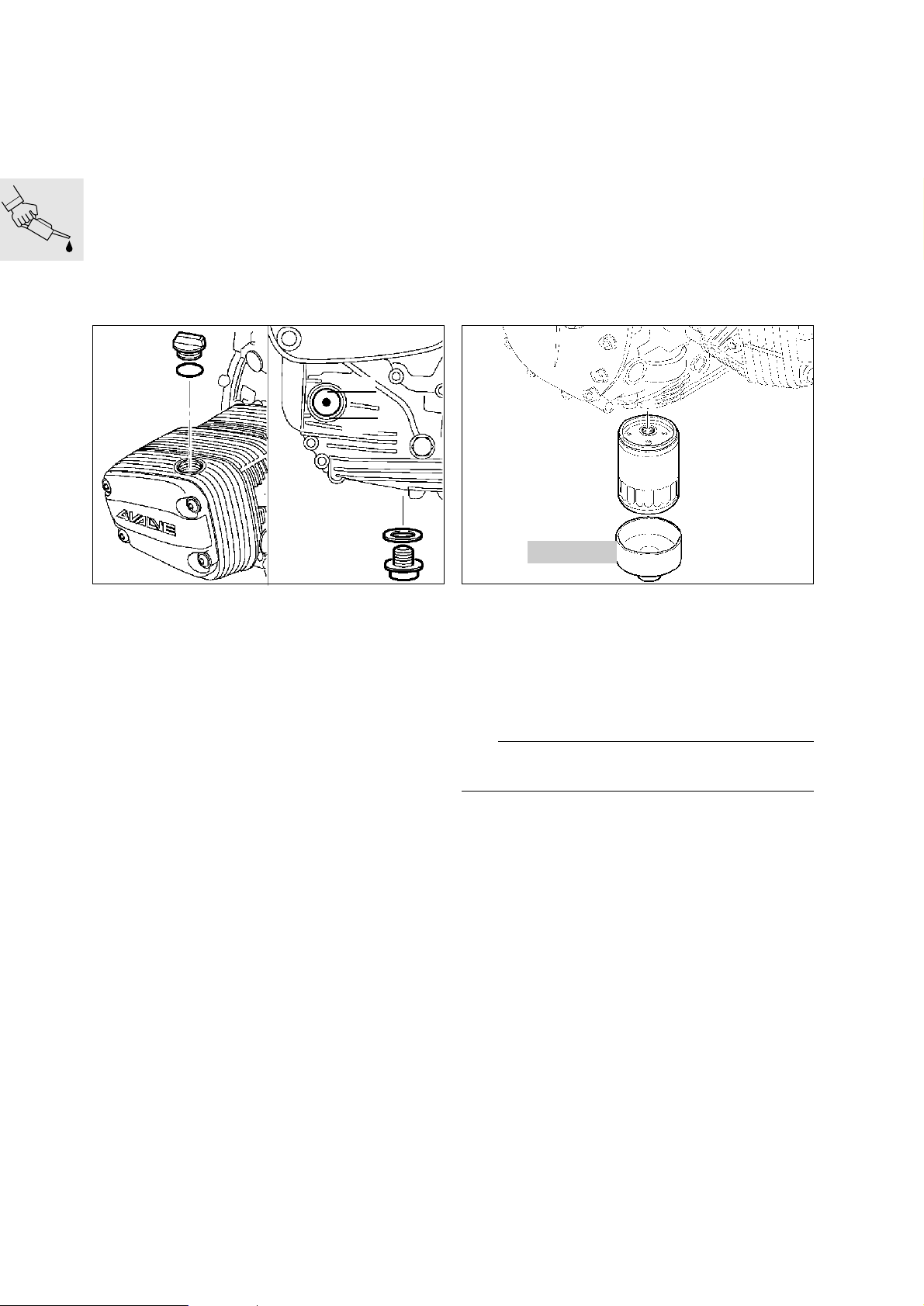

Change engine oil, renew oil filter element

(Inspection I, II, III, IV)

Max

Min

RS000180

Remove screw plug.

•

Unscrew oil drain plug and drain off oil.

•

Fit new seal and screw in drain plug.

•

11 4 650

RS110950

Using oil filter wrench, BMW No. 11 4 650,

•

unscrew and remove the oil filter element.

Coat sealing ring on new oil filter element with oil

•

and screw in.

Top up oil/seal off.

•

Do not check oil level until at least 10 minutes af-

•

ter test run/test ride.

e Caution:

Never add engine oil above the MAX mark.

X Tightening torque:

Oil filter......................................................... 11 Nm

Oil drain plug................................................ 32 Nm

Fill quantity for engine:

- with oil filter change.............3.75 l (6.6 Imp. pints)

- without oil filter change ........3.50 l (6.2 Imp. pints)

Oil volume between

MIN and MAX marks ............0.50 l (0.88 Imp. pints)

00.22

Engine oil grade:

Brand-name HD oil for four-stroke spark-ignition engine, API classifications SE,SF,SG; combination

with CC or CD specification.

Page 31

Change the oil in the gearbox and

rear wheel drive

(Inspection I, III, IV)

Changing oil in gearbox

RT

1

RS000210

[RT] Push in oil drain pipe (1), BMW No. 23 4 680

•

and turn to right.

Unscrew and remove oil filler plug and oil drain

•

plug/drain off oil.

Fit new seal and screw in drain plug.

•

Top up gearbox oil.

•

Insert oil filler plug with new seal.

•

X Tightening torque:

Oil drain plug................................................ 23 Nm

Oil filler plug ................................................. 23 Nm

Fill quantity::

gearbox up to lower rim of filler hole

Initial filling..............................1.0 l (1.76 Imp. pints)

During oil changes ...................0.8 l (1.4 Imp. pints)

Changing oil in rear wheel drive

RS000070

Unscrew and remove oil filler plug and oil drain

•

plug/drain off oil.

Fit new seal and screw in drain plug.

•

Top up gearbox oil.

•

Insert oil filler plug with new seal.

•

X Tightening torque:

Oil drain plug................................................ 23 Nm

Oil filler plug ................................................. 23 Nm

Fill quantity:

Initial filling ...........................0.25 l (0.44 Imp. pints)

During oil changes .............0.23 l (0.404 Imp. pints)

Oil grade:

Brand-name hypoid gear oil, SAE 90, API

class GL 5

00.23

Page 32

3

1

RS

2

R/GS/RT

Checking battery acid level/topping

up if necessary, cleaning/greasing

battery posts

(Inspection III, IV)

Remove dualseat.

•

[RS/RT] Take off left side fairing.

•

[GS] Take off right side fairing.

•

[R] Remove tank cover.

•

Remove air cleaner cover (1).

•

Remove intake air pipe (2).

•

[GS/R] Unscrew fuel tank fastenings.

•

[GS/R] Raise rear of fuel tank and support with a

•

suitable object.

Release the rubber battery strap (3).

•

Remove battery.

•

e Caution:

Disconnect negative terminal of battery first, then

positive terminal. Connect positive battery terminal

first, then negative terminal.

Top up battery acid level with distilled water as

•

far as the MAX mark.

Installation in reverse order.

•

RS000340

Renewing air cleaner

(Inspection III)

Remove dualseat.

•

[GS] Detach fuel tank at rear, raise it and support

•

it with a suitable object.

Renew air cleaner insert.

•

X Tightening torque:

Fuel tank to rear frame ................................. 22 Nm

Protective battery-post grease:

e.g. Bosch Ft 40 V1

X Tightening torque:

Fuel tank to rear frame ................................. 22 Nm

00.24

Page 33

RS

4

1

13 3 010

5

3

2

RS160010

Renewing fuel filter

(Inspektion III)

Remove dualseat.

•

[RS/RT] Take off side sections of fairing.

•

[RS] Detach cockpit inner panel (1) at fuel tank.

•

[GS] Remove right side fairing.

•

[R] Remove fuel tank cover.

•

[RT] Detach storage compartment

•

Unfasten fuel tank mount (2)

•

Seal off fuel feed and return line (3) with hose clip,

•

BMW No. 13 3 010, loosen and pull off.

Remove vent pipes (4).

•

Remove fuel pump connector (5).

•

Lift off fuel tank.

•

00.25

Page 34

RT

6x

C

B

A

13 3 010

A

B

C

3

4

5

6x

RT160060

00.26

Page 35

e Caution:

Fuel is flammable and a hazard to health. Observe

relevant safety regulations.

Drain fuel tank.

•

Remove fuel pump unit/detach vent hoses.

•

RS000130

00.27

Page 36

1

2

RS160030

Detach hoses from fuel filter (1)

•

Fit new fuel filter.

•

Installation in reverse order.

•

Secure non-reusable hose clips with pliers,

•

BMW No. 13 1 500.

e Caution:

Note correct direction of flow through fuel filter. Use

only an O-ring seal (2) in good condition. After

assembly, check fuel pump unit for leaks.

X Tightening torqu

Fuel tank to rear frame ................................. 22 Nm

Fuel pump unit to fuel tank. ........................... 6 Nm

00.28

Page 37

Checking/renewing spark plugs

(Inspection II, III)

12 3 510

RS000010

Pull off spark plug cap with cap assembly tool,

•

BMW No. 12 3 520.

Unscrew and remove spark plugs with spark-

•

plug wrench, BMW No. 12 3 510.

Taking up slack at cylinder heads

(Inspection I)

Remove cylinder head cover.

•

e Caution:

Trap escaping oil.

TDC

Electrode gap: ........................ 0.8 mm (0.0315 in)

Gap wear limit:............................. 1.0 mm (0.04 in)

e Caution:

Do not bend electrodes - risk of breakage!

RS00002

Select a gear and turn the rear wheel, or set the

•

piston to TDC by turning the belt pulley.

Top dead centre on ignition stroke:

1. The OT (TDC) mark appears and

2. the inlet and exhaust valves of the cylinder in

question are closed.

Tighten cylinder head nuts.

•

Tightening procedure after 1000 km ( 600 miles )

1. Tighten cylinder head nuts individually in a crosswise pattern

1.1.Slacken off one nut

1.2.Tighten nut to init. torque....................... 20 Nm

1.3.Tighten nut to specified wrench angle....... 180°

2. Unfasten/retighten M10 screw ................ 40 Nm

RS 00. 002

00.29

Page 38

Checking/adjusting valve operating clearances

(Inspection I, II, III)

RS110980

Check valve clearance with feeler gauge and, if

•

necessary, correct with adjusting nut/lock.

Adjust valve clearances with the engine cold

(max. 35°C):

Inlet.......................................... 0.15 mm ( 0.006 in)

Exhaust.................................... 0.30 mm (0.012 in )

X Tightening torque:

Locknut.......................................................... 8 Nm

Check valve clearance again; it must be possible

•

to insert the feeler gauge between valve stem

and rocker with only slight resistance to movement.

Assemble in reverse order

•

e Caution:

Make sure that gasket is correctly seated. Gaskets

and sealing faces must be free from oil or grease

X Tightening torqu

Cover screw...................................................8 Nm

Spark plug (without lubricant)....................... 20 Nm

00.30

Page 39

3

2

4

1

RS110480

Adjusting Poly-V belt

(Inspection I, II, III)

Renewing Poly-V belt

(40 000 km/24 000miles)

(renew maintenance-free belts every 60 000 km/

36 000 miles)

RS110490

Poly-V belt adjusting procedure:

Poly-V belt installation procedure:

Place the Poly-V belt in position, tension it and

•

turn the engine over once, then release belt tension.

Poly-V belt tensioning procedure:

Screw hex nut (1) on adjusting screw (2) up

•

handtight (no tools to be used!)

Tighten adjusting screw (2) with a torque wrench,

•

fully tighten retaining nut (3), slacken adjusting

screw and tighten screws fully.

X Tightening torque:

Poly-V belt preload......................................... 8 Nm

Alternatorto alternator support cover............ 20 Nm

L Note:

aSee also Service Information 12 020 95 (700).

[RS/RT] Remove left side fairing.

•

[R] Remove left fuel tank cover.

•

Remove front cover.

•

Slacken off alternator mounting screws (1,3,4)

•

and install a new Poly-V belt if necessary.

00.31

Page 40

Checking brake pads and discs for wear/renewing

(Inspection III)

(ABS: Inspection II, III)

Checking brake pads for wear

1

Renewing brake pads – front brake

RS340020

Unfasten/remove brake caliper.

•

LT000090

[RS] Measure brake pad thickness (arrows).

•

GS000390

[GS/R/RT] Check wear marks.

•

e Caution:

Brake pad thickness must not fall below the minimum

value.

Change pads only as a complete set.

e Caution:

[RS/R/RT] Do not scratch the wheel rim; mask it off

with tape if necessary

Remove keeper from retaining pin (1).

•

Drive out retaining pin (1).

•

Remove brake pads by pulling downwards.

•

.

34 1 500

LT000100

Before installing the brake caliper, push the

•

pistons back fully with resetting tool,

BMW No. 34 1 500.

Install in the reverse order of work.

•

Minimum lining thickness: ........ 1.5 mm (0.059 in)

00.32

X Tightening torque:

Brake caliper to rear wheel drive.................. 40 Nm

Page 41

[RS] Renewing brake pads - rear brake

1

Checking brake discs for wear

LT000120

Lever off cap from brake caliper.

•

Drive out retaining pins (1), working from the

•

wheel side.

Lift brake pads upwards to remove.

•

Install in the reverse order of work.

•

If necessary, push pistons fully back with reset-

•

ting tool, BMW No. 34 1 500.

[GS/R/RT] Renewing brake pads - rear

brake

1

LT000110

Carefully inspect brake discs for cracking, dam-

•

age, distortion, wear and scoring.

Brake disc wear limit:................ 4.5 mm (0.177 in)

[RS] rear:.................................... 4.6 mm (0.181 in)

Checking brake fluid level/topping up

(Inspection III)

Max.

Min.

Max.

Min.

GS000400

[RT] Take out the rear wheel.

•

Unfasten/remove brake caliper.

•

Remove keeper from retaining pin (1).

•

Drive out retaining pin (1) towards the wheel side.

•

Remove brake pads.

•

Before installing the brake caliper, depress the

•

piston fully.

Install in the reverse order of work.

•

X Tightening torque:

Brake caliper at rear wheel drive: ................. 40 Nm

RS000160

Remove reservoir cover together with dia-

•

phragm.

Add brake fluid up to the MAX mark.

•

Fit diaphragm and reservoir cover.

•

Carefully tighten retaining screws.

•

Brake fluid grade:

Use only brake fluid of DOT 4 quality classification

(e.g. ATE "SL“ brake fluid)

00.33

Page 42

Bleeding/renewing the brake fluid

using the handbrake lever/brake

pedaln

(Inspection III, IV)

Bleeding front brake circuit/renewing fluid

Remove front brake pads.

•

e Caution:

Do not tilt the brake calipers when removing. There

is a risk of dmage to the brake pads.

Press the pistons back in the second brake cali-

•

per, and leave the resetting tool in position.

Apply handbrake lever several times until brake

•

pressure can be detected.

Maintain pressure on handbrake lever, then open

•

bleed screw while maintaining firm pressure on

the handbrake lever.

Unscrew brake fluid reservoir cover and remove

•

together with diaphragm.

Add brake fluid up to the MAX mark.

•

e Caution:

During the bleeding process, brake fluid level must

not drop below the MIN mark, or else air will be

drawn into the brake system.

If this occurs, repeat the bleeding operation.

Connect a vessel to the brake caliper to trap

•

brake fluid as it emerges from the bleed screw;

slacken off the bleed plug by a half-turn.

34 1 500

LT000100

e Caution:

Do not release the lever/pedal until the bleed screw

has been closed.

Close bleed screw and release handbrake lever.

•

Allow brake fluid to emerge from both brake cal-

•

ipers in succession until it is clear and free from

bubbles.

Close bleed screw.

•

Install brake pads/brake calipers.

•

Brake fluid level = MAX mark.

•

Fit diaphragm and reservoir cover.

•

Carefully tighten retaining screws.

•

Turn handlebar from lock to lock, actuating brake

•

several times while doing so.

Perform a functional check on the brake system.

•

Bleeding rear brake circuit/renewing brake fluid

[RS/GS] The rear brake caliper does not have to

•

be removed, nor the pistons pushed back.

[R/RT] To bleed, slacken off the brake caliper

•

and position it so that the bleed nipple is at the

highest point.

After this, the procedure is the same as for

•

bleeding/renewing the front brake fluid.

Press the brake pistons fully back with the piston

•

resetting tool, BMW No. 34 1 500.

Remove the piston resetting tool and insert

•

spacer, BMW No. 34 1 520, in its place.

00.34

Page 43

Grease the centre stand [RS], side

stand and clutch cable nipple

[RS] Cleaning and greasing the

windshield adjusting shaft

(Inspection II, III, IV)

RS000330

Clean and grease the nipple with a grease gun

•

until grease starts to emerge at the bearing point.

Lubricant:.................. e.g. Staburags NBU 30 PTM

(Inspection III)

RS000360

Unscrew, clean and grease the shaft, then screw

•

it back in.

Lubricant:................................ e.g. Shell Retinax A

RS330320

Lubricant:................................ e.g. Shell Retinax A

[RS] Grease front suspension strut at

its lower attachment lug

(version with plain bearing only)

(Inspection II, III)

Lubricant:....................................e.g. Never Seeze

X Tightening torque:

Spring strut to control arm ........................... 43 Nm

00.35

Page 44

Checking/adjusting clutch operating clearance

(Inspection I, II, III)

A

RS210020

Set distance A at the adjusting screw.

•

Distance A:.................................. 12 mm (0.472 in)

1

2

B

RS210040

Set to distance B at the handlebar clutch lever,

•

using the adjusting screw on the release lever.

Distance B: ............................... 7.0 mm (0.276 in)

X Tightening torque:

Locknut on adjusting screw ......................... 22 Nm

21 3 610

RS210030

[GS] If necessary, slacken off hydraulic spring

•

adjuster with 6 mm Allen key,

BMW No. 31 5 600.

[RT] Slacken off the power socket holder.

•

Using socket wrench, BMW No. 21 3 610,

•

slacken off locknut (1) at adjusting screw (2) on

the clutch release lever/gearbox.

00.36

Page 45

Checking tightness of rear wheel studs

Checking front wheel bearings/

checking tilt play at rear wheel

(Inspection I)

X Tightening torque:

Rear wheel nuts ......................................... 105 Nm

[RS] Check tightness of screws at

adjustable handlebar

(Inspection I)

(Inspection III)

Relieve load on front wheel.

•

Tilt the front wheel to and fro across the axle.

•

No play should be detected.

•

If play is detected in the wheel bearings, renew

•

them.

Tilt the rear wheel to and fro across the wheel

•

axle.

If play is detected, fit new shims to rear wheel

•

drive or renew bearings.

Checking swinging arm bearings,

adjusting if necessary

(Inspection I, II, III)

Grip rear tyre and try to move it sideways,

•

bracing against the frame.

RS000350

X Tightening torque:

Handlebar adjusting screw........................... 20 Nm

[R] Check steering damper

(Inspection II, III)

Freedom from play at ball head.

•

Freedon from play at piston rod.

•

– Turn steering to left and rock to and fro radially at

front end of housing.

Taking up slack on hose clips at

intake stub pipen

(Inspection I, III)

X Tightening torque:

Hose clips on air intake pipe .......................... 2 Nm

00.37

Page 46

Checking/adjusting throttle synchronisation and CO emission value

(Inspection I, II, III, IV)

RS130020

[RT] Remove left side section of fairing.

•

Adjust wire cable for increased idle speed

•

(choke).

Choke cable play:.............................< 1 mm (0.039 in)

RS130040

Pre-adjust the wire connecting cable between

•

the throttle stub pipes with the left or right adjusting screw .

Adjust the connecting cable to zero play.

•

RS130030

Adjust the wire cable from the throttle twistgrip

•

when the handlebar is on full right lock.

Throttle cable play:.......... app. 0.5 mm (0.0197 in)

00.38

Page 47

RS130050

Rectify any faults found.

•

[RT] Remove the flap at the bottom of the right

•

fairing.

Connect the BMW Synchrotester,

•

BMW No. 13 0 800, to the vacuum

bores in the throttle stub pipes.

Ride the motorcycle until the engine is warm, or

•

alternatively allow it to warm up at a standstill for

approx. 10 minutes.

e Caution:

The engine must not run for more than

20 minutes when the motorcycle is not moving.

Oil temperature:................................at least 90 °C

(FID: at least 5 bars)

Switch on the Synchrotester and select the bar

•

chart display with maximum resolution..

L Note:

If the differences between the individual col-umns

are very large (greater than 5 mm), switch to graph

display and compare the cylinders; carry out fault diagnosis if necessary.

RS130060

Set idle speed using recirculating air screws

•

while maintaining synchronous running.

L Note:

Make sure that both throttle valves are closed.

+ 150

Idle speed: ................................... 1000

min

e Caution:

The sealed stop screws on the throttles must not be

tampered with, or else the basic idle flow setting will

have to be reset by the manufacturer.

-1

a See BMW Synchrotester diagnosis instructions.

00.39

Page 48

With cable junction block

2

1

RT000080

Push back the protective rubber cap (1) at the

•

throttle and choke cables.

Turn adjusting screw (2) at the throttle and choke

•

cables to adjust play.

Choke cable play: ................. app. 1 mm (0.039 in)

Throttle cable play:............... app. 1 mm (0.039 in)

Connect the BMW Synchrotester,

•

BMW No. 13 0 800, to the vacuum

bores of the throttles..

Ride the motorcycle until the engine is warm,

•

or alternatively allow it to warm up at a

standstill for approx. 10 minutes.

e Caution:

Engine must not run for more than 20 minutes when

motorcycle is not moving.

Oil temperature: ...............................at least 90 °C

(FID: at least 5 bars)

Switch on the Synchrotester and select the bar

•

chart with maximum resolution.

L Note:

If the differences between the individual

columns are very large (greater than 5 mm), switch

to graph display and compare the cylinders; carry

out fault diagnosis if necessary.

a See BMW Synchrotester diagnosis instructions.

RT000070

Turn adjusting screws at the left and right throt-

•

tles to adjust play.

Throttle cable play:............. app. 2 mm (0.0787 in)

00.40

Page 49

1

2

RT000140

Rectify any faults found.

•

Set idle speed using recirculating air screws

•

while maintaining synchronous running.

Idle speed: ...................................1000

+ 150

L Note:

Make sure that both throttle valves are closed.

min

Push the protective rubber cap (2) back over the

•

adjusting screw.

Throttle cable play:.......... app. 0.5 mm (0.0197 in)

1

RT000080

-1

Adjust choke cable to zero play at screw (1).

•

Push the protective rubber cap (2) over the ad-

•

justing screw.

Check the setting by turning the handlebar be-

•

tween the full right and left lock positions. Engine

speed must not change during this check.

2

RS 11.055

e Caution:

The sealed stop screws on the throttles must not be

tampered with, or else the basic idle flow setting will

have to be reset by the manufacturer.

RT000070

Carefully reduce play at the left throttle until the

•

bar display on the Syncrotester changes.

Turn the adjusting screw until the bar display re-

•

verts to its original height.

Tighten the locknut.

•

L Note:

The height of the bar display must not change when

the locknut is tightened.

Repeat this procedure at the right throttle

•

L Note:

If play is zero, the throttle butterflies may chatter.

Adjust throttle cable play at screws (1).

•

00.41

Page 50

RS130070

Final inspection with road safety

and functional check

(Inspection I, II, III, IV)

Road safety check

Check wheels and tyres.

•

Check/correct tyre pressures.

•

Tyre pressures:

Rider only.............................. front 2.2 bar(31.9 psi)

........................................... rear 2.5 bar (36.26 psi)

With pillion passenger......... front 2.5 bar(36.26 psi)

............................................ rear 2.7 bar(39.16 psi)

With pillion passenger + luggage.............................

........................................... front 2.5 bar(36.26 psi)

............................................ rear 2.9 bar(42.06 psi)

Roadworthiness check

Lights

•

Telltale/warning lights

•

Horn

•

Instruments

•

Special equipment

•

Clutch

•

Gear shift

•

Steering

•

Foot brake and handbrake

•

If necessary, take motorcycle for a trial run.

•

RS130080

On motorcycles without catalytic converter

•

make sure that the idle-speed CO content of the

exhaust gas is in accordance with the nominal

value and correct at the idle potentiometer if necessary.

± 0.5

Idle-speed CO content:............1.5

Check synchronisation of throttles by opening

•

them repeatedly but slowly up to an engine

speed of app. 2500 rpm; the vacuum columns

on the Synchrotester must drop together. Correct if necessary by turning the adjusting screws

for the connecting cable.

When doing this, ensure that both throttles return

to the limit position when closed.

(% by vol.)

L Note:

Make sure that both throttle valves close against

their stops when the throttle twistgrip is released.

Tighten locknuts and check synchronous run-

•

ning again.

Seal the vacuum bores.

•

00.42

Page 51

11

11 Motor

Contents Page

Technical Data ............................................................................................................................... 5

Sectioned drawing of engine ...............................................................................................37

Lubricating oil circuit ...............................................................................................................38

Coolant circuit ..............................................................................................................................39

Cooling oil circuit (with oil thermostat) ..........................................................................40

Removing engine ........................................................................................................................41

Fitting auxiliary frame .........................................................................................................................52

Take off auxiliary frame. .....................................................................................................................53

Dismantling engine ....................................................................................................................54

Removing cylinder head cover ................................................................................................55

Locking the engine in the TDC position ..............................................................................56

TDC on ignition stroke: ......................................................................................................................56

Removing and installing chain tensioner ............................................................................57

Assembly specification for timing chain tensioner: ............................................................................57

Removing valve gear holder .....................................................................................................58

Dismantling/reassembling valve gear holder ....................................................................59

Removing cylinder head ............................................................................................................61

Dismantling, checking, repairing and re-assembling cylinder head ......................62

Removing and installing valves ..........................................................................................................62

Removing valve stem seals ...............................................................................................................62

Checking valves for wear ..................................................................................................................63

Remachining valve seat .....................................................................................................................63

Checking and repairing cylinder head ...............................................................................................63

Checking valve guide for wear ...........................................................................................................63

Replacing valve guides ......................................................................................................................64

Installing valve and valve stem seal ...................................................................................................65

Removing cylinder barrel ...........................................................................................................66

Removing/dismantling piston ..................................................................................................66

Checking pistons and cylinders .............................................................................................67

Assemble pistons .........................................................................................................................67

11.1

Page 52

Contents Page

Removing/installing conrod ......................................................................................................68

Removing and installing alternator cover with engine installed ...............................69

Removing alternator mount cover .........................................................................................69

Renewing radial shaft seal in alternator mount cover ...................................................70

Renewing radial shaft seal for rotary breather .................................................................70

Removing auxiliary-shaft drive ................................................................................................71

Removing oil pump ......................................................................................................................72

Oil temperature regulator ..........................................................................................................72

Removing radial shaft seal on crank-shaft with engine installed .............................73

Dismantling crankcase ...............................................................................................................74

Removing crankshaft, auxiliary shaft and timing chain tensioning and

slide rails ...........................................................................................................................................76

Removing and installing oil pick-up basket .......................................................................77

Replacing oil level sight glass .................................................................................................77

Removing conrods .......................................................................................................................77

Checking conrods ........................................................................................................................77

Measuring main and big end bearing play .........................................................................78

easuring radial bearing play ...............................................................................................................78

Install main bearings ....................................................................................................................79

Measuring axial bearing play .............................................................................................................79

Measuring big end bearing play .............................................................................................80

Assembling engine ....................................................................................................................81

Installing conrod ............................................................................................................................81

Installing crankshaft .....................................................................................................................82

Installing timing chain tensioning and slide rails .............................................................82

Installing auxiliary shaft/timing chains ..................................................................................82

Assembling engine block ..........................................................................................................83

Installing radial seal on crankshaft ........................................................................................85

Installing clutch housing ............................................................................................................86

Installing oil pump .........................................................................................................................87

11.2

Page 53

Contents Page

Installing auxiliary shaft drive ...................................................................................................88

Installing pistons ............................................................................................................................89

Installing cylinders ........................................................................................................................90

Installing cylinder head ...............................................................................................................91

Adjusting valve clearances .......................................................................................................92

Installing right cylinder head ....................................................................................................93

Adjustment specification ...................................................................................................................93

Installing left cylinder head .......................................................................................................94

Adjustment specification ...................................................................................................................94

Installing alternator mount cover ............................................................................................96

Installing magnetic gate/belt pulley ......................................................................................96

Timing the ignition .............................................................................................................................97

Installing alternator .......................................................................................................................98

Installing engin ............................................................................................................................99

11.3

Page 54

11.4

Page 55

11

Technical Data R 1100 RS

Engine, general

Engine design Four-stroke flat twin, air-cooled with oil-cooled

exhaust ports, installed longitudinally, 4 valves

per cylinder, two high-mounted camshafts, elec-

tronic fuel injection.

Location of engine number Crankcase

Cylinder bore mm (in) 99.0 (3.898)

Stroke mm (in) 70.5 (2.776)

Effective displacement cc 1085

Compression ratio 10.7 : 1

Power output kW(bhp)/min

Max. torque Nm/min

Permissible maximum engine speed min

Permissible continuous engine speed min

Idle speed min

-1

-1

-1

-1

-1

66(90)/7250

95/5500

7900

7600

+150

1000

Direction of rotation Clockwise, looking at

ignition system

Compression test pressure

good

normal

bar (psi)

bar (psi)

above 10 (145.04)

8.5...10

(123.28...145.04)

poor

bar (psi)

below 8.5(123.28)

Intake port dia./cylinder head mm (in) 44 (1.732)

Lubrication system

Theoretical volume in circulation at 6000 min

Lubricating oil l (Imp. pints)

Cooling oil l (Imp. pints)

-1

36 (63.36)

30 (52.8)

Oil filter Full-flow type

Pressure differential needed to open bypass

bar (psi) 1.5 (21.756)

valve

Oil pressure warning light comes on below bar (psi) 0.2...0.5 (2.9...7.25)

Pressure relief valve opens at bar (psi) 5.5 (79.77)

Operating pressure bar (psi) 3.5...6.0 (50.76...87.02)

Oil content

without filter change l (Imp. pints)

with filter change l (Imp. pints)

min/max l (Imp. pints)

Permissible oil consumption l/1000 km

Imp.pint/miles

3.50 (6.16)

3.75 (6.6)

0.50 (0.88)

1.0

(1.41/500)

Oil pump

Oil pump 2 Duocentric pumps

Housing depth mm (in)

mm (in)