Page 1

Installation Instructions

Transmission Oil Temperature Gauge

(See www.bmracing.com for the latest technical product information)

Part Number 80212/80226

©2005 by B&M Racing and Performance Products

Your new B&M transmission oil temperature gauge will

accurately monitor transmission oil temperature and

warn you before excessive heat ruins transmission uid

or causes damage. High heat conditions are destructive

of both transmission friction materials and transmission

components. Transmission operation in the normal operating range of 150°F to 250°F will ensure long life and

dependable service. This gauge will work with all 12 volt

negative ground electrical systems.

STEP 1. Disconnect positive terminal battery cable to

prevent accidental shorts and/or damage. Mount temperature gauge.

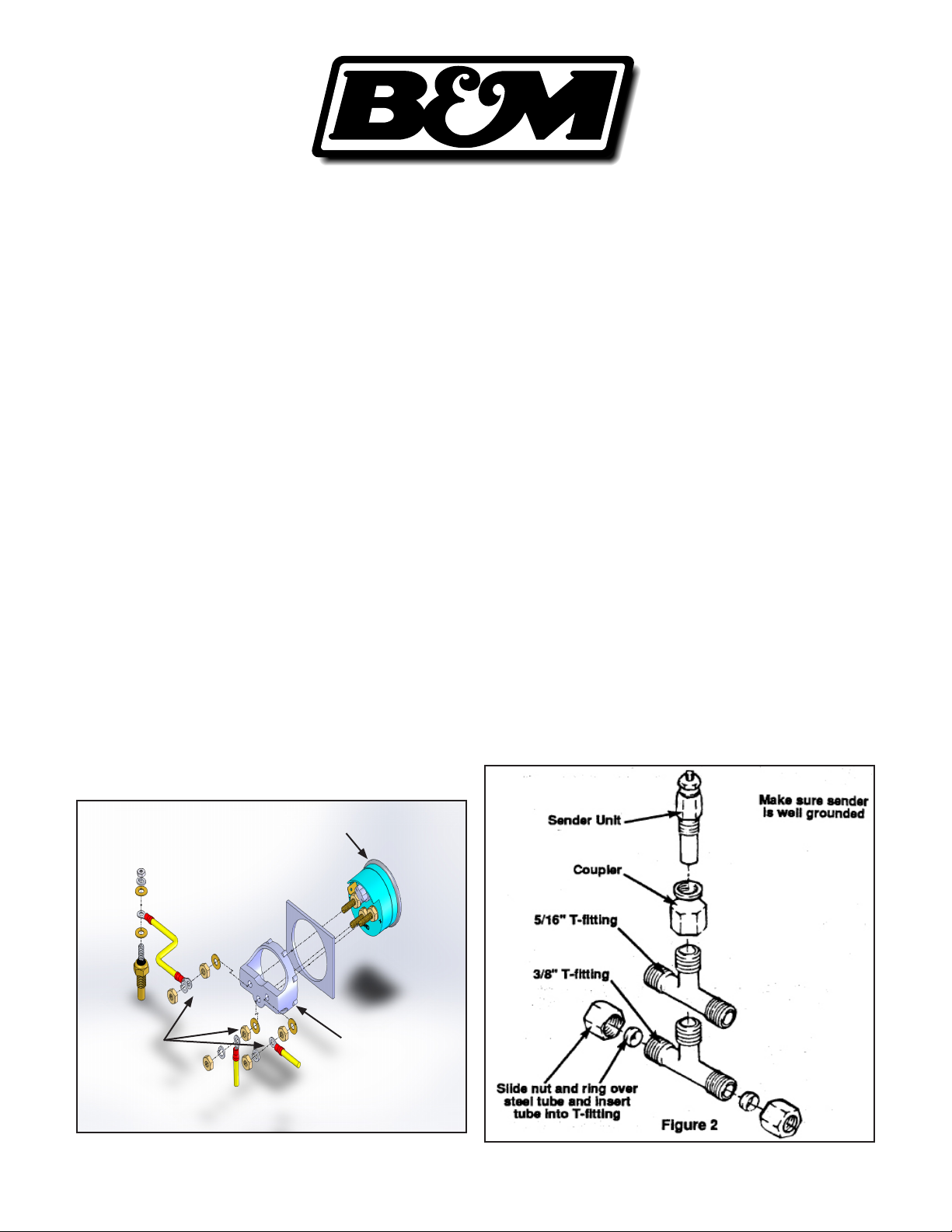

Mounting panel: Install panel in position and secure using

the two sheet metal screws supplied with the kit.

Dashboard or console: Drill 2-1/16" hole into surface

you wish to mount the gauge in.

Gauge pod: Gauge will t into 2-1/16" gauge pod hole.

Position gauge in mounting hole. Install mounting bracket,

nuts and lock washers in position. (See Fig. 1) Install one

brass at washer, one lock washer and one nut on each stud.

Rotate gauge until it is properly aligned and tighten each

nut nger tight.

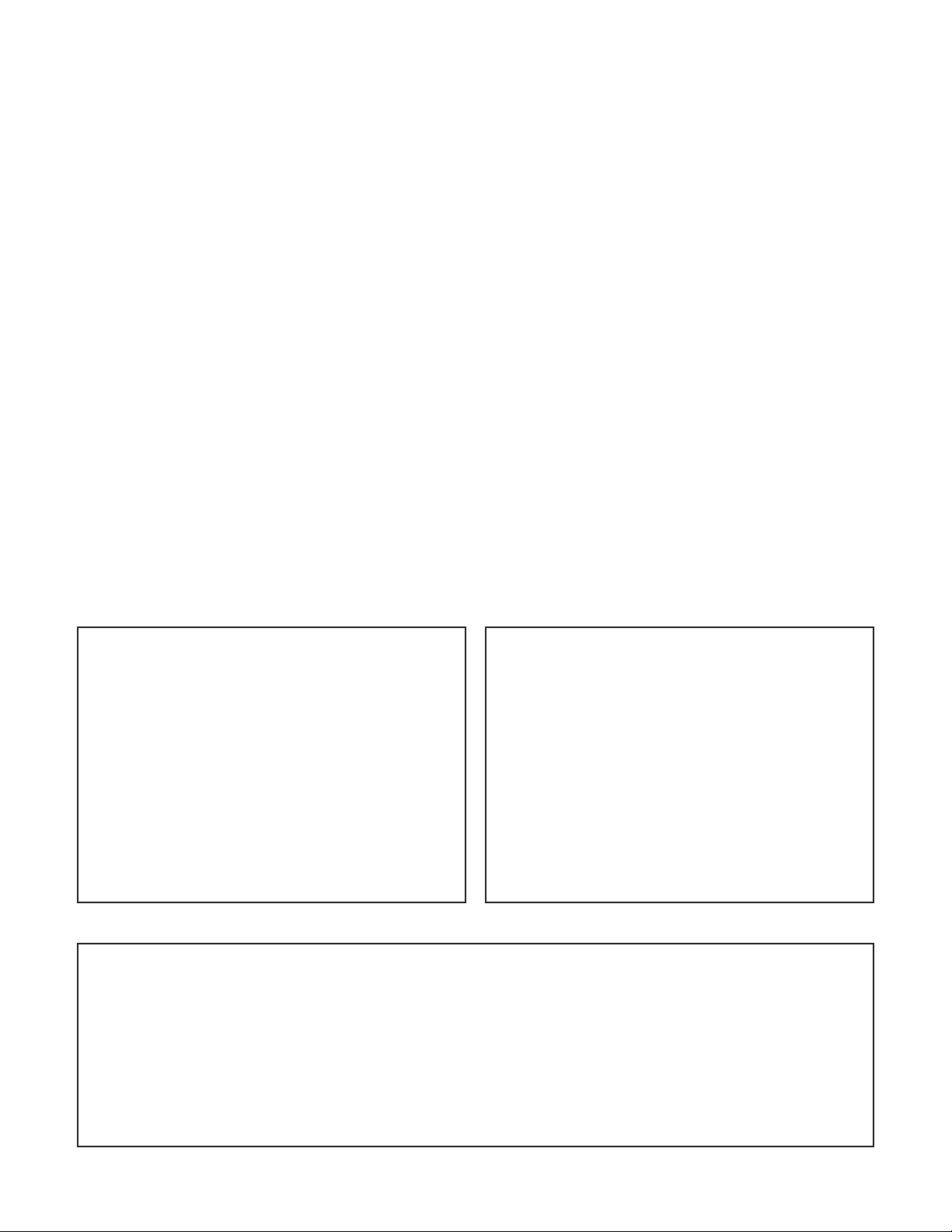

STEP 2. Locate the oil return line to the transmission. On

Chrysler and most Ford transmissions, this is the line to

the rear of the transmission case. On GM TH-350, TH400, TH-700R4, and Powerglide transmissions, this is the

upper oil line to the transmission case. On GM TH-200,

TH-200R4, 4L80E and Ford AOD transmissions, this is the

lower oil line to the transmission case. Note: This loca-

tion is recommended to monitor the true transmission

temperature going in, as well as checking the oil cooler

efciency. Cut the steel tube oil line in a convenient location using a tubing cutter or hacksaw. Carefully deburr the

ends of the tubing. Select the proper T-tting and tighten

the compression nuts securely. Be sure to double-check

T-tting holes are bored through all the way.

STEP 3. Place a small amount of sealer on the threads of

the T-tting, install the proper coupler and tighten securely. Place a small amount of sealer on the threads of the

temperature gauge sender unit. Install the sender unit into

Supplied

Hardware &

Terminals

Printed in U.S.A.

Temp Gauge

2 - 1/16" Dia Hole

(Mounting Panel, Dash,

or Gauge Pod)

Mounting Bracket

Figure 1: Mechanical Layout

1

9500048-09

Page 2

the coupler and TIGHTEN VERY LIGHTLY!

STEP 4. Run a length of wire from the temperature gauge

to the sender unit using the wire supplied with the kit. Bare

1/4" of the end of the wire supplied at the sender unit.

Install an eyelet terminal supplied with the kit on the end

of the wire and crimp it tightly. Install the terminal onto

the sender unit stud. Install nut on to the stud and tighten

securely. Be sure the connector/wire does not touch the

body of the sender. Secure the wire in position so it cannot

touch any hot engine components. Be sure that the base

of the sending unit is properly grounded. A sending unit

installed in a rubber cooling line is not properly grounded.

Improper grounding will cause a false reading. Install another eyelet terminal at the gauge end of the temperature

wire. Remove the nut and lock washer from the negative

("-") stud on the temperature gauge (see Figure 3). Install

the terminal onto the stud and install lock washer and nut.

Tighten nut snugly. DO NOT OVER-TIGHTEN AS THIS

COULD DISTORT BRACKET OR DAMAGE GAUGE.

STEP 5. Run a length of wire from the temperature gauge

to the ignition switch or fuse block using the wire supplied

with the kit. Bare 1/4" of the end of the wire at the temperature gauge. Install an eyelet terminal on the end of the

wire and crimp it tightly. Remove the nut and lock washer

from the positive ("+") stud on the temperature gauge (see

Figure 3). Install the terminal onto the stud and re-install

lock washer and nut.

Tighten nut snugly. DO NOT OVER-TIGHTEN AS THIS

COULD DISTORT BRACKET OR DAMAGE GAUGE.

Connect other end of wire to an accessory or ignition

circuit that is "hot" when the ignition key is on. DO NOT

ALLOW "HOT" WIRE TO TOUCH THE "-" STUD ON

THE TEMPERATURE GAUGE.

STEP 6. Run a ground wire from the "GND" stud to

chassis ground (frame or body). See gure 3. DO NOT

OVER-TIGHTEN AS THIS COULD DISTORT BRACKET

OR DAMAGE GAUGE.

STEP 7. Run a length of wire from the temperature gauge

to the dashboard instrument light wires or terminal board.

Bare 1/4" of the end of wire at the temperature gauge.

Install the female spade connector furnished and crimp

tightly. Slip connector onto gauge spade terminal (see

Figure 3). Secure all wires up out of the way from heat or

any moving parts to prevent damage.

STEP 8. Re-connect battery cable. Turn ignition key on.

Gauge will read oil temperature. Start engine and check

T-tting for leaks. As transmission oil temperature warms

up, the gauge will indicate properly. Turn on lights to check

operation of illumination bulb.

Tool List

7/16" Wrench

1/2" Wrench

9/16" Wrench

5/8" Wrench

3/8" Socket or Nut driver

Pliers

Wire strippers

Wire Crimping Tool

Tubing cutter

Small le

Phillips Screwdriver

Temperature Gauge

Bracket

Eyelet terminals (3)

Spade terminal

Brass washers (3)

Lock washers (4)

Nuts (3)

Coupler

Hook-up wire

Mounting screws (2)

Mounting panel

3/8 " T-tting

5/16" T-tting

Sender Unit (1/8" NPT)

Parts List

TROUBLE SHOOTING GUIDE

Malfunction Probable Cause

Gauge shows no reading -Gauge is not hooked to power, or is not grounded properly

Gauge shows false reading -Sending unit no properly grounded

Reading too high -Power and ground wire reversed

2

Page 3

Spade Terminal - To

Instrument Illumination

Circuit

Negative ("-") Stud - To

Temperature Sender

Temperature Sender

Note: Sender Body / Connecting

T-tting must be connected to

Chassis Ground

Temp Gauge

Positive ("+") Stud - To

Ignition Terminal (Switched

12V circuit)

GND Stud - To Chassis Ground

( )

Figure 3: Electrical Details

3

Loading...

Loading...