Page 1

Installation Instructions

Transpak 1982-93 GM TH-700R4

(4L60) Non Electronic Transmission

Part Number 70235

©2001, 1996 by B&M Racing and Performance Products

The B&M TH-700 (4L60) Transpak

has been designed to work on all 1982

thru 1993 TH-700’s (4L60's). This kit

WILL NOT work on 1992 and later

4L60E (electronic) models. During 1982

thru 1993 model years four major

changes were made to the TH-700’s

hydraulic circuitry. It is important that

you know the year model of the transmission your working on so that you

can identify the correct checkball placement diagram. Figure 1 describes

where to look on your transmission for

model year identification. If the original

transmission in your vehicle was replaced by a factory rebuild, the I.D.

number may have been changed. In

this case you will have to compare the

components in your transmission with

the check ball placement diagrams in

the instructions to determine the correct check ball placement.

WARNING: Incorrect checkball

placement can result in serious

transmission damage. Be sure to

follow the instructions carefully.

We have included a section on TV

cable installation that will be helpful to

individuals using the TH-700 with aftermarket carburetors, manifolds or in a

custom vehicle installation.

B&M's TH-700 Transpak can be installed by anyone with minimum mechanical experience. It is however, im-

portant to closely follow the instructions.

We recommend that you read

through the instructions completely

before beginning the installation,

so you can familiarize yourself with

the installation procedure and tools

required. Check the tool list at the

end of these instructions for the

tools required to install your B&M

TH-700 Transpak.

NOTE: The B&M TH-700 Transpak is

not a cure-all for an ailing transmission. If your transmission is slipping or

in poor general shape, the installation

of this Transpak may worsen the condition. However on a properly operating

transmission in average condition, the

Transpak will provide the kind of transmission performance your looking for.

When installing your Transpak there

are several other B&M products you

may wish to consider:

TH-700 R4 KICKDOWN KIT #70237

The TH-700 has a hydraulic circuit that

causes a forced 4-3 down shift whenever the throttle is opened past two

thirds travel. In some applications a

part throttle forced 4-3 down shift is

undesirable, after many customer requests B&M has developed an easily

installed kit that will eliminate the part

throttle 4-3 down shift feature. This kit

does not alter normal shift speeds or

affect detent (wide open throttle 4-3)

operation. This kit is best installed

along with B&M’s #70235 Transpak.

However it can also be installed independent of other modifications, and

valve body removal is not required (pan

gasket not included).

Converter Lockup Control #70244/

70248 Provides electronic control of

the vehicle speed where lockup takes

place on GM transmissions with lockup

converter. Eliminates lock and unlock

cycling and premature unwanted

lockup. Also ideal for lockup operation

in vehicles that did not come with

lockup converter transmissions. Works

with all GM lockup transmissions.

TRANSMISSION OIL COOLER We

feel that it is very important that every

vehicle in addition to the radiator heat

exchanger should have an oil cooler.

Heat is the major cause of transmission failures, and an oil cooler is an

inexpensive safeguard against overheating. B&M offers a wide range of

transmission coolers to suit every need,

which are available at your B&M dealer.

The TH-700 runs hotter than most other

automatic transmissions, making an

oil cooler almost a necessity.

TRICK SHIFT PERFORMANCE ATF

Trick Shift performance automatic transmission fluid is the industry’s leading

performance ATF. A specially blended

Printed in U.S.A.

9500260-12

Page 2

oil with foam inhibitors, extreme pressure agents and shift improvers, this

fluid assures protection while delivering the fastest possible shifts. You

literally “Pour in performance.” Available at your B&M dealer.

DRAIN PLUG KIT #80250 TH-700

transmissions do not come from the

factory equipped with drain plugs. The

B&M Drain plug kit is inexpensive

and easy to install. It eliminates the

mess of a fluid change or pan removal.

POWER SWITCH KIT #80217 (1982

through 1989 TH-700’s only) This kit

will enable you to select between normal Torque Converter Clutch (TCC)

operation and having it unlocked in all

gears except fourth. This kit can also

be utilized for TCC control in custom

installations of the TH-700. Keeping

the TCC in the unlocked mode during

city driving saves wear and tear on the

TCC as well as minimizing TCC engagement at low speeds. The B&M

Power Switch Kit will not prevent the

TCC from locking in fourth gear (overdrive). TCC engagement in fourth gear

is required to prevent transmission overheating. Kit does not work on 1990 or

later TH-700’s.

TH-700 DEEP OIL PAN #70289 The

B&M TH-700 deep oil pan ads approxi-

mately 3 quarts of extra oil capacity to

your transmission. The additional oil

capacity will help reduce the temperature of your transmission, thereby promoting longer transmission life.

TEMPERATURE GAUGE KIT #80212

Most transmission and converter failures can be traced directly to excessive heat. The B&M transmission temperature gauge can save you a costly

repair bill by warning you ahead of time

of an overheated transmission. The

B&M temperature gauge is extremely

accurate and dependable, it comes

with all necessary hardware and is

easy to install.

INTRODUCTION

This kit can be installed in a few

hours by carefully following the instructions. Read all instructions first to

familiarize yourself with the parts

and procedures. Transmission com-

ponents are precision fit, work slowly

and do not force any parts. Burrs and

dirt are the number one enemies of an

Figure 1

automatic transmission. Cleanliness

is very important, so a clean work

surface from which oil can easily be

removed is necessary.

This kit contains all parts necessary to obtain two different levels of

performance, depending on intended

use:

1. Heavy Duty; Towing, campers, motor homes and 4-wheel drive vehicles.

Shift feel is firm and positive.

2. Street; Dual purpose performance

vehicles, street and strip performance

cars. Street level produces the firmest

shift feel.

DISASSEMBLY

Automatic transmissions operate

at temperatures between 150° F and

250° F. We suggest the vehicle be

allowed to cool for several hours before

disassembly to avoid burns from hot oil

and parts. Have an oil drain pan ready

to catch oil and a tray on which to put

small parts so they won’t get lost. The

vehicle should be raised so there is at

least 2 feet ground clearance for ease

of installation and safety.

MAKE SURE THE VEHICLE IS RIGIDLY AND SECURELY SUPPORTED,

JACK STANDS, WHEEL RAMPS OR

A HOIST WORK BEST, DO NOT USE

JACKS ALONE.

STEP 1. The TH-700 does not have a

drain plug. Position your drain pan

beneath the transmission to catch the

oil. Remove the oil pan by removing the

rear bolts first, then work towards the

front. Loosen but do not remove the

three front bolts. If the pan sticks to the

gasket, insert a flat screwdriver between the pan and case and pry down

gently to break the pan loose. Now

remove the front three bolts slowly to

permit draining the rest of the oil. Remove pan gasket material from the pan

and the case.

STEP 2. Remove the oil filter by gently pulling it straight down. The pickup

tube has an O-ring (or seal) around the

end that fits into the pump housing.

Sometimes the O-ring (or seal) remains in the pump bore, if so remove Oring (or seal) from the pump and discard both the O-ring ( or seal) and filter.

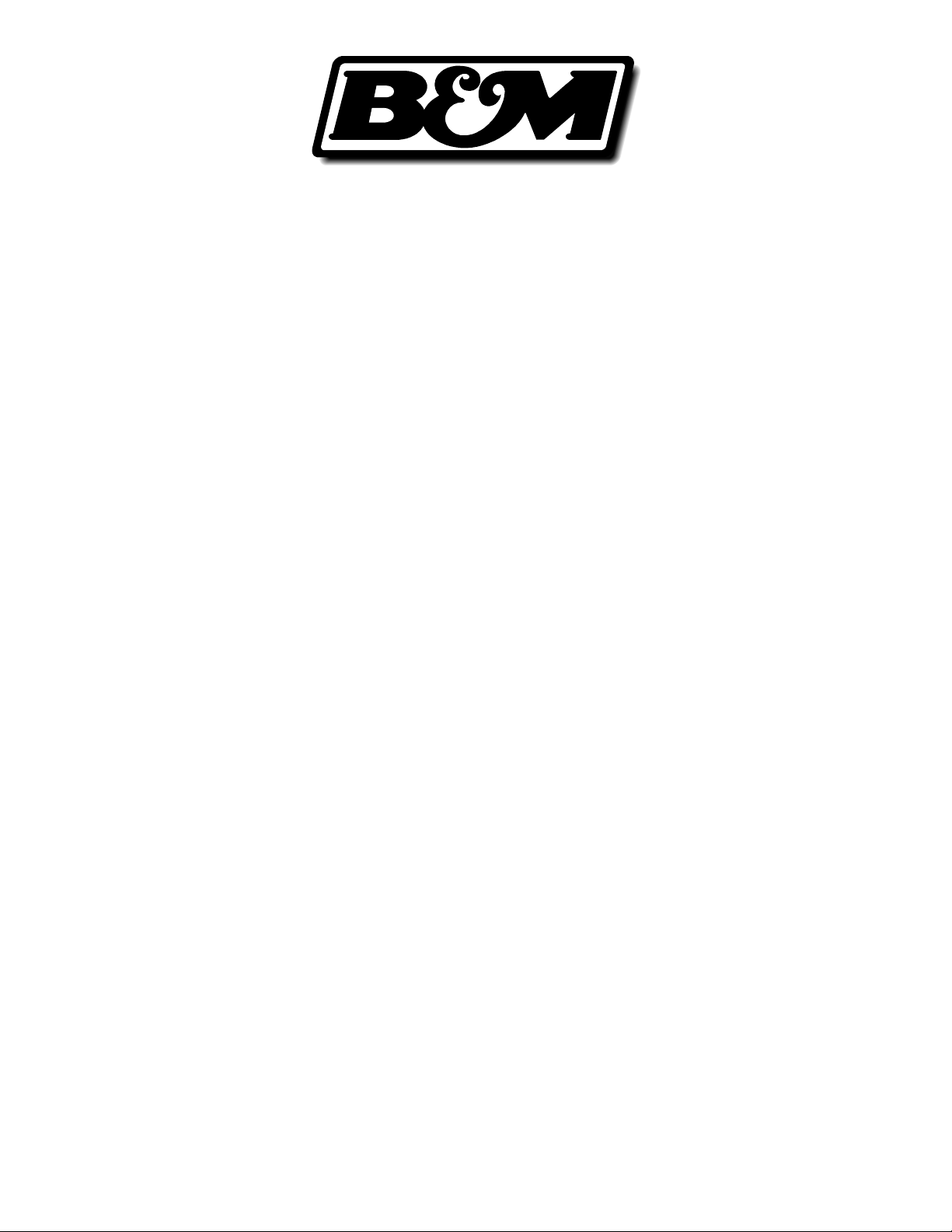

STEP 3. (See Figs. 2 and 3) There

are a variety of different wiring harnesses used on the TH-700. Before

proceeding further make a sketch and

some notes describing your particular

unit, recording which connectors go to

which switch. Notice that the connec-

2

Page 3

tors are color coded. Now remove connectors from switches. Unplug the wiring harness from the case electrical

connector by prying the lock tab away

from the plug and pulling down on the

plug, do not pull on the wires. Removing solenoid is not required, just tie

the wires up out of the way.

STEP 4. Remove all except the center valve body bolt (See Fig. 2.) Beginning with the mid 1987 model year, TH700’s have a tube crossing over the

valve body. This tube is removed by

simultaneously pulling both ends out of

their respective bores. With the tube

removed (if equipped) hold the valve

body up firmly with one hand and remove the remaining bolt slowly. There

are several check balls in the valve

body along with several pints of oil.

Have your drain pan ready to catch the

oil and check balls (should they fall

out.) Save all check balls in a safe

place where they won’t get lost.

STEP 5. Beginning mid 1987 model

year, TH-700’s have an auxiliary valve

body located where earlier models have

a cover plate (See Fig. 2.) Remove the

cover plate or auxiliary valve body. Be

careful not to drop the check ball located in the auxiliary valve body (See

Fig. 8.) Remove the 1-2 accumulator

housing while holding the separator

plate up to the case. Then slowly lower

the separator plate and retrieve the

check balls located above the plate.

Make note of the color and location of

the 1-2 and 2-3 accumulator springs for

correct reassembly (See Fig. 10.)

Remove all old gasket material from

Servo vent

Do not block

this hole

Throttle valve

linkage

Filter retaining

spring

1-2 accumulator

B

B

C

housing

Converter clutch

lockup solenoid

B

C

B

B

B

A

Crossover

tube

Selector lever

detent spring

E

F

body

B

B

B

B

B

Electrical

connector

B

B

B

B

B

C

C

Auxiliary valve

Figure 2

3

Page 4

these parts. Note: Early 1982 TH-

700’s had a support plate located

under the 1-2 accumulator housing. If your transmission is fitted with

this plate, carefully save the gasket as

you will have to re-use the gasket upon

reassembly (Gasket GM P/N 8642129

is not included in kit.)

MODIFICATIONS

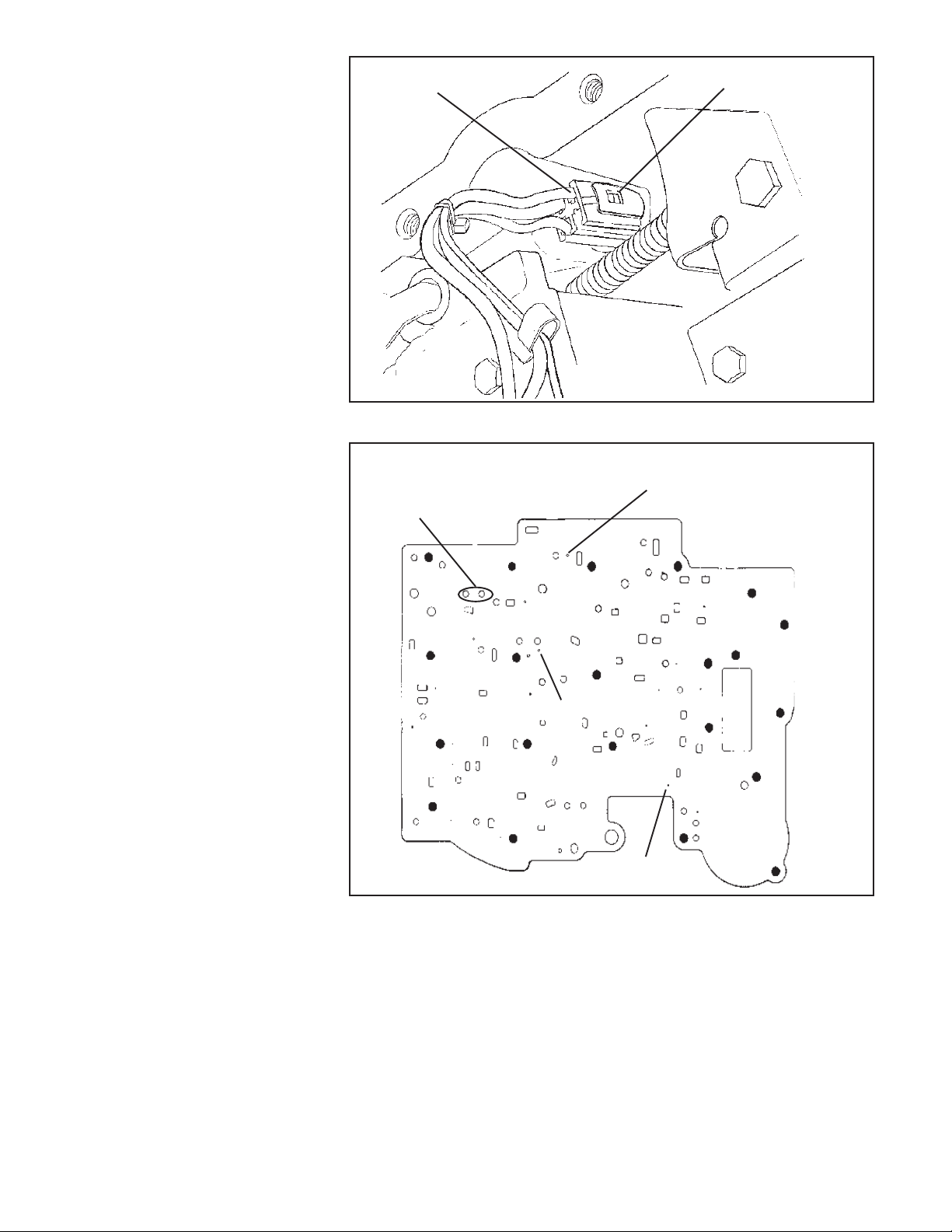

STEP 6. Using the supplied drills, en-

large the holes in your separator plate

as indicated in Fig. 4. Carefully deburr

the holes after drilling.

STEP 7. Rinse off valve body with

clean solvent to remove any dirt or grit.

Move to a clean working area. The valve

body consists of precision fit components which will not tolerate dirt or

burrs.

STEP 8. Heavy Duty and Street;

MTV upshift valve (See Fig. 5.)

Remove the pin at the end of the MTV

upshift valve bore. Remove the plug,

valve and spring from the bore. Set the

spring aside (it will not be re-used.) Reinstall the valve, plug and pin in reverse

order of removal.

STEP 9. Street Only; Line bias

valve.

Compress and remove the large roll pin

retaining the line bias valve (See Fig.

5.) Take care to not distort the roll pin

more than is required to remove it.

Remove the aluminum plug, valve and

spring from bore. The spring will not be

re used. Insert the blocker rod from the

kit into the bore. Install the valve and

aluminum plug as removed. If the aluminum plug extends into the roll pin

hole, remove the blocker rod and grind

or file a small amount from either end of

the blocker rod until the aluminum plug

clears the roll pin hole when all parts

are installed.

STEP 10. Heavy Duty and Street;

Pressure regulator.

Remove the snap ring at the end of the

pressure regulator bore in the oil pump

assembly (See Fig. 6.) Use a screw-

driver to hold the pressure regulator

assembly while removing the retaining

ring. If the sleeves stick in the bore,

lightly rap the sleeve with a small rod

and a mallet. Remove two sleeves with

valves and the pressure regulator spring.

The pressure regulator valve may fall

out but it does not need to be removed.

Wiring harness plug

Figure 3

Note: additional model year I.D.

1982 thru mid-87 (2) holes

mid-1987 to 1988 (2) holes

1988 and later (1) hole

Drill 1/8" (.125")

Drill 3/32" (.094")

Figure 4

Reassemble the pressure regulator

assembly using the BLUE spring from

the kit (See Fig. 7.) Use the new

retaining ring from the kit. Make sure

the retaining ring is firmly seated in its

groove when assembled. CAUTION:

The pressure regulator valve train

MUST be installed in the proper

order with the sleeves and valves

oriented in the indicated directions.

There are several ways the sleeves and

Pry lock tab aside

to remove plug

Drill 1/8" (.125")

valves can be installed, however, only

the orientation shown will work properly. Improper installation will cause

low line pressure, resulting in slipping

clutches and burned friction elements.

It is very important to reassemble the

pressure regulator correctly to insure

proper operation of the transmission.

Take a little extra time with this step

and work slowly. This is a precision fit

valve assembly so do not force the

4

Page 5

Aluminum plug

recess should

face out

Roll pin

MTV upshift

valve

Remove

spring

Street level only, replace line

bias valve spring with blocker

rod from kit

Line bias

valve

Aluminum plug

recess should

face out

Large diameter

roll pin

Pressure

regulator bore

Figure 5

Pressure regulator valve assembly must

be installed as shown in this order

Pressure regula-

tor retaining ring

Manual valve link must

be assembled as shown

Figure 6

Figure 7

5

Page 6

Check ball position "A", 1984 1/2 and later

models have larger check ball in this position

(earlier models have nothing in position "A")

Check ball

position #4

Do not install check

ball in this position

Check ball

position #6

Check ball

position #3

Check ball

position #3

Check ball

position #2

Figure 8 - Transmission without auxiliary valve body (Before mid-1987)

Check ball position "A",

copper flashed ball larger than

other check balls

Check ball

position #1

Auxiliary valve

body

Check ball

position #5

Check ball

position #4

Do not install check

ball in this position

Do not install check

ball in this position

Check ball

position #6

Check ball

position #2

Do not install check

ball in this position

Figure 8A - Transmission with auxiliary valve body (mid-1987 to 1988)

Check ball

position #1

6

Check ball

position #5

Do not install check

ball in this position

Page 7

Check ball

position #3

Check ball

position #2

Check ball position "A",

copper flashed ball larger than

other check balls

Do not install check

ball in this position

Do not install check

ball in this position

Auxiliary valve

body

Check ball

position #1

Do not install check

ball in this position

Check ball

position #5

Check ball

position #6

Check ball

capsule

1988 and

later. Must

be in original location.

Do not install check

ball in this position

Check ball

position # 3

Check ball

position # 2

Check ball

position # 7

Figure 8B - Transmission with auxiliary valve body (1988-92)

Check ball position "A"

Copper flashed ball larger

than other check balls

Auxiliary valve

body

Check ball

position # 1

Do not install check

ball in this position

C

V

Case side

gasket

Valve body

side gasket

1993 case check balls same as Figure 8B

Figure 8C - Transmission with aux. valve body

(1993 Only)

Seperator plate gaskets

Figure 9

7

Page 8

valves back into the bore. During reassembly, you can smear grease on the

valve and spring before you insert them

into the bore to hold them in place while

you install the boost valve assembly.

To ease installation a thin blade screwdriver can be used to hold the assembly up into the bore while you install the

snap ring. Place the snap ring around

the screwdriver and slide it up into

place with the snap ring pliers. Be sure

the snap ring goes into the groove and

is not against the step in the bore.

ASSEMBLY

STEP 11. Heavy Duty and Street;

Check ball placement (See Fig’s. 8,

8a and 8b.) Place check balls in the

valve body, auxiliary valve body and

case in the positions shown. Use a dab

of grease or petroleum jelly to hold

check balls in position. Beginning mid

1984 model year TH-700’s have a check

ball which is larger than the others in

the valve body position ‘A’. If your

transmission is equipped with this

check ball replace it in position ‘A’. If

your transmission does not have this

check ball then place nothing in posi-

tion ‘A’, pre mid 1984 transmissions

were not equipped with a check ball in

this position.

STEP 12. Place the new separator

plate gaskets on the separator plate

(See Fig. 9.) Use a dab of grease or

petroleum jelly to help hold the gaskets to the plate. The gasket with the

‘C’ cut in it goes next to the case and

the gasket with the ‘V’ cut in it goes

next to the valve body. Make sure no

holes in the separator plate are cov-

ered by the gasket.

If your gaskets become damaged

anytime during the installation of the

kit, replace them. If you cannot obtain

B&M replacement gaskets then purchase OEM gaskets for your specific

year and model vehicle.

STEP 13. Heavy Duty Only; Place

the 3-4 accumulator pin in the case.

Over the pin place the RED (3/8") spacer

sleeve, accumulator piston and spring

(spring is installed at step 18.) Use a

dab of grease or petroleum jelly to hold

components in place (See Fig. 10)

Proceed to step 15.

STEP 14. Street Only; Place the 3-4

accumulator pin in the case. Over the

pin place the BLUE (3/4") spacer and

accumulator piston, using a dab of

grease or petroleum jelly to hold them

in place (See Fig. 11). Important

note: With piston and spacer installed

in bore rub a straight edge on the case

surface across the accumulator bore

and verify the piston does not extend

beyond the case surface. If the straight

edge contacts the accumulator piston,

grind or file a small amount from the

spacer until the piston clears the

straight edge. No spring is used for

Street level performance.

STEP 15. Heavy Duty Only; Remove

the spring and piston from the 1-2

accumulator housing (See Fig. 10.)

Install over the pin the YELLOW spacer,

piston (notice orientation) and spring.

Proceed to step 17.

STEP 16. Street Only; Remove the

spring and piston from the 1-2 accumulator housing (See Fig. 12.) Install

both the BLUE and the RED spacers

over the pin, then the piston (notice

orientation.) No spring is used for

Street level performance.

Figure 10 Figure 11

8

Page 9

STEP 17. With the 3-4 accumulator

components and case check balls in

place, place the separator plate / gasket assembly up to the case followed

by the 1-2 accumulator housing assembly. Carefully line up the gaskets

and install three accumulator housing

bolts, tighten ONLY finger tight (See

Fig’s. 2, 10 and 11.)

STEP 18. Install the auxiliary valve

body (with check ball in correct position) or cover plate using the appropriate screws tightened ONLY finger tight

(See Fig’s. 2 and 8.)

STEP 19. Valve body installation.

Make sure check balls are in proper

locations. Position the manual valve so

the link rod can be engaged (See Fig.

6.) The link rod must be placed into the

hole of the manual rod at a right angle,

then rotated to allow the valve to enter

the valve body bore. Do not force the

valve at any time. When the valve is

fully engaged, align the valve body and

Figure 12

case holes then install one bolt finger

tight to hold valve body in place. Engage all of the remaining bolts to finish

lining up the separator plate and gaskets (See Fig. 2.) Tighten all the valve

body, auxiliary valve body (or cover)

and accumulator bolts (except cross

over tube clamp bolts and throttle

valve linkage bolts) to 11 NM (8 Ft.

Lb.) Avoid striped threads, Do not

over tighten bolts.

STEP 20. Install the throttle valve (TV)

Figure 13

linkage onto the valve body as shown

(See Fig. 12.) Engage the cable link

with the large lever first. Hold the large

lever up and the smaller one down.

Then slip the assembly into position

aligning it with the hold down bolt holes

and engage the roll pin in the slot on the

bracket. Insert bolts and tighten to 11

NM (8 Ft. Lb.) then make sure large

lever operates freely. IMPORTANT

NOTE: The TV cable MUST be reset

before operating vehicle refer to

9

step 25.

STEP 21. Carefully insert ends of

cross over tube in their respective bores

and push in evenly until fully engaged

(See Fig. 2.) Install cross over tube

bolts and clamps and tighten to 11 NM

(8 Ft. Lb.)

Reconnect wiring harness connectors

to the terminals from which they were

removed. Refer to sketch or notes made

at Step 3. Reconnect the harness to

the case connector making sure it is

Page 10

firmly seated and locked.

STEP 22. Double check installation;

1: make sure all bolts are installed and

torqued. 2: Throttle valve linkage operates freely. 3: Wiring properly connected. 4: Regulator valve retaining

ring fully seated in groove.

Coat the filter pickup tube seal with

clean ATF then push the filter tube into

the pump bore until it is fully seated.

Install filter retainer clip so it is located

at the small depression on the top side

of filter housing (See Fig. 2).

STEP 23. Remove any old pan gasket

material from pan and case pan rail.

Clean inside of pan with solvent. You

may want to install a B&M Drain plug

kit (80250) at this time. Install the new

pan gasket on the pan and align the

holes. Use grease or petroleum jelly to

help hold the gasket in place during

installation of pan. Do not use any

gasket sealer or silicone compounds. To prevent premature band

failure make sure the hole shown in

Fig. 2 is not obstructed. Place pan up

to case, align holes and install all bolts

finger tight. Tighten bolts to 14 NM (10

Ft. Lb.) Do not over tighten bolts. If the

bolts are over tightened the gasket will

deform excessively and result in oil

leaks.

STEP 24. Fill transmission with ATF

to the full mark on dip stick. You will

need about 4 to 6 quarts. Dexron II is

fine for Heavy Duty Level applica-

tions however, we recommend B&M

Trick Shift ATF for Street level appli-

cations. With vehicle still off the ground,

start the engine and shift transmission

through all gears. Check for leaks

around oil pan flange and drain plug.

Place selector in neutral and check the

fluid level. Stop engine and lower vehicle.

STEP 25. You must reset the TV

cable before operating vehicle, Figure 14 shows the correct procedure. Failure to reset the TV cable

may result in poor shift quality and/

or transmission failure.

STEP 26. Test drive vehicle and re-

check for leaks while transmission is

hot. Check fluid level again, adjusting

level as required.

SERVICE

For best performance of your TH-700

we recommend changing both the ATF

and filter every 15,000 miles (25,000

km) if the vehicle is driven under one (or

more) of the following conditions:

A. High performance applications

where the vehicle is regularly driven

hard.

B. In heavy city traffic where the out-

side temperature regularly reaches

90 F (32 C) or higher.

C. In hilly or mountainous terrain.

D. Uses such as taxi, police car or

delivery service.

If you do not use the vehicle under any

of these conditions, change the ATF

and filter every 50,000 miles (80,000

km). It’s also a good idea to check the

torque converter bolts when servicing

the transmission.

Diagnosis procedure

If you experience a performance problem after installing the Transpak, it can

generally be traced to either an Im-

properly set TV Cable or a Misinstalled component in the valve body

or pressure regulator. The following

procedure along with the trouble shooting guide will assist you to correct the

problem.

1. Check and correct ATF level.

2. Check TV Cable adjustment (See

Fig. 13).

3. If engine performance indicates

an engine tune up is required, this

should be completed before road

testing or transmission correction is

attempted. Poor engine performance

can sometimes be mistaken for

transmission problems.

4. Check and correct vacuum lines

and fittings.

5. Check and correct shifter linkage.

6. Install oil pressure gage and

check line pressures. Compare

pressures with appropriate values

from Figure 14.

Hydraulic jack

Jack stands or Wheel ramps

Oil drain pan

3/8" drive ratchet wrench

2" extension

8mm, 10mm, 13mm, Sockets

Torque wrench

Internal retaining ring pliers

Needle nose pliers

Pan gasket

Upper valve body gasket

Lower valve body gasket

Pressure regulator spring

Filter with seal

Retaining ring

TOOL LIST

Gasket scraper

3/8" Drill motor

Fine cut flat file

Wet or Dry sand paper

Grease or petroleum jelly

Small punch or scribe

Small flat screwdriver

Funnel

PARTS LIST

Red accumulator spacer

Yellow accumulator spacer

(2) Blue accumulator spacer

Line bias valve blocker rod

3/32" drill

1/8" drill

10

Page 11

OIL PRESSURE CHECK PROCEDURE

PRELIMINARY CHECK PROCEDURE

* CHECK TRANSMISSION OIL LEVEL

* CHECK AND ADJUST T.V. CABLE

* CHECK OUTSIDE MANUAL LINKAGE

* CHECK ENGINE TUNE

* INSTALL 0-300 PSI PRESSURE GAGE

* CONNECT TACHOMETER TO ENGINE

* CHECK OIL PRESSURE AS FOLLOWS

MINIMUM T.V. LINE PRESSURE CHECK:

With the T.V. Cable properly adjusted and the brakes applied, take the Line Pressure readings in the Ranges and at

the engine RPM’s indicated in the chart.

FULL T.V. LINE PRESSURE CHECK:

Full T.V. Line Pressure readings are obtained by holding the T.V. Cable to the full extent of it’s travel then take the Line

Pressure readings in the Ranges and at the engine RPM’s indicated in the chart.

CAUTION: Limit running time at FULL T.V. Pressure to two (2) minutes maximum to prevent over heating.

CAUTION: Brakes should be applied at all times.

TH700-R4 TRANSMISSION OIL PRESSURES

(A) ATTACH PRESSURE GAUGE

RANGE MODEL NORMAL OIL PRESSURE NORMAL OIL PRESSURE

AT MINIMUM T.V. AT FULL T.V.

kPa PSI kPa PSI

PARK, NEUTRAL, ALL MODELS SEE 517-586 75-85 1145-1400 166-203

OVERDRIVE, SEE NOTE BELOW

MANUAL 3RD

@1000 RPM

REVERSE ALL MODELS 862-955 100-140 1869-2296 180-340

@ 1000 RPM SEE NOTE BELOW

@ 2000 RPM

MANUAL 2ND & ALL MODELS 1517-1689 160-245 1517-1689 160-295

MANUAL LOW SEE NOTE BELOW

@ 1000 RPM

NOTE: Oil Pressure at FULL T.V. Pressure depends on the particular T.V. Boost valve and Line Bias Valve arrangement

of the unit. The Pressure reading obtained should be within the range shown.

Base Line Pressure is controlled by the Pressure Regulator Valve and Spring. Line pressure is boosted a fixed amount

by the Reverse Boost valve when the selector lever is placed in Second or Low Range. The Line Pressure is also boosted

in Neutral, Drive, Drive 3 and Reverse with throttle opening because of the T.V. system. The pressure is controlled by

the T.V. Cable via the Throttle Lever and Bracket assembly to the Valve Body assembly.

The Line Pressure tap is located on the left side of the transmission case above the outside Manual Lever.

Figure 14 Oil Pressure Check Procedure

11

Page 12

THROTTLE VALVE MECHANISM

The purpose of the TH700-R4 Throttle

Valve (T.V.) and it’s mechanical linkage is to control both the shift feel and

shift timing as a function of vehicle

speed and load conditions. As the

accelerator pedal is depressed and the

throttle opens, the T.V. mechanical

linkage relays the motion to the throttle

plunger in the valve body by way of the

T.V. cable. In factory installations of

the TH700-R4 the geometric relationship between the T.V. cable and throttle

shaft bellcrank produces the required

T.V. cable extension (pull) to throttle

opening for the transmission to function properly. In custom installations

the correct T.V. cable mounting geometry must be accurately determined

if the transmission is to function properly. It cannot be overstated that for the

TH700-R4, proper T.V. cable installation and adjustment are paramount to

proper transmission function and life.

The following procedure will help you

design a custom T.V. Cable installation that works. The main objective is

to accurately position the T.V. cable

mounting bracket in relation to the

throttle shaft axis to obtain the proper

T.V. cable extension (PULL) to throttle

OPENING relationship.

STEP 1. Measure your T.V. cable to

establish it’s particular mounting dimension (there are several lengths in

use.) as follows (See Fig. 15). Retract

the slider by depressing the lock tab

then pull the cable housing until the

flats on the slider are flush with the end

of the adjuster housing then fully extend the cable by pulling the cable end

fitting out (slider must remain retracted)

until it stops. Holding the end fitting

out, measure the dimension from the

face on the adjuster housing that registers with the mounting bracket to the

center of the cable end connector.

STEP 2. Add 3/16" (0.19 in.) to the

measurement obtained in Step 1, this

is the perpendicular measurement from

the REAR FACE of the T.V. cable

mounting bracket to the WIDE OPEN

THROTTLE position of the T.V. cable

connector pin on the throttle bellcrank

(See Fig. 16).

STEP 3. The T.V. cable bellcrank must

be perpendicular (90 degrees) to the

T.V. cable when the throttle is 25

percent (1/4) open (See Fig. 16), this

geometric relationship is critical to

insure that the T.V. mechanism moves

in the correct proportion to the throttle

opening. The mounting location for the

T.V. cable connector pin will have to be

established on the throttle bellcrank at

a radius of 1.094 / 1.125 in. There may

a suitable existing hole at the correct

radius on the throttle bellcrank,

otherwise you will have to fabricate an

attachment to the bellcrank that will

properly locate the connector pin.

Diagrams of several typical factory installations are shown for reference (See

Fig. 17), notice the geometric relationship between the T.V. cable bellcrank

and mounting bracket.

Several things should be kept in

mind during this stage of the design:

1. The proper location of the T.V. cable

mounting bracket is determined by

the angular and radial position of

the T. V. cable connector pin on the

throttle bellcrank.

2. Make sure that all of the cables or

rods that will be attached to the

throttle bellcrank do not interfere

with each other when the throttle is

advanced from idle to wide open.

3. Mount the T.V. cable adjuster

housing so that the locktab is readily

accessible and not blocked by other

cables, rods, brackets or

accessories.

STEP 4. Fabricate T.V. cable bracket

using 0.090 - 0.125 in. sheet metal

(See Figure 18) for the adjuster housing cutout dimensions. If you use the

thicker stock a chamfer will be required

on two sides of the cable mounting

cutout to allow the lock tabs to expand

properly. The T.V. cable adjuster requires a pull of about 18 lbs. to ratchet

out, so try to make the mounting bracket

as rigid as possible. If the mounting

bracket flexes the T.V. pressure will

not be consistent.

Measure this dimension

(with other end attached

to linkage)

Figure 15

12

Page 13

Figure 16

Figure 17

Figure 18

13

Page 14

TROUBLESHOOTING GUIDE FOR THE HYDRAMATIC TH-700-R4 TRANSMISSION

SLIPSValve body bolts loose

Low fluid level

1-2 and / or 3-4 accumulator seals missing or damaged.

1-2 and / or 2-3 accumulator piston(s) protruding above gasket surface.

Pressure regulator and boost valve assembly improperly installed.

Throttle valve linkage improperly installed.

TV cable not properly set.

Throttle valve sticking.

Misaligned or interchanged valve body gasket.

Filter O-ring damaged or missing.

OVERHEATING, FOAMING OIL AT DIPSTICK OR BREATHER

Oil cooler insufficient.

Oil cooler plugged.

High fluid level.

ERRATIC SHIFTING

Shifter not properly adjusted.

Manual valve not properly engaged.

Low fluid level.

TV cable binding or improperly set.

LATE HARD SHIFTS

Valve body gaskets not positioned properly

TV cable not properly set.

WILL NOT SHIFT

Check balls missing or mis-located.

Governor failure.

TV cable not properly set.

PUMP BUZZ OR WHINE

Low oil level.

Filter tube O-ring cut or missing.

Filter clogged.

SOFT 2-3 SHIFTS

Pressure regulator and boost valve assembly not properly installed.

TV cable not set properly.

WILL NOT MOVE

Check balls missing or mis-located.

Manual valve not properly engaged.

Accumulator piston(s) left out or seals damaged.

Pressure regulator retaining ring did not seat in groove.

Pressure regulator and boost valve assembly not properly installed.

NO CONVERTER CLUTCH APPLY

Voltage not reaching solenoid.

Harness plug not fully engaged.

Connectors not on correct switches.

Wires pinched and grounded out.

Converter clutch valve stuck or sleeve improperly installed.

NO CONVERTER CLUTCH RELEASE

Converter clutch apply valve stuck open.

NO PART THROTTLE DOWN SHIFT

TV cable not set properly.

Throttle valve binding.

NO REVERSE AND SLIPS IN FORWARD RANGES

Pressure regulator valve assembly not properly installed.

Pressure regulator retaining ring did not seat in groove.

14

Loading...

Loading...