Page 1

Installation Instructions

Shift Plus 2 TCU

for 4L60E, 4L65E, 4L70E, 4L80E and 4L85E

Part Number 120001

©2011 by B&M Racing and Performance Products

Thank you for purchasing the B&M Shift Plus 2 Transmission Controller Unit (TCU).The Shift Plus 2 TCU

allows users to adjust nearly any aspect of a transmissions behavior for street/strip use. No software, laptop

computer or tuning experience is required. This kit provides tuning right out of the box. Simply install this new

transmission control unit according to the enclosed instructions, and then start the system by answering the

simple setup wizard questions on the included hand-held unit.Read the instructions and review the

illustrations thoroughly before beginning the installation.

P ARTS

Handheld user

Interface

Transmission Control Unit

(TCU)

Wiring

Harness

RPM Module

Printed in the U.S.A.

Communications Cable

Manual Shifter Connector

Power Cable

9500858-00

Page 2

TCU - IMPORTANT!:

The TCU is water tight when connected to the wiring harness. It can be mounted in the engine compartment or in the

vehicle’s interior. It is good practice to mount the TCU with the connector facing down. This way, there is less chance

of moisture getting into the TCU if it needs to be disconnected in wet conditions.

The TCU should not be mounted close to other electrically “noisy” components. In particular , keep good spacing (try

for 2 feet minimum) from ignition components (ignition boxes, coils, distributors, etc.)

If mounting the TCU in the engine compartment, selecting a location towards the rear will make it easier to route the

communications cable to the interior to allow the handheld user interface to be monitored while driving.

There is an LED on the front face of the TCU (the side with the logo). It will flash if the on-board diagnostics detects a

problem (the LED is lit solid when the TCU is powered up and working normally). To take advantage of this feature, the

TCU will need to be mounted so that the front face of the TCU is visible. The handheld user interface will also indicate

if any faults have been detected.

WIRING HARNESS- IMPORTANT!:

The wiring harness should be kept away from ignition components (ignition boxes, coils, distributors, etc.) as much as

possible. Do not bundle the wiring harness together with other “noisy” wiring in the vehicle.

As with any wiring, it is good practice to avoid routing the wiring harness around sharp edges or near high temperature

components such as headers or exhaust components.

WIRING HARNESS CONSISTS OF THE FOLLOWING CONNECTION:

BATTERY POSITIVE (red wire) / NEGATIVE (black wire)

These must be connected DIRECTLY to the positive (red wire) and negative (black wire) posts of the battery . These

must be run independently to the battery. DO NOT splice other power or ground wires into these wires. Failure to

follow these requirements invites problems with electrical noise. These kinds of problems are difficult to diagnose.

The wires may be extended if needed using automotive grade 16 gauge (or larger) wire.

12V SWITCHED (pink wire)

Connect this wire to a switched ignition source that is hot with the key in the On/Run and Crank positions. DO NOT

connect to the positive side of an ignition coil. Strange problems can sometimes arise when t apping into existing

switched ignition sources. When in doubt, run this wire through its own switch and then directly to the positive post

of the battery.

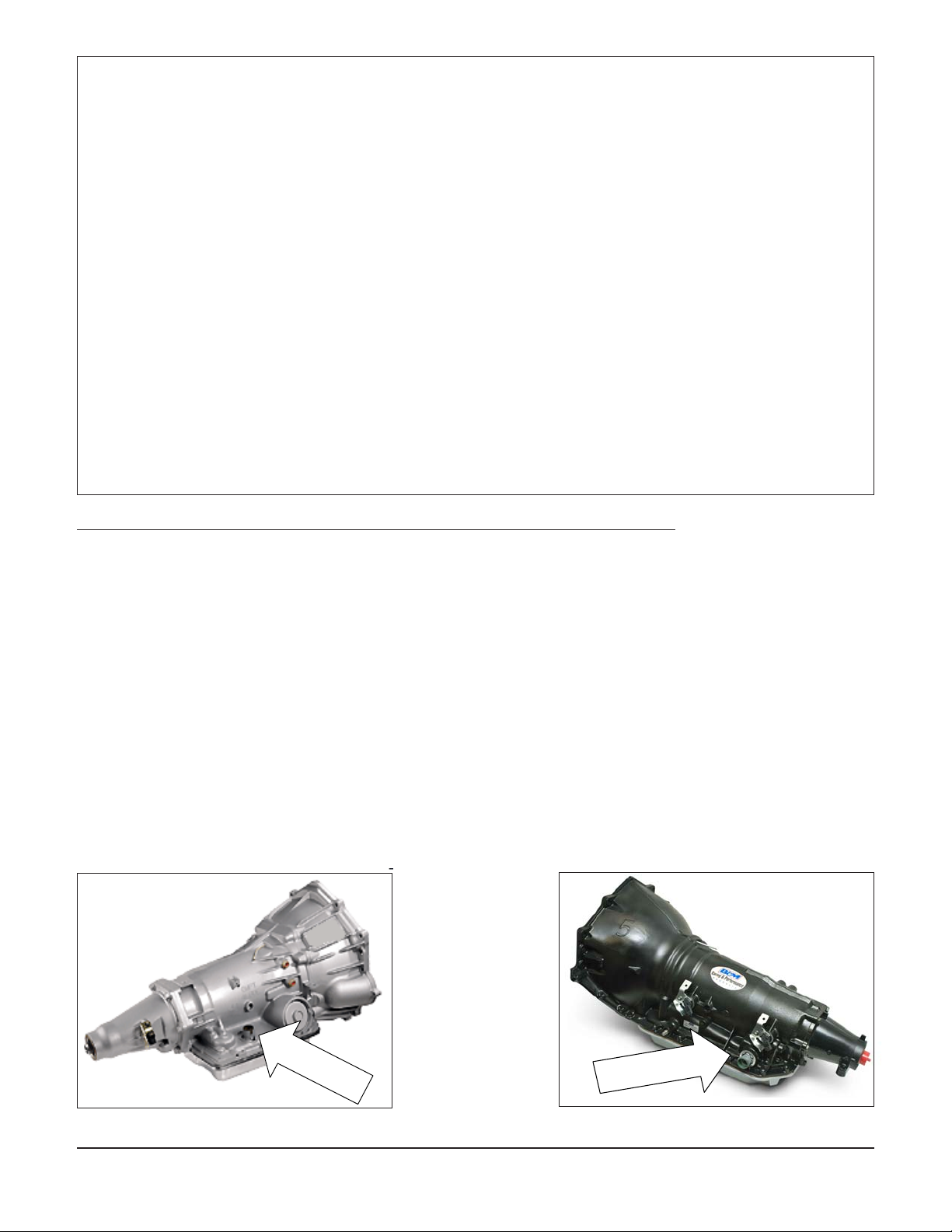

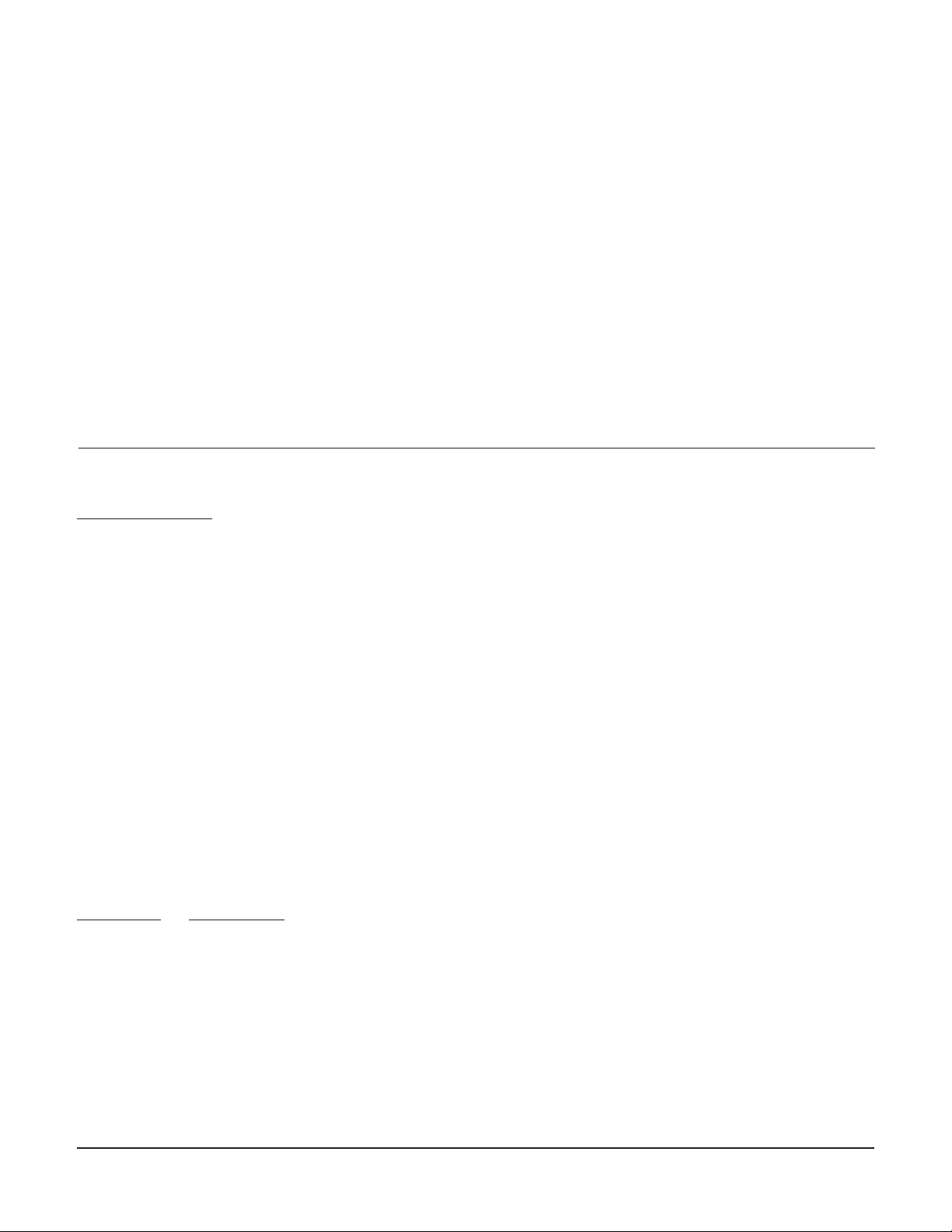

TRANS

This connects to the round connector on the passenger side of a 4L60E transmission or on the driver side of 4L80E.

Note: Pre-1993 4L80E's will need an updated internal wiring harness.B&M part# 120003, GM part# 24200161 or

equivalent.

4L60E

4L80E

2

Page 3

OUTPUT SHAFT SPEED

This connects to a speed sensor at the rear of the transmission. In the case of the 4L80E transmissions, use the rear

most sensor.

THROTTLE / TPS SIGNAL

The THROTTLE connector can be plugged into an early style GM TPS sensor . Wiring adapters are available from

FAST™ ( fuelairsp ark.com) to accommodate a later style GM TPS (round, 3 pin connector). The harness can also be

modified for use with any 0-5V TPS.

Original

Pin Location Color Function

A Black/Pink Ground

B White/Red TPS signal

C Red/White 5V

The loose TPS SIGNAL wire is provided to facilitate sharing the TPS signal between two systems (TCU and a fuel

injection system, for example) if needed. It splits off from the THROTTLE connector’s signal wire inside the harness.

Remote mount TPS kits are available from B&M to provide a TPS signal for carbureted applications (part # 120002) .

When installing one, adjust the linkage so that there is some preload on the sensor when the throttle is closed. Also

adjust it so that opening the throttle all the way causes the sensor to sweep through a majority of its range - but

without the sensor reaching its mechanical limit. Allowing the sensor to operate at it s mechanical limits (high or low)

can lead to premature failure. It will cause a TPS error code to be set if the signal voltage goes above or below approximately 4.9V or 0.1V respectively . If needed, the signal voltage can be measured on the TPS SIGNAL wire.

TACH IN / RPM MODULE

The wire with the female terminal can go from the tach output from an ignition box, other RPM signal source or to the

Shift Plus 2 RPM Module depending on the application. See RPM Module notes. DO NOT connect this directly to the

ignition coil.

A second wire is provided to facilitate sharing the tach signal between two systems (TCU and a fuel injection system,

for example) if needed. The terminal on the second wire is the opposite gender . So something that would normally

connect to an ignition box tach output or the Shift Plus 2 RPM Module can instead be plugged into this second wire in

the TCU harness for a splice-free hook up.

MANUAL SHIFT

This connector contains the wires needed to enable and use manual bump up/bump down shifting. Buttons can be

mounted where ever they are convenient in the vehicle – on the steering wheel, on the shift lever , etc.

Pin Color Function Notes

A Re d Bump Down Use momentary switch to ground to request a downshift.

B Y ellow Bump Up Use momentary switch to ground to request an upshift.

C Blue Auto/Manual Use a toggle switch to ground to enable Manual Shifting.

D Black Ground Can be used as the ground source for switches.

SPEEDOMETER OUTPUT (orange wire)

This wire puts out a 12V square wave to drive an electronic speedometer . The number of pulses per mile is selected in

the handheld user interface.

ECONOMY / PERFORMANCE (purple wire)

When switched to ground through a toggle switch, this TCU input can be used to select a more performance oriented

shift strategy . Line pressure and shift points will be altered according to settings entered in the handheld user inter-

face.

3

Page 4

TCC APPLY (grey wire)

When switched to ground, (and when some very basic requirements are met) this TCU input forces the torque

converter clutch to lock up. Otherwise, the TCC will lock and unlock automatically based on user configurable

settings.

FLASH ENABLE (blue wire)

This wire is only used in the rare case that new firmware needs to be loaded into the TCU. This wire would be

grounded as the TCU is keyed on. Be sure that this wire is not accidentally grounded in normal operation. If the TCU

accidentally starts up in Flash Mode (LED flashing steady on/off pattern – a slower pattern than the rapid flashing

that indicates an error code has been set), the transmission will not function properly . If that occurs, make sure the

FLASH ENABLE wire is not grounded, then key off, wait about 10 seconds and key back on.

HANDHELD

This connects to the communications cable that links the main wiring harness to the handheld user interface.

SPEEDOMETER CONTROL UNIT

This connects to an optional B&M Speedometer Control Unit (SCU) (p art# 120004). A SCU uses an electric motor to

spin a special speedometer cable to drive a mechanical speedometer.

RPM MODULE:

There are two basic options for supplying the Shift Plus 2 with an RPM input.

1. Clean, processed Tach signal from engine electronics

Electronics involved in running the engine – fuel injection, ignition, etc. – will need to know engine RPM. So there

may be an existing tach signal wire that can be tapped into. The Shift Plus 2 requires a square wave type tach

signal that pulses once per cylinder firing. Ignition systems – such as aftermarket capacitive discharge (CD) ignition

boxes – often have dedicated “T ach” output s that are a perfect RPM signal source for the TCU.

If using a clean, processed Tach signal, the T ACH IN / RPM MODULE wire in the Shift Plus 2 wiring harness is

connected directly to that source - the “Tach” output from an ignition box, etc. The RPM Module included with the kit

is not used in this case and no part of the Shift Plus 2 system is connected to the coil.

2. Inductive coil

Another RPM signal source is the negative side of the ignition coil in a traditional dwell controlled inductive ignition

system. One in which the coil is fed power on one side and is charged by grounding the other side - either by

“points” or some form of electronic module. An HEI is one example of this type of ignition system.

To use this RPM signal option, the RPM Module is required. The RPM Module connects to the negative side of the

coil and outputs a “Tach” signal to the TCU. The RPM Module is connected as follows:

Wire color Connection

Black Engine block

Black Engine block

White Negative side of coil

Yellow TACH IN / RPM MODULE wire in the Shift Plus 2 wiring harness

The RPM Module is provided to allow this convenient installation option. But keep in mind that it has limitations.

The negative side of an ignition coil is one of the noisiest points on the engine. In most applications, the RPM

Module will be able to deal with this and feed a clean RPM signal to the TCU. But the old saying – garbage in,

garbage out - applies here. If the inductive ignition system is just too noisy or inconsistent, a different RPM signal

source will be needed. A poor RPM signal can cause the RPM display on the Live Dat a screen to appear erratic. It

can also lead to inconsistent shift points under heavy load.

4

Page 5

RPM MODULE - IMPORTANT:

HEI distributors (and possibly others) have a terminal labeled “T ACH”. However , this is usually not a clean,

processed tach signal like many aftermarket ignition boxes would supply. Instead, it is simply another terminal

connected to the negative side of the coil. DO NOT connect the T ACH IN / RPM MODULE wire in the Shif t Plus 2

wiring harness directly to these terminals. The TCU will be damaged. In cases like this, the supplied RPM Module

is

required and will allow connection to the negative side of a dwell controlled coil.

DO NOT bypass the RPM Module and connect the TACH IN / RPM MODULE wire in the Shift Plus 2 wiring harness

directly to the negative side of the coil. This may actually function for a short time but eventually the TCU will be

damaged and system performance will degrade.

DO NOT connect anything from the Shift Plus 2 system to the coil – RPM Module or TACH IN / RPM MODULE wire

when using an aftermarket ignition box.

Use resistor type spark plugs. Non-resistor plugs are very electrically noisy and cause interference with electronics–

including the Shift Plus 2 system. DO NOT use solid core spark plug wires, these are also very noisy .

B&M Speedometer Control Unit (SCU) (Not include in kit):

An optional B&M SCU is available, part# 120004. It uses an electric motor to spin a special speedometer cable to drive

a mechanical speedometer. The SCU wiring mates directly to the Shif t Plus 2 wiring harness.

T o configure the SCU for use with the Shift Plus 2, remove the SCU's lid to access a row of DIP switches. Set switches

4,5 and 8 to the "ON" position. All others should be "OFF". Once the switches are set, the lid can be replaced. In the

setup wizard or in the advanced options menu, set the SPEEDO PPM to "4000PPM OR SCU".

In other applications, the SCU needs the DIP switches to be set according to a formula based on various drive train

information. The calculation is not required for use with the Shift Plus 2. Once the switches are set as described above,

the Shift Plus 2 handles the rest.It sends a calibrated speed signal to the SCU.

Installation

This is a general outline of the installation process. Read all of the component specific installation instructions for

more detail before beginning the installation.

1. Connect the TRANS and OUTPUT SHAFT SPEED connectors from the wiring harness to the transmission.

Route the rest of the harness into the engine compartment.

2. Determine the appropriate method for getting an RPM signal into the TCU. Install RPM Module if needed.

3. Connect the wiring harness to the RPM signal source.

4. Connect the wiring harness to a TPS signal source.

If a mechanical speedometer will be used, install the optional B&M SCU and connect the wiring harness to it.

5. Find a suitable location and mount the TCU. Make sure the wiring harness will reach the mounting location.

6. Connect the BATTER Y POS and BATTERY NEG wires DIRECTLY to the battery . These must be run

independently to the battery . DO NOT splice other power or ground wires into these wires. Extend the wires

if necessary to reach the battery. Use automotive grade 16 gauge (or larger) wire.

7. Connect the 12V SWITCHED wire to a switched ignition source (hot in On/Run and Crank). DO NOT

connect to the positive side of an ignition coil.

5

Page 6

8. If Manual Shifting will be used, route the MANUAL SHIFTING connector into the cockpit and wire in an

enable switch and a pair of buttons for upshift and downshift.

9. To use the Forced TCC Lockup feature, route the TCC APPLY wire into the cockpit and connect it to a switch

or button.

10. T o access Performance Mode, route the ECONOMY/PERFORMANCE wire into the cockpit and connect it to

a switch.

1 1. If an electronic speedometer will be used, route the SPEEDOMETER OUTPUT wire into the cockpit and

connect it to the speedometer.

12. Connect the wiring harness to the TCU.

HANDHELD:

The Shift Plus 2 handheld serves as the user interface with the Shift Plus 2 system. It has a straight forward menu

system that offers advanced features without requiring a laptop or any computer skills. Its first task is to take you

through the Setup Wizard. It also serves as a scan tool by displaying live data and diagnostics information. Beyond

basic setup, you can also adjust other settings to suit your preferences.

Communications

Cable

Power Cable

Power On / Off

HANDHELD - IMPORTANT:

The handheld has two cables that must be connected. A communications cable that links the handheld to the

HANDHELD connector on the main wiring harness. And a power cable that goes to a cigarette lighter recept acle.

For convenience, the handheld power source should be hot in On/Run and Crank. If it loses power while cranking,

there will be a short wait before the handheld can be used as it powers back up.

The B&M Racing logo will appear once the unit is turn on. To turn off the handheld, disconnect the power cable either

at the handheld itself or from the cigarette lighter receptacle. Reconnect the power cable to restart the handheld.

If the handheld displays a “COMM ERROR” message, make sure the handheld’s communication cable is connected

and that the TCU is powered on. Reset the handheld.

If monitoring live data or making adjustments while driving is necessary . Be safe by bringing a friend along to operate

the handheld while driving.

6

Page 7

Live Data:

The Live Data feature allows the monitoring of various engine and transmission parameters in real time. There are

two screens that can be selected using the UP and DOWN arrows. To return to the main menu, press the POWER/

MENU button.

Scroll Up

Enter/ Back

Scroll Down

In addition to live data readings, the Live Data screens also feature several St atus Indicators. They show when

certain conditions are met. In the picture below-on the left, the TC indicator is “off”. The PM and MM indicators are

“on”. These indicators can serve as a troubleshooting tool by offering a way to verify that the various switched inputs

are wired and functioning properly .

DASH 1

RPM Engine speed

MPH Vehicle speed

GEAR Current gear

Status Indicator Meaning

TC

PM

MM

T orque Converter Clutch. This indicates that the torque converter clutch

is locked. It is normally controlled automatically by the TCU but can

also be forced to lock by grounding the TCC APPLY wire.

Performance Mode. This indicates that the ECONOMY / PERFORMANCE wire has been grounded to select the more aggressive Performance Mode. When this indicator is off, the TCU operates in normal

Economy Mode.

Manual Mode. This indicates that manual bump up

bump down shifting has been enabled by grounding the

Auto/Manual wire in the MANUAL SHIFT connector .

The TCU will hold the current gear until told to shift,

unless the vehicle comes to a stop. In that case, it will

downshift into 1st gear.

7

Page 8

DASH 2

TOT(F) Transmission Oil T emperature in degrees Farenheit.

BA T( V) Battery voltage.

TPS% Throttle Position Sensor. It’ s range is from 0 (resting idle position) to 100 (full open position). The Setup Wizard

takes care of calibrating this sensor. It can easily be verified using this display. If you ever notice the TPS

reading is not 0 at idle, it should be re-calibrated by selecting TPS CALIBRA TE in the Advanced Options section

of the handheld.

SG R Selected Gear. This shows the position of the shift lever .

PN Park/Neutral

R Reverse

OD 4th lever detent / Overdrive

L3 3rd lever detent / Drive

L2 2nd lever detent / 2

L1 1st lever detent / 1

Status Indicator Meaning

Bump Up. This indicates that an upshift is being requested by

BU

grounding the Bump Up wire in the MANUAL SHIFT connector .

Manual Shifting must be enabled for the Bump Up input to be

recognized by the TCU and for this indicator to work.

Bump Down. This indicates that a downshift is being requested by

BD

grounding the Bump Down wire in the MANUAL SHIFT connector .

Manual Shifting must be enabled for the Bump Down input to be

recognized by the TCU and for this indicator to work.

nd

st

SE

System Error. This indicates that an error code has been set. It

acts like a Check Engine Light. Select ERROR CODES from the

main menu to check and clear error codes.

8

Page 9

Setup Wizard:

The Shift Plus 2 Setup Wizard will walk you through the initial TCU setup. Once you select SETUP WIZARD from

the main menu, you will be asked:

ST ART A NEW TUNE?:

YES - will let you continue the Setup Wizard. It will also reset most settings in the Advanced Options menu.

NO - will take you back to the main menu.

TRANSMISSION MODEL: Select the transmission type.

NUMBER OF CYLINDERS: Enter the number of cylinders your engine has.

TIRE DIAMETER:

If you know the rear wheel tire diameter, select ENTER DIAMETER and enter the value when prompted.

Or

select USE TIRE SIZE to use the tire size calculator . It will prompt you to enter the tire section wid th,

aspect ratio and wheel size that is molded into the sidewall of the tire. The tire diameter will be calculated and

displayed for you to review before continuing.

SPEEDO OUTPUT : Different speedometers require dif ferent numbers of pulses per mile (PPM). Select the appropriate PPM setting.

If an optional B&M Speedometer Control Unit (SCU),part# 120004, will be used to drive a mechanical speedometer ,

select "4000PPM OR SCU".

If you won’t be using the Shift Plus 2 speedometer output, it doesn’t matter what setting is selected.

If you will be using the Shift Plus 2 speedometer output but you don’t know what PPM your speedometer requires,

select the “4000PPM OR SCU” option. Later while driving, this setting can be adjusted with the SPEEDO PPM

setting in the Advanced Options menu.

Some aftermarket speedometers are programmable. For those speedometers, this setting may not be critical.

REAR AXLE GEAR RA TIO: Enter the gear ratio. This is an important setting. If you aren’t sure of the exact ratio,

enter your best guess for now. Later , you should use the ADJUST SPEEDO setting in the Advanced Options menu

to dial in the TCU’s speed reading.

MAX SHIFT RPM: Enter the highest RPM you want your engine to reach during wide open throttle shifting.

TPS CALIBRA TION SCREENS: The throttle position sensor (TPS) sends a voltage to the TCU that varies with

throttle movement. The TCU needs to know what voltage corresponds to closed and full throttle. Y ou will be asked

to leave the throttle at the idle / closed position. Once that value is captured, you’ll be asked to hold the throttle wide

open. The Setup Wizard will tell you how long to hold the throttle open while it captures that value.

NOTE: The full throttle procedure is meant to be performed with the engine NOT running!

That’s it! The TCU is configured and almost ready to go. The only remaining step is to power cycle the TCU - keyoff, wait 10 seconds, and turn it back on.

9

Page 10

Advanced Options:

The Advanced Options menu allows you to make adjustment s beyond the basic settings configured by the Setup

Wizard.

Advanced Setup 1:

SPEEDO PPM:

setting is used, the speedometer readings will be off by a large margin. The speedometer would read quarter speed,

half speed, double speed, etc. - something pretty obvious. If you don’t know what input your speedometer is expecting, try other PPM settings until the speedometer displays a reasonable speed.

Some aftermarket speedometers are programmable. For those speedometers, this setting may not be critical.

Different speedometers require different numbers of pulses per mile (PPM). If the wrong PPM

ADJUST SPEEDO: This setting can be used to fine tune the TCU’s speed reading. It compensates for errors in

the entered tire size and rear axle gear ratio.

(NOTE: If an external speedometer - as opposed to the MPH display on the Shift Plus 2 handheld - is grossly mis-

calibrated, refer to the SPEEDO PPM setting.)

While the vehicle is being driven, the screen will display the TCU’s current speed reading. Using the arrow keys, the

speed reading can be adjusted up or down. Once satisfied that the displayed speed is accurate, use the DONE

button to lock in the adjustment.

Since the point of this adjustment is to verify the speed as reported by the TCU, you will need an independent speed

reference for comparison. For example, you could…

- pace yourself against another car being driven at a known speed

- use a GPS unit that displays ground speed

- drive the car on a chassis dyno

TPS CALIBRA TE: The throttle position sensor is calibrated in the Setup Wizard. This let s you repeat that

process by itself. Just like in the Setup Wizard, you will be asked to leave the throttle at the idle / closed position.

Once that value is captured, you’ll be asked to hold the throttle wide open.

NOTE: The full throttle procedure is meant to be performed with the engine NOT running!

TIRE SIZE: Rear wheel tire diameter can be adjusted or re-calculated here.

DIFF GEAR: Rear axle gear ratio can be adjusted here.

MORE: This brings up another page of Advanced Options.

10

Page 11

Advance Setup 2:

MAX SHIFT RPM: The highest RPM you want your engine to reach during wide open throttle shifting can be

adjusted here.

LOWSPEED SHIFT: This setting is used to adjust the vehicle speeds at which the transmission shifts under very

light load, i.e., when the TPS reading is small. A higher number means the transmission will shif t at higher speeds.

NOTE: The handheld uses the setting entered here to perform calculations related to shift speeds. The results are

what actually get written to the TCU ( not this value setting itself ) Anytime you access this setting, it will display the

same default value to start. This is not an indication of a problem. The TCU does retain the shift speed information.

SHIFT AGGRESS: This setting adjusts how aggressive the overall shift strategy is. A higher number means that

the transmission will hold gears longer and be quicker to downshift. This setting has a big impact on the overall

demeanor of the transmission.

SHIFT FIRMNESS: This setting adjusts the base transmission line pressure. A higher number means higher

pressure which is felt as firmer shifts. Higher pressure also tends to allow less slip as the gears engage. Line

pressure automatically increases with increasing throttle and will always be maxed out during full throttle operation.

So line pressure does not need to be set uncomfortably high in normal part throttle driving in order to get full pressure

shifts under heavy load.

Keep in mind that the parts and techniques used in assembling a transmission can have a large effect on line

pressure and shift feel. Adjusting this setting will cause the TCU to call for more or less pressure. But it is possible

for the mechanical/hydraulic components of the transmission to overpower the control the electronics can have on

line pressure and shift feel.

MORE: This brings up another page of Advanced Options.

11

Page 12

Advance Setup 3:

MIN TCC LOCK: This setting is the minimum vehicle speed required for the TCU to lock the torque converter

clutch. Locking the TCC while cruising is good for fuel economy . It also allows the transmission fluid to cool.

However, TCC lockup can be completely disabled if desired by entering an unobt ainable speed in this setting. The

vehicle would then always be below the minimum speed for TCC lockup.

MAX TCC TPS: This setting is the maximum throttle opening allowed before the torque converter clutch is un-

locked. When the TCC locks up, it can feel similar to shifting into a higher gear . RPM’ s typically drop and the

engine has to work harder to accelerate the vehicle. If this setting is too low, TCC will unlock too easily. This can be

an annoyance as it locks and unlocks too often in the course of normal cruising. If this setting is too high, the

vehicle may feel unresponsive during medium to high speed cruising. As more throttle is applied, the engine may feel

like it is struggling until the TCC finally unlocks and allows the engine to more easily accelerate the vehicle. The

proper setting is subjective and also dependant on the characteristics of the vehicle and its powertrain – vehicle

weight, engine torque, etc. Some experimentation will likely be required to find the preferred value for this setting.

PERF AGGRESS: This setting determines how much more aggressive the shift strategy becomes when in Performance Mode. A higher number means that the transmission will hold gears longer and be quicker to downshift. This

adjustment is applied on top of whatever adjustment is already in place through the SHIFT AGGRESS setting.

PERF FIRMNESS: This setting determines how much shifts are firmed up when in Performance Mode. A higher

number means firmer shifts. This adjustment is applied on top of whatever adjustment is already in place through the

SHIFT FIRMNESS setting.

DONE: This will take you back to the main menu.

12

Page 13

Error Codes:

The Shift Plus 2 system features a diagnostics feature. The TCU constantly monitors various inputs for any deviations from normal operation. If any is detected, the LED on the front face of the TCU flashes rapidly as a warning that

there is a problem (the LED is lit solid when the TCU is powered on and working normally or it will flash a slower on/

off pattern if the TCU st arted up in Flash Mode). Also, the SE S tatus Indicator displayed on the Live Dat a screen

acts like a Check Engine Light. It will signal if an error code has been set. The handheld can be used to read any

error codes that have been set.

Once an error code is set, it is saved in the TCU until the TCU is reset by keying-off and allowing the TCU to complete its shutdown procedure (takes approximately 5-10 seconds) Error codes can be cleared with the handheld at

any time.

The picture on the left is showing error codes. Af ter clearing them, the picture on the right shows what the Shift Plus

2 Codes screen normally looks like.

The following error codes are possible:

Fault Monitors

TOT Transmission oil temperature sensor open or shorted. The sensor is inside the transmission.

OVER TEMP Transmission oil temperature has gone over 262°F.

TPS

Throttle position sensor signal voltage above or below approximately 4.9V or 0.1V respec-

tively .

BATT Battery voltage below 7V or above 19V for 10 seconds.

PSWM

Invalid pattern from pressure switch manifold (internal transmission sensor that

tells TCU what gear is selected.)

If the TCU is completely disabled – power is lost, harness is cut, etc. – the transmission can still be driven with

limited functionality . Line pressure will be maxed out. The reverse gear will work. The transmission will default to 3

rd

gear with the shift lever in Overdrive or L3/Drive. 2nd gear can be selected by moving the shift lever into the L2 position.

13

Page 14

Shift Plus 2 System Features and Operations:

Performance Mode

When Performance Mode is enabled, the TCU will use a more aggressive shift strategy (transmission will hold gears

longer and be quicker to downshift) and higher line pressure for firmer shifts. The degree to which both are affected

by enabling Performance Mode can be adjusted independently through the Advanced Options in the handheld. This

allows Performance Mode to be adjusted to suit the driver’s preferences.

Manual Shifting (Bump Up / Bump Down)

By enabling Manual Shifting, the transmission can be controlled with two buttons – one for upshift, one for downshift.

The buttons can be mounted where ever they are convenient in the vehicle – on the steering wheel, on the shift lever,

etc.

In this mode, the TCU will hold the current gear until told to shift, unless the vehicle comes to a stop. In that case, it

will downshift into 1st gear to ensure easy acceleration away from the stop. A side effect of this feature is that the

rear wheels must be turning before the TCU will accept an upshift request.

Because the TCU will not upshift on its own when Manual Shifting is enabled, care should be taken to avoid over

revving the engine. A rev limiter in a fuel injection or ignition system can act as a safety net to protect the engine in

case the driver waits too long to upshift.

Depending on vehicle speed, the TCU may ignore downshift requests. This is done to prevent over revving the engine

and/or destabilizing the vehicle.

TCC Lockup / Forced TCC Lockup

The TCU locks up the torque converter clutch during cruising conditions for improved fuel economy and to allow the

transmission fluid to cool. In order for the TCC to lock, several conditions must be met:

- Transmission fluid warmed up

- Transmission above 3rd gear (unless transmission fluid is overheated)

- Vehicle speed above user adjustable minimum (see MIN TCC LOCK setting)

- Throttle above idle position

- Throttle below user adjustable maximum (see MAX TCC TPS setting)

NOTE: TCC lockup can be completely disabled if desired by entering an unobtainable speed for the MIN TCC LOCK

setting. The vehicle would then always be below the minimum speed for TCC lockup.

There is also a Forced TCC Lockup mode. When the TCC APPLY wire is grounded, the TCC will lock without the

normal requirements being met. The only conditions that must be met are in place to prevent stalling if this feature is

accidentally turned on or left on:

- Transmission above 1st gear

- Vehicle speed above 10 mph

L2 Shift Lever Position

In normal operation, the TCU controls shifting and the transmission will upshift through the gears at the appropriate

speeds up to the shift lever position. For example, it will upshift until it gets to 3rd gear when the shift lever is in the

L3/Drive position. Putting the shift lever into the L2 position is a special case. Instead of just being the upper limit

for gear selection, it actually puts the transmission directly into 2nd gear. This can be useful in special situations.

For example, it may help reduce wheel spin when pulling away from a stop on a slippery surface.

Speed Checks

There are vehicle speed checks in place to protect the drive train if a gear is selected (either with the shift lever or

with manual bump up / bump down shifting) that is too low for the current vehicle speed. In this case, the TCU will

not electronically execute the requested downshift. However , due to the mechanical / hydraulic makeup of a transmission, the TCU does not always have absolute control over gear selection. So even though the TCU is programmed

to do all it can to protect the drive train, the driver must still use caution and common sense when requesting a

downshift. Ultimately , the well being of the vehicle and its occup ants is the driver’s responsibility.

14

Page 15

The LED on the front face of the TCU operates as follows:

On Solid:

TCU powered up and working normally .

Rapid Flashing: An error code has been set. Select ERROR CODES from the main menu to check

and clear error codes.

Slow flashing: TCU is in Flash Mode. Make sure the FLASH ENABLE wire is not grounded,

then key off, wait about 10 seconds and key back on.

Transmission Information

Transmission Troubleshooting

The Shift Plus 2 system relies on properly functioning components within the transmission to do its job correctly.

Some of those components can be checked by measuring resistance between the appropriate terminals in the TCU’s

main connector. To perform the testing, disconnect the main connector from the TCU and probe the pairs of terminals with a multi-meter set to measure resistance. Terminal number are molded into the main connector.

Transmission Retrofit Details

The mechanical portion of this transmission swap is similar to swapping a 700R4 into an older model vehicle that was

originally equipped with a Powerglide, TH350 or TH400 transmission. Depending on the application, the driveshaft

may need to be lengthened or shortened. The crossmember may need to be moved and the transmission mount,

bellhousing and shift linkage may need to be modified. The starter may need to be replaced as well. If you are

installing a high performance aftermarket converter , you may even need to drill the flexplate holes oversize in order to

accommodate larger-than-factory bolts. Be sure to check this before attempting the swap. (It’s a hassle to have to

remove the transmission from the car simply because the converter bolts would not go through the flexplate!)

15

Page 16

Use the dimensions listed below to determine the proper amount to move the crossmember and the amount to have

the driveshaft shortened or lengthened.

*Fit-all: refers to a bellhousing configured to accept either a Chevy or BOP engine

(BOP = Buick, Olds, Pontiac, Cadillac)

Both the 4L60E/4L65E and 4L80E/4L85E have Chevy bellhousing bolt patterns.

16

Page 17

Additional 4L60E/4L65E Notes

Header / Exhaust Clearance

There are several different bellhousing configurations for the 4L60E/4L65E transmission. The earlier models (1993-

1996) have an integral bellhousing identical to the 700R4. In some cases, the dust cover mounting ears will have to

be cut off to accommodate header collectors. This can easily be accomplished with a hacksaw . The later models

(1996-later) have a fully circumferential, bolt-on bellhousing. It is important to use the correct bellhousing for your

application. The LS1-style 4L60E/4L65E transmissions have a unique bellhousing and input shaft. These types are

not direct replacements for the non-LS1 applications.

Some headers will interfere with the starter hump on the bolt-on bellhousings. It may be necessary to either dimple

the header or cut off the starter hump.

Starter Clearance

The bellhousing may require modifications if you intend to use a stock starter.

Shift Lever

Many 1996-later, two-piece case transmissions (primarily trucks) have a shift lever that is about 1" longer than the

early-style found on 700R4, TH350 and TH400.

Cooler Lines

Y our existing lines may have to be bent to connect to a 1996-later , two-piece case transmission. These units have

fittings that are parallel to the ground instead of being angled down. You may also need to change the case fittings

as many 1996-later transmissions are equipped with the factory quick-connect style.

NOTE: Do not use Teflon® tape if replacing cooler fittings. It can cause the case to crack due to over tightening.

17

Page 18

18

Page 19

--1 Year Limited Warranty -–

This B&M product is covered for one year from the date of retail purchase to be free of defects in material and workmanship to the original purchaser (not warranted against normal wear, misuse or

abuse).This warranty covers the original purchasing consumer. This warranty is limited to rep air or

replacement by B&M of any B&M part that fails because of a defect in materials or workmanship. Implied

warranty: Any warranties implied by law are limited to the duration of this warranty. (except in those

states where prohibited by law).

Note: Complement your Shift Plus 2 Transmission Control Unit with some of the following products. Check the

B&M Racing website at www.bmracing.com for various shif ter , transmission, and torque converter options:

Cast Aluminum Deep Pan

#70295 (4L80E)

#70260 (4L60E)

B&M Speedometer Control Unit

#120004

#80701 (without aluminum cover)

A highly trained technical service department is maintained by B&M Racing to answer your technical questions,

provide additional product information and offer various recommendations.

T echnical service calls, correspondence, and warranty questions should be directed to the following address:

B & M Racing and Performance Products

Monday-Friday 7AM to 4PM PST

Bracket/Lever Kit

4L60E/4L65E/4L80E/4L85E

with PRNDL switch

#70499 (Bracket only)

#75498 (Bracket and Lever)

Pro Stick Shifter

4L80E / 4L85E

with PRNDL switch

#80706 (with aluminum cover)

Technical Service

9142 Independence Ave.

Chatsworth, CA 91311

Phone (818) 483-1366

B&M Throttle Position Sensor

for

Carbureted applications

#120002

Quicksilver Shifter

4L60E/4L65E/4L80E/4L85E

with PRNDL switch

#80683

19

Loading...

Loading...