Page 1

Torque Converter

Installation Instructions

for

Ford, Lincoln, Mercury

C-4, C-6 and AOD

© 1995, 2002 B&M Racing and Performance Products

Congratulations. You have just

purchased the best performing and highest quality torque converter available.

We feel the installation instructions on

the following pages are as complete

and clear as possible. Anyone with a

minimum of mechanical experience

should be capable of installing a torque

converter using the proper tools and

following instructions. It is important to

closely follow the instructions. Read

each step and if you don’t understand

go back and read it again.

Included are part numbers for

flexplates and other components which

may aid in installation. Every attempt

has been made to assure the accuracy

of this information. These instructions

are aimed at making your installation

as easy and simple as possible.

INTRODUCTION

The torque converter in your automatic transmission is a unique device

and must perform several functions:

First, it must provide some slip at an

idle so the engine does not stall when

the vehicle is stopped and the engine is

running.

Second, it multiplies torque under initial accelerations to provide more power

to the rear wheels. The typical torque

multiplication of a torque converter is

about 2:1. This means that the torque

converter is actually doubling engine

torque or power on initial acceleration.

Some high stall converters have torque

multiplication as high as 2.6:1.

Printed in the U.S.A.

Third, the torque converter must have

as little slippage as possible under

normal driving conditions so the engine

operates efficiently. High stall speed

converters are designed to be as efficient as possible at high rpm for maximum mph.

Fourth, the torque converter must have

reverse coupling to slow the vehicle

when you downshift to second or low.

Traveler torque converters are designed

to give maximum deceleration for improved engine braking.

All of the above functions occur

automatically under various operating

conditions. The torque converter is a

simple and yet complex piece of equipment. Improper installation will re-

sult in poor performance and possible damage to the torque converter

and/or transmission. Read all in-

structions first to familiarize yourself

with the parts and procedures. Work

slowly and do not force any parts.

Burrs and dirt are the number one

enemies of automatic transmission

assembly. Cleanliness is very important. Avoid getting any dirt or foreign

particles in the transmission or torque

converter.

Automatic transmissions operate

at temperatures between 1500F and

2500F. It is suggested that the vehicle

be allowed to cool for a few hours to

avoid burns from hot oil and parts. The

vehicle should be off the ground for ease

of installation. Jack stands, wheel

ramps or a hoist will work fine. Make

sure the vehicle is firmly supported!! Try to raise it 1 - 2 feet so you have

plenty of room to work easily. Also

have a small box or pan handy to put

bolts in so they won’t be lost, and a

drain pan to catch oil. We suggest you

rent a transmission jack from a rental

yard to remove the transmission as the

transmission/converter assembly is

heavy. A regular floor jack may be used

if a transmission jack is unavailable.

Due to variations between different

car models, exact instructions for every

vehicle cannot be provided. These

instructions are sufficient for all vehicle

installations. You may find it necessary to disconnect and lower exhaust

pipes during transmission removal.

STEP 1. Drain oil pan. This will make

less of a mess during transmission

removal. C-6, C-4 and AOD transmissions do not have drain plugs. Some

models of C-4 transmissions have a

dipstick tube which screws into the oil

pan. This can be loosened to drain the

oil pan. If you do not have a drain plug,

you should consider installing a B&M

Drain Plug Kit, P/N 80250, while transmission is out of vehicle. If your transmission does not have a drain plug or a

dipstick tube in the oil pan, loosen the

oil pan bolts to allow the fluid to drain.

After the fluid has drained, snug the oil

pan back into place.

STEP 2. Remove driveshaft. Be careful

not to damage the smooth bushing

diameter on slip yoke models. Do not

let the cups fall off the U-joint crosses.

9500198-03

Page 2

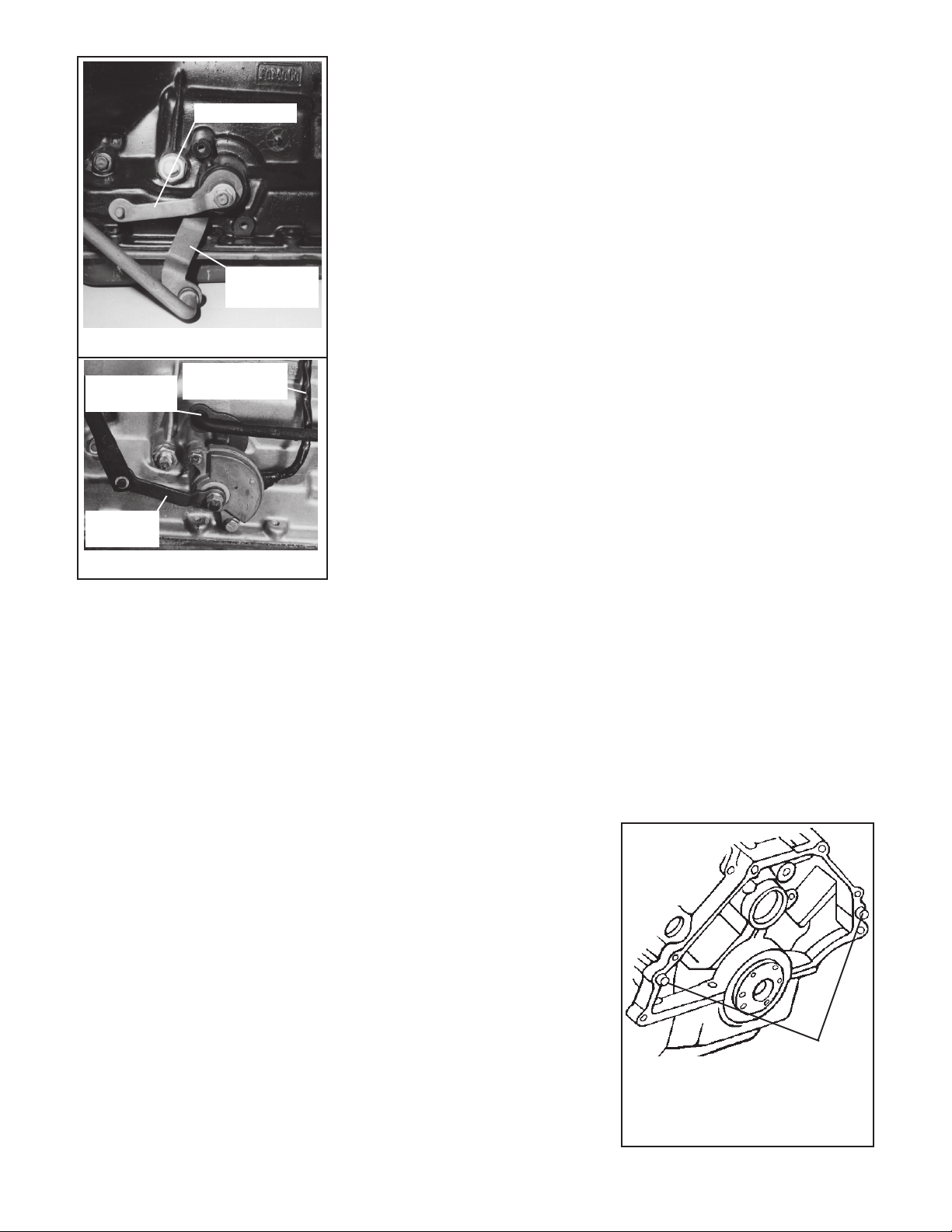

Kickdown lever

Column Shift

lever

Figure 1

Console Shift

lever

Kickdown

lever

You may lose some of the needle

bearings if the cups fall on the ground.

It is a good idea to tape the cups to the

U-joint cross, so they won’t fall off.

Now is a good time to clean and inspect your U-joints.

STEP 3. Disconnect vacuum line to

vacuum modulator. Disconnect

kickdown linkage. (See Figs. 1&2)

Remove clip holding rod or cable to

kickdown lever and allow rod or cable to

hang free. Disconnect shifter:

Column Shift Models: Disconnect

rod or cable from shift lever on transmission. (See Fig. 1) The rod or

cable is retained by a clip or by

snapping into a plastic grommet.

Remove clip or pry rod out of grommet and allow linkage to hang free.

Cable models; unbolt cable bracket

from bell housing and allow cable to

hang free.

Console Shift Models: Disconnect

rod from shift lever on transmission.

(See Fig. 2) The rod is retained by a

clip or by snapping into a plastic

grommet. Remove clip or pry rod out

of grommet and allow linkage to hang

free.

'70 and Later Vehicles Equipped

Neutral saftey

switch harness

Figure 2

With Locking Steering Column And

Console Shifter: Disconnect col-

umn lock rod from transmission shift

lever and allow it to hang free.

4 Wheel Drive Models: Remove

knob from transfer case shift lever.

STEP 4. Loosen and disconnect speedometer cable:

Clamp Type Cable: Remove bolt or

speedometer cable clamp. Pull

speedometer cable out of extension

housing and let it hang free.

Sleeve Type Cable: Loosen cable

sleeve. Pull speedometer cable out of

speedometer housing and let it hang

free.

STEP 5. Disconnect oil cooler lines.

Use a fitting wrench, if available, to avoid

damage to compression nuts. We

recommend that the oil cooler lines be

flushed out to remove any foreign particles trapped in the cooler. Cooler lines

should be flushed in both directions with

solvent and air pressure.

STEP 6. Remove dipstick and tube

assembly. Remove torque converter

access cover bolts and remove converter access cover. Remove flexplate

to converter nuts. Use starter motor to

“bump” each bolt into position.

STEP 7. Disconnect neutral safety

switch on vehicles equipped with neutral safety switch mounted on the transmission by unplugging connector ends

on wire harness. Allow connector ends

to hang free.

STEP 8. Remove starter motor assembly and tie it up out of the way. On some

vehicles, it is difficult to remove the

starter completely, so it is easier to

simply support it out of the way.

STEP 9. Support the transmission with

a jack. Remove the transmission rear

mount bolts. Raise the transmission

slightly and remove the crossmember.

Be sure the transmission jack supports

the transmission on a wide area so you

don’t crush the oil pan.

STEP 10. Remove the bellhousing

bolts. Lower transmission until the

engine is supported. Pull transmission

back slightly away from engine. Make

sure converter stays with transmission.

Lower transmission/converter assembly and remove from vehicle. Caution:

4 Wheel Drive Vehicles: Transmission/converter transfer case assembly

is heavy. Exercise care during removal

if your transfer case bolts to the transmission.

STEP 11. Pull converter off the front of

the transmission. Some oil will leak

out at this time. On C-4, C-6 and AOD

transmission, the input shaft may pull

out of the transmission when you remove the torque converter. Do not be

alarmed.

C-4: Install the short splined end

of the input shaft into the transmission until the splines engage the

drum inside the transmission. Push

the shaft in all the way until it stops.

C-6: Install the long splined end of

the input shaft into the transmission

until the splines engage the drum

inside the transmission. Push the

shaft in all the way until it stops.

Important C-4 ONLY: C-4 transmissions have either a 24T or 26T (Early &

Late models) spline input shaft. Remove the input shaft and insert it into

your B&M converter. Be sure that the

input shaft engages the spline inside of

the torque converter and is a good fit

into the spline. Install input shaft into

transmission as previously described.

STEP 12. Inspect your engine block

and engine plate. Make sure there are

no burrs that will prevent the transmission from bolting down flat against the

engine. File off any burrs that may be

present. Dowel pins should stick out of

the engine block a minimum of 1/2" for

proper alignment. (See Fig. 3) Insufficient dowel pin engagement can cause

front seal and/or bushing failure due to

improper engine/transmission alignment. Bellhousing bolts alone will

not align the transmission properly.

Dowel pins must

stick out 1/2" for

proper transmission engagement

Figure 3

Page 3

Inspect converter stud holes, crankshaft

bolt holes and starter ring gear teeth for

damage, cracks and excessive wear.

Figure 4

STEP 13. Inspect your flexplate. Check

for distortion, excessive warpage or

worn/elongated stud holes. (See Fig.

4) The flexplate should not be “dished”

backwards. Check condition of starter

ring gear teeth. Distorted or worn

flexplates should be replaced.

STEP 14. Check the bolt pattern of

your B&M torque converter and make

sure it matches your flexplate. There

are several bolt patterns possible from

Ford Motor Company:

C-4: (4) 3/8" studs on 11.40" B.C.

(4) 3/8" studs on 10.50" B.C.

(4) 3/8" studs on 9.28" B.C.

C-6: (4) 3/8" studs on 11.40" B.C.

(4) 3/8" studs on 9.28" B.C.

B&M Converter Applications

Converter B&M B&M Converter Flexplate

Part Number Converter Bolt Pattern Modifications

40425 C-6 Traveler 3/8"-24 x 11.40" B.C. Stock flexplate

40412 C-6 Holeshot 2400 7/16"-20 x 11.40" B.C. Drill 15/32"

40422 C-6 Holeshot 2400 7/16"-20 x 11.40" B.C. Drill 15/32"

40442 C-6 Holeshot 3000 7/16"-20 x 11.40" B.C. Drill 15/32"

40427 C-6 TorkMaster 2000 7/16"-20 x 11.40" B.C. Stock flexplate

50412 C-4 Holeshot 2400 3/8"-24 x 10.50" B.C. Stock flexplate

50416 C-4 Holeshot 2400 3/8"-24 x 10.50" B.C. Stock flexplate

50432 C-4 Holeshot 3000 7/16"-20 x 10.50" B.C. Drill 15/32"

50436 C-4 Holeshot 3000 7/16"-20 x 10.50" B.C. Drill 15/32"

50440 C-4 TorkMaster 2000 3/8"-24 x 10.50" B.C. Stock flexplate

40430 AOD Holeshot 2400 7/16"-20 x 11.40" B.C. Drill 15/32"

40431 AOD Holeshot 3000 7/16"-20 x 11.40" B.C. Drill 15/32"

40437 AOD TorkMaster 2000 3/8"-24 x 11.40" B.C. Stock flexplate

Note: B&M AOD 40430 & 40431 Open Converters (non-split path) do not

require any transmission modifications.

Refer to the following chart for flexplate and starter nose-piece cross reference.

Stock Flexplate Replacement Starter Nosepiece

Flexplate

C-4 Applications

C5AZ-6375-T Do not change Use same starter

11.40" bolt circle nosepiece

164 tooth ring gear

D5ZZ-6375-A C3AZ-6375-L D1AZ-11130-A

9.28" bolt circle 10.50" bolt circle

141 tooth ring gear 157 tooth ring gear

FMX: (4) 3/8" studs on 11.40" B.C.

(4) 3/8" studs on 10.50" B.C.

(4) 3/8" studs on 9.28" B.C.

AOD: (4) 3/8" studs on 11.40" B.C.

If your flexplate does not match up

to the bolt pattern on your B&M torque

converter, you will have to replace your

flexplate. You may enlarge your original flexplate holes to accept larger 7/

16"-20 studs used on most B&M Performance coverters. Use a 15/32" (.468")

dia. drill and deburr the holes after

drilling.

C-6 Applications

D1ZZ-6375-C D1ZZ-6375-A Use same starter

9.28" bolt circle 11.40" bolt circle nosepiece

164 tooth ring gear 164 tooth ring gear

AOD Applications

Use same flexplate

Factory part numbers are for reference only, and are not guaranteed for

accuracy.

Make sure that the replacement flexplate has an equivalent balance weight

on it. Improper flexplate balance will cause severe engine vibration.

Page 4

Note: C-4 transmission bellhousings

have two different mounting designs.

1. Flared case: The bellhousing bolts

directly to the transmission case with

5 bolts and the oil pump bolts are

separate. (See Fig. 5) The case flares

out to meet the bellhousing.

2. Pump Mount: The bellhousing bolts

to the transmission with the same

bolts that hold the oil pump. (See Fig.

6) There is a 1/4" gap between the case

and the bellhousing.

Caution: Do not use a 10.50" bolt

circle torque converter with a flared

case bellhousing C-4. Do not use an

11.40" bolt circle converter with Pump

Mount bellhousing C-4. Improper pilot

hub or oil pump engagement will result

which could damage the transmission

and/or torque converter.

STEP 14. Install flexplate onto crankshaft if you have removed or replaced

it. When properly installed, the raised

inner lip on the flexplate crankshaft

diameter is away from the crank-

shaft. Install flexplate to crankshaft

bolts and torque to 55 lb. ft.

STEP 15. Install B&M torque converter

against crankshaft and flexplate. The

converter should fit the crank snugly

with no excessive slop. A tight fit may

indicate burrs or rust in the pilot diameter of the crank. This can be cleaned

with some emery paper or a file. If your

flexplate is new or in good condition the

converter may not contact the flexplate

before it bottoms in the crankshaft. A

1/16 - 1/8" gap is normal. When the

flexplate to converter bolts are tightened the flexplate will bow backwards

slightly and hold the torque converter

against the crankshaft. Make sure

flexplate clears any drain plugs on

converter.

STEP 16. Remove the front pump seal

in the transmission and replace with

the new seal supplied with the converter. Lubricate the seal with ATF or

white grease. Pour one quart of B&M

Trick Shift ATF into the B&M torque

converter so there will be some lubrication on initial start-up. While Trick Shift

is superior in lubrication, heat capacity

and friction material performance, if

Trick Shift is unavailable be sure to use

Ford Type F fluid.

STEP 17. Install B&M torque converter

onto transmission. Push and rotate

C-4 Flared case 289, 302,

351C,351W

C-4 Step case 289, 302,

351C,351W

converter to engage input shaft, stator

shaft and oil pump rotors. Place a

straightedge across the face of the

transmission bellhousing. Measure the

distance from the face of the bellhousing

to the base of the torque converter drive

stud. (See Fig. 7) The base of the stud

must be at least 13/16" (4 cyl-351 V-8)

or 1-1/8" (360 Larger-V-8) inside the

bellhousing. A measurement of less

than 13/16" (4 cyl-351 V-8) or 1-1/8"

(360-Larger V-8) indicates the torque

converter is not fully engaged in the

transmission, except torque converters specially built for motor plate applications. (Subtract the thickness of

your motor plate from the 13/16" or 1-1/

8" dimension for proper measurement.)

Continue to rotate and turn the converter to obtain full engagement. If you

install the transmission without full

converter engagement, you will

damage the oil pump and/or converter.

STEP 18. Place transmission in posi-

tion on transmission jack. Be sure the

jack supports the transmission on a

wide area so you don’t crush the pan.

Align converter drive studs with holes in

flexplate. Install transmission/torque

converter against engine. Transmission should engage dowel pins and sit

flat against the engine block with hand

pressure only. If the transmission will

not sit flat against the engine, the converter is not installed into the transmission all the way or there is some inter-

Figure 5

Figure 6

C-4 Flared case

C-4 Step case

ference problem. Do not attempt to

pull the transmission up against the

engine with the bellhousing bolts

as this can cause transmission and/

or torque converter damage.

STEP 19. Once the transmission is in

position against the engine, install transmission bellhousing bolts and tighten

25-30 lb.ft. At this point, the torque

converter should be free to move back

and forth slightly. A tight converter

indicates improper pump engagement,

badly burred crankshaft, distorted

flexplate or flexplate stud holes not

drilled to size. This condition must

be corrected before going any further.

STEP 20. Inspect rubber transmission

mount. Worn, cracked or oil soaked

transmission and/or engine mounts

should be replaced. Raise transmission and install crossmember and transmission mount bolts securely. Install

starter motor in place. Install starter

bolts and tighten securely. Connect

neutral safety switch on vehicles with

switch mounted on transmission.

STEP 21. Install four flexplate to converter nuts. Use the starter motor to

“bump” each stud into position. Tighten

nuts:

3/8" - 24 23 - 28 lb.ft.

7/16" - 20 26 - 32 lb.ft.

Install converter access cover and

tighten bolts 30-60 lb.in.

Page 5

Drive lug face (base of stud) must be at

least 13/16" (4 cyl to 351 V8) or 1-1/8" (360

to Larger V8) inside front edge of

bellhousing

Figure 7

STEP 22. Install dipstick and tube

assembly. Use a small amount of

sealer on dipsticks with an O-ring to

prevent leaks. Connect oil cooler lines.

Use a fitting wrench on the compression nuts to avoid damage to the nuts

and hold the fittings with a wrench while

tightening compression nuts 75 lb.in.

STEP 23. Connect speedometer cable:

Clamp Type Cable: Use a small

amount of sealer on the O-ring to prevent leaks. Push speedometer cable

assembly into extension housing. Install clamp bolt and tighten to 150 lb.in.

Sleeve Type Cable: Push speedometer cable into speedometer housing

and tighten sleeve.

STEP 24. Connect shifter:

Column Shift Models: Connect rod or

cable to shift lever on transmission.

(See Fig. 1) Snap rod into grommet

retainers by squeezing rod and lever

together with a pair of pliers. Connect

rod or cable to clip retainer levers and

install clip.

Console Shift Models: Connect rod

to shift lever on transmission. (See Fig.

2) Snap rod into grommet retainers by

squeezing rod and lever together with a

pair of pliers. Connect rod to clip

retainer levers and install clip.

'70 and Later Vehicles Equipped

With Locking Steering Column And

Console Shifter: Connect column

lock rod to transmission shift lever and

install clip. Check shifter adjustment.

Selector lever must coincide with detent feel in transmission. There must

be equal clearance between the Neu-

tral stop and detent position and the

Drive stop and detent position.

4 Wheel Drive Models: Install knob

on transfer case shift lever.

STEP 25. Connect kickdown linkage.

(See Fig. 1 & 2) Connect rod or cable

kickdown lever and install clip. Kickdown

linkage should work smoothly with a

positive spring return action.

STEP 26. Inspect vacuum line. Replace any vacuum lines that are broken, cracked, kinked or restricted. Vacuum source should be from the manifold for proper vacuum sensing to automatic valve bodies.

STEP 27. Install driveshaft. Make sure

U-joint cups are installed properly.

Tighten U-joint bolts or nuts securely.

STEP 28. Lower vehicle but keep the

rear wheels off the ground if possible.

Add 3 quarts (C-4), 4 quarts (FMX) or 6

quarts (C-6 or AOD) of B&M Trick Shift

to the transmission. While Trick Shift

is superior in heat capacity, lubrication

and friction material performance, if

Trick Shift is unavailable be sure to use

Ford Type F fluid.

STEP 29. Start engine and place

shifter in the Neutral position. Add

fluid until the oil level is between the

Add and Full marks. Shift transmission through all gear positions. If the

rear wheels are off the ground, allow the

transmission to shift through all gears

several times. Place selector in Neu-

tral and check fluid level. Do not

overfill. This can cause foaming and

overheating. Check for leaks at cooler

lines, etc.

OPERATING RECOMMENDATIONS

Torque Converter Performance

The torque converter is a component of the automatic transmission

however it must be properly matched to

the engine for maximum performance.

A torque converter reacts to torque.

The more torque you put to the converter the better your performance.

However this torque must match the

operating RPM of the converter. To

make a converter operate properly, your

engine must make sufficient bottom-

end torque. You cannot build an

engine for an automatic transmission

the same way you would build an engine for a 4-speed because the operating ranges are different . Your engine

must be built to produce as much

bottom-end and mid-range torque

possible for your operating conditions.

This is especially important for good

street performance.

Do not make the mistake of overcamming your engine. You will need to

limit camshaft duration to 245o @ .050

for street engines. We also suggest

you run the cam 2o-4o advanced. Small

CFM carburetors give better bottomend response. Be careful not to over

carburete your engine.

Approximate stall speed of B&M

torque converters is indicated by the

B&M model. For example, a Holeshot

3000 has a stall speed of approximately 3000 RPM. This is a general

guide and should be used for reference

only. Exact stall speeds are impossible to predict. A specific stall speed

cannot be guaranteed due to the many

variables involved in each car. If you are

experiencing stall speed difficulties, the

following items can contribute to low

stall speeds:

Light cars

Small displacement engines

Very high compression ratios

Large throttle bore carburetors

Mechanical carburetor secondary

linkage

Long duration camshafts

Retarded cam timing

Poor rear brakes

High-ram manifolds

Multiple carburetion

Low stall speeds, poor throttle

response, sluggish performance and

Page 6

high idle speed requirements indicate

poor bottom-end torque characteristics which will need to be corrected

to obtain maximum converter performance.

Modified torque converters are installed

to improve performance and durability

not available from a stock torque converter. Heavy Duty and racing applications impose higher loads and greater

heat dissipation than stock operating

conditions.

Oil Cooling: The factory heat exchanger is usually inadequate for Heavy

Duty and/or Racing applications. The

following B&M Oil Coolers are recommended for performance applications.

Heat is the major enemy of automatic

transmissions and a cooler will also

prolong the life of your transmission.

B&M will not warranty torque converters which show heat damage from misuse or inadequate cooling.

B&M

Part No. Rating/Application

70255 16,000 GVW Street perfomance

70268 19,000 GVW Campers, small

motor homes, high stall converters

70264 24,000 GVW Large motor homes,

towing, high stall converters

70266 28,000 GVW Road & off-road race

cars (high flow race cooler)

Driving Techniques:

Traveler:

Traveler torque converters should

be driven like a stock torque converter.

Stall speeds and converter slip will

coincide with torque demand and adjust automatically. Additional deceleration will be noticed during manual

downshifts.

Holeshot and TorkMaster:

Holeshot and TorkMaster torque converters are designed for street performance and should not be considered

as a low cost race converter. Under

normal driving conditions Holeshot and

TorkMaster torque converters will function like stock converters with some

additional slip. High stall speeds are

available at torque demand. The best

standing start acceleration performance

is usually obtained by “stalling” the

converter at 1500-2000 rpm with the

brakes locked just prior to launching

the car. Bang the throttle and release

the brake pedal at the instant of launch.

Marginal traction situations may require you to “drive the car out” or feel for

traction with the gas pedal as you leave

the starting line. Remember, Holeshot

and TorkMaster torque converters are

designed for street performance and

occasional drag strip use. Race cars

need Race converters.

Maintenance:

Street Use: Change fluid and filter

every 10,000 - 12,000 miles. This will

also help the life of the transmission.

Check torque converter bolts or nuts

every 20,000 - 24,000 miles.

Ballooning: Ballooning is expansion

of the torque converter along the axis of

rotation (front to back). This is caused

by high rpm use and/or continuous

wide open throttle stall speeds. A

ballooned converter can lose thrust

washer piloting and must be cut open

for repair. You can check for ballooning

by measuring the end play clearance of

the stator and turbine. (See Fig. 8) You

will have to make a hooked tool to grab

the stator or turbine. (See Fig. 9) Maximum stator or turbine end play is .050

inch. If stator or turbine end play

exceeds .050 inch the converter will

have to be cut open to repair the cover.

Cracks and Leaks:

Leaks can be caused by several

reasons. The most common are front

seal failure and vibration cracks.

Front seal failure is due to improperly installed seal (damaged during installation), misalignment, worn pump

bushing, or worn converter impeller hub.

A ballooned converter can have a slightly

bent impeller hub. Inspect the pump

bushing when you replace the seal.

Check dowel pins in the engine block

for sufficient engagement and polish

the converter impeller hub with 400 grit

wet and dry sandpaper and oil.

Cracks can develop in the impeller

hub or perimeter weld from stress and

vibration. If a crack occurs around the

impeller or pilot hub we recommend

you return it for repair.

Measure end play

by hooking the

tool to the stator and

lifting up and down

12"

Typical homemade tool

used to check torque

converter end play

Figure 8 Figure 9

Loading...

Loading...