Page 1

Installation Instructions

Pro Bandit Shifter

Part Number 80793 & 80794

©2004, 2000 by B&M Racing and Performance Products

(Visit www.bmracing.com for additional products and product information)

The B&M Pro Bandit Shifter is a gate

pattern type shifter mechanism. It is

available in a rear exit cable model only

and it is designed for Powerglide

transmissions with standard or reverse

pattern valve bodies. The B&M Pro

Bandit Shifter features a positive

reverse lockout mechanism and a

neutral safety switch as required by

NHRA and IHRA.

Please read the instructions and review

the illustrations thoroughly before

beginning the installation.

IMPORTANT: You must first install

the shifter cable and an air slave cylinder (such as B&M's #80883 KIT)or

electric solenoid onto the shifter before

positioning it in your vehicle. This is to

insure that you allow for proper clearance at the rear of the shifter for these

components before you permanently

mount the shifter body into the vehicle.

Mounting the shifter first without the

cable and the air slave cylinder attached can cause possible interference from frame rails or other components. Poor cable routing and cable

binding will result in poor shifter operation.

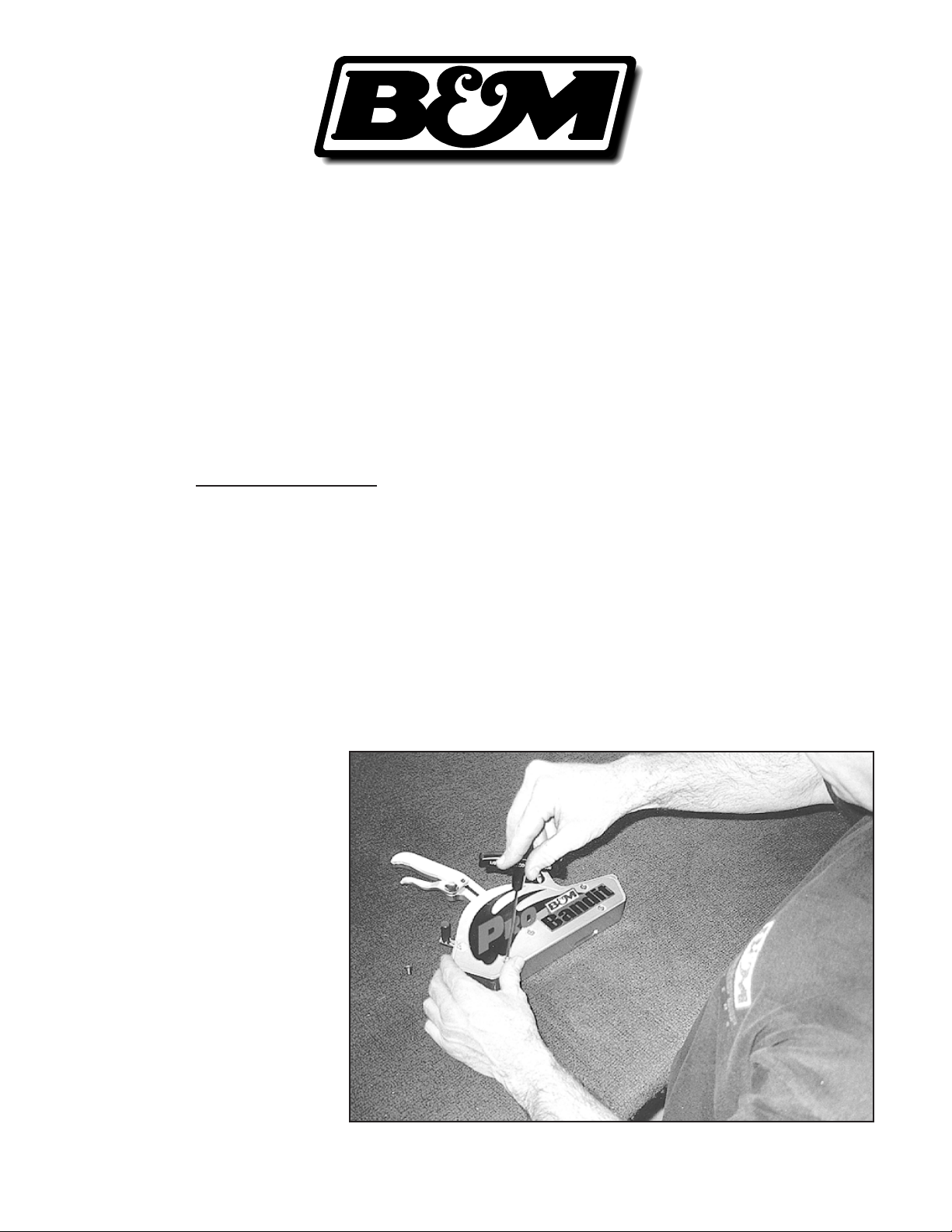

position furthest from the red reverse

lockout release lever. Remove the five

countersunk screws from the B&M Pro

Bandit Shifter cover (See Photo #1).

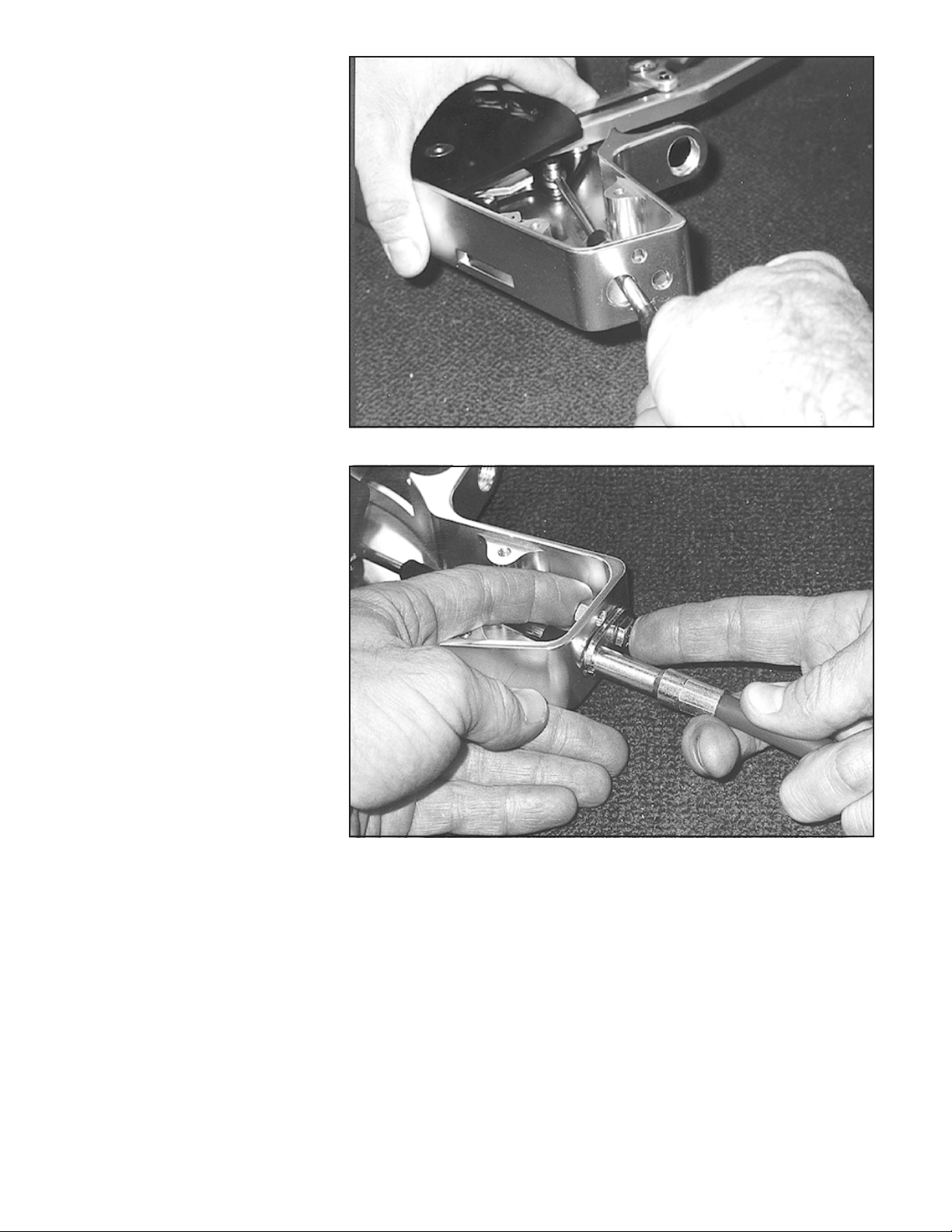

STEP 2. Locate the cable attachment

pin at the rear of the shifter stick. The

pin is visible just under the black shift

pattern gate plate. Do not remove the

black gate plate (See Photo #2).

STEP 3. Fully extend the stamped

loop end of the shifter cable #80834

(included in #80793 KIT), (See Photo

#3).

STEP 4. Insert the extended stamped

loop end of the cable through the largest access hole in the rear of the shifter

body. Slip the stamped loop cable end

over the cable attachment pin at the

rear of the shifter stick and attach the

supplied e-clip to the pin. Check to

make sure you have the e-clip firmly

and accurately in the locating groove in

the pin (See Photo #4).

STEP 5. Push the cable anchor tab

flush to the rear of the shifter body.

Align the 17/64" cable flange hole with

INSTALLING THE SHIFTER CABLE

STEP 1. Pull the shifter stick all the

way back to the Low gear position, the

Printed in U.S.A.

Photo #1

9500702-03

Page 2

the 9/32" hole in the shifter body. Be

sure to use the hole directly above the

large cable access hole (See Photo

#5). Install the 1/4" bolt from the outside of the shifter body through the

cable mounting flange until the bolt

sticks through to the inside of the

shifter body. Place the supplied 1/4"

washer over the exposed threads on

the inside, then thread on the 1/4" nut

and tighten (See Photo #5).

INSTALLING THE NEUTRAL

SAFETY SWITCH WIRES

STEP 6. The smallest hole in the rear

of the shifter body is 13/64", it will serve

as the exit for the jacketed neutral

safety switch wires. Since this switch

is a breaker that keeps the starter from

engaging until the switch is closed in

Neutral or Park, the color of the wires

is not critical. It is only being used to

break the 12V wire from the starter

switch to the small wire on the starter

solenoid. If your wiring is different,

follow the instructions that pertain to

your specific wiring layout.

STEP 7. With needle nose pliers

gently plug the connectors onto the

neutral safety switch terminals. You

will see that the wires are designed to

fit the staggered terminals on the

switch. Be careful not to force the

connectors onto the switch terminals

or you will damage the switch. These

connectors should slide onto the switch

terminals with light pressure (See

Photo #6). Once the connectors are

firmly in place, feed the loose end of

the jacketed wires through the 13/64"

hole at the rear of the shifter body from

the inside to the outside. The wires are

now ready to be integrated into your

vehicle wiring harness.

INSTALLING THE B&M AIR

SLAVE CYLINDER KIT (#80883)

(OPTIONAL PRODUCT)

STEP 8. Screw the air slave cylinder

into the mounting flange on the shifter

body and tighten the cylinder against

the flange. Install the jam nut onto the

exposed threads of the cylinder and

tighten the jam nut. Screw the black

rubber bumper onto the slave cylinder

shaft (use a drop of red LOCTITE ® on

Photo #2

Photo #3

these threads), (See Photo #7). There

are flats for a 1/4" wrench on the center

shaft. These are so you can hold it while

you tighten the rubber bumper with a

small pair of pliers. Do not hold the

center shaft anywhere else other than

where the designated flats are. It will

damage the shaft surface and will

cause the cylinder to stick and possibly leak. With the shifter in the High gear

position, extend the rubber bumper/shaft

out of the cylinder by hand. There should

be approximately .060"-.065" clearance

between the end of the bumper and the

shifter stick. This clearance is critical to insure that when the air slave

activates and shifts the shifter into

the High gear it does not slam the

stick into the stop on the gate plate.

If you need to adjust this to obtain the

proper clearance, loosen the jam nut

and back the air slave cylinder out to

the desired spacing and retighten

the jam nut.

STEP 9. At this stage the shifter

cable, the neutral safety switch and

the air slave cylinder should be installed. Before you proceed with

2

Page 3

mocking up the B&M Pro Bandit

Shifter in your vehicle, temporarily

reinstall the side cover with the center

screw only. This is to insure that the

gate plate and the mechanism do not

move from the inside of the shifter body

when you are positioning it in your

vehicle. You are now ready to locate

your B&M Pro Bandit Shifter in your

vehicle.

If for any reason the internal shifter

mechanism becomes pulled off or

away from the shifter body, make

sure to check the spring loaded

detent lever at the front of the

mechanism. The best way to do this

is to move the stick all the way back

to the Low gear position. This will

clear the neutral safety switch detents away from the actuator on the

neutral safety switch. If they are

aligned improperly you can easily

break the switch. Apply light downward pressure to the black shift

pattern gate plate while using

needle nose pliers to rotate the

spring loaded detent lever to the

left. You will feel the detent locate

itself back into position (See Photo

#8).

Photo #4

INSTALLING THE B&M PRO

BANDIT SHIFTER INTO YOUR

VEHICLE

STEP 10. With the driver sitting in the

vehicle, find the best location that allows the driver full range of motion to

easily work the shifter through the entire shift pattern, Park to Low gear.

(Read the section on HOW TO OPERATE YOUR B&M PRO BANDIT

SHIFTER). The two slotted holes at

the bottom of the shifter body are designed for mounting tabs access from

the chassis. The chassis' tabs should

slip up inside the slotted holes. Because the B&M Pro Bandit Shifter

has flush mount hardware and bottom

entry mounting, it is possible to tuck it

inside the frame tubes and out of the

driver's leg and arm areas without worry

of the mounting hardware rubbing the

inside of the body panels. (Figure #3

shows the recommended tab dimensions along with a sample drawing of

the standard chassis' tabs position).

Be sure when choosing your shifter

Photo #5

mounting location you route the

shifter cable where it can be easily

looped through the vehicle without

binding or kinking. Most importantly, it is critical not to crush, bind

or kink the shifter cable as it exits

the rear of the shifter body. Poor

cable routing will result in improper

shifter operation and potential

cable damage.

STEP 11. The B&M Pro Bandit Shifter

is designed to bring the cable to the

transmission from the front of the transmission using the engine mid-plate as

the shifter cable bulk head anchor. The

#80323 quick disconnect cable exten-

sion (included in #80793 KIT), will complete the shifter cable connection to

the transmission’s selector lever. We

recommend the B&M Powerglide Pro

Lever #70465 (included in #80793 KIT).

If your transmission has a different

selector lever, it must have the cable

attachment hole at 2" from the centerline

of the selector shaft. If your vehicle

does not have a full engine mid-plate,

then you will have to fabricate a strong

cable anchor bracket to work in your

3

Page 4

application. (Figure #2 provides optimum cable position). Dimensions

are critical when making your cable

anchor, be accurate.

Mounting the cable anchor to the

chassis is not recommended. The

cable should always be mounted to

the (engine/transmission) combination. This is important because if

the (engine/transmission) combination were to move forward or backward the cable anchor would stay

in the same position. If the cable

anchor is attached to the chassis,

any movement of the (engine/transmission) combination could cause

the transmission to accidentally be

forced into a different gear. This

could result in serious transmission

damage as well as the possible loss

of vehicle control should the vehicle be under acceleration or deceleration.

STEP 12. The mounting tab holes

measure 5 1/2" (center to center). Once

the shifter location is determined, firmly

mount the tabs to the chassis. The

method of the chassis' tab attachment

is your choice, but welding is preferred.

These tabs must be solid to avoid flex

and vibration. We recommend the

material thickness of 3/16". (Figure

#3 shows the recommended tab

shape and dimensions). With the

tabs on the chassis, slip the shifter

body over the top of the tabs. Carefully

remove the single screw that is temporarily holding the cover in place. Make

sure that your tabs do not interfere with

any of the internal mechanism components.

STEP 13. Install the supplied 5/16" x

3/4" countersunk bolts through the

countersunk mounting holes from the

outside of the shifter body and through

the holes in the chassis' tabs. From

inside of the shifter body, place the

supplied 5/16" nyloc nuts onto the

bolts and tighten. This will clamp the

chassis' tabs to the shifter body. Be

sure not to move the internal shifter

mechanism or the gate plate while the

cover is off.

STEP 14. Reinstall the side cover with

all five screws and tighten. Once the

cover is installed, check to make sure

that the shifter operates smoothly with

no binding. If the shifter seems to bind

Photo #6

Photo #7

check to make sure that the reverse

lockout spring loaded detent lever did

not get pulled out from inside the mechanism (See Photo #8). With needle

nose pliers reset the detent while lightly

pushing down on the gate plate.

ADJUSTING THE SHIFTER CABLE

STEP 15. Place the shifter into the

true Neutral position by releasing the

reverse lockout. Hand place the selector lever on the transmission into the

Neutral position. With both, the shifter

and the transmission in the Neutral

position you can begin the final shifter

cable attachment.

STEP 16. Remove from the cable end

the 10-32 nut, the two dust seals and

one 7/16" jam nut and lock washer.

Leave one jam nut and one locking

washer on the cable. Route the cable

through the mid plate so that the cable

end is pointing towards the back of the

car. Once the cable is through the midplate, reinstall the 7/16" lock washer

and the jam nut along with the two dust

seals. Leave loose for the moment.

4

Page 5

STEP 17. Screw the 10-32 jam nut all

the way onto the threaded cable end till

it stops. Then thread the #80323 quick

disconnect extension onto the 10-32

threaded cable end. Leave the jam nut

and the extension loose. Install the

male ball pin from the #80323 quick

disconnect onto the B&M Power glide

Pro Lever selector lever on transmission in the hole marked #2. The ball

end should point outward (See Photo

#9). Use the two jam nuts on the

threaded end so that one nut is on the

front side of the selector lever bracket

and one on the backside. This will

allow you to position the male ball pin

on the selector lever so that it does not

interfere with the transmission case,

the pan, the shield or the chassis (See

Figure #3).

STEP 18. Again, be sure that the

shifter and the transmission are both in

true Neutral. Use the 7/16" jam nuts at

the mid-plate to get the line up of the

male ball pin on the selector lever and

the female pocket of the quick disconnect coupler close, then snug them

against the mid-plate. Use the red 1032 cable extension to obtain the final

micro adjustment by slipping the female quick disconnect coupler over the

ball on the selector lever off and on.

Carefully check to make sure that the

lever is not being pulled forward or

backward (See Photo #10). As you

check each gear position, remove the

quick disconnect coupler from the selector lever ball and shift the shifter and

the transmission separately. Carefully

slip the quick disconnect over the ball

at each gear position. This adjustment

technique will keep you from damaging

the cable should the adjustment be off

slightly. There may be some backlash

in the cable when you’re checking the

adjustment. This is normal. This comes

from the bending of the cable during

routing. The more bends, the more

backlash. Keep your bends to a minimum for best performance. Do your

best to find the most neutral adjustment. When finished, be sure to tighten

all the jam nuts thoroughly. If adjustment does not seem accurate, be sure

that you have the male ball in the

proper #2 hole on the selector lever of

the transmission. If you are not using a

B&M Powerglide Pro Lever the proper

Photo #8

Photo #9

selector radius is 2" from the center of

the selector lever shaft.

Always start your adjustment process with the shifter in Neutral and

the transmission in Neutral. (Do not

use Park to begin adjustment).

HOW TO OPERATE YOUR B&M

PRO BANDIT SHIFTER

This example of the Pro Bandit’s

operation is for use with the Powerglide transmissions utilizing a forward pattern valve body only. The

gate plate is the same for a Powerglide with a reverse pattern valve

body, the only change is that the

Low gear and High gear positions

switch. Other gate plate patterns

are available. The available patterns and their respective part numbers are listed at the end of these

installation instructions.

From the Park position, squeeze the

trigger to allow the release of Park lock

and pull the stick back. The first detent

will be the Reverse position. The second detent will be Neutral. The reverse

5

Page 6

lockout lever function is between the

Reverse position and the Neutral position. The trigger is not required to pull

the stick back to Low gear from Neutral. The third detent will be the High

gear position and the fourth detent will

be the Low gear position.

From Low gear, to shift forward to High

gear just push the stick forward, this

gate is accessible without having to

squeeze the trigger. From High gear

position to access Neutral, squeeze

the trigger and push the stick forward,

this is Neutral for drive around purposes. For true Neutral, you must

push the red reverse lockout lever forward. (Do not hold your hand on the

shifter stick. The stick will move

forward internally by the spring

loaded mechanism). Once the lock-

out lever is forward and the shifter stick

has automatically clicked forward. The

lockout mechanism will now stay open

on it’s own, with no assistance from

the driver. At this point the shifter is in

the true Neutral position. To access

Reverse from the true Neutral position,

simply push the shifter stick forward,

without squeezing the trigger. Squeezing the trigger will open the next gate,

which will be the Park position.

If you wish to rearm the reverse lockout

from the true Neutral position, pull

back slightly on the shifter stick and

you will see the lockout lever snap

back into the lock position.

Optional/Replacement Products

#80710 3-Speed/reverse pattern valve body

#80711 3-Speed/forward pattern valve body

#80712 4-Speed/forward pattern valve body

#80609 Replacement Neutral Safety Switch

#80883 Air Slave Cylinder with bumper

#80323 Quick Disconnect & Cable Extension

#80880 Electronic Control Valve

#80834 8' Super Duty Race Cable

#80833 5' Super Duty Race Cable

#80832 4' Super Duty Race Cable

#80831 3' Super Duty Race Cable

Photo #10

80794:

1 Pro Bandit Shifter

1 Accessory Bag

1 Neutral Safety Switch Wires

1 Installation Instruction

80793 Also Includes:

1 Accessory Bag

1 #80834 Super Duty Race Cable

1 #80323 Quick Disconnect Kit

1 #70465 Pro Lever Kit

1 Neutral Safety Switch Wires

1 Installation Instructions

5/16" out

from dowel pin

hole center

Mid plate

2"

H

B&M

1

T

#2 B&M

2

hole

Jam nuts will

allow positioning

in or out

Figure #1

Mid plate

(out line)

Drill 7/16" hole

for cable anchor

7" down from

center of

dowel pin

Figure #2

(Visit www.bmracing.com for additional products and product information)

6

Page 7

7

Loading...

Loading...