Page 1

Inst allation Instructions

Pro Ratchet Shifter

Part Nos. 80840 and 80841

© B&M Racing & Performace Products 1993

The B&M Pro Ratchet shifter is a full

ratchet shifter that is equally at home on the

strip and on the street. It will work with most

popular three speed automatic transmissions.

It has a positive ratchet design so that you will

not miss a shift, either up or down. It works

with both standard and reverse pattern valve

bodies. It has a unique “one hand” reverse

lockout feature that meets NHRA and IHRA

requirements. You don’t need to use two

hands to shift into reverse.

Part No. 80840 is for use only with aluminum Powerglide transmissions. 80841 is for

use with three speed automatic transmissions: GM TH-400, TH-350, TH-250 and

TH-200; Ford C-4 and C-6; and Chrysler

1966 and later Torqueflite A-727 and A-904.

Your B&M Pro Ratchet comes equipped

with a Neutral safety and backup light

switches, transmission brackets and levers

and a five foot shift cable. Optional shifter

cables in 2 ft. (80830),3 ft. (80831), 4 ft.

(80832), 8 ft. (80834), 10 ft. (80835) and 12

ft. (80836) are also available.

Please read the instructions and review

the illustrations thoroughly before beginning

the installation.

The mechanical components of this

shifter are precision made and assembled at

our factory. Any modification or disassembly

of these parts can cause the shifter to malfunction and will void the warranty. You should

disassemble only those items outlined in the

instructions.

The vehicle should be about 2 feet off the

ground for ease of installation. Use jack

stands, wheel ramps or a vehicle lift. Make

sure the vehicle is firmly supported before

attempting to work on it.

IMPORTANT: If your vehicle is equipped

with a locking steering column. Securing the

column lock lever in the engine compart-

ment in the full up position will allow the

steering wheel to be locked and unlocked

and the ignition key to be removed.

WARNING: This allows the steering wheel

to be locked WHENEVER the ignition key is

turned to the “lock” position WHILE THE

VEHICLE IS MOVING, OR AT ANY OTHER

TIME. Securing the steering column lock

lever in any other position will both PREVENT the steering wheel from locking and

removal of the ignition key.

INS TALLATION

STEP 1. Remove stock shift linkage;

Column Shifters: Remove all rods, levers or

cables from column and transmission. Place

column shift lever in “Park” position. Remove

pin holding shift lever in column and remove

lever assembly. If your vehicle is equipped

with a locking steering column, secure the

column lock lever in the full up position.

WARNING: This allows the steering wheel

to be locked and ignition key removed WHENEVER the ignition key is turned to the “lock”

position WHILE THE VEHICLE IS MOVING, OR AT ANY OTHER TIME.

Console Shifters: Remove shifter mechanism from console. Disconnect rod or cable

from transmission. Remove cable bracket if

equipped. If there is a cable or linkage from

the console shifter or transmission to the

steering column lock, it must be blocked in

the “Park” position as described above.

NOTE: Shifter installation may require console modification or complete console removal depending on the space available in

your vehicle.

STEP 2. Pull the carpet, if any, away from

the floorboard where the shifter is to be

mounted. If the vehicle has a bench type

seat, move seat to the full forward position.

Place the shifter on the floor with the stick

shifted to the rearmost position. Locate the

shifter for ease and convenience of operation. See figure 2 for shifter dimensions.

(The rear mounting hole of the mechanism

must be at least 1¾” from the front of the seat

when the seat is in the full forward position.)

Make sure the knob clears the dash with the

shifter in the forward position. Mark the position of four mounting holes on the floor.

STEP 3. Drill four 9/32" mounting holes

where marked. Temporarily mount the shifter

in place using washers as required to get it

level. Mark the location for the shifter cable

hole, 3" ahead of the front shifter mounting

hole. Drill or cut 1½” diameter cable hole in

floorboard. NOTE: Some floorboards are

extremely thin and will not adequately support the shifter mechanism when bolted to

the floor. For those vehicles we recommend

that you fabricate a stiffener plate for additional strength.

STEP 4. Install (but do not secure) carpet

back to it’s original position. Cut holes in the

carpet for the mounting holes and a 1½” slit

for the cable. DO NOT use a drill bit to make

holes in carpet.

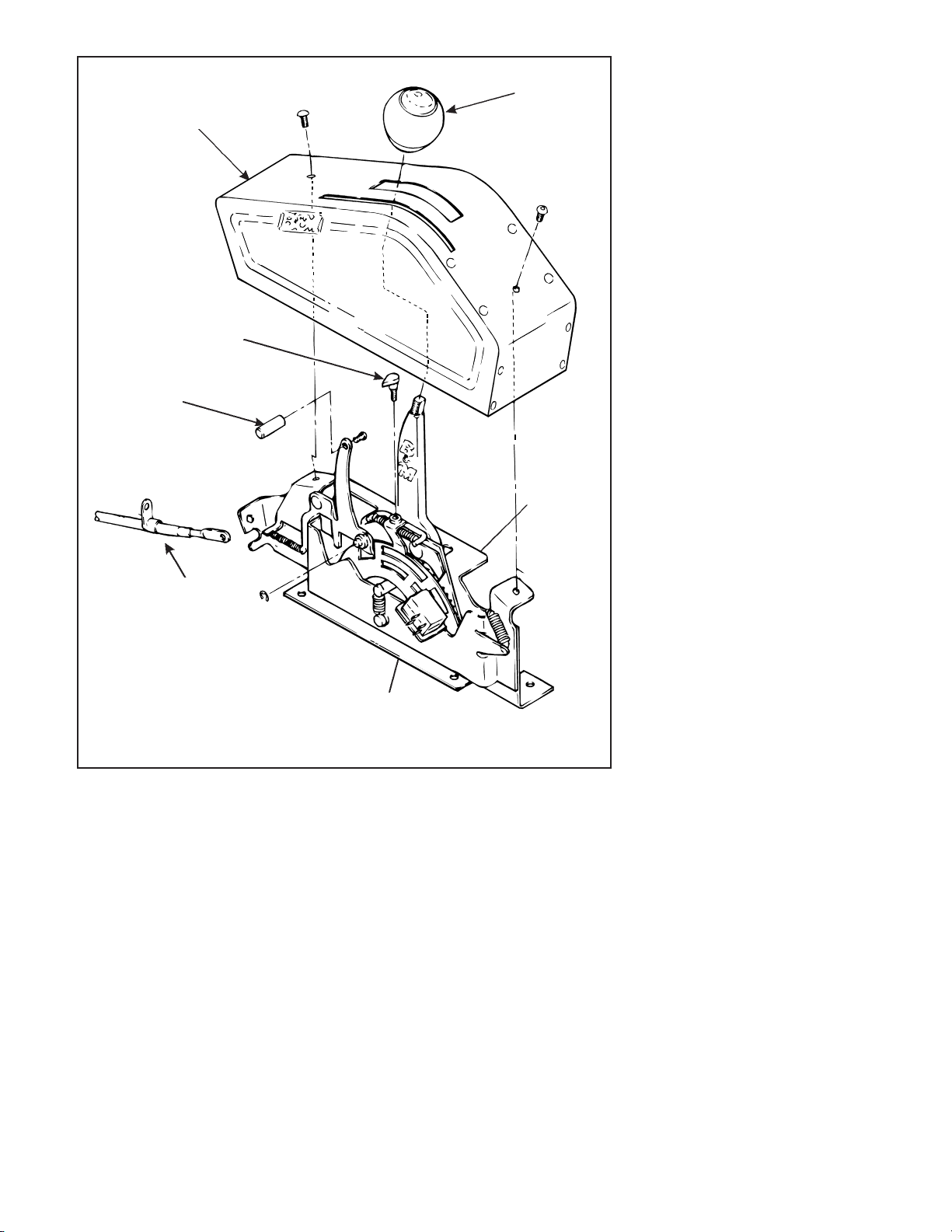

STEP 5. Install the cable on shifter as

shown in figure 1. The cable attachment tab

should be bolted to the outside surface of the

shifter base using ¼” X ½” bolt, lock washer

and nut. Install E-Ring to secure the cable.

STEP 6. Install the backup light switch and

the neutral safety switch in place on the

shifter mechanism. Install using two #4-40

screws, nuts and lock washers, as shown in

figure 1. If necessary bend the fingers slightly

so that they engage the slots. Beware, Over

tightening the switch attachment screws will

crack the switch housings. Adjust switches

so that the neutral safety switch (the lower

switch) operates in Neutral and Park only

and so that the backup light switch (the

Printed in U.S.A.

9500513-02

Page 2

Cover

Pointer

Reverse lockout

handle

Cable

E-ring

Figure 1

upper switch) operates in Reverse only by

loosening screws and sliding switch as required. Then retighten screws.

STEP 7. Install the shifter mechanism into

vehicle. Slide the shifter cable through carpet

and hole in floor. Bolt shifter down using four

¼” hex bolts and nuts. If required use ¼”

washers as shims between the shifter mechanism and the floor to level shifter. Do not

bend the shifter mounting tabs. ROUTE

CABLE AS SHOWN IN FIGURE 3, AVOID

SHARP BENDS WHICH WILL KINK AND

DAMAGE CABLE. Use cable clamps or tie

wraps to secure the cable housing to the

chassis to avoid contact with hot engine or

exhaust system. Seal cable hole shut to

avoid the entry of exhaust fumes or water.

For General Motors vehicles with three speed

transmissions go to Step 8, For Ford ve-

hicles got to Step 13, For Chrysler vehicles

go to Step 19. For aluminum Powerglide

equipped vehicles go to Step 25.

Knob

Backup light

switch

(Upper)

Neutral safety

switch

(Lower)

GENERAL MOTORS

STEP 8. If you have not already done so,

remove the stock selector lever nut and selector lever. Discard stock lever and stock shifter

linkage. Install B&M selector lever in position

using stock selector lever nut, see figure 4.

Torque nut to 23 lb. ft. The lever should move

smoothly from front to rear with a positive click

in each gear position.

STEP 9. Remove two transmission oil pan

bolts from the middle of the left side of the oil

pan. Install cable bracket in position, see fig-

ure 4.) The bracket must be installed with two

spacers between the pan and bracket. (If your

transmission is equipped with a cast aluminum oil pan, these spacers should be omitted

however the cable bracket may have to be

modified.) Install the two 5/16-18 x 1.00" bolts

supplied and tighten 12-13 lb-ft. Do not overtighten as this can damage pan gasket.

STEP 10. Route the shifter cable according to

figure 3. Avoid kinks and sharp bends and

route the cable away from hot engine or

exhaust parts.

Remove the two rubber boots, one

large nut, and a large lockwasher her from

the threaded end of the shifter cable. Slide

the end of the cable into the cable bracket,

Install large nut and lockwasher loosely

over end of cable. Install two rubber boots

onto end of cable. Install the swivel on the

threaded end of the cable and position it in

the center of the threaded portion.

STEP 11. Move the transmission selector

lever by hand to full rear position (LOW).

Operate the shifter lever to the low gear

position (ratcheted all the way back). Adjust the large nuts on the cable so that the

swivel will slide into the rear hole on the

selector lever. Tighten the large nuts completely. Be sure that the swivel will slide

freely in and out of the hole in the selector

lever. Note: The shifter will not operate

correctly unless the rear hole in the

shift lever is used.

Leave the swivel out of the hole and

move the selector lever to PARK, all the

way forward. Also move the shifter to PARK

position (all the way forward). Reinsert the

swivel into the rear hole in the selector

lever. Check to see that the swivel will slide

freely in and out of the rear hole in the

selector lever in this position. If it does not

slip in freely, adjust the swivel slightly until it

will slip into the hole in the lever.

Move the shifter back to the low gear

position and check that the swivel will still

slide easily in and out of the rear hole in the

selector lever. (If you do not use the rear

hole in the lever, it will be impossible to

correctly adjust the cable.) Operate shifter

through all gear positions. Check to make

sure swivel will slide in and out of the rear

selector lever hole in each gear position.

The shift cable is now correctly adjusted.

Install cotter key supplied with shifter into

swivel and spread key ends.

If you have a problem, DO NOT FORCE

THE SHIFTER, this will damage the cable,

the shifter or the transmission. Simply start

at the beginning and check all your steps.

STEP 12. On GM vehicles, the Neutral

safety/backup light switch is located on the

console shifter or steering column. Locate

and identify the Neutral safety switch (the

engine will not crank unless these wires are

connected together). Disconnect Battery

ground cable before beginning to wire the

Neutral safety switch. Reroute the wires to

the B&M Pro Ratchet.

On GM vehicles the neutral safety switch

may be located on the shifter (steering

column or console), or it may be a mechanical interlock in the steering column

that prevents the key from turning to the

Start position unless the shifter is in the

Park or Neutral position. Identify the type of

2

Page 3

neutral safety system you have. If the key will

not turn to the Start position unless the stock

shifter is in Park or Neutral, you have a

mechanical interlock, otherwise you have a

neutral safety switch. With either type, disconnect battery ground cable to prevent

accidental shorts. If you have a neutral safety

switch, locate and identify the neutral safety

wires (engine will not crank unless these

wires are connected together). Extend the

wires from the GM switch to the shifter. Strip

1/4" insulation off the wires and install slip-on

terminals supplied in kit. Crimp terminals

onto wires using a crimping tool or pliers.

Connect the Neutral safety wires to the

LOWER switch and the backup light wires to

the UPPER switch, see figure 1. Tape termi-

nal connections and all other connections to

prevent shorts.

If you have a mechanical interlock cut the

wire that goes from the start position on the

ignition switch to the solenoid on the starter.

This wire is usually a 10 or 12 gauge purple

wire. Run wires from both ends of the cut

wire to the B&M Pro Ratchet. Put slip-on

terminals on the ends of the lengthened wire.

Crimp terminals onto wires using a crimping

tool or pliers. Connect the wires to the

LOWER switch on the shifter. The backup

Figure 2

Figure 3

3

Page 4

GM cable bracket

Spacer

Use these two holes for

TH-400 transmission. Use

other two holes for other

GM transmissions

Spacer

Cable swivel

Cotter pin

(Use rear hole)

light switch is usually located on the steering

column behind the instrument panel.

Lengthen these wires and run them to the

UPPER switch on the shifter. Tape terminal

connections and all other connections to

prevent shorts.

Reconnect battery ground cable, disconnect coil wire and set the parking brake.

Check switch operation by attempting to

start motor in each shifter position. The

starter must crank only when shifter is in

the Park or Neutral position. Check

Backup light operation when the shifter is

shifted to the Reverse position. Adjust

switches if required. Reconnect coil wire. Go

GM lever

5/16 x 1" bolt and spacer

(Metric trans use M8 x 25 bolt)

7/16" nut

GM cable bracket (Trimming of bracket

required if used on cast aluminum pan)

Figure 4

to Step 37.

FORD

STEP 13. If you have not already done

so, remove the nut and lockwasher holding

the downshift linkage onto the downshift

lever shaft. The downshift lever is the outer

lever on C-4, C-5 and C-6 transmissions.

Pull the lever off the shaft and allow the

linkage to hang free. Remove and discard

stock shift linkage rods. Some C-6, late C-4

and all C-5 transmissions have a neutral

safety/backup light switch on the transmission shift lever. If your transmission is so

equipped, remove the two bolts holding the

1/4 x 1-1/2" bolt, lockwasher and nut

switch in place and slide it off the shift shaft.

Disconnect the switch at the factory plug and

discard it.

STEP 14. Install the B&M selector lever, see

figure 5 or 6. Note: The B&M lever must

point downward for proper operation. If the

stock shift lever on your transmission points

down, you will have to remove the lower part

of the stock arm by cutting it off to clear the

B&M lever, see figure 5. Install B&M selector lever onto shift shaft of transmission. Align

selector lever so when it points straight down

it travels equal arcs in both directions from

center, then tighten ¼”-20 x 1 ½” pinch bolt

and nut. The lever should travel smoothly

Ford lever

Cable swivel

Cotter pin

Figure 5

C-4 cable bracket

4

7/16" nut

Remove shaded

portion of lever

Page 5

from front to back with a positive click in each

gear position. Make sure O-ring is in position

on downshift shaft and install downshift lever

in position on shaft. Install lockwasher and

nut and tighten securely. Downshift lever

must operate smoothly. Reconnect downshift linkage.

STEP 15. Cable bracket installation:

C-4, C-5: Remove the two lower bolts from

the rear servo cover. Install cable bracket in

position, see figure 5. Install two servo cover

bolts as removed and tighten 12-13 ft. lb. Do

not overtighten as this can distort servo cover.

C-6: Remove the two transmission oil pan

bolts from the left rear corner of the oil pan.

Install cable bracket in position, see figure 6.

with two spacers between the pan and

bracket. (If your transmission is equipped

with a cast aluminum oil pan, these spacers

are omitted.) Install the two 5/16-18 x 1.00"

bolts supplied and tighten 12-13 ft-lb. Do not

overtighten as this can damage pan gasket.

STEP 16. Route the shifter cable according

to figure 3 Avoid kinks and sharp bends and

route the cable away from hot engine or

exhaust parts.

Remove the two rubber boots, one large

nut, and a large lockwasher from the threaded

end of the shifter cable. Slide the end of the

cable into the cable bracket, Install large nut

and lockwasher loosely over end of cable.

Install two rubber boots onto end of cable.

Install the swivel on the threaded end of the

cable and position it in the center of the

threaded portion.

STEP 17. Move the transmission selector

lever by hand to full rear position (LOW).

Place the shifter lever to the low gear position

(ratcheted all the way back). Adjust the large

nuts on the cable so that the swivel will slide

into the hole on the selector lever. Tighten

the large nuts completely. Be sure that the

swivel will slide freely in and out of the hole in

the selector lever.

With the swivel in the selector lever,

move the shifter to PARK position, as far

forward as the shifter will go without forcing

it. (The shifter has further travel that is used

to reach the GM park position but is not used

on Ford transmissions. Trying to force the

cable will damage the cable.) The shift lever

on the transmission should be all the way

forward. Check to see that the swivel will slide

freely in and out of the hole in the lever in this

position. If it does not slip in freely, adjust the

swivel slightly until it will slip into the hole in the

lever in both LOW and PARK positions.

Operate shifter through all gear positions.

Check to make sure swivel will slide in and

out of the selector lever hole in each gear

position. Install cotter key supplied with

shifter into swivel and spread key ends.

If you have a problem, DO NOT FORCE

THE SHIFTER, this will damage the cable,

the shifter or the transmission. Simply start at

the beginning and carefully check all your

1/4" x 1-1/2" bolt,

lockwahsher, nut

Ford

lever

Cable swivel

Cotter pin

5/16" x 1" bolt

and spacer

Figure 6

steps.

IMPORTANT: Do not froce the shifter to

over travel into the Park position. This will

move the shifter into GM Park position and

will damage the cable or transmission.

STEP 18. On Ford vehicles, the Neutral

safety/Backup light switch is located on the

transmission (or on the steering column on

some early vehicles). If the vehicle has an

AOD transmission the Neutral safety/Backup

light switches on the B&M shifter will NOT be

used. The Neutral safety/Backup light switch

on the AOD transmissions will continue to

function normally.

On the C-4 and C-5 transmissions it is

necessary to completely remove the stock

Neutral safety/Backup light switch in order to

install the B&M transmission shift lever. On

C-4, C-5 and C-6 transmissions, it will be

necessary to hook up the Neutral safety/

Backup light switches on the B&M Pro

Ratchet. Locate and identify the Neutral

safety (the engine will not crank unless these

wires are connected together), and Reverse

light wires. Disconnect Battery ground cable

before beginning to wire the Neutral safety

and Reverse light switches. Reroute the

wires to the B&M Pro Ratchet . Strip 1/4"

insulation off wires and install supplied slipon terminals. Crimp terminals onto wires

using a crimping tool or pliers. Connect the

Neutral safety wires to the LOWER switch

and the Reverse light wires to the UPPER

switch, see figure 1. Tape terminal connec-

tions to prevent shorts. Reconnect battery

ground cable, disconnect coil wire and set

the parking brake. Check switch operation

by attempting to start motor in each shifter

C-6 cable

bracket

7/16" nut

position. The starter must crank only when

shifter is in the Park or Neutral position.

Check Backup light operation when the shifter

is shifted to the Reverse position. Adjust

switches if required. Reconnect coil wire. Go

to Step 37.

CHRYSLER

STEP 19. If you have not already done so,

loosen pinch bolt on throttle lever on transmission. This is the lever on the small diameter shaft. Pry the lever off with a screwdriver

and allow linkage to hang free. Remove and

discard stock shift lever and stock shift linkage. Install B&M selector lever in position and

tighten pinch bolt securely, see figure 7.

Make sure lever is not pushed down so far as

to touch the transmission case. This will

cause the lever to bind on the case. The lever

should travel smoothly from front to back with

a positive click in each gear position. Install

stock throttle lever in position on small diameter shaft as removed and tighten pinch bolt

securely. Throttle lever must operate

smoothly.

STEP 20. Remove the two transmission

oil pan bolts directly below the shift lever.

Install cable bracket in position, see figure 7.

with two spacers between the pan and

bracket. (If your transmission is equipped

with a cast aluminum oil pan these spacers

can be omitted.) Install the two 5/16-18 x

1.00" pan bolts supplied and tighten to 1213ft-lb. Do not overtighten as this can damage pan gasket.

STEP 21. Route the shifter cable according

to figure 3 . Avoid kinks and sharp bends and

route the cable away from hot engine or

exhaust parts.

5

Page 6

7/16" nut

Chrysler cable

bracket

5/16" x 1" bolt and spacer

Figure 7

Remove the two rubber boots, one large

nut, and a large lockwasher from the threaded

end of the shifter cable. Slide the end of the

cable into the cable bracket, Install large nut

and lockwasher loosely over end of cable.

Install two rubber boots onto end of cable.

Install the swivel on the threaded end of the

cable and position it in the center of the

threaded portion.

STEP 22. Move the transmission selector

lever by hand to full forward position (LOW).

Place the shifter lever to the low gear position

(ratcheted all the way back). Adjust the large

nuts on the cable so that the swivel will slide

into the hole on the selector lever. Tighten

the large nuts completely. Be sure that the

swivel will slide freely in and out of the hole in

the selector lever.

With the swivel in the selector lever,

move the shifter to PARK position, as far

forward as the shifter will go without forcing

it. (The shifter has further travel that is used

to reach the GM park position but is not used

on Chrysler transmissions. Trying to force

the shifter will damage the cable.) The shift

lever on the transmission should be all the

way back. Check to see that the swivel will

slide freely in and out of the hole in the lever

in this position. If it does not slip in freely,

adjust the swivel slightly until it will slip into the

hole in the lever in both LOW and PARK

positions. Operate shifter through all gear

positions. Check to make sure swivel will

slide in and out of the selector lever hole in

each gear position. Install cotter key supplied with shifter into swivel and spread key

ends.

If you have a problem, DO NOT FORCE

THE SHIFTER, this will damage the cable,

the shifter or the transmission. Simply start at

Chrysler lever

1/4" x 1-1/2" bolt,

lockwasher, nut

Cable swivel

Cotter pin

the beginning and carefully check all your

steps.

IMPORTANT: Do not froce the shifter to

over travel into the Park position. This will

move the shifter into GM Park position and

will damage the cable or transmission.

STEP 23. Check operation of throttle linkage again. Linkage must operate smoothly

with no bind. All transmissions using automatic valve bodies must have the throttle

linkage connected and operating or transmission damage will result.

STEP 24. Neutral Safety/Backup Light

switch.

’66-’68: The Neutral safety switch will continue to function normally. It will not be necessary to hook up the Neutral safety switch

wires on the shifter. Disconnect the battery

ground cable before wiring the Backup light

switch. Locate the original Backup Light

switch on the steering column or console

shifter. Run these wires to the UPPER switch

on the B&M Pro Ratchet, see figure 1.

Reconnect ground wire and check light for

proper operation. Adjust switches on the

shifter if required.

’69 and Later: The Neutral Safety/Backup

switch is located on the transmission and will

continue to function normally. It will not be

necessary to connect any wires to the

switches on the shifter. Go to Step 37.

POWERGLIDE

STEP 25. Disconnect the throttle to trans-

mission linkage, if any and discard. The

Powerglide shift lever supplied with this shifter

has no provision for a throttle linkage.

STEP 26. Drain transmission oil pan. Caution: Be sure transmission is cool before

attempting to drain oil. Place drain pan

under transmission. Remove drain plug, if so

equipped. If your pan does not have a drain

plug, remove oil pan bolts one at a time,

working towards the front. As you loosen the

last two bolts, the oil pan will tilt down and

allow the oil to drain. Note; If your oil pan

sticks to the gasket, pry it down with a screwdriver before loosening the last two bolts to

break it free. Remove oil pan and set aside.

Step 27. Remove manual valve guide plate

by removing two bolts. See figure 8. Unhook and remove detent roller spring. Allow

detent roller to pivot out of the way. Not how

the pin on the manual valve selector engages the groove in the manual valve.

STEP 28. If your transmission has a throttle

valve lever on the outside of the shift lever,

loosen the inner pinch bolt on the throttle

lever. Slide the throttle lever and shaft out of

the transmission. Remove the inner throttle

valve lever. Discard these parts.

STEP 29. Loosen the pinch bolt on the selector lever. This can be either an Allen head

bolt of a 12 point bolt head. Do not remove

the pinch bolt. Slightly pry the manual valve

lever and slide selector shaft from the transmission. Discard selector shaft.

STEP 30. This transmission includes the

B&M Powerglide Pro-Lever shift lever, which

is a two piece lever with separate lever and

shaft. Install B&M selector shaft into transmission with the lever pointing down. Hold

the stock selector lever in position in the

case, engage the pin on the selector lever

with the manual valve and rotate the B&M

shaft until the flat on the shaft engages the

serrations on the lever. Push B&M lever

firmly into the transmission until lever stops

on shoulder of shaft. Tighten pinch bolt securely.

STEP 31. Install manual valve guide plate in

place. (Make sure that pin on selector lever is

engaged in groove in manual valve.) Install

the two bolts and tighten to 15 lb-ft. Install

detent roller spring. Hook spring to detent

roller and tab. Selector lever must travel

freely and smoothly from front to back with a

positive click in each gear position.

STEP 32. Clean oil pan and scrape old gasket off of pan and case. (Note: if your pan

does not have a drain plug, you may wish to

install a B&M Drain Plug Kit, part number

80250, at this time.) Old gasket can cause

leaks. Install oil pan with new gasket. Install

pan bolts except for the two center bolts on

left side of pan. Tighten pan bolts to 8 lb-ft. Do

not overtighten as this can damage the pan

gasket.

STEP 33. Install cable bracket in position

with the two remaining pan bolts. See figure

8. Install the B&M lever onto the shaft with the

lever pointing down. If your cable comes

from the front (usually a rear engined car) the

lever is installed pointing upwards. You will

have to make your own cable bracket for this

installation.

STEP 34. Route the shifter cable according

6

Page 7

Cable bracket

mounts on outside

of oil pan

Detent roller spring

Manual valve guide plate

Manual valve

Note that pin on

selector lever fits in

groove in valve.

B&M shifter lever

B&M selector

shaft

Figure 8

to figure 3. Avoid kinks and sharp bends and

route the cable away from hot engine or

exhaust parts.

Remove the two rubber boots, one large

nut, and a large lockwasher her from the

threaded end of the shifter cable. Slide the

end of the cable into the cable bracket, Install

large nut and lockwasher loosely over end of

cable. Install two rubber boots onto end of

cable. Install the swivel on the threaded end

of the cable and position it in the center of the

threaded portion.

STEP 35. Move the transmission selector

lever by hand to full rear position (LOW).

Operate the shifter lever to the low gear

position (ratcheted all the way back). Adjust

the large nuts on the cable so that the swivel

will slide into the hole in the selector lever that

is labeled "B&M 2". See figure 9. Tighten the

large nuts completely. Be sure that the swivel

will slide freely in and out of the hole in the

selector lever. Note: The shifter will not

operate correctly unless the B&M2 hole

in the shift lever is used.

WARNING

PERIODIC INSPECTION AND MAINTENANCE OF YOUR SHIFTER

IS RECOMMENDED TO ENSURE THAT THE MECHANISM IS WELL

LUBRICATED, FREE FROM DIRT OR RUST AND THAT THE CABLE

IS PROPERLY ADJUSTED. LACK OF MAINTENANCE COULD RE-

SULT IN A FAILURE INCLUDING A FAILURE OF THE REVERSE

LOCKOUT SAFETY FEATURE.

Selector lever

pinch bolt

Use this hole for Hurst

shifter and B&M Bandit shifter

Use this hole for B&M

Pro Stick, Megashifter

or Street Stick

Use this hole for B&M

Pro Ratchet, Quick

Silver, Star Shifter, Zgate, or Quick Click

Use this hole for Turbo

Action shifter

Figure 9

7

Page 8

TOOL LIST

1 Phillips screwdriver

1 7/16 socket

1 Ratchet or speed handle

1 7/16" wrench

1 1/2" wrench

1 9/16" wrench

2 11/16 wrench

1 3/32" Allen key

1 1/8" Allen key

1 9/32 drill bit

1 drill motor

1 1-1/2" holesaw

1 Crimping tool

1 Torque wrench 0-50 ft.lbs.

1 File

1 Tin snips

1 Wire strippers

1 Ruler

1 Dividers

1 Electrical tape

1 Hacksaw

1 Hammer

1 Drift pin

2-4 Jackstands

A/R Cable ties

CHECK LIST

__ Locking steering column lever is permanently fastened in the full up position. Step 1.

__ Shifter is convenient to reach and has ample room for your hand in both park and low gear.

Step 2.

__ Carpet covers floorboard holes. Step 4.

__ Cable is securely fastened to the shifter and held with E-Ring. Step 5.

__ Shifter is securely mounted to floorboard. Step 7.

__ Shifter cable is clear of exhaust system, engine and any moving parts. Step 7.

__ Throttle lever and shift lever are tight on transmission. GM step 9, Ford Step 14, Chrysler

Step 20, Powerglide Step 30.

__ Oil pan bolts are tightened to 12-13 lb.ft. GM Step 10, Ford Step 16, Chrysler Step 21,

Powerglide Step 33.

__ Shifter is properly adjusted. Cable boots are installed, cable nuts are tightened and swivel

is secured with cotter key. GM Step 11, Ford Step 17, Chrysler Step 22, Powerglide

Step 35.

__ The Neutral safety switch is connected and properly adjusted to prevent engine starts

in drive gears and reverse. GM Step 12, Ford Step 18, Chry not required, Powerglide

Step 36.

__ There is no debris in the shifter mechanism.

__ Cover installed. Step 37.

__ Shifter moves freely in all positions as described in Shifter Operation.

__ If your shifter is not working properly do not attempt to drive your car. Make sure you have

followed all instructions. If the shifter is broken or defective return it to your B&M dealer.

Leave the swivel out of the hole and

move the selector lever to PARK, all the way

forward. Also ratchet the shifter to PARK

position (all the way forward). Reinsert the

swivel into the B&M2 hole in the selector

lever. Check to see that the swivel will slide

freely in and out of the B&M2 hole in the

selector lever in this position. If it does not slip

in freely, adjust the swivel slightly until it will

slip into the B&M2 hole in the lever.

Move the shifter back to the low gear

position and check that the swivel will still

slide easily in and out of the B&M2 hole in the

selector lever. (If you do not use the B&M2

hole in the lever, it will be impossible to

correctly adjust the cable.) Operate shifter

through all gear positions. Check to make

sure swivel will slide in and out of the B&M2

selector lever hole in each gear position. The

shift cable is now correctly adjusted. Install

cotter key supplied with shifter into swivel

and spread key ends.

If you have a problem, DO NOT FORCE

THE SHIFTER, this will damage the cable,

the shifter or the transmission. Simply start at

the beginning and carefully check all your

steps.

STEP 36. Disconnect battery ground

cable to prevent accidental shorts. Identify

the neutral safety wires (engine will not crank

unless these wires are connected together).

Extend the wires to the shifter. Strip 1/4"

insulation off the wires and install slip-on

terminals supplied in kit. Crimp terminals

onto wires using a crimping tool or pliers.

Connect the Neutral safety wires to the

LOWER switch and the backup light wires to

the UPPER switch, see figure 1. Tape termi-

nal connections and all other connections to

prevent shorts.

Reconnect battery ground cable, disconnect coil wire and set the parking brake.

Check switch operation by attempting to

start motor in each shifter position. The starter

must crank only when shifter is in the

Park or Neutral position. Check Backup

light operation when the shifter is shifted to

the Reverse position. Adjust switches if required. Reconnect coil wire.

STEP 37. With the shifter bolted securely

to the floor be sure that the shifter operates

correctly. Check to see that There is a piece

of insulating tape on the inside of the brushed

aluminum cover on the drivers’s side. This is

to prevent the terminals on the switches from

shorting out. Install the brushed aluminum

cover over the shifter. Put the cover over the

stick and then push the stick forward. Hook

the front of the cover over the front of the

shifter mechanism and then put the rear of

the cover over the rear of the mechanism.

The cover is secured by two button head

#10-32 screws. Install the handle on the

Reverse lockout lever using the #8-32 button head screw, The handle should stick out

to the left of the shifter for easier one hand

operation. Screw the red indicator pointer

through the slot in the cover into the threaded

IMPORTANT

Before installing the knob onto the

shifter put Loctite on the threads of

the stick. The knob may gall on the

threads of the stick and make it impossible to remove the knob from the

stick. If this occurs it can cause the

stick to break if you use excessive

force while attempting to remove the

knob from the stick.

8

end of the indicator lever. Use loctite to keep

the indicator pointer from turning. Select the

correct indicator tape from the sheet and

install it to the left of the pointer.

STEP 37. Tighten knob onto stick securely. Thread sealer will help keep the knob

from loosening. Position knob insert on top

of knob and align Pro Ratchet logo. Push

down on insert to snap it in place. Secure

carpet to floorboard and door edges. Your

shifter is now ready to use.

OPERATION

The B&M Pro Ratchet is a ratchet shifter.

You push the stick forward for up shifts and

pull it back for down shifts (with a standard

pattern valve body). The ratchet shift allows

firm, positive, no-miss upshifts and downshifts. Move the knob forward or backwards

as far is it will go to select the next gear. Then

let the spring return the stick to the central

position. When you shift from Drive to Neutral the reverse lockout prevents the shifter

from shifting any further (to prevent accidental selection of Reverse). To shift to Reverse

the reverse lockout lever must be pushed

forward. When the reverse lockout lever is

pushed forward (with the shifter in Neutral)

the lever snaps into the up position and is

held there until the shifter is shifted to Reverse, so only one hand is needed.

On GM TH-200, TH-250, TH-350, TH400 and Powerglide transmissions it is necessary to shift the ratchet twice to get from

Reverse to Park. These transmissions have

twice the travel from Reverse to Park as

between the other gears. If you only ratchet

once out of Reverse you will not be fully

in Park gear and the car may move.

Loading...

Loading...