Page 1

Installation Instructions

Precision Sport Shifter

2003 and up Nissan 350Z/370Z

2003 and up Infiniti G35/G37

(see www.bmracing.com for the latest vehicle fitment applications and model years)

Part Number 45163

©2009, 2004, 2003 by B&M Racing and Performance Products

This B&M Short Throw Shifter has been designed to work on most 2003 and up Nissan 350Z/370Z and 2003 and up

Infiniti G35/G37 model vehicles. It has been engineered to greatly reduce shift throw and improve shifter feel. Check the

parts and tools lists at the beginning of these instructions for the supplied parts and the tools required to install your B&M

Short Throw Shifter. Installation of this B&M Short Throw Shifter can be accomplished by anyone with minimal

mechanical experience.

INTRODUCTION

This B&M Short Throw Shifter can be installed in less than an hour by carefully following the instructions. Read all

instructions first to familiarize yourself with the parts, tools, and procedures. This kit contains all the parts necessary to

install the shifter .

*NOTE: Do not attempt to disassmble shifter unit. This shifter has been precision assembled at B&M under

exacting tolerances and at extreme pressures. Disassembly of the shifter unit will void warranty.

Shifter*

A

Sleeve

M6 bolt (3),

Flat washer (3),

& Serrated

washers (3)

PARTS

B

D

Grease

Mounting Plate

C

E

Printed in the U.S.A.

9500791-05

Page 2

Socket(10 & 12mm)

TOOLS

Socket Drive/

Torque Wrench

Extension

Channel Locks

File

Hex Drive (5 mm)

DISASSEMBLY

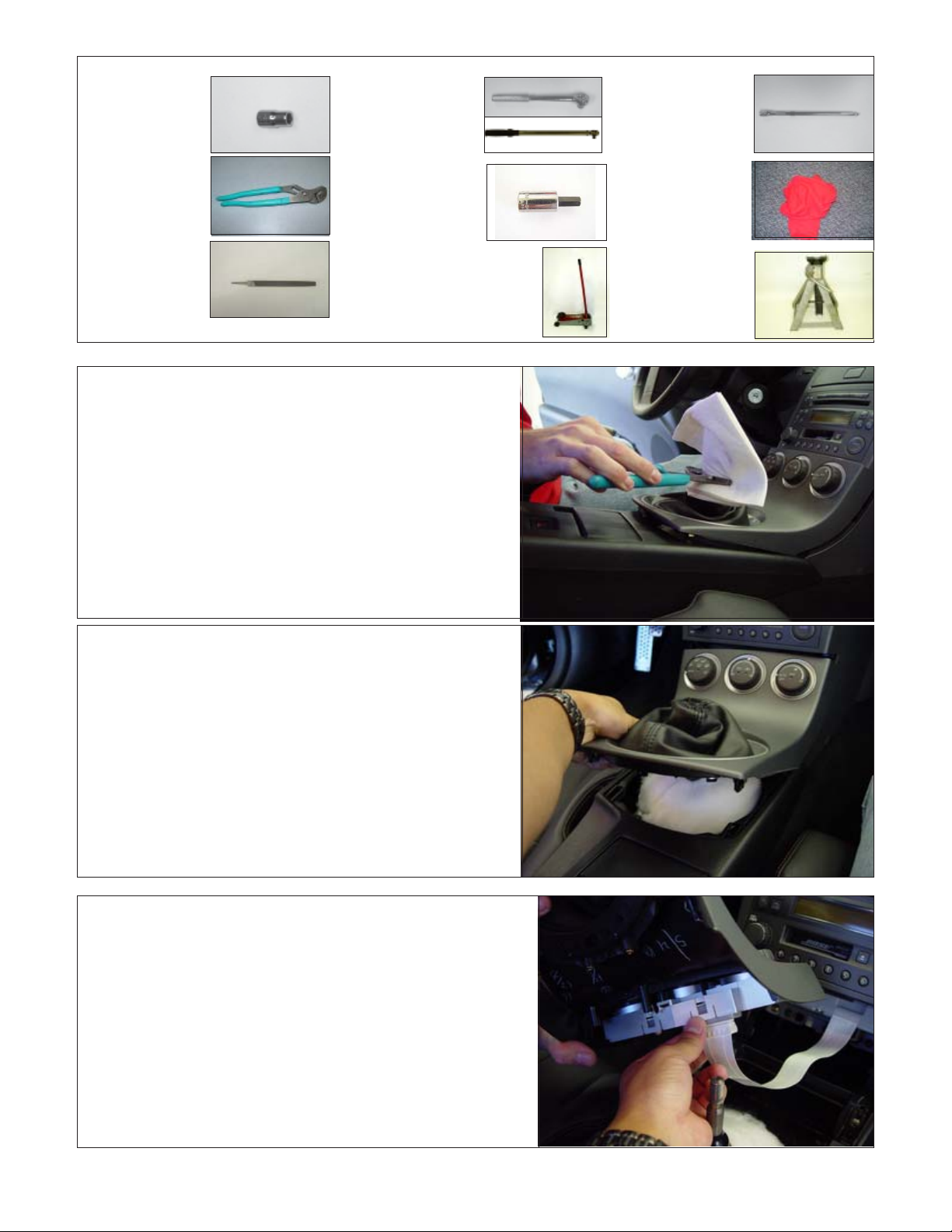

STEP 1. Park vehicle on a level area and allow time to cool.

Unscrew knob and remove. Also, remove small

insert under knob (will not be used on new shifter).

TOOLS: Channel Locks & Towel.

NOTE: In some vehicles it may be VERY difficult to

remove the shift knob without damaging it. If

this is the case in your vehicle, it may be

possible to proceed through all the disassembly

steps carefully lifting up on the center console

plate and rubber boots to access the hardware.

Then finally removing the knob as described in

the final disassembly step 13.

Jack

Towel

Jack Stands (4)

STEP 2. Lift up console plate.

STEP 3. Unplug wiring harness from console plate and

remove console plate.

Page 3

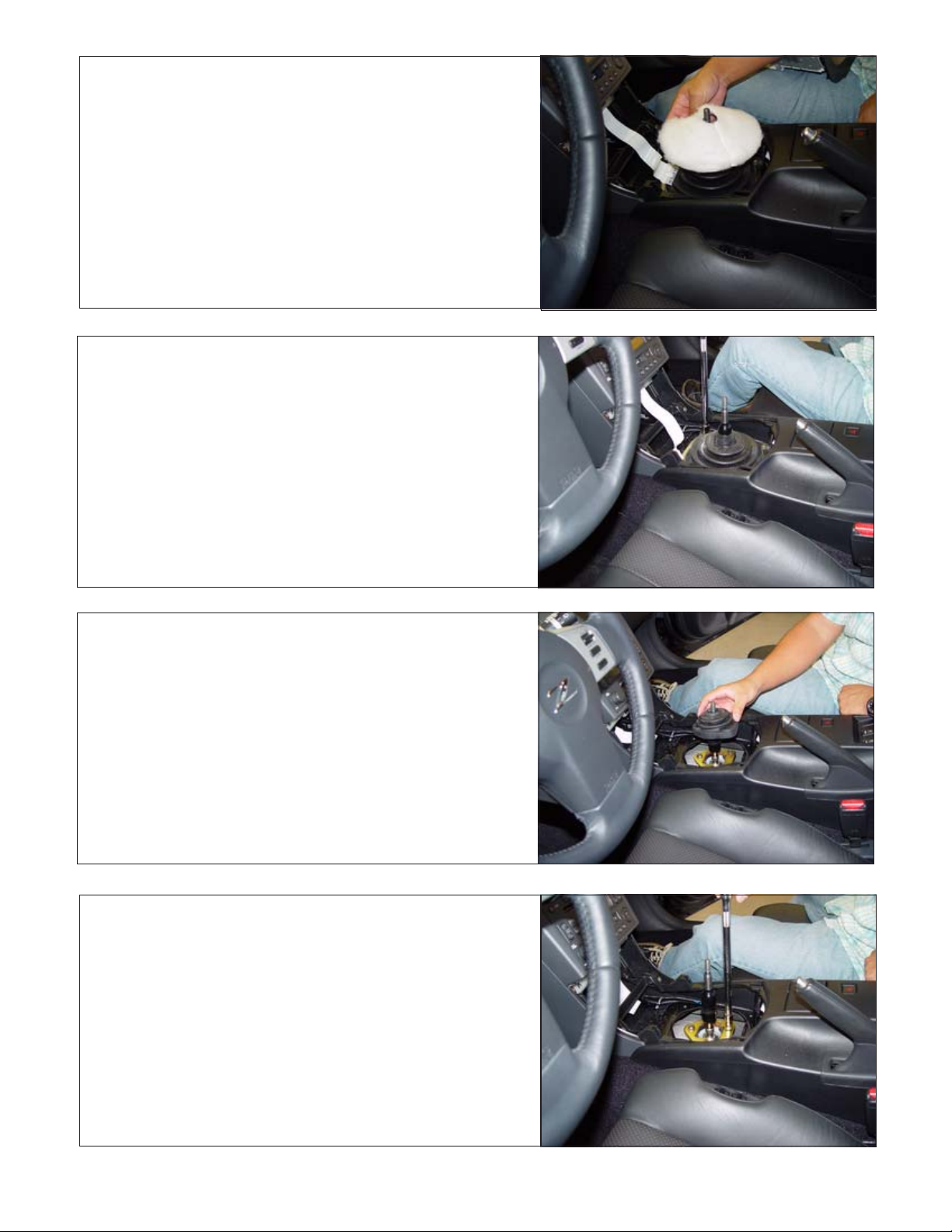

STEP 4. Remove white foam cover (350Z/G35 only).

STEP 5. Remove shifter cover bolts and wire harness connec-

tions, then remove plate from vehicle.

TOOLS: Socket(10 mm), Drive, and Extension.

NOTE: 370Z/G37 vehicles may require removal of the center

console side covers and center console by removing several

interior screws (use a Phillips screwdriver) to access the

above bolts.

STEP 6. Remove rubber boot(s).

NOTE: 370Z/G37 vehicles have an extra outer boot that will

also need to be removed in this step.

STEP 7. Remove bolts holding down metal shifter plate.

TOOLS: Socket(10 mm), Drive, and Extension.

Page 4

STEP 8. Carefully raise and support vehicle.

TOOLS: Floor Jack, Jack Stands (4)

STEP 9. Remove soft rubber boot from shifter casting.

f

STEP 10. Remove shift linkage bolt.

TOOLS: Socket(12 mm) and Drive

STEP 11. Remove shifter from car. (metal plate and spring will be

used on new shifter)

Page 5

STEP 12. File out approx. .125" from shifter casting in indicated

area. Clean out metal chips and relube entire pocket

with provided grease.

TOOLS: File and towel.

NOTE: This step allows for engagement of reverse.

STEP 13. If you were unable to remove the shift knob in step 1,

then carefully place the knob in a vise (shifter inverted) and

using the long extension or other long tool through the lower

connection hole, carefully rotate (unscrew) the shifter

assembly off of the shift knob.

TOOLS: Long extension & Towel (to protect knob)

E

ASSEMBLY

STEP 14. Install sleeve B onto bottom of shifter A.

Please note reverse pin on shifter.

STEP 15. Install mounting plate E on shifter, make sure that

reverse pin is lined up with cleared out area on plate

as shown.

A

Reverse

Pin

B

E

Reverse

Pin

Page 6

STEP 16. Install stock spring and shifter using stock plate and M6

bolts, washers, then serrated washers

D . Make sure that

reverse pin is turned towards passenger side of vehicle.

TOOLS: Socket Drive, Extension, and Hex Drive(5 mm)

NOTE: DO NOT TIGHTEN BOLTS FULLY AT THIS

POINT. ENSURE SERRATED WASHERS ARE COMPRESSED BETWEEN FLAT WASHER AND STOCK

PLATE.

STEP 17. Reinstall shift linkage bolt.

TOOLS: Socket(12 mm) and Drive

D

STEP 18. Reinstall soft rubber boot.

STEP 19. Adjust shifter plate so that reverse pin rides on stock

stock plate while going into 6th gear. Shifter should need

to be pushed down to engage reverse.

Evenly torque bolts to 10 ft-lbs (13.6Nm).

Test movement of shifter into all gears. DO NOT operate

vehicle until all gears can be fully engaged smoothly.

NOTE: This B&M Shifter has been designed to provide an

audible click(noise) when the shifter pops out from the

reverse-down position. This should signal that reverse has

been "locked-out" until the shifter is once again depressed.

TOOL: Torque Wrench, Extension, & Hex Drive (5 mm)

Page 7

STEP 20. Carefully lower vehicle.

TOOLS:Floor Jack, Jack Stands (4)

STEP 21. Reinstall rubber boot(s).

STEP 22. Reinstall shifter cover and bolts. Caution- do not over

tighten these bolts. Reinstall center console and console

side plates (370Z/G37) if they had been removed.

TOOLS: Socket(10 mm), Drive, and Extension.

STEP 23. Reinstall white foam (350Z and G35 only) and console

plate, making sure to replug in wiring harness.

D

C

C

Page 8

STEP 24. Reinstall knob. Take care not to screw knob down

through shifter boot.

ENJOY!!!

Loading...

Loading...