Page 1

Installation Instructions

Power Switch

for GM Lockup Torque Converters

(All TH200C, TH250C, TH350C, TH200-4R

and 1982 thru 1989 TH700-R4)

Part Number 80217

© 2003, 2000 by B&M Racing & Performance Products

This kit will enable the driver to

control the operation of the torque

converter lockup clutch. The driver can

select between the converter's normal

function and having it unlocked in all

gears with a three speed automatic

transmission and in all gears but

overdrive (fourth) on four speed overdrive

transmission. Keeping the converter

out of lockup mode during city driving

saves wear and tear on the converter

clutch in addition to making the vehicle

more pleasurable to drive, as you will

no longer have the constant bump of

apply and release during stop and go

driving. The switch will not stop the

converter from locking up in fourth

(overdrive) gear of overdrive four speed

transmissions. GM four speed

transmissions should always be in

lockup mode in fourth gear due to the

increased possibility of overheating

the torque converter.

This kit will work on all TH200C,

TH250C and TH350C three speed

automatic transmissions. It will also

work with 1981-86 TH200-4R overdrive

automatic transmissions and on 1982

through 1989 TH700-R4 overdrive

automatic transmissions. (On 1990 and

later TH700-R4 transmissions the fourth

gear oil pressure tap has been

Printed in the U.S.A.

removed.)

Between 1979 and 1981 theTH200,

TH250 and TH350 three speed

automatic transmissions were made in

both lockup and non-lockup converter

versions. After 1981, only lockup

converter versions were manufactured.

A lockup torque converter transmission

can be identified by one or more wires

leading to a connector on the driver's

side of the transmission.

The power switch is simple to operate

and easy to install. You will need a

minimum of tools and mechanical

experience to install this kit. The tool

list and parts lists are on the last page.

Carefully read these instructions and

take your time with each step.

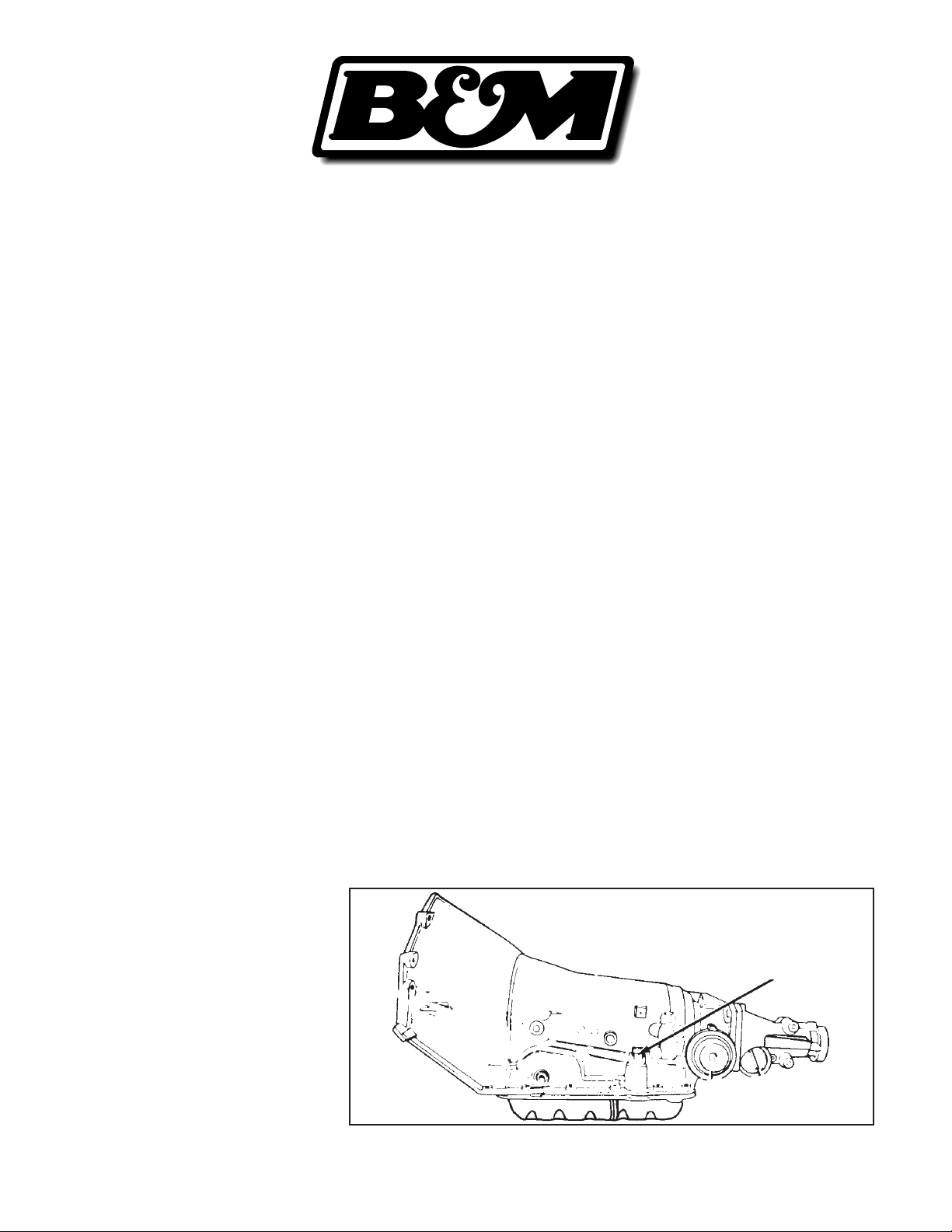

Figure 1

INSTALLATION TH200C,

TH250C AND TH350C THREE

SPEED TRANSMISSIONS

STEP 1. Raise and support the vehicle

high enough to give yourself plenty of

room to work. Use jackstands or ramps

to support the vehicle safely. Do not

use a jack alone.

STEP 2. Locate the plastic electrical

connector on the driver's side of the

transmission. See Fig. 1. The

connector will have from one to three

wires connected to it. If there is more

than one wire, select the wire going to

the terminal marked "A" on either the

plug or the socket. Cut the selected

wire about 3-4" away from the plug.

Plastic electrical connector

for lockup converter switch

9500282-06

Page 2

Strip both ends of the wire back about

1/8" and crimp a butt connector onto

each end.

STEP 3. Decide on a mounting position

for the toggle switch, some place where

the driver has easy access to the

switch and the indicator light is not

visually obstructed. The most common

mounting locations are under the

dashboard or to the console (if

equipped). When choosing a mounting

location for the power switch keep in

mind a route for the wires from the

switch to the transmission. Keep in

mind the following cautions:

1. Do not route wires near the engine

or exhaust system. The wire's in sulation may melt or burn off, caus ing a short circuit.

2. Keep the wires from dangling be neath the car or the dashboard as

they may become tangled with se lector linkage or other moving parts.

Do not secure wires to any moving

parts. Secure wires to frame mem bers or other supports using en-

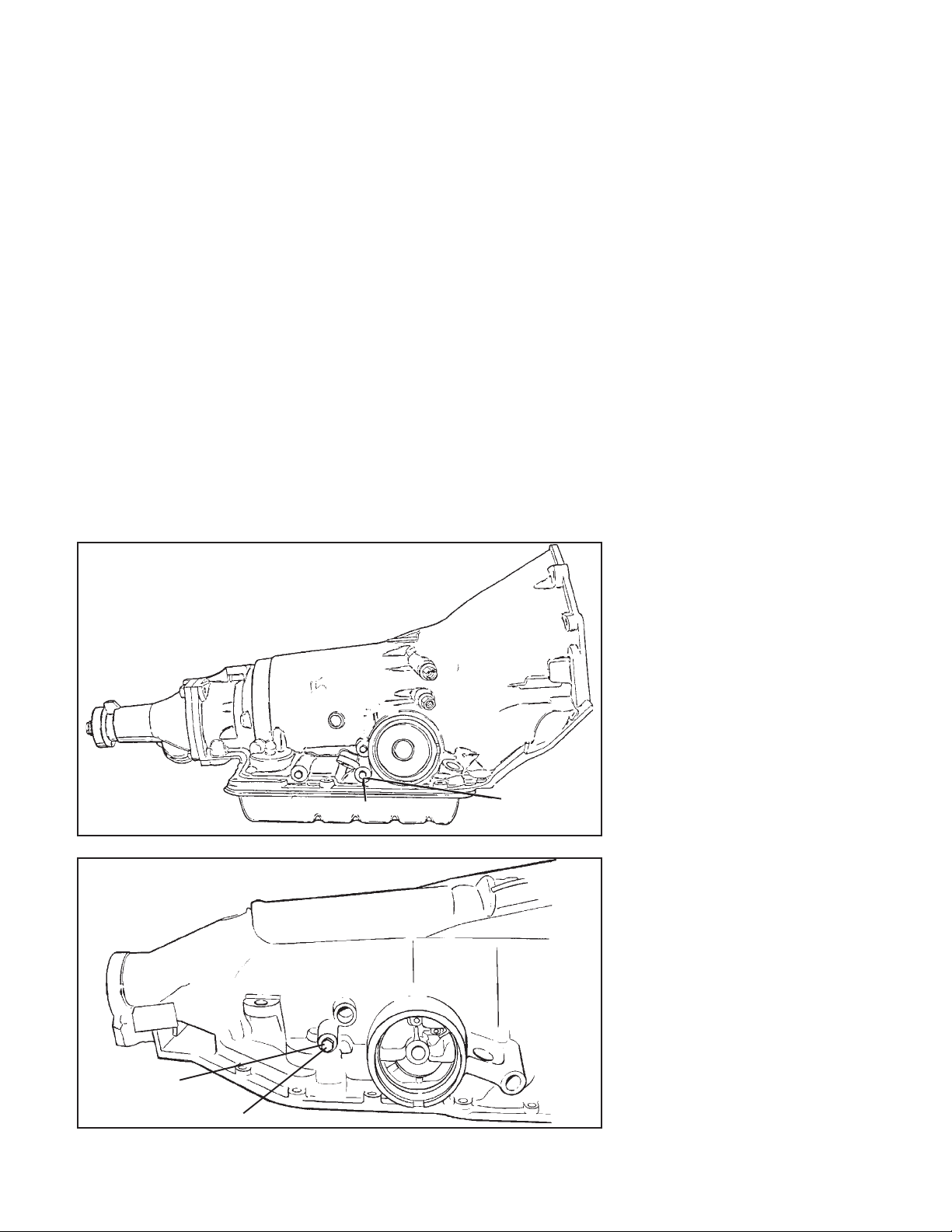

TH700-R4

Fourth gear oil pressure tap

Figure 2A

TH200-4R

Remove pipe plug and

install supplied pressure

switch here

Fourth gear oil pressure tap

Figure 2B

closed wire ties.

3. The wires should be kept out of the

way of the driver's and passenger's

hand and foot movement to avoid

snagging and possible disconnec tion.

4. Two long wires will route to the butt

end connectors installed in Step 2.

This may mean drilling a 5/16 inch

diameter hole in the floor or firewall

for the wires to pass through. Be

careful there are no obstructions

on the other side of the surface to

be drilled as they may become

damaged. Check for a suitable

existing hole first before drilling a

new hole.

STEP 4. Drill two 1/16" diameter holes

in the switch mounting surface, using

the bracket as a template for the

mounting hole spacing. From the wire

supplied in the kit, install a female

spade connector. Place this onto

terminal #3 of the switch. Route this

wire to a good ground. The ground

MUST be metal and should not have

Remove pipe plug

and install

supplied pressure

switch here

any paint in between the connector and

the metal. Cut ground wire to length

and install the tongue spade connector

on the end. Install spade connector to

ground.

STEP 5. Onto the remaining wire install

two spade connectors. Attach these

connectors to the terminals marked #1

and #2 on the switch. If there is no

existing hole in the firewall or floorboard

of the vehicle, drill a 5/16" hole. Feed

the two long wires through the supplied

rubber grommet then through the 5/16"

hole. Press the rubber grommet into

place. Route wires to the transmission

electrical connector. Cut the wires to

length and connect them to the two

butt connectors on the wire cut in step

2. See Figure 3. Make sure all wires

are secured and properly connected.

INSTALLATION TH200-4R AND

TH700-R4 FOUR SPEED

TRANSMISSIONS

STEP 1. Raise and support the vehicle

high enough to give yourself plenty of

room to work. Use jackstands or

ramps to support the vehicle safely.

Do not use a jack alone.

Locate the plastic electrical

connector on the driver's side of the

transmission. See Fig. 1. Locate the

fourth gear oil pressure tap on the

transmission case. See Figure 2A for

the TH700-R4 location and Figure 2B

for the TH200-4R tap location.

STEP 2. Remove the fourth gear oil

pressure tap plug. Install the supplied

pressure switch. On most applications

you will require a 45 degree elbow so

the switch will clear the exhaust pipe or

floor pan. Make sure that the switch is

not overtightened or cross threaded.

STEP 3. Install two female spade

connectors on the supplied wire. Install

them on the pressure switch terminals.

Run the wires over the top of the

transmission. Unplug the plastic

electrical connector from the case.

Locate pin "A". Cut the wire going to

pin "A" about 3-4" from the connector.

Strip the wires and place a butt end

connector on each end of the cut wire.

Connect the two pressure switch wires

to the other sides of the butt connectors.

(Polarity is not important.)

Note: If your transmission has a wire

Page 3

TH350C

3

2

1

TH700-R4

3

2

1

TH200-4R

3

2

1

ground

ground

ground

Figure 3

Figure 4

Figure 5

fourth gear

oil pressure

switch

tap

connectors

fourth gear

oil pressure

switch

tap

connectors

butt end

connectors

butt end

connectors

butt end

connectors

AB

from wire

harness

(+12 V)

B

A

from wire

harness

(+12 V)

A

B

from wire

harness

(+12 V)

on pin "D", cut the wire and ground the

end of the wire that goes to the plug.

Tape off the other end of the wire.

STEP 4. Decide on a mounting position

for the toggle switch, some place where

the driver has easy access to the

switch and the indicator light is not

visually obstructed. The most common

mounting locations are under the

dashboard or to the console (if

equipped). When choosing a mounting

location for the power switch keep in

mind a route for the wires from the

switch to the transmission. Keep in

mind the following cautions:

1. Do not route wires near the engine

or exhaust system. The wire's in sulation may melt or burn off, caus ing a short circuit.

2. Keep the wires from dangling be neath the car or the dashboard as

D

they may become tangled with se lector linkage or other moving parts.

Do not secure wires to any moving

parts. Secure wires to frame mem bers or other supports using en closed wire ties.

3. The wires should be kept out of the

way of the driver's and passenger's

hand and foot movement to avoid

snagging and possible disconnec tion.

4. Two long wires will route to the

wires installed in Step 3. This may

mean drilling a 5/16 inch diameter

hole in the floor or firewall for the

wires to pass through. Be careful

D

there are no obstructions on the

other side of the surface to be

drilled as they may become dam aged. Check fora suitable existing

hole first before drilling a new hole.

STEP 5. Drill two 1/16" diameter holes

in the switch mounting surface, using

the bracket as a template for the

mounting hole spacing. From the wire

supplied in the kit, install a female

Install run wireButt tap wire against stop

Fold and squeeze with pliers until latch locks

Figure 6

Page 4

spade connector. Place this onto

terminal #3 of the switch. Route this

wire to a good ground. The ground

MUST be metal and should not have

any paint in between the connector and

the metal. Cut ground wire to length

and install the tongue spade connector

on the end. Install spade connector to

ground.

STEP 6. Onto the supplied wire install

two spade connectors. Attach these

connectors to the terminals marked #1

and #2 on the switch. If there is no

existing hole in the firewall or floorboard

of the vehicle, drill a 5/16" hole. Feed

the two long wires through the supplied

rubber grommet then through the 5/16"

hole. Press the rubber grommet into

place. Route wires to the transmission

electrical connector. Connect the wires

from driver's control switch to the wires

from the oil switch using the remaining

tap connectors. See Figure 4 for the

TH700-R4 or Figure 5 for the TH200-

4R. Make sure all wires are secured

and properly connected.

OPERATION

When the toggle switch is lighted

the lockup clutch is disabled (except

in overdrive). With the light out the

lockup clutch functions normally. See

the trouble shooting guide below if

there are any problems.

TOOL LIST

Jackstands or wheel ramps

Small Punch or scribe

Funnel

Wirecutting, stripping and cripming tools

Pliers or vicegrips

3/8" drill motor

Needle nose pliers

5/16" drill bit

Small screwdriver

3/8" and 7/16" open end or fitting wrenches

TROUBLE SHOOTING GUIDE

MALFUNCTION

No converter clutch apply

PROBABLE CAUSE

Voltage not reaching solenoid. Plug not properly engaged.

Connectors not installed on proper terminals

Wires for solenoid pinched and grounded

Poor or broken electrical connection

Wire insulation stripped or bared causing short circuit

Faulty or damaged switch

PARTS LIST

1 Power switch with bracket

1 Oil pressure switch

2 Switch fittings

21' Wire

3 Splice connectors

2 Butt splices

6 Female spade connectors

1 Male spade connector

4 Wire wraps

Converter works despite switch

Indicator light does not work

Wrong wire clipped,"A" wire must be clipped

Short circuit or blown fuse in light circuit

Poor or broken electrical connections

Improper wire chosen to tap into electrical circuit

Bulb in switch broken or burned out

Wire from #1 switch terminal not properly grounded

Loading...

Loading...