Page 1

Installation Instructions

Launch Control

(see www.bmracing.com for the latest technical product information)

Part Number 46075

© 2007, 2002 by B&M Racing and Performance Products

This Launch Control must be

installed according to these

instructions for safe operation. The

unit can be used in either the front

wheel part of the brake system or the

rear wheel part of the brake system

of a passenger car or light duty truck.

Install the launch control in the rear

brake system only for use as a hill

holder system on the street.

The B&M Launch Control is a

standard design with one connection

from the master cylinder and one

connection to the brakes.

WARNING: The B&M Launch

Control is designed primarily for use

on high performance vehicles used in

drag racing. It is for short term use

(60 seconds maximum) to lock the

wheels while staging the vehicle for

drag racing. It is not intended for use

as a long term brake holding device.

It should only be used on passenger

cars and light trucks (3/4 ton or less)

using a standard hydraulic brake

system that is in good safe operating

condition. If your vehicle is equipped

with a dual diagonal braking system

(the left front is connected to the

right rear and the right front is

connected to the left rear; common

to front drive imports), two launch

controls must be utilized. The B&M

Launch Control should never be used

as a temporary brake holding device

in place of a parking brake or in place

of a driver depressing the brake pedal.

IMPORTANT: Read and fully

understand these instructions before

installing the B&M Launch Control.

Note that these instructions contain

warnings that must be observed in

order to reduce the risk of improper

installation that could make the

vehicle unsafe and result in possible

serious injury. If you are not

experienced or qualified at doing this

type of installation, we strongly

recommend that you have the B&M

Launch Control installed by a qualified

and certified automotive mechanic.

Do not cut or attempt to flare steel

tubing. Do not use copper tubing. Use

a tube bender when bending the

tubing to avoid crushing the tube. Pre

assembled steel braided BRAKE

hoses may be an acceptable

substitute for steel lines in high

performance applications.

INSTALLATION NOTES

On rear wheel drive applications, the

solenoid valve can be installed in the

front wheel brake system as a staging

device for drag racing and in the rear

wheel brake system for short term use

as a hill holder (60 seconds

maximum). On front wheel drive

applications, the solenoid valve(s)

should be mounted in the rear braking

system(s) for use either as a staging

device or hill-holder (60 seconds

maximum), The solenoid valve does

not interfere with normal operation of

the brakes or with safety regulations

when installed according to these

instructions.

The brake light system on the rear

of the vehicle must operate when any

part of the brake system is

pressurized. A hydraulic pressure

brake light switch must be installed in

the system if the launch control valve

defeats the operation of the stock

brake light switch. See the electrical

section for details.

The launch control valve must be

mounted to a rigid surface to prevent

vibrations that could cause failures of

the joints or lines· The firewall is a

good mounting location. Keep the

valve and the brake lines away from

the heat of the exhaust system.

Two basic types of master

cylinders have been used on

production cars, single master

cylinder and dual master cylinder·

Dual master cylinders have been

required on all production cars built

since approximately 1970, earlier cars

have single master cylinders. The dual

master cylinders have the brake fluid

reservoir divided into two separate

sections while single master cylinders

have a single compartment reservoir.

SOME CARS (MOSTLY FRONT

WHEEL DRIVE) HAVE

DIAGONALLY SPLIT SYSTEMS

WHERE THE RIGHT FRONT

Printed in the USA

9500553-05

Page 2

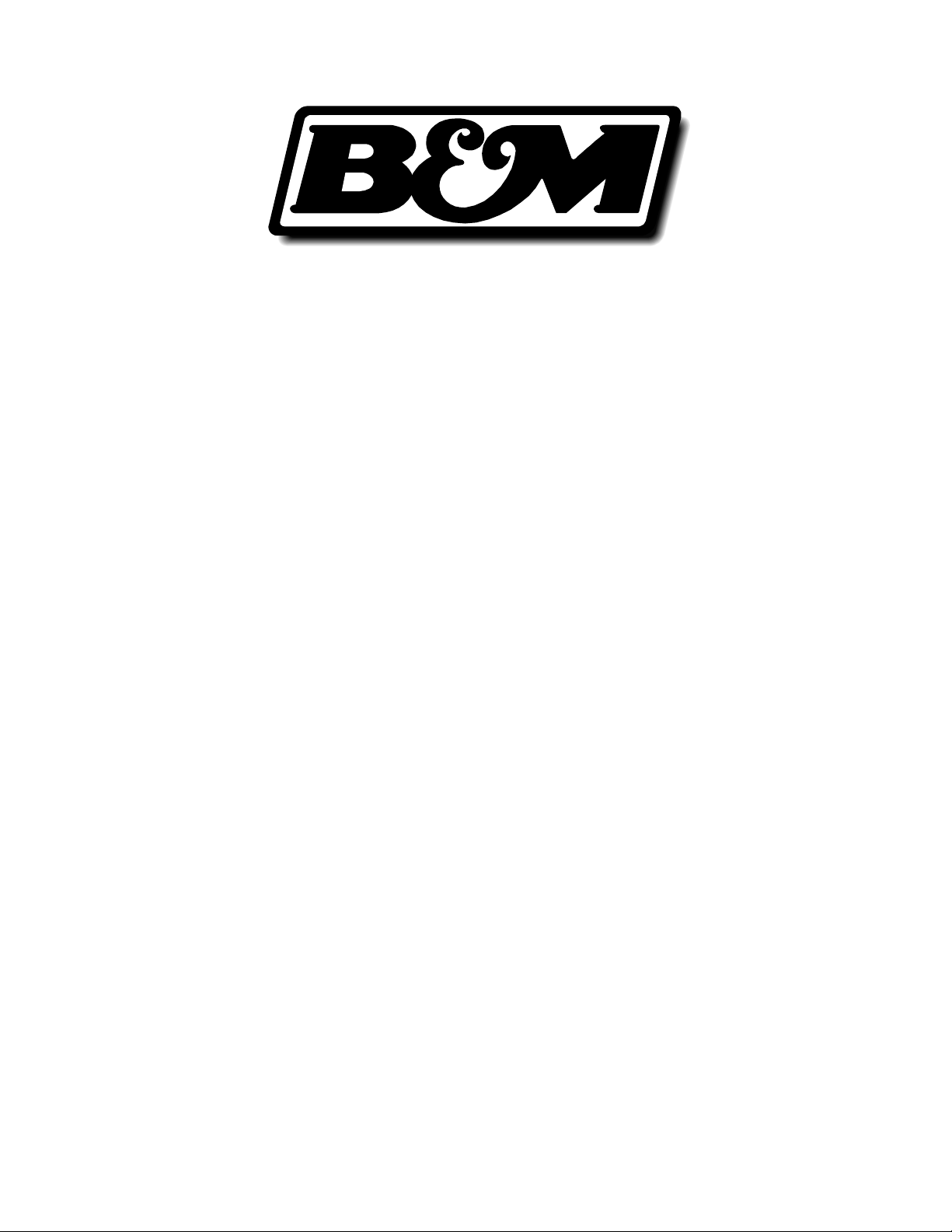

SYSTEM A

Dual Master Cylinder

SYSTEM B

Dual Master Cylinder

SYSTEM C

Dual Master Cylinder

Master

Cylinder

Pressure differential

switch block

Wire to

warning light

To rear

brakesTo left front brake

To right front brake

Distribution block

TYPICAL STOCK SYSTEMFRONT BRAKE INSTALLATIONS REAR BRAKE INSTALLATIONS

New

line

connector

Cylinder

Male

Master

Connector

To rear

brakes

The size of this

tube nut determines the size

of the new line

To left front brake

To right front brake

Male

Launch

control

solenoid

valve

Pressure

differential

switch block

To left front

brake

The size of this

tube nut determines the size

of the new line

To left front

brake

To right

front brake

New line

To right

front brake

To rear

brakes

Master

Cylinder

To rear

brakes

Master

Cylinder

May require a new

line to reach valve.

Wire to

warning light

Launch control

solenoid valve

Male

connector

Use a union.

Distribution

block

Pressure

differential switch

block

To right

front brake

To left front

The size of this

tube nut determines the size

of the new line

To right

front brake

Launch control

solenoid valve

To left front

brake

brake

New line

Master

Cylinder

warning light

Master

Cylinder

Male

connector

To rear

Wire to

brakes

To rear

brakes

May require a new

line to reach valve.

Use a union.

Master

The size of this

tube nut determines the size

of the new line

Original line

redirected to

solenoid valve

To left front brake

To right front brake

New

line

Cylinder

connector

Male

To rear

brakes

Launch

control

solenoid

valve

BRAKE AND THE LEFT REAR

BRAKE ARE ON ONE CIRCUIT

WITH THE LEFT FRONT BRAKE

AND RIGHT REAR BRAKE ARE ON

THE SECOND CIRCUIT. FOR

THESE SYSTEMS, IT IS

RECOMMENDED THAT TWO

LAUNCH CONTROLS BE UTILIZED

, ONE IN EACH SYSTEM.

Illustrations are given for the hydraulic

portion of six typical single and dual

master cylinder brake systems. These

represent the hydraulic system of

most domestic and import vehicles.

The electrical section of the

To right

front brake

Male

branch

tee fitting

To left front

brake

Male

connector

Launch

control

solenoid

valve

From master

cylinder

New

line

Master

Cylinder

Steel plug

straight

thread

To rear

brakes

brakes

To

The size

of this

tube nut

determines

the size

of the

new line

Left

front

original

line

Union

Male

branch

tee

fitting

To right

front brake

Steel plug

straight

thread

Launch control

solenoid valve

New line

Master

Cylinder

The size of this

tube nut determines the size

of the new line

To rear

Male

connector

Note: Connect left front original line to male

branch tee fitting. If original line doesn’t reach,

connect new line with union as shown,

brakes

instructions is the same for all

systems. Read the instructions

thoroughly and identify the additional

brake line and fittings that you will

require. These lines and fittings are

available for most popular vehicles. In

order to determine the correct fittings

required, a tube nut gauge is included

with this kit. The locations to check

the fittings are shown on the

illustrations for the different types of

brake systems.

INSTALLATION

Step 1. Measure the stock tube nut

at the position indicated on the

2

Page 3

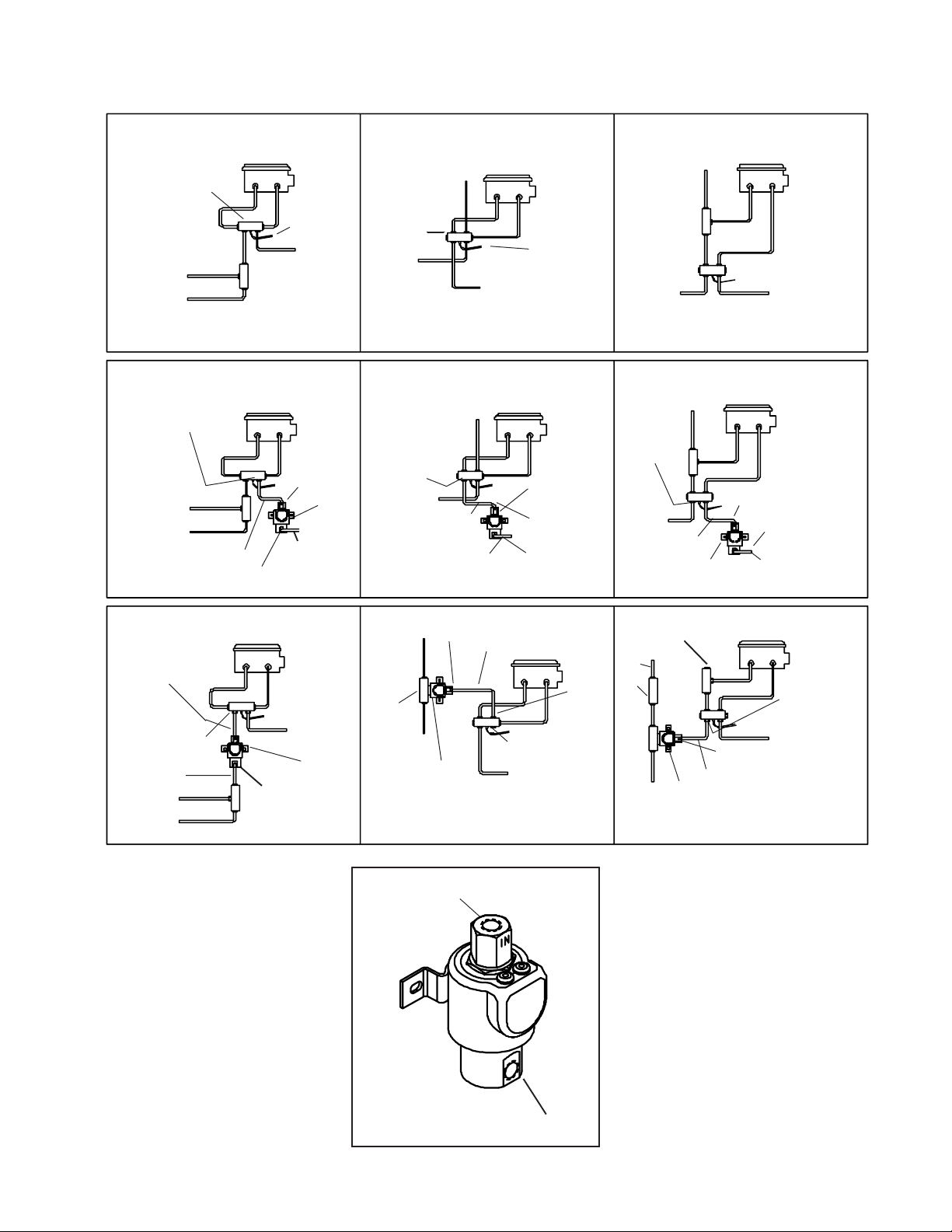

SYSTEM D

Single Master Cylinder

To right

front brake

To left front

brake

Distribution

block

Distribution

To right

front brake

New line

To left front

brake

The size of this

tube nut determines the size

of the new line

New line

block

Launch control

solenoid valve

Master

Cylinder

To rear

brakes

Master

Cylinder

Male

connector

To rear

brakes

May require a new

line to reach valve.

Use a union.

SYSTEM E

Single Master Cylinder

To right

front brake

To rear

brakes

Distribution

block

To left front

Male

connector

To rear

brakes

Launch

control

solenoid

valve

New line

The size of this

tube nut determines the size

of the new line

brake

To right

front brake

To left front

brake

Master

Cylinder

Master

Cylinder

SYSTEM F

Metric Diagonal Braking System

To right

front brake

To left rear

To right

front brake

Metric to

SAE adapter

To left rear

brake

brake

Distribution

block

Distribution

block

New

lines

Master

Cylinder

To left front

brake

To right

rear brake

Master

Cylinder

To left front

brake

Metric to

SAE adapter

To right

rear brake

Master

connector

To right

front brake

To left front

brake

Steel plug

straight thread

Male

The size of this

tube nut determines the size

of the new line

New line

Cylinder

Launch control

solenoid valve

Male

branch

tee

fitting

To rear

brakes

drawing that matches your brake

system. The size of the tube nut

measured across the flats with the

gauge indicates the size of the female

threads in the distribution block or the

differential pressure switch block. You

must use two female fittings for the

launch control solenoid valve, one for

the inlet and one for the outlet. These

fittings will have a male 1/8" NPT

tapered pipe thread on one side. If a

male connector is called for on the

diagram of your sys-tem, you want a

male connector with the 1/8" NPT pipe

thread on one end and a flare fitting

Launch

control

solenoid

valve

Steel plug

straight thread

The size of this

tube nut determines the size

of the new line

Master

Cylinder

To right

front brake

Male

branch

tee

fitting

To left front

brake

To rear

brakes

Male

connector

with female threads the same size as

the threads that was measured with

the gauge. Where a male branch tee

is called for on the diagram, you want

a tee fitting with a 1/8" NPT male pipe

thread on one end and flare fittings

on the other two sides of the tee.

Step 2. Install the male connectors

and/or male branch tees in the correct

ports of the solenoid valve. In all cases

the Master Cylinder connects to port

labeled “IN” and the line to the brakes

connects to the port marked “OUT”.

Mount the valve in a position that

locates the connectors close to the

line to which they will be connected.

The mounting position of the valve is

not important. Using the holes in the

bracket of the valve as a guide, drill

two .185" (No. 13 drill) holes for

mounting.

Step 3. Install a new length of steel

brake line tubing in the specified

location and reroute the existing brake

lines. When bending brake line use a

tube bender to avoid crushing the

tubing. If an existing brake line must

be lengthened, a flare union must be

used. Where there is an unused port

in the distribution block or pressure

differential switch block use a steel

plug designed for flare fittings. These

plugs, like all of the tube nuts used in

the system, have straight machine

threads, not tapered pipe threads. Do

not attempt to force a tapered pipe

plug or fitting into a port with straight

threads.

ELECTRICAL INSTALLATION

Make sure that all electrical

connections are properly joined

together by either soldering the

con-nection or by using a crimp-on

3

Page 4

To supplied or

other switch

insulated connector. All soldered

connections should be wrapped with

plastic electrical tape. All wires should

be as short and direct as possible, but

not short enough to put any tension

on the wires. Electrical wires should

not be under tension even when the

engine and transmission move on the

their mounts.

Step 1. Disconnect the negative

battery cable.

Step 2. A momentary push button

switch is supplied and may be

mounted in any convenient position.

You may want to use the B&M THandle with push button (#80659

chrome or #80658 brushed aluminum)

or the push button knob (#46112),

These knobs and T-Handles will fit

most S.A.E. sizes of shifter stick

threads.

Step 3. Run a length of 18 gauge wire

from the end of the switch cable to

the solenoid valve(s). At the solenoid

valve(s) splice the newly installed wire

to one lead of the solenoid(s), ground

the other solenoid lead(s).

Step 4. Connect one end of the fuse

holder to a switched ignition terminal.

Run a length of 18 gauge wire from

the other end of the fuse holder to the

other wire of the switch cable. Splice

this wire at both ends.

Step 6. Connect the battery. The

solenoid valve(s) should operate

when the push button is depressed.

If the fuse blows out there is a short

circuit. Check all of the splices and

connections to be sure they are

insulated and that there are no short

circuits.

Step 7. Apply the brakes hard, push

and hold the launch control button and

release the brakes. Have someone

check to see if the brake lights remain

on. If the lights go out it will be

necessary to add an additional

hydraulic brake light switch. The

switch should be installed on the

brake side of the solenoid valve, as

shown in the illustration. The two

terminals of the new brake light switch

should be wired in parallel with the

existing brake light switch.

OPERATION

Pressing and holding the launch

control push button switch energizes

the solenoid valve. When the brake

pedal is pushed the hydraulic

pressure applies all four brakes. When

the brake pedal is released the

pressure is retained the solenoid valve

on the wheels that are controlled by

the launch control, while the pressure

is released on the other wheels. When

the push button is released the brakes

that were held on by the launch control

are released and the vehicle can

accelerate. After the installation, but

before driving the vehicle, check the

brake system thoroughly for leaks and

be sure that you have a solid brake

pedal. Apply the launch control

several times and be sure that the

wheels that are supposed to be locked

are locked and that the brakes are free

when the launch control is released.

After the installation has been

completed bleed the entire brake

system thoroughly to eliminate all air

in the system. Check all connections

for leakage under pressure and be

sure you have a hard brake pedal, not

a soft pedal. Replace any brake fluid

lost by the installation or by bleeding

with heavy duty brake fluid marked

DOT 3 or DOT 4.

For most automatic transmission

shifters we recommend that you use

the B&M T-Handle with push button

(#80659 chrome or #80658 brushed

aluminum) or the push button knob

(#46112). These knobs and THandles will fit most sizes of stick

threads. B&M also offers remote

buttons with spiral cord #46003 and

#46013.

4

Loading...

Loading...