Page 1

Torque Converter

Installation Instructions for

General Motors TH700-R4 (4L60), 4L60E,

TH200-4R and TH200C

Part Nos. 70415, 70416, 70417, 70418, 70419, 70420, 70422, 70425 , 70426, 70440 & 70441

(C) B&M Racing & Performance Products 1996, 1999, 2004

Congratulations! You have just purchased the best performing and highest

quality torque converter available. We

have endeavored to make these installation instructions as clear and complete

as possible. Anyone with a minimum of

mechanical experience should be capable of installing a torque converter

using proper tools and following the instructions. IMPORTANT: Read the instructions completely before beginning

the installation so you can familiarize

yourself with the procedures.

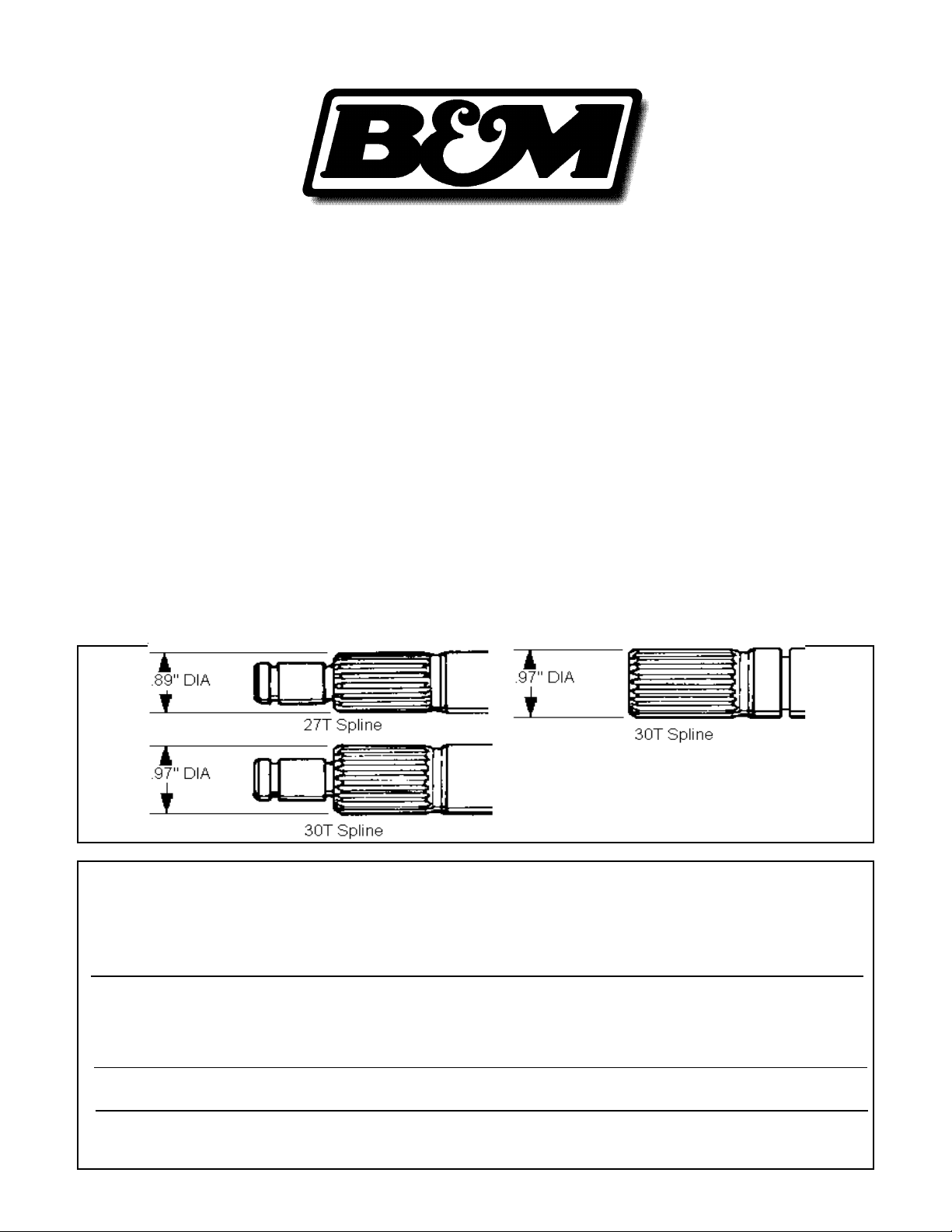

APPLICATIONS

These GM lockup clutch style (TCC)

torque converters are made in versions

for several automatic transmissions,

three different input shaft spline tooth

numbers and a range of stall speeds.

The chart below shows the applications.

The new B&M torque converter can

be used as either a lockup or non lockup

unit. If the vehicle currently has an operational TCC it will continue to operate if no

other changes are made to the vehicle.

Optionally the TCC can be bypassed

(except on 4L60E transmissions) if desired as covered in STEP 22 below.

If the torque converter is being installed into a vehicle that was not originally equipped with a transmission with

lockup torque converter the TCC will not

operate and the converter will be a nonlockup converter. The TCC in a TH700R4, 4L60, TH200-4R or TH350C can be

made to operate in this type of applica-

Fig. 1

Transmission Input Shaft Type Part No.

TH200-C 27 Tooth HoleShot 2400 70415

TH200-4R 27 Tooth HoleShot 2400 70415

TH700-R4 1982-84 27 Tooth HoleShot 2400 70415

TH200-C 27 Tooth HoleShot 2000 70416

TH200-4R 27 Tooth HoleShot 2000 70416

TH700-R4 1982-84 27 Tooth HoleShot 2000 70416

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth HoleShot 2000 70417

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth HoleShot 2400 70419

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth Tork Master 2000 70420

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth Tork Master 2400 70418

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth Traveler 70422

TH700-R4 1984-93 (4L60) & 1993-96 4L60E 30 Tooth HoleShot 3000 70425

TH200-C 27 Tooth HoleShot 3000 70426

TH200-4R 27 Tooth HoleShot 3000 70426

TH700-R4 1982-84 27 Tooth HoleShot 3000 70426

4L60E 1998-04 & 2000-04 4L65E 30 Tooth HoleShot 2000 70440

4L60E 1998-04 & 2000-04 4L65E 30 Tooth HoleShot 2400 70441

Torque Converter Applications

Printed in the U.S.A.

9500354-04

Page 2

tion by using the B&M Converter Lockup

Control (#70244 for mechanical drive

speedometers, #70248 for GM electronic speed sensor applications).

These torque converters can be

used on the GM 4L60E electronically

controlled transmission used on 1993 96 Chevrolet and GMC trucks and 199497 Camaros and Firebirds. On later

model vehicles equipped with an LS1

type engine, the input shaft is longer and

can only use the 70440 and 70441 converters. For this transmission (4L60E)

you must not make any electrical connection changes. Using it as a non

lockup unit will cause error codes to be

generated and the "Check Engine" light

will be illuminated.

TRANSMISSION REMOVAL

The TH200C, TH200-4R, TH700-R4 and

4L60E are METRIC dimensioned and

have METRIC fasteners.

Because of variations between different vehicle models we cannot cover each

in detail. Instead we will outline a basic

removal and installation procedure. The

sequence of the following procedures

may have to be changed to suit different

vehicle installations. We recommend

you change the transmission fluid and

filter when installing your B&M torque

converter.

Automatic transmissions normally

operate between 150 F and 250 F. It is

recommended that the transmission be

allowed to cool thoroughly to avoid burns

from hot oil and parts. The vehicle must

be off the ground for ease of transmission removal. A vehicle hoist is best,

however jack stands or wheel ramps will

work fine. MAKE SURE THE VEHICLE IS

FIRMLY AND SECURELY SUPPORTED!! A

transmission jack should be used to

prevent personal injury and or transmission damage during removal and installation. Have a small box handy to put nuts

and bolts in so they don’t get lost. A drain

pan to catch oil is also required.

STEP 1. Place drain pan under the

transmission to catch the oil. Drain the oil

pan by first removing the front bolts then

working from the front loosen all the

remaining pan bolts. If the pan sticks use

a screwdriver to pry the pan loose. Again

working from front to rear allow the pan to

tilt down in the front and drain as the

remaining bolts are removed. Once

drained replace the oil pan and hold in

place with one bolt at each corner. To

avoid all this mess next time you service

your transmission, you may want to consider installing a B&M Drain Plug Kit,

#80250 while the oil pan is off the transmission.

STEP 2. Remove the driveshaft (and

torque arm if equipped) being careful not

to drop the U-joint bearings. It’s a good

idea to tape the bearings in place and

wrap the smooth seal diameter of the

slip yoke to prevent damage. It may be

necessary to remove or disconnect any

exhaust pipes and/or hangers during

transmission removal. Remove transfer

case if equipped.

STEP 3. Disconnect the cooler lines.

Use a fitting wrench to avoid damaging

the tube compression nuts. Some models are equipped with a T.V. cable that

runs from the transmission up to the

throttle linkage on the engine. Disconnect the T.V. cable at the engine end and

feed the cable down so it hangs freely

from the transmission. Disconnect any

electrical connectors from the sides of

the case. Be sure to note or label the

position of each corresponding connector. Disconnect the transmission shifter

cable from the shift lever. Disconnect the

speedometer cable or electrical Vehicle

Speed Sensor connector at rear of transmission.

STEP 4. Remove the bell housing dust

cover to expose the torque converter.

Remove the three converter bolts. The

converter should now rotate freely. If it

does not pry the converter back slightly

and free it from the crankshaft.

STEP 5. Place transmission jack under

transmission and take the load off the

crossmember. If the vehicle is equipped

with a rear mounted distributor on the

engine, it is advisable at this point to

remove the distributor cap so it will not be

damaged as the transmission is lowered. Remove the crossmember assembly.

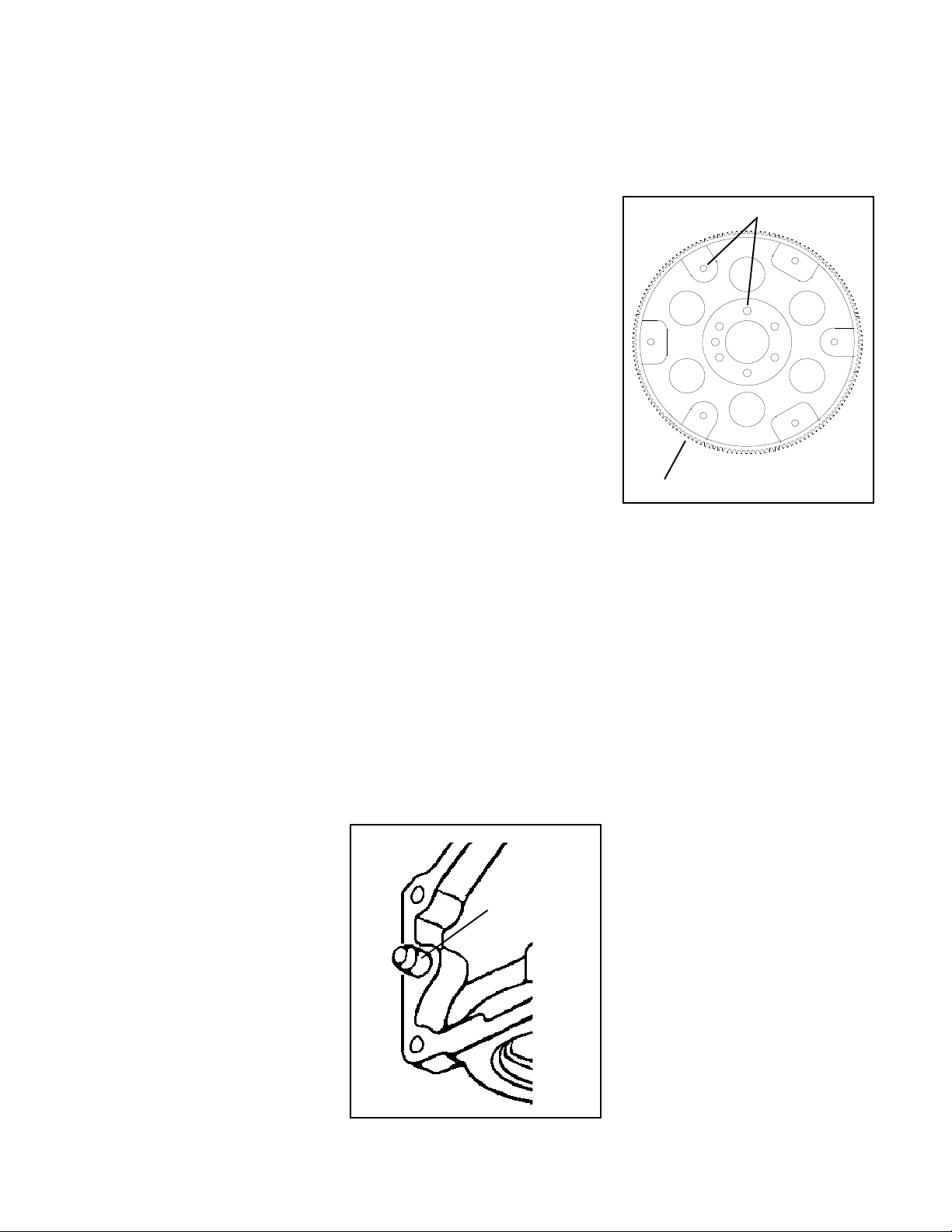

Dowel pin must

protrude 1/2" for

proper transmission engagement

Fig. 2

STEP 6. Remove the bellhousing

bolts, it may be necessary to lower the

transmission slightly to gain clear access to the bolts. Finish lowering the

transmission until engine is balanced

on it’s mounts then pull the transmission

Inspect bolt holes

Inspect ring gear teeth

Fig. 3

slightly away from the engine. Make sure

the converter stays with the transmission and does not fall out. It may be

necessary to remove the dipstick tube at

this point to continue lowering the transmission. Remove transmission and

converter assembly from vehicle.

With the transmission completely out

of the vehicle the torque converter can

easily be removed by pulling it straight off

the front. Drain the torque converter as

completely as possible then cover the

hub to keep out dirt.

STEP 7. Inspect the engine block’s

transmission mounting face to be free of

any dirt or burrs. Make sure both dowel

pins are installed and stick out of the

block at least 1/2" to insure proper transmission alignment, see (Fig. 2).

STEP 8. Remove and inspect the

flexplate for distortion, cracks or damaged ring gear teeth, see (Fig. 3). If the

flexplate shows any damage it should be

replaced. Do not attempt to repair a damaged flexplate.

STEP 9. Assemble the flexplate to

crankshaft and align all holes before

installing the bolts. When properly installed the raised inner lip on the

flexplate should face away from the

crankshaft flange. Torque the bolts to 60

ft.lbs.

STEP 10. Carefully remove the front seal

from the oil pump housing. CAUTION:

The oil pump housing used in these

transmissions is made of an aluminum

2

Page 3

Pump seal removal and installation

Locate seal retainer tab

at 5 O'clock position

alloy and can be easily damaged during

seal removal. We recommend the following seal removal procedure to minimize the chance of damaging the pump

housing, see (Fig. 4).

1. Raise the transmission (or place on

bench) so that the seal is accessible

from the lower side of the transmission.

2. Using a common (flat) screwdriver

collapse the seals outer flange as

shown. Be careful not to damage the

housing with the screwdriver.

3. With the outer flange collapsed the

seal should pry out easily. Again take

care not to damage or gouge the housing. Once the seal is removed use a lint

free rag wrapped around a thin piece of

wood or other soft material, (to avoid

scratching the seal bore) to clean the

seal bore thoroughly.

STEP 11. Coat the outer diameter of the

new oil seal with “Locktite, 609” or

“Permatex, Secures Gears” cylindrical

retaining compound. Then using a small

block of wood between the seal and

hammer, carefully tap the seal evenly

into the housing until fully seated. If the

transmission was equipped with a seal

retainer, install the retainer onto the

housing as shown, see (Fig. 4).

STEP 12. Hold your B&M torque converter against the crankshaft and

flexplate to check the pilot hub fit. The

converter pilot hub should fit in the crankshaft snugly with no excessive slop. A

tight fit indicates burrs or debris in the

crankshaft pilot diameter. The burrs or

debris can be removed with sand paper.

STEP 13. Pour 1 quart of transmission

Fluid into the B&M torque converter so

there will be some lubrication on initial

startup. Lubricate the converter’s pump

drive hub with clean transmission fluid.

STEP 14. Install the B&M torque converter onto the transmission. Push the

converter in while rotating it to engage the

input shaft, reaction shaft and pump

Fig. 4

drive tangs. Place a straight edge across

the bellhousing face and measure the

distance to the torque converter’s drive

lug face. The drive lug must be at least 1"

inside the bellhousing, see (Fig. 5). A

measurement of less than 1" indicates

the torque converter is not fully engaged

in the transmission. Continue to push in

and rotate the converter until you obtain

full engagement. If you install the trans-

mission without full converter engagement, you will damage the oil pump.

STEP 15. Place the transmission in po-

sition on transmission jack. Make sure

the jack supports the transmission on a

wide area so the oil pan is not crushed.

Install the transmission / converter

against the engine. The transmission

should engage the dowel pins and sit flat

against the block with hand pressure

only. If the transmission does not sit flat

against the engine, the converter is not

fully engaged in the transmission or

some other interference problem exists.

Drive lug face must be at least 1"

inside front edge of bellhousing

Fig. 5

Do not attempt to pull the transmission

up to the engine with the bellhousing

bolts as this can cause transmission or

torque converter damage.

STEP 16. Once the transmission is in

position against the engine, install the

bellhousing bolts and torque to 35 lb.ft. At

this point the torque converter should

turn freely. A tight converter indicates

improper engagement, distorted

flexplate or binding pilot hub. This condi-

tion must be corrected before going

any further.

STEP 17. Inspect transmission mount.

Worn, cracked or broken transmission

and/or engine mounts should be replaced. Raise transmission and install

crossmember assembly then tighten all

bolts. Install three (M10 x 1.5) flexplate to

converter bolts. Install the first bolt finger

tight then use the starter motor to “bump”

each drive lug into position. When all

three bolts are installed torque them to

47 Nm (35 lb.ft.).

STEP 18. Remove the oil pan and filter.

The filter suction tube O-ring may stick in

the pump body, if it does make sure to get

it out. Assemble two (2) O-rings on a new

oil filter. Some filters have a

preassembled seal on the suction tube,

if the filter you are using has a

preassembled seal do not use the Orings. Lubricate the suction tube seal

with clean transmission fluid and install

filter into the transmission.

STEP 19. Remove all old gasket material from the pan and case flange. Install

a new pan gasket then assemble pan to

the transmission. Install ALL of the pan

bolts (install shifter cable bracket if

equipped) finger tight first then torque to

8 lb.ft. DO NOT use a sealant on the pan

gasket and don’t over torque the pan

bolts, this will damage the gasket and

cuase the pan to leak transmission fluid.

STEP 20. If your transmission is

3

Page 4

equipped with a TV cable, reconnect and

adjust the TV cable, see (Fig. 6). IMPOR-

TANT: You must reset the TV cable before

operating the transmission. Failure to

reset the TV cable may result in poor shift

quality and early transmission failure.

STEP 21. Reconnect speedometer

cable or VSS connector, any electrical

connectors and shifter cable. Make sure

the cooler tube connector fittings are tight

in transmission case, then either connect cooler lines and tighten tube compression nuts with a fitting wrench (to

avoid damaging the nuts) or reinstall the

retaining clips.

STEP 22. If the vehicle originally had a

TCC and transmission installed, plug in

the electrical connector on the left side of

the case (See Fig. 7) and the TCC in the

new converter will operate. If you do not

want the TCC to operate, cut the wire

going to pin marked “A” on the TCC plug

going into the electrical connector on the

left side of the case. Tape the ends of the

wire to prevent shorts.

If the transmission is installed in a

vehicle that did not originally have a TCC

and transmission the TCC will not operate. The lockup clutch can be made to

operate in this type of application by

using the B&M Converter Lockup Control

(#70244 for mechanical drive speedometers, #70248 for GM electronic speed

sensor applications). This unit connects

to the speedometer drive cable or to the

plug for the electronic speed sensor and

lets the driver set the speed at which the

TCC will lock and unlock to any speed

between 30 and 90 mph.

STEP 23. Install driveshaft (and torque

arm if used). Make sure the U-joint bearings are properly positioned in their

seats. Tighten U-joint nuts or bolts securely.

STEP 24. Lower vehicle but keep the

rear wheels off the ground if possible.

Add five quarts of transmission fluid to

the transmission. Place transmission in

NEUTRAL and start the engine. Add fluid

to transmission (as per the manufacturers' rfluid check recommendation) until

the fluid level is between the FULL and

ADD marks. Shift the transmission

through all gear positions. If the wheels

are off the ground, allow the transmission to shift through all gears several

times. Place selector in NEUTRAL and

check the fluid level again. DO NOT

OVERFILL. Check for leaks around the oil

pan, cooler lines, etc. Turn off engine

then lower vehicle and test drive.

OTHER B&M PRODUCTS

TV Cable adjustment proceedure

Fig. 6

B&M Manufactures several other

transmission products ideally suited for

4L60E, TH700-R4 and TH200-4R transmissions.

1. TH700-R4 (#70235) & 4L60E

(#70265) TRANSPAK The Transpak kits

are designed to increase the torque capacity and significantly improve the shift

feel in addition to promoting longer

transmission life. All of the necessary

parts and instructions, including gaskets and a new oil filter are supplied with

the kit.

2. TH200-4R TRANSPAK (#35229) The

TH200-4R Transpak is designed to increase the torque capacity and significantly improve the shift feel in addition to

promoting longer transmission life. All of

the necessary parts and instructions,

including gaskets and a new oil filter are

supplied with the kit.

3. POWER SWITCH KIT (#80217) The

B&M Power Switch Kit allows the lock-up

portion of the converter to be temporarily

eliminated and the converter reverted to

a standard type converter. This gives the

ability to operate the vehicle with a standard type torque converter when it is

more desirable than the lock-up type.

TH700-R4 (4L60) Shown

4. TH700-R4 Special Deep Pan (#70289)

adds approximately 3 quarts extra oil

capacity. This attractive chrome pan also

incorporates a built in drain plug to help

simplify the more frequent oil changes

required of high performance transmissions. The larger surface area and fluid

volume of this pan helps reduce the

transmissions oil temperature thereby

promoting longer transmission life.

5. TRANSMISSION OIL COOLERS. Design features of the new “High Tech”

transmissions cause them to run hotter

than earlier transmissions. We recommend that every vehicle using an automatic transmission in heavy duty applications (racing, towing, RV, commercial,

off road, fleet) have an auxiliary transmission oil cooler. Addition of an auxiliary oil

cooler will not only reduce transmission

oil temperature but it will also significantly reduce the heat load on the radiator. Heat is a major cause of automatic

transmission failure, an auxiliary oil

cooler is an inexpensive guard against

overheating and failure. B&M offers a

complete range of transmission coolers

to suit every application, available at your

B&M dealer. A non-lockup torque con-

Connector for TCC Plug

TCC Plug

Fig 7

4

Page 5

verter installation will run warmer than

a lockup installation, and particularly

needs a transmission cooler.

6. TEMPERATURE GAGE (#80212) Most

transmission and converter failures are

traced directly to excessive heat. The

B&M transmission temperature gage

can save you a costly repair bill by warning you ahead of time of an overheating

transmission. The B&M temperature

gage is extremely accurate and dependable, it comes with all necessary hardware and is easy to install.

7. TH700-R4 KICKDOWN KIT (70237)

The TH-700 has a hydraulic circuit that

causes a forced 4-3 down shift whenever

the throttle is opened past two thirds

travel. In some applications a forced 4-3

down shift is undesirable. After many

customer requests B&M has developed

an easily installed kit that will eliminate

the part throttle 4-3 down shift feature.

This kit does not alter normal shift

speeds or affect detent operation. This

kit is best installed along with B&M’s

70235 Transpak. It can also be installed

independent of other modifications, and

valve body removal is not required.

8. 4L60E SHIFTPLUS (#70380) For those

of you who have a 1993-1998 electronically controlled 4L60E, the SHIFTPLUS

is a great addition to firming up those soft

feeling factory shifts. With in a few minutes for installation, you can quickly and

simply increase your transmission line

pressure with just a flip of a switch. There

is no need to remove the transmission

pan to install the SHIFTPLUS. You transmission will benefit from reduced wear

and slippage, which causes excessive

heat and can lead transmission life failure. You only need simple tools to install

and can easily go back to stock by simply

flipping a switch.

Trans cooler lines

w/retaining clips

2 Piece Bellhousing

Electrical Connector

4L65E shown

Fig. 8

5

Loading...

Loading...