Page 1

Installation Instructions

Fuel Pressure Gauge Set

Honda Civic/CRX/del Sol

Acura Integra/NSX - Eagle Talon

Mitsubishi Eclipse - Plymouth Laser

Part Number 46054

©2000 by B&M Racing and Performance Products

The B&M Fuel Pressure Gauge Set

has been designed to work on all late

model Honda Civics/CRX's/del Sols,

Acura Integras/NSX's, Mitsubishi

Eclipses, Eagle Talons & Plymouth

Lasers.

The B&M Fuel Pressure Gauge Set

allows the user to accurately measure

fuel pressure. When used in conjuction

with the B&M CommandFlo Fuel

Flow Modifier, the user may

accurately adjust fuel pressure to

compensate for engine modifications.

Most factory computers will

compensate for minor airflow

modifications (low restriction intake

and exhaust) at part throttle operations

but have no way to adjust at WOT

(Wide Open Throttle). The results are

a lean mixture right where you need

more fuel! One way to correct this is

to adjust fuel flow via fuel pressure.

Most people don't understand that by

increasing fuel pressure (on a fuel

injection system), fuel flow increases.

The formula for calculating flow

increase based on fuel pressure is:

F1 = Injector Flow (cc/min)

P1 = Current Fuel Pressure (psi)

F2 = New Injector Flow (cc/min)

P2 = New Fuel Pressure (psi)

P2 = P1 x

Example:

You've added a high flow exhaust

that increases airflow 10%. What

pressure should the system be set

to?

F1 = 270 cc/min

F2 = 297 cc/min (270 + 10%)

P1 = 43 psi

P2 = 43 psi x

or

P2 = 52 psi

The B&M Fuel Pressure Gauge

Set requires the user to assemble

the gauge to the banjo bolt (and 90°

fitting depending on application).

Since the gauge and fitting are connected with a 1/8" NPT (National Pipe

Thread), please use a pipe sealer

such as Teflon® to avoid possible

fuel leaks. The connection between

( )

INTRODUCTION

2

F2

F1

297

( )

270

2

the fitting and the fuel line requires no

sealer since they employ washers.

INSTALLATION

The fuel pressure tap on the late

model Honda Civic/CRX/del Sol,

Acura Integra/NSX, Mitsubishi

Eclipse, Eagle Talon & Plymouth

Laser is located on top of the fuel

filter which is mounted on the passenger side firewall (driver's side

for the NSX). We suggest the vehicle be allowed to cool for a while

before you begin since you will be

working around the fuel system.

CAUTION: THE FUEL SYSTEM

CONTAINS FUEL UNDER HIGH

PRESSURE EVEN WHEN THE

ENGINE IS NOT RUNNING. BEFORE DISCONNECTING A FUEL

LINE, WRAP THE FITTING WITH

A RAG TO PREVENT FUEL

SPRAY.

Remove the fuel pump fuse from

the fusebox. Try starting the vehicle several times until it will not

remain running. This will help relieve pressure in the fuel system

Printed in the U.S.A.

9500666-04

Page 2

(NOTE: For some vehicles it may

be helpful to remove the battery).

Place a towel around the top of the

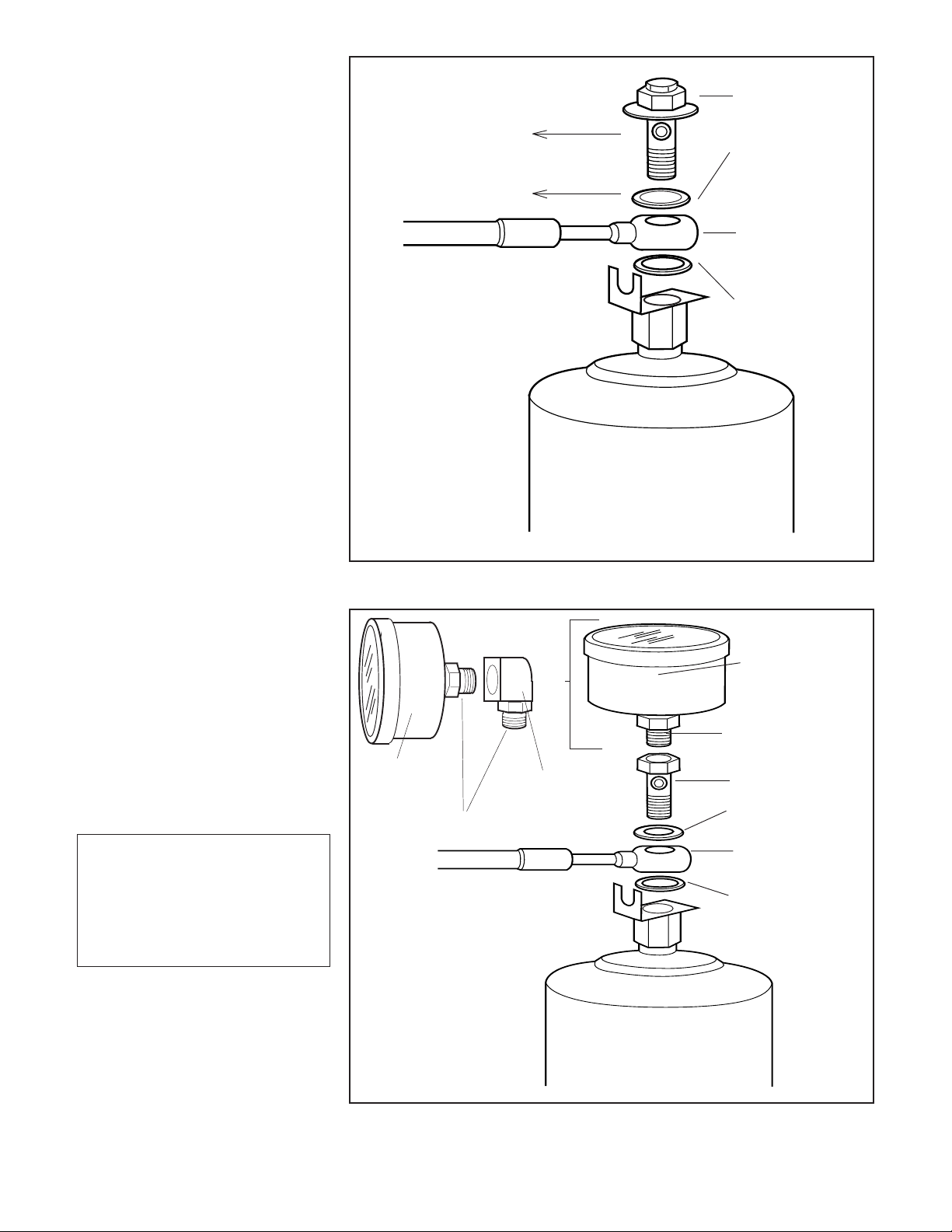

fuel filter. Remove the banjo bolt

assembly (be careful of spraying

fuel!). See Figure One. Replace

the top washer with the supplied

copper washer (Note: If the bottom washer is damaged it must be

replaced with Acura p/n 90428PD6003 or Mistubishi p/n

MB906711. Install the fitting assembly with the copper washer,

banjo fitting (fuel line) and stock

washer into the fuel filter (See

Figure Two). Tighten to 16 ft-lb.

When installing the gauge, you

have the option of mounting the

gauge face up (as shown in Fig-

ure Two) or face sideways by

using the supplied 90° brass fitting. Make sure to use Teflon tape

(not supplied) on the fuel pressure

gauge threads (and 90° fitting, if

applicable), then either screw the

gauge into the banjo bolt or 90°

fitting. Tighten the gauge to 10 ftlb while using a backup wrench on

the banjo bolt or brass fitting. DO

NOT OVERTIGHTEN! If you used

the 90° fitting, screw the fitting\gauge

assembly into the banjo bolt. Tighten

the 90° fitting to 10 ft-lb while

using a backup wrench on the banjo

bolt. DO NOT OVERTIGHTEN!

Note: Carefully lower hood (without fully closing) and check for

sufficient clearance between the

top of the gauge and the hood.

Reinstall fuse. Start engine and

check for fuel leaks.

Fuel Pressure

Gauge

(Apply Teflon Tape)

Remove

Replace

Figure One

or

90° Fitting

Banjo Bolt

Assembly

Stock Washer

Banjo (Fuel Line)

Stock Washer

Fuel Filter

Fuel Pressure

Gauge

(Apply Teflon Tape)

Brass Fitting

Copper Washer

Parts List

1 Fuel Pressure Guage, 0 - 100 psi

1 Brass Banjo Bolt

1 90° Brass Fitting

1 Copper Washer

1 Instruction Sheet

Banjo (Fuel Line)

Stock Washer

(replace if damaged)

Fuel Filter

Figure Two

Loading...

Loading...