Page 1

Installation Instructions

6L80 Cast Aluminum

Deep Transmission Fluid Pan

SPECIFICALLY DESIGNED FOR 2010-2014 CAMARO SS (V8)

Part Number 70391

(see www.bmracing.com for the latest vehicle fitment applications and model years)

© 2013 by B&M Racing and Performance Products

Congratulations! You have just purchased one of the finest cast aluminum pans available for the GM 6L80

transmissions. This B&M Cast Alu-

minum Deep Transmission Fluid

Pan has been designed to work on

most GM vehicles equipped with 6L80

transmissions (specifically 2010-2014

Camaro SS equipped with an automatic transmission). The B&M Cast

Aluminum Deep Fluid Pan provides

several advantages over stock factory

oil pans. The extra capacity provides

increased oil volume and added cooling, while the finned aluminum construction increases case rigidity and

improved heat transfer. The magnetic

drain plug feature allows regular transmission maintenance and oil changes

without the usual mess associated

with “dropping the pan,” and limits ferrous debris from circulating in the

transmission.

WARNING!: This B&M Cast Aluminum Deep Transmission Fluid Pan

has been designed with added capacity and external cooling fins which

cause the pan to hang as much as

¾” or more, lower than the original

transmission pan. Extra care and

caution should be taken when driving

the vehicle over objects and/or straddling debris. As always, check underneath the vehicle if objects or features come into contact with under ve-

hicle components before continuing

driving.

NOTE: The 6L80 transmissions do

not come with a dip stick. For ease

of fluid measurement and fill, it is

suggested to use a B&M 6L80 Lock-

ing Dipstick P/N 22168 to measure

fluid level and have a convenient

location to fill the transmission.

When installing your B&M Cast Aluminum Deep Fluid Pan you may

wish to consider a B&M Transmission Temperature Gauge. Most

transmission and converter failures

can be traced directly to excessive

heat. This accurate temperature

gauge comes with a light kit, colorcoded dial face, antiglare enclosure,

wires, terminals, special sending unit,

and T -fitting for easy installation. A vailable at your B&M dealer.

INTRODUCTION

This deep fluid pan can be installed in

about an hour by carefully following

the instructions. Check the tool list

at the end of these instructions for the

tools required to install your B&M Cast

Aluminum Deep Fluid Pan. Transmission components are precision fit

and dirt is the number one enemy of

an automatic transmission. Automatic transmissions operate at tem-

peratures between 150°F and 250°F .

It is suggested that the vehicle be allowed to cool off for a few hours to

avoid burns from hot oil and parts. The

vehicle should be off the ground for

ease of installation – jack stands,

wheel ramps or a hoist will work fine.

MAKE SURE VEHICLE IS FIRMLY

SUPPORTED - DO NOT WORK UNDER A VEHICLE IF IT IS SUPPORTED BY ONLY A JACK! Try to

raise the vehicle 1-2 feet so you will

have plenty of room to work. Also, have

a small box to put bolts in and a drain

pan to catch oil.

NOTE: This kit does not come with

a transmission filter or gasket.

INST ALLATION

BEFORE BEGINNING INSTALLATION IT IS RECOMMEND TO INSTALL B&M 6L80 LOCKING DIPSTICK P/N 22168 FIRST TO INSURE

CORRECT FLUID FILL LEVEL!

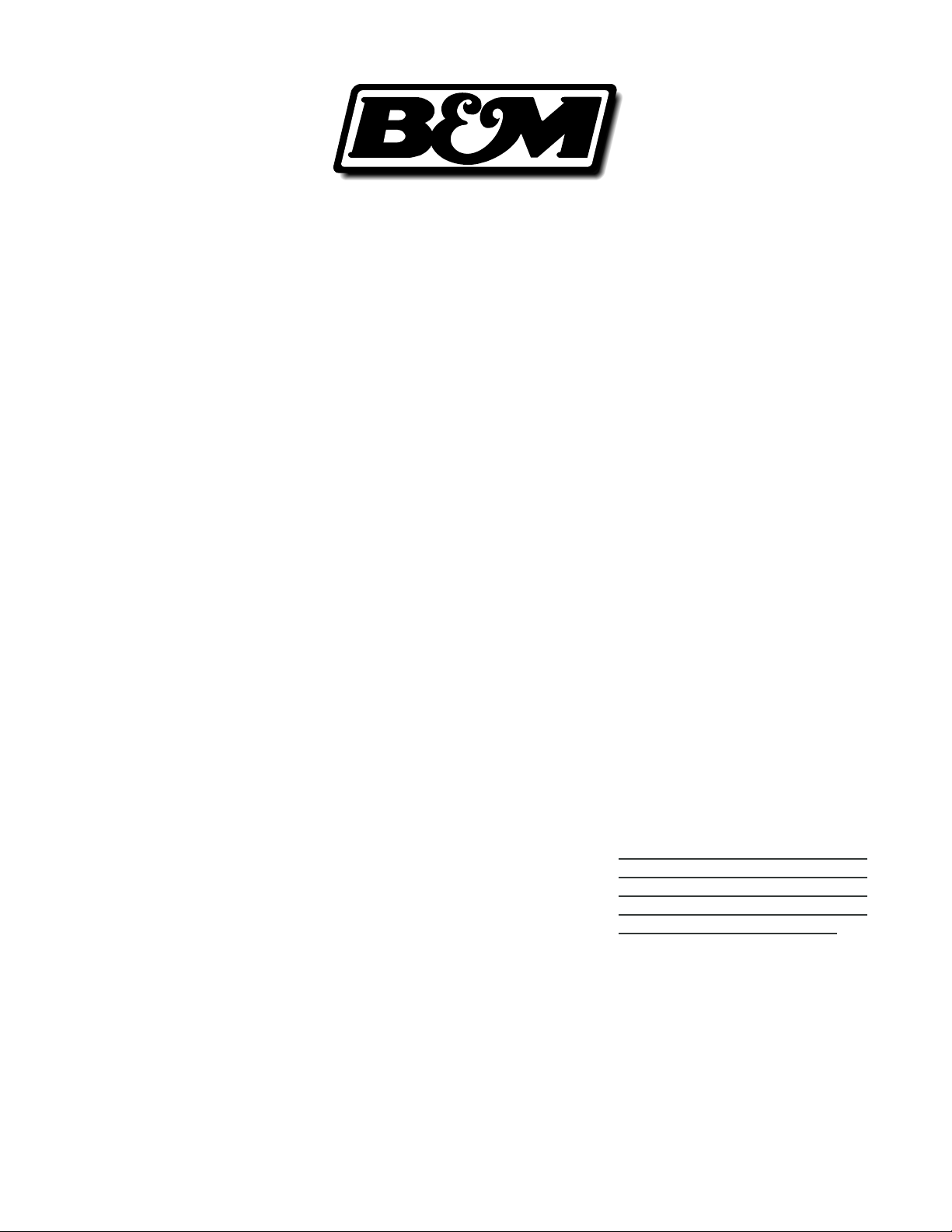

STEP 1. Place a drain pan underneath

transmission. To drain the oil pan, first

unscrew the rear center oil level check

plug, using a 14mm deep socket and

ratchet (see figure 1). Allow the transmission fluid to drain and then re-install the check plug.

NOTE: At this point only a small portion of the fluid in the pan has

Printed in the USA 9500871-00

Page 2

drained (~ 1.5 quarts (1.4L) – cold

transmission).

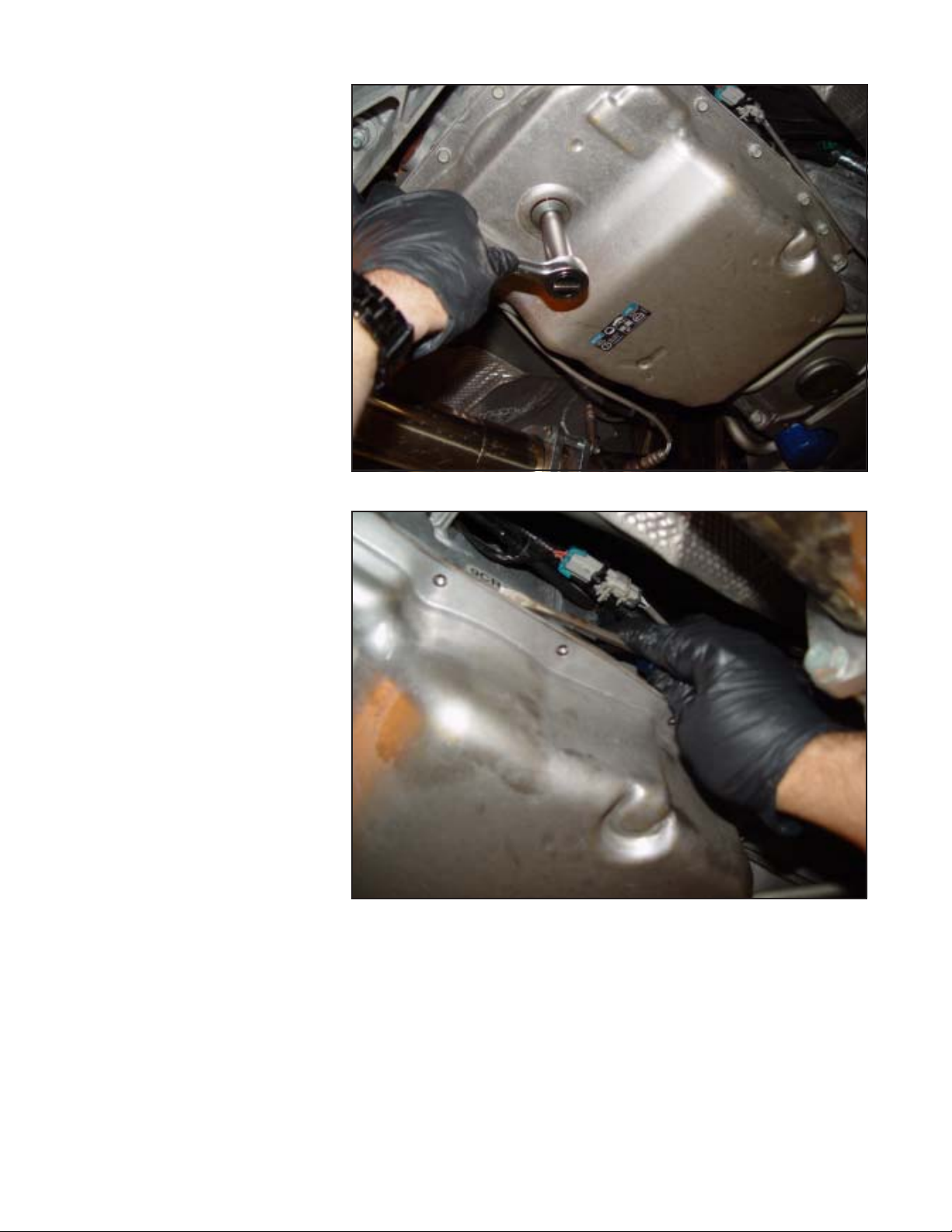

STEP 2. Loosen two opposing corner

bolts and remove the rest of the pan

bolts using a 10mm socket, extension, and ratchet. If the pan and gasket sticks, pry it down slightly with a

screwdriver to break the seal (see fig-

ure 2).

NOTE: Be careful not to damage

the transmission surface and/or

pan gasket as leaks could develop.

STEP 3. Carefully remove the two re-

maining corner bolts while holding the

pan and lower the pan without spilling

the remaining fluid. The pan will be

about 7/8 or more, full of fluid (~4

quarts (3.8L)), so keep the pan level

and slowly move it out from underneath the vehicle where it can be safely

drained (see figure 3).

STEP 4. Remove the magnet from the

pan, fully clean it and set it aside as

it will be re-used.

STEP 5. The oil filter will now be exposed. If changing the filter (recommended), pull the filter out of the valve

body , being careful not to bend the filter pickup tube as it is plastic and may

crack or break (see figure 4). If the

seal remains in the valve body and

does not come out with the filter, remove it by using a flat head screwdriver. Be careful not to damage the

surface. Then install the new filter

(GM p/n: 24236931).

STEP 6. Place the magnet removed

earlier on the bottom of the B&M Cast

Aluminum Deep Transmission

Fluid Pan directly on top of the star

feature with threaded hole (see figure 5). Using the supplied button head

screw and over-sized washer, af fix the

magnet to the bottom of the pan and

tighten with a 4mm hex wrench.

STEP 7. Place Teflon tape on the

threads of the magnetic drain plug and

temperature sensor plug (or sending

unit if using a temperature gauge) and

tighten them into the pan using a 3/8"

hex wrench and 7/16" box wrench (see

figure 6).

STEP 8. Using a 14mm deep socket,

extension, and ratchet; remove the oil

level check plug from the stock pan

and install it into the oil level check

recess of the B&M Cast Aluminum

Figure 1

Figure 2

Deep Fluid Pan. Tighten to 18 ft-lbf

(25 N-m).

STEP 9. Closely inspect the transmission pan gasket for any signs of problems including, rips, tears, or excessive deformation. Replace with a new

gasket (GM p/n: 24224781) if necessary . Align the gasket onto the mounting flange of the B&M Cast Alumi-

num Deep Fluid Pan and push the

nubs of the gasket into the guide hole

of the pan to hold the gasket in place

(see figure 7).

STEP 10. Clean the transmission

mating surface with a clean rag (see

figure 8).

STEP 11. Install the B&M Cast Aluminum Deep Oil Pan using the sup-

plied bolts and washers (see figure

9). Using a 5mm hex drive, extension,

and torque wrench tighten the bolts

to 80 in-lbf (9N-m) in the sequence

Page 3

Figure 3 Figure 4

Figure 5

shown in diagram A. Do not over

tighten as this can cause leaks or

damage to the transmission case or

gasket.

STEP 14. Add ~7.3 quarts (6.9L)

Dexron VI transmission fluid (only) to

the transmission using one of these

methods:

-Method A (preferred): With the dipstick removed, use a funnel and slowly

add the transmission fluid through the

previously installed B&M 6L80 Lock-

ing Dipstick P/N 22168 tube. Pouring the fluid in too quickly can cause

fluid to back-up in the tube and spill.

Pour slowly and carefully .

-Method B: Locate the fill plug on the

right side of the transmission case

(see figure 10) and remove it by pull-

ing it straight out from the top. Using

a tube and a pump, pump the fluid into

the transmission pan through the fill

plug hole.

-Method C: Remove the oil level

check plug and using a tube and

pump, pump the fluid into the transmission pan through the oil level check

hole. NOTE: Using this method you

will only be able to add ~5.8 quarts

(5.5L) of fluid before the fluid starts to

spill back through the oil level check

hole. At this point, you will need to

proceed to the next steps and then

return to this step to add additional

fluid.

STEP 15. Reinstall any caps or plugs

that were removed during the transmission fluid fill procedure in the previous step and then lower the vehicle.

STEP 16. Check the fluid level of the

transmission. CAUTION!: The trans-

mission fluid level must be checked

Figure 6

when the operating range of the transmission fluid temperature (TFT) is between 86-122°F(30-50°C). If the transmission fluid is outside this range the

level of the transmission fluid cannot

be accurately determined resulting in

either an over filled or under filled transmission.

A. Observe the TFT using the

driver information center (DIC)

or other temperature measuring tool.

B. Start and idle the engine.

C. Depress the brake pedal

and move the shift level

through each gear range.

Pause for at least 3 seconds

in each range. Move the shift

level back to P ARK. Ensure

the engine RPM is low (500800 RPM).

Page 4

Figure 7 Figure 8

Figure 9

D. Allow the engine to idle

for at least 1 minute.

STEP 17. CAUTION!: THE ENGINE

MUST BE RUNNING AND TFT

WITHIN THE RANGE AS STATED

ABOVE when the transmission fluid

level is checked:

- Method A (preffered):Using the previously installed B&M 6L80 Locking

Dipstick P/N 22168 unscrew the dipstick cap and check the transmission

fluid level according to the instructions.

Add (see step 14) or remove fluid (use

drain plug or oil level check plug) accordingly.

-Method B: Carefully raise and support the vehicle (with the engine still

running and TFT in range). Ensure the

vehicle is level. Remove the oil level

check plug from the pan and allow any

fluid to drain until the fluid begins to

drip. If no fluid comes out, add fluid

as described in step 14.

WARNING!: An under-filled transmission will cause premature component wear and damage. An

over-filled transmission will cause

fluid to discharge out the vent tube,

fluid foaming, and/or pump cavitation. DO NOT operate the vehicle

Figure 10

with an incorrect transmission

fluid level.

STEP 18. Inspect the pan gasket and

any of the ports for any signs of leaks

and correct immediately before operating vehicle.

STEP 19. Reset the oil life monitor in

the DIC.

STEP 20. Over the next several

cycles of vehicle operation inspect

the transmission, pan, and ports for

any signs of leaks and periodically

check the transmission fluid level as

described in steps 16 & 17.

Page 5

FRONT OF VEHICLE

PAN BOLT TORQUE SEQUENCE

Diagram A

Parts List

1 B&M Cast Alum. Pan

1 Magnetic Drain Plug

1 1/8” NPT Pipe Plug

1 M6-1.0x10mm Screw

1 Oversized Washer

18 M6-1.0x25 mm Bolts

18 M6 Flat Washers

1 Transmission Filter*

*(not included - but

recommended)

Drain Pan

14mm Deep Socket

Ratchet Extension

Ratchet

10mm Socket

Flat Blade Screwdriver

4mm & 3/8” Hex Wrench

5mm Hex Drive

7/16” Box Wrench

T eflon T ape

T ools List

T orque Wrench(s)

Clean Rags

8 Quarts (7.6L)Dexron VI Trans Fluid

Jack & Jack Stands

Funnel

B&M P/N 22168-Locking Dip Stick

(suggested - otherwise use:)

Fluid Pump

Tubing

Technical Service

A highly trained technical service department is maintained by B&M Racing and Performance Products to answer

your technical questions, provide additional product information and offer various recommendations.

B&M offers a wide variety of transmission related products to improve cooling and ultimately longevity of your

transmission. See your local retailer of B&M products for specific prices.

Technical service calls, correspondence, and warranty questions should be directed to the following address:

B&M Racing and Performance Products

100 Stony Point Rd., S te. 125

Santa Rosa, CA 95401

Phone (707) 544-4761

Monday-Friday 7AM to 5PM PST

Page 6

P/N 22168

LOCKING TRANSMISSION DIPSTICK

FOR 6L80 TRANSMISSIONS

(specifically designed for 2010-2014 Camaro

SS with Automatic Transmission)

www .bmracing.com

P/N 70297

HI-TEK ENGINE OIL & AUT OMATIC

TRANSMISSION COOLER

( for 2010-2014 Camaro SS with Automatic

Transmission)

www .bmracing.com

P/N 70274

SUPERCOOLER - TRANSMISSION OIL

COOLER

( for 2010-2014 Camaro SS with Automatic

Transmission)

www .bmracing.com

Loading...

Loading...