Page 1

SB-6G, SB-10G and SB-16G

CONVECTION STEAMER ON A GAS FIRED BOILER BASE

INSTALLATION – OPERATION – MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 864-0183

S00046 Rev D (4/09)

1

Page 2

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment,

alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing,

operating or servicing this equipment.

This manual should be retained for future reference.

FOR YOUR SAFETY: Do not store or use gasoline or other

flammable vapors or liquids in the vicinity of this or any other

appliance. Intended for commercial use only. Not for household use.

PURCHASER: Instructions to be followed in the event that the operator of

this appliance smells gas must be posted in a prominent location. This

information shall be obtained by consulting the local gas supplier.

Keep the appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air.

Adequate clearances must be maintained for servicing and proper

operation.

Do not attempt to operate this unit in the event of a power failure.

NOTICE: Contact the factory, the factory representative or local service

company to perform maintenance and repairs.

It is recommended that this manual be read thoroughly and that all instructions be

followed carefully.

2

Page 3

TABLE OF CONTENTS

DESCRIPTION PAGE

Important Notes for Installation and Operation ............................................................... 2

1.0 Service Connections ............................................................................................... 4

2.0 Installation Instructions ............................................................................................ 5

3.0 Operation Instructions ......................................................................................... 10

4.0 Operation Instructions for Boilers with CSD-1 Controls ........................................ 12

5.0 Operation Instructions, Cooker Section ............................................................... 15

6.0 Periodic Maintenance .......................................................................................... 17

7.0 Adjustments ........................................................................................................ 19

8.0 Troubleshooting ................................................................................................... 21

9.0 Cooking Chart ........................................................................................................ 24

3

Page 4

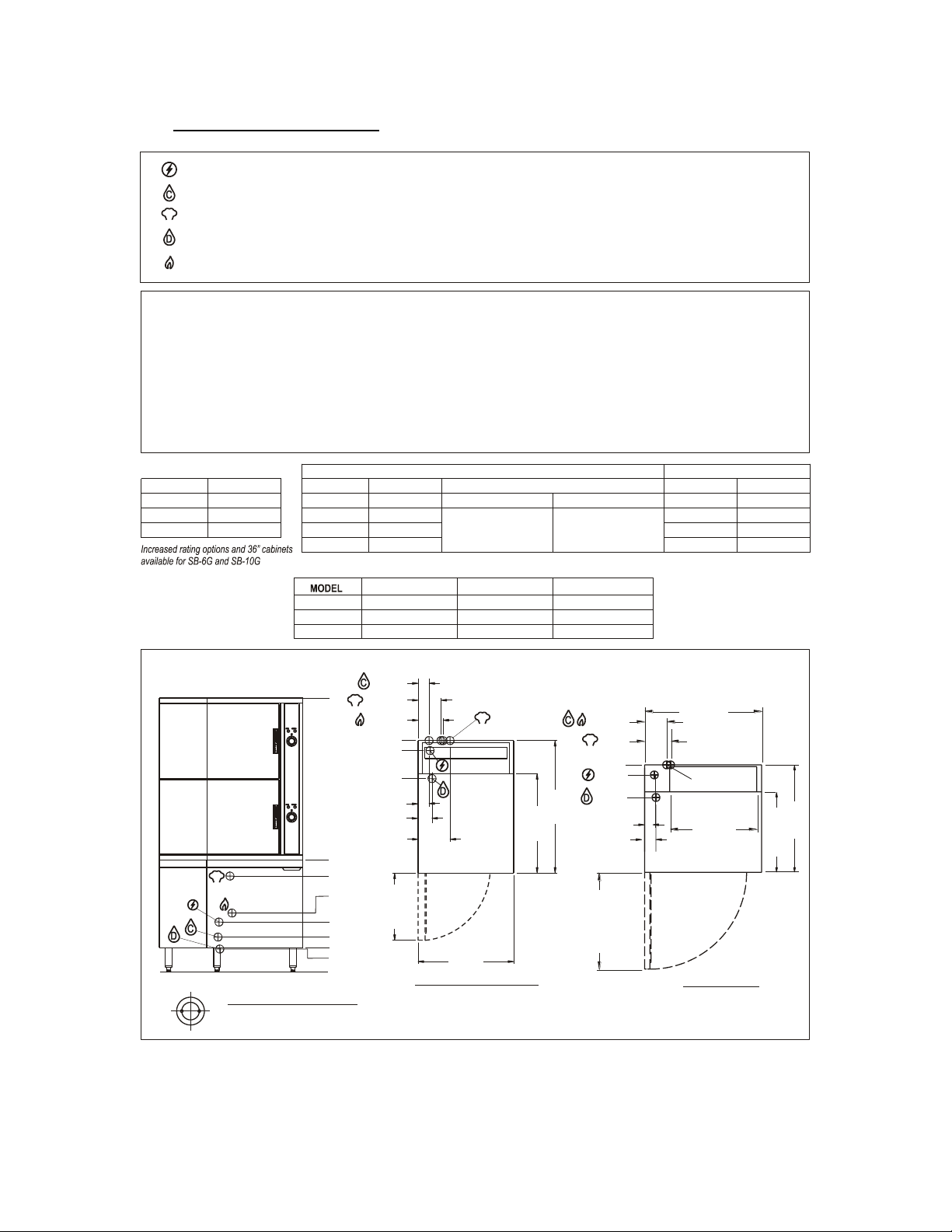

1.0 SERVICE CONNECTIONS

ELECTRICAL CONNECTION: 1/2" conduit connection to controls. 120VAC-60Hz-1PH 2 AMPS per compartment or to be as specified on data plate.

COLD WATER: 3/8" O.D. tubing at 25-50 PSI(170-345 kPa)

STEAM TAKE-OFF CONNECTION: 3/4"IPS optional to operate adjacent equipment.

DRAIN: 2"IPS piped to open floor drain. No Solid Connection.

GAS CONNECTION: 3/4"IPS supply line required.

S

AVAILABLE CABINET WIDTH

GAS SUPPLY

41.0

140,000

300,000

200,000

250,000

87.9

73.3

58.6

BTU/HOUR kW/HOUR

YES

YES

YES

NO

NO

YES

YES

YES

24"

36"

WATER COLUMN PRESSURES

NATURAL

PROPANE

Water quality is the major factor affecting the performance of your appliance. If you are unsure of water quality, consult a

local water treatment specialist and have the water analyzed. Your water supply must be within these general guidelines:

Water which fails to meet these standards should be treated by installation of water conditioner.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR WATER QUALITY IS NOT COVERED UNDER WARRANTY.

Total dissolved solids

Total alkalinity

Silica

Chlorine

pH Factor

Less than 13 PPM

Less than 1.5 PPM

7.0-8.5

WATER QUALITY STATEMENT

Less than 60 PPM

Less than 20 PPM

[178mm-355mm]

7" - 14"

[279mm-355mm]

11" - 14"

REAR FLANGED FOOT DETAIL

7/16" [11mm] HOLES

ON 2.5 [63] B.C.

2 EQUALLY SPACED Ø

DIMENSIONS ARE IN INCHES [MM]

S

A

28 [711]

6 [152]

0 [0]

24 [610]

C

8.75 [222]

5.75 [146]

B

S

16.75 [425]

33 [838]

6.25 [159]

24 [610]

5.75 [146]

3.5 [89]

2.75 [70]

25 [635]

8 [203]

S

9.5 [241]

2.5 [64]

0 [0]

36” cabinet

3 [76]

SB-6G and SB-10G TOP VIEW

10 [254]

2.5 [64]

0 [0]

3.5 [89]

2916.75 [756]

S

8 [203]

6.75 [171]

3.5 [76]

36 [914]

33 [838]

24.75 [629]

SB-16G TOP VIEW

26.75 [679]

MODEL

SB-6G

SB-10G

SB-16G

STD INPUT

140,000

200,000

300,000

A

SB-6G

SB-10G

SB-16G

55.5 [1410]

68.5 [1740]

67 [1702]

C

B

12.5 [318]

12.5 [318]

6 [152]

14.75 [375]

14.75 [375]

13.5 [343]

DIMENSIONS

4

Page 5

GENERAL

The gas boiler is designed to ASME Code and approved as a steam heating boiler

restricted to operation at pressure not to exceed 15 psi. The gas boiler may be

operational on Natural or Propane gas. Boilers have electronic ignition and may have

optional CSD1 controls.

2.0 INSTALLATION INSTRUCTIONS

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the appliance is

found to be damaged, save the packaging material and contact the carrier within 15

days of delivery.

Before installing, verify that the gas (natural or propane), the elevation from sea level

and the electrical supply agree with the specification on the data plate. NOTE: If this

appliance is being installed above 2000 feet altitude, contact your authorized service

office to assure that the proper orifice size for your elevation has been installed.

LOCATION

The installation location must be kept free and clear of combustibles. Do not obstruct

the flow of combustion and ventilation air. Clearance from combustible construction

must be a minimum of 3 inches from the sides and 6 inches from the back. The

appliance should be installed on a noncombustible floor. Provide adequate clearances

for cleaning, maintenance, service and proper operation.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion for the gas burners. Do not

obstruct the air flow into and around the appliance. Do not obstruct the flow of flue

gases from the flue duct located at the rear and above the cabinet. Position the

appliance in its final location. Check that there are sufficient clearances to service the

controls, for door swings, etc., so there will be no problem in making the required supply

and drain connections.

Allow enough space between any other piece of equipment or a wall for service access.

Service on the cabinet base may require access to the left and/or right side panels.

5

Page 6

LEVELING AND ANCHORING THE APPLIANCE

1. Place appliance in the installation position.

2. Place a carpenter’s level on top of the appliance and turn the adjustable feet to level

side-to-side and front-to-back.

3. Mark hole locations on the floor through the anchoring holes provided in the rear

flanged adjustable feet.

4. Remove appliance from installation position and drill holes in locations marked on

the floor. Insert proper anchoring devices (not supplied).

5. Place appliance back in the installation position.

6. Place carpenter’s level on top of appliance and re-level side-to-side and front-to-

back.

7. Bolt and anchor appliance securely to the floor.

8. Seal bolts and flanged feet with silastic or equivalent compound.

INSTALLATION CODES AND STANDARDS

Gas installation to conform to local codes, or in absence of local codes, with the National

Fuel Gas Code - ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation

Code, CSA B149.1, as applicable, including:

1. The appliance and its individual shut off valve must be disconnected from the gas

supply piping system during any pressure testing of that system at pressures in

excess of ½ psig (3.5 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its

individual manual shut off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ psig (3.5 kPa).

Electrical grounding must be provided in accordance with local codes, or in the absence

of local codes, with the National Electrical Code ANSI/NFPA 70. In Canada, installation

must be in accordance with the Canadian Electrical Code CSA C22.2.

6

Page 7

WIRING DIAGRAM FOR APPLIANCE IS LOCATED INSIDE CABINET DOOR.

NOTICE: If this equipment is being installed at over 2,000 feet

altitude and was not so specified on order, contact service

department. Failure to install with proper orifice sizing may void the

warranty.

WARNING: Plumbing connections must comply with applicable

sanitary, safety, and plumbing codes.

EXHAUST FANS AND CANOPIES

Canopies are set over ranges, ovens, kettles, etc., for ventilation purposes. It is

recommended that a canopy extend 6" past the appliance and be located 6 feet 6 inches

from the floor. Filters should be installed at an angle of 45 degrees or more with the

horizontal. This position prevents dripping of grease and facilitates collecting the run-off

grease in a drip pan, usually installed with the filter. A strong exhaust fan tends to create

a vacuum in the room and may interfere with burner performance or may extinguish pilot

flames. Makeup air openings approximately equal to the fan area will relieve such

vacuum. In case of unsatisfactory performance on any appliance, check with the

exhaust fan in the “OFF” position.

SERVICE CONNECTIONS

PLUMBING CONNECTIONS

WATER SUPPLY CONNECTION

The incoming cold water supply connection, at the rear of the steamer cabinet, requires

3/8" tubing and water pressure of 25 - 50 psi. A manual shut-off valve must be provided

convenient to the appliance; this valve should be open when the boiler is in operation.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR WATER

QUALITY IS NOT COVERED UNDER WARRANTY. SEE WATER QUALITY

STATEMENT (PAGE 4)

DRAIN CONNECTION

The steamer drain (2" IPS) should be piped to a floor drain near the steamer. There

should be no solid drain connection; an “open gap” between the steamer and the floor

drain is required.

7

Page 8

GAS CONNECTION

CAUTION: The pipe thread compound used when installing

pipes must be a type that is resistant to the action of liquified

petroleum or propane gases.

WARNING: Prior to start-up, check all joints in the gas supply

line for leaks. Use soap and water solution. Do not use an

open flame.

NOTICE: If applicable, the vent line from the gas appliance pressure regulator shall be

installed to the outdoors in accordance with local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and

Propane Installation Code CSA B149.1, as applicable.

1. The data plate on the cabinet door of the boiler indicates the type of gas your unit is

equipped to burn. DO NOT connect to any other gas type.

Keep the appliance area free and clear from combustible substances. Do not

obstruct the flow of combustion and ventilation air.

2. A 3/4" NPT line is provided at the rear for the connection. Each boiler is equipped

with an internal pressure regulator which is set at 3.5" W.C. manifold pressure for

natural gas or 10.5" W.C. for L.P. gas. Use the 1/8" pipe tap on the burner manifold

for checking pressure.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A steady supply pressure, between

7" W.C. and 14" W.C. for natural gas and 11" W.C. and 14" W.C. for propane gas is

recommended. With all units operating simultaneously, the manifold pressure on all

units should not show any appreciable drop. Fluctuations of more than 25% on natural

gas, and 10% on propane gas, will create pilot problems and affect burner operating

characteristics. Contact your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt, or foreign matter before connecting the

line to the unit.

Codes require that a gas shut-off valve be installed in the gas line prior to the steamer.

Make sure the pipes are clean and free of obstructions, dirt, and piping compound.

8

Page 9

ELECTRICAL CONNECTIONS

WARNING: Electrical and grounding connections must comply with the applicable

portions of the National Electrical Code and/or other local codes.

120 VAC-60 Hz - Single Phase

Make electrical connection to terminal block in rear of unit. A separate 15 amp supply is

needed for each unit.

Refer to the electrical diagram located inside cabinet on door.

9

Page 10

3.0 OPERATION INSTRUCTIONS

WARNING: Do not force the gas control knob. Use only your hand to turn the gas

control knob. Never use any tool. If the gas control knob will not operate by hand

the gas control should be replaced by a qualified service technician.

WARNING: Do not disassemble the gas control; it contains no replaceable

components. Attempted disassembly or repair may damage the gas control.

WARNING: In the event of main burner ignition failure, a 5 minute purge period

must be observed prior to re-establishing ignition source.

CAUTION: If you smell gas during the lighting procedure, immediately shut off the

gas supply until the leak has been corrected.

For CSD-1 equipped boilers, see section 4.0 for Operation Instructions for CSD-1

Equipped Boiler.

BOILER CONTROLS (Inside Cabinet)

Main Power Switch - ON fills the boiler tank and turns the boiler controls on.

You should allow 20 minutes to fill the tank and generate

steam.

- OFF shuts off the boiler controls and opens the automatic

blowdown valve, emptying the boiler tank and releasing

water and steam to the drain. This should be done at least

once daily to remove sediment, lime, or scale.

Pilot Light - Indicates main power is ON.

Boiler Pressure Gauge - Should read 9 -11 psi during operation; 0 psi during

shutdown.

Water Level Sight Glass - Observe level of water in the boiler and water quality.

Murkiness in the water indicates inadequate water quality;

the owner must supply proper water to the boiler (see page

4, Water Quality Statement).

Water Level Control - While ON, briefly open the water level control daily to

remove any sediment that might accumulate.

Safety - This valve will release (pop off) if the boiler has too much

pressure. Once a week, this valve should be tripped

during operation to make sure it functions properly.

10

Page 11

1. START-UP - BOILER OPERATION WITH STANDING PILOT IGNITION

Open manual gas shut off supply valve and if the appliance has a manual blowdown

valve, close it. Open cabinet door and turn ON power switch located on left side. Green

pilot light will come on, water will begin to enter boiler and required water level will be

reached in about three minutes. Observe water gauge glass to verify.

The dial on the combination gas control valve has three positions (ON-PILOT-OFF) for

manual gas control of main burners and pilot. Turn DIAL to PILOT. Depress dial and

light burner located on centre main burner of boiler. Maintain dial in depressed position

for about 30 seconds and release. Observe that the pilot burner flame stays on. If at

any time the flame should become extinguished, a 5 minute period of complete shut off

of gas supply is required before relighting.

Turn dial to ON and burners should ignite. Steam generation will now commence and

be completed in approximately 15 minutes. Steam generation should reach

approximately 11 psi as indicated on the pressure gauge on the boiler.

2. START UP - BOILER OPERATION WITH ELECTRONIC IGNITION

Open manual gas supply valve.

Open cabinet door and turn main power switch ON. Green pilot light will come on, water

will begin to enter boiler and required water level will be reached in about three minutes.

Observe water gauge sight glass to verify.

11

Page 12

4.0 OPERATION INSTRUCTIONS FOR BOILERS WITH CSD-1 CONTROLS

WARNING: In the event of main burner ignition failure, a 5 minute purge period

must be observed prior to re-establishing ignition source.

INITIAL START-UP PROCEDURE

1. Open the manual gas shut-off supply valve.

2. Close the manual blowdown valve, if so equipped.

3. Light the pilot burner.

The dial on the gas combination valve has three positions (ON - OFF - PILOT) for

manual gas control of main burners and pilot burner. Turn the dial on the gas

combination valve to “PILOT”, depress the dial and light the pilot burner on the

centre burner. Maintain the dial in depressed position for about 30 seconds and

release. Observe the pilot flame stays ON. Turn dial to “ON”.

If at any time the flame should become extinguished, a five (5) minute purging is

required before relighting is attempted.

4. Open cabinet door and turn “ON” the power switch.

The green pilot light will come “ON”. Water should begin to enter the boiler. When

enough water has entered the boiler the (amber) “STANDBY” pilot light will come

on.

5. Press the “RESET” switch to begin boiler operation.

The “STANDBY” pilot light will go off and the boiler will begin operation.

12

Page 13

4.0 OPERATION INSTRUCTION FOR BOILERS WITH CSD-1 CONTROLS

(Continued)

Daily Startup Procedure

1. Close the manual blowdown valve, if so equipped.

2. Examine that the pilot burner flame is burning. If the pilot burner is out, a five (5)

minute period of complete gas supply shut off is required before relighting.

3. Open cabinet door and turn “ON” the power switch.

The green pilot light will come “ON”. Water will begin to enter the boiler. When

enough water has entered the boiler the (amber) “STANDBY” pilot light will come

on.

4. Press the “RESET” switch to begin the boiler operation. The “STANDBY” pilot light

will go off and the boiler will begin operation.

Daily Shutdown Procedure

1. Turn “OFF” the power switch. Observe that the burners go off.

2. Open the manual blowdown valve, if so equipped. If the appliance is equipped with

an automatic blowdown solenoid valve, the boiler’s contents, water and steam will

be blown out and exhausted through the appliance drain. The cold water solenoid

valve will be activated.

Complete Shutdown Procedure

If the appliance is not intended to be operational for a lengthy period, then shut it down

completely.

1. Open the manual blowdown valve, if so equipped.

2. Shut off all supplies of power, gas and water to the appliance.

Normal Boiler Operating Cycle

Water Fill Cycle

On the initial filling of the boiler, the reset switch must be activated to initialize the safety

lockout circuit. Once the water in the boiler has reached the proper level, the level

control will open the circuit to the fill solenoid valve, stopping the flow of water to the

boiler. As the water is consumed in the production of steam, the level control will close

the circuit to the fill solenoid and water will be supplied to the boiler.

13

Page 14

4.0 OPERATION INSTRUCTION FOR BOILERS WITH CSD-1 CONTROLS

(Continued)

Firing Cycle

The gas valve is operated by pressure sensing devices. On the initial operation of the

boiler, steam generation should reach 11 psi in approximately 15 minutes. At this point

the “Operating Pressure” switch will open, closing the gas valve. When pressure drops

to 9 psi, the pressure switch closes, the gas valve will open and ignition should occur.

Should the pressure rise more than 14.5 psi the “Override Pressure Switch” will close

the circuit to the override solenoid valve, releasing excess steam.

Condensing Drain

A thermostat is located in the drain assembly and is activated by the temperature of

steam. The thermostat opens the cooling solenoid valve, in turn supplying water to the

drain to condense steam.

Automatic Blowdown Valve

If the unit has an automatic blowdown valve, it is activated by the main power switch.

The boiler will be drained should the main power switch be turned “OFF”.

SAFETY LOCKOUT CONDITIONS

High Temperature Condition

A high temperature safety device is installed on the boiler. Should the temperature

exceed the limit of this device, the boiler will be shut down and put in a state of lockout.

The “Temperature” pilot light (red), and the “Standby” pilot (amber), will come on.

High Pressure Condition

A high pressure safety switch is installed on the boiler. Should the pressure exceed the

limit of this device, the boiler will be shut down and put into a state of lockout. The

“Pressure” pilot light (red), and the standby pilot light (amber), will come on. Should this

device fail to operate, the safety relief valve will open.

Low Water Condition

A second low water safety cut off is supplied with the boiler. Should the water level fall

below normal operating levels, this device will shut down and put the boiler in a state of

lockout. The “Low Water” pilot light (red), and the “Standby” pilot light (amber) will come

on.

14

Page 15

5.0 OPERATION INSTRUCTIONS

CAUTION: Live steam and accumulated hot water in the compartment may be

released when the door is opened.

CAUTION: An obstructed drain can cause personal injury or property damage.

COOKER SECTION

Start-up procedures for your cooker must be completed once daily prior to operation

(see instruction plate or previous section in this manual for boiler start up procedures).

With ready pilot light on, preheat cooker compartment for one minute when the cooker is

to be first used for the day or whenever the compartment is cold.

1. Close compartment doors and set timer to “1 minute”.

2. When buzzer sounds, set timer to the “OFF” position.

3. Cooker is now ready for cooking.

4. With cooking compartment preheated and ready pilot light on, place pans of food to

be cooked into compartment and shut door.

5. Set timer to cooking time desired. Cooking cycle may be interrupted at any time by

opening door and resumed again by closing door.

6. When buzzer sounds, it indicates the end of the cooking cycle and that no more

steam is entering the compartment. Cooking pilot light will go off and ready pilot

light will come on. Buzzer must be shut off by turning the timer to its off position.

Frequently check that the compartment drain and plumbing are free of all obstructions.

Never place food containers, food or food portion bags in the cooking compartment in

such a way that the compartment drain becomes obstructed.

Each compartment is equipped with a removable drain screen. Frequently check the

drain screen for accumulation of food particles. Should food particles accumulate

against, or clog the drain screen, remove it, clean it thoroughly and then replace it in its

original position.

15

Page 16

WARNING: Never spray water into electric controls.

NOTICE: Contact the factory, the factory representative or a local service company to perform

maintenance and repairs should the appliance malfunction. Refer to warranty terms.

COOKER SECTION (Continued)

SHUTDOWN

a) To shut down cooking compartment, set timers to their OFF position and leave

doors slightly open.

b) At the end of the day, the steam supply must be shut off. Details are on boiler

instruction plate or previous section of this manual.

16

Page 17

WARNING: Disconnect the unit from the power supply before cleaning or

servicing appliance.

6.0 PERIODIC MAINTENANCE

IMPORTANT INSTRUCTIONS

Be sure to flush your boiler water level control daily. Failure to follow this procedure can

cause the control to malfunction resulting in serious boiler damage.

The Boiler Water Level Control installed on your boiler requires periodic maintenance.

As boiler water circulates into the float chamber, sand, scale and other sediment may be

deposited in the float chamber. While the chamber has been designed with a large

accumulation bowl, it is necessary to flush the sediment from the chamber by blowing

down the control so that the accumulation of sediment does not interfere with the

movement of the float in the control. Control must be flushed at least once a day.

17

Page 18

IMPORTANT INSTRUCTIONS (Continued)

CAUTION: Protect yourself. When flushing control, hot water and steam will flow

out of the drain.

CAUTION: If burner does not shut off during blowdown, immediately discontinue

use of appliance and call for service.

CAUTION: Do not use cleaning agents that are corrosive.

When flushing control, note water level in gauge glass, allow the boiler to fill if

necessary, and also to come up to temperature.

Before flushing control, note that water level in gauge glass is within operating range and

the boiler pressure is at least 6 psi. While the boiler is being fired, open blowdown valve

at bottom of control by rotating the handle counterclockwise about 1/4 turn to fully open

the valve. Opening the blowdown valve also checks the cut-off operation. Float should

drop shutting burners off, hot water and steam will flow out the drain flushing away

sediment.

Continue draining water for about fifteen (15) seconds, from control until water is clean.

Manually close valve. Recheck gauge glass. If water level has dropped significantly,

wait for the boiler to restore water level and pressure and repeat if necessary.

CLEANING

1. Keep exposed cleanable areas of unit clean at all times.

2. Thoroughly wash oven cavities, door liners, and pan racks at the end of each day, or

as required, with a mild detergent and water to prevent bacterial growth and odours.

3. Remove drain screens from inside compartment drains. Using a plastic bottle brush

and mild detergent, clean inside the drain opening ensuring there is no food residue

or blockage. Clean the drain screen and replace in its original position.

4. Wash gasket sealing surface daily with mild detergent to remove harmful food acids.

5. Clean around burner air mixer and orifice if lint has accumulated.

6. Visually assure carry over ports are unobstructed.

18

Page 19

7. Rinse entire unit and dry. DO NOT GET WATER in electrical box or any electrical

component.

7.0 ADJUSTMENTS

At least twice a year have an authorized service person clean and adjust the unit for

maximum performance.

BOILER DESCALING INSTRUCTIONS

It is recommended that the boiler should be checked every 90 to 120 days for scale build

up. Regular maintenance should be carried out at this time.

If the boiler has been descaled, a new Anode should be installed in the boiler to help

extend its life.

1. With boiler empty, close manual blowdown valve. If appliance is equipped with

automatic blowdown, turn water supply OFF to appliance. Turn power switch ON.

This will energize and close blowdown valve.

2. Remove 3/4" pipe plug from fitting on left front of boiler.

3. Insert appropriate hose or tube through fitting and pour in (½) half gallon (U.S.) of

CLR Descaling Solution or use the Optional Deliming Assembly DPA-1 available

from your dealer.

For appliances equipped with CSD-1, descaling solution must be introduced

through hand hole.

4. Replace 3/4" pipe plug securely.

5. Open water supply to appliance allowing water to fill boiler to required level.

6. Let appliance cycle, allow two hours for descaling and cleaning. DO NOT TURN

STEAM ON TO THE COMPARTMENTS.

7. Open both the blowdown and low water level control valves for complete drainage

and then close both valves.

Appliance equipped with automatic blowdown - turn OFF power switch and open

low water control valve. This will allow complete drainage. Once drained close

water level control valve.

8. Turn appliance switch ON. When boiler is completely filled, turn power switch OFF.

This will rinse and drain boiler. Appliance with manual blowdown valve must be

opened to drain.

9. Complete Step 8 twice to assure boiler is completely rinsed.

19

Page 20

NOTE: Pressure switches are factory set. Calibration is only required if pressure switches are

replaced or if adjustment is required.

10. Appliance is now ready for use.

TO CALIBRATE PRESSURE SWITCHES

Pressure switch range is from 1 to 15 psi.

Adjust all settings to maximum on high signal adjustment screw on pressure switches.

Adjust in the following sequence:

- High limit pressure switch.

- Override pressure switch.

- Operating pressure switch.

- Turning screw clockwise to increase, counterclockwise to decrease pressure.

- Use relief valve to release pressure from boiler for setting adjustments.

1. HIGH LIMIT PRESSURE SWITCHES

Allow pressure to build until unit shuts off. This should occur at 15 psi. Set the high

signal to switch at 14.5 psi on the gauge and the low signal to 13.0 psi.

2. OVERRIDE PRESSURE SWITCHES

Allow pressure to increase to 13 psi. Set the high signal to switch at 13 psi on the

gauge and the low signal to 11 psi.

3. OPERATING PRESSURE SWITCHES

Set the high signal to switch at 11 psi on the gauge and the low signal to 9 psi.

4. Release pressure in boiler to below 9 psi. Burner will come on. Once pressure has

reached 11 psi, burners will shut off. Repeat this process several times to make sure

burners come on at 9 psi and shut off at 11 psi.

20

Page 21

TO CALIBRATE PRESSURE SWITCHES (Continued)

NOTICE: Contact the factory, the factory representative or local service company to

perform maintenance and repairs.

Once completed, pressure switches have been calibrated.

Should your unit not have the High Limit pressure switch, start procedure at Override

pressure switch.

SERVICE

Contact your local authorized service office for any repairs or adjustments needed on

this equipment.

21

Page 22

8.0 TROUBLESHOOTING

DOOR LEAKS

1. Check for damage to door gasket.

2. Compartment drain opening or associated piping may be blocked.

WATER ACCUMULATES IN THE COMPARTMENT

1. Compartment drain screen clogged. Remove and clean thoroughly and replace.

WATER NOT BEING SUPPLIED TO BOILER

1. Water supply is “OFF”.

2. Defective water fill solenoid valve.

3. Water level control clogged or defective, unable to operate fill valve.

4. Check drain valve is closed. Also check that water level control valve is closed.

5. Supply water pressure too low.

AUTOMATIC BLOWDOWN VALVE DOES NOT DRAIN

1. Defective blowdown valve.

2. Heat exchanger build up of scalant clogging drain lines and valve.

BOILER ACHIEVES PRESSURE SLOWER THAN NORMAL

1. Heavy build up of lime or scalant hampering heat transfer. Call for service to inspect

interior of boiler. Should a considerable amount of scalant be found, have steam

lines, water level control and valve also inspected.

SAFETY VALVE BLOWS

1. Defective safety valve.

2. Pressure too high. Pressure switch requires adjustment (lower) or may be defective.

22

Page 23

BURNERS PRODUCE CARBON DEPOSITS

1. Wrong size orifices.

2. Burner air not adjusted properly.

3. Wrong gas supply.

4. Incorrect pressure at supply.

BURNERS DO NOT COME ON

1. Gas supply to unit is “OFF”.

2. Manual shut off valve is “OFF”.

3. Pilot is out.

4. Power supply is “OFF”.

5. Water level has not been reached. Check water supply and water level control.

6. Pilot may require flame adjustment on option electronic ignition units.

7. If water at proper level, check relay which energizes pressure switch and gas valve.

8. Pressure switch may need to be replaced if relay is operating.

9. Check gas control. If energized but not operating, have replaced.

PILOT LIGHT DOES NOT IGNITE (ELECTRONIC IGNITION)

1. Gas control knob is in “OFF” position.

2. Loose or dirty wire connection to ignition module, clean/or tighten.

3. Ignition cable shorting out. Check that it is not in contact with metal or damaged.

4. Defective ignition module.

5. Unit is 100% lock out. Turn off and try in five minutes.

6. Dirty flame sensor. Clean with emery cloth.

7. Pilot burner/ignitor sensor, cracked ceramic insulator. Have replaced.

8. Check for too much draft in room.

23

Page 24

PRODUCTS TO BE COOKED IN SOLID PANS

Product

Timer Setting

in Minutes

Weight Per

Pan

Eggs, Scrambled

10 - 12

8 Dozen

Rice, Long Grain (Cover with 4 cups water/lb)

25

2 Lb

Pasta

(Place perforated pan inside solid pan, cover pasta with cold

water)

Spaghetti - Regular/Vermicelli

Macaroni - Shells/Elbows

Noodles - ½" Wide

Lasagna Noodles

12 - 15

15 - 18

12 - 15

15 - 18

Frozen Casseroles, Lasagna

35

Full Pan

Meat Loaf, 3 - 5 Lb Each

40

15 Lb

Beef

Ground Chuck

Slices as Purchased

20 - 25

35 - 40

10 Lb

10 Lb

Shrimp, Frozen, 10 Shrimp per Lb

5

4 Lb

Beans

Baked

Refried

9

9

10 Lb Can

10 Lb Can

Canned Vegetables

6

10 Lb Can

Prunes, Dried

12 - 15

9.0 COOKING CHART

The following table lists suggested cooking times and weights. These times, which will

vary depending on initial product temperature, size, shape, etc., are approximate and

should be adjusted to suit your operation.

24

Page 25

PRODUCTS TO BE COOKED IN PERFORATED PANS

Product

Timer Setting

in Minutes

Weight Per

Pan

Clams

Frozen

Fresh, Cherrystone

10 - 12

5 - 6

3 Dozen

3 Dozen

King Crab, Frozen

Claws

Legs

4

4 - 6

2 ½ Lb

4 ½ Lb

Lobster Tail, Frozen

Lobster, Live, 10" - 12"

6

5

10 Lb

4 Per Pan

Salmon Fillets, Frozen, 8 oz Each

5

7 ½ Lb

Scallops, Fresh

4

3 Lb

Scrod Fillets, Fresh

3 - 5

4 Lb

Eggs

Hard Cooked

Soft Cooked

Soft Yolk for Caesar Salad

15

9 - 10

6 - 8

4 Dozen

4 Dozen

4 Dozen

Chicken, Breasts, Legs, Thighs

20

15 Lb

Turkey, Frozen

Breasts (2)

Cut length wise

90

55

6 - 7 Lb Ea.

20 - 25 Lb

Corned Beef

40 - 75

6 - 8 Lb

Hot Dogs or Wieners

3

80 - 100 Count

Asparagus Spears

Frozen

Fresh

10 - 12

5

3 Dozen

5 Lb

Beans

Green, 2" Cut, Frozen/Fresh

Lima, Frozen

Baby Lima, Frozen

6

8

5

5 Lb

5 Lb

5 Lb

Broccoli

Spears, Frozen

Spears, Fresh

Flowerettes, Frozen

8

6

6

4 Lb

5 Lb

5 Lb

25

Page 26

PRODUCTS TO BE COOKED IN PERFORATED PANS

Product

Timer Setting

in Minutes

Weight Per

Pan

Brussel Sprouts, Frozen

6

5 Lb

Cabbage, Fresh, 1/6 Cut

8

5 Lb

Carrots

Baby Whole, Frozen

Crinkle Cut, Frozen

Sliced, Fresh

8

7 - 8

11

7 Lb

4 Lb

9 Lb

Cauliflower, Flowerettes

Frozen

Fresh

6

7 - 8

4 Lb

5 Lb

Celery, 1" Diagonal Cut

7

5 Lb

Corn

Yellow Whole Kernel, Frozen

Cobbettes, Frozen

Corn-On-Cob, Fresh

5

8

16-18

10-12

16-18

5 Lb

27 Ears

80 Ears

18 Ears

54 Ears

Peas, Green

6

5 Lb

Potatoes, Whole Russet

55

10 Lb

Spinach

Chopped, Frozen

Defrosted

Fresh Cut

17

5

3

6 Lb

6 Lb

2 Lb

Squash, Acorn, Halves

25

10 Halves

Zucchini, Slices

8

10 Lb

Frozen Mixed Vegetables

6 - 7

5 Lb

Fruit, Blanch for Peeling

Grapefruit

Oranges

3

Pineapple, Whole for Cutting

4

COOKING HINTS

Where possible, spread food out evenly in pans. Do not allow food to protrude above

pans, since this will interfere with steam circulation between pans in the compartment.

Always preheat compartments for satisfactory results. When time does not allow for

defrosting of frozen vegetables, such as loose-pack peas, corn diced carrots, etc., they

may be cooked at once provided just half of the suggested portions in the cooking chart

are used.

26

Loading...

Loading...