Page 1

TMIN

PSIN

COS-5HA

INSTALLATION AND OPERATION INSTRUCTIONS

FOR SHIPBOARD USE

FSCM 07695

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN R10303 Rev J (10/05)

E 2005 --- Blodgett Corporation

Page 2

TMIN # XXXXXXXXXXXXXXXXXXXXX

SAFETY SUMMARY

The following are general safetyprecautions thatare not related to any specific procedures

and therefore do not appear elsewhere in this publication. These recommend precautions

that personnel must understand and apply during many phases of operation and maintenance.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must at all times observe all safety regulations. Do not replace components or make adjustments inside the equipment with the high voltage supply turned

on. Under certain conditions, dangerous potentials may exist when the power control is

in the off position, due to the charge retain ed in capacitors. To avoid casualties, always remove power and discharge and ground a circuit before touching it.

DO NOT SERVICE OR ADJUST ALONE

Under no circumstances should any person reach into or enter the enclosure for the purpose of servicing or adjusting the equipment except in the presence of someone who is

capable of rendering aid.

RESUSCITATION

Personnel working with or near high voltages should be familiar with modern methods of

resuscitation.

The following appear in the text of this volume, and are repeated here for emphasis.

WARNING:

Before performing any maintenance or replacing any component

on this unit, disconnect oven from

electrical source.

Page 3

TMIN # XXXXXXXXXXXXXXXXXXXXX

CHANGE RECORD

CHANGE NO. DATE TITLE/BRIEF DESCRIPTION SIGNATURE OF

VALIDATING OFCR.

Page 4

TMIN # XXXXXXXXXXXXXXXXXXXXX

LIST OF EFFECTIVE PAGES

Insert latest changed pages. Destroy superceded pages.

NOTE:The portion of the text affected by the changes is indicated by a vertical line in the

outer margins of the page. Changes to illustrations are indicated by miniature pointing hands. Changes to diagrams are indicated by shaded areas.

Dates of issue for original and changed pages are:

Original MARCH 2002...

The total number of pages in this publication are: 54

consisting of the following:

PAGE NO.

CHANGE NO.* PAGE NO. CHANGE NO.*

* Zero in this column indicates an original page

Page 5

TMIN # XXXXXXXXXXXXXXXXXXXXX

APPROVAL AND PROCUREMENT RECORD

APPROVAL DATA FOR: COS-5H

Electric Combination Oven

TITLE OF MANUAL: Technical Manual, COS-5H

Electric Combination Oven

APPROVAL AUTHORITY: Defense General Supply Center

Letter Dated ?? ???

??

CONTRACT NO. NSN NO. OF UNITS APL

REMARKS

DATE: 5 Mar 98

CERTIFICATION:

It is hereby certified that the technical manual provided under contract number XXX-XXXXX-X-XXXX for COS-5H has been approved by the approval data shown above.

(Signed) _____________________________

John Bardeau

(Title) VP Sales and Marketing

Blodgett Combi

55 Boyer Circle

Williston, VT 05495

FSCM 07695

Page 6

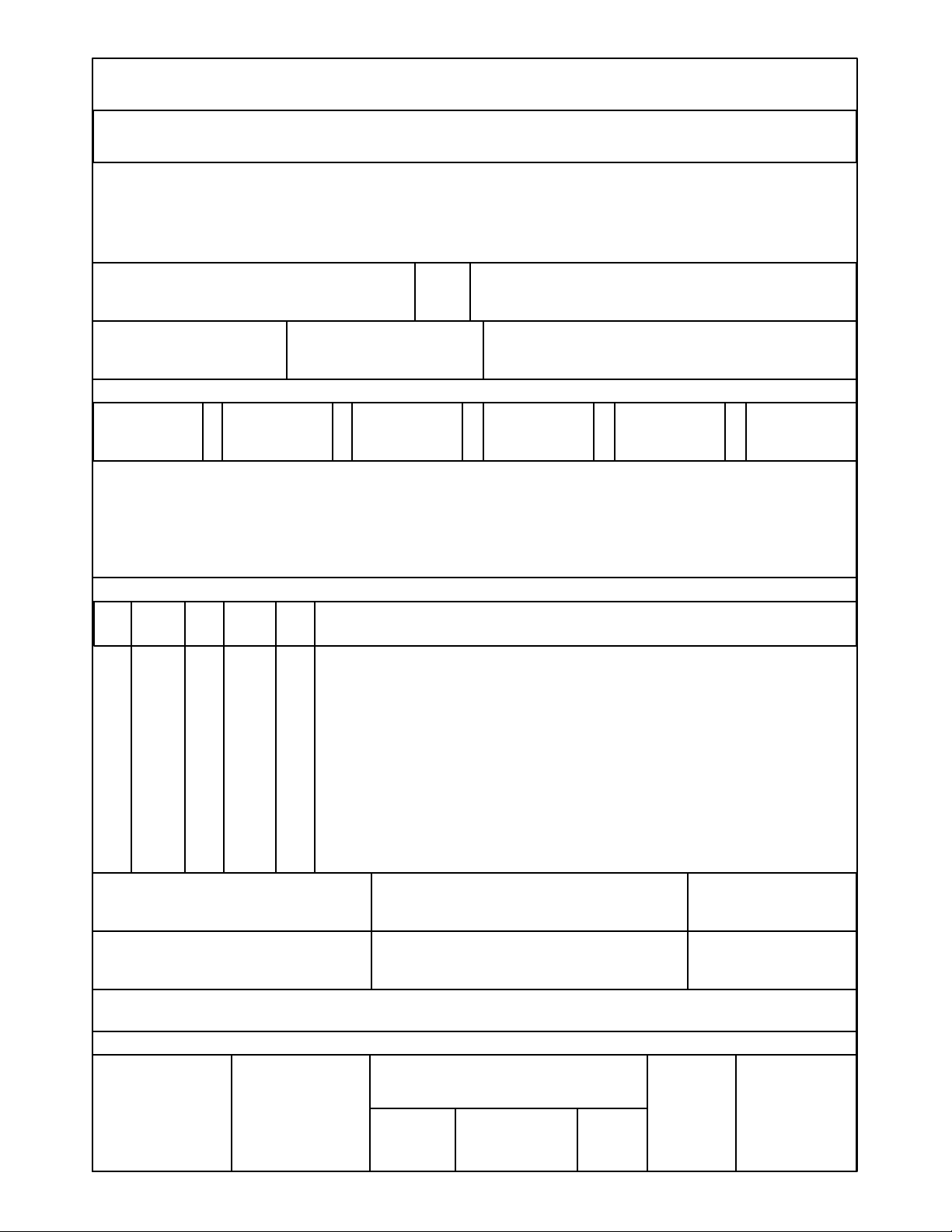

(Insert Classif. of TMDER Here and At Bottom of Page) CLASSIFICATION:

NAVSEA (USER) TECHNICAL MANUAL DEFICIENCY/EVALUATION REPORT (TMDER)

(NAVSEA S0005--AA --GYD--030/TMMP & NAVSEAINST 4160.3)

Instructions: Insert classification at top and bottom of page. Read the following before completing this

form. Continue on 8½I x11I paper if additional space is needed.

1. USE THIS REPORT TO INDICATE DEFICIENCIES, USER REMARKS, AND RECOMMENDATIONS RELATING TO PUBLICATION

2. BLOCKS MARKED WITH ” * ” ARE TO BE FILLED IN BY THE CONTRACTOR BEFORE PRINTING.

3. FOR UNCLASSIFIED TMDER’S FILL IN YOUR RETURN A DDRESS IN SPACE PROVIDED ON THE BACK. FOLD AND TAPE WHERE

INDICATED AND MAIL. (SEE OPNAVINST 5510.1E FOR MAILING CLASSIFIED TMDERS.)

4. FOR ADDITIONAL INFORMATION, CALL AUTOVON 360---4809 ---9084 OR COMM ERCIAL 905---882---5064

1. NAVSEA NO. * 2. VOL.

4. REV DATE OR TM CH.

DATE

A. EXCELLENT B. GOOD C. FAIR D. POOR E. COM PLETE F. INCOMPLETE

8. GENERAL COMMENTS

PAG E

NO.

PAR A

GRAPH

A.

LINE

FIG.

NO.

B.

NO.

C.

D.

PAR T *

5. SYSTEM/EQUIPMENT 6. IDENTIFICATION/NOMENCLATURE (MK/MOD/ AN)

7. USERS EVALUATION OF MANUAL (CHECK APPROPRIATE BLOCKS)

9. RECOMMENDED CHANGES TO PUBLICATION

TABLE

E.

3. TITLE *

F. RECOMMENDED CHANGES AND REASONS

10. ORIGINATOR AND WORK CENTER

13. SIGNATURE OF WORK CENTER HEAD 14. SIGNATURE OF DEPARTMENT OFFICER 15. AUTOVON/COMM

16. SHIP HULL NO. AND/OR STATION ADDRESS (DO NOT AB BREVIATE)

A.CONTROLNO. B.COGISEA C.DATE D.PRIORITY E.TRANSMITTEDTO

NAVSEA 9066/10 (REV. 6.85) S/N 0116 ---LF - -- 090 --- 9651

(REPLACES 4--- 84 EDITI ON & NAVS EA 4160/1 --DESTROY STOCK)

(PRINT)

11. ORIGINATOR’S RANK, R ATE OR GRADE, AND TITLE 12. DATE SIGNED

NO.

17. THIS SPACE ONLY FOR NSDSA

RECEIVED FORWARDED DUE

CLASSIFICATION:

Page 7

PLEASE CLOSE WITH TAPE --- DO NOT STAPLE --- THANK YOU

FOLD HERE

COMMANDING OFFICER

NAVAL SHIP WEAPON SYSTEMS ENGINEERING STATION

NAVAL SEA DATA SUPPORT ACTIVITY (CODE 5B00)

PORT HUENEME, CA 93043 --5007

FOLD HERE

Page 8

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAM AGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructions will result in satisfactory baking results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 9

APERSONALWORD

FROM BLODGETT COMBI

Congratulations on your purchase of the BLODGETT Combi-Oven/Steamer.

We firmly believe that your choice has been a wise one, and trust you will receive many years of excellent service from your new multi-purpose oven.

The Combi-Oven/Steamer concept offers completely new potential for cooking which minimizes shrinkage, while maintaining food’s essential vitamins

and valuable nutrients. In addition, you w ill find that cooking with the CombiOven/Steamer will save time, labor and extensive cleaning of both the kitchen

and the appliance.

With the Combi-Oven/Steamer the quality, taste, consistency, and look of the

food are improved, thus endorsing the policy to which we’ve always adhered:

“For Better Cooking!”

Once you’ve had a chance to use your multi-purpose oven, please tell us, your

dealer and colleagues about any creative and interesting applications you

have discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems be encountered (...we’re here to help!) and above all “Enjoy Cooking the

BLODGETT Combi-Oven/Steamer Way!

Page 10

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Page 11

Tabl e o f C o n tents

Introduction

The Blodgett Combi-Oven/Steamer 2.................................

Description of the Combi-Oven/Steamer 3............................

Oven Features 4...................................................

Installation

General Installation Information 5....................................

Delivery and Location 6.............................................

Installation Base 7.................................................

Utility Connections 9...............................................

Oven Installation --- No Dismantling Required 10........................

Oven Installation --- Some Dismantling Required 11.....................

Oven Dismantling 11.............................................

Oven Re-Assembly 17............................................

Operation

Oven Startup and Shutdown 20.......................................

Optional Meat Probe 21..............................................

Standard Controls 22................................................

Cooking Guide

The Steam Mode 24.................................................

The Hot Air Mode 26................................................

The Combi Mode (Steam and Hot Air) 27..............................

Summary of Functions 28............................................

General Tips and Procedures 29......................................

Suggested Times and Temperatures 30................................

Page 12

Tabl e o f C o n tents

Maintenance

Cleaning and Preventive Maintenance 32..............................

Decalcification 33...................................................

Troubleshooting Top Oven Section 34.................................

Cool Down Mode 34.............................................

Hot Air Mode 35.................................................

Steam Mode 37..................................................

Combi Mode 39.................................................

Sequence of Operation --- Hot Air 40...............................

Sequence of Operation --- Steam 41................................

Sequence of Operation --- Combi 42................................

Sequence of Operation --- Cool Down 42............................

Troubleshooting Bottom Oven Section 43..............................

Cool Down Mode 43.............................................

Hot Air Mode 44.................................................

Steam Mode 46..................................................

Combi Mode 48.................................................

Sequence of Operation --- Hot Air 49...............................

Sequence of Operation --- Steam 50................................

Sequence of Operation --- Combi 51................................

Sequence of Operation --- Cool Down 51............................

S c h e m a t i c --- To p O v e n 52...........................................

Schematic --- Bottom Oven 53........................................

Schematic --- Oven Base 54..........................................

Page 13

Introduction

The Blodgett Combi-Oven/Steamer

For quite some time, commercial cooking equipment has remained more or less unchanged.

There are kettles, deck ovens, the good old range

with its legion of pots and many other extra

appliances. The result: time expenditure, excessive manual work, and countless cleaning processes. The last few years have paved the way for

a revolution in the equipment of restaurant and institutional kitchens.

The Blodgett Combi-Oven/Steamer offers a completely new method of cooking. With the Oven/

Steamer you have the choice of two cooking pro-

cesses: Steam and Hot Air, either...

D

Separately

D

Combined, or

D

In Sequence

And for easy operation you can choose from three

modes:

Steam Hot Air

Combi

Steam &

Hot Air

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanch preserve braise

poach

In the Hot Air mode you can

roast bake

grill gratinate

broil

In the Combination Steam and Hot Air mode you

can:

defrost roast rethermalize

reheat bake forced steaming

Not only that, you can use two or three functions

in sequence during one cooking process. We call

this:

D

combi-steaming

D

combi-roasting

D

combi-baking

The combination of circulating hot air and steam

in the space saving, high performance CombiOven/Steamer leads to improvements in the following areas:

D

increased productivity in the kitchen

D

a reduction in capital expenditures for multiple

equipment replacement

D

a wider range of menu choices

D

a simplified cleaning process

The work process is simplified since products are

prepared on or in steam table pans and trays.

Food can be cooked, stored, and transported with

the same pans. Small amounts of product can be

processed efficiently; pre-cooked and convenience foods can be reheated within minutes.

Many frozen foods can be processed without prethawing. This flexibility in preparation reduces the

need for kettles and steam tables since there is no

need for large amounts of food to be kept warm for

long periods of time.

Today the improvement of food quality is more important than ever. Vegetables are cooked in the

Blodgett Combi-Oven/Steamer without water at

the optimal temperature of just under

212_F/100_C, maintaining valuable vitamins, minerals, nutrients and trace elements. Cooking meat

intheCombiresultsinlessshrinkageandafirmer,

juicier product. The Blodgett Combi-Oven/Steamer is being used more and more for baking. Steam

and Hot Air modes make it a general purpose baking appliance.

2

Page 14

Introduction

Description of the Combi-Oven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett Combi-Oven/Steamers are quality produced using high-grade stainless steel with first

class workmanship.

The high performance fresh steam generator with

its control system makes it possible to enjoy all of

the advantages of a high quality steamer at the

flick of a switch. Fresh steam enters the oven cavity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while providing convenient working methods. The steam

generator is completely automatic and protected

from running dry.

The exhaust system is effective in all cooking

modes and results in better quality foods and no

flavor transfer. The fan, which is guarded against

accidental finger contact, is driven by a quiet and

powerful motor. The condenser draws out excess

steam from the appliance. Condensation and

waste water, which result during steaming and

cleaning, are continuously drained.

The use of high quality insulation impedes excessive heat radiation and saves energy.

OVEN/STEAMER OPERATION

Ease of operation is guaranteed through the simple a rrangement of the controls. Graphic symbols

make the appliance easy for even inexperienced

kitchen staff to operate. Steam, Hot Air and Combi

modes can be selected with one switch. A fourth

function on the mode selection switch, the Cool

Down mode, allows the oven cavity to cool down

rapidly with the door opened or closed.

Cleaning is kept to a minimum. The interior is

sprayed with a self-acting cleaning solution which

interacts with steam to easily remove crusts and

stains. The oven is designed for easy care and is

welded water tight so that the internal cooking

cavity may be rinsed with a hose after the steam

cleaning process.

SPECIFICATIONS -- COS-5HD/AB

Electrical

Specifications 440-480 VAC, 3 phase, 44 KW, 58 amps

Water Atmospheric Vented Drain

Water Pressure 40 PSI (276 kPa) minimum

50 PSI (345 kPa) maximum

Water Connection 3/4” NPT Female

3

Page 15

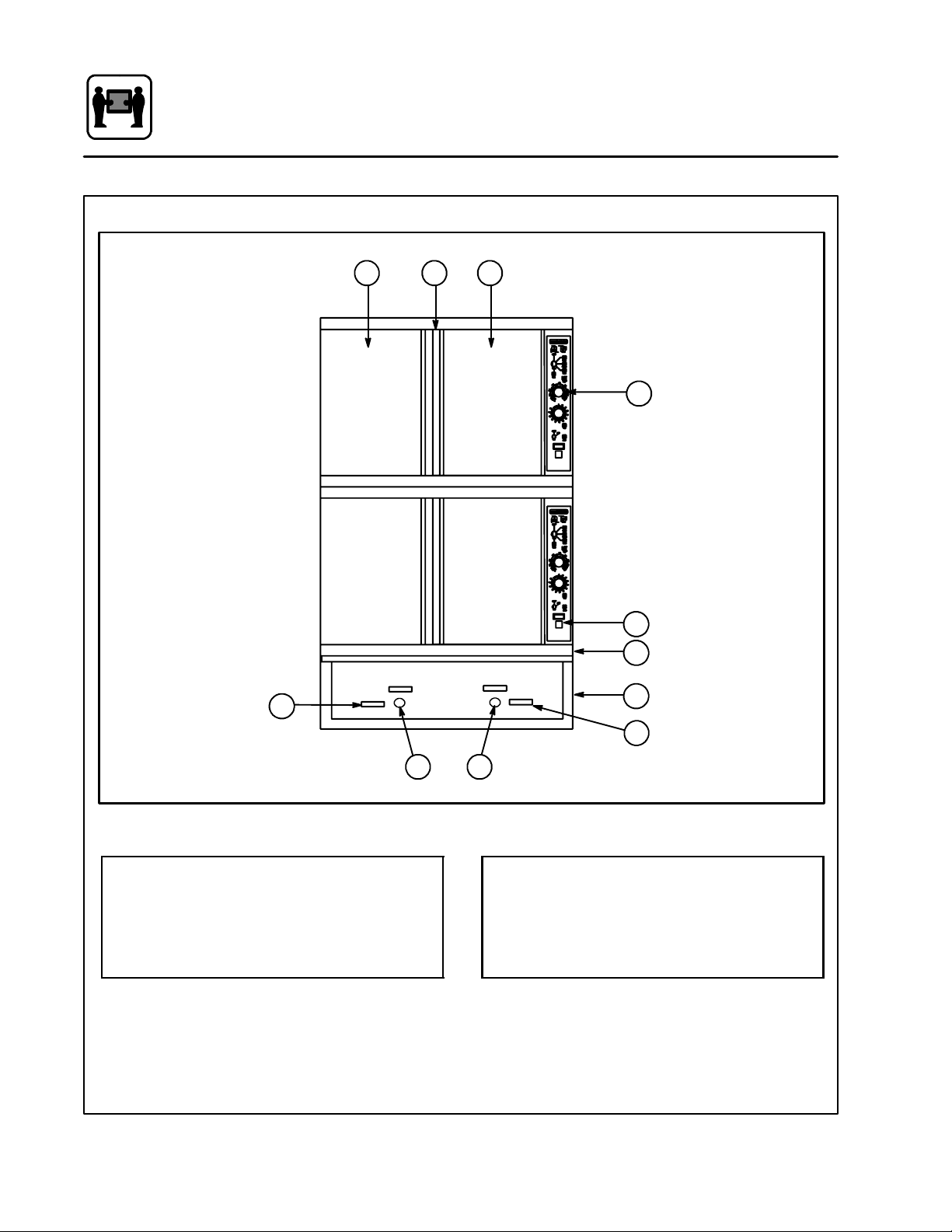

Introduction

Oven Features

2 23

6

Standard Features

1

7

8

4

1

Control Panel

2 Oven Doors

3 Rotating Door Latch

4 Base Section

5

Figure 1

4

6

5

5 Deliming Port

6 Deliming Handle

7 Optional Meat Probe

8 Door Drip Pan

Page 16

Installation

General Installation Information

The purpose of the installation section of this

manual is to assist the designers and naval architects engineering the installation of a Blodgett

Combi COS-5HA Hatchable Combination Oven

into a new or existing ship.

Blodgett Combi has developed the COS-5HA to fit

in the same footprint as a Blodgett Mark V convection Oven. The COS-5HA Combination oven can

be used as a convection oven, steamer, or in a

“Combi” mode in which pulsed steam is combined with convection to provide faster cooking

and increase the moisture content of cooked

foods. Because of these features, the oven utilizes

water for generating steam. The Combi is a multisystem cooking oven and is more complex than a

convectional oven. Therefore, more attention has

to be paid to the installation process than that of

a convection oven.

The COS-5HA requires the following support systems:

D Power 440VAC,3phase,60ampservice

D Water Potable, 40 to 50 psi

D Drain Atmospheric vented drain,

1” minimum diameter

D Hood Air venting required for steam

removal

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN A ND/ OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D The installation of electrical wiring from the elec-

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiencedinsuchwork,befamiliarwithallprecautions required and have complied with all requirements of state or local authorities having

jurisdiction.

Reference: National Electrical Code, ANSI/NFPA

70---Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code of the Building Offi-

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration (FDA).

5

Page 17

Installation

Delivery and Location

DELIVERY AND LOCATION

The COS-5HA hatchable combination oven is

shipped fully assembled on a special vibration resistant pallet. In addition, the oven is mounted on

two hardwood skids to facilitate removal from the

pallet. These skids were designed to match the

height of the separate installation base. This allows the assembled oven to be slid directly onto

the base after the installation base is mounted in

position and hard plumbed with potable water and

electric power.

COS-5HA dimensions:

Height 62.25” with legs

68.25” with 6” legs

65” with base

Width 38.19”

Depth 44.13”

The following clearances are required for the

COS-5HA:

Sides 0”

Rear 6”

UNPACKING

1. Remove the protective cover around the oven.

Inspect the unit for visible damage.

2. Remove the bolts that lock the 2-1/2” x 4”

hardwood skids to t he pallet base.

3. Us e a forklift to raise the oven assembly off the

pallet.Theskidscanbeleftinpositiontoassist

in moving an assembled oven onto the installation base or discarded after the oven assembly is unbolted into separate components for

passage through hatches.

ASSISTANCE

Blodgett Combi also provides engineering assistance when custom installation kits are required.

Our goal is to ensure that each oven installation

can be made in the most efficient and economical

manner.

For further information, please contact the Blodgett Combi Engineering Department:

D Phone 1-800-331-5842

D Fax 802-860-3702

6

Page 18

Installation

Installation Base

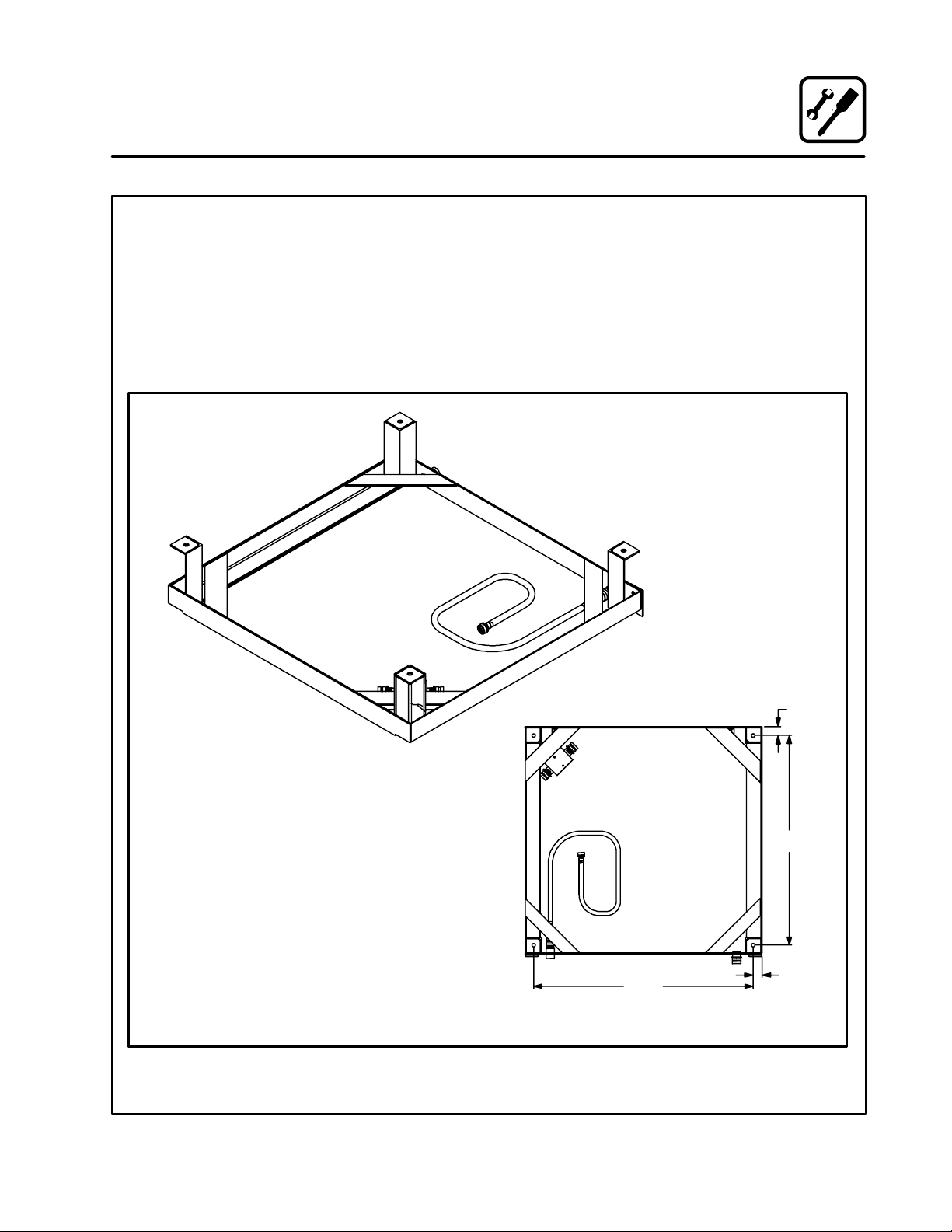

The Blodgett Combi COS-5H utilizes a stainless

steel locking installation base. The base is available with or w ithout legs. The installation base was

designed to facilitate the installation process and

to improve the access to the oven if and when major service is required.

Since the COS-5H is slightly narrower than the

installation base, multiple bases can be installed

side by side on the deck with no allowance for side

clearance.

1. Secure the 2-1/2” high installation base using

one of the following methods:

a.) Weld the base directly to the deck.

b.) Bolt the base to the deck.

2. Seal the base with an NSF approved sealant.

Base Shown Upside Down

INSTALLATION BASE WITH LEGS

Figure 2

BOTTOM VIEW

35.50

1.44

33.91

1.44

7

Page 19

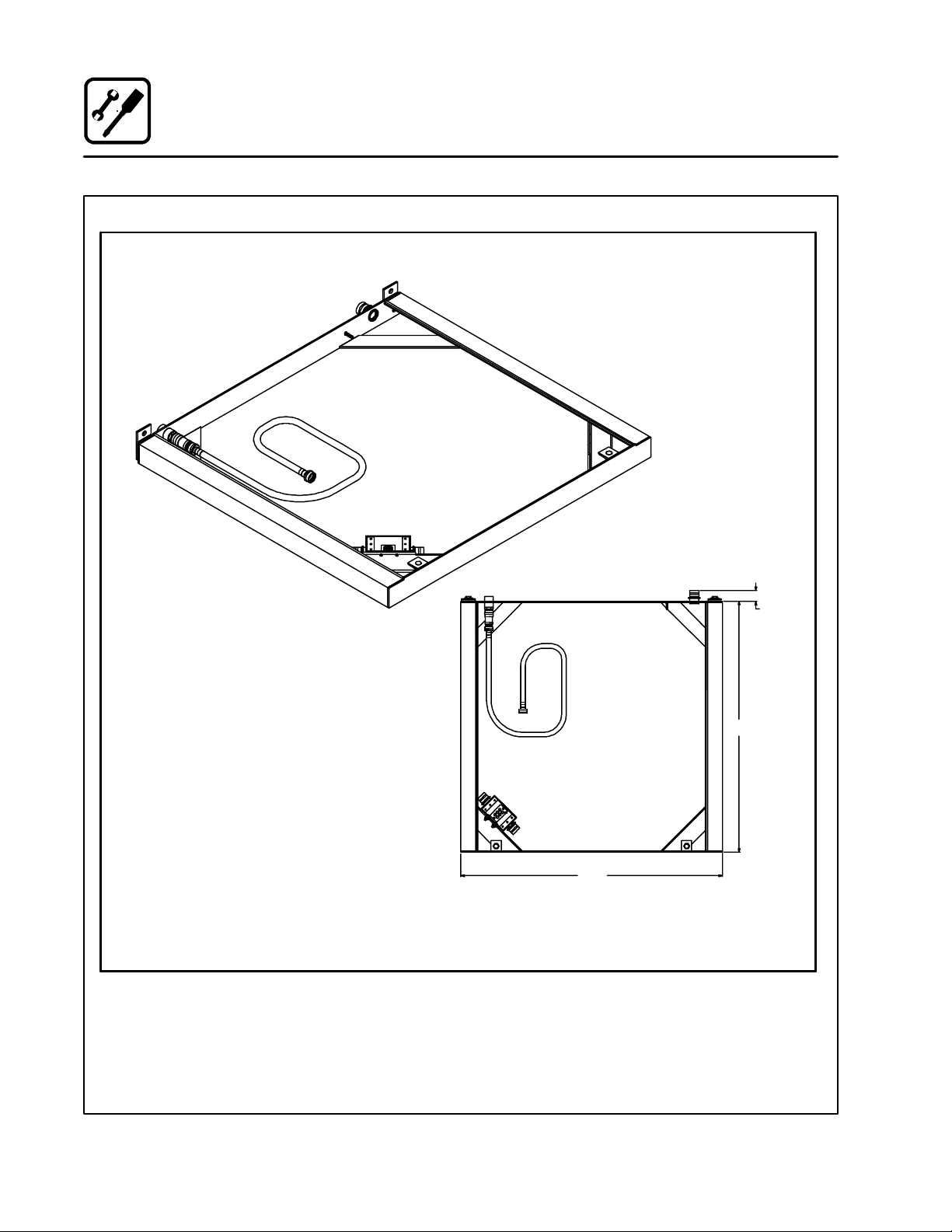

Installation

Installation Base

INSTALLATION BASE

Figure 3

1.56

36.78

38.37

8

Page 20

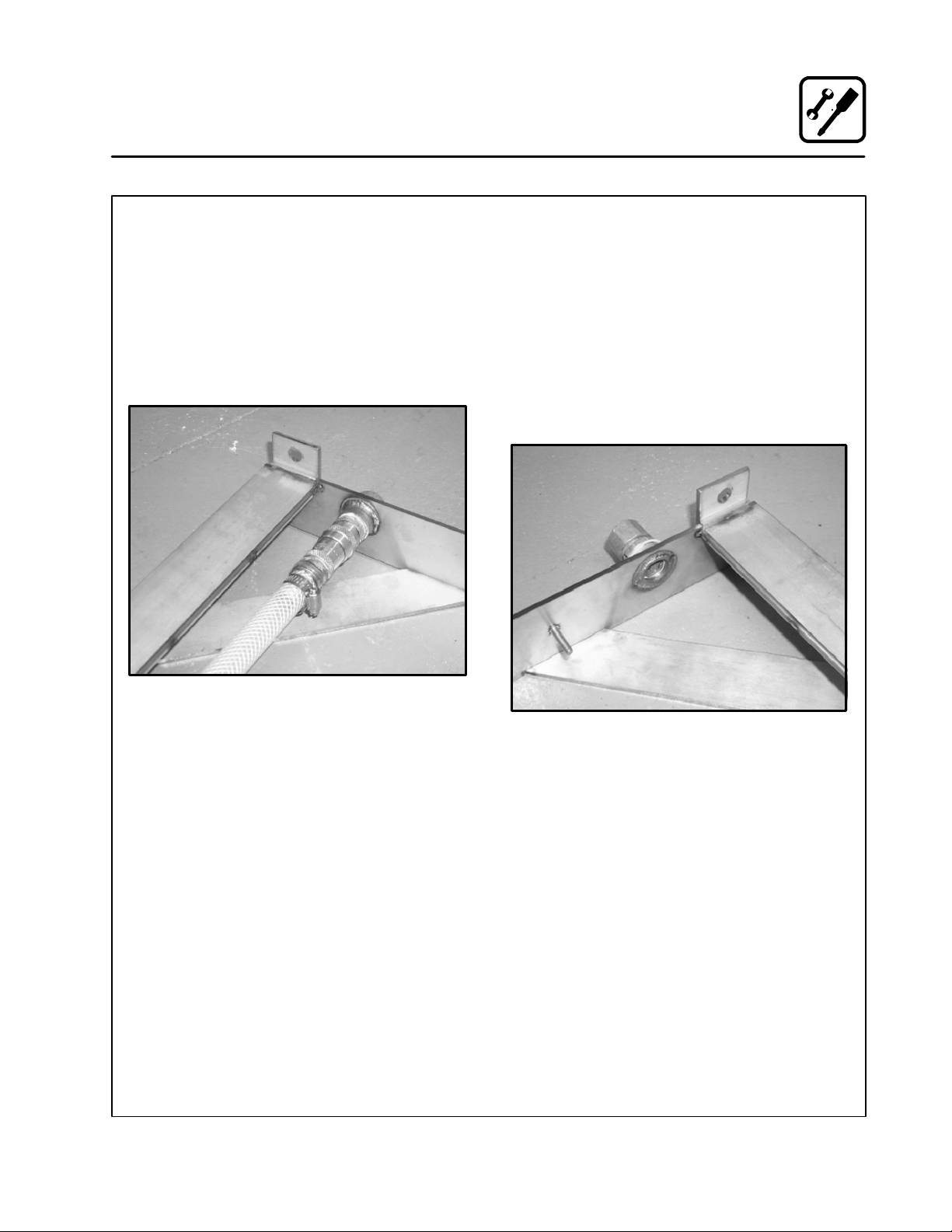

Installation

Utility Connections

WATER CONNECTION

The oven requires access to potable water with a

pressure of approximately 40 to 50 PSI.

1. The water is connected to the rear of the installation base at the 3/4” NPT female coupling.

2. The water is directed to the oven through an

in-line pressure regulator and a flexible internal hose which connects to a fitting in the front

of the oven.

ELECTRICAL CONNECTION

The power requirement of the oven is 440 volt, 3

phase, 60 amp service.

1. The electrical service is brought into the oven

through the seal tight connector located on

therearoftheinstallationbase.

2. The power leads are brought into a splash

proof terminal box located in the front of the

installation base.

3. A grounding stud is supplied on the inside of

the installation base. See Figure 5.

Figure 4

DRAIN CONNECTION

An open drain s ystem utilizing a fixed funnel is recommended. For multiple oven installations, install

a deck mounted sloping drain with individual funnels positioned to accept the drain outlets of the

individual ovens.

Figure 5

9

Page 21

Installation

Oven Installation --- No Dismantling Required

Use this procedure if the oven a ssembly does not

have to be dismantled to bring it into the galley

where the installation base has been fitted.

1. Slide the oven assembly on the shipping skids

in front of the installation base.

2. Remove the two 1/2” bolts from the front of the

installation base. See Figure 6.

1/2” Bolt

Figure 6

3. U nscrew the front panel from the oven base

section. Leave the hoses connected to the

front panel and the oven base section.

4. Remove the two bolts securing the skids to the

front of the oven base section. See Figure 7.

1/2” Bolt

5. Removethetwoboltsandangleplatessecuring

the skids to the rear of the oven base section.

Bolt & Plate

Figure 8

6. Move the oven assembly to the installation

base as follows:

a.) Lubricate the top surface of the installa-

tion base with a little grease or silicone

spray.

b.) Slide the oven assembly off the skids onto

the tracks of the installation base.

c.) The locking pins on the rear of the oven

base section will fit into and lock the base

to the upright tabs attached to the installation base.

7. Reinstall the two bolts that were removed in

Step 2, from the installation base through the

oven base section into the installation base.

SeeFigure7forinstallationlocation.

8. Hook up water and electrical connections to the

oven base section. Apply NSF approved sealant to the cover of the splash proof terminal

box.

Bolt & Plate

1/2” Bolt

Figure 7

10

Page 22

Installation

Oven Installation --- Some Dismantling Required

Use this procedure if the oven a ssembly will be

dismantled to bring it into the galley where the

installation base has been fitted.

The assembled oven consists of three sections:

D

upper oven section

D

lower oven section

D

oven base section.

The oven base section consists of the major electrical components, steam generator, and the attachment components for mating the oven assembly to the installation base which is mounted

directly to the deck. In order to dismantle the oven

assembly, you will have to separate electrical w ire

harnesses and plumbing lines. We recommend

that you tape both sides of each electrical and

hose connection and mark them for easy identification during reassembly.

If you are installing more than one oven assembly,

keep all hardware and panels associated with one

oven assembly separate from the other oven assemblies. If the oven assembly has to be dismantled in order to fit through the hatches, use the

following procedure:

OVEN DISMANTLING

1. Remove the racks from the inside of both the

upper and lower oven sections. See Figure 9.

Figure 9

2. Remove the side support racks from the in-

side of both the upper and lower oven sections.SeeFigure10.

Figure 10

11

Page 23

Installation

Oven Installation --- Some Dismantling Required

3. Remove the drip pan from the front of both

ovens.SeeFigure11.

Figure 11

4. Remove the locking tab plate above the control panel by removing the Phillips screw. See

Figure 12. Do this to both the upper oven and

the lower oven.

5. Remove the control panel cover by lifting and

pulling the “D” handle toward you about 6”.

See Figure 13. Do this to both the upper oven

and the lower oven.

Remove Screw

Figure 12

Figure 13

12

Page 24

Installation

Oven Installation --- Some Dismantling Required

6. Remove the right side rear panel by sliding it

forward about an inch and then lifting the entire panel to free the retaining springs. See

Figure 14. Do this to both the upper oven and

the lower oven.

7. Cut the wire tie holding the copper drain tubes

together. See Figure 15.

Figure 14

Figure 15

13

Page 25

Installation

Oven Installation --- Some Dismantling Required

8. D isconnect the electrical wire harnesses (J1,

J3, J7, and J8) that connect the upper and

lower oven section to the oven base section.

See Figure 16. Mark connections prior to disconnecting for ease of re-assembly.

Disconnect

Figure 17

Figure 16

9. Disconnect and remove the steam lines to the

upper and lower oven sections at locations

shown in Figure 17 and Figure 18. The top of

thehoseissecuredwithabandclamp.The

bottom of the hose pulls out of the boiler in the

oven base section.

Disconnect

Figure 18

10. Remove the rear body panel on the lower oven

section.

14

Page 26

Oven Installation --- Some Dismantling Required

11. Remove the three bolts (1/2 inch diameter)

that connect the top and lower oven sections

together.

Two bolts are located in the rear upper left and

right corners of the lower oven section. These

bolts can be accessed from the back of the

lower oven section. See Figure 19.

The third bolt is accessed from the right side

of the lower oven section. It is located in the

upper right hand corner. See Figure 20.

Bolt

Bolt

Installation

Bolt

Figure 20

Figure 19

15

Page 27

Installation

Oven Installation --- Some Dismantling Required

12. Remove the upper oven section from atop the

lower oven section. Use care not to chafe any

of the harnesses that come from the base section. Use gloves to protect hands from any

sharp edges.

13.Removetherearbodypanelfromtheoven

base section. Unscrew the front panel from

the oven base section. Leave the hoses connected to the front panel and the oven base

section.

14. Removethefourbolts(1/2inchdiameter)that

connect the lower oven section and ovenbase

section together.

Two bolts are located in the rear upper left and

right corners of the oven base section. These

bolts can be accessed from the back of the

oven base section. See Figure 21 and

Figure 22.

The third bolt is accessed from the right side

of the oven base section. It is located in the upper front right hand corner. See Figure 23.

The fourth bolt is accessed from the left side

of the oven base section. It is located in the upper front left hand corner. See Figure 24.

15. Remove the lower oven section from atop the

oven base section. Use care not to chafe any

of the harnesses that come from the base section. Use gloves to protect hands from any

sharp edges.

Figure 22

Figure 23

Figure 21

Figure 24

16

Page 28

Oven Installation --- Some Dismantling Required

OVEN RE-ASSEMBLY

After the installation base is secured in position,

connected to potable water and electrical power,

the oven sections may be assembled onto it. In

galleys where ovens are located next to each other, the oven sections should be assembled prior to

sliding the oven assembly into the final position on

the installation base.

1. Remove the two 1/2” bolts from the front of the

installation base. See Figure 25.

1/2” Bolt

Figure 25

1/2” Bolt

Installation

4. Install t he four bolts (1/2 inch diameter) that

connect the lower oven section and ovenbase

section together.

Two nuts are located in the rear lower left and

right corners of the lower oven section. These

nuts can be accessed from the back of the oven

base section. See Figure 21 and Figure 22 on

page 16.

The third nut is accessed from the right side of

the oven base section. It is located in the lower

front right hand corner of the lower oven section. See Figure 23 on page 16.

The fourth nut is accessed from the left side of

the oven base section. It is located in the lower

frontlefthandcornerofthelowerovensection. See Figure 24 on page 16.

5. Install the rear body panel on the oven base

section.

6. Apply a 1/8 inch bead of clear silicone RTV to

the perimeter of the top edge of the lower oven

section. Lift the upper oven section onto the

lower oven section. Use gloves to protect

hands from any sharp edges.

2. Lubricate the top surface of the installation

basewithalittlegreaseorsiliconespray.Position the oven base section onto the flat track

surface of the installation base approximately

4” to 5”. Support the front of the oven base

section with a piece of 2” pipe (2-3/8” OD

approximately) by 39” (minimum) long.

3. Apply a 1/8 inch bead of clear silicone RTV to

the perimeter of the top edge of the oven base

section. Lift the lower oven section onto the

oven base section. Use gloves to protect

hands from any sharp edges.

17

Page 29

Installation

Oven Installation --- Some Dismantling Required

7. Install the three bolts (1/2 inch diameter) that

connect the top and lower oven sections together.

Two nuts are located in the rear lower left and

right corners of the upper oven section. These

nuts can be accessed from the back of the

lower oven section. See Figure 26.

The third nut is accessed from the right side of

the lower oven section. It is located in the upper front right hand corner of the upper oven

section. See Figure 27.

Bolt

Bolt

8. Install the rear body panel on the lower oven

section.

9. Install and reconnect the steam line to the upper oven section at locations shown in

Figure 28 and Figure 29. Secure the top of the

hose with a band clamp. Insert the bottom of

the hose in the fitting on the steam generator

intheovenbasesection.

Disconnect

Figure 28

Figure 26

Bolt

Figure 27

Disconnect

Figure 29

18

Page 30

Oven Installation --- Some Dismantling Required

10. Reconnect four electrical wire harnesses (J1,

J3, J7, and J8) that connect the upper and

lower oven section to the oven base section.

Installation

Top O v e n D r a i n

Figure 30

11. Locate the bag of parts inside the oven.

12. Install the barb fitting into the coupling to the

right of the copper drain tubes on the bottom

base of the oven.

13. Using the provided clamp, tighten the clamp

around the hose and barb fitting connection,

and the hose and reducer on the copper drain

assembly.

14. Wire tie the two copper drain tubes together

at location shown in Figure 31.

Bottom Oven Drain

Wire Tie

Figure 31

15. Review instructions in STEPS 1 thru 10 to ensure that all connections have been made properly, hoses are not kinked, and all electrical wire

harnesses are routed correctly to prevent chafe

or damage.

16. Complete the attached checklist document.

17. Replace oven electrical control panels on both

upper and lower oven sections. See Figure 13

and Figure 14.

18. Slide the oven assembly back onto the installation base. The locking pins on the rear of the

oven base section will fit into and lock the base

to the upright tabs attached to the installation

base. Install the two bolts (1/2 inch diameter)

removed in STEP 1 (Figure 25), thru the oven

base section and into the installation base. Insure that the drains from the upper and lower

ovens are located over the floor drain.

19. Hook up water and electrical connections to

oven base section. Apply NSF approved sealant to cover of splash proof terminal box.

INSTALLATION COMPLETE. PROCEED WITH

CHECK-OUT PROCEDURE.

1

2

3

Cold Plate Cooling

2

System Drain

19

Page 31

Operation

Oven Startup and Shutdown

OVEN START-UP

1. Turnthemodeswitchtothedesiredmode,

Steam, Hot Air, Combi, Cool Down.

STEAM MODE

1. Turn the mode switch selector knob to the

Steam Position. The green “POWER” indicator lamp illuminates on the front control panel.

2. Steam fills the cavity and is controlled by a

non-accessible internal thermostat.

Preheating for the STEAM mode

Before the first use of the appliance, daily or after

the oven has been idle for 3 hours, preheat with

the STEAM function until steam enters the oven

cavity. The appliance can then be loaded.

HOT AIR MODE

1. Turn the mode selector switch to the Hot Air

position. The green “POWER” indicator lamp

illuminates on the front control panel.

2. Set the Hot Air thermostat to the desired temperature. The Thermostat lamp illuminates indicating the cavity temperature is below the

desired set point.

3. When the cavity temperature reaches the desired set point, the temperature indicator lamp

goes off.

Preheating for the HOT AIR mode

COMBI MODE

1. Turn the mode selector switch to the Combi

position. The green “POWER” indicator lamp

illuminates on the front control panel.

2. Set the Hot Air thermostat to the desired temperature.

3. The hot air thermostat lamp illuminates, indicating the cavity temperature is below the desired set point.

4. Once the cavity temperature reaches the desired set point, the temperature indicator lamp

goes off.

5. The steam and hot air modes come on to satisfy the thermostat set points.

Preheating for the COMBI mode

Always preheat the appliance prior to loading.

Open the door and load the product quickly.

COOL DOWN

1. Turn the mode selector switch to the Cool

Down mode.

2. The convection blower comes on with the

door open or closed.

OVEN SHUT DOWN

1. Turn the mode selector switch to the off position.

Always preheat the appliance prior to loading.

Open the door and load the product quickly.

20

Page 32

Operation

Optional Meat Probe

CONTROLS IDENTIFICATION

1. MEAT PROBE SWITCH

Controls power to the meat probe.

2. MEAT PROBE CONTROL

Use to set the desired probe temperature. Indicates the actual temperature of the product

3. MEAT PROBE CONNECTOR

Receptacle for the plug in meat probe.

NOTE: For sanitation it is recommended that

the meat probe remain plugged into

the front panel receptacle at all times.

OPERATION

Measuring the product core temperatures during

long roasting periods is very practical. It is especially important for products such as Roast Beef to

reach a specific internal temperature.

Place the probe through to the middle of the product’s thickest section. B e sure the probe does not

touch any bone and the tip is not in a fat pocket.

These conditions can ca use inaccurate readings.

1. Set the MODE SELECTOR Switch to the de-

sired function.

2. Turn the MEAT PROBE Switch (1) to ON.

3. To set the desired core temperature press the

blueSETBUTTON(4)ontheMEATPROBE

CONTROL (2).

Use the up arrow key (6) to increase the setpoint temperature. Use the down arrow key

(5) to decrease the setpoint temperature.

Press the set button again to store the setpoint.

4. Set the TIMER to STAY ON. The cooking pro-

cess runs automatically.

When the selected core temperature is reached,

the buzzer will sound and the appliance shuts off

automatically.

The temperature and mode can be changed

at any time during the process.

5. Shut the appliance off by setting all switches

to OFF.

NOTE: When setting the internal temperature, be

sure to allow for carry-over cooking after

the roast is removed from the oven

1

2

3

Figure 32

21

WATLOW

1

2

RDY

SET

4 5 6

Page 33

Operation

Standard Controls

1

3

4

CONTROLS IDENTIFICATION

1. DON’T STEAM LIGHT

Indicates the unit is too hot to operate in the

steam mode. Place the unit in the Cool Down

mode until the temperature is below 230_F

(110_C). This light does not inhibit steam pro-

2

5

duction.

2. POWER ON LIGHT

Indicates the unit is in Steam, Hot Air or

Combi.

3. MODE SELECTOR SWITCH

Turns power to the oven on or off. Allows selection of Steam, Hot Air, Combi or Cool Down

Modes.

4. TEMPERATURE DIAL

Used to set desired cooking temperature.

5. HEATING INDICATOR LIGHT

Lights when the Hot Air heating is in operation.

6. TIMER DIAL

Used to set desired cooking time.

6

Figure 33

22

Page 34

OPERATION

1. Turn the MODE SELECTOR Switch (3) to the

desired function.

The POWER ON Light (2) illuminates.

2. Set the TIMER (6) for the desired cooking time

orsetittoSTAY ON. The buzzer sound and the

unit shuts off when the time has expired.

3. For the HOT AIR and COMBI modes, set the

TEMPERATURE Dial (4) to the desired cook

temperature. The HEATING INDICATOR Light

(5) illuminates and stays lit until the desired

temperature is reaches.

4. The selected mode operates automatically.

The temperature, time and mode can be al tered at any time during the cooking process.

The operation can be stopped by the use of

the Mode Selector Switch or by opening the

door.

Operation

Standard Controls

5. At the end of the specified time period, the

buzzer sounds and the appliance will shut off

automatically. Move the TIMER (6) to the STAY

ON position to stop the buzzer and restart the

unit.

6. To cool down the oven cavity, switch the

MODE SELECTOR Switch (3) to COOL

DOWN. In the Cool Down mode neither the

temperature dial or the timer will be operational. The blower will function with the door open

or closed.

7. The mode selector switch is also the main

power switch. In the OFF position the appliance is not operational.

NOTE: Always disconnect the power supply be-

fore servicing the unit.

23

Page 35

Cooking Guide

The Steam Mode

INFORMATION ABOUT THE STEAM MODE

How steaming works

This mode gently cooks food using non-pressurized steam. Fresh steam is directed into the oven

from the generator. It is not necessary to add water

to foods during the cooking process.

What can be steamed

Vegetables, side dishes, fish, meat, poultry, diet

foods, garnishes, dumplings, casseroles, meat

loaf, fruits, desserts and eggs.

How to operate the Steam mode

Simply turn the M ode Selector Switch to the

STEAM position and set the Timer.

Theadvantagesofsteaming

Steaming is a well-known cooking process frequently used in restaurant and institutional kitchens. With this appliance it is now possible to enj oy

the many advantages of steaming, some of which

are:

DDDD

Shorter Cooking Times

The continuous processing of large amounts of

product is no problem and long cooking times

arenolongernecessary.Evenwithfullloads,

relatively shorter cooking time for food is needed.

DDDD

High Quality Foods

With the useof steam, valuabletaste and aroma

are preserved since steamed foods retain their

own natural taste. During the steaming process

foods retain the nutrients and vitamins w hich

are lost in water during boiling. Therefore, when

compared, steamed foods have much better

color than foods that have been boiled. Also, by

using shallow containers the product is not layered as deeply and mushing is avoided.

DDDD

Vitamin Retention

Vitamins are not destroyed. This is due to the

shorter cooking times, the use of less or little

water and the use of a low temperature; slightly

less than 212_F/100_C.

DDDD

Firmness

With the use of steam, overcooking is not a

problem and firmness can be individually controlled.

DDDD

Simultaneously Steaming Different Foods

Thereisnoflavortransferwhencookingwiththe

STEAM mode. For this reason, various types of

food with different cooking times can be loaded

or removed at any point during the cooking process.

24

Page 36

Cooking Guide

The Steam Mode

TIPS AND PROCEDURES

Containers

Both solid and perforated steam table pans of varying sizes (full, half, and one-third size) may be

used in the appliance. Small pans may be placed

on wire racks.

Stocks for Sauces

When trays are used for cooking there is usually

enough stock collected for making sauces. When

using perforated pans, insert a solid pan in the bottom rack to collect the stock.

Seasoning

Since there is no liquid added during the steaming

process, season using one of the following methods:

DDDD

Season before cooking: Sprinkle the spice

mixture evenly over the food prior to cooking.

DDDD

Oil seasoning after cooking: Stir the oil mixture into the product. Steam again for two minutes in some cases.

Blanching and Prep Work

Large amounts of product can be blanched in a

short amount of time. T rays should not be filled

higher than 3 inches.

The STEAM mode is excellent for preparing vegetables for peeling.

Canning and Preserving

The diameter of the containers must not exceed

4-5 inches when canning.

Thawing

Thawing time is much shorter when using steam

and produces higher quality food.

Reheating

The use of steam creates an even distribution of

heat, which gives food better taste and retention

of nutrients.

Foods a re reheated in the trays in which they were

cooked. Reheating times vary according to the

height and content of the containers.

SAMPLE DISHES

Vegetables

Fresh and frozen vegetables may be steamed together. Frozen vegetables should be loosely scattered on the trays. Perforated trays shorten cooking time, although solid trays may be used.

Cooking times will vary depending on the quality

of the vegetables. When steaming fresh vegetables, check the product

cooking period.

Steamed vegetables tend to soften after cooking.

Sincethereisadelaybetweencookingandserving,

it is best not to steam vegetables too soft. This is

especially important for foods prepared for transport.

Rice and Potatoes

Rice requires the addition of water for steaming.

Remember that the rice continues to s w ell after

cooking; plan your quantities accordingly.

Always cook potatoes in perforated pans. Steam

can permeate the potatoes better if they are quartered through the width and not the length.

Eggs

Eggs are inserted onto wire racks, either in t he

cardboard container or placed into perforated

trays (there is no need to puncture them). Cooking

eggs with the STEAM function saves work and results in less waste since steamed eggs do not

break. Also, the degree of hardness can be controlled exactly. Begin timing w hen the oven window is misted over.

Fish

Fish can be steamed in trays w ithout using extra

stock. Use a 1 inch pan for fresh fish (Fillets). For

larger or frozen pieces, use a 2 inch pan.

Poachedfish can be prepared with aromatic herbs

and vegetables in either solid or perforated pans.

Steam w ithout stock.

Shell fish can be steamed in perforated pans. Use

a solid pan to catch drippings for stock.

3

/4of the w ay through the

25

Page 37

Cooking Guide

The Hot Air Mode

INFORMATION ABOUT THE HOT AIR MODE

How cooking with hot air works

Hot air is circulated at high speed on all sides of

the product, providing a concentrated cooking

process. This function is extremely effective for intensive browning.

What can be cooked with hot air

Hot air can be used for all foods which need a short

cooking time and intensive browning. For example: steaks, cutlets, fillets, breaded foods, and various baked foods. This function may also be used

for au gratin.

COOKING WITH THE HOT A IR MODE

Temperatures

For intensive browning and crispy crusts, preheat

the oven to the maximum temperature of

500_F/260_C. This is especially important when

searing.

Performance

The charts showing performance examples (See

Cooking Guide) are based on full capacity. Better

results may be obtained by reducing product

quantities.

Cooking Times

Due to the constant hot air circulation, this appliance cooks faster than conventional grills and

deck ovens.

Cooking times will vary according to the quality,

weight, and height of the product.

Trays or Racks?

This is a question of individual choice. Racks have

the advantage of browning food on all sides; the

underside of tightly packed foods may be lighter

when using trays.

TIPS AND PROCEDURES

Loading the Oven

Place like sized product together on one rack. In

order to ensure proper air circulation, racks and

trays s hould not be crowded.

Oiling

The quality of some foods, such as steaks and

breaded meats, can be enhanced by coating with

oil or a paprika oil mixture.

Breaded Foods

The degree of browning is dependent on the

amount of raw material in the breading. Oil can be

used to intensify the browning. Press the breading

firmly but don’t overload the oven. Flouring seared

foods is not recommended.

Baking

Forbaking,theModeselectorswitchmaybeset

to HOT AIR, STEAM, COMBI or any combination

according to the type of product. Steam added to

the baking process opens up a wide range of possibilities:suchashardcrustsandgoodshineon

certain types of breads. Here are some tips for

baking:

D

Preheat oven to the baking temperature.

D

Baking temperatures can generally be set

50-75_F/20-25_C lower than with a conventional baking or roasting oven. When in doubt, lower the temperature.

D

The baking time can be shorter than with conventional methods.

D

Slightly reduce your quantities of mixtures with

excessive moisture.

D

Use deep trays for light mixtures in order to ensure undisturbed baking. Baking forms should

not be higher than 3 inches.

D

Cake forms (pans, tins, etc.), should be placed

on racks.

D

Distributefoods evenly w hen loadinghalf loads.

D

Use every second tier for baking bread, heavy

mixtures (yeast doughs, etc.) and well filled

forms.

26

Page 38

Cooking Guide

The Combi Mode (Steam and Hot Air)

INFORMATION ABOUT THE COMBI (STEAM

AND HOT AIR) MODE

How Combi Mode Works

With this function, the advantages of steam (short

cooking time, less shrinkage) and hot air (intensive aroma, appetizing color) are combined.

Steam and hot a ir circulate at high speeds, enveloping the product on all sides and providing an intensive cooking process.

What can be cooked in Combi mode?

All types of roasts, duck ling, pork, beef, lamb,

meat loaf, ground chuck foods, casseroles, poultry, stuffed vegetables, vegetables au gratin and

yeast doughs.

TheadvantagesofCombimode?

DDDD

Productivity

Previously, several different appliances, and

multiple procedures, were necessary to combine heat andsteam preparation. Now all of

these methods can be used without time wasting interruptions, with one appliance.

DDDD

Less Shrinkage

The usual weight loss during roasting in conventional appliances can be reduced by approximately 13% of the original weight.

DDDD

Juiciness and Crunchy Crusts

When used at the beginning of the cooking procedure, the searing action of steam instantly

closes all pores. This reduces the loss of protein

and meat juices. Therefore, products with long

roasting times remain juicy. Foods retain their

moisture and roasts develop a pleasing color as

well as an appetizing crust. Meats have a pronounced roasted taste and burning of the surface is almost impossible.

COOKING IN THE COMBI MODE

The COMBI function can be used for the entire

cooking process or for any portion of the cooking

procedure you desire.

What do Combi-roasting, Combi-steaming and

Combi-baking mean?

We have created these names since both modes,

STEAM and HOT AIR, can be applied in any combination as follows:

D

Together, as in the COMBI function.

D

In sequence

Example: first STEAM and then HOT AIR.

D

Orinsequenceandthenincombination

Example: first HOT AIR and then COMBI

Or conversely: first COMBI and then HOT AIR.

D

Or all three functions in sequence

Example: first STEAM, then HOT AIR, then

COMBI.

For additional tips on when to use each of these

Combi Modes see the “Summary of Functions” on

the following page.

27

Page 39

Cooking Guide

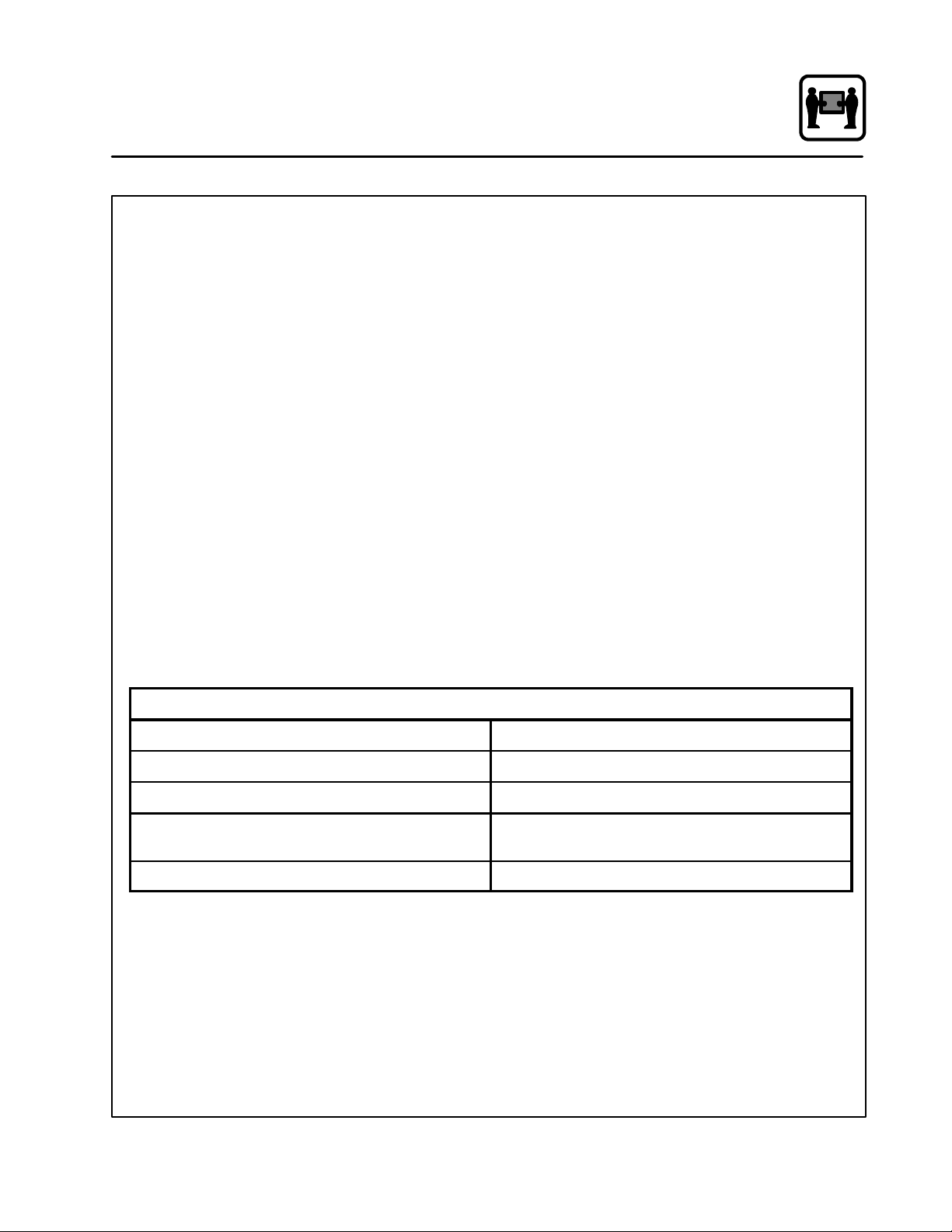

Summary of Functions

MODE SELECTION COOKING METHODS PRODUCTS

Steam

Hot Air

Combi

Steam Hot Air

Hot Air Combi

Steaming, defrosting, thawing, reheating-reconstituting, blanching,

preserving, poaching, simmering,

braising, stew ing.

Roasting, grilling, baking,

au gratin.

Combi-steaming, Combi-roasting,

Combi-baking, defrosting-thawing,

reheating-reconstituting.

Combi-steaming,

Combi-braising,

Combi-roasting,

Combi-baking,

(Begin with steam, then with dry heat

for crusting, browning, gratinating.)

Combi-steaming,

Combi-roasting, Combi-baking,

(Start with dry heat, switch over to

Combi for slow but gentle even

browning, switch back and forth as

necessary.)

Convenience food, potatoes, rice,

fresh or frozen vegetables, fresh or

frozen fish, poultry, meat, fruit, eggs,

puddings, casseroles.

Roast beef, pork, veal, lamb, chicken, hamburger, fish, stuffed vegetables,toast,lasagne,potatoes,pies,

shortbread, puff pastry, Danish and

French pastry, bread.

Prime rib, whole bone ham, goose,

turkey, fish, mutton, beef, pork roast,

French pastry, bread, rolls, puff

pastry, Danish pastry, convenience

food.

Stuffed peppers, gratinated vegetables, fennel, broccoli, cauliflower ,

rack of lamb, pork

French pastry, puff pastry, yeast

dough, turkey, duck, goose, lamb,

stuffed vegetables.

Combi Hot Air

Steam Hot Air Combi

Combi-braising,

Combi-roasting,

Combi-baking,

(Start with Combi, finish with dry heat

for crusty, crisp, brown surface,

switch back and forth as necessary.)

Combi-steaming,

Combi-roasting, Combi-baking,

(For meats: sear pores closed with

steam, then brown with dry heat, then

switch between Combi and dry heat.

For stuffed vegetables: steam first

and switch between dry heat and

Combi during the rest of the cooking

process.)

28

Whole bone ham, ham in bread

dough (English Ham), whole fillets of

beef, pastry dough, yeast dough

(bread, rolls).

Veal, pork, beef, leg of lamb, goose,

duck, turkey, prime rib, puddings,

stuffed peppers; ideal for all products which need a humid cooking

process.

Page 40

Cooking Guide

General Tips and Procedures

USING RACKS

Use racks for roasts needing a longer roasting

time, large roasts (pork, veal, beef, venison,

lamb), searing, toast, au gratin, (chicken, duck,

goose, legs, chops), cooking in containers, thawing, baking in tins, etc. When cooking in racks it is

important to turn food products.

USING PANS

DDDD

1I Deep Steam Table Pan

Forfried potatoes, hamburgers, au gratin, thawing, meat loaf, meat balls, fried, poached and

steamed fish, baked goods, vegetable casseroles, duck and goose.

DDDD

2I Deep Steam Table Pan

For cabbage rolls, stuffed peppers, stews, rice,

vegetables, sauerkraut, assorted fruits and

compote. Also for collecting stock, preparing

sauces, etc.

DDDD

2½IDeep Perforated Steam Table Pan

For vegetables without stock, side dishes

(breads) and products with shorter cooking

times.

DDDD

4IDeep Perforated Steam Table Pan

For vegetables (blanching spinach for example), potatoes, shelled or unshelled eggs.

DDDD

6IDeep Perforated Steam Table Pan

For potatoes.

LOADING THE OVEN

To ensure that the product will brown on all sides,

do not place foods too close together. Place the

grain of meats parallel to the air stream (left to

right). This ensures better absorption and shortens the cooking process. Place like sized pieces

together on the same rack, smaller pieces cook

more quickly.

Place the food in the appropriate pans/trays or distribute it on the racks. Insert racks and trays into

the pan rack. It is recommended that the pan rack

be loaded outside of the oven wh en processing

large amounts of product. The pan rack for table

models is well suited for this purpose; it allows for

a higher hourly production and an efficient w ork

sequence.

REMOVING THE PRODUCT

Turn the Mode Selector Switch to OFF before

opening the appliance door.

NOTE: Open the door slowly after steaming! Hot

Steam Will Be Present!

COOKING TIMES

The length of the cooking process depends on the

quality, weight and thickness of the food product.

TEMPERATURES

Typically, the longer the cooking process, the lower the temperature.

29

Page 41

Cooking Guide

Suggested Times and Temperatures

PRODUCT SUGGESTED CORE TEMPERATURE

Beef

Fillet of Beef

Roast Beef

Pot Roast

Veal

Saddle of Veal

Loin

Shoulder

Stuffed or Boned

Leg, Top-side

Pork

Leg

Picnic Shoulder

Ham

Smoked Pork Chops

Ribs

Tongue

medium rare

medium rare

well done

medium

well done

well done

fricandeau

well done

well done

juicy

well done

well done

130_-140_F

130_-140_F

170_F

160_F

165_-175_F

165_-175_F

165_-170_F

172_F

185_F

185_F

155_F

158_F

150_F

195_F

54_-60_C

54_-60_C

78_C

70_C

75_-80_C

75_-80_C

75_-78 _C

78_C

85_C

85_-80_C

68_C

70_C

70_C

90_C

Poultry

Chicken

Goose

Tur k ey, Du ck

Lamb

When the meat is well done it has a core temperature between 173_-185_F(79_-85_C). The core has

a slightly pink color and the juices are clear.

Saddle

Saddle

Leg

Leg

Pâtés

Pâté 160_-165_F72_-74_C

NOTE: Actual temperatures may vary from those shown. Write in your proven temperatures for ready ref -

erence.

well done

well done

well done

slightly pink

well done

slightly pink

well done

185_F

195_-198_F

175_-185_F

158_-165_F

175_F

165_-170_F

180_-185_F

85_C

90_-92_C

80_-85_C

70_-75_C

80_C

75_-78_C

82_-85_C

30

Page 42

Cooking Guide

Notes

31

Page 43

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaning of the appliance is essential for sanitation, and to ensure against operational difficulties.

For difficult cleaning, allow the spray-on oven

cleaner to work longer before rinsing.

1. Cool the oven down to 140_F/60_Cor,ifthe

oven has been idle, turn the steam mode on

for 3 to 4 minutes in order to warm the oven

surfaces.

2. Spray the interior of the oven with a cleaning

solution.

NOTE: Never spray water into the unit when

the temperature is above 212_F. N E V ER SPRAY WATER IN THE UNIT AFTER

USING THE HOT AIR OR COMBI

MODES.

3. Let the cleaner work for 10 to 20 minutes with

the oven off. For difficult, baked on grease,

etc. allow to work over night.

4. Set the timer for 15 to 20 minutes.

5. Set the mode selector switch to Steam. This

will soften all burned on residue.

6. Rinse the oveninteriorwith w a ter (a hose may

be used, but take care that only the oven’s interior cavity is sprayed with water).

7. Setthe mode selectorto steam for anotherfive

minutes to flush out the oven interior and remove all detergent residue.

NOTE: The oven cavity should never be scoured

or scraped.

On stainless interiors, deposits of baked on splat ter, oil, grease or light discoloration may be removed with a good non toxic industrial stainless

steel cleaner. Apply cleaners when the oven is

cold and always rub with the grain of the metal.

The racks, rack supports and the blower wheel

maybecleanedintheovenorbyremovingthem

from the oven and soaking them in a solution of

ammonia and water.

NOTE: DO NOT use corrosive cleaners on the

Oven/Steamer.

CLEANING THE EXTERIOR

Oven exteriors may be cleaned and kept in good

condition with a light oil. Saturate a cloth and wipe

the oven when it is cold; wipe dry with a clean

cloth.

NOTE: The outside of the appliance is not to be

sprayed with water.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

the proper initial installation of the equipment and

a program for cleaning the oven routinely. The

Oven/Steamer requires no lubrication. Contact

the factory, the factory representative or a local

Blodgett Combi service company to perform

maintenence and repairs should they be required.

WARNING!!

Disconnect appliance from power supply

before servicing or cleaning.

32

Page 44

Maintenance

Decalcification

The COS-5HA has a separate boiler for each unit.

There are deliming ports and handles for each boiler

located on the base unit. The left deliming port and

handle is for the bottom unit. The right deliming port

and handle is for the top oven. To save time the boilers should be delimed simultaneously.

The COS-5HA should be delimed on a monthly basis regardless of water quality or usage. Use the

following procedure to delime the boilers.

WARNING!!

ALWAYS USE PROPER SAFETY EQUIPMENT WHEN DELIMING. Gloves and eye

safety equipment are recommended.

1. Set both mode selector switches to Steam

mode. Wait until steam is produced. This will

ensure that the water in the steam generators

is hot.

2. TurnthemodeselectorswitchestoOFF.

3. Remove both deliming port covers on the

base unit.

4. Add 10 ounces of deliming solution to the de-

liming bottle and then add 1-3/4 gallons of

warm water.

NOTE: Lime-a-way

are recommended. The main active

ingredient should be a deluted concentration of phospheric acid.

5. Delime the boilers as follows:

a.) Connect the deliming hose to one of the

deliming ports on the base section.

b.) Turn the corresponding red deliming han-

dle on the base unit so it is vertical. This

opens the deliming port.

c.) Pump in all of the solution.

d.) Close the deliming handle and remove

the deliming hose from the deliming port.

Thehandleisnowhorizontal.

6. Repeat STEPS 4 and 5 for the other oven.

7. Allow the ovens to sit with the deliming solution in them for at least 1/2 hour.

NOTE: For heavy lime build up, allow to stand

for 1 hour.

t

or a generic equivalent

8. Drain and flush the boilers as follows:

a.) Connect a drain hose to one of the delim-

ing ports. Allow the boiler to drain completely. The drain hose is not supplied.

b.) Carefully rinse out the deliming container

and fill it with 1-3/4+ gallons of fresh water

only.

c.) Turn the oven to Steam and allow the boil-

er to fill. Wait at least 2 minutes.

d.) Connect the deliming pump to the same

deliming port on the base section.

e.) Turn the red deliming handle on the base

unit so it is vertical. This opens the deliming port.

f.) Pump in all of the water in the deliming

pump.

g.) Close the deliming handle and remove

the deliming hose from the deliming port.

Thehandleishorizontal.

h.) Connect the drain hose to the same de-

limingportonthebasesection.

i.) Turn the red deliming handle on the base

unit so it is vertical. This opens the delim-

ing port.

j.) Let all the water drain from the boiler.

k.) Remove the drain hose and turn the han-

dle to the horizontal position.

9. Repeat STEPS b. and 8 for the other boil er.

10. Reattatch the covers to the deliming ports.

Deliming

Deliming

Port

Port

33

Figure 34

Page 45

Maintenance

Troubleshooting Top Oven Section

COOL DOWN MODE

POSSIBLE CAUSE(S)

SYMPTOM: Motor doesn’t run in cool down.

S

Blown 2 amp input fuses.

S

Transformer is defective

S

Blown 2 amp secondary fuse.

S

P13 snap disk on the solid state relay assembly

is open (SSR assembly is to the left of the boiler)

S

Mode selector switch (S1) is not closing

between 23 & 24.

S

Motor contactor (K1-A) is not pulling in.

S

Motor protector (PKZM-A) has tripped.

S

Convection motor is bad.

SUGGESTED REMEDY

S

Remove and check fuses. Determine cause of circuit overload.

S

Verify input to transformer. Check transformer

coils. Approximately 2.2 ohms primary / .7 ohms

secondary. Replace if necessary.

S

Remove and check fuse. Determine the cause of

circuit overload.

S

Verify water is on ohm out snap disk P13

S

Check closing of switch with meter. Replace if

needed.

S

Verify voltage to coil A1 to A2 of motor contactor.

(Coil resistance is 500+ ohms) Replace if defective.

S

Motor protector is defective or see “Convection

Motors Run Intermittently” below.

S

Check windings of coil motor. Resistance of

windings is approximately 85 ohms. Running

current .5 amps.

SYMPTOM: Convection motor runs intermittently.

S

Thermal overload on motor (M1) is opening and

closing (automatically resets when cooled).

S

Electrical compartment cooling fan is not running.

NOTE: SSR refers to Solid State Relays which are

water cooled on a cold plate.

S

Check current draw. See if motor seal is out of

alignment. (Requires removal of blower wheel.)

Adjust seal if needed. Evaluate motor. Replace if

defective.

S

Check windings on fan (600+ ohms coil resistance) if open, replace.

34

Page 46

Troubleshooting Top Oven Section

HOT AIR MODE

NOTE: Confirm cool down works before proceeding with hot air.

Maintenance

POSSIBLE CAUSE(S)

SYMPTOM: Mode switch is in the hot air position but no control panel lights are on.

S

Cavity high limit (F3) is open. (opens at 662_F)

S

Power on light (H4) has 220V but is not lit.

SYMPTOM: Hot air temperature light (H5) will not come on but power on light (H4) is lit.

S

Oven is up to temperature.

S

Mode selector switch (S1) is not closed betw een

terminals 9 & 10.

S

Door switch (S2) is not closing.

S

Relay (R5) is open.

S

Hot air thermistor is out of tolerance. Unplug from

thermostat and check resistance. (Use ohm chart)

Replace if needed.

S

Defectivehotairthermostat.Replace

S

Cavity high limit is defective. Replace

S

Replace light (H5)

S

Everything is OK.

S

Defectivemodeselectorswitch(S1).Replace

switch.

S

Proximity door switch (S2) is not engaging. Remove access plate & inspect. Replace if defective.

S

Optional meat probe control has reached temperature and s hut off oven by supplying 220V to

terminals 7 & 8 on (R5).

SUGGESTED REMEDY

S

Timer (S4) has timed out to zero minute position.

S

Defective timer (S4).

S

Relay (R5) is defective. Replace

S

Reset timer to a timed position or fully into the stay

on positio n if continued operation is desired.

S

Replace timer (S4). Verify voltage 220V is present on terminals 6 & 7 before replacement.

35

Page 47

Maintenance

Troubleshooting Top Oven Section

HOT AIR MOD E (continued)

POSSIBLE CAUSE(S)

SYMPTOM: Hot air temperature light (H5) will not come on but power on light (H4) is lit. (continued)

S

Hot air thermostat (P5) is not getting 220V at

inputs L1 and C.

S

Hot air thermostat (P5) is getting voltage 220V to

inputs but has no 220V to terminal “NO” and

common.

SYMPTOM: No heat in Hot Air Mode but hot air (H5) and power light (H4) are both on.

S

Motor is running and the centrifugal switch is

open.

S

Hot air SSR (K2-A) does not pull in.

S

Hot air SSR (K2-A) is energized 220V at coil but

no heat.

S

Check wire connections.

S

Hot air thermistor probe is bad or out of tolerance. Refer to OHM chart. Replace if needed.

77 = 100,000 212 = 6,780 347 = 1,070.

S

Defective hot air temperature control (P5). Replace.

S

OHM out switch (red wires in motor) while motor

is running, if it is open, remove motor and inspect

centrifugal switch through access plate for loose or

disconnected wires. Replace if defective. If you replace a motor, always replace the motor seal.

S

Verify 220V to coil. Replace if needed. See if red

LED is on.

S

Contactor is not closing on one or more poles.

Replace.

SUGGESTED REMEDY

S

Hot air elements are open. Replace as needed.

SYMPTOM: Oven appears to be working properly, but the bake pattern has changed or is uneven.

S

Oneormorehotairelementsareopen.

S

Check continuity of elements. Replace as needed.

36

Page 48

Maintenance

Troubleshooting Top Oven Section

STEAM MODE

NOTE: Confirm cool down and hot air modes work before continuing. By checking hot air mode first, you

have trouble shot all common components in both the hot air and steam mode up to and through

the timer (S4).

POSSIBLE CAUSE(S)

SYMPTOM: Mode switch is in the steam mode position but power light is off.

S

Mode selector switch (S1) is not closed betw een

terminals 3 & 4.

S

Power on light (H4) is defective.

S

High limits F3 has tripped.

SYMPTOM: Steam generator overfills.

S

Float assembly is hanging up.

S

Relay R2 is stuck close

S

Solenoid is staying open.

S

SYMTOM: TO HOT FOR STEAM light is on.

S

Defectivemodeselectorswitch(S1).Replace

mode switch.

S

Replace light.

S

Return to Troubleshooting Hot Air Mode.

S

Delime steam generator / remove float assembly

if needed and clean / move float assembly up /

down, verify reed switch is opening & closing

with VOM

S

Verfy coil (7 & 8) has no power to it, replace R2

relay.

S

Replace if needed.

S

TOO HOT FOR STEAM light is a information light

only, if it is “ON” it does not affect operation

S

Open door and cool down cooking cavity if TOO

HOT FOR STEAM light comes on in the steam

mode, P1 is defective.

SUGGESTED REMEDY

37

Page 49

Maintenance

Troubleshooting Top Oven Section

STEAM MODE (continued)

POSSIBLE CAUSE(S)

SYMPTOM: Mode switch is in the steam mode, power on light is on, but no steam.

NOTE: If the water level is not maintained properly, a safety F6 --- A (caliary type thermostat, opens

at 275F & must be manualy reset) Before continuing, review the sequence of operation to

understand the float circuit / fill logic.

S

Mode switch terminals 1 & 2 open

S

Mode switch terminals 5 & 6 open

S

Boiler high limit F6-A has tripped. (Also review if

you are having water fill issues)

S

Boiler is not filling deliming port to determine if

boiler has water

S

Use VOM to ohm out terminals, replace mode

switch in needed

S

Use VOM to ohm out terminals, replace mode

switch in needed

S

Continued resetting of F6-A boiler high limit may

weaken the high limit and cause premature tripping.

S

Ball float is hung up in boiler and staying open.

Ohm out between R1 relay terminal 2 & R2 relay

terminal 7 Removal of float assembly may be necessary to determine if float is hanging up due to

mineral build up or internal reed switch has failed.

S

Quesent timer is not supplying flat water check (90

secondson/10off)veritypowerinonbothinputs,

terminals 2/3 & 7/3. Verify output on terminal 4.

S

Relay R1 supplies power to the float / verify terminals 6 to2 are closed.

SUGGESTED REMEDY

SYMPTOM: Steam contactor K3-A is not engaged.

S

Defective SSR / See if RED LED on SSR is lit

S

Steam solid state contactor K3-A has power in to

input, but no heat.

S

Relay R2 supplies power to the fill solenoid /

verify the terminals 7 & 8 have power (relay coil)

/ verify terminals 5 to 3 are closed.

S

Coil for the fill solenoid Y1 is open / verify input.

Ohm out coil windings, should be approximately

1800 ohms. Replace Yi if needed.

S

Verify power to coil / replace if needed

S

Solid state contactor is not closing on one or

more poles. Replace.

S

Steam elements are open. Ohm out elements.

Replace as needed.

38

Page 50

Maintenance

Troubleshooting Top Oven Section

COMBI MODE

NOTE: Confirm cool down, hot air and steam modes work before continuing. By confirming previous

modes you have tested most of the components in Combi.

POSSIBLE CAUSE(S)

SYMPTOM: Mode switch is in the Combi position but no control panel lights are on.

S

Mode selector switch (S1) terminals 21 & 22 are

open.

SYMPTOM: Power light (H4) is on, hot air heat light (H5) is on and off, but no steam.

S

Mode selector switch (S1) terminals (15 & 16) or

(17 & 18) are open.

S

Solid state combi timer is not operating. (no

steam in the combi mode only)

SYMPTOM: Power light (H4) is on, steam works, but no hot air.

S

Mode selector switch (S1) terminals 19 & 20 are

open.

S

Replace switch.

S

Replace sw itch.

S

Verifyresister assembly (with adjusting knobs) is

plugged fully in

S

Verity power in on terminals 2 & 3

S

Verify output on terminal 1

S

Verify timer knob settings (15 sec “on” / 45 sec

“off”)

S

Replace sw itch.

SUGGESTED REMEDY

SYMPTOM: Not enough steam in the Combi mode.

S

Cavity temperature is too high (over 400_F)

S

Timing sequence needs adjusting to increase

steam.

S

Reduce temperature.

S

Left knob is time “ON” /right knob is time “OFF”

39

Page 51

Maintenance

Troubleshooting Top Oven Section

SEQUENCE OF OPERATION -- HOT AIR

NOTE: Electricity flows through these components

in the order listed.

1. Terminal block L1, L2, L3 (440V/3ph)

2. Primary 2 amp slow blow fuses F2 / F3

3. Primary coil of transformer (step down 440V

to220V)

4. Secondary coil of transformer 220V

5. Secondary 2 amp slow blow fuse F1

6. P13 Solid State cold plate snap disk high limit

(opens at176F)

7. Plug connector (J3) terminal 9

8. Cooking compartment high limit (F3) terminals 1 to 2

9. Plug connector terminal 2 (J9)

10. Mode selector switch (S1) terminal 9 to 10

11. Power ON light (H4)

12. Plug connecter terminal 5 (J9)

13. Electrical compartment cooling fan (CF)

14. Door switch (S2)

15. Plug connector (J9) terminal 13

16. Meat probe relay (R5) terminal 6 to 1

17. Timer (S4) terminals 4 to 6 or Timer (S4) termi nal 4 to 5 if timer is timed out

18. Buzzer (T1)

19. Plug connector (J9) terminal 11

20. Plug connector (J3) terminal 1

21. Power junction: to follow motor operation to

step 26.

22. Motor contactor (K1-A) terminal A1 to A2

23. Power in L1, L2 & L3 (440V/3ph) motor contactor (K2-B)

24. Motor protector (PKZM-A)

25. Plug connector terminal 1, 2 & 3 (J1)

26. Convection motor

27. Mode selector switch (S1) terminal 11 to 12

28. Hot air thermostat (P5) C to L1

29. Hot air thermostat (P5) COM to NO

30.Hotairlight(H5)

31. Plug connector (J9) terminal 10

32. Motor centrifugal switch (CS1)

33. Plug connector (J3) terminal 7

34. Hot air contactor (K2-A) terminal A1 to A2

35. Power in L1, L2 & L3 (440V/3ph)

36. Hot air contactor (K2-A) L1, L2 & L3 to T1, T2

&T3