Page 1

TMIN

PSIN

COS-5H

INSTALLATION AND OPERATION INSTRUCTIONS

FOR SHIPBOARD USE

FSCM 07695

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN R7354 Rev G (8/02)

E 2002 --- BlodgettCombi

Page 2

TMIN # XXXXXXXXXXXXXXXXXXXXX

SAFETY SUMMARY

Thefollowing aregeneral safetyprecautionsthat are notrelated toanyspecificprocedures

andtherefore donotappear elsewhereinthis publication.Theserecommendprecautions

that personnel must understandand apply during many phases of operation and maintenance.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must at all times observe all safety regulations. Do not replacecomponents or make adjustments inside the equipment with the high voltage supply turned

on. Under certain conditions, dangerous potentials may exist when the power control is

in the offposition, dueto thechargeretained incapacitors. To avoid casualties, always remove power and discharge and ground a circuit before touching it.

DO NOT SERVICE OR ADJUST ALONE

Under no circumstances should any person reach into or enter the enclosure for the purpose of servicing or adjusting the equipment except in the presence of someone who is

capable of rendering aid.

RESUSCITATION

Personnel working withor near high voltages should befamiliar with modern methods of

resuscitation.

The following appear in the text of this volume, and are repeated here for emphasis.

WARNING:

Before performing any maintenanceor replacing anycomponent

on this unit, disconnect oven from

electrical source.

Page 3

TMIN # XXXXXXXXXXXXXXXXXXXXX

CHANGE RECORD

CHANGE NO. DATE TITLE/BRIEF DESCRIPTION SIGNATURE OF

VALIDATING OFCR.

Page 4

TMIN # XXXXXXXXXXXXXXXXXXXXX

LIST OF EFFECTIVE PAGES

Insert latest changed pages. Destroy superceded pages.

NOTE:The portion of the text affected by thechanges is indicatedby a vertical line in the

outermarginsofthepage.Changestoillustrationsareindicatedby miniaturepointing hands. Changes to diagrams are indicated by shaded areas.

Dates of issue for original and changed pages are:

Original MARCH 1998...

The total number of pages in this publication are: 29

consisting of the following:

PAGE NO.

CHANGE NO.* PAGE NO. CHANGE NO.*

* Zero in this column indicates an original page

Page 5

TMIN # XXXXXXXXXXXXXXXXXXXXX

APPROVAL AND PROCUREMENT RECORD

APPROVAL DATA FOR: COS-5H

Electric Combination Oven

TITLE OF MANUAL: Technical Manual, COS-5H

Electric Combination Oven

APPROVAL AUTHORITY: Defense General Supply Center

Letter Dated ?? ???

??

CONTRACT NO. NSN NO. OF UNITS APL

REMARKS

DATE: 5 Mar 98

CERTIFICATION:

It is hereby certified that the technical manual provided under contract number XXX-XXX-

XX-X-XXXX for COS-5H has been approved by the approval data shown above.

(Signed) _____________________________

John Bardeau

(Title) VP Sales and Marketing

Blodgett Combi

55 Boyer Circle

Williston, VT 05495

FSCM 07695

Page 6

Table of Contents

Introduction

The Blodgett Combi-Oven/Steamer 2.................................

Description of the Combi-Oven/Steamer 3............................

Oven Features 4...................................................

Installation

General Installation Information 5....................................

Delivery and Location 6.............................................

Installation Base 7.................................................

Utility Connections 9...............................................

Oven Installation --- No Dismantling Required 10........................

Oven Installation --- Some Dismantling Required 11.....................

Oven Dismantling 11.............................................

Oven Re-Assembly 18............................................

Operation

Oven Startup and Shutdown 22.......................................

Optional Meat Probe 23..............................................

Standard Controls 24................................................

Cooking Guide

The Steam Mode 26.................................................

The Hot Air Mode 28................................................

The Combi Mode (Steam and Hot Air) 29..............................

Summary of Functions 30............................................

General Tips and Procedures 31......................................

Suggested Times and Temperatures 32................................

Baked Goods 32.................................................

Eggs 33........................................................

Pork 34.........................................................

Starches 35.....................................................

Beef 36.........................................................

Fish 37.........................................................

Poultry 38.......................................................

Vegetables 39...................................................

Page 7

Table of Contents

Maintenance

Cleaning and Preventive Maintenance 41..............................

Decalcification 42...................................................

Troubleshooting Information 43.......................................

Component Indentification 44........................................

Sequence of Operation 47...........................................

Top Oven Section --- Cool Down 47.................................

Top Oven Section --- Hot Air 47....................................

Top Oven Section --- Steam 48.....................................

Bottom Oven Section --- Cool Down 50.............................

Bottom Oven Section --- Hot Air 50.................................

Bottom Oven Section --- Steam 51.................................

Schematic --- Steam 53..............................................

Schematic --- Hot Air 56..............................................

Schematic --- Cool Down 59..........................................

Schematic --- Base Section 62........................................

Schematic --- Bottom Oven Section 63.................................

Schematic --- Top Oven Section 64....................................

Troubleshooting 65..................................................

Cool Down Mode 65.............................................

Hot Air Mode 66.................................................

Steam Mode 68..................................................

Combi Mode 72.................................................

Wire Harness and Plug Connector Designations 73.....................

Page 8

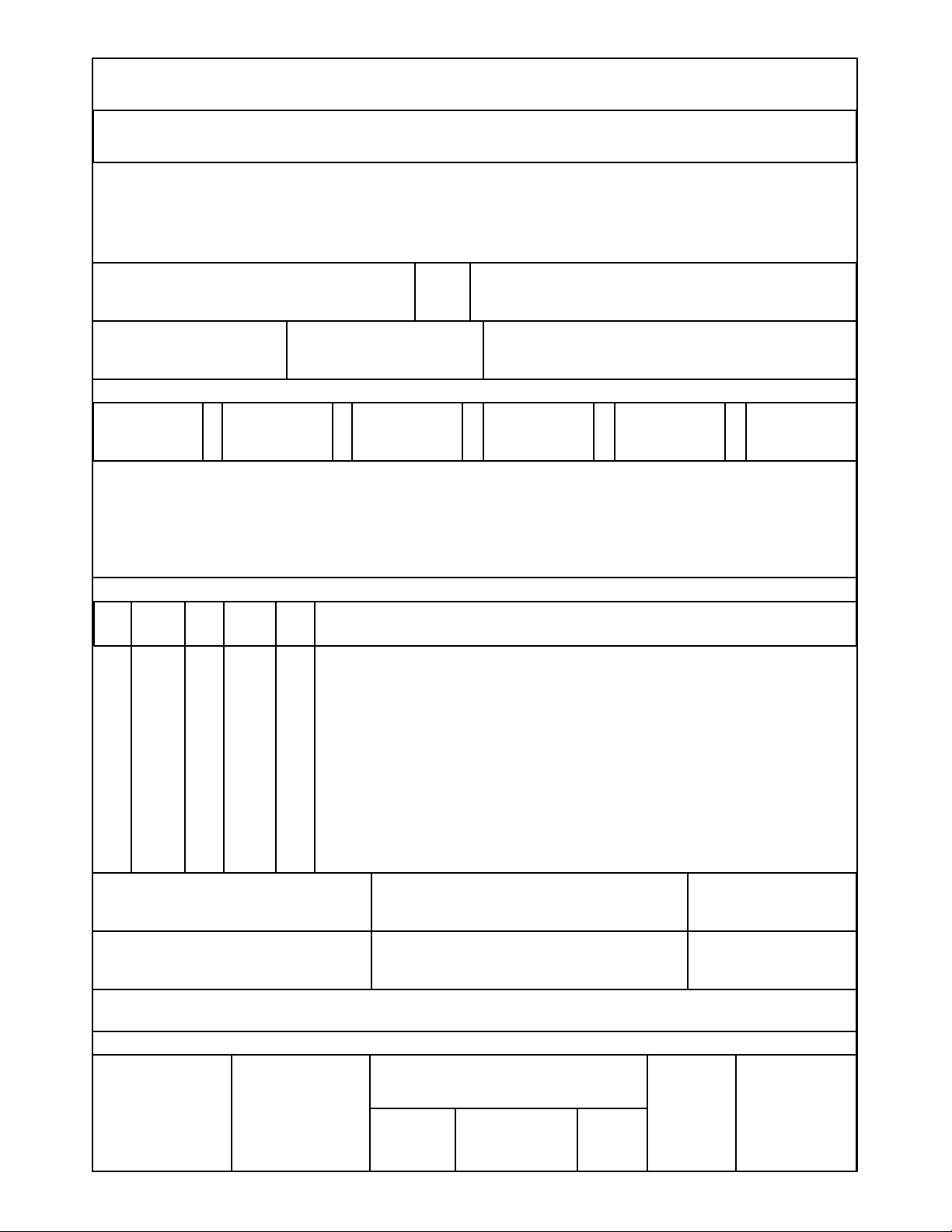

(Insert Classif. of TMDER Here and At Bottom of Page) CLASSIFICATION:

NAVSEA (USER) TECHNICAL MANUAL DEFICIENCY/EVALUATION REPORT (TMDER)

(NAVSEA S0005--AA--GYD--030/TMMP & NAVSEAINST 4160.3)

Instructions: Insert classification at top and bottom of page. Read the following before completing this

form. Continue on 8½I x11I paper if additional space is needed.

1. USE THIS REPORT TO INDICATE DEFICIENCIES, USER REMARKS, AND RECOMMENDATIONS RELATING TO PUBLICATION

2. BLOCKS MARKED WITH ” * ” ARE TO BE FILLED IN BY THE CONTRACTOR BEFORE PRINTING.

3. FOR UNCLASSIFIED TMDER’S FILL IN YOUR RETURN ADDRESS IN SPACE PROVIDED ON THE BACK. FOLD AND TAPE WHERE

INDICATED AND MAIL. (SEE OPNAVINST 5510.1E FOR MAILING CLASSIFIED TMDERS.)

4. FOR ADDITIONAL INFORMATION, CALL AUTOVON 360---4809---9084 OR COMMERCIAL 905---882---5064

1. NAVSEA NO. * 2. VOL.

4. REV DATEOR TM CH.

DATE

A. EXCELLENT B. GOOD C. FAIR D. POOR E. COM PLETE F. INCOMPLETE

8. GENER ALCOMMENTS

PAGE

NO.

PARA

GRAPH

A.

LINE

FIG.

NO.

B.

NO.

C.

D.

PART *

5. SYSTEM/EQUIPMENT 6. IDENTIFICATION/NOMENCLATURE (MK/MOD/AN)

7. USERS EVALUATIONOF MANUAL (CHECK APPROPRIATEBLOCKS)

9. RECOMMENDED CHANGESTO PUBLICATION

TABLE

E.

3. TITLE *

F. RECOMMENDED CHANGES AND REASONS

10. ORIGINATOR AND WORK CENTER

13. SIGNATURE OF WORK CENTER HEAD 14. SIGNATURE OF DEPARTMENT OFFICER 15. AUTOVON/COMM

16. SHIP HULL NO. AND/OR STATION ADDRESS (DO NOT ABBREVIATE)

A.CONTROLNO. B.COGISEA C.DATE D.PRIORITY E.TRANSMITTEDTO

NAVSEA 9066/10 (REV. 6.85) S/N 0116---LF---090---9651

(REPLACES 4---84 EDITION & NAVSEA 4160/1--DESTROY STOCK)

(PRINT)

11. ORIGINATOR’S RANK, RATE OR GRADE,AND TITLE 12. DATE SIGNED

NO.

17. THIS SPACE ONLY FOR NSDSA

RECEIVED FORWARDED DUE

CLASSIFICATION:

Page 9

PLEASE CLOSE WITH TAPE --- DO NOT STAPLE --- THANK YOU

FOLD HERE

COMMANDING OFFICER

NAVAL SHIP WEAPON SYSTEMS ENGINEERING STATION

NAVAL SEA DATA SUPPORT ACTIVITY (CODE 5B00)

PORT HUENEME, CA 93043--5007

FOLD HERE

Page 10

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAM A GE, INJU RY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The informationcontained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructionswill result in satisfactory baking results

and long,trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorialerrors are subject to correc-

tion. Specifications are subject to change without notice.

Page 11

APERSONALWORD

FROM BLODGETT COMBI

Congratulations on your purchase of the BLODGETT Combi-Oven/Steamer.

We firmly believe that your choice hasbeen a wise one, and trust you will receive many years of excellent service from your new multi-purpose oven.

The Combi-Oven/Steamerconcept offers completely new potential for cooking which minimizes shrinkage, while maintaining food’s essential vitamins

and valuable nutrients. In addition, you will find that cookingwith the CombiOven/Steamerwillsavetime, laborandextensive cleaningof boththekitchen

and the appliance.

With the Combi-Oven/Steamerthe quality, taste, consistency, andlook of the

foodare improved,thusendorsing thepolicytowhichwe’vealways adhered:

“For Better Cooking!”

Onceyou’vehad achance touseyourmulti-purposeoven,pleasetellus, your

dealer and colleagues about any creative and interesting applications you

have discovered; exchange ideas with other users. Be sure to advise us or

yourdealerimmediatelyshouldany mechanicalortechnical problemsbeencountered (...we’re here to help!) and above all “Enjoy Cooking the

BLODGETT Combi- Oven/Steamer Way!

Page 12

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Page 13

Introduction

The Blodgett Combi-Oven/Steamer

For quite some time, commercial cooking equipment has remained more or less unchanged.

There are kettles, deck ovens,thegoodoldrange

with its legion of pots and many other extra

appliances. The result: time expenditure, excessive manual work, and countless cleaning processes.The lastfewyearshavepavedthew ay for

a revolutionin the equipment of restaurant and institutional kitchens.

The Blodgett Combi-Oven/Steamer offers a completely new method of cooking. With the Oven/

Steameryou have thechoiceof twocookingpro -

cesses: Steam and Hot Air, either...

D

Separately

D

Combined, or

D

In Sequence

And for easy operationyoucan choose from three

modes:

Steam Hot Air

Combi

Steam &

Hot Air

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanch preserve braise

poach

In the Hot Air mode you can

roast bake

grill gratinate

broil

IntheCombinationSteamand HotAirmodeyou

can:

defrost roast rethermalize

reheat bake forced steaming

Not only that, youcan use two or three functions

in sequence during one cooking process. Wecall

this:

D

combi-steaming

D

combi-roasting

D

combi-baking

The combination of circulating hot air and steam

in the space saving, high performance CombiOven/Steamer leads to improvements in the following areas:

D

increased productivity in the kitchen

D

a reduction in capital expenditures for multiple

equipment replacement

D

a wider range of menu choices

D

a simplified cleaning process

The work process issimplified since products are

prepared on or in steam table pans and trays.

Foodcanbe cooked,stored,andtransportedwith

the same pans. Small amounts of product can be

processed efficiently; pre-cooked and convenience foods can be reheated within minutes.

Many frozen foods can be processed withoutprethawing. This flexibility in preparation reduces the

needforkettles and steam tablessincethere is no

needforlargeamounts offoodtobekeptwa rm for

long periods of time.

Todaytheimprovement of food qualityis moreimportant than ever. Vegetables are cooked in the

Blodgett Combi-Oven/Steamer without water at

the optimal temperature of just under

212_F/100_C, maintainingvaluablevitamins, minerals,nutrients and traceelements.Cookingmeat

intheCombiresultsinlessshrinkageandafirmer,

juicier product.The BlodgettCombi-Oven/Steamerisbeing used more and more for baking.Steam

andHotAirmodesmake itageneralpurposebaking appliance.

2

Page 14

Introduction

Description of the Combi-Oven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett Combi-Oven/Steamers are quality produced using high-grade stainless steel w ith first

class workmanship.

The high performance fresh ste amgeneratorwith

its controlsystem makes it possible toenjoy allof

the advantages of a high quality steamer at the

flickof a switch. Fresh steam entersthe ovencavity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while providing convenient working methods. The steam

generator is completely automatic and protected

from running dry.

The exhaust system is effective in all cooking

modes and results in better quality foods and no

flavortransfer. The fan, which is guardedagainst

accidental finger contact, is driven by a quiet and

powerful motor. Thecondenser draws out excess

steam from the appliance. Condensation and

waste water, which result during steaming and

cleaning, are continuously drained.

The use ofhigh qualityinsulationimpedes excessive heat radiation and saves energy.

OVEN/STEAMER OPERATION

Ease of operation is guaranteed through the simplearrangementofthecontrols.Graphicsymbols

make the appliance easy for even inexperienced

kitchenstaff tooperate.Steam, HotAirand Combi

modes can be selected with one s witch. A fourth

function on the mode selection switch, the Cool

Down mode, allows the oven cavity to cool down

rapidly with the door opened or closed.

Cleaning is kept to a minimum. The interior is

sprayed with a self-acting cleaning solution which

interacts with steam to easily remove crusts and

stains. The oven is designed for easy care and is

welded water tight so that the internal cooking

cavity may be rinsed with a hose after the steam

cleaning process.

3

Page 15

Introduction

Oven Features

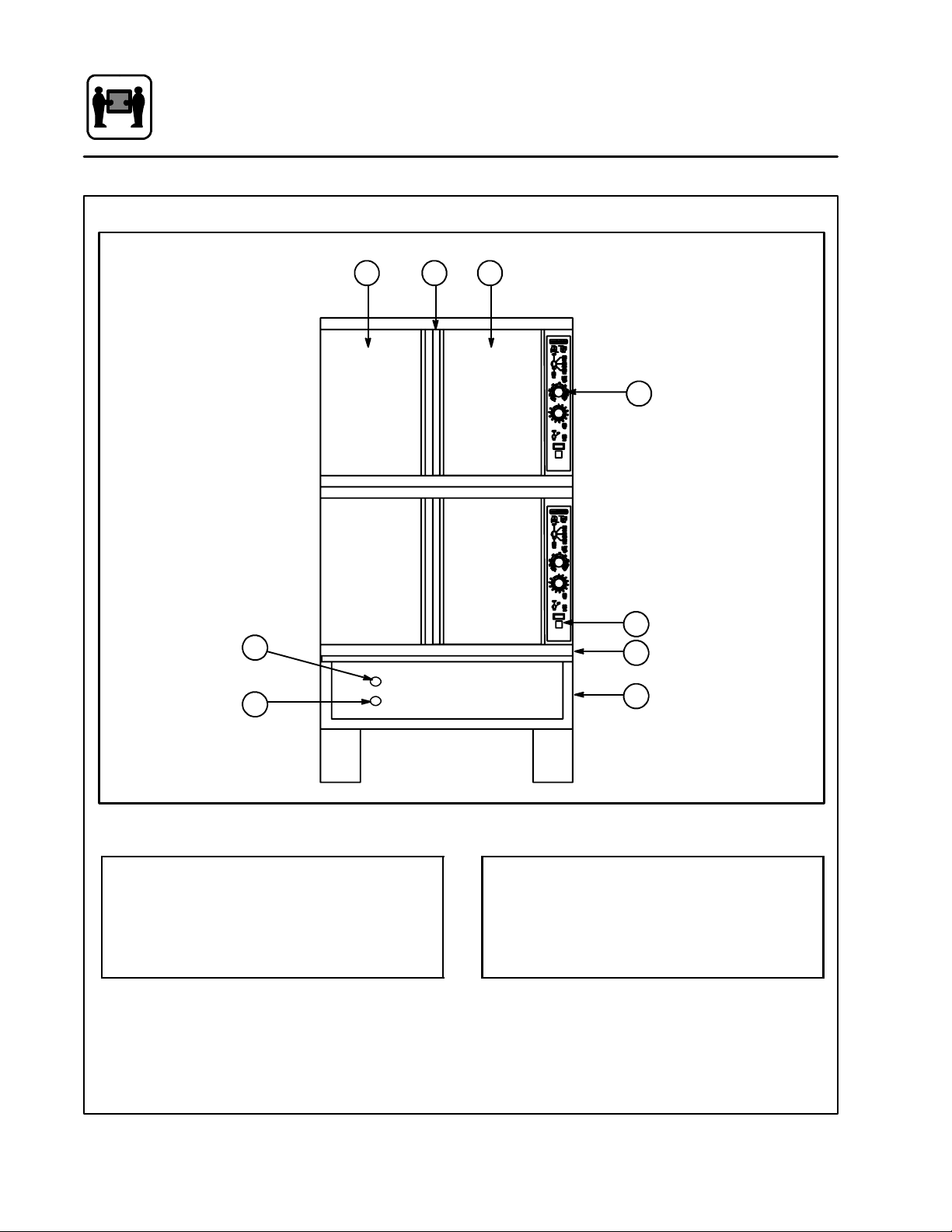

2 23

5

6

Standard Features

1

7

8

4

Control Panel

1

2 Oven Doors

3 Rotating Door Latch

4 Base Section

Figure 1

5 Deliming Inlet

6 Boiler Drain

7 Optional Meat Probe

8 Door Drip Pan

4

Page 16

Installation

General Installation Information

The purpose of the installation section of this

manual is to assist the designers and naval architects engineering the installation of a Blodgett

CombiCOS-5HHatchableCombinationOveninto

a new or existing ship.

Blodgett Combi has developed the COS -5H to fit

inthe same footprint asa BlodgettMark V convectionOven.The COS-5H Combinationoven can be

used as aconvection oven, steamer,orin a“Combi” mode in which pulsed steam is combined with

convection to provide faster cooking andincrease

the moisturecontent of cookedfoods.Because of

these features, the ovenutilizeswater for generating steam. The Combi is a multi-system cooking

oven and is more complex than a convectional

oven. Therefore, moreattention has to be paid to

the installation process t han that of a convection

oven.

The COS-5H requires the following support systems:

D

Power 440VAC,3phase,60ampservice

D

Water Potable, 40 to 50 psi

D

Drain Atmospheric vented drain,

1” minimum diameter

D

Hood Air venting required for steam

removal

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIEDINSTALLATIONAND SERVICEPERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D

Theinstallationofelectricalwiringfromtheelectric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiencedinsuchwork,befamiliarwithallprecautions required and have complied with allrequirements of state or local authorities having

jurisdiction.

Reference: National Electrical Code, ANSI/NFPA

70---Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

withtheBasicPlumbing Code of theBuildingOffi -

cials and Code Administrators International Inc.

(BOCA) and theFood Service Sanitation Manual of

the Food and Drug Administration (FDA).

5

Page 17

Installation

Delivery and Location

DELIVERY AND LOCATION

The COS-5H hatchable combination oven is

shipped fullyassembled on a special vibration resistant pallet. In addition, the oven is mounted on

two hardwood skidsto facilitate removal from the

pallet. These skids were designed to match the

height of the separate installation base. This allows the assembled oven to be slid directly onto

the base after the installation base is mounted in

positionandhardplumbedwithpotable waterand

electric power.

COS-5H dimensions:

Height 62.25” with legs

68.25” with 6” legs

64.75” with base

Width 38.12”

Depth 43”

The following clearances are required for the

COS-5H:

Sides 0”

Rear 6”

UNPACKING

1. Removetheprotectivecoveraroundthe oven.

Inspect the unit for visible damage.

2. Remove the bolts that lock the 2-1/2” x 4”

hardwood skids to t he pallet base.

3. Useaforklifttoraisetheovenassemblyoff the

pallet.Theskidscanbeleftinpositiontoassist

in moving an assembled oven onto the installationbaseordiscardedafterthe ovenassembly is unbolted into separate components for

passage through hatches.

ASSISTANCE

Blodgett Combi also provides engineering assistance when custom installation kits are required.

Our goal is to ensure that each oven installation

can be made inthe most efficient and economical

manner.

For further information, please contact the Blodgett Combi Engineering Department:

D

Phone 802-860-3708

D

Fax 802-860-3784

D

Email wgoldm@maytag.com

6

Page 18

Installation

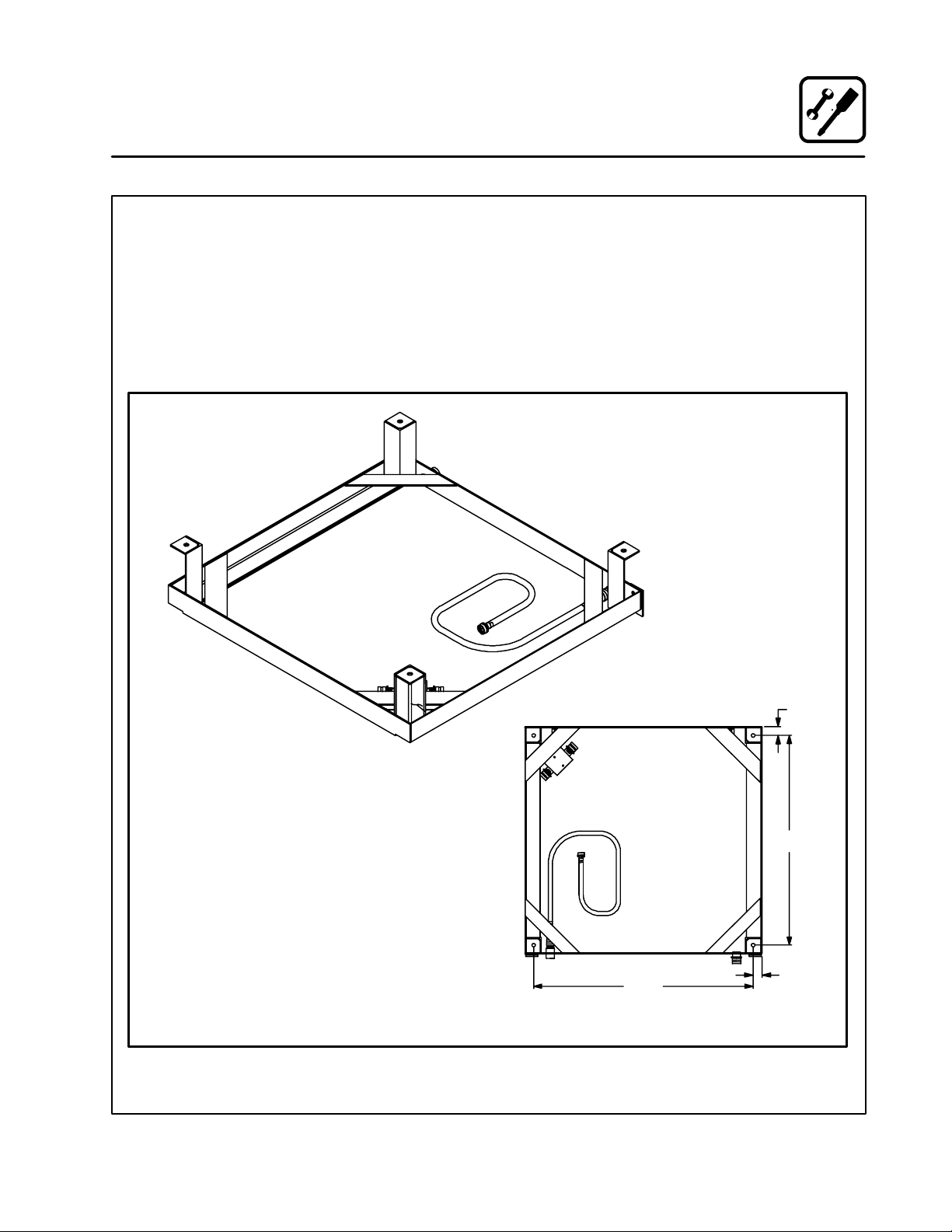

Installation Base

The Blodgett Combi COS-5H utilizes a stainless

steel locking installation base. The base is availablewithorwithoutlegs. Theinstallationbase was

designed to facilitate the installation process and

toimprovethe accesstotheoven ifandwhenmajor service is required.

Since the COS-5H is slightly narrower than the

installation base, multiple bases can be installed

sideby sideon thedeckwith noallowanceforside

clearance.

1. Secure the 2-1/2”high installation base using

one of the following methods:

2. Weldthebasedirectlytothedeck.

3. Boltthebasetothedeck.

4. Seal the base with an NSF approved sealant.

Base S hown Upside Down

INSTALLATION BASE WITH LEGS

Figure 2

BOTTOM VIEW

35.50

1.44

33.91

1.44

7

Page 19

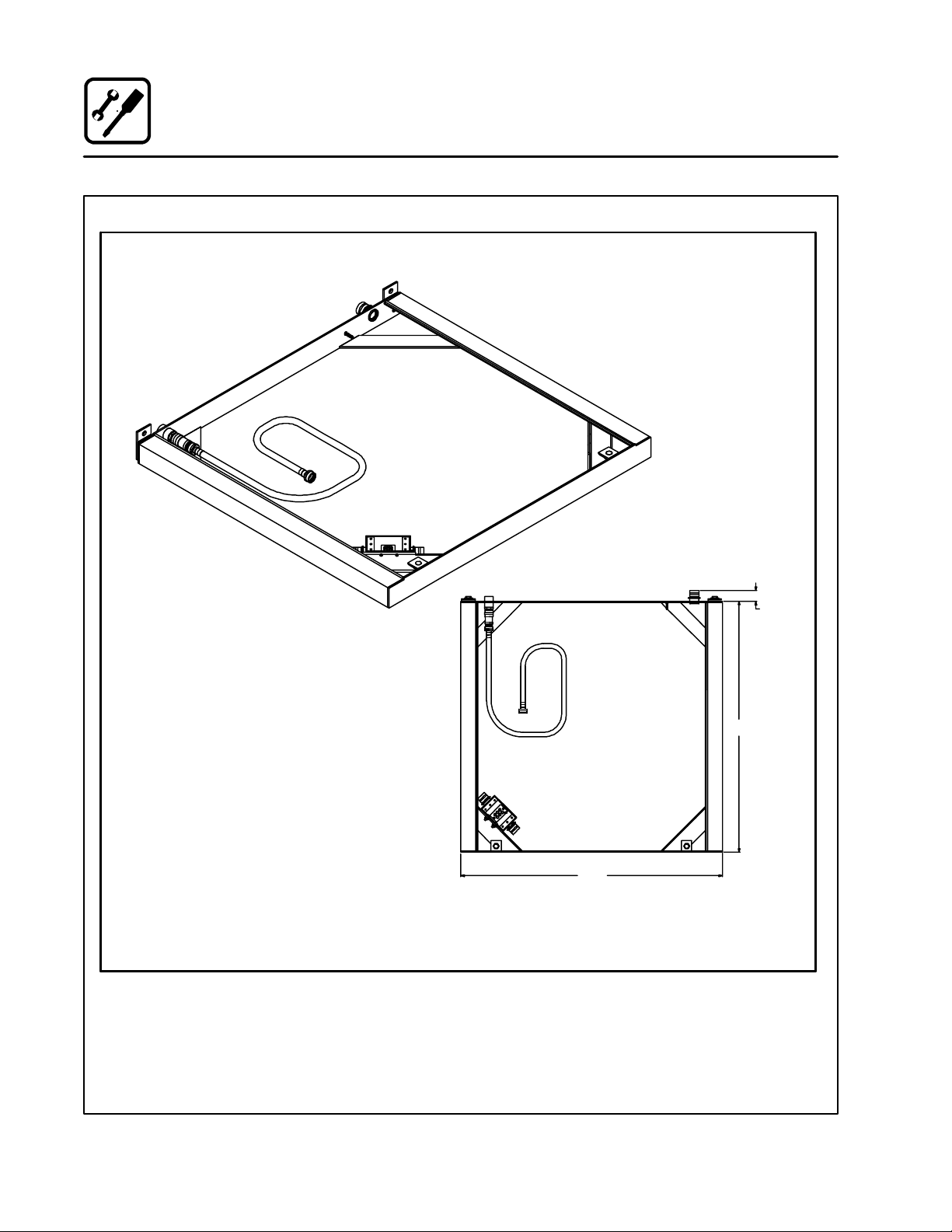

Installation

Installation Base

INSTALLATION BASE

Figure 3

1.56

36.78

38.37

8

Page 20

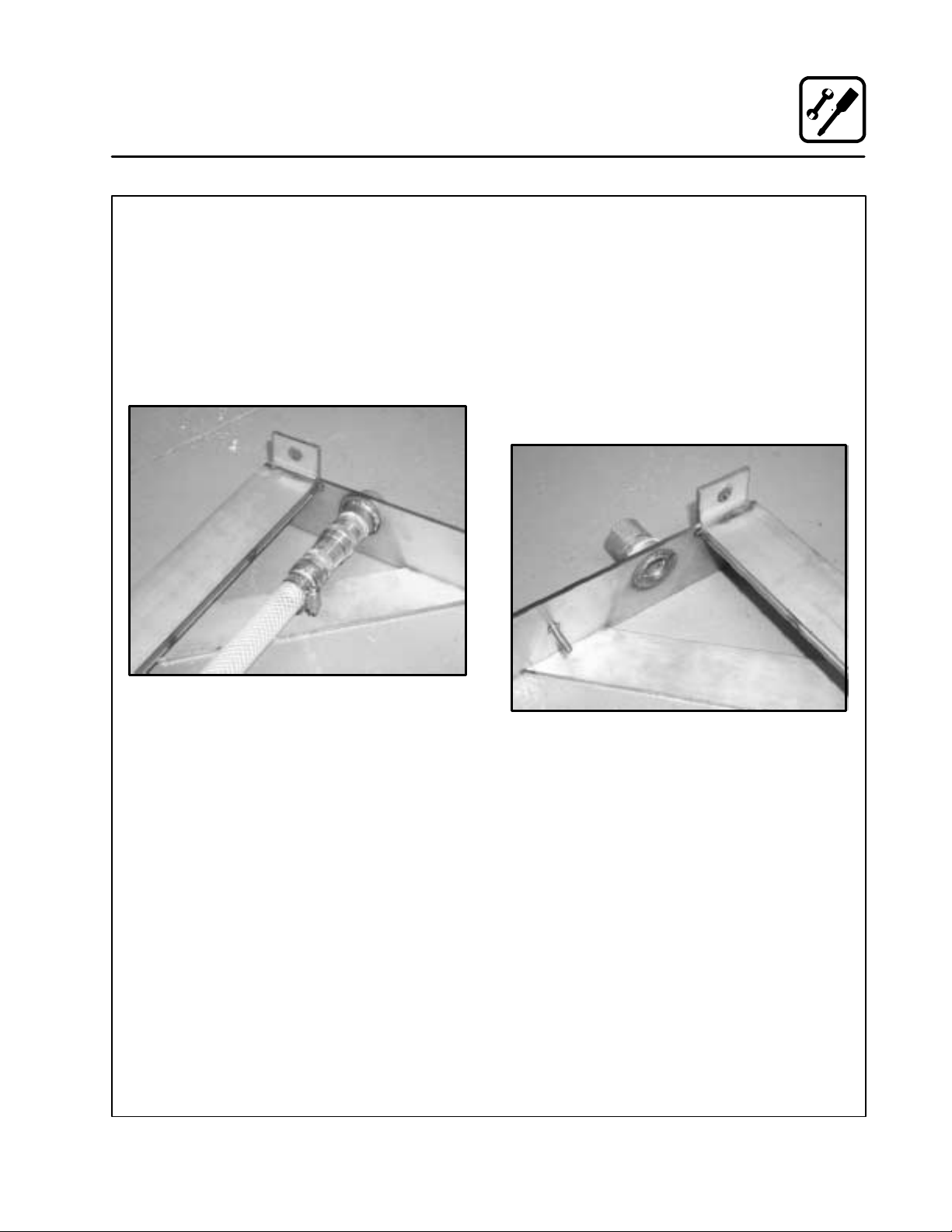

Installation

Utility Connections

WATER CONNECTION

The oven requires access to potablewater with a

pressure of approximately 40 to 50 PSI.

1. The wateris connectedtotherearof theinstallation base at the 3/4” NPT female coupling.

2. The water is directed to the oven through an

in-line pressure regulator and a flexible internalhose whichconnectsto a fittingin thefront

of the oven.

ELECTRICAL CONNECTION

The power requirement of the oven is 440 volt, 3

phase, 60 amp service.

1. The electrical service is brought into the oven

through the seal tight connector located on

therearoftheinstallationbase.

2. The power leads are brought into a splash

proof terminal box located in the front of the

installation base.

3. A grounding stud is supplied on the inside of

the installation base. See Figure 5.

Figure 4

DRAIN CONNECTION

Anopendrain systemutilizingafixedfunnelisrecommended. For multiple oven installations, install

a deck mounted sloping drain with individualfunnels positioned to accept the drain outlets of the

individual ovens.

Figure 5

9

Page 21

Installation

Oven Installation --- No Dismantling Required

Use this procedure if the ovenassemblydoesnot

have to be dismantled to bring it into the galley

where the installation base has been fitted.

1. Slidetheovenassembly onthe shippingskids

in front of the installation base.

2. Remove the two1/2”bolts fromthefront ofthe

installation base. See Figure 6.

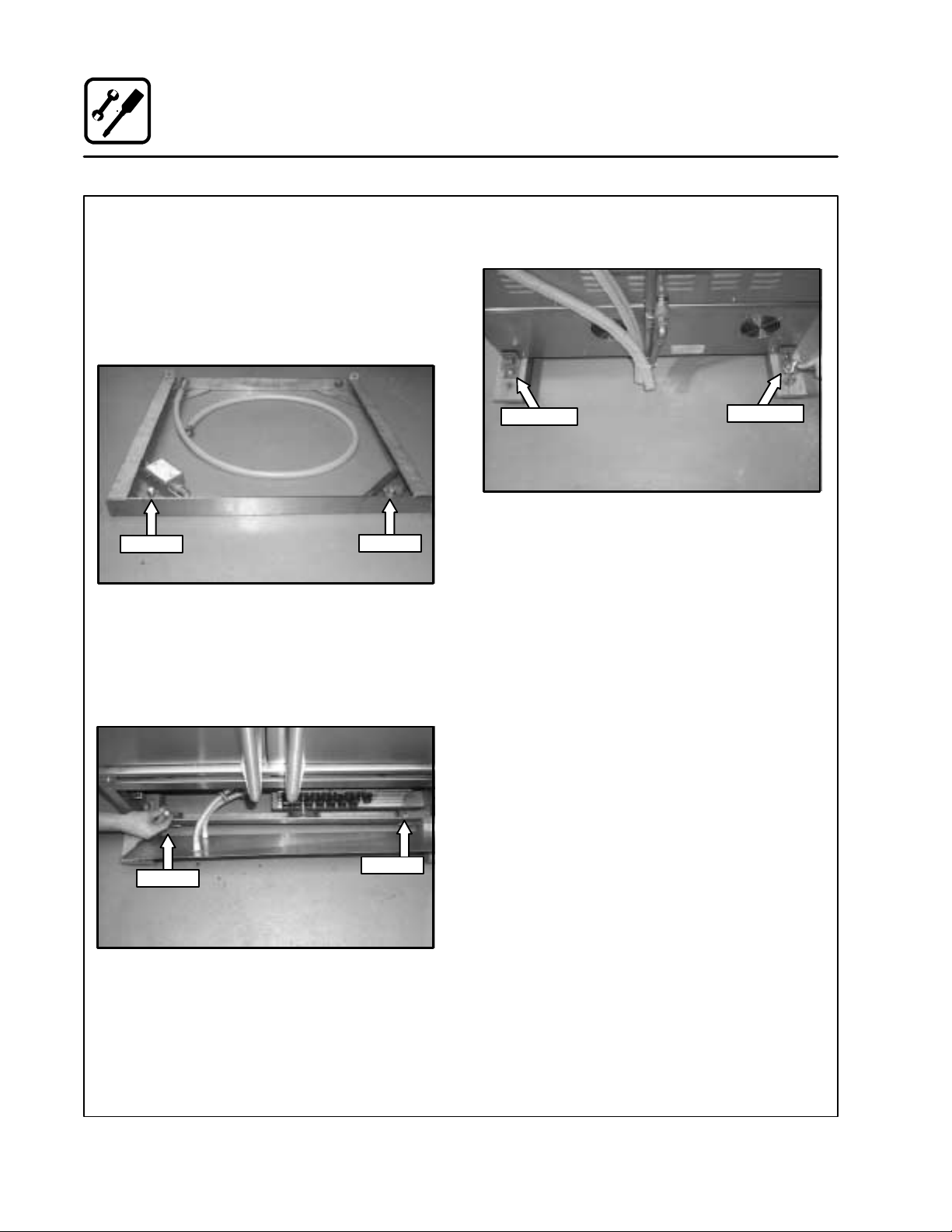

1/2” Bolt

1/2” Bolt

Figure 6

3. Unscrew the front panel from the oven base

section. Leave the hoses connected to the

front panel and the oven base section.

4. Removethetwoboltssecuringthe skidstothe

front of the oven base section. See Figure 7.

1/2” Bolt

1/2” Bolt

5. Removethetwoboltsandangleplatessecuring

the skids to the rear of the oven base section.

Bolt & Plate

Bolt & Plate

Figure 8

6. Move the oven assembly to the installation

base as follows:

1. Lubricate the top surface of the installa-

tion base with a little grease or silicone

spray.

2. Slide theovenassemblyoffthe skidsonto

the tracks of the installation base.

3. The locking pins on the rear of the oven

base section will fit into and lock the base

tothe uprighttabsattached tothe installation base.

4. Reinstall the two bolts that were removed in

Step 2, from the installation base through the

oven base section into the installation base.

SeeFigure7forinstallationlocation.

5. Hookup waterand electric alconnections to the

oven base section. Apply NSF approved sealant to the cover of the splash proof terminal

box.

Figure 7

10

Page 22

Installation

Oven Installation --- Some Dismantling Required

Use this procedure if the oven a ssembly will be

dismantled to bring it into the galley where the

installation base has been fitted.

The assembled oven consists of three sections:

D

upper oven section

D

lower oven section

D

oven base section.

The oven base section consists of the majorelectrical components, steam generator, and the attachment components for mating the oven assembly to the installation base which is mounted

directlyto the deck. In order todismantle the oven

assembly, youwillhave to separate electricalwire

harnesses and plumbing lines. We recommend

that you tape both sides of each electrical and

hose connection and mark them for easy identification during reassembly.

Ifyouareinstallingmore than one ovenassembly,

keepallhardwareandpanels associated withone

oven assembly separate from the other oven assemblies. If the oven assembly has to be dismantledin orderto fitthrough thehatches, usethe

following procedure:

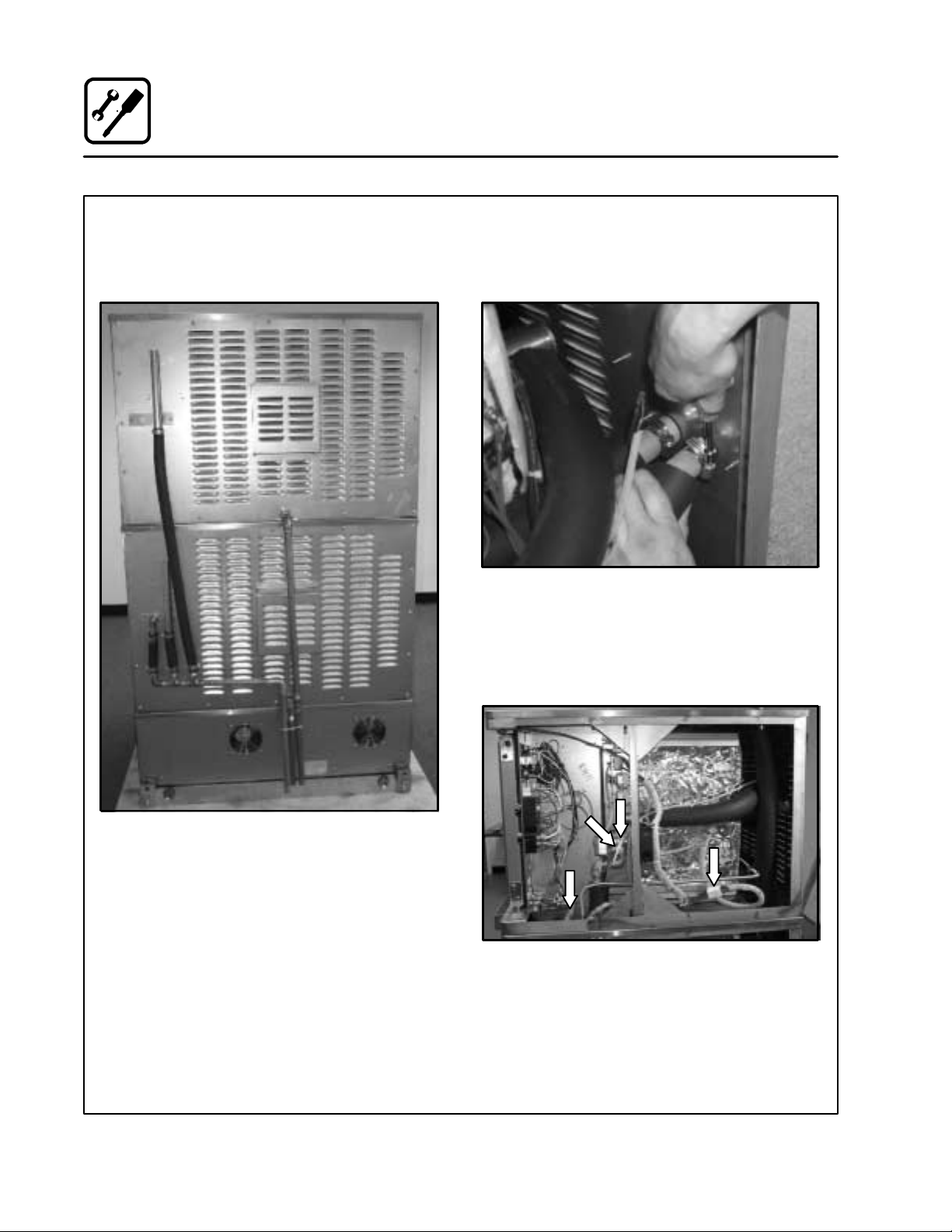

OVEN DISMANTLING

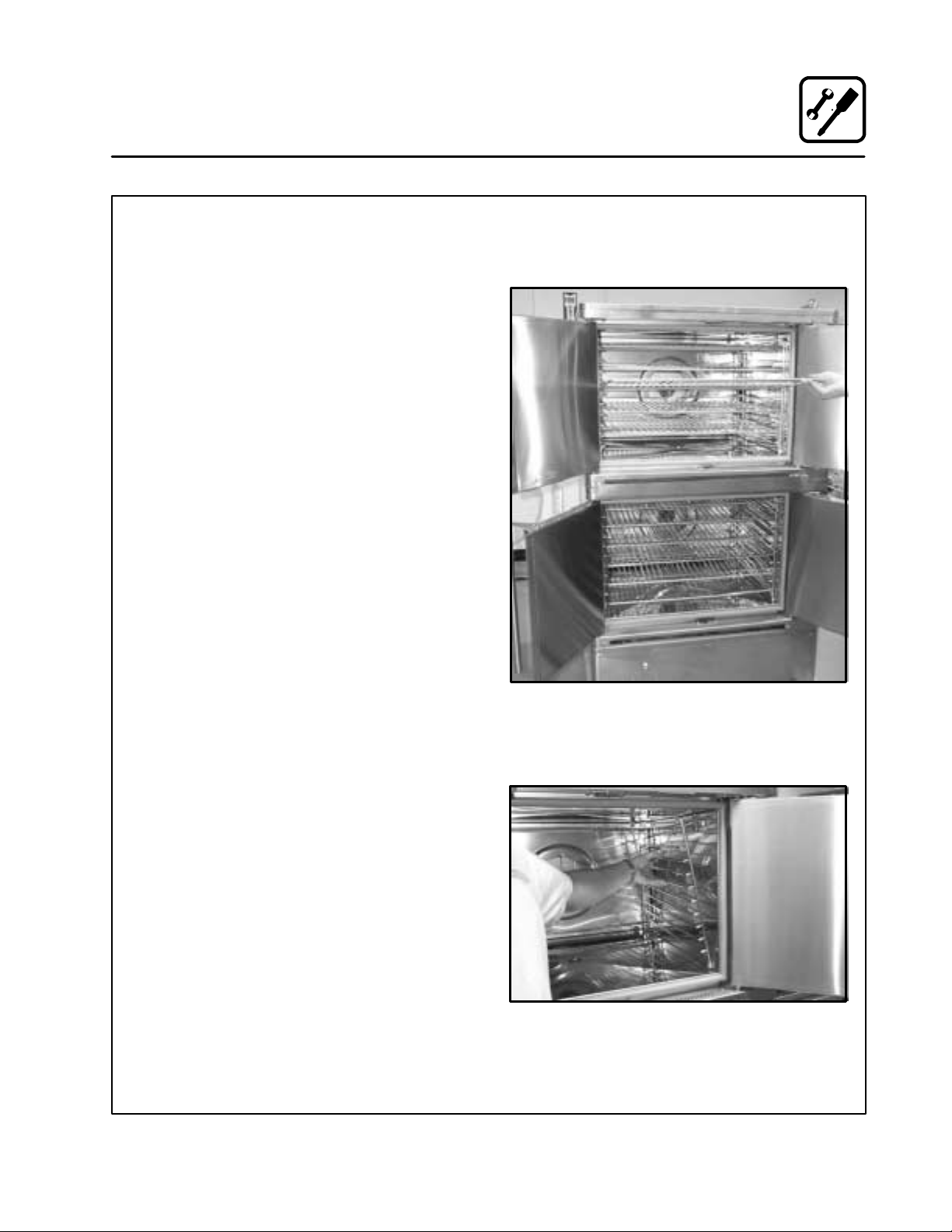

1. Remove the racks fromthe inside of both the

upper and lower oven sections. See Figure 9.

Figure 9

2. Remove the side support racks from the in-

side of both the upper and lower oven sections.SeeFigure10.

Figure 10

11

Page 23

Installation

Oven Installation --- Some Dismantling Required

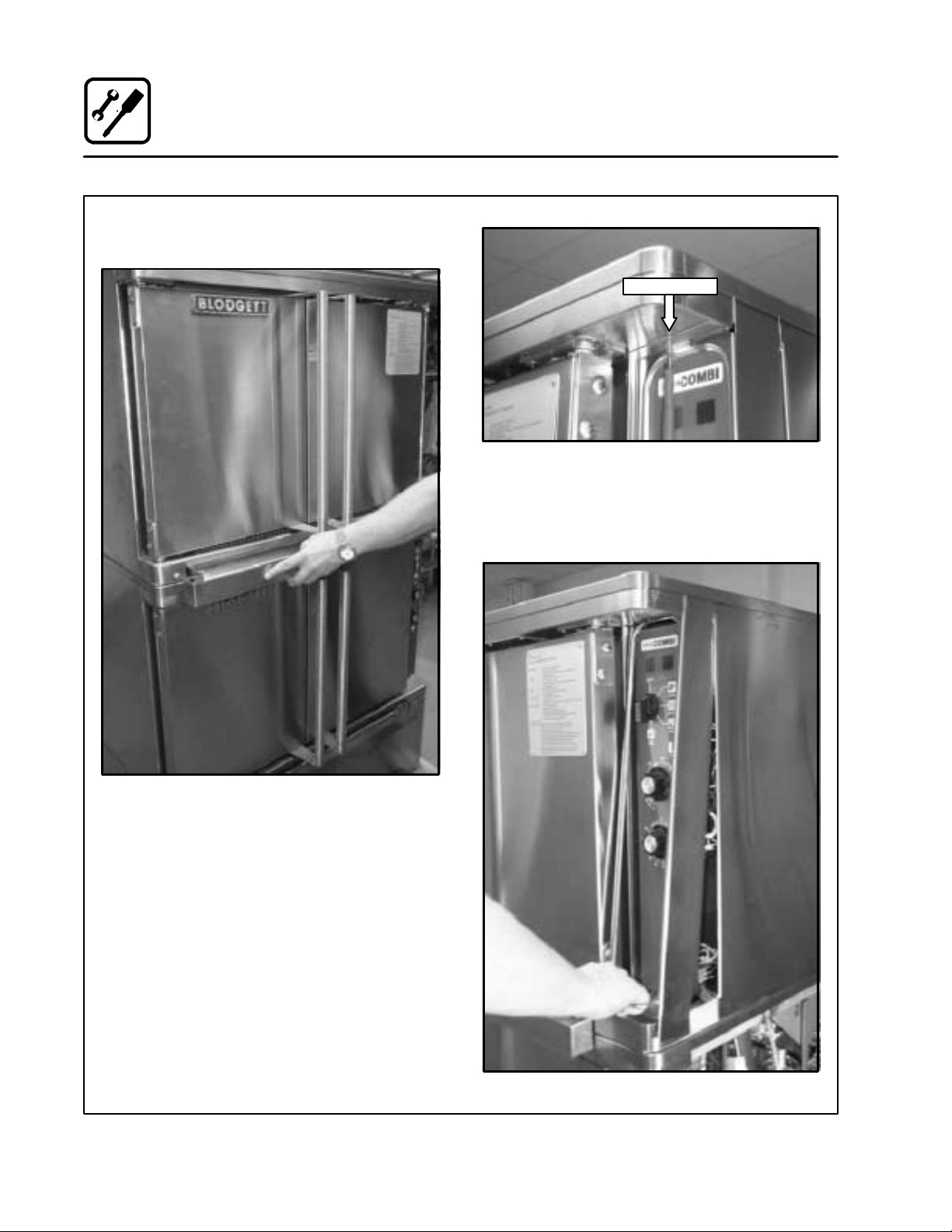

3. Remove the drip pan from the front of both

ovens.SeeFigure11.

5. Remove the control panel coverby liftingand

pulling the “D” handle toward you about 6”.

See Figure 13. Do this to both the upperoven

and the lower oven.

Remove Screw

Figure 12

Figure 11

4. Remove the locking tab plate above the control panelby removing the Phillips screw. See

Figure 12. Dothis toboth the upper ovenand

the lower oven.

Figure 13

12

Page 24

Installation

Oven Installation --- Some Dismantling Required

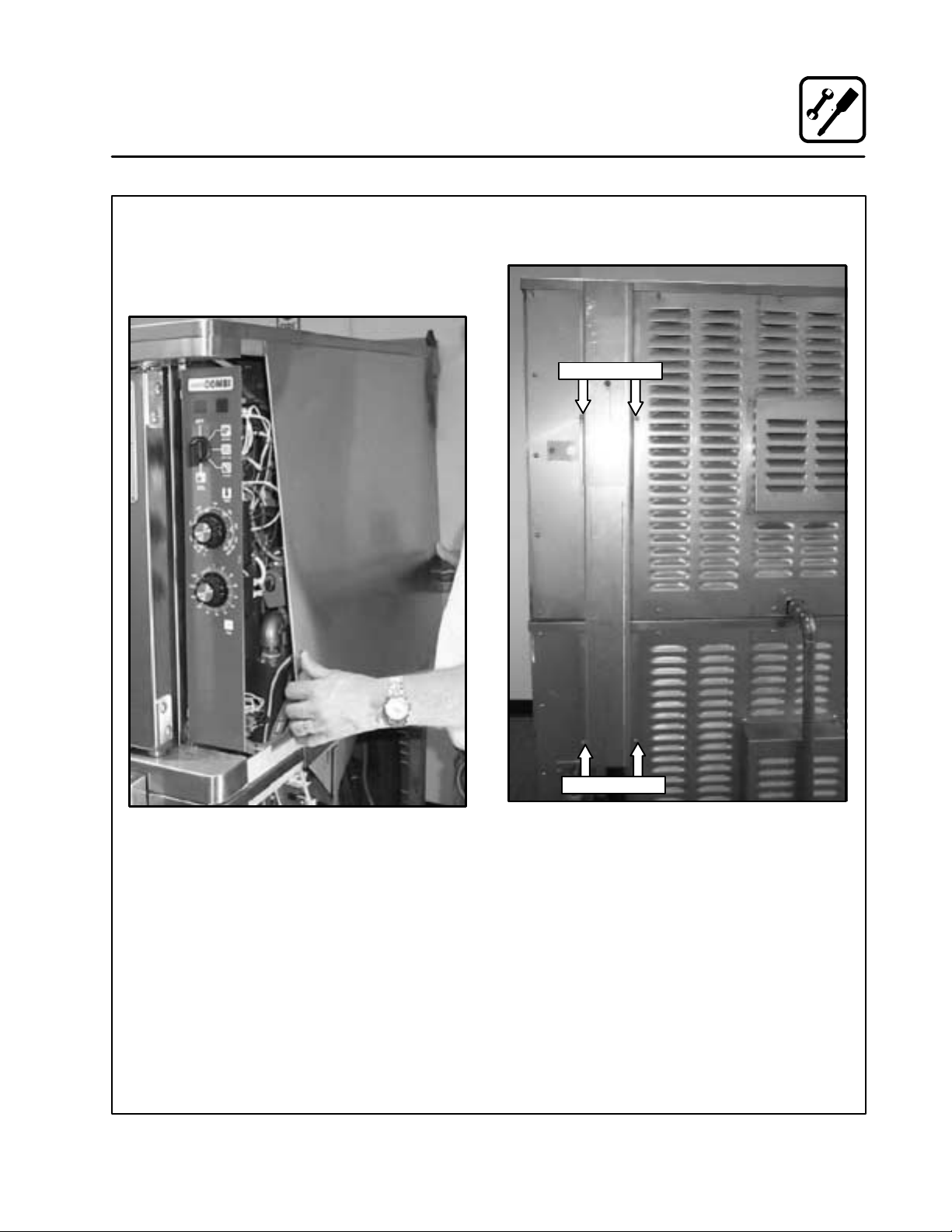

6. Remove the right side rear panel by sliding it

forwardaboutaninchand then liftingtheentire panel to free the retaining springs. See

Figure 14. Dothis toboth the upper ovenand

the lower oven.

7. Remove thefourscrews holdingtherearverticalductontherearofthe oven.SeeFigure 15.

Remove Screws

Figure 14

Remove Screws

Figure 15

13

Page 25

Installation

Oven Installation --- Some Dismantling Required

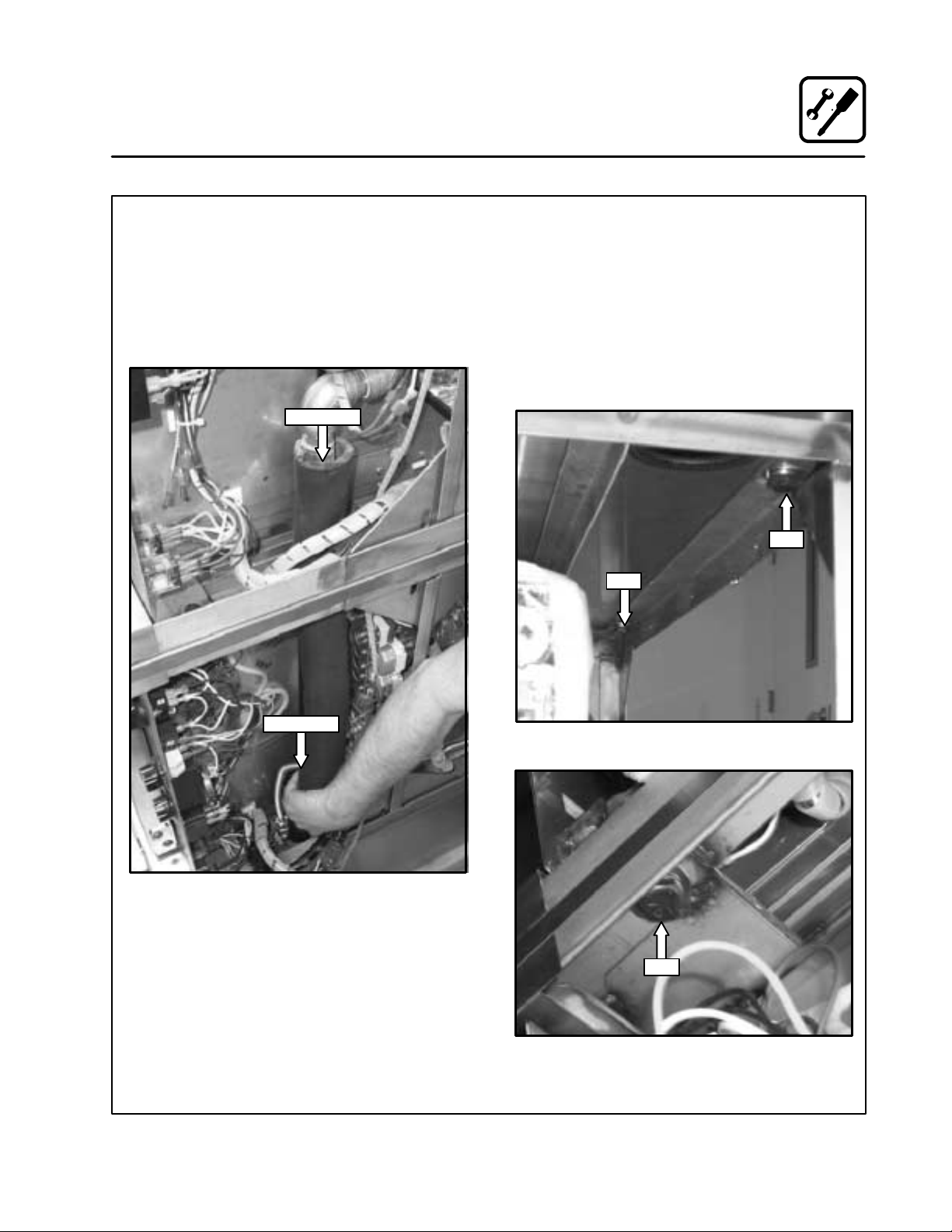

8. Cut the wiretieholdingthecopperdraintubes

together. Remove the fiverubber drain hoses

fromtheupperandlowersections.See

Figure 16.

9. Disconnect the two orange hoses from the fitting on the rear body panel. See Figure 17.

Both of these hoses have black foam insulation on them.

Figure 17

10. Disconnect the electrical wire harnesses (J1,

J3, J7, and J8) that connect the upper oven

section to the oven base section. See

Figure 18. Mark connections prior to disconnecting for ease of re-assembly.

Figure 16

Figure 18

14

Page 26

Installation

Oven Installation --- Some Dismantling Required

11. Disconnect and remove the steam line to the

upper oven section at locations shown in

Figure 19. Thetop of the hoseis securedwith

a band clamp. The bottom of the hose pulls

out of the boilerin the oven base section. This

orangehose hasablackfoaminsulatedcover

around it. Remove hose with insulation from

oven assembly.

Disconnect

13. Remove the three bolts (1/2 inch diameter)

that connect the top and lower oven sections

together.

Two boltsarelocatedinthe rear upperleftand

right corners of the lower oven section. These

bolts can be accessed from the back of the

lower oven section. See Figure 20.

The third bolt is accessed from the right side

of the lower oven section. It is located in the

upper right hand corner. See Figure 21.

Bolt

Bolt

Disconnect

Figure 19

12. Removetherearbodypanelontheloweroven

section.

Figure 20

Bolt

Figure 21

15

Page 27

Installation

Oven Installation --- Some Dismantling Required

14. Removetheupperovensection from atopthe

lower oven section. Use care not to chafeany

ofthe harnesses thatcome fromthe basesection. Use gloves to protect hands from any

sharp edges.

15. Disconnect the electrical wire harnesses (J2,

J4, J5, and J6) that connect the lower oven

section to the oven base section. See

Figure 22. Mark connections prior to disconnecting for ease of re-assembly.

Figure 22

16. Disconnect and remove the steam line to the

lower ovensection. See Figure 23. The top of

thehoseissecuredwithabandclamp.The

bottomof thehosepulls outof the boilerinthe

oven base section. This orange hose has a

black foam insulated cover around it (shown

with blackfoaminsulation removed).Remove

hose with insulation from oven assembly.

16

Figure 23

Page 28

Oven Installation --- Some Dismantling Required

17. Seal the outlets of the steam generator in the

oven base section with the plastic caps provided with the installation kit. The caps will

prevent water from splashing over the electrical equipment as the oven base section is

tipped on it’s side when passing through a

hatch.SeeFigure24.Theovenbasesection

shouldbe tipped onto it’s left side forpassing

through a hatch.

Installation

Figure 25

Figure 24

18.Removetherearbodypanelfromtheoven

base section. Unscrew the front panel from

the oven base section. Leave the hoses connected to the front panel and the oven base

section.

19. Removethefourbolts(1/2inchdiameter)that

connectthelowerovensectionandovenbase

section together.

T wo bolts are located in the rear upper left and

right corners of the oven base section. These

bolts can be accessed from the back of the oven

base section. See Figure 25 and Figure 26.

The third bolt is accessed from the right side

oftheovenbasesection. Itislocatedintheupper front right hand corner. See Figure 27.

The fourth bolt is accessed from the left side

oftheovenbasesection. Itislocatedintheupper front left hand corner. See Figure 28.

20. Removethe lower oven section from atop the

oven base section. Use care not to chafe any

ofthe harnesses thatcome fromthe basesection. Use gloves to protect hands from any

sharp edges.

Figure 26

Figure 27

17

Figure 28

Page 29

Installation

Oven Installation --- Some Dismantling Required

OVEN RE-ASSEMBLY

After the installation base is secured in position,

connected to potable water and electrical power,

the oven sections may be assembled onto it. In

galleyswhere ovens are located next toeachother, the ovensectionsshouldbe assembledpriorto

sliding the oven assemblyintothe final positionon

the installation base.

1. Remove the two1/2”bolts fromthefront ofthe

installation base. See Figure 29.

1/2” Bolt

Figure 29

1/2” Bolt

4. Install the four bolts (1/2 inch diameter) that

connectthelowerovensectionandovenbase

section together.

Two nuts are located in the rear lower left and

right corners of the lower oven section. These

nuts can beaccessedfromthe back oftheoven

base section. See Figure 25 and Figure 26 on

page 17.

Thethirdnut isaccessedfrom the right sideof

theoven basesection. Itis locatedinthelower

front right hand corner of the lower oven section. See Figure 27 on page 17.

The fourthnutisaccessed from theleft side of

theoven basesection. Itis locatedinthelower

frontlefthandcornerofthelowerovensection. See Figure 28 on page 17.

5. Remove the two plastic caps that were inserted onto the steam generator.

2. Lubricate the top surface of the installation

basewithalittlegreaseorsiliconespray.Position the oven base section onto the flat track

surface of theinstallation base approximately

4” to 5”. Support the front of the oven base

section with a piece of 2” pipe (2-3/8” OD

approximately) by 39” (minimum) long.

3. Apply a 1/8 inch bead of clear silicone RTV to

theperimeterofthetop edge oftheovenbase

section. Lift the lower oven section onto the

oven base section. Use gloves to protect

hands from any sharp edges.

Figure 30

18

Page 30

Installation

Oven Installation --- Some Dismantling Required

6. Installandreconnectthesteam linetothelower

oven section. See Figure 31. Secure the top of

the hose with a band clamp. Insert the bottom

of the hosein the fitting on the steam generator

intheovenbasesection.Thisorangehosehas

a black foam insulated cover around it (shown

with black foam insulation removed).

9. Apply a 1/8 inch bead of clear silicone RTV to

theperimeterofthetop edgeoftheloweroven

section. Lift the upper oven section onto the

lower oven section. Use gloves to protect

hands from any sharp edges.

10. Install the three bolts (1/2 inch diameter) that

connect the top and lower oven sections together.

Two nutsare located in the rearlower left and

right corners of the upperoven section.These

nuts can be accessed from the back of the

lower oven section. See Figure 33.

Thethirdnut isaccessedfrom the rightsideof

the lower ovensection. It is located in the upper front right hand corner of the upper oven

section. See Figure 34.

Bolt

Bolt

Figure 31

7. Reconnect the electrical wire harnesses (J2,

J4, J5, and J6) that connect the lower oven

section to the oven base section.

Figure 32

8. Install the rear body panel on the oven base

section.

Figure 33

Bolt

Figure 34

19

Page 31

Installation

Oven Installation --- Some Dismantling Required

11. Install the rear body panel on the lower oven

section.

12. Installandreconnectthesteam linetotheupper oven section at locations shown in

Figure 35. Secure the top of the hose with a

band clamp. Insert the bottom of the hose in

the fittingon the steam generator in the oven

base section. This orange hose has a black

foam insulated cover around it.

Reconnect

13. Reconnectt h ree electricalwireharnesses(J1,

J3, J7, and J8) that connect the upper oven

section to the oven base section.

Figure 36

14. Reconnect the two orange hoses onto the fittingsonthelowerrearbodypanel.Assurethat

the foam insulation is also reinstalled.

Reconnect

Figure 35

Figure 37

20

Page 32

Installation

Oven Installation --- Some Dismantling Required

15. Reconnect the five rubber hoses to the upper

and lower sections. Wire tie the three copper

drain tubes together at location shown in

Figure 38.

20. Slide the oven assembly back ontothe installation base.The lockingpinson the rear ofthe

ovenbasesectionwill fitintoandlockthebase

to the upright tabs attached to the installation

base. Install the two bolts (1/2 inchdiameter)

removed in STEP1 (Figure 29), thru the oven

base sectionand into the installationbase. In sure that the drains from the upper and lower

ovens and the orange hose and black hoses

from the P2 stack tubes are located over the

floor drain.

21. Hook up water and electrical connections to

oven base section. ApplyNSF approved sealant to cover of splash proof terminal box.

INSTALLATION COMPLETE. PROCEED WITH

CHECK-OUT PROCEDURE.

Reinstall Screws

Wire Tie

Figure 38

16. Reinstall the rear vertical duct to the rear of the

oven stack with four screws. See Figure 39.

17. Review instructions in STEPS 1 thru 16 to ensure that allconnections havebeenmadeproperly, hoses are not kinked, andallelectricalwire

harnesses are routed correctly to prevent chafe

or damage.

18. Complete the attached checklist document.

19. Replaceoven electricalcontrol panels on both

upperandlower ovensections. SeeFigure 13

and Figure 14.

Reinstall Screws

Figure 39

21

Page 33

Operation

Oven Startup a nd Shutdown

OVEN START-UP

1. Turnthemodeswitchtothedesiredmode,

Steam, Hot Air, Combi, Cool Down.

STEAM MODE

1. Turn the mode switch selector knob to the

Steam Position. The green “POWER” indicatorlampilluminates on thefrontcontrolpanel.

2. Steam fills the cavity and is controlled by a

non-accessible internal thermostat.

Preheating for the STEAM mode

Before the first use of the appliance, daily or after

the oven has been idle for 3 hours, preheat with

the STEAM function until steam enters the oven

cavity. The appliance can then be loaded.

HOT AIR MODE

1. Turn the mode selector switch to the Hot Air

position. The green “POWER” indicator lamp

illuminates on the front control panel.

2. Set theHot Air thermostat to the desired temperature. The Thermostat lamp illuminates indicating the cavity temperature is below the

desired set point.

3. When the cavity temperature reaches the desiredsetpoint,thetemperatureindicatorlamp

goes off.

Preheating for the HOT AIR mode

COMBI MODE

1. Turn the mode selector switch to the Combi

position. The green “POWER” indicator lamp

illuminates on the front control panel.

2. Set theHot Air thermostat to the desired temperature.

3. The hot air thermostat lamp illuminates, indicating the cavity temperature is below the desired set point.

4. Once the cavity temperature reaches the desiredsetpoint,thetemperatureindicatorlamp

goes off.

5. The steamand hot air modes come on to satisfy the thermostat set points.

Preheating for the COMBI mode

Always preheat the appliance prior to loading.

Open the door and load the product quickly.

COOL DOWN

1. Turn the mode selector switch to the Cool

Down mode.

2. The convection blower comes on with the

door open or closed.

OVEN SHUT DOWN

1. Turn the mode selector switch to the off position.

Always preheat the appliance prior to loading.

Open the door and load the product quickly.

22

Page 34

Operation

Optional Meat Probe

CONTROLS IDENTIFICATION

1. MEAT PROBE SWITCH

Controls power to the meat probe.

2. MEAT PROBE CONTROL

Use to set the desiredprobe temperature. Indicates the actual temperature of theproduct

3. MEAT PROBE CONNECTOR

Receptacle for the plug in meat probe.

NOTE: For sanitation it is recommended that

the meat probe remain plugged into

the front panel receptacleat all times.

OPERATION

Measuring the product core temperatures during

long roasting periods is very practical. It is especiallyimportantfor productssuch as RoastBeefto

reach a specific internal temperature.

Placet he probe through to the middleof the product’s thickest section. B e sure theprobedoesnot

touch any bone and the tip is not in a fat pocket.

These conditions can ca use inaccurate readings.

1. Set the MODE SELECTOR Switch to the de-

sired function.

2. Turn the MEAT PROBE Switch (1) to ON.

3. Toset thedesired coretemperature pressthe

blueSETBUTTON(4)ontheMEATPROBE

CONTROL (2).

Use the up arrow key (6) to increase the setpoint temperature. Use the down arrow key

(5) to decrease the setpoint temperature.

Press the set button again to store the setpoint.

4. Set the TIMER to STAY ON. The cooking pro-

cess runs automatically.

When the selected core temperature is reached,

the buzzer will sound and the appliance shuts off

automatically.

The temperature and mode can be changed

at any time during the process.

5. Shut the appliance off by setting all switches

to OFF.

NOTE: When setting the internal temperature, be

sure to allow for carry-over cooking after

the roast is removed from the oven

1

2

3

Figure 40

23

WATLOW

1

2

RDY

SET

4 5 6

Page 35

Operation

Standard Controls

1

3

4

CONTROLS IDENTIFICATION

1. DON’T STEAM LIGHT

Indicates the unit is too hot to operate in the

steam mode. Placethe unit inthe Cool Down

mode until the temperature is below 230_F

(110_C). This light does not inhibit steam pro-

2

5

duction.

2. POWER ON LIGHT

Indicates the unit is in Steam, Hot Air or

Combi.

3. MODE SELECTOR SWITCH

Turns power to the oven on or off. Allows selection of Steam, HotAir, Combior Cool Down

Modes.

4. TEMPERATURE DIAL

Used to set desired cooking temperature.

5. HEATING INDICATOR LIGHT

LightswhentheHotAirheatingisinoperation.

6. TIMER DIAL

Used to set desired cooking time.

6

Figure 41

24

Page 36

OPERATION

1. Turn the MODE SELECTOR Switch (3) to the

desired function.

The POWER ON Light (2) illuminates.

2. SettheTIMER (6) for the desiredcookingtime

orsetittoSTAYON.The buzzersound andthe

unit shuts off when the time has expired.

3. For the HOT AIR and COMBI modes, set the

TEMPERATURE Dial (4) to the desired cook

temperature. The HEATINGINDICATORLight

(5) illuminates and stays lit until the desired

temperature is reaches.

4. The selected mode operates automatically.

The temperature, time and mode can be al tered at any timeduringthe cookingprocess.

The operation can be stopped by the use of

the Mode Selector Switch or by opening the

door .

Operation

Standard Controls

5. At the end of the specified time period, the

buzzer sounds and the appliance willshut off

automatically.MovetheTIMER (6) totheSTAY

ON positionto stop the buzzer and restart the

unit.

6. To cool down the oven cavity, switch the

MODE SELECTOR Switch (3) to COOL

DOWN. In the Cool Down mode neither the

temperaturedialorthetimer willbeoperational. The blower will functionwith the door open

or closed.

7. The mode selector switch is also the main

power switch. In the OFF position the appliance is not operational.

NOTE: Always disconnect the power supply be-

fore servicing the unit.

25

Page 37

Cooking Guide

The Steam Mode

INFORMATION ABOUT THE STEAM MODE

How steaming works

This mode gently cooks food using non-pressurized steam. Freshsteam is directed into the oven

fromthegenerator.Itisnot necessaryto add water

to foods during the cooking process.

What can be steamed

Vegetables, side dishes, fish, meat, poultry, diet

foods, garnishes, dumplings, casseroles, meat

loaf, fruits, desserts and eggs.

How to operate the Steam mode

Simply turn the Mode Selector Switch to the

STEAM position and set the Timer.

Theadvantagesofsteaming

Steaming is a well-known cooking process frequently used in restaurant and institutional kitch ens. With thisapplianceit is nowpossibleto enjoy

the manyadvantagesofsteaming, some ofwhich

are:

DDDD

Shorter Cooking Times

The continuousprocessing of large amounts of

product is no problem and long cooking times

arenolongernecessary.Evenwithfullloads,

relatively shorter cooking time for food is needed.

DDDD

High Quality Foods

Withthe useofsteam, valuabletasteandaroma

are preserved since steamed foods retain their

ownnaturaltaste. During the steamingprocess

foods retain the nutrients and vitamins w hich

arelostinwaterduringboiling.Therefore,when

compared, steamed foods have much better

colorthan foodsthat have beenboiled.Also, by

using shallow containers the product is not layered as deeply and mushing is avoided.

DDDD

Vitamin Retention

Vitamins are not destroyed. This is due to the

shorter cooking times, the use of less or little

water and the use of a low temperature; slightly

less than 212_F/100_C.

DDDD

Firmness

With the use of steam, overcooking is not a

problem and firmness can be individually con trolled.

DDDD

Simultaneously Steaming Different Foods

Thereisnoflavortransferwhencookingwiththe

STEAM mode. For this reason, various types of

food with different cooking timescan be loaded

orremoved at anypoint duringthecooking process.

26

Page 38

Cooking Guide

The Steam Mode

TIPS AND PROCEDURES

Containers

Both solidand perforated steam t able pans of varying sizes (full, half, and one-third size) may be

used in the appliance.Smallpans may be placed

on wire racks.

Stocks for Sauces

When trays are used for cooking there is usually

enough stock collected for making sauces. When

using perforatedpans,insert asolidpaninthebottom rack to collect the stock.

Seasoning

Sincethere is noliquidadded duringthesteaming

process, season using one ofthe following methods:

DDDD

Season before cooking: Sprinkle the spice

mixture evenly over the food prior to cooking.

DDDD

Oil seasoning after cooking: Stir the oil mixture into the product. Steam again for two minutes in some cases.

Blanching and Prep Work

Large amounts of product can be blanched in a

short amount of time. Trays should not be filled

higher than 3 inches.

The STEAM mode is excellent for preparing vegetables for peeling.

Canning and Preserving

The diameter of the containers must not exceed

4-5 inches when canning.

Thawing

Thawing time is much shorter when using steam

and produces higher quality food.

Reheating

The use of steam creates an even distribution of

heat, which gives food better taste and retention

of nutrients.

Foodsarereheatedin the traysinwhich they were

cooked. Reheating times vary according to the

height and content of the containers.

SAMPLE DISHES

Vegetables

Fresh and frozen vegetables may be steamed together. Frozen vegetables shouldbe looselyscat tered on the trays. Perforated trays shorten cooking time, although solid trays may be used.

Cooking times will vary depending on the quality

of the vegetables. When steaming fresh vegetables,check the product

cooking period.

Steamed vegetables tend tosoften after cooking.

Sincethereisadelaybetweencookingandserving,

it is best notto steam vegetables too soft. This is

especially important for foods prepared for transport.

Rice and Potatoes

Rice requires the addition of water for steaming.

Remember that the rice continues to swell after

cooking; plan your quantities accordingly.

Always cook potatoes in perforated pans. Steam

can permeate the potatoes better if they are quartered through the width and not the length.

Eggs

Eggs are inserted onto wire racks, either in the

cardboard container or placed into perforated

trays(thereisnoneed topuncture them).Cooking

eggs with the STEAM function saveswork and results in less waste since steamed eggs do not

break. Also, the degree of hardness can be controlled exactly. Begin timing when the oven window is misted over.

Fish

Fish can be steamed in trays without using extra

stock. Use a 1 inch pan for fresh fish (Fillets). For

larger or frozen pieces, use a 2 inch pan.

Poachedfishcanbe preparedw ith aromaticherbs

and vegetables in either solid or perforated pans.

Steam w ithout stock.

Shellfish can be steamed in perforated pans. Use

a solid pan to catch drippings for stock.

3

/4ofthewaythroughthe

27

Page 39

Cooking Guide

The Hot Air Mode

INFORMATION ABOUT THE HOT AIR MODE

How cooking with hot air works

Hot air is circulated at high speed on all sides of

the product, providing a concentrated cooking

process. This function is extremely effective for intensive browning.

What can be cooked with hot air

Hotaircanbeusedfor allfoodswhichneedashort

cooking time and intensive browning. For example:steaks, cutlets,fillets,breadedfoods, andvarious baked foods. Thisfunctionmayalsobeused

for au gratin.

COOKING WITH THE HOT AIR MODE

Temperatures

Forintensive browning and crispycrusts,preheat

the oven to the maximum temperature of

500_F/260_C. This is especially important when

searing.

Performance

The charts showing performance examples (See

Cooking Guide) are based on full capacity.Better

results may be obtained by reducing product

quantities.

Cooking Times

Due to the constant hot air circulation, this appliance cooks faster than conventional grills and

deck ovens.

Cooking times will vary according to the quality,

weight, and height of the product.

Trays or Racks?

This is a questionof individualchoice.Racks have

the advantage of browning food on all sides; the

underside of tightly packed foods may be lighter

when using trays.

TIPS AND PROCEDURES

Loading the Oven

Place like sized product together on one rack. In

order to ensure proper air circulation, racks and

trays s hould not be crowded.

Oiling

The quality of some foods, such as steaks and

breaded meats, can be enhanced by coatingwith

oil or a paprika oil mixture.

Breaded Foods

The degree of browning is dependent on the

amountofrawmaterialin the breading. Oil can be

usedtointensifythe browning.Press thebreading

firmlybutdon’t overload the oven. Flouringseared

foods is not recommended.

Baking

Forbaking,theModeselectorswitchmaybeset

to HOT AIR, STEAM, COMBI or any combination

according to the type of product.Steam added to

thebakingprocess opensup a wide range ofpossibilities:suchashardcrustsandgoodshineon

certain types of breads. Here are some tips for

baking:

D

Preheat oven to the baking temperature.

D

Baking temperatures can generally be set

50-75_F/20-25_C lower than with a conventional bakingor roastingoven.When in doubt, lower the temperature.

D

The baking time can be shorter than with conventional methods.

D

Slightlyreduce your quantities of mixtures with

excessive moisture.

D

Use deep trays for lightmixtures inorder to ensure undisturbed baking. Baking forms should

not be higher than 3 inches.

D

Cakeforms(pans, tins, etc.), shouldbeplaced

on racks.

D

Distributefoodsevenlywhenloadinghalfloads.

D

Use every second tier for baking bread, heavy

mixtures (yeast doughs, etc.) and well filled

forms.

28

Page 40

Cooking Guide

The Combi Mode (Steam and Hot Air)

INFORMATION ABOUT THE COMBI (STEAM

AND HOT AIR) MODE

How Combi Mode Works

With this function, the advantages of steam (short

cooking time, less shrinkage) and hot air (intensive aroma, appetizing color) are combined.

Steam and hot a ir circulateat h igh speeds,envelopingthe productonall sidesand providing anintensive cooking process.

What can be cooked in Combi mode?

All types of roasts, duck ling, pork, beef, lamb,

meat loaf, ground chuck foods, casseroles, poultry, stuffed vegetables, vegetables au gratin and

yeast doughs.

TheadvantagesofCombimode?

DDDD

Productivity

Previously, several different appliances, and

multiple procedures, were necessary to combine heat andsteam preparation. Now all of

these methods can be used without time wast ing interruptions, with one appliance.

DDDD

Less Shrinkage

The usual weight loss during roasting in conventional appliances can be reduced by approximately 13% of the original weight.

DDDD

Juiciness and Crunchy Crusts

Whenusedat the beginningofthe cookingpro cedure, the searing action of steam instantly

closesallpores.Thisreducesthelossofprotein

and meat juices. Therefore, products withlong

roasting times remain juicy. Foods retain their

moisture and roastsdevelop apleasingcoloras

well as an appetizing crust. Meats have a pronounced roasted taste and burning of the surface is almost impossible.

COOKING IN THE COMBI MODE

The COMBI function can be used for the entire

cooking process or for any portionof the cooking

procedure you desire.

WhatdoCombi-roasting,Combi-steaming and

Combi-baking mean?

We have created these names s ince bothmodes,

STEAM and HOT AIR, canbe appliedinanycombination as follows:

D

Together, as in the COMBI function.

D

In sequence

Example: first STEAM and then HOT AIR.

D

Orinsequenceandthenincombination

Example: first HOT AIR and then COMBI

Or conversely: first COMBI and then HOT AIR.

D

Or all three functions in sequence

Example: first STEAM, then HOT AIR, then

COMBI.

For additional tips on when to use each of these

Combi Modes see the“Summaryof Functions” on

the following page.

29

Page 41

Cooking Guide

Summary of Functions

MODE SELECTION COOKING METHODS PRODUCTS

Steam

Hot Air

Combi

Steam Hot Air

Hot Air Combi

Steaming, defrosting, thawing, reheating-reconstituting, blanching,

preserving, poaching, simmering,

braising, stew ing.

Roasting, grilling, baking,

au gratin.

Combi-steaming, Combi-roasting,

Combi-baking, defrosting-thawing,

reheating-reconstituting.

Combi-steaming,

Combi-braising,

Combi-roasting,

Combi-baking,

(Begin withsteam, then with dryheat

for crusting, browning, gratinating.)

Combi-steaming,

Combi-roasting, Combi-baking,

(Start with dry heat, switch over to

Combi for slow but gentle even

browning, switch back and forth as

necessary.)

Convenience food, potatoes, rice,

fresh or frozen vegetables, fresh or

frozenfish, poultry, meat, fruit, eggs,

puddings, casseroles.

Roast beef, pork, veal, lamb, chicken, hamburger, fish, stuffed vegetables,toast,lasagne,potatoes,pies,

shortbread, puff pastry, Danish and

French pastry, bread.

Prime rib, whole bone ham, goose,

turkey,fish,mutton, beef, porkroast,

French pastry, bread, rolls, puff

pastry, Danish pastry, convenience

food.

Stuffed peppers, gratinated vegetables, fennel, broccoli, cauliflower,

rack of lamb, pork

French pastry, puff pastry, yeast

dough, turkey, duck, goose, lamb,

stuffed vegetables.

Combi Hot Air

Steam Hot Air Combi

Combi-braising,

Combi-roasting,

Combi-baking,

(Start with Combi,finishwithdry heat

for crusty, crisp, brown surface,

switch back and forth as necessary.)

Combi-steaming,

Combi-roasting, Combi-baking,

(For meats: sear pores closed with

steam, then brown with dry heat,then

switch betweenCombi and dry heat.

For stuffed vegetables: steam first

and switch between dry heat and

Combi during the rest of thecooking

process.)

30

Whole bone ham, ham in bread

dough (EnglishHam), whole filletsof

beef, pastry dough, yeast dough

(bread, rolls).

Veal, pork, beef, leg of lamb,goose,

duck, turkey, prime rib, puddings,

stuffed peppers; ideal for all products which need a humid cooking

process.

Page 42

Cooking Guide

General Tips and Procedures

USING RACKS

Use racks for roasts needing a longer roasting

time, large roasts (pork, veal, beef, venison,

lamb), searing, toast, au gratin, (chicken, duck,

goose, legs, chops), cooking in containers, thawing, bakingintins, etc.When cooking inracks itis

important to turn food products.

USING PANS

DDDD

1I Deep Steam Table Pan

Forfriedpotatoes,hamburgers, augratin,thawing, meat loaf, meat balls, fried, poached and

steamed fish, baked goods, vegetable casse roles, duck and goose.

DDDD

2I Deep Steam Table Pan

Forcabbage rolls, stuffed peppers, stews, rice,

vegetables, sauerkraut, assorted fruits and

compote. Also for collecting stock, preparing

sauces, etc.

DDDD

2½IDeep Perforated Steam Table Pan

For vegetables without stock, side dishes

(breads) and products with shorter cooking

times.

DDDD

4IDeep Perforated Steam Table Pan

For vegetables (blanching spinach for example), potatoes, shelled or unshelled eggs.

DDDD

6IDeep Perforated Steam Table Pan

For potatoes.

LOADING THE OVEN

To ensure thatthe product will brown on allsides,

do not place foods too close together. Place the

grain of meats parallel to the air stream (left to

right). This ensures better absorption and shortens the cooking process. Place like sized pieces

together on the same rack, smaller pieces cook

more quickly.

Placethefoodin theappropriatepans/trays ordistribute it on the racks. Insert racks and trays into

the panrack. It is recommendedthatthepanrack

be loaded outside of the oven w hen processing

large amounts of product. The pan rack for table

models is well suited for this purpose;it allows for

a higher hourly production and an efficient work

sequence.

REMOVING THE PRODUCT

Turn the Mode Selector Switch to OFF before

opening the appliance door.

NOTE: Open the door slowly after steaming! Hot

Steam Will Be Present!

COOKING TIMES

Thelengthofthe cookingprocess dependsonthe

quality, weight and thickness ofthe food product.

TEMPERATURES

Typically,the longer the cooking process, the lower the temperature.

31

Page 43

Cooking Guide

Suggested Times and Temperatures

NOTE: (Alltimesandtemperaturesareestimatesandshouldbeverifiedinactual practice. Startingtemper-

ature of food, pan size/fullness and opening oven during cooking will affect cooking times.)

BAKED GOODS

Menu Item Mode Temp Cooking

Time

Angelfood Cake Hot air 325F/165C 50 min Tube pans on wire racks

Apple Cinnamon Muffins Hot air 350F/175C 20 min See other muffin procedures

AppleCoffeeCake Hot air 300F/150C 25 min Also test in combi mode

Bear Claws Combi 350F/175C 20 min Alsotest in hot air

Biscuits Hot air 325F/165C 15 min Also test in combi mode @

350F/175C

Comments

Bread Sticks (Soft Style, Raw

Dough)

Butter Sugar Cookies Combi 300F/150C 10 min Also try on hot air

Cake Layers Hot air 300F/150C 25 min Sheet pans

Carrot Cake Layers Hot air 325F/165C 25 min Sheet pans

Cheese Danish Combi 350F/175C 20 min Alsotest in hot air

Cheesecake Combi 325F/165C 1hr

Cherry Crisp Combi 325F/165C 30 min 2½” pan, uncovered

Cherry Pie Hot air 350F/175C 40 min Pie tins on wire rack

Cherry Strudel Hot air 350F/175C 30 min

Chocolate Brownies Hot air 325F/165C 25 min Sheet pans

Chocolate Chip Muffins Hot air 350F/175C 20 min See other muffin procedures

CinnamonRaisinBiscuits Hot air 325F/165C 15 min Also try in combi mode

Cream Cheese Noodle Bake Combi 300F/150C 40 min 2½“ pan, uncovered

Dinner Rolls Combi 325F/165C 20 min Alsotest in hot air

Dutch Apple Pie Combi 350F/175C 50 min Pie tins on wire rack

French Bread Combi 375F/190C 20 min See hard roll procedure also

Hard Rolls Combi 375F/190C

Combi 325F/165C 10 min 375F/190C for crispy style

250F/120C

350F/175C

Preheat

5min

15 min

Low temp stage produces better crust – can be eliminated –

keep total time

Hot Seasoned Apples Combi 250F/120C 15 min 2½“ pan, uncovered

Indian Pudding Steam NA 35 min 2½“solidpan

Mile High Apple Pie Hot air 350F/175C 50 min Pie tins on wire racks

32

Page 44

Cooking Guide

Suggested Times and Temperatures

BAKED GOODS

Menu Item Mode Temp Cooking

Time

Comments

Muffins (Blueberry, Banana

Nut)

Oatmeal Raisin Cookies Hot air 325F/165C 15 min

Peanut Butter Choc. Chunk

Cookies

Pecan Rolls Combi 325/165C 20 min Also test in hot air mode

Sour Cream Coffee Cake Hot air 300F/150C 25 min Also try in combi mode

Strawberry Rhubarb Pie Hot air 350F/175C 50 min Pie tins on wire rack

Sweet Rolls Combi 325F/165C 20 min Also try in hot air mode

WhiteChocolateFudgeCook-

ies

Whole Wheat Rolls Combi 325F/165C 25 min Alsotest on hot air

Menu Item Mode Temp Cooking

Cheese Soufflé Combi 350F/175C 30 min 2½“solidpan

Chilean Cheese Quiche

Hot air 350F/175C 20 min Preheat to 400F/205C, load

oven, turn off for 6---8 min,

then bake at indicated temperature

Hot air 300F/150C 12 min Highertempforcrispiercookie

Hot air 300F/150C 15 min

EGGS

Comments

Time

Combi 325F/165C 40 min 2½“solidpan

Egg Foo Yung Steam NA 15 min 2½“solidpan

Hard Cooked Eggs Steam NA 15 min Perforated steam pans or in

cardboard flats on sheet pans

Mixed Vegetable Quiche Combi 325F/165C 40 min 2½“solidpan

Onion Cheese Quiche Combi 325F/165C 40 min 2½“solidpan

Spanish Omelet Steam NA 10 min ½“ size sheet pan, lined

Spinach Quiche Combi 325F/165C 40 min 2½“ pan, uncovered

33

Page 45

Cooking Guide

Suggested Times and Temperatures

PORK

Menu Item Mode Temp Cooking

Time

Bacon Slices Combi 325F/165C 15 min Single layer on sheet pan

Bacon Slices Combi 325F/165C 15 min Single layers on sheet pan

Baked Ham Combi 300F/150C 1hr Sheet pan

Baked Pork Chops Combi 325F/165C 20 min Single layer on sheet pan

Comments

BBQ Boneless Rib For Sandwich (Retherm)

BBQ Pork For Sandw ich (Boston Butts, Raw)

Bratwurst Steam NA 15 min 2½“ pan, uncovered

Canadian Bacon Combi 400F/205C 5min Single layer on sheet pans

Grilled Butterflied Pork Chops Combi 400F/205C 10 min Oiled chops on sheet pan

Grilled Ham Slice Combi 400F/205C 10 min Cook on wire racks---preheat

Grilled Pork Cutlet Combi 400F/205C 15 min Single layer on sheet pan

Grilled Pork Tenderloin Combi 400F/205C 15 min Oiled wire rack

Italian Sausage Combi 375F/190C 15 min Sheet pan

Kielbasa For Sandwiches Combi 375F/190C 15 min Single layer on sheet pan

Knockwurst Steam NA 20 min 2½“ pan, uncovered

Pork Sausage Links Combi 350F/175C 15 min Single layer on sheet pan

Roast Pork (150_ Internal,

Rest 20 Min)

Sausage Patties Combi 300F/150C 15 min Steam for better yield (no col-

Combi 250F/120C 15 min Shingled on sheet pan

Combi 250F/120C 2hrs On sheet pan w/sauce

450

Combi 300F/150C 50 min Usesheetpanorwirerack

or)

34

Page 46

Cooking Guide

Suggested Times and Temperatures

STARCHES

Menu Item Mode Temp Cooking

Time

Baked Beans Combi 300F/150C 40 min 2½“ pan, uncovered

Baked Potato Combi 400F/205C 45 min On sheet pan, unwrapped

Comments

Baked Sweet Potatoes

(Whole)

Black Bean Enchilada Combi 300F/150C 15 min 2½“solidpan

Brown Rice Steam NA 30 min 2½“ pan, uncovered

Cheesy Rice Casserole Combi 300F/150C 30 min 2½“ pan, uncovered

Chili Cornbread Casserole Hot air 325F/165C 35 min 2½“solidpan

Glazed Sweet Potatoes Combi 300F/150C 30 min 2½“solidpan

Hash Brown Potatoes Combi 400F/205C 15 min Oiled pan, brush tops w/oil

Lasagna Combi 300F/150C 40 min 2½“ pan, uncovered

Macaroni & Cheese Combi 275F/135C 40 min 2½“solidpan

Parsley Potatoes Steam NA 25 min 2½“solidpan

Pizza (Scratch Crust) Combi 350F/175C 15 min Sheet pan

Potato Puffs (Frozen) Combi 375F/190C 20 min Single layer on sheet pan

Rice Steam NA 25 min 2½“ pan, uncovered

Rice Pilaf Steam NA 25 min 2½“solidpan

Rissole Potatoes Combi 350F/175C 20 min Single layer on sheet pan

Roast Potatoes Combi 375F/190C 30 min Single layer on sheet pan

Shells Florentine (Precooked

Pasta W/Sauce)

Combi 375F/190C 40 min Sheet pan

Combi 275F/135C 30 min 2½“ pan, uncovered

Spaghetti (Retherm, W/Sauce) Combi 250F/120C 15 min 2½“ pan, uncovered

Tri --- Taters Combi 375F/190C 20 min

White & Wild Rice (Parboiled,

Conditioned)

Yorkshire Pudding Hot air 350F/175C 30 min 2½“solidpan

Steam NA 30 min 2½“ pan, uncovered

35

Page 47

Cooking Guide

Suggested Times and Temperatures

Menu Item Mode Temp Cooking

BEEF

Comments

Time

BBQ Beef For Sandwich (Raw

Brisket)

Beef Sausage Links Combi 350F/175C 15 min May also be steamed

Beef --- A ---Roni (Precook ed,

Retherm)

Braised Beef W/Mushrooms Combi 250F/120C 1hr 2½“ pan, uncovered

Breakfast Steak Combi 500F/260C 5min Brush w/butter, use oiled pan

Corned Beef Hash Combi 250F/120C 25 min 2½“solidpan

Grilled Flank Steak Combi 500F/260C 10 min Oil steak, cook on wire rack

Hamburger Pie Combi 325F/165C 30 min 2½“ pan, uncovered

Hamburgers (Frozen Patties) Combi 400F/205C 10 min Perforated sheet pan preferred

Herbed Pot Roast Combi 250F/120C 3hrs 2½“solidpan

Hot Dogs Steam NA 15 min 2½“perforatedpan

Italian Beef For Sandwich (Re-

therm)

London Broil Combi 500F/260C 15 min Oiled s teak, preheated racks

Marinated Sirloin Steak Combi 500F/260C 10 min Oiled s heet pan

Meatloaf Combi 300F/150C 40 min 2½“ pan, uncovered

Combi 250F/120C

375F/190C

Combi 260F/125C 20 min 2½“ pan, uncovered

Combi 275F/135C 20 min 2½“solidpan

90 min +

10 min

Cook with sauce @ low heat,

raise temp to set glaze

New York Strip Combi 500F/260C 8min Oiled steaks on w ire racks

Prime Rib (Rest Before Carv-

ing)

Rib Eye Sandwich Steak Combi 500F/260C 5min Brush w/melted butter, cook

Roast Beef Combi 275F/135C 2 ½ hrs Sheetpanorwirerack

Roast Beef Hash (Retherm) Combi 250F/120C 25 min 2½“solidpan

Salisbury Steak W/Gravy (Re-

therm)

Teriyaki Steak Combi 400F/205C 10 min Single layer on sheet pan

Combi 275F/135C 2 ½ hrs Wire rack, check internal temp

on w ire racks, catch pan on

bottom (preheat oven w ell)

Combi 250F/120C 20 min 2½“solidpan

36

Page 48

Cooking Guide

Suggested Times and Temperatures

FISH

Menu Item Mode Temp Cooking

Time

Baked Cod Combi 375F/190C 10 min/in. Single layer on sheet pan

Baked Sole Combi 275F/190C 10 min Flat filets on sheet pan

Cod Fish For Sandwich Combi 350F/175C 10 min Single layer on sheet pan

Grilled Yellow Fin Tuna Combi 375F/190C 10 min/in Sheetpanorwirerack

Comments

Rainbow Trout (Whole,

Thawed)

Salmon En Croute (Fillet In

Puff Pastry)

Steamed Clams Steam NA 10 min Perforated pan

Stuffed Flounder Combi 350F/175C 20 min Single layer on sheet pan

Tuna Noodle Casserole Combi 275F/135C 30 min 2½“solidpan

Whole Lobsters – 1# Steam NA 15 min Perforated pan

Combi 375F/190C 15 min Single layer on sheet pan

Combi 375F/190C 20 min Sheet pan

37

Page 49

Cooking Guide

Suggested Times and Temperatures

POULTRY

Menu Item Mode Temp Cooking

Time

Baked Chicken Combi 375F/190C 35 min Single layer on sheet pan

Baked Chicken Thighs Combi 375F/190C 25 min Single layer on sheet pan

Comments

BBQ Chicken (Sauced,

Pieces)

BBQ Turkey For Sandwich

(Retherm)

Chicken & Vegetable Stir Fry

(Low Fat Version)

Chicken/MexicanQuesadilla Combi 300F/150C 30 min 2½“perforatedpan

ChickenCordonBlue Combi 375F/190C 20 min Single layer on sheet pan

Chicken Kiev Combi 375F/190C 20 min Single layer on sheet pan

Chicken Parmesan Combi 375F/190C 20 min Single layer on sheet pan

Chicken Patties For Sand-

wiches (Frozen)

Chicken Pot Pie Combi 350F/175C 45 min 2½“ pan, uncovered

Chicken Tenders Combi 400F/205C 15 min Toss w/oil, cook on sheet pan

Chicken Tettrazini Combi 275F/135C 30 min 2½“ pan, uncovered

Cornish Hens Combi 375F/190C 25 min Sheet pan

Grilled Marinated Chicken

Breast

Hot Turkey Sandwich (Re-

therm Sliced Turkey)

Combi 325F/165C 35 min Sheet pan

Combi 250F/120C 15 min Shingled in shallow layers

Combi 375F/190C 15 min Toss raw ingredients w/oil, add

sauce after cooking

Combi 375F/190C 20 min Single layer on sheet pan

Combi 375F/190C 15 min Single layer on sheet pan

Combi 250F/120C 15 min Shingled in shallow layers

Sherried Chicken Combi 250F/120C 40 min 2½“solidpan

Turkey W/Dressing (Portioned,

Retherm)

Combi 250F/120C 15 min 2½“ pan, uncovered

38

Page 50

Cooking Guide

Suggested Times and Temperatures

VEGETABLES

Menu Item Mode Temp Cooking

Time

Asparagus Steam NA 10 min 2½“perforatedpan

Asparagus & Egg Au Gratin Steam NA 20 min 2½“solidpan

Broccoli (Fresh Spears) Steam NA 12 min Perforated pan

Broccoli Cheese Casserole Combi 300F/150C 40 min 2½“ pan, uncovered

Cauliflower (Fresh Florets) Steam NA 12 min 2½“perforatedpan

Corn (Frozen Niblets) Steam NA 20 min 2½“perforatedpan

Corn On The Cob Steam NA 15 min 2½“perforatedpan

Fingerling Carrots Steam NA 15 min 2½“perforatedpan

French Cut Green Beans (Fro-

zen)

Garden Peas (Frozen) Steam NA 10 min 2½“perforatedpan

Glazed Carrots (Frozen W/

Sauce)

Green Beans W/Water Chest-

nuts

Italian Vegetables (Frozen) Steam NA 20 min 2½“perforatedpan

MexicanCorn(Frozen) Steam NA 20 min 2½“perforatedpan

Mixed Vegetables (Frozen) Steam NA 15 min 2½“perforatedpan

Pea Pods W/Water Chestnuts Steam NA 10 min 2½“perforatedpan

Peas & Mushrooms (Frozen) Steam NA 20 min 2½“perforatedpan

Ratatouille Combi 300F/150C 20 min Toss veg w/oil before cooking

Sliced Carrots (Raw) Steam NA 20 min 2½“perforatedpan

Spinach (Frozen) Steam NA 20 min 2½“perforatedpan

Sugar Snap Peas (Frozen,

Seasoned)

Vegetable Primavera Casse-

role

Vegetarian Stir Fry (Low Fat

Version)

Vegetarian Stuffed Peppers Combi 300F/150C 30 min 2½“solidpan

Whole Green Beans Steam NA 15 min 2½“perforatedpan

Zucchini W/Basil Steam NA 10 min 2½“perforatedpan

Steam NA 15 min 2½“perforatedpan

Steam NA 15 min 2½“ pan, uncovered

Steam NA 15 min 2½“perforatedpan

Steam NA 15 min 2½“ pan, uncovered

Combi 275F/135C 30 min 2½“solidpan

Combi 375F/190C 10 min Toss raw ingredients w/oil, add

sauce after cooking

Comments

39

Page 51

Notes

Cooking Guide

40

Page 52

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaningof the applianceis essentialfor sanitation, and to ensure against operational difficulties.

For difficult cleaning, allow the spray-on oven

cleaner to work longer before rinsing.

1. Cool theoven down to 140_F/60_Cor,ifthe

oven has been idle, turn the steam mode on

for 3 to 4 minutes in order to warm the oven

surfaces.

2. Spray the interior of the oven with a cleaning

solution.

NOTE: Never spray water into the unit when

the temperatureis above 212_F. NEV ERSPRAYWATERINTHEUNITAFTER

USING THE HOT AIR OR COMBI

MODES.

3. Let the cleaner work for 10to20 minutes with

the oven off. For difficult, baked on greas e,

etc. allow to work over night.

4. Set the timer for 15 to 20 minutes.

5. Set the mode selector switch to Steam. This

will soften all burned on residue.

6. Rinsetheoveninteriorwithwater(ahosemay

beused,but takecarethatonlytheoven’sinterior cavity is sprayed with water).

7. Setthemodeselectortosteamforanotherfive

minutes to flush out the oven interior and remove all detergent residue.

NOTE: Theovencavity should never bescoured

or scraped.

On stainless interiors, deposits of baked on splat ter, oil, grease or light discoloration may be removed with a good non toxic industrial stainless

steel cleaner. Apply cleaners when the oven is

cold and always rub with the grain of the metal.

The racks, rack supports and the blower wheel

maybecleanedintheovenorbyremovingthem

from the oven and soaking them in a solution of

ammonia and water.

NOTE: DO NOT use corrosive cleaners on the

Oven/Steamer.

CLEANING THE EXTERIOR

Oven exteriors may be cleaned and kept in good

condition witha light oil. Saturate acloth and wipe

the oven when it is cold; wipe dry with a clean

cloth.

NOTE: The outside of the appliance is not to be

sprayed with water.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

theproperinitialinstallationof theequipmentand

a program for cleaning the oven routinely. The

Oven/Steamer requires no lubrication. Contact

the factory, the factory representative or a local

Blodgett Combi service company to perform

maintenenceand repairs shouldthey berequired.

WARNING!!

Disconnectappliance from power supply

before servicing or cleaning.

41

Page 53

Maintenance

Decalcification

The oven should be delimed on a monthly basis

regardless of water quality or usage. Use the following procedure to delime the boiler.

1. Turnthe ModeSelection Switchto the STEAM

mode. Wait until steam is produced. This will

ensure that the water in the steam generator

is hot.

2. Turn the Mode Selection Switch to OFF.

3. In the deliming bottle included with the oven,

mix together 12 oz. of deliming solution to 2

gallons of warm water.

NOTE: These volumes are approximate. You

mayneedslightlymoreorless hotwater depending on your site.

4. Place the deliming bottle on the floor in front

of the oven. Connect the tubing from the deliming bottle to the top deliming valve on the

oven base section.

5. Pump the entire solutioninthe delimingbottle

into the boiler. Disconnect the tubing from the

topdelimingvalve. Allowthesolution to stand

intheboilerfor30minutes.

6. Disconnectthetubingfromthedelimingbottle

at the joint. Place a containercapable of holding six gallons in front of the oven.

7. Insert theendofthetubing disconnectedfrom

thedelimingbottleintot he container.Connect

the other end of the tubing to the bottom deliming valve and drain the boiler entirely. Dispose of the solution.

8. Disconnect the tubingfromthe bottomdeliming valve and reassemble to the deliming

bottle. Refill the deliming bottle with fresh water. Connect the tubing from the deliming

bottle to the top deliming valve on the oven

base section.

9. Pump the entire solutioninthe delimingbottle

into the boiler. Disconnect the tubing from the

top deliming valve.

10. Disconnectthe tubingfromthe delimingbottle

at the joint. Place a containercapable of holding six gallons in front of the oven.

11. Inserttheendofthe tubingdisconnectedfrom

thedelimingbottleintot he container.Connect

the other end of the tubing to the bottom deliming valve and drain the boiler entirely. Dispose of the solution.

12. Repeat STEPS 8 thru 11.

13. Disconnectthetubingfromthe bottom deliming

valve and reassemble to the deliming bottle.

Top Deliming Valve (inlet)

Bottom Deliming Valve (drain)

Figure 42

42

Page 54

Maintenance

Troubleshooting Information

How to Use this Trouble Shooting Section

Thetroubleshooting section inthisbookisdivided

into the following :

1. Component Identification – pages 44 to46.

This sectionlistsallthe electricalcomponents

with a description, location, and resistance

reading w here applicable.