Page 1

Installation and Operation Manual

Blackmagic Cintel

October 2015

Page 2

Welcome!

Thanks for purchasing your new Cintel scanner!

Your new Cintel scanner runs film in real time so you can transfer film much faster

than a traditional scanner that runs non real time using a constant start-stop

motion. However it’s important to understand that your Cintel scanner is not a

telecine and it does not transfer film to video, as it transfers film direct to DaVinci

Resolve where you have the power to edit the film rolls back together and the

scans can be color graded, reframed, noise reduced and the audio extracted.

Using DaVinci Resolve to operate the scanner means you have much more

creative control than a simple telecine because DaVinci Resolve has many more

features than is possible to do in hardware. Plus because the Cintel scanner

takes advantage of the power of the DaVinci Resolve system and the GPU’s in

the host computer, this scanner itself does not need to be cluttered with bulky

expensive electronics assemblies.

This means the Cintel scanner is smaller, lighter and has more value engineered

into the parts of the scanner that result in better quality film scans, such as

precision mechanical film handling components, optics, high intensity defuse

light source and the built in camera.

The Cintel scanning workflow is simple as all you need to do is scan your film to

intermediate Cintel RAW files and then once you have joined the film rolls back

together in the timeline, added noise reduction, color grading and reframing,

you can use DaVinci’s deliver page to render out files to any format you like.

You might need to render to DPX frames to use third party film restoration

software or you might want to render to DNX or ProRes files for use in editing

software. You can even render out digital cinema package files if you want to

digitally project the film!

Your Cintel scanner is designed to work in conjunction with DaVinci Resolve

so you get incredible power and amazing quality, so please read through this

manual carefully so you can learn all about how to use your new scanner.

Of course with all the power of DaVinci Resolve available with your scanner, it’s

also important to check out the DaVinci Resolve manual and tutorials available.

There are also some great customer tutorial videos on using DaVinci Resolve

as well as high quality training available from third party vendors to help you

get the most out of your DaVinci Resolve system.

Grant Petty

CEO Blackmagic Design

Page 3

Contents

Blackmagic Cintel

Getting Started 4

Unpacking and Mounting Cintel 4

Getting Started with Blackmagic Cintel 5

Using Cintel 8

Wind Types 8

Switching to 16mm 9

Playback Controls 11

Standby Mode 12

Servicing 12

Specifications 13

Help 14

Safety 15

Limited Warranty 15

Page 4

Getting Started

Unpacking and Mounting Cintel

Blackmagic Cintel’s architecturally inspired design allows

it to serve as an aesthetic feature in your studio, but it is

also a large, heavy professional tool. As such, care should

be taken when unpacking and mounting your Cintel unit.

Once you have opened Blackmagic Cintel’s road case, you

will see that spaces have been cut in the foam padding to

give you a sturdy grip on your scanner.

Please note that Cintel weighs over 130 pounds and is too

heavy to be unpacked by one person. Unpacking should

be undertaken by 2 people using correct lifting techniques.

1

1

Bend your knees, keep a straight back and lift with careful,

controlled movements.

Once you have gently removed your scanner from its road

case, place it upright on a flat surface capable of supporting

its weight and follow the getting started procedure in the

‘getting started with Blackmagic Cintel’ section.

Blackmagic Cintel’s wall mounts conform to industry

standard television mounting hardware and any television

mount rated higher than 130 pounds will allow you to mount

your scanner securely to your studio wall.

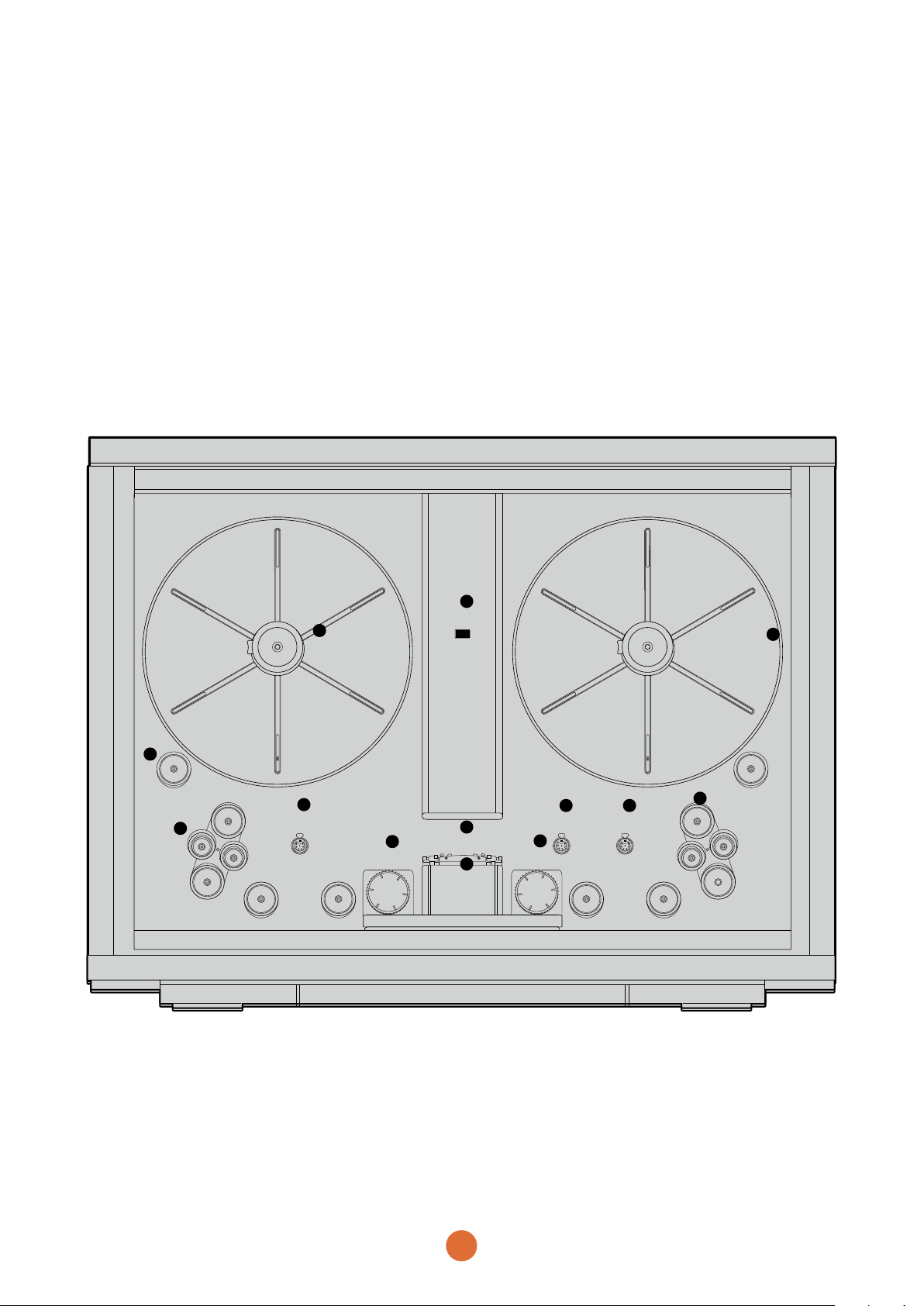

13

13

12

12

2

2

11

4

4

3

3

5

5

6

6

7

7

9 10

9 10

8

8

11

1. Core clamp 2. Roller 3. Particle transfer roller 4. Left options interface 5. Tensioner sprocket wheel

6. Skid plate 7. Light source 8. Drive sprocket wheel 9. Pin registration expansion port

10. Right options interface 11. Compliance arm 12. Spooler backplate 13. Focus wheel

4

Page 5

Getting Started

Getting Started with Blackmagic Cintel

Getting started is as simple as plugging in power, connecting

to your computer via Thunderbolt, launching Blackmagic

DaVinci Resolve, and lacing your film. If you just want to

get started previewing your scan, you can load film,

manually tension it, and output it to a HDMI monitor using

the ‘lacing film,’ and ‘playback controls’ section of this

manual. Capture controls for Blackmagic Cintel are located

in DaVinci Resolve’s Cintel scanner palette, therefore, the

first thing you’ll need to do when you’re ready to scan is

make sure DaVinci Resolve is installed.

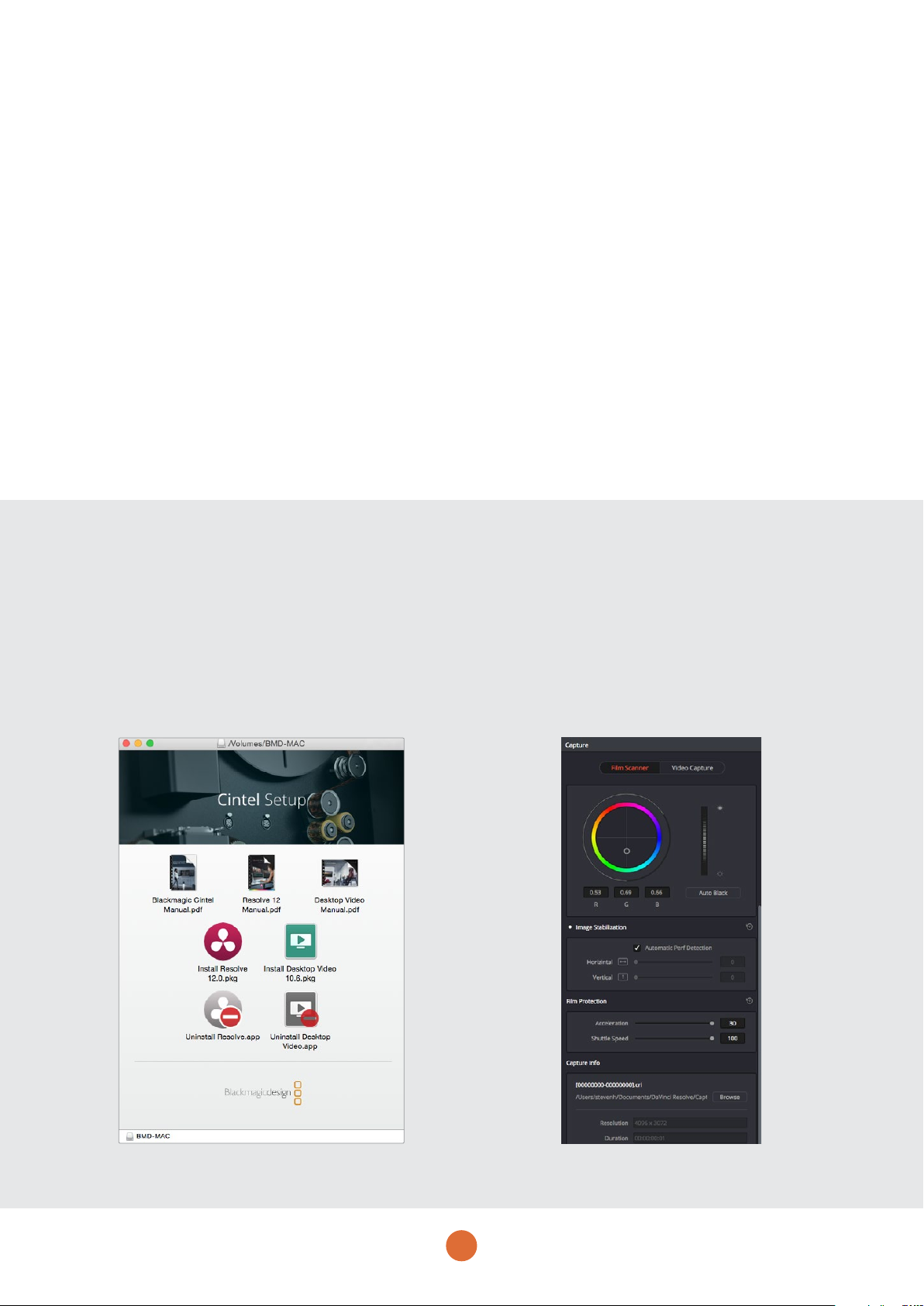

Your scanner comes with Cintel Installer software comprising

Blackmagic Desktop Video and DaVinci Resolve, as well

as a DaVinci dongle allowing you to use the full version of

DaVinci Resolve.

You can use the packaged installer to get started, however,

we recommend downloading the latest versions of the

Cintel Installer from the Blackmagic Design support center

at: www.blackmagicdesign.com/support

Step 1. Turning your scanner on

Power Blackmagic Cintel by connecting a standard IEC

cable to the AC power socket on the lower right side

of the back panel. Your scanner’s power indicator LED

should glow green.

Step 2. Connecting your scanner to your computer

Connect Blackmagic Cintel to your Mac OS X or

Windows computer via the Thunderbolt port on

your scanner’s lower right side.

Once your download has completed, unzip the file and run

the installer within the uncompressed folder. Simply follow

the prompts in the installer app and DaVinci Resolve and

Blackmagic Desktop Video will soon be available on

your system.

As the scanner will capture a large amount of image data

you should select in Resolve where you wish to record the

captured files. This is easily done by first launching DaVinci

Resolve, clicking on preferences in the DaVinci Resolve

menu bar and then clicking on the ‘plus’ icon in the ‘media

storage’ tab. Browse to and select a drive or folder path,

click ‘save’, and restart DaVinci Resolve.

Now that DaVinci Resolve is installed on your computer,

we can get started using Blackmagic Cintel.

You won’t need to do anything further with Blackmagic

Desktop Video, it simply allows DaVinci to communicate

with your scanner.

You can also connect to an external monitor via

your scanner’s HDMI port for focusing or preview

purposes.

Step 3. Launching DaVinci Resolve

Launch DaVinci Resolve, select the Media page and

then open the Cintel palette by clicking on the ‘capture’

button at the top right of the screen. If you have

additional capture devices installed on your computer,

click the Cintel tab to switch to the correct palette.

The Cintel palette in DaVinci Resolve controls

5

all capture settings.

Page 6

Getting Started

Lacing Film

Now that Blackmagic Cintel and DaVinci Resolve are

communicating with each other, it’s time to lace up your film.

Step 1. Accessing the scanner

Open Blackmagic Cintel’s sliding doors.

On the internal front panel you’ll see a feeding spool on

the left, and a taking spool on the right. The feeding spool

holds the film to be scanned, and the taking spool collects

the scanned film.

Step 2. Setting film wind

Set the ‘wind type’ so the spools turn in the appropriate

direction. Go to DaVinci Resolve’s Cintel scanner palette

and set the ‘wind type’ to B/A by clicking ’B’ and ‘A’ on the

‘feed’ and ‘take up’ buttons, respectively.

B/A is your scanner’s default wind type which has the

feeding spool traveling in a clockwise direction and the

taking spool traveling counter clockwise. Refer to the ‘wind

types’ section in this manual for more information.

This is also a good time to make sure that your settings

are appropriate for your film type and size.

You can select from positive, negative, interpositive and

internegative in DaVinci Resolve’s Cintel palette, as well

as 16mm, 35mm and various perforation layouts.

Step 3. Preparing the take up spool

Slide the supplied 75mm spool core and core clamp onto

your scanner’s taking spindle. To apply the core clamp,

hold in the clamp’s button and push it onto the spindle until

you feel resistance, then release the button and push the

clamp on the rest of the way until you hear a ‘click.’

Step 4. Loading film

Load your film reel or core onto the feeder spindle following

the same procedure in step 3. Note that the procedure

differs slightly depending on if your film is on a core or a

reel, and whether it is 35 or 16mm.

For example, when loading a core, you’ll need to insert the

provided backing plate, whereas loading a reel only requires

the use of spacers.

Step 5. Lacing film

Gently lace several feet of the film leader through your

scanner’s rollers following the illustration below.

The sprockets on the sprocket wheels are designed to fit

16mm and 35mm film. It’s important that your film is laced

over the appropriate sprockets so it glides smoothly over

the skid plate, and that the sprockets are engaged cleanly

with the film perforations to ensure gentle film loading.

Step 6. Tensioning film

To secure your film to the taking spool, insert the end of

your film into the small notch provided in the spool, or tape

it down; then gently hand wind the spool a few times to

hold the film in place.

You can begin tensioning by pressing the ‘load button,’ or

by manually turning the feeding and taking spools

simultaneously.

Cintel’s default B/A wind loads from the bottom of the feeding

spool and onto the top of the taking spool.

6

When loading film on a spool, the

supplied backing plate is required.

When loading film reels, the backing

plate is not required, simply use the

spacers provided.

Page 7

Getting Started

Manual Tensioning

For manual tensioning, turn the feeding spool and taking

spool counter clockwise for a B/A wind.

You’ll notice the compliance arms below each spool begin

to move as you manually introduce tension as in the diagram

below. Once these are about a third of the way through

their range of motion, hold the spools in place for a second

or two. Your scanner will detect secured film on the taking

spool, and its tensioning feature will automatically activate,

taking up the rest of the slack.

If at any point in a manual or automatic load you notice a

problem, you can cancel the load procedure by pressing

the ‘load’ button again or firmly holding the feeding or

taking spool. Your scanner will recognise either action and

abort the load.

Step 7. Inspect your film

Check that the film is laced properly by pressing the ‘play’

button on your scanner or clicking the ‘play’ button in the

Cintel Palette in DaVinci Resolve. If you see your film image

playing in the Cintel palette preview window on your

computer or on an external HDMI monitor, if attached, you’ll

know your scanner is working.

Depending on the wind type you’ve used, you may find

that the image is flipped horizontally or vertically. You can

fix this by selecting the appropriate film type. For instance,

negative f ilm may appear flipped left to right until the

‘negative’ setting is selected. If you can’t fix this by selecting

your film type, you may need to reload your film using a

different wind type.

Step 8. Focusing

This is easily done by selecting ‘workspace’ on the DaVinci

Resolve menu bar and then selecting ‘video scopes’ and

turning the scopes on. Keep an eye on the red, green, and

blue scopes as you scroll your scanner’s focus wheel. Your

image will be in perfect focus when the red, green, and

blue scopes are ‘peaking,’ or displaying the maximum

amount of information. As you approach perfect focus, the

readout on each scope will become taller, before shrinking

as you move away from the optimal point.

You can also make quick focal adjustments by previewing

your film on an Ultra HD external monitor with your scanner’s

HDMI output. A good way to dial in focus this way is to pay

attention to the edges of your film’s perforations. When

these are sharp, your film should be in focus.

Step 9. Closing the doors

As the top of film is quite shiny it may reflect any spotlights in

the roof of your scanning room that are located in the vicinity

of the scanner. These can show up as black blotches in your

scan. Your scanner’s high quality light source eliminates light

pollution in all but the most brightly lit workspaces, but for the

best quality scan we recommend closing the sliding doors

just in case. The scanner doors are designed to block the

light from the film gate area and closing them will stop any

light getting in. Your scanner has a spring loaded door that

will gently complete the closing procedure once the doors

are nearly shut.

Your film is now laced and ready to be captured!

Please refer to the Cintel section of the DaVinci Resolve

reference manual for details on calibrating the light source,

setting the stabiliser, and the capture palette settings for

capturing images.

Focus your film using DaVinci Resolve’s RGB Parade scope

to achieve perfect focus.

The reference manual also details how to sync optical audio

and manage the large number of files you will generate when

capturing from your scanner.

A B C

A When manually tensioning film, you only need to apply enough tension to move the compliance arms into the ‘sweet spot’

of their movement range - a lit tle under half way. Cintel will automatically take up any additional slack.

B When loading 35mm film, use the outer sprockets on the sprocket wheels.

C Use DaVinci Resolve’s video scopes to achieve perfect focus. The scope on top represents and out of focus frame,

while the scope below shows the same frame in focus. Note the taller peaks in the focused image.

7

Page 8

Using Cintel

Taking spoolFeeding spool

Wind Types

The ‘wind type’ refers to the loading and unloading position,

as well as the turn direction of film on your scanner’s feeding

and taking spools. As you can see in the diagram below,

an ‘A’ wind refers to film loading/unloading from the top of

the spool, while a B type loads or unloads from the bottom.

This is true for both the feeding and taking spools. Wind

type affects which direction each spool turns, the position

of the audio information and perforations, and whether

your film travels across the skid plate emulsion side up or

down, so it is important to use the appropriate combination

for your project.

Feeding spool

Select the appropriate wind type in DaVinci Resolve’s Cintel

scanner settings.

The default wind type for your scanner is a B/A wind,

meaning the feeding spool unloads from the bottom and

the taking spool loads across the top. If the film you are

working with has been wound a different way, other

combinations of A and B winds are supported; simply select

the appropriate wind type via the ‘feed’ and ‘take up’

buttons in DaVinci Resolve’s Cintel scanner palette.

Taking spool

‘A’ wind

‘B’ wind

An easy way to remember the difference bet ween A and B winds is that A winds unload and

take up film from the top of the reel or spool, while B winds do the same from the bottom.

8

Page 9

Using Cintel

Switching to 16mm

The optional 16mm kit contains all the parts you’ll require and the changes to your scanner’s setup are minimal.

16mm skid plate

Outer spacer

Inner spacer

The 16mm kit contains a 16mm skid plate, two inner spacers and two outer spacers.

9

Page 10

Using Cintel

Switching to 16mm scanning is easy:

Step 1. Swapping the skid plate

Swap the 35mm skid plate with the 16mm skid plate by

opening the retention levers on the front of the plate,

removing the outgoing plate and inserting the 16mm plate.

When fitting a skid plate, make sure that the retention levers

are lifted all the way up before turning them inwards, or

the plate may not seat properly.

Step 1.1: When removing the skid plate

you will need to turn the retention

levers outward.

Step 1.2: Removing the 35mm skid plate. Step 1.3: To secure a skid plate lift

Step 2. Inserting the 16mm spacer

Insert the rubber 16mm spacer at the base of the feeding

and taking spools. The 16mm spacer goes on grooved side

inwards prior to a backing plate, spool or reel.

Step 3. Additional spacers (optional)

Depending on if you are using a spool with a backing plate

or a reel, you may need to insert additional 1mm rubber

spacers to align your film with your scanner’s rollers. These

are included with your scanner. Additional 1mm spacers

are included with the 16mm kit.

the retention levers all the way up and

turn them inward.

Step 4. Mounting your film

After mounting your 16mm core or reel to the feeding spool,

and a backing plate and core to the taking spool, you’ll

need to install the outer 16mm spacer to secure the spools.

This spacer has both a notch and a rubber ring on its inside

edge to secure it to cores or reels, respectively. Once this

is in place, secure the spools as you would normally.

Step 4: Loading a 16mm reel. Shown from spindle outwards:

inner 16mm spacer, 1mm spacers, 16mm reel,

outer 16mm spacer, and core clamp

Step 5. Lacing

Complete the lacing procedure as you would for 35mm

film, with the exception of lacing your 16mm film through

the inner sprockets on the sprocket wheels. Before pressing

‘load’ or manually tensioning your 16mm film, make sure

that the film is properly threaded over the sprocket wheels’

teeth, as otherwise these teeth can damage the film.

Step 5: When loading 16mm f ilm, make sure that f ilm’s

perforations are threading cleanly over the

sprockets on the sprocket wheels.

10

Page 11

Using Cintel

Playback Controls

The following playback controls are available in DaVinci Resolve and on Blackmagic Cintel itself.

Cintel has built in controls for loading, unloading, and previewing scans.

Load

Pressing ‘load’ will tension the film loaded onto your

scanner’s feeding and taking spools as described in the

section ‘lacing film.’

Pressing load once your film is properly tensioned will

unload the film by returning the compliance arms to their

slack position.

Rewind

Press rewind to wind your film back onto the feeding

spool. Pressing this button once will rapidly rewind your

film until it reaches the threshold of a fully loaded 75mm

spool, at which point it will stop. Press rewind again to

slowly wind the the rest of your film all the way onto the

feeding spool and unload your scanner.

If you are using a 50mm spool, your scanner will still

stop at the 75mm threshold. Pressing rewind a second

time will slowly rewind until the point a 75mm spool

should have been fully rewound. If your scanner detects

that there is still film loaded at this point, it will resume

rewinding quickly until reaching the 50mm threshold,

where it will stop again. Press ‘rewind’ a third time to

completely rewind a 50mm spool.

Due to the rarity of 100mm spools, Cintel is not

programmed to stop prior to hitting the 100mm threshold.

If you are using a 100mm spool, take care with your

method of loading film onto the taking spool. It is

important to use the provided notch, rather than tape to

ensure that film unloads cleanly.

Step back

Rewinds the film one frame.

Stop

Stops playback, fast forward and rewind commands.

Play

Plays the film at either Cintel’s default 24 fps, or a frame

rate selected in the Cintel palette in DaVinci Resolve.

Step forward

Advances the film one frame.

Fast forward

Rapidly advances the film onto the taking spool. This acts

in the same way as rewind with regards to 50, 75 and

100mm spools.

11

Page 12

Using Cintel

Standby Mode

When inactive, your scanner will enter standby mode to

preserve the longevity of the light source. This happens

after 15 minutes when connected via Thunderbolt, or 1.5

minutes when not connected. Your scanner will signal that

it is entering standby mode by flashing the light source green.

Servicing

To ensure optimal scan quality, it is important to keep your

scanner clean and dust free. This is easily done by regularly

cleaning the particle transfer rollers and using an air duster

to clean the rest of your scanner’s contact surfaces.

Cleaning the particle transfer rollers

Cleaning the particle transfer rollers, or PTRs, should be

done after every film run. To clean the rollers, simply remove

the O-ring at the end of each PTR spindle and slide off the

roller. Wash the rollers in warm, soapy water using household

dishwashing detergent and allow them to air dry. We don’t

recommend towel or blow drying as this can deposit new

particles on the rollers or heat deform them. Once dry,

simply slide the rollers and O-ring back on and you’re

ready to scan.

You can easily bring your scanner out of standby mode by

initiating any movement of the feeding or taking spool,

by manually moving the spools, for instance, pressing

‘load’ or so on.

If you find your particle transfer rollers losing stickiness

even after washing, or difficult to mount and remove, you

can purchase new rollers from the Blackmagic Design

website www.blackmagicdesign.com

Dusting

Dusting your scanner should be performed daily. This is

as easy as using an air duster to remove any particles from

your scanner’s skid plate, sprocket wheels and any other

film contact surface. This is best performed with the skid

plate removed.

You may occasionally wish to clean the lens over your

scanner’s RGB light source. This can be done with a clean

cloth and a small amount of isopropyl alcohol.

Both air dusters and isopropyl alcohol are available at

most electronics stores.

Removing the particle transfer rollers for cleaning.

12

Page 13

Specifications

1055mm

2010mm

Weight : 132lbs / 6 0kg. Dimensio ns wall mo unted: ( H) 785m m, (D) 265mm

Scanner

Features

Film Stocks

- Print, Negative, Interpositive,

Internegative.

- Mono and Colour.

Film Gauges

- 35mm: 2, 3, 4 perforations

- Super 35mm: 2, 3, 4

perforations

- 16mm, Super 16mm

Native Resolution

- 4096 x 3072

Effective Resolutions

- 3840 x 2880 - Super 35

- 3390 x 2864 - Standard 35

- 3390 x 2465 - Anamorphic 35

- 1903 x 1143 - Super 16

- 1581 x 1154 - Standard 16

360mm

880mm

HDMI Formats

3840 x 2160 Ultra HD or

1920 x 1080 HD, auto selected

to match monitor resolution.

Audio

- Extraction from

scanned image.

Dirt and Scratch Reduction

- Diffuse light source

- Cleaning Rollers

Mounting Options

- Desk Mount

- Wall mount

Transport

Features

Continuous Motion

- Run speed: 1 - 30 fps

- Shuttle: 1 - 100 fps (35mm),

1 - 200 fps (16mm)

Acceleration

5 - 30 fps/s

Connections HDMI Video Output

1 x HDMI 1.4 10-bit 4:2:2

for preview purposes only

Computer Interface

Thunderbolt 2 port for capture

of image and audio.

Accessories 16mm accessory pack

Power

Requirements

Ideal Film

Conditions

Voltage Range

90 - 240V AC

Operating Temperature

18 - 28C

Film Shrinkage Tolerance

Up to 2% guaranteed, more

may be possible if user

care is taken.

Options Interface

- Programmable sync output

- Balanced line level

Analog Audio In

- AES Digital Audio In

Power

200W

Relative Humidity

Maximum 65% non - condensing

Capacity

2000ft (35mm)

13

Page 14

Help

The fastest way to obtain help is to go to the Blackmagic

Design online support pages and check the latest support

material available for your Cintel film scanner.

Blackmagic Design Online Support Pages

The latest manual, software and support notes can

be found at the Blackmagic Design support center at

www.blackmagicdesign.com/support.

Contacting Blackmagic Design Support

If you can’t find the help you need in our support material,

please use the ‘send us an email’ button on the support

page to email a support request. Alternatively, click on the

‘find your local support team’ button on the support page

and call your nearest Blackmagic Design support office.

Checking the Software Version Currently

Installed

To check which version of DaVinci Resolve is installed on

your computer, open DaVinci Resolve.

On Mac OS X, open ‘DaVinci Resolve’ within your

‘applications’ folder. The software version number

appears by clicking on the ‘About DaVinci Resolve’

menu heading under the ‘DaVinci Resolve’ menu.

On Windows 7, click the ‘start’ button>all

programs>DaVinci Resolve>DaVinci Resolve and click

the DaVinci application. The software version number

appears by clicking on the ‘About DaVinci Resolve’

menu heading under the ‘DaVinci Resolve’ menu.

To check which version of Blackmagic Desktop Video

Utility software is installed on your computer, open

Blackmagic Desktop Video Utility.

On Mac OS X, open ‘Blackmagic Desktop Video

Utility’ within your ‘applications’ folder. The software

version number appears by clicking on the ‘about

Blackmagic Desktop Video Utility’ menu heading.

On Windows 7, click the ‘start’ button>all

programs>Blackmagic Design>Desktop Video

and click the Blackmagic Desktop Video Utility

application. The software version number appears

by clicking on the ‘about Blackmagic Desktop Video

Utility’ menu heading.

On Windows 8, from the ‘start’ page type ‘Blackmagic’

and then click the Blackmagic Desktop Video Utility

application. The software version number appears

by clicking on the ‘about Blackmagic Desktop Video

Utility’ menu heading.

How to Get the Latest Updates

After checking the versions of DaVinci Resolve and

Blackmagic Desktop Video Utility installed on your

computer, please visit the Blackmagic Design support

center at www.blackmagicdesign.com/support to check

for the latest updates. While it is advisable to run the latest

updates, you should avoid updating software when in the

middle of an important project.

On Windows 8, from the ‘start’ page type ‘DaVinci

Resolve’ and then click the DaVinci Resolve

application. The software version number appears

by clicking on the ‘About DaVinci Resolve’ menu

heading under the ‘DaVinci Resolve’ menu.

14

Page 15

Safety

User interaction is required to operate Cintel, and the film

loading process is inherently hands on. However, it is still

important to be aware that moving parts can be hazardous.

Limited Warranty

Blackmagic Design warrants that this product will be free

from defects in materials and workmanship for a period of

12months from the date of purchase. If a product proves

to be defective during this warranty period, Blackmagic

Design, at its option, either will repair the defective product

without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, you the

Customer, must notify Blackmagic Design of the defect

before the expiration of the warranty period and make

suitable arrangements for the performance of service. The

Customer shall be responsible for packaging and shipping

the defective product to a designated service center

nominated by Blackmagic Design, with shipping charges

pre paid. Customer shall be responsible for paying all

shipping charges, insurance, duties, taxes, and any other

charges for products returned to us for any reason.

This warranty shall not apply to any defect, failure or damage

caused by improper use or improper or inadequate

maintenance and care. Blackmagic Design shall not be

obligated to furnish service under this warranty: a) to repair

damage resulting from attempts by personnel other than

Blackmagic Design representatives to install, repair or

service the product, b) to repair damage resulting from

improper use or connection to incompatible equipment, c)

to repair any damage or malfunction caused by the use of

non Blackmagic Design parts or supplies, or d) to service

a product that has been modified or integrated with other

products when the effect of such a modification or integration

increases the time or difficulty of servicing the product.

Be sure to keep fingers and other body parts clear of your

scanner when film is scanning.

THIS WARRANTY IS GIVEN BY BLACKMAGIC DESIGN IN

LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED.

BLACKMAGIC DESIGN AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. BLACKMAGIC DESIGN’S

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE WHOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR ANY INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER BLACKMAGIC DESIGN OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILIT Y

OF SUCH DAMAGES. BLACKMAGIC DESIGN IS NOT LIABLE

FOR ANY ILLEGAL USE OF EQUIPMENT BY CUSTOMER.

BLACKMAGIC IS NOT LIABLE FOR ANY DAMAGES

RESULTING FROM USE OF THIS PRODUCT. USER

OPERATES THIS PRODUCT AT OWN RISK.

© Copyright 2015 Blackmagic Design. All rights reserved. ‘Blackmagic Design’

and ‘Cintel’, are regi stered trademarks in the US and other countries. A ll other

compan y and product n ames may be trade marks of their respec tive compan ies

with which they are associated.

Thunderbolt and the Thunderbolt logo are trademarks of Intel Corporation in

the U.S. and/or other countries.

15

Loading...

Loading...