Page 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed

during all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating

the instrument at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specied by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety

standards of design, manufacture, and intended use of the instrument. B&K Precision assumes no

liability for a customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard denes safety category ratings that specify the amount of electrical energy

available and the voltage impulses that may occur on electrical conductors associated with these category

ratings. The category rating is a Roman numeral of I, II, III, or IV. This rating is also accompanied by a

maximum voltage of the circuit to be tested, which denes the voltage impulses expected and required

insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be

connected to the mains supply. The voltages in the environment are typically

derived from a limited-energy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected

to the mains supply at a standard wall outlet or similar sources. Example

measurement environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be

connected to the mains installation of a building. Examples are measurements

inside a building’s circuit breaker panel or the wiring of permanently-installed motors.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

3

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be

connected to the primary power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specied

in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or

higher than the instrument’s category rating to maintain the instrument’s category rating. Failure to do

so will lower the category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains

power should be 115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and

ensure it is appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety

ground. This instrument is grounded through the ground conductor of the supplied, three-conductor AC

line power cable. The power cable must be plugged into an approved three-conductor electrical outlet.

The power jack and mating plug of the power cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible

conductive parts (including control knobs) may provide an electric shock. Failure to use a properlygrounded approved outlet and the recommended three-conductor AC line power cable may result in

injury or death.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

4

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference

of potential only and is not to be used as a safety ground. Do not operate in an explosive or ammable

atmosphere.

Do not operate the instrument in the presence of ammable gases or vapors, fumes, or nely-divided

particulates.

The instrument is designed to be used in oce-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or ammable fumes, gases, vapors, chemicals, or nely-divided

particulates.

• In relative humidity conditions outside the instrument’s specications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any

liquid can condense on the instrument.

• In air temperatures exceeding the specied operating temperatures.

• In atmospheric pressures outside the specied altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air ow, even if the air temperatures are within specications.

• In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating

temperature range is 0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed.

Measurements made by this instrument may be outside specications if the instrument is used in nonoce-type environments. Such environments may include rapid temperature or humidity changes, sunlight,

vibration and/or mechanical shocks, acoustic noise, electrical noise, strong electric elds, or strong

magnetic elds.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on

or inside the instrument, remove the instrument’s power cord, remove the instrument from service, label

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

5

it as not to be operated, and return the instrument to B&K Precision for repair. Notify B&K Precision of

the nature of any contamination of the instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants,

solvents, acids/bases, or other such chemicals. Clean the instrument only with a clean dry lint-free cloth

or as instructed in this manual. Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a

life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal

adjustments must be made by qualied service-trained maintenance personnel who are aware of the

hazards involved when the instrument’s covers and shields are removed. Under certain conditions,

even with the power cord removed, dangerous voltages may exist when the covers are removed. To

avoid injuries, always disconnect the power cord from the instrument, disconnect all other connections

(for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there are

no hazardous voltages present on any conductors by measurements with a properly-operating voltagesensing device before touching any internal parts. Verify the voltage-sensing device is working properly

before and after making the measurements by testing with known-operating voltage sources and test for

both DC and AC voltages. Do not attempt any service or adjustment unless another person capable of

rendering rst aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition

in the circuit exists.

Fuse replacement must be done by qualied service-trained maintenance personnel who are aware of

the instrument’s fuse requirements and safe replacement procedures. Disconnect the instrument from

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

6

the power line before replacing fuses. Replace fuses only with new fuses of the fuse types, voltage

ratings, and current ratings specied in this manual or on the back of the instrument. Failure to do so

may damage the instrument, lead to a safety hazard, or cause a re. Failure to use the specied fuses

will void the warranty.

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the

instrument to B&K Precision for service and repair to ensure that safety and performance features are

maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air ow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other

European countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste electrical

and electronic equipment (WEEE), and in jurisdictions adopting that

Directive, is marked as being put on the market after August 13, 2005,

and should not be disposed of as unsorted municipal waste. Please

utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Safety Symbols

Symbol Description

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, will result in minor or

moderate injury.

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

7

Chassis ground

Earth ground

Indicates the In position of the power switch when instrument is ON.

Indicates the Out position of the power switch when instrument is OFF.

Indicates practices not related to physical injury.

Table 1 Safety Symbols

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

Contents

1 Introduction 11

1.1 Product Overview 11

1.2 Contents 12

1.3 Features 12

1.4 Dimensions 13

1.5 Rackmount Installation 14

1.6 Front Panel 15

1.7 Display 16

1.8 Rear Panel 17

2 Getting Started 18

2.1 Input Power and Fuse Requirements 18

2.2 Fuse Requirements 19

2.3 Check or Replace Fuse 19

2.4 Preliminary Check 21

2.5 Self test Errors 22

3 Basic Front Panel Operation 23

3.1 Keys 23

3.1.1 Main Keys 23

3.1.2 Soft Keys 24

3.1.3 Numeric Keys 24

3.1.4 Output Control 24

3.2 Display 25

3.3 Check Model and Firmware Version 28

3.4 Setting Voltage and Current 29

4 Output Conguration 30

4.1 Protection Settings 30

4.1.1 Over Voltage Protection (OVP) 30

4.1.2 Over Current Protection (OCP) 30

4.1.3 Over Temperature Protection & Over Temperature Warning (OTP & OTW) 30

4.1.4 Vmax/Vmin 31

4.1.5 Protection Clear 31

4.2 Output Settings 31

4.2.1 Remote Sense 31

4.2.2 Output Timer 32

4.2.3 Voltage Slew 33

4.2.4 Current Slew 33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

9

4.2.5 On/O Delay 33

4.3 Operating Mode and Coupling 34

4.3.1 Normal Mode 34

4.3.2 Series Mode 36

5 List Mode 47

5.1 List Setup 47

5.2 Edit List 49

5.2.1 Load/Save List 50

5.2.1 List Number 51

5.2.2 Next 52

5.2.3 Repeat 52

5.2.4 Steps 52

5.3 List Run 55

6 Data Logger 58

6.1 Using the Data Logger Function 58

6.2 Parameters 59

6.2.1 Sampling Interval 59

6.2.2 File Path 59

6.2.3 T. Stamp Filename 59

6.2.4 Log Data 60

6.2.5 Status Code 61

6.2.6 Trigger Source 61

6.2.7 Datalog Start/Stop 62

7 Utilities Menu 63

7.1 User Settings 63

7.1.1 Key Lock Output 63

7.1.2 Beep Sound 63

7.1.3 Date 64

7.1.4 Time 64

7.1.5 Screen Intensity 64

7.1.6 Language 64

7.2 Remote Interface 65

7.2.1 USB Settings 66

7.2.2 LAN 67

7.3 GPIB (optional) 73

7.4 Digital I/O 74

7.4.1 Functions 75

7.4.1 Polarity 76

7.4.1 Inhibit Mode 76

7.5 Test/Admin 77

7.5.1 Self Test 77

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

10

7.5.2 Security 77

7.6 Error Log 79

7.7 Help 81

7.8 On Screen Help 82

8 Key Lock 83

9 Save/Recall 84

9.1 Save the Output Settings 84

9.2 Recall the Instrument’s Settings 85

9.3 Power-On Settings 86

9.4 Screenshot 87

10 Calibration Adjustment Procedure 89

10.1 Voltage Calibration Adjustment 90

10.2 Current Calibration Adjustment 91

10.3 OVP Calibration Adjustment 92

10.4 OCP Calibration Adjustment 93

10.5 RTC Calibration Adjustment 94

11 Performance Verication 95

12 Specications 98

13 Service Information 99

14 LIMITED THREE-YEAR WARRANTY 100

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Introduction

1.1 Product Overview

9140: 32 V / 8 A / 300 W 9141: 60 V / 4 A / 300 W

Figure 1.1 Front View

The 9140 Series triple output multi-range DC power supplies combine industry-leading power density

and performance with an extensive set of features in a compact 2U form factor.

Three isolated output channels each produce 100 W of clean power with exceptionally low ripple and

noise characteristics. Combine channels to output up to 300 W, distributing the power across all three

channels. Multiple outputs paired with advanced list mode programming, data logging, and protection

features make these power supplies suitable for a wide range of benchtop or test system applications.

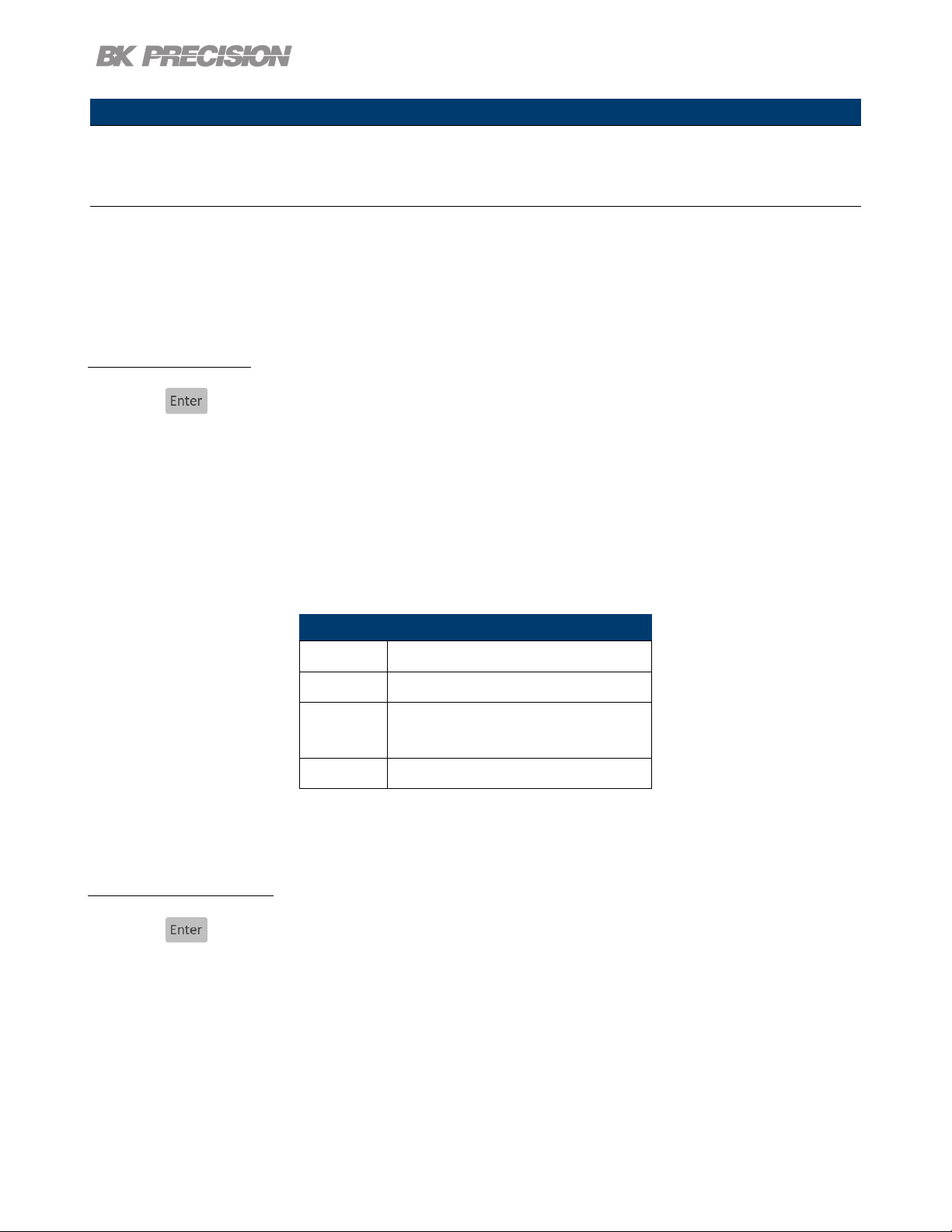

Model 9140 9141

Voltage per Channel 0 to 32 V 0 to 60 V

Current per Channel 0 to 8 A 0 to 4 A

Maximum Power per Channel 100 W

Maximum Combined Power 300 W

Table 1.1 Models

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Introduction 12

1.2 Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from the

shipping carton, and check for any obvious signs of physical damage that may have occurred during

transportation. Report any damage to the shipping agent immediately. Save the original packing carton

for possible future reshipment. Every power supply is shipped with the following contents:

• 1 x 9140 or 9141 Power Supply

• 1 x AC Power Cord

• 1 x Certicate of Calibration

• 1 x Test Report

Note:

Ensure the presence of all the items above. Contact

the distributor or B&K Precision if anything is missing.

1.3 Features

• Three independent galvanically isolated, oating output channels providing up to 100 W per channel

or 300 W total when combining all three channels

• High power density, compact 2U half-rack form factor

• Multi-ranging operation delivers rated power at various voltage/current combinations

• Combine outputs in parallel or series to increase current or voltage (up to 24 A or 180 V depending

on the model)

• Advanced list mode programming with internal storage for up to 10 list mode programs and list

sequencing capabilities

• Digital I/O block oers external triggering, voltage fault and remote inhibit capabilities

• Overvoltage (OVP), overcurrent (OCP), overtemperature (OTP), and includes a key-lock function

• NISPOM-compliant sanitization procedure to securely erase and return the instrument to factory

settings

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Introduction 13

• USB (USBTMC-compliant) and LXI compliant LAN interfaces standard, GPIB optional

• LabVIEW

𝑇 𝑀

, IVI-C, and IVI.NET drivers provided

1.4 Dimensions

The 9140 power supply’s dimensions are approximately:

213 mm (8.4 in) x 88.2 mm (3.47 in) x 330 mm (13 in) (W x H x D).

Figure 1.2 Dimensions

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Introduction 14

1.5 Rackmount Installation

The 9140 Series is compatible with the optional 19-inch rackmount kit model RK2US. The RK2US

installation instructions can be downloaded from bkprecision.com

Figure 1.3 Dimensions

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

1.6 Front Panel

Introduction 15

Figure 1.4 Front Panel

Item Name Description

1 Power Button Power the instrument ON or OFF

2 Function Keys See section ?? for details.

3 USB Host Port USB port used to connect ash drives.

4 Display Visual presentation of the device function and measurements.

5 Numeric Keypad Used to enter precise values.

6 Rotary Knob Used to navigate menues or congure parameters.

7 Output

8 Soft Keys Used to invoke any functions displayed above them.

Isolated and oating output channel supporting sheathed banana

plugs and spade lug type connectors

Table 1.2 Front Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

1.7 Display

Icon Description

Introduction 16

The output is disabled.

The output is enabled and in constant voltage mode

The output is enabled and in constant current mode

Data loggin is enabled but not recording.

Data logging is enabled and recording.

The instrument is connected to a network.

An issue occured when attempting to connect to a network.

The instrument is not connected to a network.

All keys excluding softkey F6 are locked.

Over voltage protection was triggered.

Over current protection was triggered.

Over temperature protection was triggered.

The instrument is set to remote mode

Remote sense is enabled.

Remote

Table 1.3 Display Icons

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

1.8 Rear Panel

Introduction 17

Figure 1.5 Rear Panel

Item Name Description

1 Output/Sense

2

3

4 Digital I/O Send or receive a signal to or from an external device.

5 USB interface Connect a USB type B to type A to remotely control the unit.

6 LAN interface

7 Chassis ground

8

Kensington

security slot

GPIB Interface

(Optional)

AC power input

& fuse box

Rear panel output with remote sense. Internal relays switch between

local and remote sensing.

Lock the instrument to a xed location using the security lock via the

lock hole. Lock is not included.

Connect a GPIB cable to remotely control the unit `

Connect a Cat 5/6 Ethernet straight-through patch cable to remotely

control the unit.

Provides a zero potential voltage reference and a dissipation point for

interference, transient voltages and static.

Houses the fuse as well as the AC input.

Table 1.4 Rear Panel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Getting Started

Before connecting and powering up the instrument, please review and go through the instructions in this

chapter.

2.1 Input Power and Fuse Requirements

The supply has a universal AC input that accepts line voltage input within:

9140 9141

AC Line Input 100 - 240 VAC±10%, 47 to 63 Hz

AC Line Phase Single Phase

Maximum Rated

Input Power

Before connecting to an AC outlet or external power source, be sure that the power switch is in the OFF

position and verify that the AC power cord, including the extension line, is compatible with the rated

voltage/current and that there is sucient circuit capacity for the power supply. Once veried, connect

the cable rmly.

The included AC power cord is safety certied for this instrument operating in rated range. To

change a cable or add an extension cable, be sure that it can meet the required power

ratings for this instrument. Any misuse with wrong or unsafe cables will void the warranty.

500 VA

SHOCK HAZARD

The power cord provides a chassis ground through a third conductor. Verify that your

power outlet is of the three-conductor type with the correct pin connected to earth ground.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Getting Started 19

2.2 Fuse Requirements

An AC input fuse is necessary when powering the instrument. The below table shows the fuse required

for all models.

Model Fuse Specication

9140 3.15 AT, 250 V

9141 3.15 AT, 250 V

2.3 Check or Replace Fuse

For safety, no power should be applied to the instrument while changing line voltage

operation. Disconnect all cables connected to the instrument before proceeding.

– Locate the fuse box next to the AC input connector in the rear panel. (See gure 1.5)

– Insert a small athead screwdriver into the fuse box slit to pull and slide out the fuse box as indicated

below.

– Check and replace fuse if necessary. (See gure 2.1)

Figure 2.1 Fuse Removal

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

Getting Started 20

Any disassembling of the case or changing the fuse not performed by an

authorized service technician will void the warranty of the instrument

SHOCK HAZARD:

Hazardous voltages may exist at the outputs and the load connections when using a power supply

with a rated output greater than 60 V. To protect personnel against accidental contact with hazardous

voltages, ensure that the load and its connections have no accessible live parts. Ensure that the load

wiring insulation rating is greater than to the maximum output voltage of the power supply.

The rear output terminals can accept wire sizes AWG 24 to AWG 12 (See Table 2.1).However, we

recommend using 12 AWG if current output is between 5 to 10 A. Refer to Table 2 below to determine

the proper wire size.

Wire Gauge Rating

AWG 10 12 14 16 18 20 22 24 26 28

Imax (A) 40 25 20 13 10 7 5 3.5 2.5 1.7

mΩ/meter 3.3 5.2 8.3 13.2 21 33.5 52.8 84.3 133.9 212.9

Table 2.1 Wire Gauge Rating

Output Isolation

The output terminals of the 9240 Series are isolated from earth ground. An earth ground terminal is

provided on the front panel for convenience. Any output terminal may be grounded. However, output

terminals must not exceed ±200 VDC.

SHOCK HAZARD:

Floating voltage must not exceed 200 VDC.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

2.4 Preliminary Check

Complete the following steps to verify the Power supply is ready for use.

Getting Started 21

Verify AC

Input Voltage

Connect Power

& Self-Test

After Power on, during the self-test, the following should be displayed:

Verify and check to make sure proper AC voltages are available to power the

instrument. The AC voltage range must meet the acceptable specication as

explained in section “2.1 Input Power and Fuse Requirements”.

Connect AC power cord to the AC receptacle in the rear panel and press the

power button. It will run through a self-test procedure initially before booting to

the main screen.

Figure 2.2 Initializing

After the system scan is complete the LCD will display as shown in Figure 2.3

Note:

The initial power on state is based on the settings set on Power-ON

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

2.5 Self test Errors

Getting Started 22

Figure 2.3 Home Display

The following errors will be displayed if the self-test did not complete successfully:

Error Message Description

EEPROM Fail The internal EEPROM is corrupted or damaged.

System Lost Last system settings within the EEPROM are lost.

Module Fail Channel response failure.

Cal Lost Calibration data within the EEPROM is lost.

Fact Loss Factory calibration data is lost.

Model Lost Channel initialization failed.

Table 2.2 Error Message

If any of these errors occur, please contact B&K Precision.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Basic Front Panel Operation

At power-on, the power supply will automatically enter the front-panel operation mode and the instrument

can be controlled via the front panel keys and knob.

3.1 Keys

3.1.1 Main Keys

There are three main keys:

Navigates the 5 available screens.

When navigating any menu

returns the key will return "Home"

main display

5 available displays:

– Main page:

Overview of the 3 outputs.

– Single Channel Display 1 to

3: Detailed channel overview.

– Live Output Monitoring:

Oscilloscope like overview

of the measured output

parameters.

More information on each display in 3.2.

Opens up a menu giving access

to various save and load options,

regardless of the current display

of the screen.

Opens the main menu bar. If

a menu bar is already open,

pressing will navigate to

the main menu bar.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Basic Front Panel Operation 24

3.1.2 Soft Keys

The unit has six soft keys, which are located beneath the screen. Each key selects the corresponding

function. Functions will vary depending on the current menu or display.

Figure 3.1 Soft Keys

3.1.3 Numeric Keys

The numeric keys allow the conguration of various parameters. Using the numeric keys provides a fast

and precise input. The key can be found with the numeric keys. Pressing enter will assign the

selected value to the desired parameter.

Figure 3.2 Numeric Keys

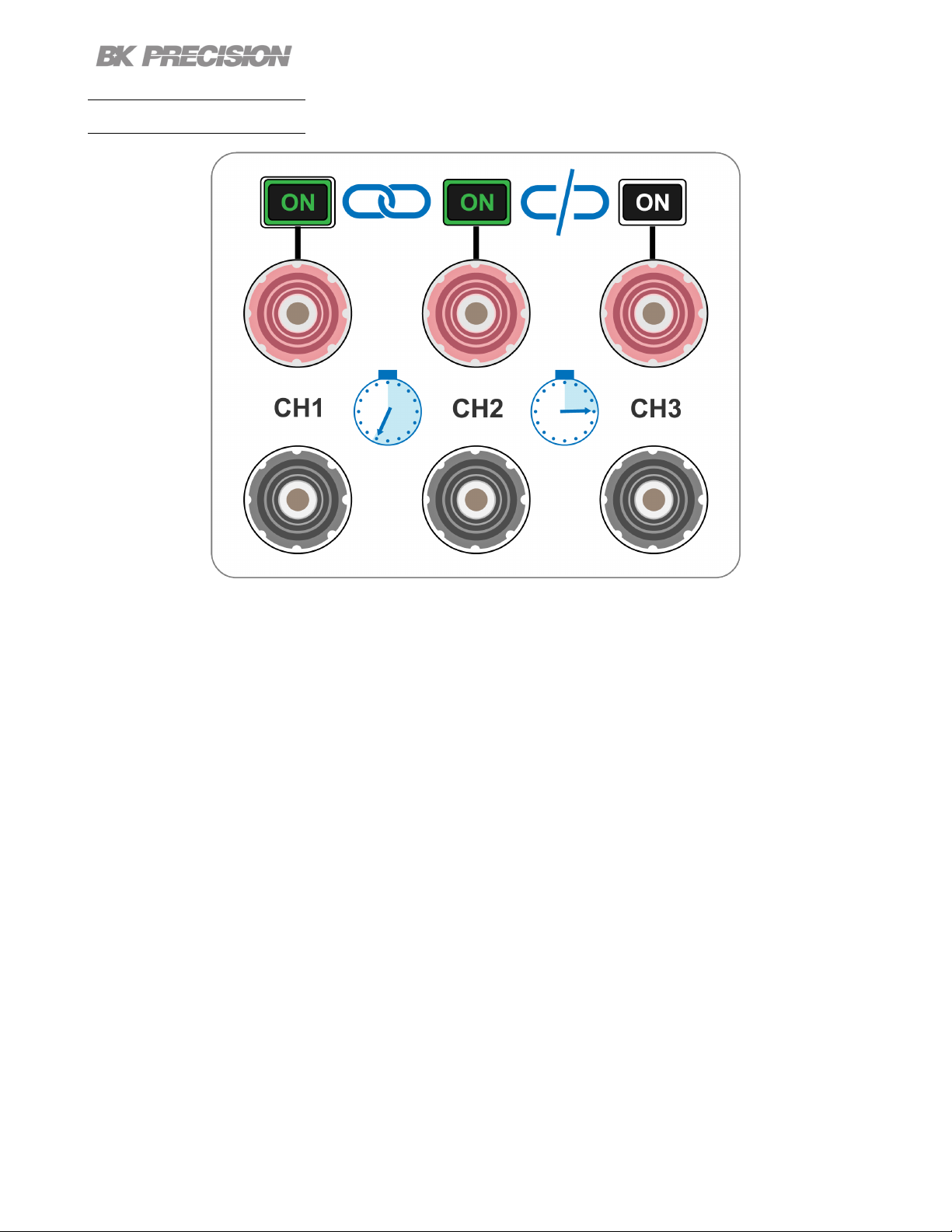

3.1.4 Output Control

The button toggles the output On/O. When output is enabled, the ON button will turn green

and the supply will display the state of the channel.

represents constant current mode. represents constant voltage mode. This is indicated for

each channel independently. When output is disabled, the channel state will display .

The key toggles all the channels On/O simultaneously. Its function may vary depending on the

coupling state of the channels. For more information go to Coupling.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Basic Front Panel Operation 25

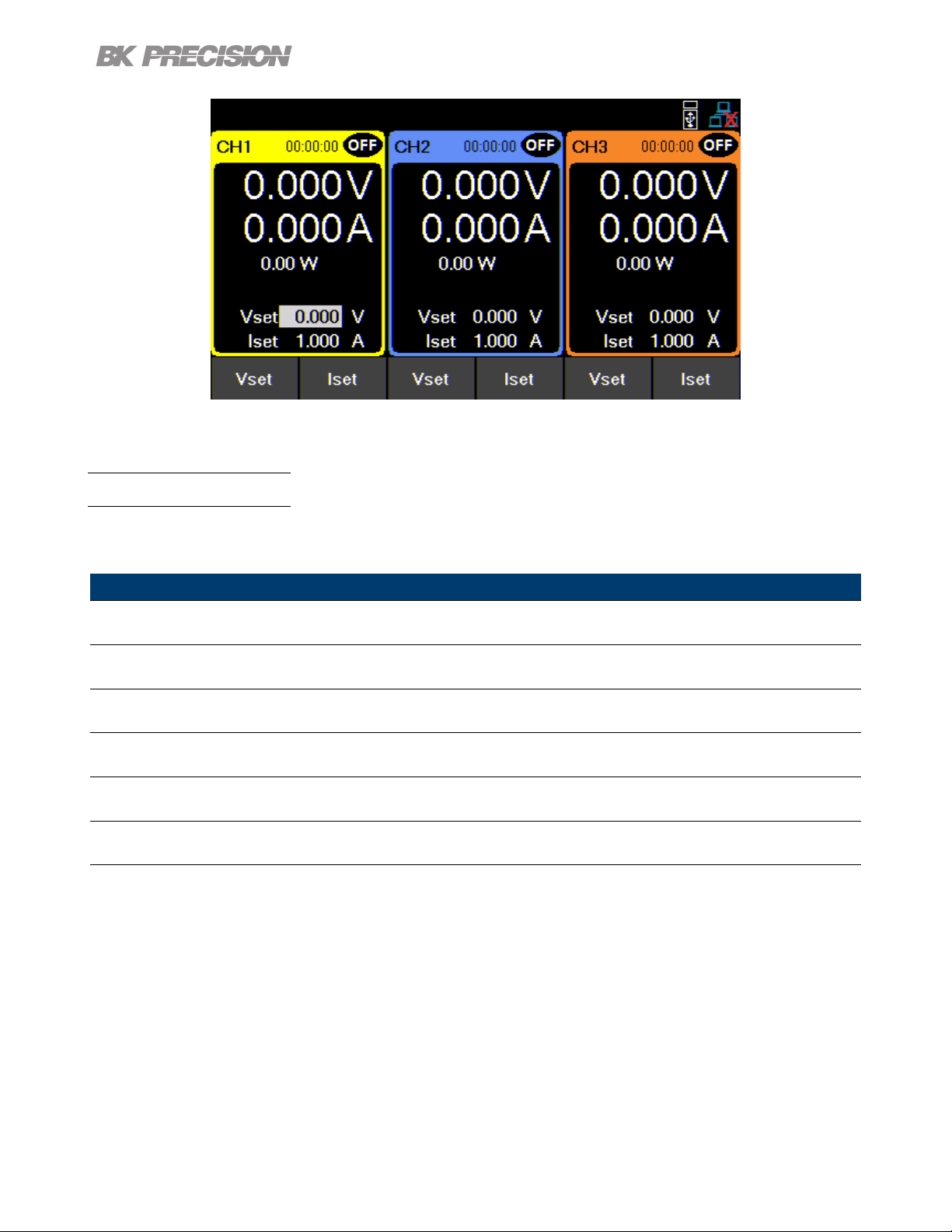

3.2 Display

These power supplies have three main display modes: three channel display, single channel display, and

live output monitoring display. Press the button to cycle between the dierent display modes or to

return home when viewing any other menu.

Three Channel Display

Provides information of the outputs’:

• State

• Run time

• Voltage

• Current

• Power

Allows conguration of:

• Vset

• Iset

Figure 3.3 Three Channel Display

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Single Channel Display

Basic Front Panel Operation 26

Provides information of the outputs’:

• State

• Run time

• Voltage

• Current

• Power

• Vmax/Vmin

• OVP/OCP

• OnDelay/ODelay

Allows conguration of:

• Vset

• Iset

• Vmax/Vmin

• OVP/OCP

• OnDelay/ODelay

Figure 3.4 Single Channel Display

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Basic Front Panel Operation 27

Live Output Monitoring

The live output monitoring display shows metered output voltage and current over time.

It is always active and will continuously plot and overwrite the oldest value when the display graph is full.

Figure 3.5 Live Output Monitoring Display

The Live output display can be congured by setting the: Voltage, Current, and Time Scale.

Voltage Scale

The voltage scale of each output can be set from 10 mV/Div up to 20 V/Div.

1. While in Live Output Display use the softkeys to select Voltage Scale.

2. Select a channel to congure.

3. Use the rotary knob to navigate through the available scales.

Current Scale

The current scale of each output can be set from 10 mA/Div up to 3 A/Div.

1. While in Live Output Display use the softkeys to select Current Scale.

2. Select a channel to congure.

3. Use the rotary knob to navigate through the available scales.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Basic Front Panel Operation 28

Time Scale

The time scale of each output can be set from 1 s/Div up to 10 min/Div.

1. While in Live Output Display use the softkeys to select Time Scale.

2. Use the rotary knob to navigate through the available scales.

Voltage Oset

A voltage oset can be added to each output. The oset can be set from 0 V up to 60.6 V on the 9141

and 0 V up to 32.2 V on the 9140.

1. While in Live Output Display use the softkeys to select Voltage Oset.

2. Select a channel to congure.

3. Use the rotary knob to navigate through the available scales.

Current Oset

A current oset can be added to each output. The oset can be set from 0 A up to 4.4 A on the 9141

and 0 A up to 8.8 A on the 9140.

1. While in Live Output Display use the softkeys to select Current Oset.

2. Select a channel to congure.

3. Use the rotary knob to navigate through the available scales.

3.3 Check Model and Firmware Version

The rmware version, model, and serial number can be veried by entering the security settings. Press

button then use the soft keys to select Utilities > Help > System Info to view model and rmware

information.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Basic Front Panel Operation 29

3.4 Setting Voltage and Current

Follow the steps below to set the output voltage or current. The values can be entered using the numeric

keypad or the rotary knob.

1. Using the keypad: Use the soft keys to select the channel VSET or ISET settings beneath channel

view on the display. Then use the numeric keypad to input the voltage or current value then press

to conrm.

2. Using the rotary knob: Use the soft keys to select the channel VSET or ISET settings beneath

the channel view on display. Then turn the knob clockwise to increment or counter-clockwise to

decrement the value.

a. Use the below the rotary knob to move the cursor. Press the knob in to conrm.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Output Conguration

4.1 Protection Settings

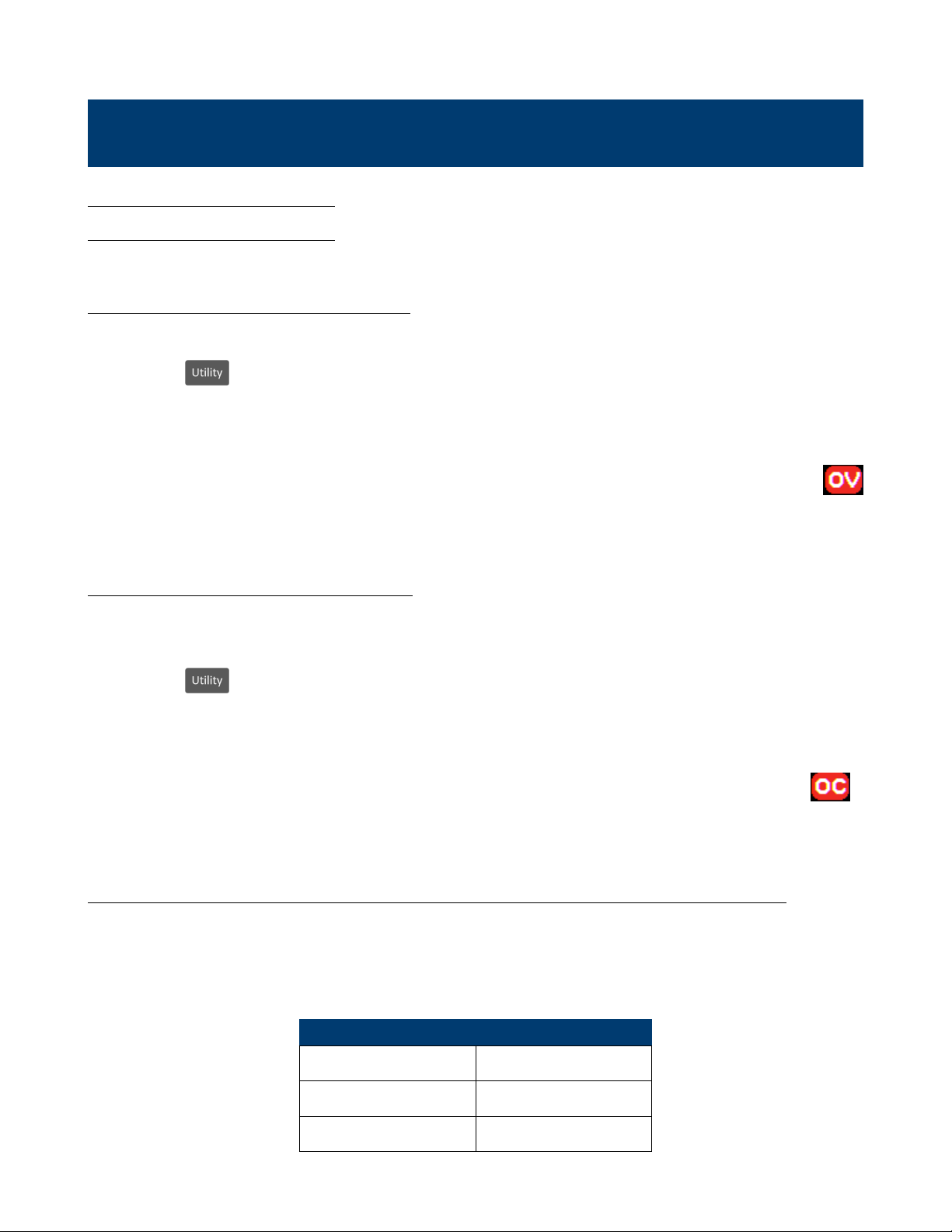

4.1.1 Over Voltage Protection (OVP)

Over voltage protection is always enabled, however the user can set the OVP voltage limits.

1. Press the button then use the soft keys to select Output cong > Protection settings

2. Use the soft keys to select a channel to adjust.

3. Select OVP Limit.

4. Use the numeric keypad or rotary knob to set the desired OVP limit.

When OVP protection is tripped during operation, the output will be de-rated to 0 V and the icon

will appear between the wattage and Vset.

4.1.2 Over Current Protection (OCP)

Over current protection state and limit can be set in the protection settings.

1. Press the button then use the soft keys to select Output cong > Protection settings

2. Use the soft keys to select a channel to adjust.

3. Press OCP State to toggle the over current protection on or o.

4. Select OCP Limit and use the numeric keypad or rotary knob to set limit value.

When OCP protection is tripped during operation, the output will be de-rated to 0 V and the icon

will appear between the wattage and Vset.

4.1.3 Over Temperature Protection & Over Temperature Warning (OTP & OTW)

The state and limit of both OTP & OTW cannot be set or congured in the protection settings. OTP is set

to 85 °C and OTW is set to 75 °C. If the temperature reaches either OTW, the OT icon will blink on the

display with a low period beep sound. If temperature reaches OTP the OT icon will show on the display

and the output will turn o. The output will not be allowed to turn on until the temperature drops to 75 °C.

Fan Speed Control

2 A 0%

2 to 5 A 25%

5 A 100%

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Output Conguration 31

4.1.4 Vmax/Vmin

Congure the maximum or minimum voltage value the user can set from the protection

settings.

1. Press the button then use the soft keys to select Output cong >

Protection settings

2. Use the soft keys to select a channel to adjust.

3. Select Vmax or Vmin and set a maximum or minimum value using the numeric keypad or rotary knob.

4.1.5 Protection Clear

Protections are cleared from the output conguration settings as shown in the following steps.

1. Press the button then use the soft key to select Output cong >

Protection Clear.

2. Press the soft key to clear the protection for the corresponding channel, or select

All CH Clear to clear protections on all three channels.

4.2 Output Settings

4.2.1 Remote Sense

Remote sense can be used to compensate for voltage drops (up to 1 V) due to resistance from test leads

connected to your device under test (DUT), thus providing more accurate output voltage. When remote

sense is enabled, the positive (+S) and positive lead (+) of the DC output are connected to the positive

(+) of the load. Similarly, the negative sense (-S) and negative lead (-) of the DC output are connected

to the negative (-) end of the load shown in gure 4.1

Figure 4.1 Remote Sense

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Output Conguration 32

Never connect any power source into any of the terminals at any time during operation.

When output is enabled, DO NOT use your hands to touch the terminals or the screws that are

designed to tighten wires to the terminals. Doing so may create a shock hazard under high

voltage output conditions.

DO NOT at any time disconnect the wires from the S+ and S- terminals to the DUT while output

is enabled (ON). Doing so may damage the power supply and cause unstable output.

Remote sense is disabled by default, see the following steps to enable remote sense:

1. Press the button then use the soft key to select Output cong > Output Settings.

2. Select a desired channel to congure.

3. Press Remote Sense using the soft key to enable remote sense.

4.2.2 Output Timer

Output timer can be set for each channel individually. When the output timer is enabled, an hourglass

icon will be displayed next to the channel number. The timer countdown will begin when the channel

output is enabled. The output is disabled when the countdown reaches 0. The timer can be set from 1

second to 99 hours 59 minutes and 59 seconds.

Follow the steps below to enable and set the output timer:

1. Press the button then use the soft key to select Output cong > Output Settings.

2. Select a desired channel to congure. Push Timer State to enable the timer.

3. Select Timer Setting and set a desired time for the output to be enabled using the numeric keypad or

rotary knob. The timer format is: HH:MM:SS. Use the keys to move the cursor.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Output Conguration 33

4.2.3 Voltage Slew

The rising voltage slew rate can be set in volts per second. The voltage slew range can be set from

0.001 V/s to 3200.0 V/s.

1. Press the button then use the soft key to select Output cong > Output Settings.

2. Select a desired channel to congure.

3. Select Voltage Slew and use the numeric keypad or rotary knob to adjust the slew rate value. Press

to conrm input.

4.2.4 Current Slew

The rising current slew rate can be set in amps per second. The current slew range can be set from

1 A/s to 800 A/s.

1. Press the button then use the soft key to select Output cong > Output Settings.

2. Select a desired channel to congure.

3. Select Next Pg. > Current Slew and use the numeric keypad or rotary knob to adjust the slew rate

value. Press to conrm input.

4.2.5 On/O Delay

A channel on or o delay in seconds can be applied to any channel. These delays can be set from

0.001 s to 3600.0 s.

1. Press the button then use the soft key to select Output cong > Output Settings.

2. Select a desired channel to congure.

3. Select Next Pg. > On Delay to set an on delay or O Delay to set an o delay.

4. Use the numeric keypad or rotary knob to adjust the delay value. Press to conrm input.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

Output Conguration 34

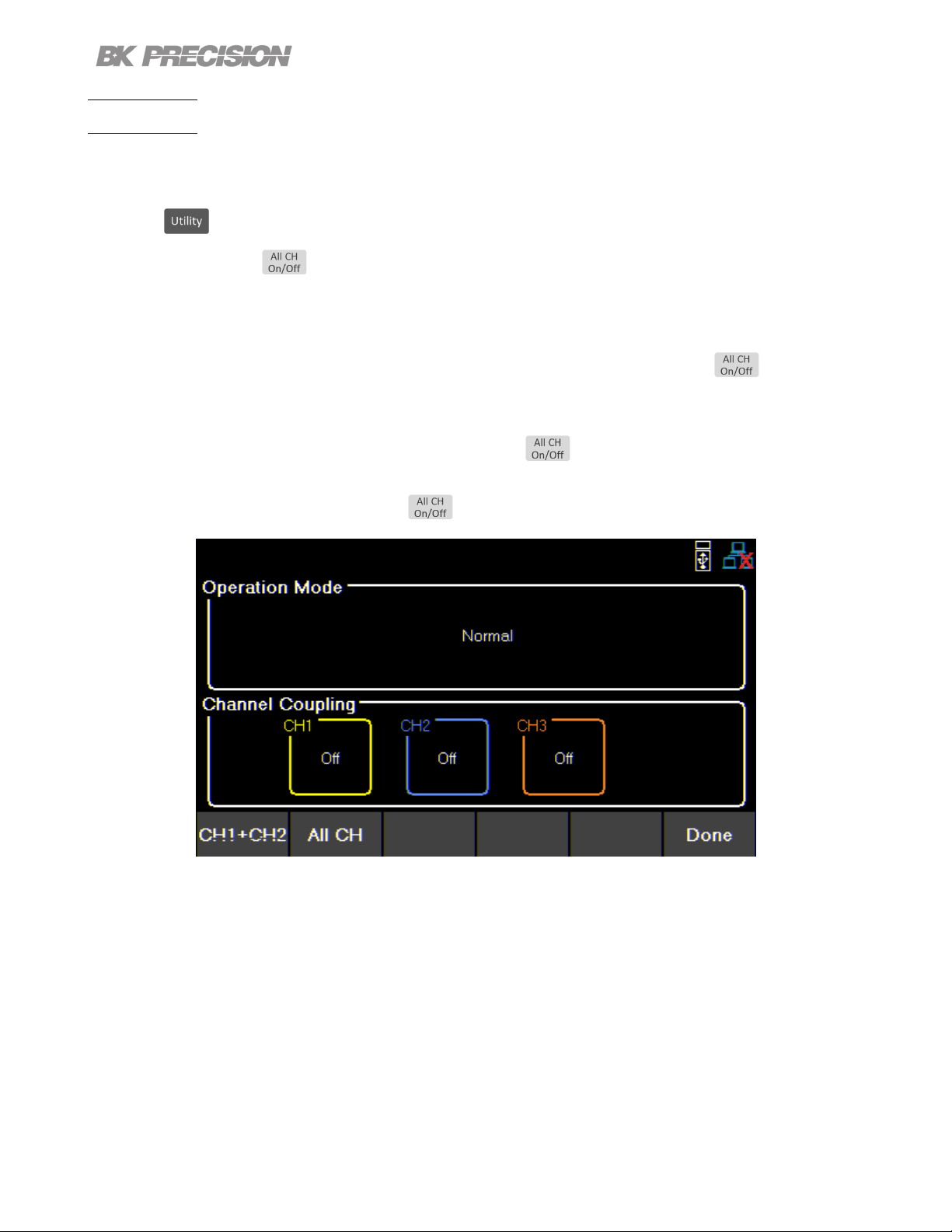

4.3 Operating Mode and Coupling

Set the operation mode or coupling.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode.

4.3.1 Normal Mode

Sets operation mode to Normal.

Normal mode sets the instrument to operate as a true triple output power supply.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling >

Operation Mode > Normal.

9140 9141

Individual CH Individual CH

32 V 8 A 60 V 4 A

Figure 4.2 Normal Mode

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

In Normal mode the main page will display the three outputs.

Toggles through CH1, CH2, CH3, and live output monitoring display.

Output Conguration 35

Figure 4.3 Normal Mode Main Page

Single CH displays more information about the output, and allows conguration of more parameters.

Figure 4.4 Single Channel

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Output Conguration 36

4.3.2 Series Mode

Set operation mode to Series.

Series mode changes the UI to accurately represent the possible outputs congurations.

Series mode does not internally wire the outputs. The outputs must be connected externally to increase

the available voltage range.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode > Series.

The image below illustrates the external wiring required to connect all channels in series. If CH1+ CH2

is chosen CH2’s positive terminal does not connect to CH3’s negative terminal.

Series CH1+2 Series All

9140 9141

CH1 + CH2 All CHs CH1 + CH2 All CHs

64 V 96 V 120 V 180 V

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Output Conguration 37

CH1 + CH2

Operation mode will be set to Series 1 + 2. Changing operation mode will undo previous coupling

conguration.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode > Series > CH1 + CH2.

Figure 4.5 Series 1+2

In Series CH1 + 2 the main page will display the output of the combined outputs, as well as the output

of the individual CH3. The button will toggle through single channel display for Series CH1 + 2,

CH 3, and live output monitoring.

Figure 4.6 Series CH1+2 Main Page

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Output Conguration 38

Single CH displays more information about the output, and allows conguration of more parameters.

The voltage congurations will now range from 0 v to 64 V for model 9140 and 0 V to 120 V for model

9141.

Figure 4.7 Series CH1+2 Single Channel Display

Protection Setting menu will also adjust the congurable values.

Figure 4.8 Series CH1+2 Protection Settings

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Output Conguration 39

Series All

Operation mode will be set to Series All. Coupling will not be available in Series All mode.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode > Series > Series All.

Figure 4.9 Series All

In Series All mode will only toggle between the Series All display and live output monitoring.

Series All CH display will adjust to voltage conguration between 0 V and 96 V for model 9140 and 0 V

to 180 V for model 9141.

Figure 4.10 Series All Main Page

Protection Setting menu will also adjust the congurable values.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Output Conguration 40

Parallel Mode

Set operation mode to Parallel.

Parallel Mode does not internally wire the outputs. The outputs must be connected externally to increase

the available current range.

Parallel Mode changes the UI to accurately represent the possible output congurations.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode > Parallel.

The image below illustrates the external wiring required to connect all channels in Parallel. If CH1+ CH2

is chosen CH2’s terminals do not connect to CH3’s terminals.

Parallel CH1+2

Parallel All

9140 9141

CH1 + CH2 All CHs CH1 + CH2 All CHs

16 A 24 A 8 A 12 A

Table 4.1 Parallel Mode

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Output Conguration 41

CH1 + CH2

Operation mode will be set to Parallel 1 + 2. Selecting an operation mode will undo previous coupling

conguration.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling > Operation

Mode > Parallel > CH1 + CH2.

Figure 4.11 Parallel CH 1+2

In Parallel CH1 + 2 Mode the main page will display the output of the combined outputs, as well as the

output of the individual CH3. The button will toggle through single channel display for Parallel CH1

+ 2, CH 3, and live output monitoring.

Figure 4.12 Parallel CH 1+2 Main Display 9141

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

Output Conguration 42

The Single CH display will adjust to allow current conguration between .030 A to 16 A for model 9140

and .030 A to 8 A for model 9141.

Figure 4.13 Parallel CH 1+2 Single Channel Display

Protection Setting menu will also adjust the congurable range of each parameter.

Figure 4.14 Parallel CH 1+2 Protection Settings

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Output Conguration 43

Parallel All

Operation mode will be updated based on selected mode. Coupling is not available.

Figure 4.15 Parallel All Operation Mode

In Parallel All Mode the button will only toggle between the Parallel All display and live output

monitoring.

Parallel All CH display will adjust to allow value conguration of .045 to 24 A for model 9140 and .045 A

to 12 A for model 9141.

Figure 4.16 Parallel All Main Page

Protection Setting menu will also adjust the congurable values.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Tracking

Output Conguration 44

Figure 4.17 Parallel All Main Page

Voltage levels are tracked on either CH1+2 or All Channels.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling >

Operation Mode > Tracking.

Tracking mode allows real time voltage tracking across all channels or between CH1 and CH2.

When tracking mode is enabled, list mode will still operate independently on the channel that has list

enabled. Tracking channels will not track the list changes.

Figure 4.18 Tracking Mode

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Output Conguration 45

Coupling

Enable or disable the output coupling between multiple output channels, by using the soft keys to toggle

individual channel coupling On or O.

Press the button then use the soft key to select Output Cong > Op. Mode/Coupling

If coupling is enabled, will follow the coupling settings. Channel output On/O buttons will also

follow the coupling settings if the correlated channel is coupled to another channel.

Example:

If CH1 and CH2 are coupled and the coupled CHs are on, will not turn on

CH3. It will turn o CH1 and CH2.

However, if all channels are OFF will turn all CHs ON.

If all CHs are ON will turn all CHs OFF.

Figure 4.19 Parallel All Main Page

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

Output Sequencing

Output Conguration 46

Figure 4.20 Sequencing

Combine CH Coupling with Output On and O Delay to toggle the outputs in a set sequence.

To congure a sequence:

1. Set voltage and current output of the participating channels.

Reference section Setting Voltage and Current.

2. Synchronize output state by coupling of all participating channels.

Reference section Coupling

3. Congure the turn on order of the outputs using the On and O Delay.

Reference section Output Timer

Begin the sequence by turning on any of the participating outputs.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

List Mode

The 9140 and 9141 are capable of storing up to 10 programmable lists in the internal memory. Each list

can have up to 100 congurable steps.

List memory is shareable across all 3 channels, allowing the channels to run the same list or dierent list

simultaneously.

If all ten list numbers are taken, a list can also be saved to a USB. Lists can be loaded from a USB,

allowing for a larger collection of programmed lists.

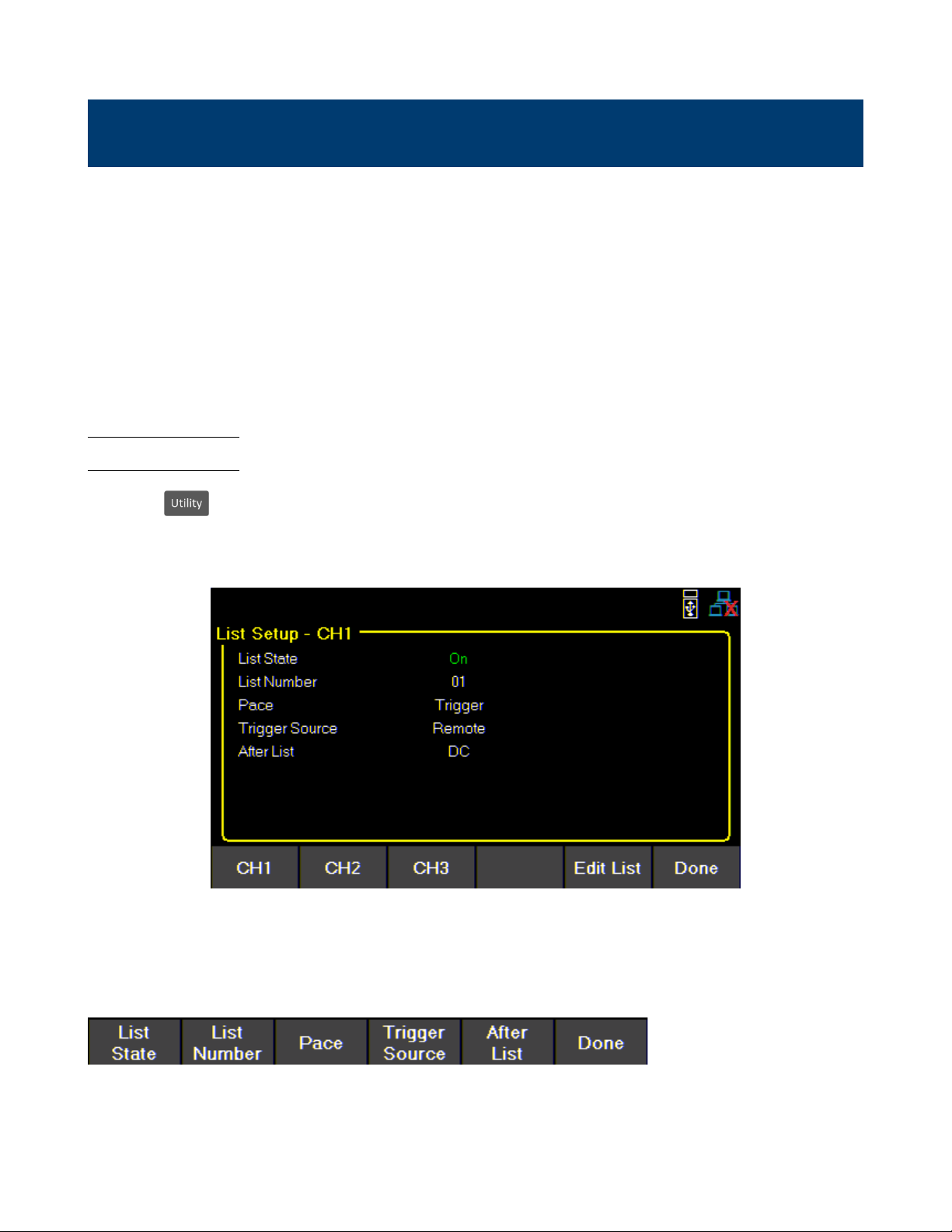

5.1 List Setup

Press the button then use the soft key to select List Setup.

Use the softkeys to select one of the channels CH1, CH2, or CH3.

Figure 5.1 List Setup

Use the softkeys to set the following parameters.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

List State:

Toggle list state On/O for the selected channel.

List Number:

Select a list program from the memory to run on the channel.

Use the numeric keypad or rotary knob to select list number.

Press to assign the list to a channel.

Pace:

Set the pace in which steps are executed.

a. Dwell: The next step outputs once the dwell time elapsed.

List Mode 48

b. Trigger: After the dwell time elapsed, wait for a trigger before outputting the next step.

Trigger Source

Set the trigger source.

a. Manual: Select to use a manual trigger. The Trigger softkeywill be availableonce List State is on and

exit out of the menu to the main display.Press it to manually trigger the list program. If the step dwell

time has not elapsed, then Trigger will not have a white background. When dwell timeelapses, Trigger background

color will turn white to indicate the trigger is ready.

Figure 5.2 Waiting for Trigger

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

List Mode 49

b. Digital IO: Select to use the digital I/O pins to receive a trigger. To assign trigger input function to a

pin see 7.4.1.

c. Remote: Select to receive a trigger from the remote interface.

After List

Sets the voltage and current settings at the end of the list program.

a. DC: Returns to the last DC output voltage and current setting prior to enabling list mode.

b. Last: Retains the last step voltage and current setting after the list program ends.

Note:

If the list is aborted, the output will return to the last set voltage and current

output values before the list began, even if After List is set to Last.

5.2 Edit List

Press the button then use the soft key to select List Setup > Edit List.

Use the softkeys to set the following parameters.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

List Mode 50

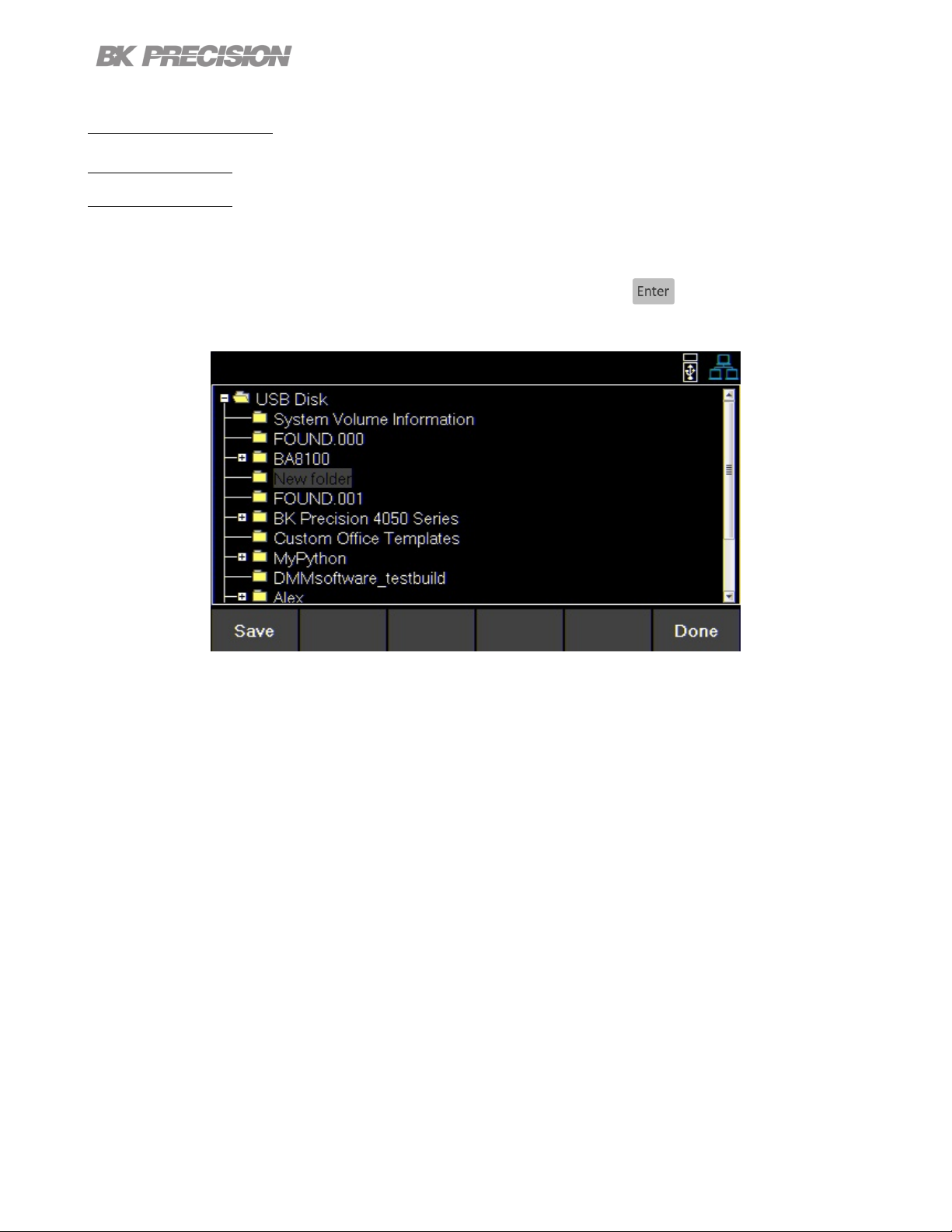

5.2.1 Load/Save List

Save to USB

Save the selected list program to a USB.

Use the rotary knob to navigate through the le paths of the USB. Use the button to expand folders.

Once the desired location has been found select Save by pressing the softkey furthest to the left.

Figure 5.3 Save to USB

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

List Mode 51

Load from USB

Load a previously saved list from a USB to selected List Number.

Use the rotary knob to navigate through the le paths of the USB. Use the button to expand folders.

Once the desired location has been found select Load by pressing the softkey furthest to the left.

Figure 5.4 Load from USB

Note:

The list must be saved/overwritten at the selected list number location before it is able to be assigned.

5.2.1 List Number

1. Select a list program from the internal memory.

2. Use the numeric keypad or rotary knob to select a list (0 to 9).

3. Press

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

List Mode 52

5.2.2 Next

Set the next list program to run after the current list elapse.

a. To make a list run continuously and indenitely, set Next to the same number as List Number.

b. To run dierent list sequences continuously, set Next to each other.

Example Set Next on List 1 to 2.

Set Next on List 2 to 1.

5.2.3 Repeat

To repeat a list, set Repeat using the numeric keypad or rotary knob and press .

5.2.4 Steps

Add, delete, clear all, or edit steps.

Add Step

Use the softkeys to add a step to the list. The step added will be a duplication of the step selected before

pressing Add Step.

To select a step to duplicate, use the rotary knob to navigate the available steps. If the list is new, only

one default step will be available. Pressing Add Step will duplicate the default step.

Figure 5.5 Default Step In New List

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

Delete Step

Delete the step selected before pressing Delete Step.

Use the rotary knob to navigate between each step.

Clear All

Clear all list parameters. See g 5.5

Edit Step

Use the rotary knob to navigate the steps available.(select a row)

To edit parameters of the step, use the keys.(selects a column)

See gure 5.6 for the parameter each row edits.

List Mode 53

Press to toggle enable/disable BOST and/or EOST.

Figure 5.6 List Conguration

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

Voltage Sets Vset value.

When setting Vset the list will not limit the voltage range based on mode.

Therefore, Vmax will be 96.960 for model 9140 and 180.800 for model 9141.

To prevent a protection trip, verify the Vset and Iset values in the list is within

the range of the congured operation mode before running the list.

Current Sets Iset value.

When setting Iset the list will not limit the current range based on mode.

Therefore, Imax will be 24.240 for model 9140 and 12.120 for the 9141.

To prevent a protection trip, verify the Vset and Iset values in the list is within

the range of the congured operation mode before running the list.

List Mode 54

Step Parameters

BOST Press the knob or to enable/disable a trigger-out signal at the beginning of the step (BOST).

EOST Press the knob or to enable/disable a trigger-out signal at the beginning of the step (EOST).

Dwell Sets the dwell time of the selected step.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

List Mode 55

5.3 List Run

List allows a sequence of outputs with up to 100 congurable steps. With sharable memory across all

three channels, a list can run simultaneously on various channels. This allows for a list to be compatible

in normal, parallel or series mode.

Before running a list its parameters must be congured.

1. Congure the parameters of each step. See 5.2

2. Set the settings of the channel which will output the list. See 5.1

a. Enable List State on desired channel.

b. Assign a List Number to the channel.

c. Select Pace {Dwell or Trigger}.

d. Select Trigger Source {Manual, Digital IO, or Remote }.

e. Select After List output {DC or Last}.

3. After conguring the list and channel parameters press to return to the main page.

– Vset will be replaced with List Start if List State was enabled.

Figure 5.7 List State Disabled

4. Select List start to start the list.

– Once the list begins List Start will change to Abort List

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

List Mode 56

Figure 5.8 List State Enabled CH 1

– The interaction with the list will vary depending on the chosen Pace. See 5.1

5. Select List Abort to end the list before all steps elapse. If the all steps elapse the list will end and the

output will be set to chosen After List parameter.

– If After List is set to DC the output will output the Vset and Iset values.

– If After List is set to Last the output will output the values of the last step in the list.

Note:

While the list is running the user can adjust the current step output by setting Vset or Iset on the main

display. Doing so will immediately change the value of the ongoing output. However, the set value will

not be saved to the list. Once the dwell time of the step has elapsed the list will continue and output

the next step.

If Trigger source is set to manual, Vset/Iset will not be available. The rotary knob and numeric keypad

can be used to adjust the selected value. To adjust both Vset/Iset navigate to the single CH display of

the output using the key.Vset/Iset will be available as shown in gure 5.9.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 57

Figure 5.9 Single Channel Display Vset/Iset

List Mode 57

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

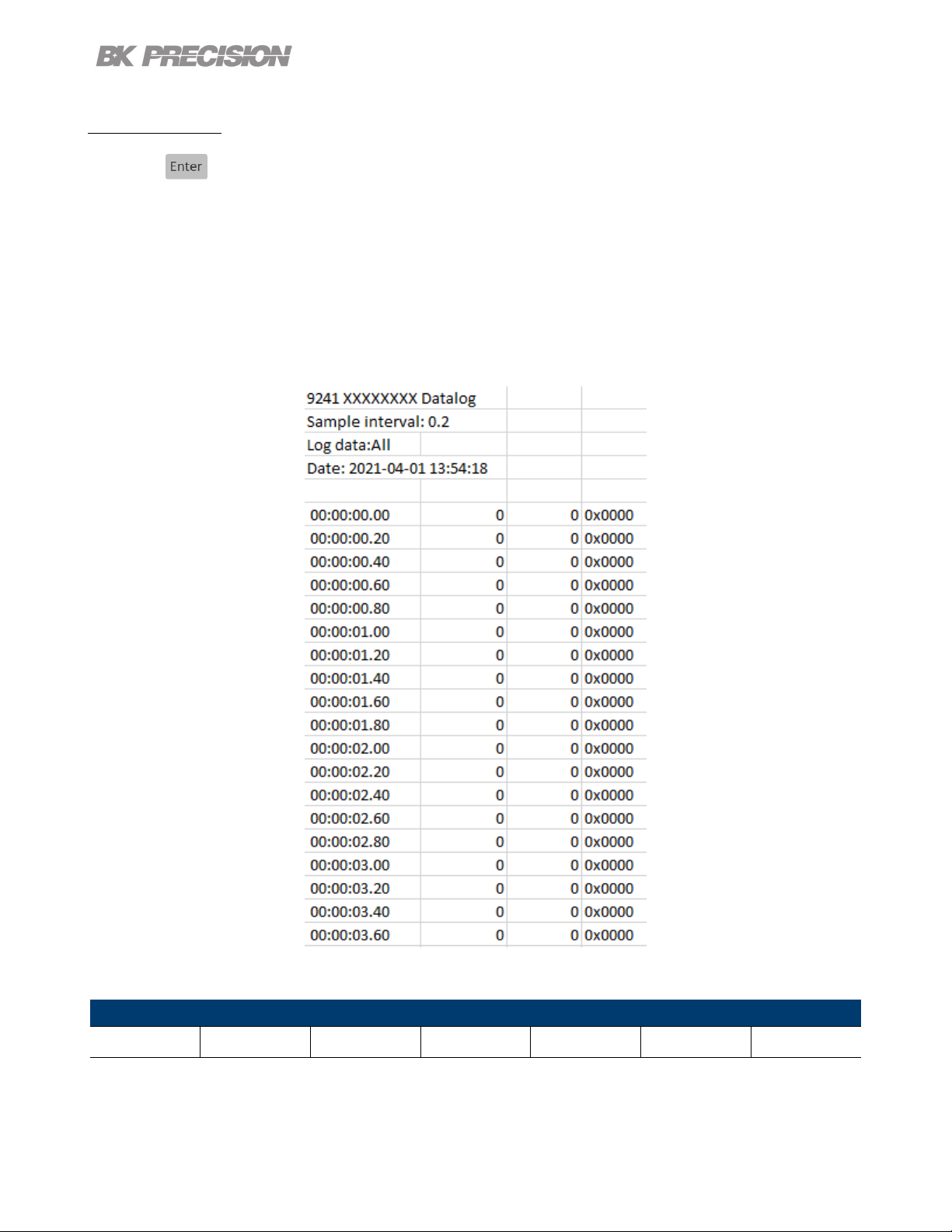

Data Logger

The data logger can record the output voltage, current, and error codes of all three channels. Log data

can be congured to record either Voltage only, Current only, or both.

Connect a USB ash drive to the front panel USB port. Max. Recording time will vary based on the ash

drive size and the amount of the data being logged.

Figure 6.1 Data Logger Max Time

6.1 Using the Data Logger Function

Press the button then use the soft key to select Data logger. The Data Logger settings can be

selected in this menu.

Before starting the Data Logger its settings must be adjusted.

1. Set the desired Sampling Interval See 6.2.1

2. Select a File Path to determine where to store the collected data. see 6.2.2

3. Enable or disable T. Stamp Filename. See 6.2.3

4. Choose what data to record. See 6.2.4

5. Enable or disable Status Code. See 6.2.5

6. Select a Trigger Source. See 6.2.6

7. After setting all desired parameters press datalog Start/Stop to begin recording. Staring data log

will vary based on chosen trigger. See6.2.7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

Data Logger 59

6.2 Parameters

6.2.1 Sampling Interval

Press the button then use the soft key to select Data logger > Sampling Interval.

Use the numeric keypad or rotary motor to select the sampling interval. Press to assign the selected

value. (.2s to 300s)

6.2.2 File Path

Press the button then use the soft key to select Data logger > File Path.

Using the rotary knob and navigate through the le path of the USB. Once the desired location

has been found select save by pressing the softkey furthest to the left.

Verify that the correct path was chosen in the Data Logger menu.

Figure 6.2 File Path Selected

6.2.3 T. Stamp Filename

Press the button then use the soft key to select Data logger > T. Stamp Filename

Toggle to enable/disable time and date on the le name.

Example Enabled 9140_log_20201017002307

Disabled 9140_log

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

Data Logger 60

6.2.4 Log Data

Press the button then use the soft key to select Data logger > Next Pg. > Log Data.

Select data to be logged.

– All: Record both voltage and current output of all channels.

– Voltage: Record the voltage output of all channels.

– Current: Record the current output of all channels.

Figure 6.3 Log Data All

The data is recorded in the following order:

CH1 Voltage CH1 Current CH2 Voltage CH2 Current CH3 Voltage CH3 Current Status Code

Table 6.1 Data Order

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

Note:

Data order will vary depending on Log Data selected.

6.2.5 Status Code

Press the button then use the soft key to select Data logger > Status Code.

Toggle to enable/disable status code.

Enabled Status Code will record all codes reported. See 6.3 for an example.

In gure 6.3 the code 0x0001 is returned. This indicates OVP has been triggered.

Data Logger 61

Table 6.2 denes each code.

Code Description

0x0001 Over Voltage Protection Triggered

0x0002 Over Current Protection Triggered

0x0004

0x0008 Sense not connected

Table 6.2 Status Code

Over Temperature

Protection Triggered

6.2.6 Trigger Source

Press the button then use the soft key to select Data logger > Trigger Source.

Datalog can be triggered in three ways: Manual, Digital IO, and Remote.

• Manual: Select to use manual trigger. The trigger softkey will be available as Datalog Start/Stop.

See section 6.2.7

• Digital IO: Select to use the digital I/O pins to receive a trigger. To assign a function to a pin see

section7.4.1.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 62

Data Logger 62

• Remote: Select to receive a trigger from a remote interface.

Note:

For Digital IO and Remote the rst trigger will turn Data log on. A second trigger will begin data

recording. will be displayed on the top right when data is being logged. See 6.2.7

6.2.7 Datalog Start/Stop

Press the button then use the soft key to select Data logger > Datalog Start/Stop. Toggle to turn

datalog On/O.

will be displayed on the top right when data logger is on but not recording.

The command INIT:IMM:DLOG will turn on data logger.

For Digital IO press Datalog Start/Stop to turn data logger on.

will be displayed on the top right when data logger is recording.

The command TRIG:DLOG:IMM will begin the recording.

For Digital IO an input high signal to the set pin will turn data logger on.

If Trigger Source is set to manual pressing Datalog Start/Stop will start/stop recording without a second

signal.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Utilities Menu

Congure the settings in the following menus:

• User Settings

• Remote Interface

• I/O Conguration

• Test/Admin

• Error Log

• Help

7.1 User Settings

Press the button then use the soft key to select Utilities > User Settings.

The system’s settings can be congured here.

7.1.1 Key Lock Output

Press the button then use the soft key to select Utilities > User Settings > Key Lock Output.

Toggle to enable/disable the key lock.

– Enabling Key Lock Output changes the function of Key Lock.

– For more information see chapter 8

– Default: OFF

7.1.2 Beep Sound

Press the button then use the soft key to select Utilities > User Settings >Beep Sound.

Toggle to enable/disable the beeper sound.

Default: ON

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

Utilities Menu 64

7.1.3 Date

Press the button then use the soft key to select Utilities > User Settings >Date.

Use the number pad to set the date.

YY/MM/DD

7.1.4 Time

Press the button then use the soft key to select Utilities > User Settings >Time.

Use the number pad to set the time.

HH:MM:SS

7.1.5 Screen Intensity

Press the button then use the soft key to select Utilities > User Settings >Next Pg. > Screen

Intensity.

Use the rotary knob or number pad to set the screen brightness.

Lowest 1

Highest 10

7.1.6 Language

Press the button then use the soft key to select Utilities > User Settings >Next Pg. > Language.

Set the language for the On Screen Help guide. It does not change the language for the menus. For

more information about On Screen Help see section 7.8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 65

Utilities Menu 65

7.2 Remote Interface

The 9140 series supports remote communication on up to three interfaces: USB, LAN, and GPIB (optional).

While in remote mode the screen displays “RMT” in the upper right corner. Switching to remote mode

does not impact the supply’s output parameters.

In remote mode, front panel operation is disabled. Only the Local button is enabled. Revert to manual

mode by pressing the key or by sending the command SYST:LOC.

The webserver remote interface requires the password BK to login.

Select and congure the following interfaces:

• USB

• LAN

• GPIB

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 66

Utilities Menu 66

7.2.1 USB Settings

Press the button then use the soft key to select Utilities > I/O Cong > USB Settings.

The USB device port is located in the rear-panel. See 1.8

The 9140 series are both USBTMC and USB VCP compliant.

In the USB Settings menu use the soft keys to select either:

– USBVCP

– USBTMC

Default: USBVCP

Figure 7.1 USB Details

The VISA Resource string gives USB0::<Vendor ID>::<Product ID>::<Serial Number>:INSTR

Example From gure 7.1 :

<Vendor ID> = 0x3121

<Product ID> = 0x0001 for 9140 or 0x0002 for 9141

<Serial Number> = 583k20101

When using USBVCP set the port setting to:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 67

7.2.2 LAN

To congure the LAN Settings

Utilities Menu 67

Figure 7.2 USB Port Settings

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings.

The following settings are available in LAN Settings:

• IP Mode

• IP Address

• Subnet

Mask

• Gateway IP

• Primary

DNS

• Hostname

• LAN Reset

• Restore

Default

• LAN Status

Figure 7.3 LAN Settings

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 68

Utilities Menu 68

Note:

To access the webserver remote interface enter the default password bk.

IP Mode

Select Dynamic Host Conguration Protocol (DHCP) or Manual to set how the LAN settings will be

congured.

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > IP MODE.

The easiest way to congure the LAN settings is to set the IP Mode to DHCP.DHCP will automatically

assign an IP address to the instrument.

The settings can manually be congured by selecting Manual.

IP Address

The IP Address is a unique string of numbers separated by periods. To enter an IP address:

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > IP

Address.

Use the numeric keypad to enter an IP address. Then keys are used to separate each number in

the string. After inputting each number press to set the address.

Subnet Mask

Subnet Mask divides the IP address into network address and host address.

To set Subnet Mask:

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > Subnet

Mask.

Use the numeric keypad to enter the subnet mask. Then keys are used to separate each number

in the string. After inputting each number press to set the address.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 69

Utilities Menu 69

Gateway IP

The gateway address is by default the IP address of the network device that connects the instrument.

If IP Mode is set to DHCP Gateway IP does not have to be set.

To set Gateway IP :

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > Gateway

IP.

Use the numeric keypad to enter an IP address. Then keys are used to separate each number in

the string. After inputting each number press to set the address.

Primary DNS

Domain Name Service (DNS) is the system that automatically translates Internet addresses to the numeric

machine addresses. The DNS address is the IP address of the system that performs this service.

If IP Mode is set to DHCP DNS will automatically be set.

To set the Primary DNS :

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > Primary

DNS .

Use the numeric keypad to enter an IP address. Then keys are used to separate each number in

the string. After inputting each number press to set the address.

Hostname

Each instrument comes with a unique hostname that can be changed. The default hostname has the

following format:

BK-<modelnumber>-<Serialnumber>

Figure 7.3 shows the example:

BK-9141-20101

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 70

Utilities Menu 70

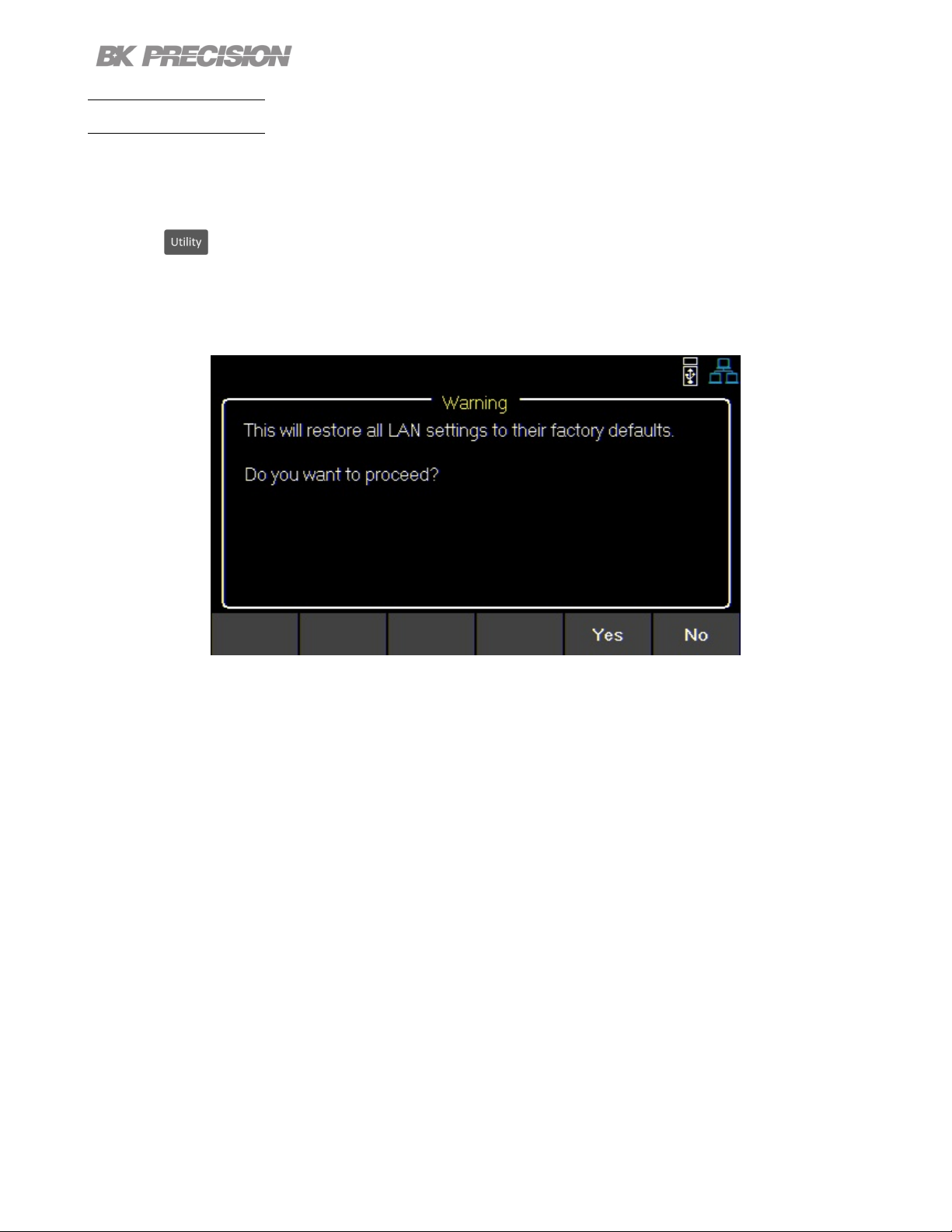

LAN Reset

LAN Reset resets all LAN settings and webpage passwords. The default webpage password is bk.

To reset LAN :

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > LAN

Reset .

Before resetting a warning will display informing both LAN settings and webpages passwords will be

reset.

Select Yes to nalize the reset.

Figure 7.4 Reset

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 71

Utilities Menu 71

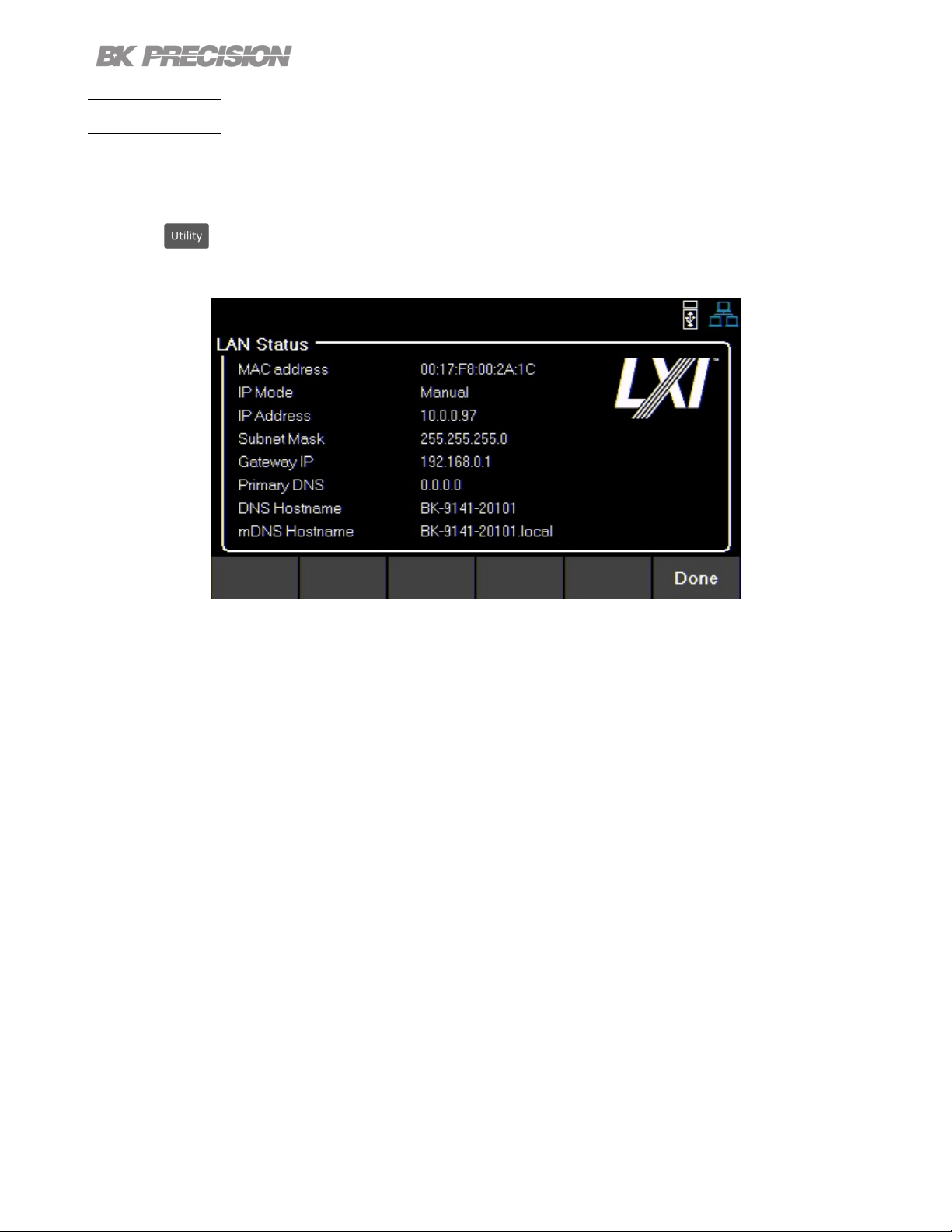

Restore Default

Restore Default will set all LAN settings to their factory defaults.

To restore factory defaults:

Press the button then use the soft key to select Utilities > I/O Cong > LAN Settings > Restore

Default .

Before restoring LAN settings to default the following warning will display.

Figure 7.5 Restore Factory Defaults

Select Yes to set to factory default.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 72

Utilities Menu 72

LAN Status

LAN Status provides an overview of the LAN settings.

To view the LAN status:

Press the button then use the soft key to select Utilities > I/O Cong > LAN Status .

Figure 7.6 LAN Status

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 73

Utilities Menu 73

7.3 GPIB (optional)

In GPIB the GPIB address can be changed from 01 to 30.

To change the GPIB address:

Press the button then use the soft key to select Utilities > I/O Cong > GPIB.

Figure 7.7 GPIB Address

Use the numeric keypad to enter the new address, then press the key.

The rotary knob can also be used to set the address. must be pressed to set the new address.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 74

Utilities Menu 74

7.4 Digital I/O

To enter the Digital I/O menu:

Press the button then use the soft key to select Utilities > I/O Cong > Digital I/O.

Select the function and polarity of pins: 1, 2, and 3.

• Pin Functions

– None

– Digital In | Out

– Trigger In | Out

– Fault Out/Inhibit In

– Polarity Pos | Neg

• Inhibit Mode

– O

– Latched

– Live

Figure 7.8 Digital I/O Menu

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 75

Utilities Menu 75

7.4.1 Functions

Default: None

To congure a pin:

Press the button then use the soft key to select Utilities > I/O Cong > Digital I/O > Pin(#).

None

Set selected pin to have no function.

Digital In | Out

Toggle to select In/Out digital function.

Digital In: Receive a signal from external device.

Digital Out: Send a signal to external device.

The input voltage range for digital I/O pins is 0 V to 5 V. To prevent damage to

the instrument, do not exceed 5 V or supply a negative voltage to the digital I/O pins.

Trigger In | Out

Toggle to select In/Out trigger function.

Trigger In: Receives signal that triggers set event.

Trigger Out: Sent trigger signal when specied. (BOST or EOST)

In List Mode, the Trigger In function can be used to trigger the next step when Trigger Source is set to

Digital IO.

In Datalog, the Trigger In function can be used to start/stop data logging when Trigger Source is set

to Digital IO.

Trigger Out is only available for list mode, step BOST and EOST.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 76

Utilities Menu 76

Fault Out

Enable a fault condition, which generates a protection fault signal on the digital port.

Dierent conditions such as over voltage, over current, or over temperature will generate a fault event.

The fault event will “disable” all outputs without turning them o.

The outputs are “disabled” by setting the outputs as low as possible.

7.4.1 Polarity

Default: Positive

Set polarity of selected pin.

Positive

A logic true signal is received as a voltage high.

Negative

A logic true signal is received as a voltage low.

7.4.1 Inhibit Mode

Receive an external input signal that controls the output state of all channels.

Default: O

To set Inhibit Mode:

1. Assign the inhibit In function to pin 3 by:

Press the button then use the soft key to select Utilities > I/O Cong > Digital I/O > Pin 3 >

Inhibit In.

2. Select Inhibit Mode: Press the button then use the soft key to select Utilities > I/O Cong >

Digital I/O > Inhibit Mode.

3. Select one of the following modes:

Note:

The following modes are only available for pin 3.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 77

Utilities Menu 77

O

The inhibit input is ignored.

Latched

A logic-true transition signal will disable the power supply. The output will remain disabled.

Live

Power supply output follows the state of the inhibit signal. If the inhibit signal is true the output is disabled.

When it is false the output is enabled.

7.5 Test/Admin

7.5.1 Self Test

Run a Module test.

Press the button then use the soft key to select Utilities > Test/Admin > Self-Test > Start.

Figure 7.9 Self Test Complete

7.5.2 Security

The Security Settings are locked and can be accessed by entering the default code 77416699.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 78

Note:

Utilities Menu 78

Figure 7.10 Security Locked

The default password can be change in the Change Code menu. If the set code is forgotten contact

B&K Precision customer support.

Use the password to gain access to the following settings.

• Change Code

• Calibrate

• Firmware Update

• NISPOM

• Lock

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 79

Utilities Menu 79

Change Code

Changes the security code.

Press the button then use the soft key to select Utilities > Test/Admin > Security > Change

Code.

Calibrate

Enter calibration mode.

Press the button then use the soft key to select Utilities > Test/Admin > Security > Calibrate .

See chapter Calibration Adjustment Procedure to adjust the units calibration.

Firmware Update

Update the rmware and module. Press the button then use the soft key to select Utilities >

Test/Admin > Security > Firmware Update .

NISPOM

Select for complete memory wipe. Press the button then use the soft key to select Utilities >

Test/Admin > Security > NISPOM .

Lock

Sets security status to Lock. Press the button then use the soft key to select Utilities > Test/Admin

> Security > Lock .

If Done is selected without locking the security settings, the user will be prompted that the security settings

will not be locked.

7.6 Error Log

View up to 50 previously set error codes.

Press the button then use the soft key to select Utilities > Error Log.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 80

Utilities Menu 80

Figure 7.11 Error Log

Errors are placed in the order that they were encountered. 1 being the most recent.

The error log displays up to 50 error codes.

After reaching 50 error codes no more codes will be reported in the error log.

To continue ling error codes the error log list must be cleared

The error log can be saved into a USB ash drive connected to the USB port on the front panel.

Save the log by:

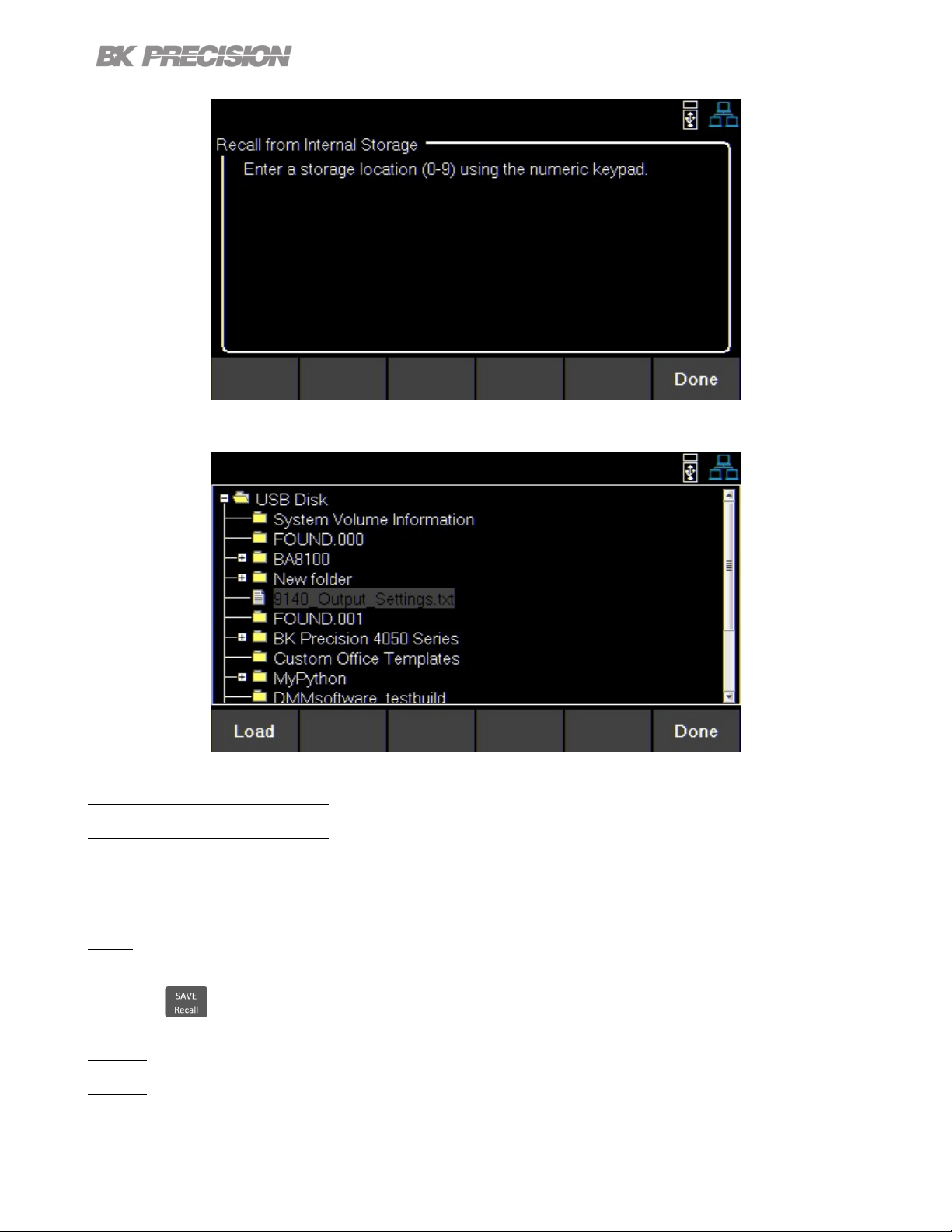

Pressing the button then use the soft key to select Utilities > Error Log > Save .