Page 1

Model: 2190E

100 MHz Digital Storage

Oscilloscope

USER MANUAL

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance

personnel and must be followed during all phases of operation, service,

and repair of this instrument.

Before applying power to this instrument:

Read and understand the safety and operational information in

this manual.

Apply all the listed safety precautions.

Verify that the voltage selector at the line power cord input is set

to the correct line voltage. Operating the instrument at an

incorrect line voltage will void the warranty.

Make all connections to the instrument before applying power.

Do not operate the instrument in ways not specified by this

manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in

this manual violates the safety standards of design, manufacture, and

intended use of the instrument. B&K Precision assumes no liability for a

customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the

amount of electrical energy available and the voltage impulses that may

occur on electrical conductors associated with these category ratings. The

category rating is a Roman numeral of I, II, III, or IV. This rating is also

accompanied by a maximum voltage of the circuit to be tested, which

defines the voltage impulses expected and required insulation clearances.

These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs

are not intended to be connected to the mains supply. The voltages in the

environment are typically derived from a limited-energy transformer or a

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

battery.

Category II (CAT II): Measurement instruments whose measurement inputs

are meant to be connected to the mains supply at a standard wall outlet or

similar sources. Example measurement environments are portable tools

and household appliances.

Category III (CAT III): Measurement instruments whose measurement

inputs are meant to be connected to the mains installation of a building.

Examples are measurements inside a building's circuit breaker panel or the

wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement

inputs are meant to be connected to the primary power entering a

building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher

category rating than what is specified in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a

category rating equal to or higher than the instrument's category rating to

maintain the instrument's category rating. Failure to do so will lower the

category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains

power environment. The mains power should be 120 V RMS or 240 V RMS.

Use only the power cord supplied with the instrument and ensure it is

appropriate for your country of use.

Ground the Instrument

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical safety ground. This instrument is grounded

through the ground conductor of the supplied, three-conductor AC line

power cable. The power cable must be plugged into an approved threeconductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground

connection, all accessible conductive parts (including control knobs) may

provide an electric shock. Failure to use a properly-grounded approved

outlet and the recommended three-conductor AC line power cable may

result in injury or death.

Unless otherwise stated, a ground connection on the instrument's front or

rear panel is for a reference of potential only and is not to be used as a

safety ground.

Do not operate in an explosive or flammable atmosphere

Do not operate the instrument in the presence of flammable gases or

vapors, fumes, or finely-divided particulates.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

iii

Page 5

The instrument is designed to be used in office-type indoor environments.

Do not operate the instrument

In the presence of noxious, corrosive, or flammable fumes, gases,

vapors, chemicals, or finely-divided particulates.

In relative humidity conditions outside the instrument's

specifications.

In environments where there is a danger of any liquid being

spilled on the instrument or where any liquid can condense on

the instrument.

In air temperatures exceeding the specified operating

temperatures.

In atmospheric pressures outside the specified altitude limits or

where the surrounding gas is not air.

In environments with restricted cooling air flow, even if the air

temperatures are within specifications.

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2

environment. The operating temperature range is 0 °C to 40 °C and the

operating humidity is ≤ 85 % relative humidity at 40 °C, with no

condensation allowed. Measurements made by this instrument may be

outside specifications if the instrument is used in non-office-type

environments. Such environments may include rapid temperature or

humidity changes, sunlight, vibration and/or mechanical shocks, acoustic

noise, electrical noise, strong electric fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid,

chemical, or other material gets on or inside the instrument, remove the

instrument's power cord, remove the instrument from service, label it as

not to be operated, and return the instrument to B&K Precision for repair.

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

Notify B&K Precision of the nature of any contamination of the instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact

cleaners, abrasives, lubricants, solvents, acids/bases, or other such

chemicals. Clean the instrument only with a clean dry lint-free cloth or as

instructed in this manual.

Not for critical applications

This instrument is not authorized for use in contact with the human body

or for use as a component in a life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel.

Component replacement and internal adjustments must be made by

qualified service-trained maintenance personnel who are aware of the

hazards involved when the instrument's covers and shields are removed.

Under certain conditions, even with the power cord removed, dangerous

voltages may exist when the covers are removed. To avoid injuries, always

disconnect the power cord from the instrument, disconnect all other

connections (for example, test leads, computer interface cables, etc.),

discharge all circuits, and verify there are no hazardous voltages present

on any conductors by measurements with a properly-operating voltagesensing device before touching any internal parts. Verify the voltagesensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

for both DC and AC voltages. Do not attempt any service or adjustment

unless another person capable of rendering first aid and resuscitation is

present.

Do not insert any object into an instrument's ventilation openings or other

openings.

Hazardous voltages may be present in unexpected locations in circuitry

being tested when a fault condition in the circuit exists.

Servicing

Do not substitute parts that are not approved by B&K Precision or modify

this instrument. Return the instrument to B&K Precision for service and

repair to ensure that safety and performance features are maintained.

Cooling fans

This instrument contains one or more cooling fans. For continued safe

operation of the instrument, the air inlet and exhaust openings for these

fans must not be blocked nor must accumulated dust or other debris be

allowed to reduce air flow. Maintain at least 25 mm clearance around the

sides of the instrument that contain air inlet and exhaust ports. If mounted

in a rack, position power devices in the rack above the instrument to

minimize instrument heating while rack mounted. Do not continue to

operate the instrument if you cannot verify the fan is operating (note some

fans may have intermittent duty cycles). Do not insert any object into the

fan's inlet or outlet.

vi

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

For continued safe use of the instrument

Do not place heavy objects on the instrument.

Do not obstruct cooling air flow to the instrument.

Do not place a hot soldering iron on the instrument.

Do not pull the instrument with the power cord, connected

probe, or connected test lead.

Do not move the instrument when a probe is connected to a

circuit being tested.

vii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Compliance Statements

This product is subject to Directive

2002/96/EC of the European

Parliament and the Council of the

European Union on waste electrical

and electronic equipment (WEEE),

and in jurisdictions adopting that

Directive, is marked as being put on

the market after August 13, 2005,

and should not be disposed of as

unsorted municipal waste. Please

utilize your local WEEE collection

facilities in the disposition of this

product and otherwise observe all

applicable requirements.

Disposal of Old Electrical & Electronic Equipment (Applicable in the

European Union and other European countries with separate collection

systems)

viii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

CE Declaration of Conformity

This instrument meets the requirements of 2006/95/EC Low Voltage

Directive and 2004/108/EC Electromagnetic Compatibility Directive with

the following standards.

Low Voltage Directive

- EN61010-1: 2001

- EN61010-031: 2002+A1: 2008

EMC Directive

- EN 61326-1:2006

- EN 61000-3-2: 2006+A2: 2009

- EN 61000-3-3: 2008

ix

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Safety Symbols

Refer to the user manual for warning information to

avoid hazard or personal injury and prevent damage

to instrument.

Electric Shock hazard

Alternating current (AC)

Chassis (earth ground) symbol.

Ground terminal

On (Power). This is the In position of the power

switch when instrument is ON.

Off (Power). This is the Out position of the power

switch when instrument is OFF.

Off (Supply). This is the AC mains

connect/disconnect switch on top of the

instrument.

CAUTION indicates a hazardous situation which, if

not avoided, will result in minor or moderate injury

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

x

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Table of Contents

Safety Summary ........................................................................................i

Compliance Statements ........................................................................ viii

Safety Symbols ......................................................................................... x

1 General Information .........................................................................1

1.1 Product Overview ......................................................................... 1

1.2 Package Contents ......................................................................... 1

1.3 Front Panel ................................................................................... 2

Front Panel Description ........................................................................ 2

1.4 Back Panel .................................................................................... 3

Back Panel Description ......................................................................... 4

1.5 Display Information ...................................................................... 4

User Interface Description ................................................................... 5

2 Getting Started .................................................................................6

2.1 Input Power Requirements .......................................................... 6

Input Power .......................................................................................... 6

2.2 Preliminary Check ......................................................................... 6

Verify AC Input Voltage ........................................................................ 7

Connect Power ..................................................................................... 7

Self-Test ................................................................................................ 7

Self Cal .................................................................................................. 7

Check Model and Firmware Version .................................................... 8

Function Check ..................................................................................... 8

Probe Safety ....................................................................................... 10

Probe Attenuation .............................................................................. 11

Probe Compensation .......................................................................... 11

3 Functions and Operating Descriptions ............................................ 13

3.1 Menu and Control Button .......................................................... 14

3.2 Connectors ................................................................................. 16

3.3 Auto Setup .................................................................................. 17

xi

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

3.4 Default Setup .............................................................................. 19

3.5 Universal Knob............................................................................ 23

3.6 Vertical System ........................................................................... 23

Using Vertical Position Knob and Volts/div Knob ............................... 24

3.7 Channel Function Menu ............................................................. 25

Setting up Channels ............................................................................ 28

3.8 Math Functions ........................................................................... 34

FFT Spectrum Analyzer ....................................................................... 36

3.9 Using REF .................................................................................... 43

3.10 Horizontal System....................................................................... 45

Horizontal Control Knob ..................................................................... 45

Window Zone ..................................................................................... 46

3.11 Trigger System ............................................................................ 47

Signal Source ...................................................................................... 48

Trigger Type ........................................................................................ 49

Coupling .............................................................................................. 67

Position ............................................................................................... 67

Slope and Level ................................................................................... 68

Trigger Holdoff ................................................................................... 69

3.12 Signal Acquisition System ........................................................... 70

3.13 Display System ............................................................................ 75

X-Y Format .......................................................................................... 79

3.14 Measure System ......................................................................... 80

Scale Measurement ............................................................................ 80

Cursor Measurement ......................................................................... 80

3.15 Storage System ........................................................................... 94

Recalling Files ..................................................................................... 96

Creating Folders and Files .................................................................. 96

Save/Recall Setup ............................................................................... 97

Save/Recall Waveform ..................................................................... 102

3.16 Utility System............................................................................ 109

System Status ................................................................................... 113

Language .......................................................................................... 114

Self Calibration ................................................................................. 115

Self Test ............................................................................................ 116

Update Firmware.............................................................................. 119

xii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Pass/Fail ............................................................................................ 120

Waveform Record ............................................................................ 125

Recorder (Scan Mode Only) ............................................................. 129

Help Menu ........................................................................................ 134

Education Mode ............................................................................... 134

4 Application Examples ................................................................... 135

4.1 Taking Simple Measurements .................................................. 135

4.2 Taking Cursor Measurements................................................... 136

4.3 Capturing a Single-Shot Signal .................................................. 138

4.4 Analyzing Signal Details ............................................................ 139

4.5 Triggering on a Video Signal ..................................................... 140

4.6 Application of X-Y Function ...................................................... 141

4.7 Analyzing a Differential Communication Signal........................ 143

5 Remote Control ............................................................................ 144

6 Message Prompts and Troubleshooting ........................................ 146

6.1 Message Prompts ..................................................................... 146

6.2 Troubleshooting ....................................................................... 147

7 Specifications ............................................................................... 149

8 Calibration .................................................................................... 153

SERVICE INFORMATION ....................................................................... 154

LIMITED ONE-YEAR WARRANTY ........................................................... 155

xiii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

1 General Information

1.1 Product Overview

The B&K Precision 2190E digital storage oscilloscope (DSO) is a portable

benchtop instrument used for making measurements of signals and

waveforms. The oscilloscope’s bandwidth is capable of capturing up to 100

MHz signals with a real time sampling rate of up to 1 GSa/s. With up to 40k

points of deep memory, more details of a signal can be captured and

displayed on a large color LCD display for analysis.

Features:

2 channels with bandwidth up to 100 MHz

Single channel real-time sampling rate of up to 1 GSa/s

Up to 40k points of memory depth

7” Color TFT LCD display

Trigger types: Edge, Pulse, Video, Slope, and Alternative

Digital filter and waveform recorder functions

Automatic measurement of 32 parameters (Voltage and Time)

Standard USB host, USBTMC device, and LAN ports

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving

it. Unpack all items from the shipping carton, and check for any obvious

signs of physical damage that may have occurred during transportation.

Report any damage to the shipping agent immediately. Save the original

packing carton for possible future reshipment. Every instrument is shipped

with the following contents:

1 x Quick Start guide (printed)

1 x AC power cord

1 x USB type A to Type B cable

2 x 1:1/10:1 Passive Oscilloscope Probes

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Front USB (Type A) Connector

Menu Function Keys, Menu On/Off, Print Key

Input Channels (1 MΩ BNC)

Probe Compensator (1 kHz and Ground)

1 2 3 4 5

10

1

2

3

4

Verify that all items above are included in the shipping container. If

anything is missing, please contact B&K Precision.

1.3 Front Panel

It is important for you to familiarize yourself with the DSO’s front panel

before operating the instrument. Below is a brief introduction of the front

panel function operation.

Figure 1.1 – Front Panel

Front Panel Description

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Horizontal Controls (Time Base)

Trigger Controls

Auto Setup Button

Menu and Measurement Buttons

Universal Knob

Vertical Controls

1 2 3

5

6

4

6

10

9 5 7

8

1.4 Back Panel

The following images show back and side panel connection locations.

Figure 1.2 – Back Panel

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Back Panel Description

Security Lock Receptacle

LAN Interface

Pass/Fail Output

Rear USB (Type B) Device Connector

Power Input Connector

AC Power Switch

1

2

3 4 5

6

1.5 Display Information

Figure 1.3 – Display Screen

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

User Interface Description

Trigger Status

USB Host Port Connection Indicator

Waveform Display Preview

Horizontal Trigger Position Marker

LAN Port Connection Indicator

Menu

Trigger Source, Type, and Level Indicator

Frequency Counter

Horizontal Delay Position

Horizontal Time Base Setting

Channel Source, Coupling Type, Volts/Division, BW Limit

Indicator

Vertical Display Markers (Ground Reference)

Trigger Level Display Marker

13

1

2

3 4 5 6 7

8

9

10

11

12

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

2 Getting Started

The included AC power cord is safety certified for this

instrument operating in rated range. To change a cable or add

an extension cable, be sure that it can meet the required

power ratings for this instrument. Any misuse with wrong or

unsafe cables will void the warranty.

Before connecting and powering up the instrument, please review and go

through the instructions in this chapter.

2.1 Input Power Requirements

Input Power

The supply has a universal AC input that accepts line voltage and

frequency input within:

100 – 240 V (+/- 10%), 50/60 Hz (+/- 5%)

100 – 127 V, 45 – 440 Hz

Before connecting to an AC outlet or external power source, be sure that

the power switch is in the OFF position and verify that the AC power cord,

including the extension line, is compatible with the rated voltage/current

and that there is sufficient circuit capacity for the power supply. Once

verified, connect the cable firmly.

2.2 Preliminary Check

Complete the following steps to verify that the oscilloscope is ready for

use.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Verify AC Input Voltage

Verify and check to make sure proper AC voltages are available to

power the instrument. The AC voltage range must meet the

acceptable specification as explained in section 2.1.

Connect Power

Connect AC power cord to the AC receptacle in the rear panel and

press the power switch to the ON position to turn ON the

instrument. The instrument will have a boot screen while

loading, after which the main screen will be displayed.

Self-Test

The instrument has 3 self-test options to test the screen, keys,

and the LED back lights of the function, menu, and channel keys

as shown below.

Figure 2.1 – Self Test Menu

To perform the self-test, please refer to the Self Test section for

further instructions.

Self-Cal

This option runs an internal self-calibration procedure that will

check and adjust the instrument. To perform the self-calibration,

please refer to the Self Calibration section for further

instructions.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Check Model and Firmware Version

The model and firmware version can be verified from within the menu

system.

Press Utility and select System Status option. The software/firmware

version, hardware version, model, and serial number will be displayed.

Press the Single key to exit.

Function Check

Follow the steps below to do a quick check of the oscilloscope’s

functionality.

1. Power on the oscilloscope. Press “DEFAULT SETUP” to show the

result of the self-check. The probe default attenuation is 1X.

Figure 2.2 – Scope Layout

2. Set the switch to 1X on the probe and connect the probe to

channel 1 on the oscilloscope. To do this, align the slot in the

probe connector with the key on the CH 1 BNC, push to connect,

and twist to the right to lock the probe in place. Connect the

probe tip and reference lead to the PROBE COMP connectors.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Figure 2.3 – Probe Compensation

PROBE

COMP

CH1

3. Press “AUTO” to show the 1 kHz frequency and about 3V peak-

peak square wave in couple seconds.

Figure 2.4 – 3 Vpp Square Wave

4. Press “CH1” two times to turn off channel 1, Press“CH2” to

change screen into channel 2, reset the channel 2 as step 2 and

step 3.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Probe Safety

SHOCK HAZARD

To avoid electric shock when using the probe, keep fingers

behind the guard on the probe body.

To avoid electric shock while using the probe, do not touch

metallic portions of the probe head while it is connected to a

voltage source. Connect the probe to the oscilloscope and

connect the ground terminal to ground before you take any

measurements.

A guard around the probe body provides a finger barrier for protection

from electric shock.

Figure 2.5 – Oscilloscope Probe

Connect the probe to the oscilloscope and connect the ground terminal to

ground before you take any measurements.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Probe Attenuation

NOTE: The default setting for the Probe option is 1X.

NOTE: When the attenuation switch is set to 1X, the probe limits

the bandwidth of the oscilloscope to 6 MHz (according to Probe

spec). To use the full bandwidth of the oscilloscope, be sure to set

the switch to 10X

Probes are available with various attenuation factors which affect the

vertical scale of the signal. The Probe Check function verifies that the

Probe attenuation option matches the attenuation of the probe.

You can push a vertical menu button (such as the CH 1 MENU button), and

select the Probe option that matches the attenuation factor of your probe.

Be sure that the attenuation switch on the probe matches the Probe

option in the oscilloscope. Switch settings are 1X and 10X.

Probe Compensation

As an alternative method to Probe Check, you can manually perform this

adjustment to match your probe to the input channel.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

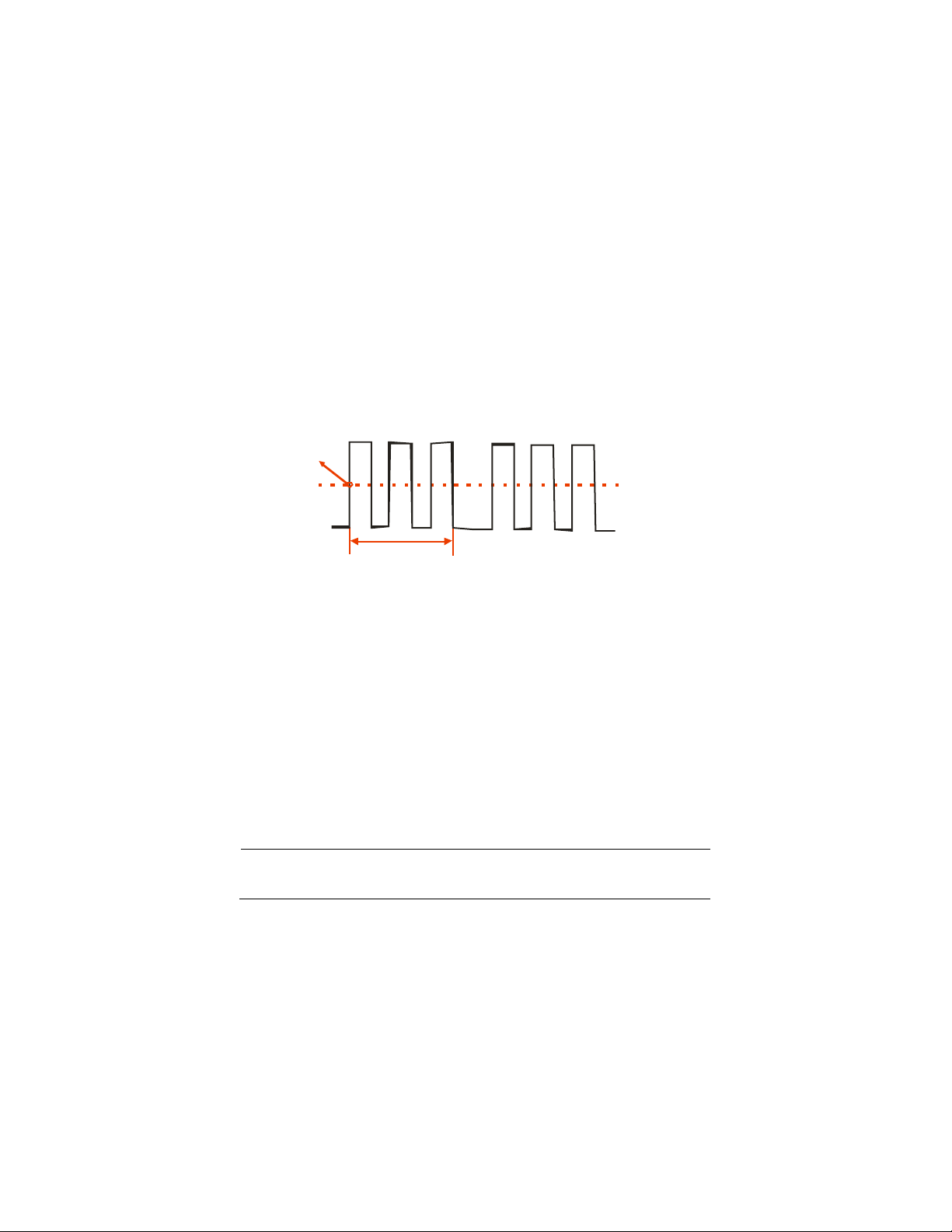

Figure 2.6 – Probe Compensation Setup

AUTO

BUTTON

PROBE

COMP

CH1

Undercompensated

Correctly Compensated

Overcompensated

1. Set the Probe option attenuation in the channel menu to 10X. Do

so by pressing CH1 button and selecting “Probe” from menu.

Select 10X. Set the switch to 10X on the probe and connect the

probe to channel 1 on the oscilloscope. If you use the probe

hook-tip, ensure a proper connection by firmly inserting the tip

onto the probe.

2. Attach the probe tip to the PROBE COMP 3V connector and the

reference lead to the PROBE COMP Ground connector. Display

the channel and then push the “AUTO” button.

3. Check the shape of the displayed waveform.

Figure 2.7 – Compensation Illustration

4. If necessary, adjust your probe’s compensation trimmer pot.

Repeat as necessary.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

3 Functions and Operating

Descriptions

To use your oscilloscope effectively, you need to learn about the following

oscilloscope functions:

• Menu and control button

• Connector

• Auto Setup

• Default Setup

• Universal knob

• Vertical System

• Channel Function Menu

• Math Functions

• Using REF

• Horizontal System

• Trigger System

• Acquiring signals System

• Display System

• Measuring waveforms System

• Utility System

• Storage System

• Online Help function

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

3.1 Menu and Control Button

Figure 3.1 – Control Buttons

Channel buttons (CH1, CH2): Press a channel button to turn

that channel ON or OFF and open the channel menu for that

channel. You can use the channel menu to set up a channel.

When the channel is on, the channel button is lit.

MATH: Press to display the Math menu. You can use the

MATH menu to use the oscilloscope’s Math functions.

REF: Press to display the Ref Wave menu. You can use this

menu to save and recall four or two reference waveforms to

and from internal memory.

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

HORI MENU: Press to display the Horizontal menu. You can

use the Horizontal menu to display the waveform and zoom

in a segment of a waveform.

TRIG MENU: Press to display the Trigger menu. You can use

the Trigger menu to set the trigger type (Edge. Pulse, Video,

Slope, Alternative) and trigger settings.

SET TO 50%: Press to stabilize a waveform quickly. The

oscilloscope can set the trigger level to be halfway between

the minimum and maximum voltage level automatically. This

is useful when you connect a signal to the EXT TRIG

connector and set the trigger source to Ext or Ext/5.

FORCE: Use the FORCE button to complete the current

waveform acquisition whether the oscilloscope detects a

trigger or not. This is useful for Single acquisitions and

Normal trigger mode.

SAVE/RECALL: Press to display the Save/Recall menu. You

can use the Save/Recall menu to save and recall up to 20

oscilloscope setups and 10 waveforms to/from internal

memory or a USB memory device (limited by memory

capacity of the USB flash drive). You can also use it to recall

the default factory settings, to save waveform data as a

comma-delimited file (.CSV), and to save the displayed

waveform image.

ACQUIRE: Press to display Acquire menu. You can use the

Acquire menu to set the acquisition Sampling Mode

(Sampling, Peak Detect, and Average).

MEASURE: Press to display a menu of measurement

parameters.

CURSORS: Display the Cursor Menu. Vertical Position

controls adjust cursor position while displaying the Cursor

Menu and the cursors are activated. Cursors remain

displayed (unless the “Type” option is set to “Off”) after

leaving the Cursor Menu but are not adjustable.

DISPLAY: Press to open the Display menu. You can use the

Display menu to set grid and waveform display styles, and

persistence.

UTILITY: Press to open the Utility menu. You can use the

Utility menu to configure oscilloscope features, such as

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

sound, language, counter, etc. You can also view system

status and update software.

DEFAULT SETUP: Press to reset the oscilloscope’s settings to

the default factory configuration.

HELP: Enter the online help system.

AUTO: Automatically sets the oscilloscope controls to

produce a usable display of the input signals.

RUN/STOP: Continuously acquires waveforms or stops the

acquisition.

Note: If waveform acquisition is stopped (using the

RUN/STOP or SINGLE button), the TIME/DIV control expands

or compresses the waveform.

SINGLE: Acquire a single waveform and then stops waveform

acquisition.

3.2 Connectors

Figure 3.2 – Connectors

Channel Connector (CH1, CH2): Input connectors for waveform

display.

EXT TRIG: Input connector for an external trigger source. Use the

Trigger Menu to select the “Ext” or “Ext/5” trigger source.

Probe Compensation: 1 kHz voltage probe compensation output

and ground. Use to electrically match the probe to the

oscilloscope input circuit.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

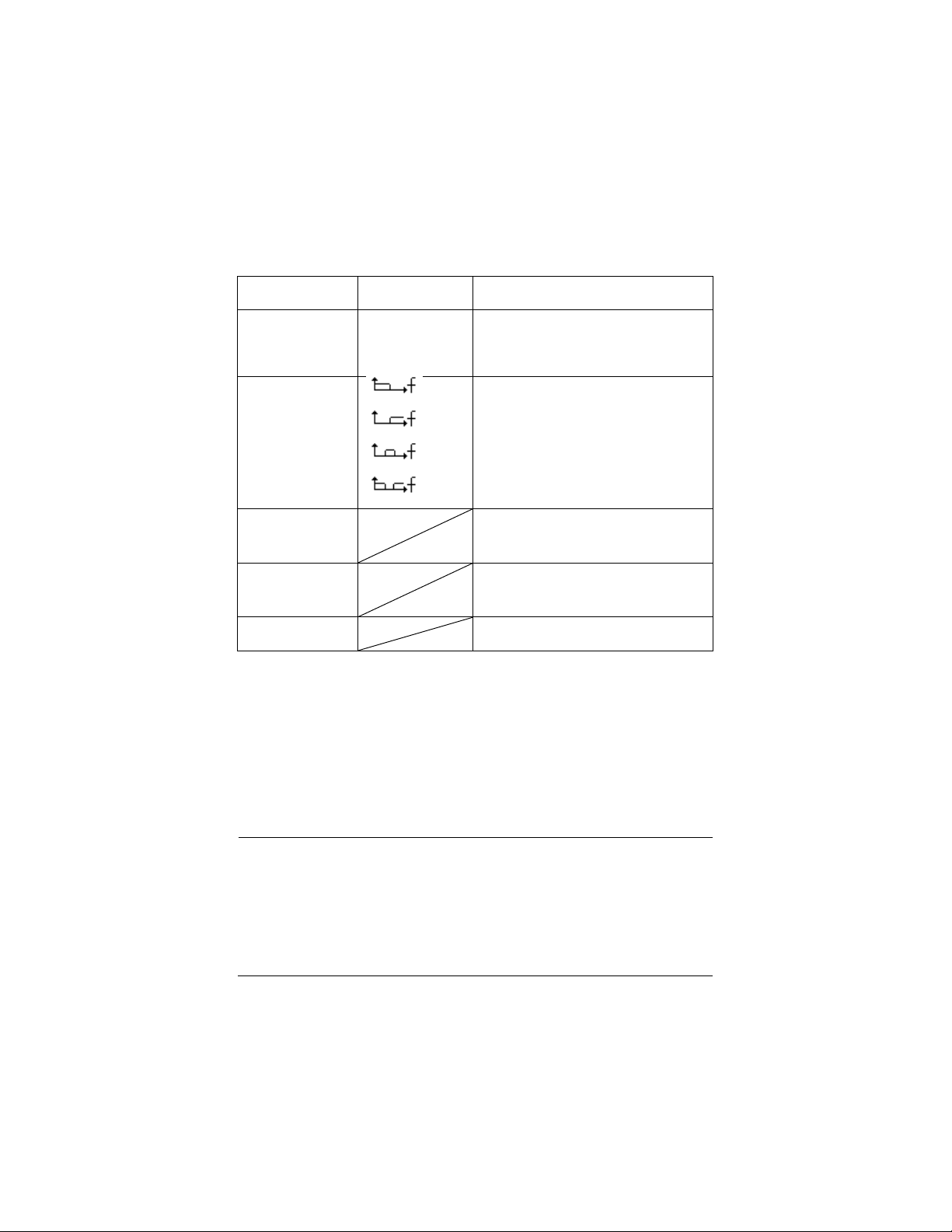

3.3 Auto Setup

Option

Description

(Multi-cycle sine)

Auto set the screen and display

several cycles signal.

(Single-cycle sine)

Set the screen and auto display

single cycle signal.

The 2190E Digital Storage Oscilloscope has an Auto Setup function that

identifies the waveform types and automatically adjusts controls to

produce a usable display of the input signal.

Press the AUTO front panel button, and then press the menu option

button adjacent to the desired waveform as follows:

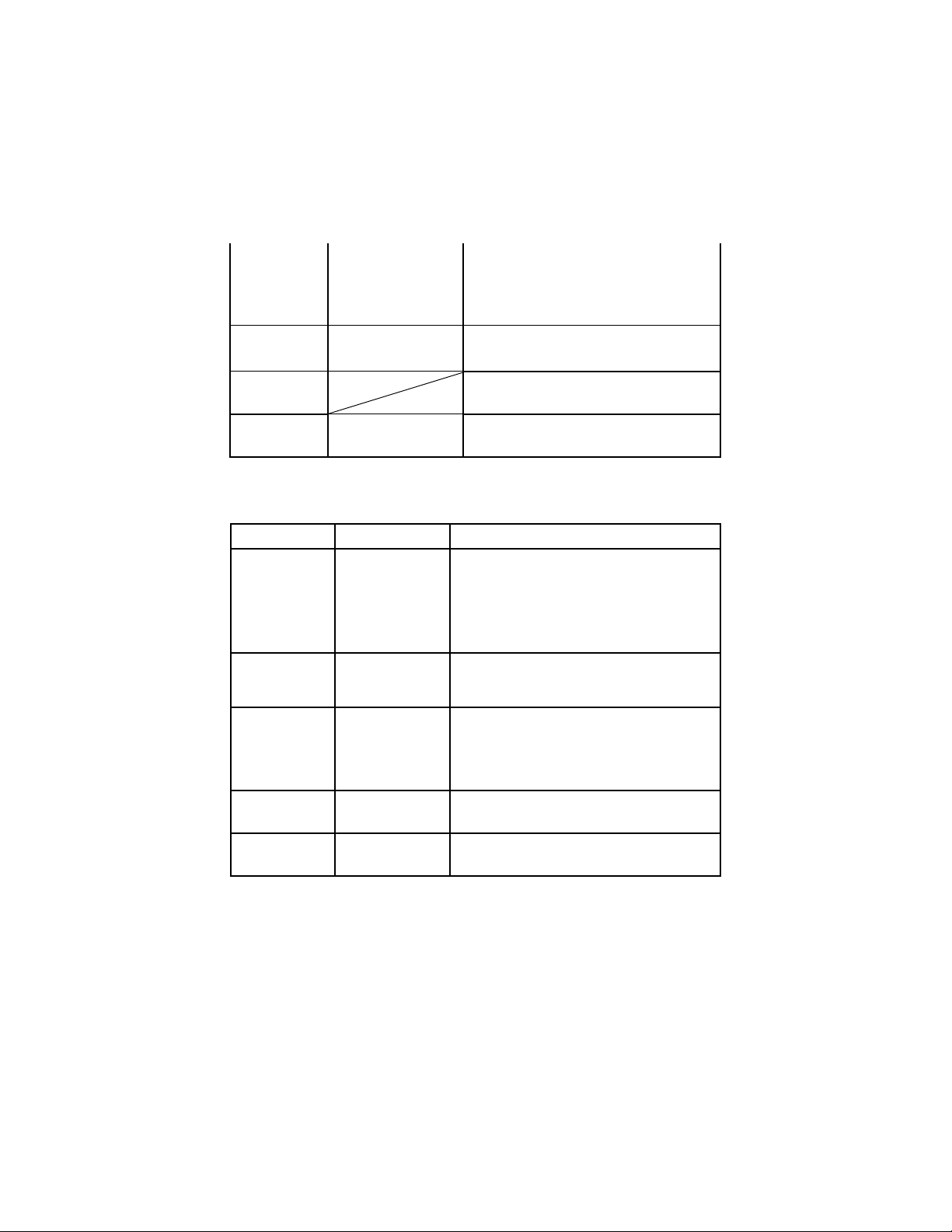

Figure 3.3 – Auto Setup

Table 3.1 – Autoset Menu

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

(Rising edge)

Auto set and show the rising time.

(Falling edge)

Auto set and show the falling time.

(Undo Setup)

Causes the oscilloscope to recall the

previous setup.

Function

Setting

Acquire Mode

Adjusted to Sampling

Display Format

Y-T

Display Type

Set to Dots for a video signal, set to

Vectors for an FFT spectrum; otherwise,

unchanged

Vertical Coupling

Adjusted to DC or AC according to the

input signal

Bandwidth Limit

Off(full)

Auto Set determines the trigger source based on the following conditions:

• If multiple channels have signals, channel with the lowest

frequency signal.

• No signals found, the lowest-numbered channel displayed when

Auto set was invoked.

• No signals found and no channels displayed, oscilloscope displays

and uses channel 1.

Table 3.2 – Auto Set Function Menu Items

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

V/div

Adjusted

VOLTS/DIV adjustability

Coarse

Signal inverted

Off

Horizontal position

Center

Time/div

Adjusted

Trigger type

Edge

Trigger source

Auto detect the channel which has the

input signal

Trigger slope

Rising

Trigger mode

Auto

Trigger coupling

DC

Trigger holdoff

Minimum

Trigger level

Set to 50%

NOTE: The AUTO button can be disabled. Please see “Education

Mode” for details.

3.4 Default Setup

The oscilloscope is set up for normal operation when it is shipped from the

factory. This is the default setup. To recall this setup, press the DEFAULT

SETUP button. For the default options, buttons and controls when you

press the DEFAULT SETUP button, refer to “Table 3.3 – Default Setup

Table” below.

The DEFAULT SETUP button does not reset the following settings:

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

• Language option

Menu or system

Options, knobs

or buttons

Default setup

CH1,CH2

Coupling

DC

BW limit

Off

Volts/div

Coarse

Probe

1X

Invert

Off

Filter

Off

Volts/div

1.00V

MATH

Operation

CH1+CH2

CH1 Invert

Off

CH2 Invert

Off

FFT operation:

Source

CH1

Window

Hanning

FFT Zoom

1X

Scale

dBVrms

Display

Split

HORIZONTAL

Window

Main

Position

0.00μs

Sec/div

500μs

Window Zone

50.0μs

Trigger knob

level

CURSOR

Type

Off

• Saved reference waveform files

• Saved setup files

• Display contrast

• Calibration data

Table 3.3 – Default Setup Table

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

21

Source

CH1

Horizontal (voltage)

+/-3.2divs

Vertical (time)

+/-5divs

ACQUIRE

three mode options

Sampling

Averages

16

Sampling mode

Real Time

DISPLAY

Type

Vectors

Persist

off

Gird

Intensity

60%

Brightness

40%

Format

YT

Menu Display

infinite

SAVE/RECALL

Type

Setups

Save To

Device

Setup

No.1

REF

REFA/REFB

REFA

Source

CH1

REFA

off

REFB

off

UTILITY

Sound

on

Counter

On

Back USB

USBTMC

Pass/Fail

off

Record

off

TRIGGER (edge)

Type

edge

Source

CH1

Slope

Rising

Mode

Auto

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

Coupling

DC

LEVEL

0.00V

TRIGGER (pulse)

Type

pulse

Source

CH1

When

=

Set Pulse Width

1.00ms

Mode

Auto

Coupling

DC

TRIGGER (Video)

Type

Video

Source

CH1

Polarity

Normal

Sync

All Lines

Standard

NTSC

Mode

Auto

TRIGGER

(Slope)

Type

Slope

Source

CH1

Time

1.00ms

Mode

Auto

TRIGGER (Alternative)

Type

Alternative

Source

CH1

Mode

Edge

Coupling

DC

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

3.5 Universal Knob

Figure 3.4 – Universal Knob

You can use the Universal knob with many functions, such as adjusting the

hold off time, moving cursors, setting the pulse width, setting the video

line, adjusting the upper and lower frequency limit, adjusting the X and Y

masks when using the pass/fail function, etc. You can also turn the

“Universal” knob to adjust the storage position of setups, waveforms,

pictures when saving/recalling, and to select menu options. With some

functions, the light indicator above the knob will turn on to indicate that

the knob can be used to make changes or adjustments for that function.

The knob can also be pushed to make a selection after

changes/adjustments have been made.

3.6 Vertical System

The vertical control could be used for displaying waveform, rectify scale

and position.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

Figure 3.5 – Vertical System Controls

Using Vertical Position Knob and Volts/div Knob

• Vertical “POSITION” Knob

1. Use the Vertical “POSITION” knobs to move the channel

waveforms up or down on the screen. This button’s

resolution varies as per the vertical scale.

2. When you adjust the vertical position of channels

waveforms, the vertical position information will display

on the bottom left of the screen. For example “Volts

Pos=24.6mV”.

3. Press the vertical “POSITION” knob to set the vertical

position to zero.

• “Volts/div” Knob

1. Use the “Volts/div” knobs to control how the

oscilloscope amplifies or attenuates the source signal of

channel waveforms. When you turn the “volts/div”

knob, the oscilloscope increases or decreases the vertical

size of the waveform on the screen with respect to the

ground level.

2. When you press the “Volt/div” knob, you can switch

“Volts/div” option between “Coarse” and “Fine”. The

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

vertical scale is set by a 1-2-5 step sequence in Coarse

Option

Setting

Introduction

Coupling

DC

AC

GND

DC passes both AC and DC

components of the input signal.

AC blocks the DC component of the

input signal and attenuates signals

below 10 Hz.

GND disconnects the input signal.

BW limit

On

Off

Limits the bandwidth to reduce

display noise; filters the signal to

reduce noise and other unwanted

high frequency components.

Volts/Div

Coarse

Fine

Selects the resolution of the

Volts/Div knob

Coarse defines a 1-2-5 sequence.

Fine changes the resolution to small

steps between the coarse settings.

mode. Increase in the clockwise direction and decrease

in the counterclockwise direction. In Fine mode, the

knob changes the Volts/Div scale in small steps between

the coarse settings. Again, increase in the clockwise

direction and decrease in the counterclockwise

direction.

3.7 Channel Function Menu

Table 3.4 – Channel Function Menu

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

Probe

1X, 5X

10X, 50X

100X, 500X,

1000X

Set to match the type of probe you

are using to ensure correct vertical

readouts.

Next Page

Page 1/3

Press this button to enter the second

page menu

Option

Setting

Instruction

Invert

on

off

Turn on invert function.

Turn off invert function.

Filter

Press this button to enter the

“Digital Filter menu”.

Next Page

Page 2/3

Press this button to enter the third

page menu.

Option

Setting

Introduction

Unit

V A Set the scale unit to voltage

Set the scale unit to current.

Skew

-100 ns –

100ns

Set the skew time between two

channels.

Next Page

Page 3/3

Press this button to return to the

first page menu.

Table 3.5 – Channel Function Menu 2

Table 3.6 – Channel Function Menu 3

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Table 3.7 – Digital Filter Menu

Option

Setting

Introduction

Digital Filter

On

Off

Turn on the digital filter.

Turn off the digital filter.

Type

Setup as LPF (Low Pass Filter).

Setup as HPF (High Pass Filter).

Setup as BPF (Band Pass Filter).

Setup as BRF (Band Reject Filter).

Upper limit

Turn the “Universal” knob to set

upper limit.

Lower limit

Turn the “Universal” knob to set

lower limit.

Return

Return to the second page menu.

NOTE:

The oscilloscope’s vertical response rolls off slowly above its

specified bandwidth. Therefore, the FFT spectrum can show valid

frequency information higher than the oscilloscope’s bandwidth.

However, the magnitude information near or above the

bandwidth will not be accurate.

• “GND” Coupling: Use GND coupling to display a zero-volt

waveform. Internally, the channel input is connected to a zerovolt reference level.

• Fine Resolution: The vertical scale readout displays the actual

Volts/Div setting while in the fine resolution setting. Changing the

setting to coarse does not change the vertical scale until the

VOLTS/DIV control is adjusted.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

If the channel is set to DC coupling, you can quickly measure the

DC component of the signal by simply noting its distance from the

ground symbol.

If the channel is set to AC coupling, the DC component of the

signal is blocked allowing you to use greater sensitivity to display

the AC component of the signal.

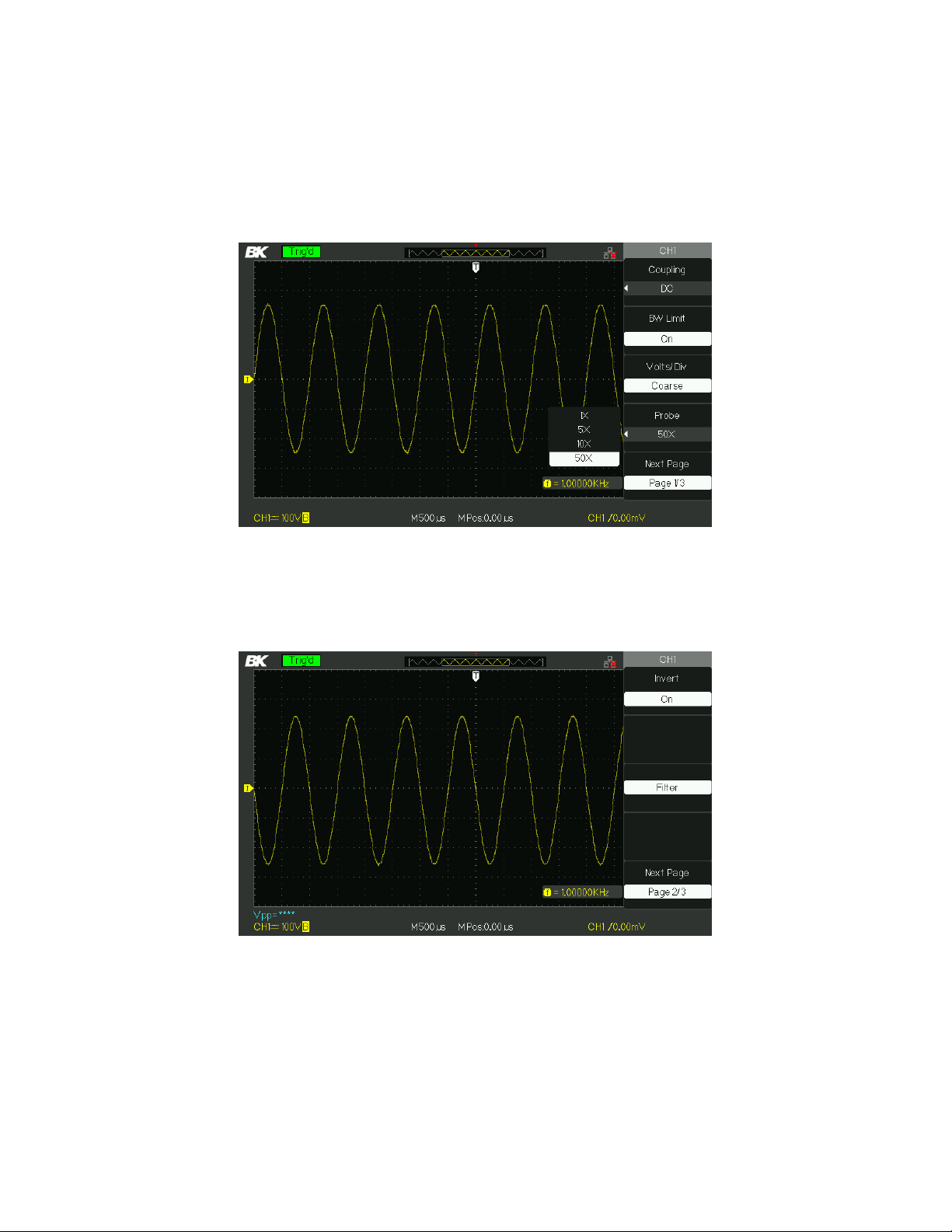

Setting up Channels

Each channel has its own separate Menu. The items are set up separately

according to each channel.

1. Setup Channel Coupling

Take CH1 for example; the tested signal is a sine wave signal with

DC deflection:

• Press “CH1”→“Coupling”→“AC”, Set to AC couple mode.

This will block the DC component of the input signal.

• Press “CH1”→“Coupling”→“DC”, Set to DC couple mode.

Both DC and AC components of the input signal will be

captured.

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

• Press “CH1”→“Coupling”→“GND”, Set to GROUND

mode. This disconnects the input signal.

2. Bandwidth Limiting

Take CH1 for example:

• Press “CH1”→“BW Limit”→ “On”, and bandwidth will be

limited to 20 MHz.

• Press “CH1”→“BW Limit”→ “Off”, and bandwidth limit

will be disabled.

Figure 3.6 – DC Coupling

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

Figure 3.7 – Bandwidth Limit

3. Volts/Div Settings

Vertical scale adjust have Coarse and Fine modes, Vertical

sensitivity range of 2 mV/div – 10 V/div.

Take CH1 for example:

• Press “CH1”→“Volts/Div”→“Coarse”. It is the default

setting of Volts/Div, and makes the vertical scaling in a 12-5-step sequence from 2 mV/div, 5 mV/div, and 10

mV/div to 10 V/div.

• Press “CH1”→ Volts/Div”→ Fine”. This setting changes

the vertical control to small steps between the coarse

settings. It will be helpful when you need to adjust the

waveform vertical size in smaller steps.

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Figure 3.8 – Coarse/Fine Control

4. Setting Probe Attenuation

In order to set the attenuation coefficient, you need to specify it

in the channel operation Menu. If the attenuation coefficient is

10:1, the input coefficient should be set to 10X, so that the

Volts/div information and measurement testing is correct.

Take CH1 for example, when you use the 100:1 probe:

• Press “CH1”→“Probe” →“100X”

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

Figure 3.9 – Probe Attenuation Setting

5. Inverting Waveforms

Take CH1 for example:

• Press “CH1”→ Next Page “Page 1/3” →“Invert”→“On”:

Figure 3.10 – Invert Waveform Screen

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

6. Using the Digital Filter

• Press “CH1”→ Next Page “Page 1/3”→ “Filter”, display

the digital filter menu. Select “Filter Type”, then select

“Upper Limit” or “Lower Limit” and turn the “Universal”

knob to adjust them.

• Press “CH1”→ Next Page “Page 1/3”→ “Filter” →“Off”.

Turn off the Digital Filter function.

Figure 3.11 – Digital Filter Menu

• Press “CH1”→ “Next Page “Page 1/3”→ “Filter” → “On”.

Turn on the Digital Filter function.

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

Figure 3.12 – Digital Filter Adjustment Screen

Function

Setting

Description

Operation

+, -, *, /, FFT

Math operates between signal

source CH1 and CH2.

Source A

CH1 – CH2

Select CH1 or CH2 as Source A.

Source B

CH1 – CH2

Select CH1 or CH2 as Source B.

Invert

on

Invert the MATH waveform.

3.8 Math Functions

Math shows the results after +,-,*, / and FFT operations of the CH1 and

CH2. Press the MATH button to display the waveform math operations.

Press the MATH button again to remove the math waveform display.

Table 3.8 – Math Function Menu

34

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

off

Turn off MATH Invert function.

Next Page

Page 1/2

Enter the second page of MATH

menu.

Function

Setting

Description

Use universal knob to adjust the

vertical position of the MATH

waveform.

Use universal knob to adjust the

vertical scale of the MATH

waveform.

Next Page

Page 2/2

Go back to first page of MATH

menu.

Operation

Setting

Description

+

A+B

Source A waveform adds Source B

waveform.

-

A-B

Source B waveform is subtracted

from Source A waveform.

*

A*B

Source A multiplied by Source B

/

A/B

Source A divided by Source B

FFT

Fast Fourier Transform.

Table 3.9 – Math Function Menu 2

Table 3.10 – Math Function Description

35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

Figure 3.13 – Math Waveform

FFT Option

Setting

Description

Source

CH1, CH2

Select this channel as the FFT

source.

FFT Spectrum Analyzer

The FFT process mathematically converts a time-domain signal into its

frequency components. You can use the Math FFT mode to view the

following types of signals:

• Analyze the harmonic wave in the Power cable.

• Test the harmonic content and distortion in the system

• Show the Noise in the DC Power supply

• Test the filter and pulse response in the system

• Analyze vibration

Table 3.11 – FFT Function Menu 1

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

Window

Hanning

Hamming

Rectangular

Blackman

Select FFT window types.

FFT ZOOM

1X

2X

5X

10X

Changes the horizontal

magnification of the FFT display.

Next Page

Page 1/2

Enter the second page of FFT

menu.

FFT Option

Setting

Description

Scale

Vrms

Set Vrms to be the Vertical Scale

unit.

dBVrms

Set dBVrms to be the vertical

Scale unit.

Display

Split

Full screen

Display FFT waveform on half

screen.

Display FFT waveform on full

screen.

Next Page

Page 2/2

Return to the first page of FFT

menu.

Table 3.12 – FFT Function Menu 2

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

To use the Math FFT mode, you need to perform the following steps:

1. Set up the source (time-domain) waveform.

2. Press the AUTO button to display an YT waveform.

3. Turn the vertical “POSITION” knob to move the YT waveform to

the center vertically (zero divisions).

4. Turn the horizontal “POSITION” knob to position the part of the

YT waveform that you want to analyze in the center eight

divisions of the screen. The oscilloscope calculates the FFT

spectrum using the center 1024 points of the time-domain

waveform.

5. Turn the “Volts/div” knob to ensure that the entire waveform

remains on the screen.

6. Turn the “S/div” knob to provide the resolution you want in the

FFT spectrum.

7. If possible, set the oscilloscope to display many signal cycles.

To display FFT correctly, follow these steps:

1. Push the “MATH” button.

2. Set the “Operation” option to FFT.

3. Press the “Source” button to select “CH1” or “CH2” according to

input signal channel.

4. Turn the “Time/div” knob to adjust the sampling rate (this

parameter is displayed behind the time base parameter), making

sure it is at least double the input signal frequency. (to avoid

aliasing according to Nyquist’s theorem)

Displaying the FFT Spectrum

Press the MATH button to display the Math Menu. Use the options to

select the Source channel, Window algorithm, and FFT Zoom factor. You

can display only one FFT spectrum at a time. You can select “Full screen”

or “Split” in “Display” option to display FFT waveform on full screen or

display channel waveform and its FFT waveform on half screen at a time.

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

Figure 3.14 – FFT Function

Window

Characteristics

Applications

Rectangular

Best frequency

resolution, worst

magnitude resolution.

This is essentially the

same as no window.

Symmetric transients

or bursts. Equalamplitude sine waves

with fixed frequencies.

Broadband random

noise with a relatively

slowly varying

spectrum.

Select FFT window

Windows reduce spectral leakage in the FFT spectrum. The FFT assumes

that the YT waveform repeats forever. With an integral number of cycles,

the YT waveform starts and ends at the me amplitude and there are no

discontinuities in the signal shape A non-integral number of cycles in the

YT waveform causes the signal start and end points to be at different

amplitudes. The transitions between the start and end points cause

discontinuities in the signal that introduce high-frequency transients.

Table 3.13 – FFT Window Description

39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

Hanning

Hamming

Better frequency,

poorer magnitude

accuracy than

Rectangular. Hamming

has slightly better

frequency resolution

than Hanning.

Sine, periodic, and

narrow-band random

noise. Asymmetric

transients or bursts.

Blackman

Best magnitude, worst

frequency resolution.

Single frequency

waveforms, to find

higher order

harmonics.

Magnifying the FFT Spectrum

You can magnify and use cursors to take measurements on the FFT

spectrum. The oscilloscope includes an “FFT Zoom” option to magnify

horizontally, press this option button to select “1X”, “2X”, “5X” or “10X”.

Moreover, you also can turn the “Universal” knob to magnify FFT

waveform horizontally in a 1-2-5 step. To magnify vertically, turn the

“Volts/div” knob.

Measuring an FFT Spectrum Using Cursors

You can take two measurements on FFT spectrums: magnitude (in dB) and

frequency (in Hz). Magnitude is referenced to 0 dB, where 0 dB equals 1

VRMS. You can use the cursors to take measurements at any zoom factor.

Use horizontal cursors to measure amplitude and vertical cursors to

measure frequency.

If you input a sine signal into channel 1, follow these steps:

• Measure FFT Amplitude

1. Input a sine signal to channel 1, and press the

“AUTO” button.

2. Press the “MATH” button to enter the “MATH”

menu.

3. Press the “Operation” option button to select “FFT”.

4. Press the “Source” option button to select “CH1”.

5. Press CH1 button to display CH1 menu.

40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

6. Turn the “Time/div” knob to adjust the sampling

rate (at least double the frequency of input signal).

7. If FFT is displayed on full screen, press CH1 button

again to remove channel waveform display.

8. Press the “CURSOR” button to enter “Cursor” menu.

9. Press the “Cursor Mode” button to select “Manual”.

10. Press the “Type” option button to select “Voltage”.

11. Press the “Source” option button to select “MATH”.

12. Press the “CurA” option button; turn the “Universal”

knob to move Cursor A to the highest point of the

FFT waveform.

13. Press the “CurB” option button, turn the “Universal”

knob to move Cursor B to the lowest point of the

FFT waveform.

14. The amplitude (△T) displays on the top of the left

screen.

Figure 3.15 – Measuring FFT Amplitude

• Measure FFT Frequency

1. Press the CURSOR button.

2. Press the “Cursor Mode” button to select “Manual”.

3. Press the “Type” option button to select “Time”.

41

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

4. Press the “Source” option button to select “MATH”.

NOTE:

The FFT of a waveform that has a DC component or offset can

cause incorrect FFT waveform magnitude values. To minimize the

DC component, choose AC Coupling on the source waveform.

To display FFT waveforms with a large dynamic range, use the

dBVrms scale. The dBVrms scale displays component magnitudes

using a log scale.

The Nyquist frequency is the highest frequency that any real-time

digitizing oscilloscope can acquire without aliasing. This frequency

is half that of the sample rate provided it is within the analog

5. Press the “CurA” option button, turn the “Universal”

button to move Cursor A to the highest position of

the FFT waveform.

6. The value of CurA displaying on the top of the left

screen is FFT frequency. This frequency should be

the same as input signal frequency.

Figure 3.16 – Measuring FFT Frequency

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

42

Page 57

bandwidth of the oscilloscope. Frequencies above the Nyquist

frequency will be undersampled, which causes aliasing.

Option

Setting

Description

Source

CH1,CH2,

CH1 off

CH2 off

Choose the waveform display to

store.

REFA

REFB

Choose the reference location to

store or recall a waveform.

Save

Stores source waveform to the

chosen reference location.

REFA

REFB

on

off

Recall the reference waveform on

the screen.

Turn off the reference waveform.

3.9 Using REF

The reference control saves waveforms to a nonvolatile waveform

memory. The reference function becomes available after a waveform has

been saved.

Table 3.14 – REF Function Menu

43

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

Press the Ref button to display the “Reference waveform menu”.

NOTE:

X-Y mode waveforms are not stored as reference waveforms.

You cannot adjust the horizontal position and scale of the

reference waveform.

Figure 3.17 – Reference Waveform Menu

Operation step:

1. Press the “REF” menu button to display the “Reference waveform

menu”.

2. Press the “Source” option button to select input signal channel.

3. Turn the vertical “POSITION” knob and “Volts/div” knob to adjust

the vertical position and scale.

4. Press the third option button to select “REFA” or “REFB” as

storage position.

5. Press the “Save” option button.

6. Press the bottom option button to select “REFA On” or “REFB On”

to recall the reference waveform.

44

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

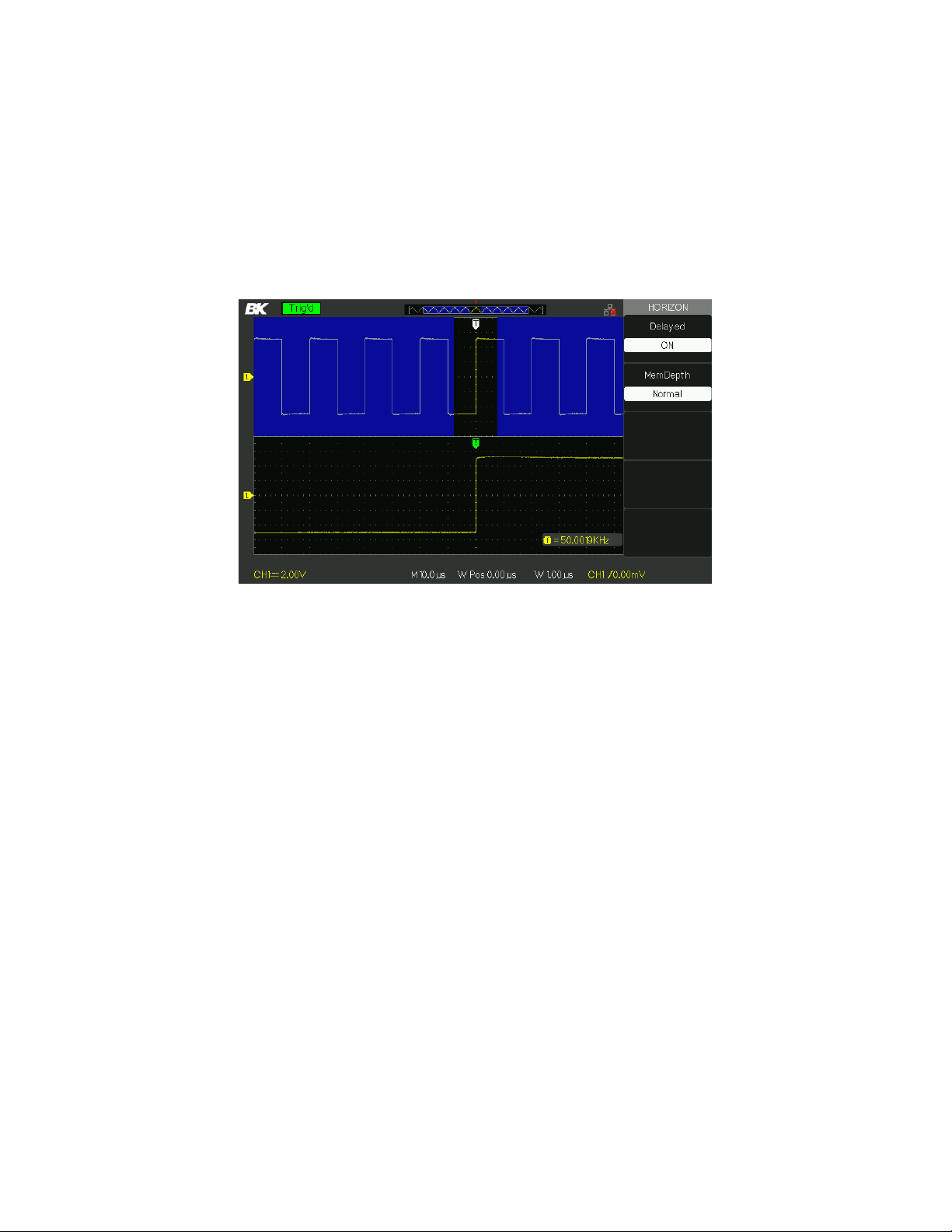

3.10 Horizontal System

Option

Setting

Description

Delayed

On

Off

Turn on this function for main time base

waveform to display on the top half screen

and window time base waveform to display

on the below half screen at the same time.

Turn off this function to only display main

time base waveform on the screen.

Shown below are two knobs and one button in the HORIZONTAL area.

Figure 3.18 – Horizontal Controls

Table 3.15 – Horizontal System Function Menu

Horizontal Control Knob

You can use the horizontal controls to change the horizontal scale and

position of waveforms. The horizontal position readout shows the time

represented by the center of the screen, using the time of the trigger as

45

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

zero. Changing the horizontal scale causes the waveform to expand or

contract around the screen center.

• Horizontal “POSITION” knob

1. Adjust the horizontal position of all channels and

math waveforms (the position of the trigger relative

to the center of the screen). The resolution of this

control varies with the time base setting.

2. When you press the horizontal “POSITION” Knob,

you can set the horizontal position to zero.

• “Time/div” knob

1. Used to change the horizontal time scale to magnify

or compress the waveform. If waveform acquisition

is stopped (using the RUN/STOP or SINGLE button),

turn the Time/div knob to expand or compress the

waveform.

2. Select the horizontal Time/div (scale factor) for the

main or the window time base. When Window Zone

is enabled, it changes the width of the window zone

by changing the window time base.

• Display scan mode

When the Time/div control is set to 100 ms/div or slower and the

trigger mode is set to Auto, the oscilloscope enters the scan

acquisition mode. In this mode, the waveform display updates

from left to right. There is no trigger or horizontal position control

of waveforms during scan mode.

Window Zone

Use the Window Zone option to define a segment of a waveform to see

more detail. This function behaves like zooming into a portion of the

captured waveform. The window time base setting cannot be set slower

than the Main time base setting.

You can turn the Horizontal Position and Time/div controls to enlarge or

minimize waveforms in the Window Zone.

If you want to see a section of the waveform in details, follow these steps:

1. Press the “HORI MENU” button to enter the “Horizontal menu”.

46

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

2. Turn the “Time/div” knob to change the main time base scale.

3. Press the “Delayed” option button to select “On”.

Figure 3.19 – Horizontal Delay Menu

4. Turn the “Horizontal Position” knob (adjust window’s position) to

select the window that your need and expanded window

waveform display on the below half screen at the same time.

3.11 Trigger System

The trigger determines when the oscilloscope starts to acquire data and

display a waveform. When a trigger is set up properly, the oscilloscope

converts unstable displays or blank screens into meaningful waveforms.

Here are three buttons and one knob in the trigger area. See below:

47

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 62

Figure 3.20 – Trigger Controls

• “TRIG MENU” Button: Press the “TRIG MENU” Button to

display the “Trigger Menu”.

• “LEVEL” Knob: The LEVEL knob is to set the

corresponding signal voltage of trigger point in order to

sample. Press the “LEVEL” knob to set trigger level to

zero.

• “SET TO 50%” Button: Use the “SET TO 50%” button to

stabilize a waveform quickly. The oscilloscope can set

the Trigger Level to be about halfway between the

minimum and maximum voltage levels automatically.

This is useful when you connect a signal to the EXT TRIG

BNC and set the trigger source to Ext or Ext/5.

• “FORCE Button: Use the FORCE button to complete the

current waveform acquisition whether the oscilloscope

detects a trigger or not. This is useful for SINGLE

acquisitions and Normal trigger mode.

Signal Source

You can use the Trigger Source options to select the signal that the

oscilloscope uses as a trigger. The source can be any signal connected to a

channel BNC, to the EXT TRIG BUS, or the AC power line (available only

with Edge Trigger).

48

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Option

Setting

Description

Type

Edge

With Edge highlighted, the rising or falling edge

of the input signal is used for the trigger.

Source

CH1

CH2

Triggers on a channel whether or not the

waveform is displayed.

EXT

Does not display the trigger signal; the Ext

option uses the signal connected to the EXT TRIG

front-panel BNC and allows a trigger level range

of -1.2V to +1.2V.

EXT/5

Same as Ext option, but attenuates the signal by

a factor of five, and allows a trigger level range

of +6V to -6V.This extends the trigger level

range.

AC Line

This selection uses a signal derived from the

power line as the trigger source; trigger coupling

is set to DC and the trigger level to 0 volts.

Slope

Trigger on Rising edge of the trigger signal.

Trigger on Falling edge of the trigger signal.

Trigger Type

The scopes have five trigger types: Edge, Video, Pulse, Slope, and

Alternate.

Edge Trigger

Use Edge triggering to trigger on the edge of the oscilloscope input signal

at the trigger threshold.

Table 3.16 – Edge Trigger Function Menu

49

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

Trigger on Rising edge and Falling edge of the

trigger signal.

Mode

Auto

Use this mode to let the acquisition free-run in

the absence of a valid trigger; This mode allows

an untriggered, scanning waveform at 100

ms/div or slower time base settings.

Normal

Use this mode when you want to see only valid

triggered waveforms; when you use this mode,

the oscilloscope does not display a waveform

until after the first trigger.

Single

When you want the oscilloscope to acquire a

single waveform, press the “SINGLE” button.

Set up

Enter the “Trigger Setup Menu” (See Table 3.17).

Option

Setting

Explain

Coupling

DC

Passes all components of the signal

AC

Blocks DC components, attenuates

signals below 50 Hz.

HF Reject

Attenuates the high-frequency

components above 150 kHz.

LF Reject

Blocks the DC component, attenuates the

low-frequency components below 7 kHz.

Holdoff

Using the “universal” knob to adjust

holdoff time (sec), the holdoff value is

displayed.

Holdoff

Reset holdoff time to 100ns.

Table 3.17 – Trigger Setup Function Menu

50

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 65

Reset

Return

Return to the first page of “Trigger main

menu”.

Figure 3.21 – Trigger Menu Screen

Operating Instructions:

1. Setup Type

Press the “TRIG MENU” button to display “Trigger”

menu.

Press the “Type” option button to select “Edge”.

2. Set up Source

According to the input signal, press the “Source” option

button to select “CH1”, “CH2”, “EXT”, “EXT/5” or “AC

Line”.

3. Set up Slope

Press the “Slope” option button to select “ ”, “

” or “ ”.

51

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 66

4. Set up Trigger mode

Option

Setting

Description

Type

Pulse

Select the pulse to

trigger the pulse match

the trigger condition.

Source

CH1

CH2

EXT

EXT/5

AC Line

Select input signal

source.

Press the “Trigger mode” option button to select “Auto”,

“Normal”, or “Single”.

Auto: The waveform refreshes at a high speed whether

the trigger condition is satisfied or not.

Normal: The waveform refreshes when the trigger

condition is satisfied and waits for next trigger event

occurring when the trigger condition is not satisfied.

Single: The oscilloscope acquires a waveform when the

trigger condition is satisfied and then stops

5. Set up Trigger coupling

Press the “Set Up” button to enter the “Trigger Setup

Menu”.

Press the “Coupling” option button to select “DC”, “AC”,

“HF Reject” or “LF Reject”.

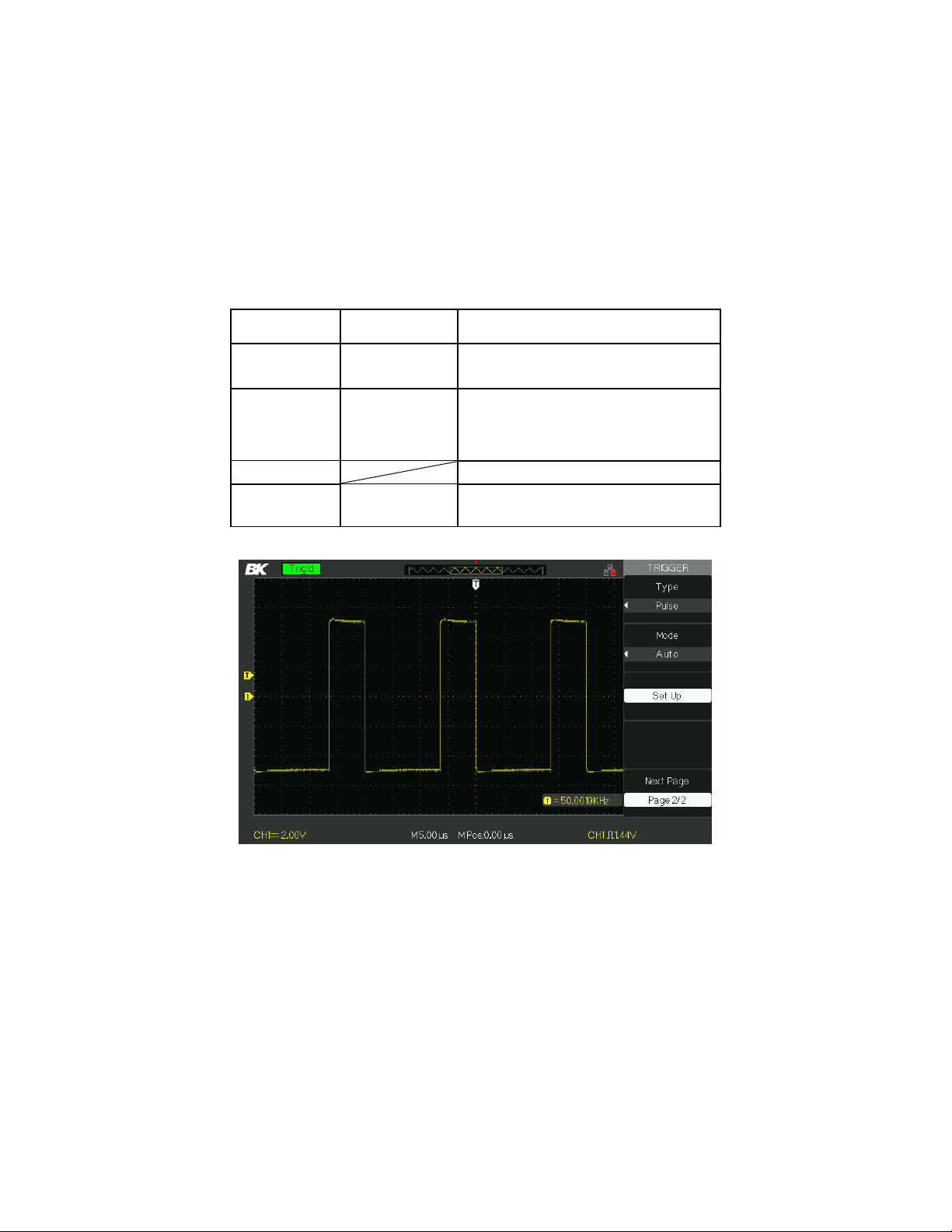

Pulse Trigger

Use Pulse Width triggering to trigger on aberrant pulses.

Table 3.18 – Pulse Trigger Function Menu 1

52

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 67

When

(Positive pulse width less

than pulse width setting)

(Positive pulse width larger

than pulse width setting)

(Positive pulse width equal

to pulse width setting)

(Negative pulse width less

than pulse width setting)

(Negative pulse width

larger than pulse width setting)

(Negative pulse width

equal to pulse width setting)

Select how to compare

the trigger pulse

relative to the value

selected in the Set

Pulse Width option.

Set Width

20.0ns~10.0s

Selecting this option

can turn the universal

to set up the pulse

width.

Next Page

Page 1/2

Press this button to

enter the second page.

Figure 3.22 – Pulse Trigger Menu 1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

53

Page 68

Option

Setting

Description

Type

Pulse

Select the pulse to trigger the pulse

match the trigger condition.

Mode

Auto

Normal

single

Select the type of triggering; Normal

mode is best for most Pulse Width

trigger applications.

Set up

Enter the “Trigger setup menu”.

Next Page

Page 2/2

Press this button to return to the first

page.

Table 3.19 – Pulse Trigger Function Menu 2

Figure 3.23 – Pulse Trigger Menu 2

Operating Instructions:

1. Setup Type

Press the “TRIG MENU” button to display “Trigger”

menu.

54

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 69

Press the “Type” option button to select “Pulse”.

Option

Setting

Description

Type

Video

When you select the video type,

put the couple set to the AC, then

you could trigger the NTSC, PAL

and SECAM video signal.

Source

CH1

CH2

Select the input source to be the

trigger signal.

EXT

EXT/5

Ext and Ext/5 use the signal

applied to the EXT TRIG

connector as the source.

Polarity

(Normal)

Normal triggers on the negative

edge of the sync pulse.

(Inverted)

Inverted triggers on the positive

edge of the sync pulse.

Sync

Line Num

All lines

Odd field

Even Field

Select appropriate video sync.

Next Page

Page 1/2

Enter the second page of

“Video trigger menu”.

2. Set up condition

Press the “When” option button to select “ ”, “

”, “ ”, “ ”, “ ”or“ ”.

3. Set up pulse width

Turn the “Universal” knob to set up width.

Video Trigger

Trigger on fields or lines of standard video signals.

Table 3.20 – Video Trigger Function Menu 1

55

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 70

Option

Setting

Description

Type

Video

When you select the video

type, put the couple set to the

AC, then you could trigger the

NTSC, PAL and SECAM video

signal.

Standard

NTSC

Pal/Secam

Select the video standard for

sync and line number count.