Page 1

INSTRUCTION

MANUAL

MANUAL DE INSTRUCCION

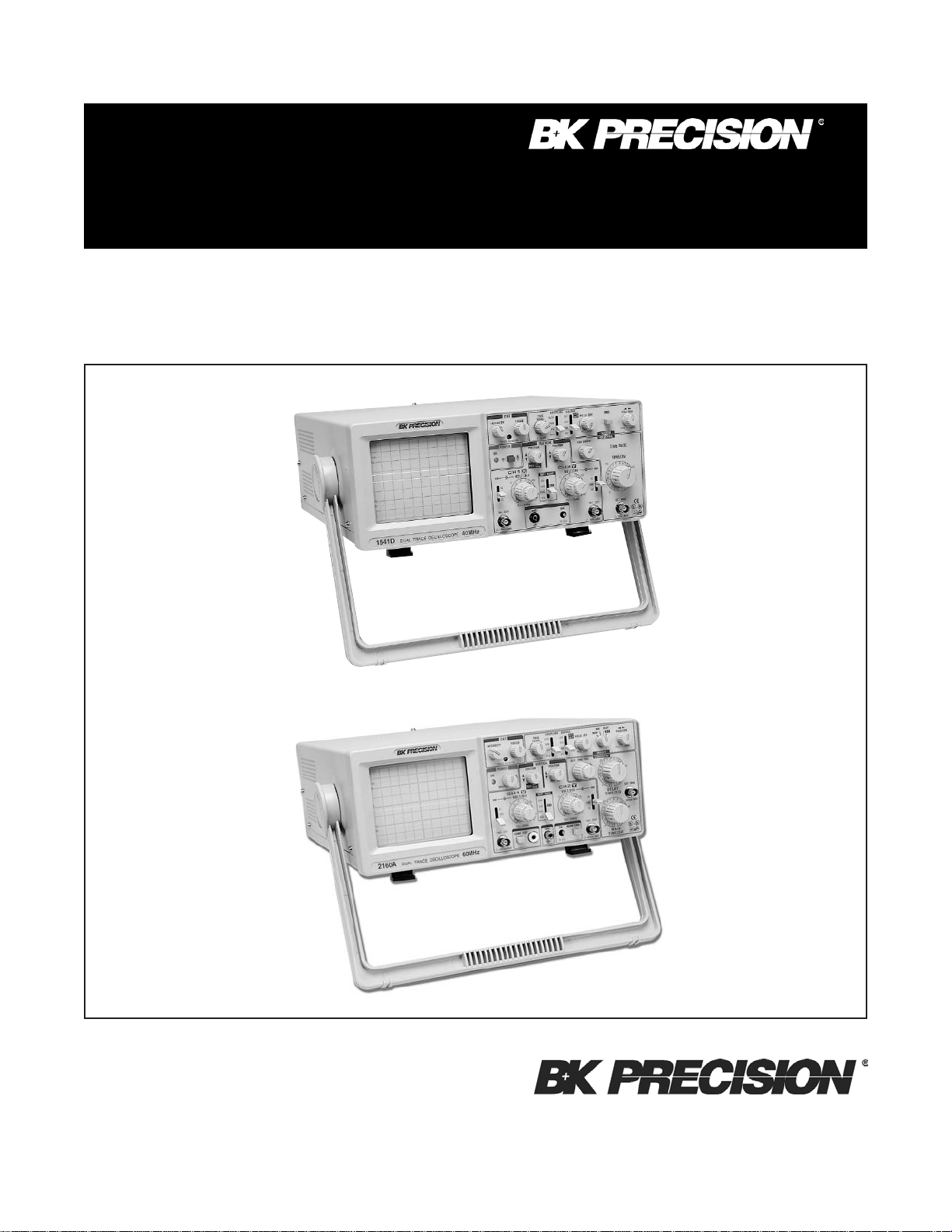

MODELS 1541D

and 2160A

MODELOS 1541D & 2160A

40 MHz & 60 MHz DUAL-TRACE OSCILLOSCOPES

40MHz & 60MHz DOBLE LINEA OSCILOSCOPIOS

Page 2

TEST INSTRUMENT SAFETY

WARNING

Normal use of test equipment exposes you to a certain amount of danger from electrical shock because

testing must often be performed where exposed high voltage is present. An electrical shock causing

10milliampsofcurrenttopassthroughthe heartwillstopmosthumanheartbeats.Voltageaslow as 35 volts

dc or ac rms should be considered dangerous and hazardous since it can produce a lethal current under

certain conditions. Higher voltage poses an even greater threat because such voltage can more easily

produce a lethal current. Your normal work habits should include all accepted practices that will prevent

contact with exposed high voltage, and that will steer current away from your heart in case of accidental

contact with a high voltage. You will significantly reduce the risk factor if you know and observe the

following safety precautions:

1. Don’t expose high voltage needlessly in the equipment under test. Remove housings and covers only when necessary.

Turn off equipment while making test connections in high-voltage circuits. Discharge high-voltage capacitors after

removing power.

2. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However,

remember that high voltage may appear at unexpected points in defective equipment.

3. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to

place equipment; make certain such surfaces are not damp or wet.

4. Use the time-proven “one hand in the pocket” technique while handling an instrument probe. Be particularly careful to

avoid contacting a nearby metal object that could provide a good ground return path.

5. When using a probe, touch only the insulated portion. Never touch the exposed tip portion.

6. When testing ac powered equipment, remember that ac line voltage is usually present on some power input circuits such

as the on-off switch, fuses, power transformer, etc. any time the equipment is connected to an ac outlet, even if the

equipment is turned off.

7. Some equipment with a two-wire ac power cord, including some with polarized power plugs, is the “hot chassis” type.

This includes most recent television receivers and audio equipment. A plastic or wooden cabinet insulates the chassis

toprotect the customer. When the cabinet is removed for servicing, a serious shock hazard exists if the chassis is touched.

Not only does this present a dangerous shock hazard, but damage to test instruments or the equipment under test may

result from connecting the ground lead of most test instruments (including this oscilloscope) to a “hot chassis”. To make

measurements in “hot chassis” equipment, always connect an isolation transformer between the ac outlet and the

equipment under test. The B+K Precision Model TR-110 or 1604A Isolation Transformer, or Model 1653A or 1655A

AC Power Supply is suitable for most applications. To be on the safe side, treat all two wire ac powered equipment as

“hot chassis” unless you are sure it has an isolated chassis or an earth ground chassis.

8. Never work alone. Someone should be nearby to render aid if necessary. Training in CPR (cardio-pulmonary

resuscitation) first aid is highly recommended.

Page 3

Instruction Manual

22820 Savi Ranch Parkway, Yorba Linda, CA 92887

for

+

BK PRECISION

®

Models 1541D

and 2160A

40 MHz and 60 MHz

Dual-Trace Oscilloscopes

©2000 B+K Precision Corp.

This symbol on oscilloscope means “refer to instruction manual

for further precautionary information”. This symbol appears in the

manual where the corresponding information is given.

+

®

Page 4

TABLE OF CONTENTS

Page Page

TEST INSTRUMENT SAFETY . . . . . . inside front cover

FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . 7

General Function Controls . . . . . . . . . . . . . . . . . . . . . . 7

Vertical Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Horizontal Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Triggering Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rear Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . 11

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment Protection Precautions. . . . . . . . . . . . . . . 11

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial Starting Procedure . . . . . . . . . . . . . . . . . . . . . . 12

Single Trace Display . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dual Trace Display. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Triggering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Magnified Sweep Operation . . . . . . . . . . . . . . . . . . . 15

OPERATING INSTRUCTIONS (Continued)

X−Y Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Video Signal Observation . . . . . . . . . . . . . . . . . . . . . 15

Applications Guidebook . . . . . . . . . . . . . . . . . . . . . . 15

Delayed Sweep Operation. . . . . . . . . . . . . . . . . . . . . 15

Component Test Operation . . . . . . . . . . . . . . . . . . . . 16

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Line Voltage Selection. . . . . . . . . . . . . . . . . . . . . . . . 20

Periodic Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . 20

Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Instrument Repair Service. . . . . . . . . . . . . . . . . . . . . 21

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Important Considerations for Rise Time and

Fall Time Measurements . . . . . . . . . . . . . . . . . . . . 22

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SPANISH MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . 25

“Guidebook To Oscilloscopes”

Availability . . . . . . . . . . . . . . . . . . . . . inside back cover

2

Page 5

FEATURES

LOW COST ,HIGH PERFORMANCE

B+K Precision’s 40 MHz and 60 MHz oscilloscopes are

among the lowest cost in the industry, yet offer high

performance and features not found on many competitors’

oscilloscopes. Model 2160A includes a built-in component

tester,which is an excellent tool for in-circuit troubleshooting. These oscilloscopes are built by and backed by B+K

Precision, a compnay that has been selling reliable, durable,

value priced test instruments for over 50 years.

CRT FEATURES

Rectangular CRT

Rectangular CRTwith large 8 x 10 centimeter viewing

area. On Model 2160A, graticule is equipped with

variable scale illumination.

Convenience

Tracerotation electrically adjustable from front panel.

0%, 10%, 90%, and 100% markers for rise time measurements.

DUAL TRACE FEATURES

Dual Trace

Models2160A and 1541D eachhavetwo verticalinput

channels for displaying two waveforms simultaneously. Selectable single trace (either CH 1 or CH 2) or

dual trace. Alternate or chop sweep selectable at all

sweep rates.

Sum and Difference Capability

Permits algebraic addition or subtraction of channel 1

and channel 2 waveforms, displayed as a single trace.

Useful for differentialvoltageand distortion measurements.

HIGH FREQUENCY FEATURES

Wide Bandwidth

Conservatively-rated −3 dB bandwidth is dc to 60

MHz for Model 2160A and dc to 40 MHz for Model

1541D.

Fast Rise Time

Rise time is less than 5.8 ns for Model 2160A and

8.8 ns for Model 1541D.

Fast Sweep

Maximum sweep speed of 10 ns/div (with X10 MAG)

assures high frequencies and short-duration pulses are

displayed with high resolution.

VERTICAL FEATURES

High Sensitivity

5 mV/div sensitivityfor full bandwidth. High-sensitivity 1 mV/div and 2 mV/div using PULL X5 gain

control.

Calibrated VoltageMeasurements

Accurate voltage measurements (±3%) on 10 calibrated ranges from 5 mV/div to 5 V/ div. Vertical gain

fully adjustable between calibrated ranges.

SWEEP FEATURES

Calibrated Time Measurements

Accurate (±3%) time measurements. The main sweep

has 23 calibrated ranges from 2 S/div to 0.1 µS/div.

The delayed sweep on the Model 2160A has 23 calibrated ranges from 2 S/div to 0.1 µS/div. Sweep time

is fully adjustable between calibrated ranges.

X10 Sweep Magnification

Allows closer examination of waveforms, increases

maximum sweep rate to 10 nS/div.

DUAL TIME BASE FEATURES (Model 2160A)

Dual Sweep Generators

Main sweep gives normal waveform display, delayed

sweepmay beoperatedat fastersweepspeed toexpand

a portion of the waveform.

Four Sweep Modes

Choice of main sweep only, delayed sweep only,

main sweep and delayed sweep sh arin g the tr ace

(percentage of mai n/d elaye d sweep adjustable), or

X−Y.

Adjustable Start Of Delayed Sweep

DELAY TIME POSition control allows adjustment of

delayed sweep starting point.

TRIGGERING FEATURES

Two Trigger Modes

Selectable normal (triggered) or automatic sweep

modes.

Triggered Sweep

Sweep remains at rest unless adequate trigger signal is

applied. Fully adjustable trigger level and (+) or (−)

slope.

3

Page 6

FEATURES

AUTO Sweep

Selectable AUTO sweep provides sweep without trigger input, automatically reverts to triggered sweep

operation when adequate trigger is applied.

Five TriggerSources

Five trigger source selections, including CH 1, CH 2,

alternate, EXT, and LINE.

Video Sync

Frame(TV V) or Line (TV H) triggering selectablefor

observingcomposite video waveforms.TV-Hposition

can also be used as low frequency reject and TV-V

position can be used as high frequency reject.

Variable Holdoff

Trigger inhibit period after end of sweep adjustable.

Permits stable observation of complex pulse trains.

OTHER FEATURES

X−Y Operation

Channel 1 can be applied as horizontal deflection

(X-axis) while channel 2 provides vertical deflection

(Y-axis).

Built-in Probe Adjust Square Wave

A 2 V p-p, 1 kHz square wave generator permits probe

compensation adjustment.

Component TestFunction (Model 2160A)

Built-inX−Ytypecomponent tester appliesfixedlevel

ac signal to components for display of signature on

CRT.

Channel 2 (Y) Output (Model 2160A)

A buffered 50Ω output of the channel 2 signal is

available at the rear panel for driving a frequency

counter or other instruments. The output is 50 mV/div

(nominal) into 50Ω.

Z-Axis Input (Model 2160A)

Rear panel Z-Axis input allows intensity modulation.

Supplied With TwoProbes

4

Page 7

SPECIFICATIONS

CRT

Type: 6-inch rectangular with integral graticule,

P31 phosphor.

DisplayArea: 8 x 10 div (1 div = 1 cm).

AcceleratingVoltage: 12 kV.

Phosphor:P31.

Trace Rotation: Electrical, front panel adjustable.

Scale Illumination: Continuously variable (Model 2160A).

Beam Finder (Model 2160A).

VERTICAL AMPLIFIERS (CH 1 and CH 2)

Sensitivity: 5 mV/div to 5 V/div, 1 mv/div to 1 V/div at

X5 MAG.

Attenuator:10 calibrated steps in 1-2-5 sequence.Vernier

control provides fully adjustable sensitivity between

steps; range 1/1 to at least 1/3.

Accuracy:±3%, 5 mV to 5 V/div; 5%, at X5 MAG.

Input Resistance:1MΩ±2%.

Input Capacitance: 25 pF ±10 pF.

Frequency Response:

5 mV/div to 5 V/div:

DC to 60 MHz (−3 dB), Model 2160A

DC to 40 MHz (−3 dB), Model 1541D.

X5 MAG:

DC to 15 MHz (−3 dB), Model 2160A

DC to 10 MHz (−3 dB), Model 1541D.

Rise Time:

5.8 nS, Model 2160A

8.8 nS, Model 1541D.

Overshoot:Less than 5%.

Operating Modes:

CH 1: CH 1, single trace.

CH 2: CH 2, single trace.

DUAL: CH 1 and CH 2, dual trace.

Alternate or Chop selectable at

any sweep rate.

ADD: Algebraic sum of CH 1 + CH 2.

Chop Frequency:Approximately 500 kHz.

PolarityReversal:CH 2 invert.

HORIZONTAL AMPLIFIER

(Input through channel 1 input)

X−Y mode:

CH 1 = X axis.

CH 2 = Y axis.

Sensitivity: Same as verticalchannel 2.

Input Impedance: Same as vertical channel 2.

Frequency Response:

DC to 1 MHz (−3 dB).

X-Y Phase Difference: 3° or less at 50 kHz.

MaximumInputVoltage: Same as vertical channel 1.

SWEEP SYSTEM

Operating Modes:

Model 2160A: Main, Mix (both main and delayed

sweep displayed), Delay (only delayed sweep

displayed), X−Y.

Model 1541D: Main only.

Main Time Base: 0.1 µS/div to 2.0 S/div in 1-2-5

sequence,23 steps. Vernier control provides fully

adjustablesweep time between steps.

DelayedTime Base (Model 2160A only): 0.1 µS/divto

2.0 S/div in 1-2-5 sequence, 23 steps.

Accuracy:±3%.

Sweep Magnification: X10 ±10%.

Holdoff: Continuously adjustable for main time base from

NORM to 5 times normal.

Delay Time Position: Control sets percentage of display

that is devotedto main and delayed sweep.

Delay Jitter: 1/10,000 of full scale sweep time.

TRIGGERING

Trigger Modes:

AUTO (free run), NORM, TV-V, TV-H.

Trigger Source:

CH 1, CH 2, Alternate, EXT,LINE.

Slope:

(+) or (–).

MaximumInput Voltage: 400 V (dc + ac peak).

5

Page 8

SPECIFICATIONS

NOTE:

Specifications and information

are

subject to change without notice.

Please visit

Trigger Coupling:

AUTO: Sweep free-runs in absence of

suitable trigger signal.

NORM: Sweep triggered only by adequate

trigger signal.

TV-V: Video vertical sync pulses are

selected. Also usable for high

frequency reject.

TV-H: Video horizontal sync pulses are

selected. Also usable for low

frequency reject.

Trigger Sensitivity:

Auto: 1.5 div (internal)

≥0.5 Vp-p (external)

100 Hz – 60 MHz (2160A)

100 Hz – 40 MHz (1541D)

Norm: 1.5 div (internal)

≥0.5 Vp-p (external)

100 Hz – 60 MHz (2160A)

DC – 40 MHz (1541D)

TV-V: 1.0 div (internal)

≥0.5 Vp-p (external)

DC – 1 kHz

TV-H: 1.0 div (internal)

≥0.5 Vp-p (external)

1 kHz – 100 kHz

MaximumExternalTriggerVoltage: 300 V (dc + ac

peak).

COMPONENTTESTER (Model 2160A)

ComponentsTested: Resistors, capacitors, inductors, and

semiconductors.

Test Voltage: 6 V rms maximum (open).

Test Current: 11 mA maximum (shorted).

Test Frequency:Line frequency (60 Hz in USA).

OTHER SPECIFICATIONS

Cal/ProbeCompensationVoltage: 2 V p-p ±3% square

wave,1 kHz nominal.

CH 2 (Y) Output (Model 2160A):

Output Voltage: 50 mV/div (nominal into 50 ohm

load).

Output Impedance: Approximately 50 ohms.

Frequency Response:20 Hz to 30 MHz, −3 dB.

IntensityModulation (Model 2160A)

Input Signal: TTL level, intensity increasing with

more positive levels, decreased intensity with more

negative levels.

Input Impedance: Approximately 50 kΩ.

Usable Frequency Range: DC to 5 MHz.

Maximum Input Voltage: 30 V (dc + ac peak).

Power Requirements: 100–130 VACor 200–260 VAC,

50/60 Hz, 38 watts.

Dimensions (H 3 W3 D):

5.2″ 3 12.8″ 3 15.7″

(132 3 324 3 398 mm).

Weight: 16.8 lbs (7.6 kg).

Environment:

Within Specified Accuracy: +10° to +35° C, 10–80%

relative humidity.

Full Operation: 0° to +50° C, 10–80% relative

humidity.

Storage: −30° to +70° C, 10–90% relative humidity.

ACCESSORIES SUPPLIED:

Two Switchable X1/X10 Probes.

Instruction Manual.

AC Line Cord.

www.bkprecision.com for the most current product information.

6

Page 9

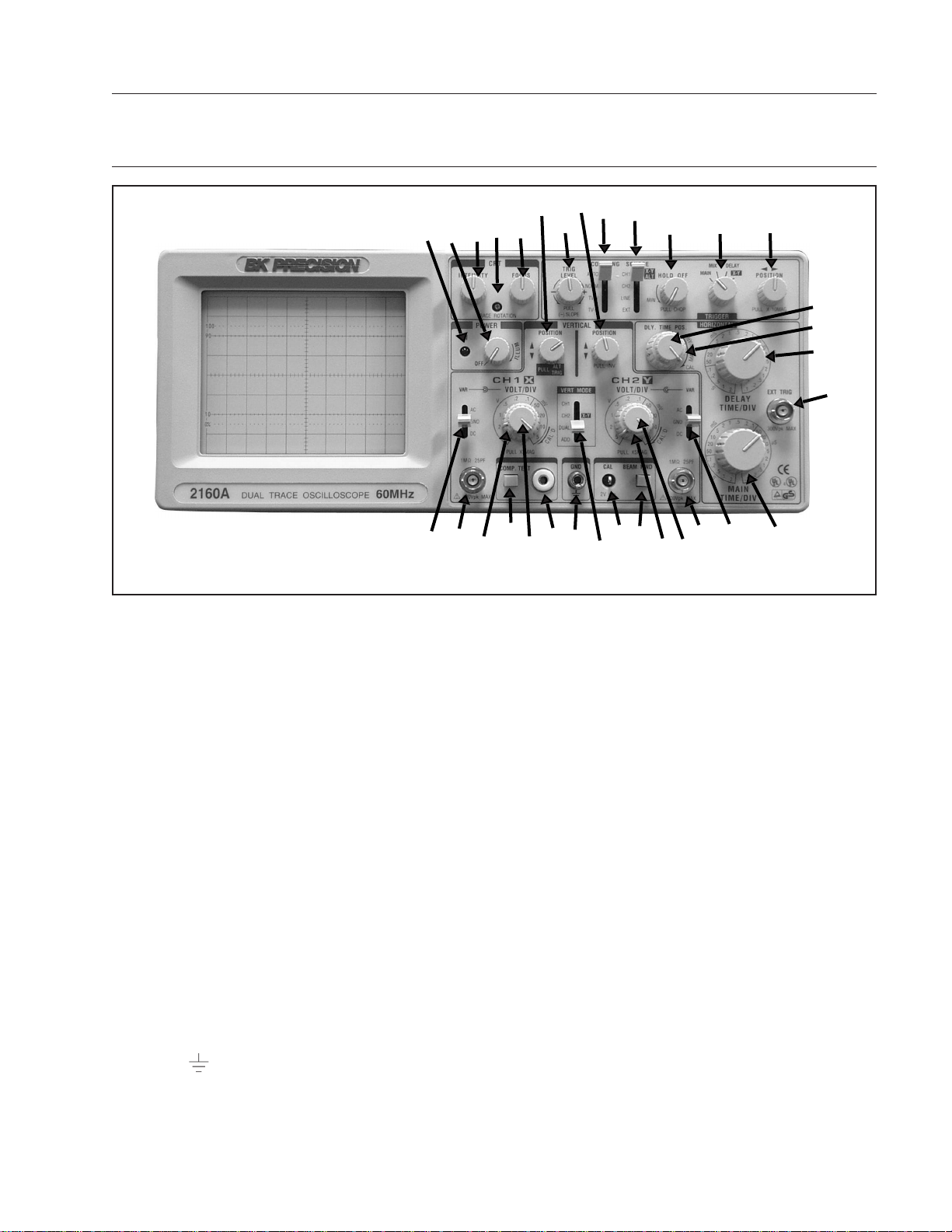

CONTROLS AND INDICATORS

18

17

6

1

5

2

4

33

32

31

30

28

27

26

25

24

34

13

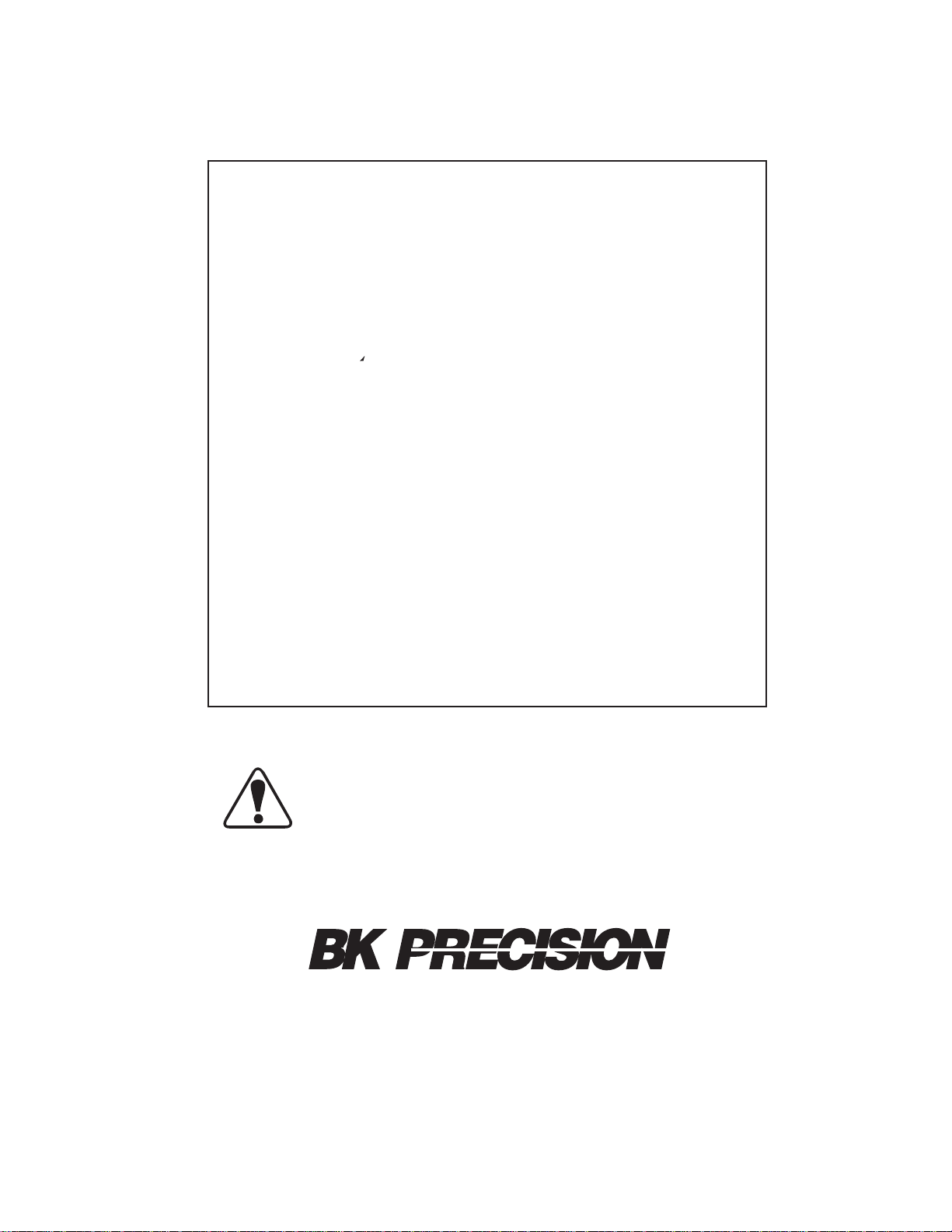

Fig. 1. Model 2160A Controls and Indicators.

GENERAL FUNCTION CONTROLS

1. ON Indicator. Lights when oscilloscope is “on”.

2. 2160A Only. POWER/Scale ILLUMination Control. Clockwise rotation from OFF position turns os-

cilloscope “on”. Further clockwise rotation increases

amount of graticule illumination.

3. 1541D Only. POWER Pushbutton. Turns oscilloscope “on” and “off”.

4. INTENSITY Control. Adjusts brightness of trace.

5. TRACE ROTATION Control. Adjusts to maintain

trace at a horizontal position.

6. FOCUS Control. Adjusts trace focus.

7. 2160A Only. COMPonent TEST Pushbutton. With

pushbutton set to “in” position, Component Test mode

is enabled. Normal scope operation is enabled with

pushbutton in “out” position.

8. 2160A Only. COMPonent TEST Jack. “Banana”type HI-side input jack for connection to component

in Component Test operating mode.

9. GND Terminal. Oscilloscope chassis ground

jack, and earth ground via three-wire ac power cord.

On Model 2160A, also serves as LO-side Component

Test jack.

14

15

7

8

16

10

12

11

19

20

9

21

22

23

10. CAL Terminal. Terminal provides 2 V p-p, 1 kHz

(nominal) square wave signal. This signal is useful for

checking probe compensation adjustment, as well as

providing a rough check of vertical calibration.

11. 2160AOnly.BEAM FIND Pushbutton. Momentary-

contact pushbutton speeds setup of trace positioning

by bringing the beam into graticule area; operates

independently of other display controls.

VERTICAL CONTROLS

12. VERTical MODE Switch. Selects vertical display

mode. Four-position lever switch with the following

positions:

CH1:

Displays the channel 1 signal by itself.

CH2/X-Y:

CH2: displays the channel 2 signal by itself.

X-Y: used in conjunction with the X-Y control and

Trigger SOURCE switch to enable X-Y display

mode.

DUAL:

Displays the channel 1 and channel 2 signals simultaneously. Dual-trace mode may be either alternate

or chop ped sweep; see the description under

HOLDOFF/PULL CHOP control.

7

Page 10

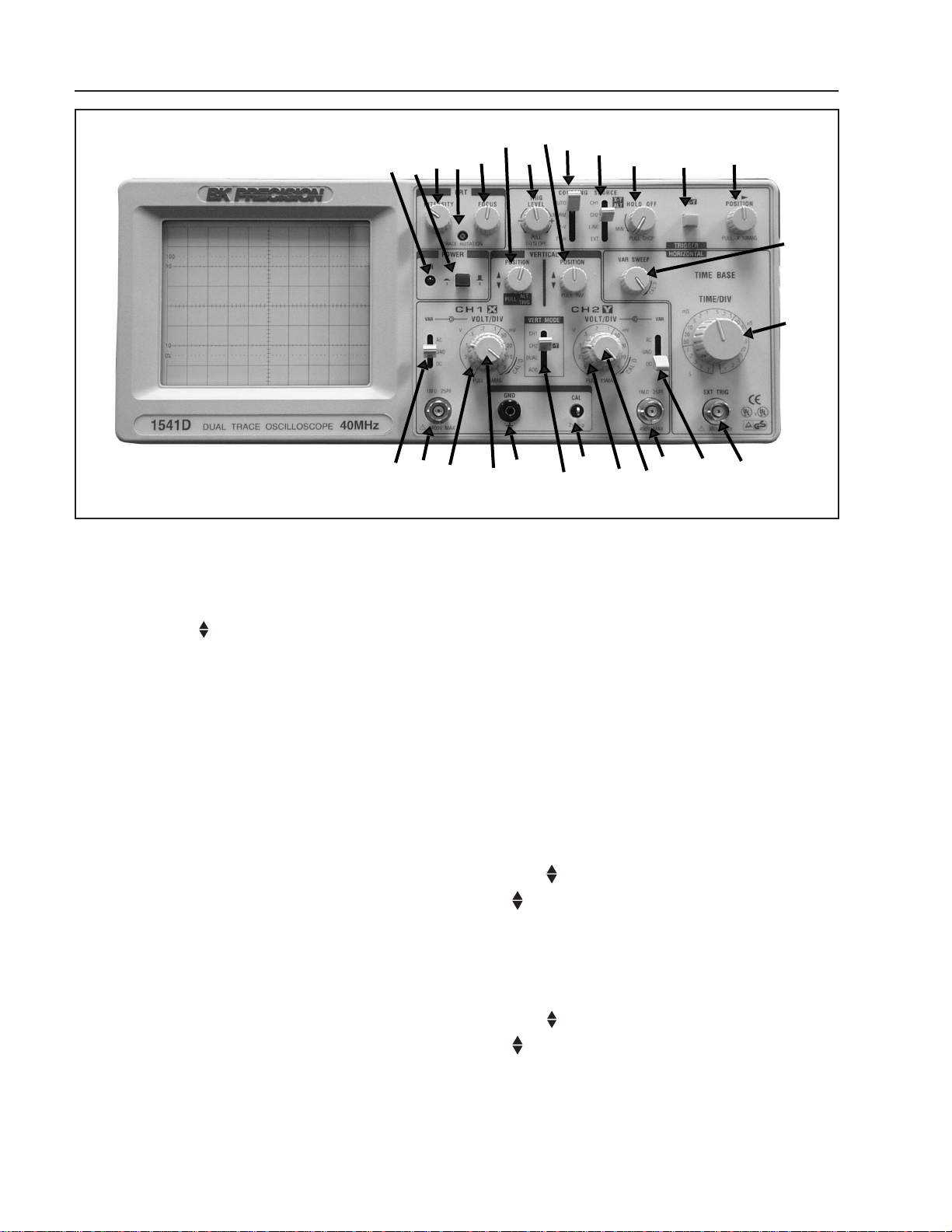

CONTROLS AND INDICATORS

18

17

6

4

1

5

3

33

32

31

30

28

27

26

33

14

13

Fig. 2. Model 1541D Controls and Indicators.

ADD:

The inputs from channel 1 and channel 2 are

summed and displayed as a single signal. If the

Channel 2 POSition/PULL INVert control is

pulled out, the input from channel 2 is subtracted

from channel 1 and the difference is displayed as a

single signal.

13. CH1 AC-GND-DC Switch. Three-position lever

switch with the following positions:

AC:

Channel 1 input signal is capacitively coupled; dc

component is blocked.

GND:

Opens signal path and grounds input to vertical

amplifier. This provides a zero-volt base line, the

position of which can be used as a reference when

performing dc measurements.

DC:

Direct coupling of channel 1 input signal; both ac

and dc components of signal produce vertical deflection.

14. CH1 (X) Input Jack. Vertical input for channel 1.

X-axis input for X-Y operation.

15. CH1 (X) VOLTS/DIV Control. Vertical attenuator

for channel 1. Provides step adjustment of vertical

sensitivity. When channel 1 VARiable control is set

to CAL, vertical sensitivity is calibrated in 10 steps

from 5 mV/div to 5 V/div in a 1-2-5 sequence. When

15

16

12

10

19

9

20

21

22

34

the X-Y mode of operation is selected, this control

provides step adjustment of X-axis sensitivity.

16. CH1 VARiable/PULL X5 MAG Control:

VARiable:

Rotation provides vernier adjustment of channel 1

vertical sensitivity. In the fully-clockwise (CAL)

position, the vertical attenuator is calibrated. Counterclockwise rotation decreases gain sensitivity. In

X-Y operation, this control becomes the vernier

X-axis sensitivity control.

PULL X5 MAG:

When pulled out, increases vertical sensitivity by a

factor of five. Effectively provides two extra sensitivity settings: 2 mV/div and 1 mV/div. In X-Y

mode, increases X-sensitivity by a factor of five.

17. CH1 POSition/PULL ALT TRIGger Control:

POSition:

Adjusts vertical position of channel 1 trace.

PULL ALT:

Used in conjunction with the Trigger SOURCE

switch to activate alternate triggering. See the description under the Trigger SOURCE switch.

18. CH2 POSition/PULL INVert Control:

POSition:

Adjusts vertical position of channel 2 trace. In X-Y

operation, rotation adjusts vertical position of X-Y

display.

8

Page 11

CONTROLS AND INDICATORS

PULL INVert:

When pushed in, the polarity of the channel 2 signal

is normal. When pulled out, the polarity of the

channel 2 signal is reversed, thus inverting the

waveform.

19. CH2 VOLTS/DIV Control. Vertical attenuator for

channel 2. Provides step adjustment of vertical sensitivity. When channel 2 VARiable control is set to

CAL, vertical sensitivity is calibrated in 10 steps from

5 mV/div to 5 V/div in a 1-2-5 sequence. When the

X-Y mode of operation is selected, this control provides step adjustment of Y-axis sensitivity.

20. CH2 VARiable/PULL X5 MAG Control:

VARiable:

Rotation provides vernier adjustment of channel 2

vertical sensitivity. In the fully-clockwise (CAL)

position, the vertical attenuator is calibrated. Counterclockwise rotation decreases gain sensitivity. In

X-Y operation, this control becomes the vernier

Y-axis sensitivity control.

PULL X5 MAG:

When pulled out, increases vertical sensitivity by a

factor of five. Effectively provides two extra sensitivity settings: 2 mV/div and 1 mV/div. In X-Y

mode, increases Y-sensitivity by a factor of five.

21. CH2 (Y) Input Jack. Vertical input for channel 2.

Y-axis input for X-Y operation.

22. CH2 AC-GND-DC Switch. Three-position lever

switch with the following positions:

AC:

Channel 2 input signal is capacitively coupled; dc

component is blocked.

GND:

Opens signal path and grounds input to vertical

amplifier. This provides a zero-volt base line, the

position of which can be used as a reference when

performing dc measurements.

DC:

Direct coupling of channel 2 input signal; both ac

and dc components of signal produce vertical deflection.

HORIZONTAL CONTROLS

23. Main Time Base TIME/DIV Control. Provides step

selection of sweep rate for the main time base. When

theVARiable Sweep control isset to CAL, sweep rate

iscalibrated. This controlhas23 steps, from0.1 µS/div

to 2 S/div, in a 1-2-5 sequence.

24. 2160A Only. DELAY Time Base TIME/DIV Control. Provides step selection of sweep rate for delayed

sweep time base. This control has 23 steps, from 0.1

µS/div to 2 S/div, in a 1-2-5 sequence.

25. 2160A Only. DELAY TIMEPOSition Control. Sets

starting point of delayed sweep. Clockwise rotation

causes delayed sweep to begin earlier.

26. VARiable Sweep Control. Rotation of control is ver-

nier adjustment for sweep rate. In fully clockwise

(CAL) position, sweep rate is calibrated. On the

Model 2160A, this control is the vernier adjustment

for both the main and delayed time bases.

27. POSition/PULL X10 MAG Control.

POSition:

Horizontal (X) position control.

PULL X10 MAG:

Selects ten times sweep magnification when pulled

out, normal when pushed in. Increases maximum

sweep rate to 10 nS/div.

28. 2160A Only. Sweep Mode Switch. Selects sweep

(horizontal) mode. Four-position rotary switch with

the following positions:

MAIN:

Only the main sweep operates, with the delayed

sweep inactive.

MIX:

The main and delayed sweep share a single trace;

main sweep occupies the left portion of the display;

delayed sweep occupies the right portion of the

display. The DELAY TIME POSition control de-

termines the percentage of display that is main

sweep and the percentage of display that is delayed

sweep (main sweep is usually brighter than the

delayed sweep). Delayed sweep speed cannot be

slower than main sweep speed.

DELAY:

Only delayed sweep operates, while main sweep

stays inactive. DELAY TIME POSition control

determines the starting point of the delayed sweep.

X-Y:

Used with the VERTical MODE switch and Trigger SOURCE switch to select X- Y operating

mode. The channel 1 input becomes the X-axis and

the channel 2 input becomes the Y-axis. Trigger

source and coupling are disabled in this mode.

29. 1541D Only. X-Y Switch. Used with the VERTical

MODE switch and Trigger SOURCE switch to se-

lect X-Y operating mode. The channel 1 input becomes the X-axis and the channel 2 input becomes the

Y-axis. Trigger source and coupling are disabled in

this mode.

9

Page 12

CONTROLS AND INDICATORS

TRIGGERING CONTROLS

30. HOLDOFF/PULL CHOP Control.

HOLDOFF:

Rotation adjusts holdoff time (trigger inhibit period

beyond sweep duration). When control is rotated

fully counterclockwise, the holdoff period is MIN-

inum (normal). The holdoff period increases progressively with clockwise rotation.

PULL CHOP:

When this switch is pulled out in the dual-trace

mode, the channel 1 and channel 2 sweeps are

chopped and displayed simultaneously (normally

used at slower sweep speeds). When it is pushed in,

the two sweeps are alternately displayed, one after

the other (normally used at higher sweep speeds).

31. Trigger SOURCE Switch. Selects source of sweep

trigger. Four-position lever switch with the following

positions:

CH1/X-Y/ALT

CH1:

Causes the channel 1 input signal to become the

sweep trigger, regardless of the VERTical

MODE switch setting.

X-Y:

Used with two other switches to enable the X-Y

mode — see the Operating Instructions under

“XY Operation”.

ALT:

Used with the channel 1 POSition/PULL

ALTernate TRIGger control to enable alternate

triggering. Alternate triggering, used in dualtrace mode, permits each waveform viewed to

become its own trigger source.

CH2:

The channel 2 signal becomes the sweep trigger,

regardless of the VERTicalMODE switch setting.

LINE:

Signal derived from input line voltage (50/60 Hz)

becomes trigger.

EXT:

Signal from EXTernal TRIGger jack becomes

sweep trigger.

32. Trigger COUPLING Switch. Selects trigger cou-

pling. Four-position lever switch with the following

positions:

AUTO:

Selectsautomatic triggeringmode.In this mode,the

oscilloscope generates sweep (free runs) in absence

of an adequate trigger; it automatically reverts to

triggeredsweepoperation when anadequate trigger

signal is present. On the Model 2160A, automatic

triggering is applicable to both the main sweep and

delayed sweep.

NORM:

Selects normal triggered sweep operation. A sweep

is generated only when an adequate trigger signal is

present.

TV-V:

Used for triggering from television vertical sync

pulses. Also serves as lo-pass/dc (high frequency

reject) trigger coupling.

TV-H:

Used for triggering from television horizontal sync

pulses.Also servesashi-pass (low frequencyreject)

trigger coupling.

33. TRIGger LEVEL/PULL (-) SLOPE Control.

TRIGger LEVEL:

Trigger level adjustment; determines the point on

the triggering waveform where the sweep is triggered. Rotation in the (-) direction (counterclockwise) s elects more negative triggering point;

rotation in the (+) direction (clockwise) selects

more positive triggering point.

PULL (—) SLOPE:

Two-position push-pull switch. The “in” position

selectsa positive-going slope and the “out” position

selectsa negative-goingslopeastriggering point for

main sweep.

34. EXTernal TRIGger Jack. External trigger input for

single- and dual-trace operation.

REAR PANEL CONTROLS (not shown)

35. Fuse Holder/Line Voltage Selector. Contains fuse

and selects line voltage.

36. Power Cord Receptacle.

37. 2160A Only. CH 2 (Y) SIGNAL OUTPUT Jack.

Output terminal where sample of channel 2 signal is

available.Amplitude of output is nominally 50mVper

division of vertical deflection seen on CRT when

terminated into 50 Ω. Output impedance is 50 Ω.

38. 2160A Only. Z-Axis Input Jack. Input jack for intensity modulation of CRT electron beam. TTL compatible (5 V p-p sensitivity). Positive levels increase

intensity.

39. Handle/Tilt Stand.

40. Feet/Cord Wrap.

10

Page 13

OPERATING INSTRUCTIONS

NOTE

All operating instructions in this chapter

apply equally to both Models 2160A and

1541D,exceptfor the sectionson“Delayed

Sweep Operation” and “Component Test”,

which apply only to the Model 2160A.

Other differences are noted when necessary.

SAFETY PRECAUTIONS

WARNING

The following precautions must be observed to help prevent electric shock.

1. When the oscilloscope is used to make measurements

in equipment that contains high voltage, there is always acertainamountofdangerfromelectricalshock.

The person using the oscilloscope in such conditions

should be a qualified electronics technician or otherwise trained and qualified to work in such circumstances. Observe the TEST INSTRUMENT SAFETY

recommendations listed on the inside front cover of

this manual.

2. Donotoperate this oscilloscope with the caseremoved

unless you are a qualified service technician. High

voltage up to 12,000 volts is present when the unit is

operating with the case removed.

3. The ground wire of the 3-wire ac power plug places

the chassis and housing of the oscilloscope at earth

ground. Use only a 3-wire outlet, and do not attempt

to defeat the ground wire connection or float the oscilloscope; to do so may pose a great safety hazard.

4. Specialprecautions are required to measureorobserve

line voltage waveforms with any oscilloscope. Use the

following procedure:

a. Do not connect the ground clip of the probe to

either side of the line. The clip is already at earth

ground and touching it to the hot side of the line

may “weld” or “disintegrate” the probe tip and

cause possible injury, plus possible damage to the

scope or probe.

b. Insert the probe tip into one side of the line voltage

receptacle, then the other. One side of the receptacleshould be “hot” and producethe waveform.The

other side of the receptacle is the ac return and no

waveform should result.

EQUIPMENT PROTECTION

PRECAUTIONS

Thefollowing precautionswill help avoid

damage to the oscilloscope.

1. Never allow a small spot of high brilliance to remain

stationary on the screen for more than a few seconds.

The screen may become permanently burned. A spot

will occur when the scope is set up for X−Y operation

and no signal is applied. Either reduce the intensity so

the spot is barely visible, apply signal, orswitch back

to normal sweep operation. It is also advisable to use

low intensity with AUTO triggering and no signal

applied for long periods. A high intensity trace at the

same position could cause a line to become permanently burned onto the screen.

2. Do not obstruct the ventilating holes in the case, as this

will increase the scope’s internal temperature.

3. Excessive voltage applied to the input jacks may damage the oscilloscope. The maximum ratings of the

inputs are as follows:

CH 1 and CH 2:

400 V dc + ac peak.

EXT TRIG:

300 V dc + ac peak.

Z-AXIS INPUT (Model 2160A):

30 V ( dc and ac peak).

4. Always connect a cable from the ground terminal of

the oscilloscope to the chassis of the equipment under

test. Without this precaution, the entire current for the

equipment under test may be drawn through the probe

clip leads under certain circumstances. Such conditionscould also pose a safety hazard,whichthe ground

cable will prevent.

5. The probe ground clips are at oscilloscope and earth

ground and should be connected only to the earth

ground or isolated common of the equipment under

test. To measure with respect to any point other than

the common, use CH 2 – CH 1 subtract operation

(ADD mode and INV 1), with the channel 2 probe to

the point of measurement and the channel 1 probe to

the point of reference. Use this method even if the

reference point is a dc voltage with no signal.

11

Page 14

OPERATING INSTRUCTIONS

OPERATING TIPS

The following recommendations will help obtain the best

performance from the oscilloscope.

1. Always use the probe ground clips for best results,

attached to a circuit ground point near the point of

measurement.Do not rely solely on an externalground

wire in lieu of the probe ground clips as undesired

signals may be introduced.

2. Avoid the following operating conditions:

a. Direct sunlight.

b. High temperature and humidity.

c. Mechanical vibration.

d. Electricalnoise and strong magnetic fields, such as

near large motors, power supplies, transformers,

etc.

3. Occasionally check trace rotation, probe compensation,and calibration accuracyofthe oscilloscope using

the procedures found in the MAINTENANCE section

of this manual.

4. Terminate the output of a signal generator into its

characteristic impedance to minimize ringing, especially if the signal has fast edges such as square waves

or pulses. For example, the typical 50 Ω output of a

square wave generator should be terminated into an

external 50 Ω terminating load and connected to the

oscilloscope with 50 Ω coaxial cable.

5. Probe compensation adjustment matches the probe to

the input of the scope. For best results, compensation

should be adjusted initially, then the same probe alwaysusedwith the same channel. Probecompensation

should be readjusted when a probe from a different

oscilloscope is used.

INITIAL STARTING PROCEDURE

Until you familiarize yourself with the use of all controls,

the settings given here can be used as a reference point to

obtain a trace on the CRT in preparation for waveform

observation.

1. Set these controls as follows:

On both models:

VERTical MODE to CH1.

CH1AC/GND/DC to GND.

Trigger COUPLING to AUTO.

Trigger SOURCE to CH1.

All POSition controls and INTENSITY control centered (pointers facing up).

Main Time Base control to 1 mS/div.

On the Model 2160A:

Sweep Mode switch to MAIN.

2. Press the red POWER pushbutton (Model 1541D), or

rotate the POWER control clockwise away from

“OFF” (Model 2160A).

3. A trace should appear on the CRT. Adjust the trace

brightness with the INTENSITY control, and the

trace sharpness with the FOCUS control.

NOTE

On the Model 2160A, you can use the

BEAM FINDER pushbutton to locate a

trace that has been moved off the screen by

the POSition controls. When the button is

pushed, a compressed version of the trace

is brought into view which indicates the

location of the trace.

SINGLE TRACEDISPLAY

Either channel 1 or channel 2 maybe used for single-trace

operation. To observe a waveform on channel 1:

1. Perform the steps of the “Initial Starting Procedure”.

2. Connect the probe to the CH 1 (X) input jack.

3. Connect the probe ground clip to the chassis or common of the equipment under test. Connect the probe

tip to the point of measurement.

4. Move the CH1 AC/GND/DC switch out of the GND

position to either DC or AC.

5. If no waveforms appear, increase the sensitivity by

turning the CH 1 VOLTS/DIV control clockwise to a

position that gives 2 to 6 divisions vertical deflection.

6. Position the waveform vertically as desired using the

CH1 POSition control.

7. Thedisplay on the CRT maybeunsynchronized.Refer

to the “Triggering” paragraphs in this section for procedures on setting triggering and sweep time controls

to obtain a stable display showing the desired number

of waveforms.

DUAL TRACE DISPLAY

In observing simultaneous waveforms on channel 1 and

2, the waveforms are usually related in frequency, or one of

the waveforms is synchronized to the other, although the

basic frequencies are different. To observe two such related

waveforms simultaneously, perform the following:

1. Connect probes to both the CH 1 (X) and CH 2 (Y)

input jacks.

2. Connect the ground clips of the probes to the chassis

or common of the equipment under test. Connect the

tips of the probes to the two points in the circuit where

waveforms are to be measured.

12

Page 15

OPERATING INSTRUCTIONS

3. To view both waveforms simultaneously, set the

VERTical MODE switch to DUAL and select either

ALT (alternate) or CHOP with the PULL CHOP

switch.

4. In the ALT sweep mode (PULL CHOP switch

pushed in), one sweep displays the channel 1 signal

and the next sweep displays the channel 2 signal in an

alternating sequence. Alternate sweep is normally

used for viewing high-frequency or high-speed waveforms at sweep times of 1 ms/div and faster, but may

be selected at any sweep time.

5. In the CHOP sweep mode (PULL CHOP switch

pulled out), the sweep is chopped (switched) between

channel 1 and channel 2. Using CHOP, one channel

does not have to “wait” for a complete swept display

of the other channel. Therefore, portions of both channel’swaveformsaredisplayedwith the phase relationship between the two waveforms unaltered. Chop

sweep is normally used for low-frequency or lowspeed waveforms at sweep times of 1 ms/div and

slower; or where the phase relationship between channel 1 and channel 2 requires measurement.

If chop sweep is used at sweep times of 0.2 ms/div and

faster, the chop rate becomes a significant portion of

the sweep and may become visible in the displayed

waveform. However, you may select chop sweep at

any sweep time for special applications.

6. Adjust the channel 1 and 2

▲

POSition controls to

▼

place the channel 1 trace above the channel 2 trace.

7. Set the CH 1 and CH 2 VOLTS/DIV controls to a

position that gives 2 to 3 divisions of vertical deflection for each trace. If the display on the screen is

unsynchronized, refer to the “Triggering” paragraphs

in this section of the manual for procedures for setting

triggering and sweep time controls to obtain a stable

display showing the desired number of waveforms.

8. WhentheVERTicalMODE switch is set to ADD, the

algebraic sum of CH 1 + CH 2 is displayed as a single

trace. When the PULL INV switch is pulled out, the

algebraic difference of CH 1 – CH 2 is displayed.

9. Iftwowaveformshavenophaseorfrequencyrelationship, there is seldom reason to observe both waveforms simultaneously. However, these oscilloscopes

do permit the simultaneous viewing of two such unrelated waveforms, using alternate triggering. Refer to

the paragraphs on “Triggering - Trigger SOURCE

Switch”, for details on alternate triggering.

TRIGGERING

The Models 2160A and 1541D Oscilloscopes provide

versatility in sync triggering for ability to obtain a stable,

jitter-free display in single-trace, or dual-trace operation.

The proper settings depend upon the type of waveforms

being observed and the type of measurement desired. An

explanation of the various controls which affect synchronization is given to help you select the proper setting over a

wide range of conditions.

Trigger COUPLING Switch

1. In the AUTO position, automatic sweep operation is

selected. In automatic sweep operation, the sweep

generator free-runs to generate a sweep without a

trigger signal. However, it automatically switches to

triggered sweep operation if an acceptable trigger

source signal is present. The AUTO position is handy

when first setting up the scope to observe a waveform;

itprovides sweepforwaveform observationuntilother

controls can be properly set. Once the controls are set,

operation is often switched back to the normal triggering mode, since it is more sensitive. Automatic sweep

must be used for dc measurements and signals of such

low amplitude that they will not trigger the sweep.

2. The NORM position provides normal triggered

sweep operation. The sweep remains at rest until the

selected trigger source signal crosses the threshold

level set by the TRIG LEVEL control. The trigger

causes one sweep to be generated, after which the

sweep again remains at rest until triggered. In the

normal triggering mode, there will be no trace unless

an adequate trigger signal is present. In the ALT

VERTICAL MODE of dual trace operation with the

SOURCE switch also set to ALT, there will be no

trace unless both channel 1 and channel 2 signals are

adequate for triggering. Typically, signals that produce even one division of vertical deflection are adequate for normal triggered sweep operation.

3. The TV H and TV V positions are primarily for

viewing composite video waveforms. Horizontal sync

pulses are selected as trigger when the trigger COU-

PLINGswitch is set to the TV H position, and vertical

sync pulses are selected as trigger when the trigger

COUPLING switch is set to the TV V position. The

TV H and TV V positions may also be used as low

frequency reject and high frequency reject coupling,

respectively. Additional procedures for observing video

waveforms are given later in this section of the manual.

13

Page 16

OPERATING INSTRUCTIONS

Trigger SOURCE Switch

The trigger SOURCE switch (CH 1, CH 2, etc.) selects

the signal to be used as the sync trigger.

1. If the SOURCE switch is set to CH 1 (or CH 2) the

channel 1 (or channel 2) signal becomes the trigger

source regardless of the VERTICAL MODE selection.CH 1,orCH 2 are often used as the triggersource

for phase or timing comparison measurements.

2. By setting the SOURCE switch to ALT (same as

CH1) and PULL ALT TRIG pulled, alternating triggering mode is activated. In this mode, the trigger

source alternates between CH 1 and CH 2 with each

sweep. This is convenient for checking amplitudes,

waveshape, or waveform period measurements, and

even permits simultaneous observation of two waveforms which are not related in frequency or period.

However,this setting isnot suitable forphase or timing

comparison measurements. For such measurements,

both traces must be triggered by the same sync signal.

Alternate triggering can only be used in dual-trace

mode (VERT MODE set to DUAL), and with alternate sweep only (PULL CHOP not engaged).

3. In the LINE position, triggering is derived from the

input line voltage (50/60 Hz) and the trigger

SOURCE switch is disabled. This is useful for measurements that are related to line frequency.

4. In the EXT position, the signal applied to the EXT

TRIG jack becomes the trigger source. This signal

must have a timing relationship to the displayed waveforms for a synchronized display.

TRIG LEVEL/PULL (–) SLOPE Control

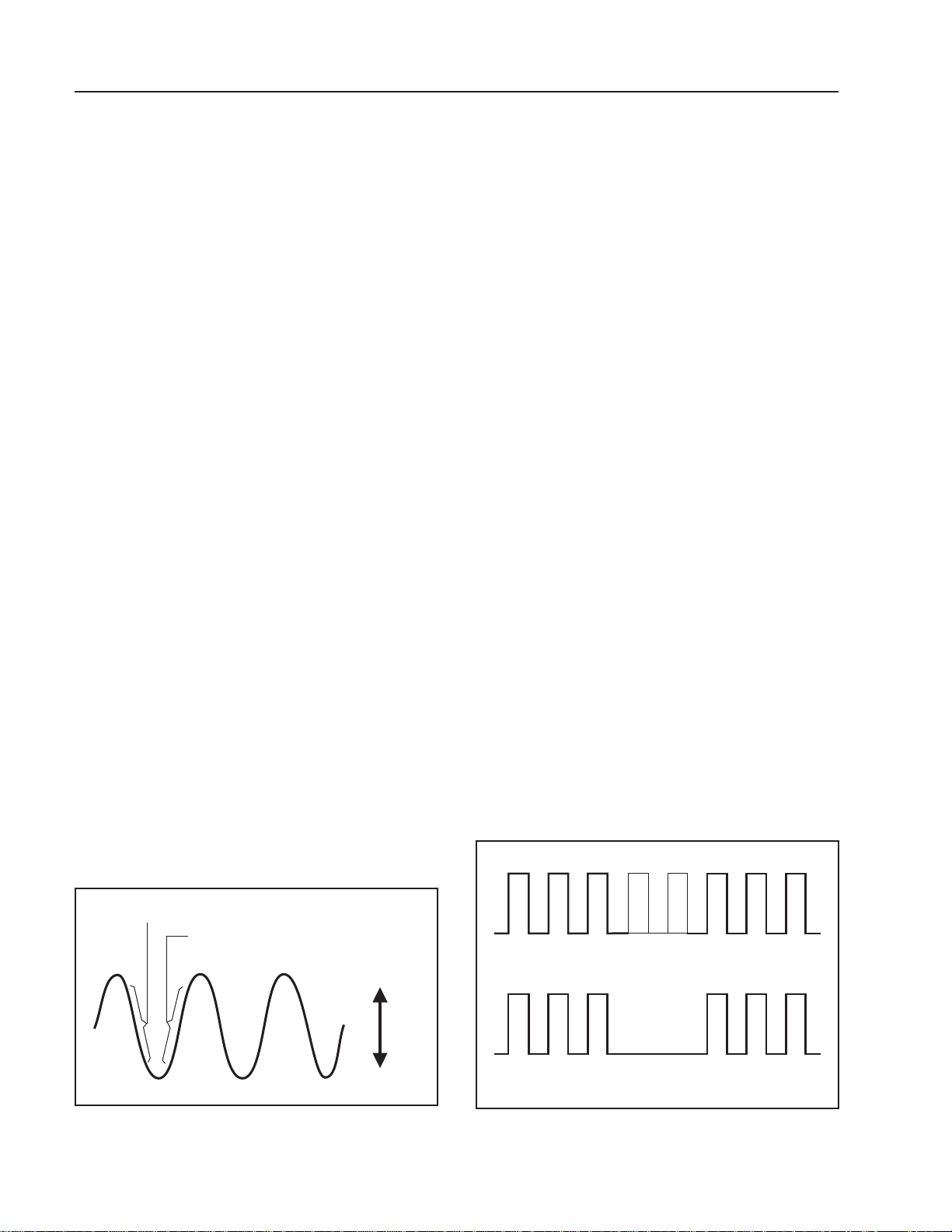

(Refer to Fig. 3)

A sweep trigger is developed when the trigger source

signalcrosses a preset threshold level.Rotation of the TRIG

LEVEL control varies the threshold level. In the + direction

(clockwise), the triggering threshold shifts to a more positive value, and in the − direction (counterclockwise), the

triggering threshold shifts to a more negative value. When

the control is centered, the threshold level is set at the

approximate average of the signal used as the triggering

source. Proper adjustment of this control usually synchronizes the display.

The TRIG LEVEL control adjusts the start of the sweep

to almost any desired point on a waveform. On sine wave

signals, the phase at which sweep begins is variable. Note

that if the TRIG LEVEL control is rotated toward its

extreme + or − setting, no sweep will be developed in the

normal trigger mode because the triggering threshold exceeds the peak amplitude of the sync signal.

When the PULL (–) SLOPE control is set to the + (“in”)

position, the sweep is developed from the trigger source

waveform as it crosses a threshold level in a positive-going

direction. When the PULL (–) SLOPE control is set to

the −(“out”) position, a sweep trigger is developed from the

trigger source waveform as it crosses the threshold level in

a negative-going direction.

MAIN TIME BASE Control

Set the Main Time Base TIME/DIV control to display

the desired number of cycles of the waveform. If there are

too many cycles displayed for good resolution, switch to a

faster sweep time. If only a line is displayed, try a slower

sweep time. When the sweep time is faster than the waveform being observed,only part of it will be displayed, which

may appear as a straight line for a square wave or pulse

waveform.

HOLDOFF Control

(Refer to Fig. 4)

A “holdoff” period occurs immediately after the completion of each sweep, and is a period during which triggering

of the next sweep is inhibited. The normal holdoff period

varies with sweep rate, but is adequate to assure complete

retrace and stabilization before the next sweep trigger is

permitted. The HOLDOFF control allows this period to be

extended by a variable amount if desired.

Slope “–” Range

Slope “+” Range

+

Level

–

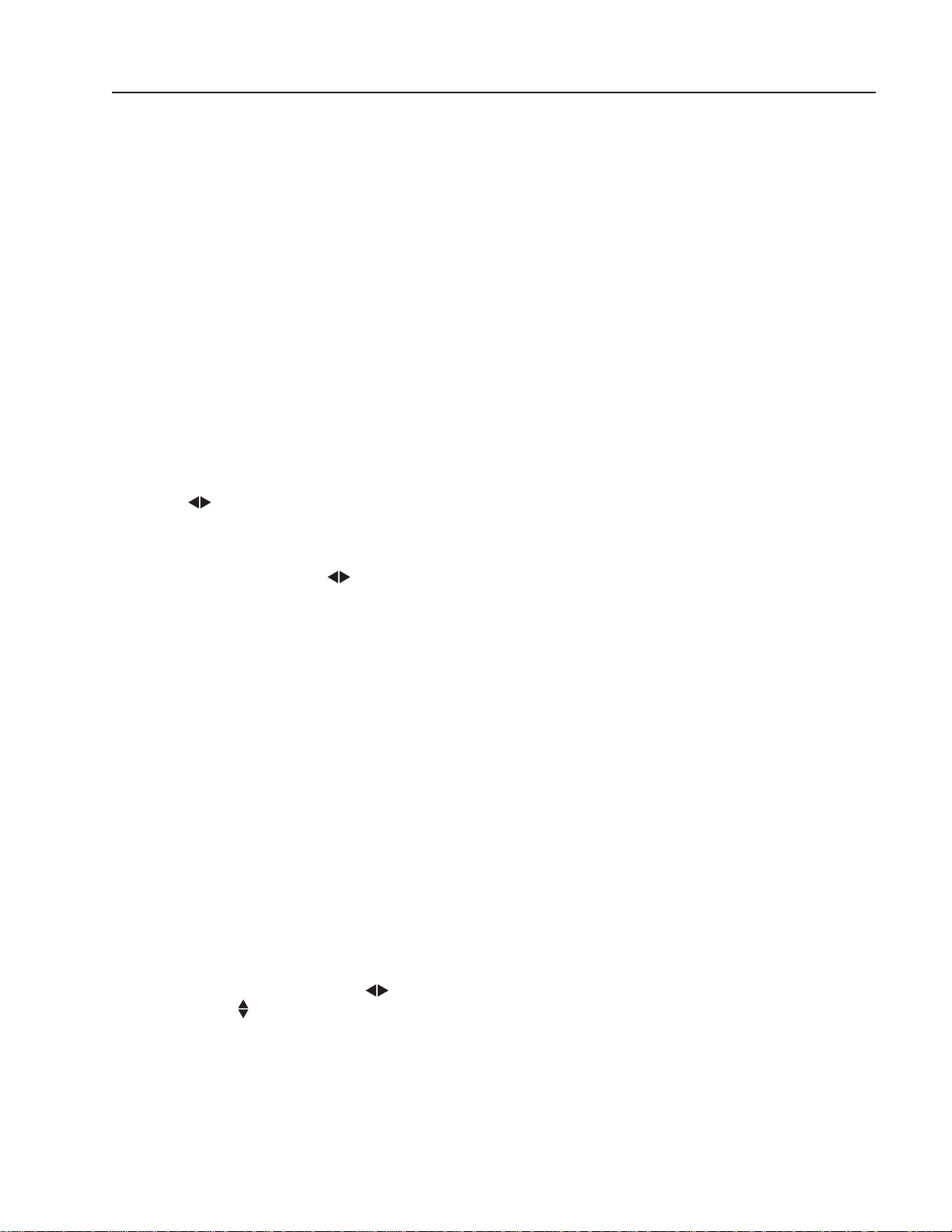

Fig. 3. Function of Slope and Level Controls.

A. Holdoff not used

B. Holdoff used

Fig. 4. Use of HOLDOFF Control.

14

Page 17

OPERATING INSTRUCTIONS

This control is usually set to the MIN position (fully

counterclockwise) because no additional holdoff period is

necessary. The HOLDOFF control is useful when a complex series of pulses appear periodically such as in Fig. 4B.

Improper sync may produce a double image as in Fig. 4A.

Such a display could be synchronized with the VA R

SWEEP control, but this is impractical because time measurements are then uncalibrated. An alternate method of

synchronizing the display is with the HOLDOFF control.

The sweep speed remains the same, but the triggering of the

next sweep is “held off” for the duration selected by the

HOLDOFF control. Turn the HOLDOFF control clockwise from the MIN position until the sweep starts at the

same point of the waveform each time.

MAGNIFIED SWEEP OPERATION

Since merely shortening the sweep time to magnify a

portion of an observed waveform can result in the desired

portion disappearing off the screen, magnified display

should be performed using magnified sweep.

Using the POSition control, move the desired portion

of waveformto the center of the CRT. Pull out the PULL X10

knob to magnify the display ten times. For this type of display

the sweep time is the Main Time Base TIME/DIV control

setting divided by 10. Rotation of the POSition control can

then be used to select the desired portion of the waveforms.

X−Y OPERATION

X−Y operation permits the oscilloscope to perform many

measurements not possible with conventional sweep operation. The CRT display becomes an electronic graph of two

instantaneous voltages. The display may be a direct comparison of the two voltages such as stereoscope display of

stereo signal outputs. However, theX−Y mode can be used

to graph almost any dynamic characteristic if a transducer is

used to change the characteristic (frequency, temperature,

velocity, etc.) into a voltage. One common application is frequencyresponse measurements,where the Yaxis correspondsto

signal amplitude and the X axis corresponds to frequency .

1. On the Model 2160A, set the SWEEP MODE switch

totheX−Yposition. On the Model 1541D, depress the

X−Y switch. On both models, set the Trigger Source

and VERTical MODE switches to X−Y.

2. In this mode, channel 1 becomes the X axis input and

channel 2 becomes the Y axis input. The X and Y

positionsare now adjusted usingthe POSitionand

the channel 2 POSition controls respectively.

3. Adjust the amount of vertical (Y axis) deflection with

the CH 2 VOLTS/DIV and VARIABLE controls.

4. Adjust the amount of horizontal (X axis) deflection

with the CH 1 VOLTS/DIV and VARIABLE controls.

VIDEO SIGNAL OBSERVATION

Setting the COUPLING switch to the TV-H or TV-V

position permits selection of horizontal or vertical sync

pulses for sweep triggering when viewing composite video

waveforms.

When the TV-H mode is selected, horizontal sync pulses

are selected as triggers to permit viewing of horizontal lines

of video. A sweep time of about 10 µs/div is appropriate for

displaying lines of video. The VAR SWEEP control can be

set to display the exact number of waveforms desired.

When the TV-Vmode is selected, verticalsync pulses are

selected as triggers to permit viewing of vertical fields and

frames of video. A sweep time of 2 ms/divis appropriate for

viewing fields of video and 5 ms/div for complete frames

(two interlaced fields) of video.

At most points of measurement, a composite video signal

is of the (−)polarity, that is, the sync pulses are negative and

the video is positive. In this case, use (− ) SLOPE. If the

waveform is taken at a circuit point where the video waveform is inverted, the sync pulses are positive and the video

is negative. In this case, use (+) SLOPE.

APPLICATIONS GUIDEBOOK

B+K Precision offers a “Guidebook to Oscilloscopes”

which describes numerous applications for this instrument

and important considerations about probes. It includes a

glossary of oscilloscope terminology and an understanding

of how oscilloscopes operate. It may be downloaded free of

charge from our Website, www.bkprecision.com.

DELAYED SWEEP OPERATION (Model 2160A)

(Refer to Fig. 5)

Delayed sweep operation is achieved by use of both the

main sweep and the delayed sweep and allows any portion

of a waveform to be magnified for observation. Unlike X10

magnification, delayed sweep allows selectable steps of

magnification.

1. SettheSweepMode switch to the MAIN position and

adjust the oscilloscope for a normal display.

2. Set the Sweep Mode switch to the MIX position. The

display will show the main sweep on the left portion

(representing the MAIN Time Base control setting)

and the delayed sweep on the right portion (representing the DELAY Time Base control setting). The

MAIN Time Base portion of the trace usually will be

brighter than the delayed time base portion. Fig. 5

shows a typical display for the MIX display mode.

3. Shift the percentage of the display that is occupied by

the main sweep by adjusting the DELAY TIME

POSition control. Counterclockwise rotation causes

more of the display to be occupied by the main sweep

15

Page 18

OPERATING INSTRUCTIONS

Delayed Sweep

100

90

Main

10

0

Sweep

Fig. 5. MIX SWEEP MODE Display.

and clockwise rotation causes more of the display to

be occupied by the delayed sweep.

4. Set the Sweep Mode switch to the DELAY position

to display only the magnified delayed sweep portion

of the display.

NOTE

In order to obtain meaningful results with

delayed sweep, the DELAY Time Base

control must set be set to a faster sweep

speed than the MAIN Time Base control.

Because of this, the oscilloscope automatically prevents (electrically) the DELAY

Time Base from being set to a slower

sweep speed than the MAIN Time Base.

Forexample, if the MAINTimeBase is set

to0.1 ms/div, theslowest possibleDELAY

TimeBase sweep speed is also 0.1ms/div,

even if the control is set slower.

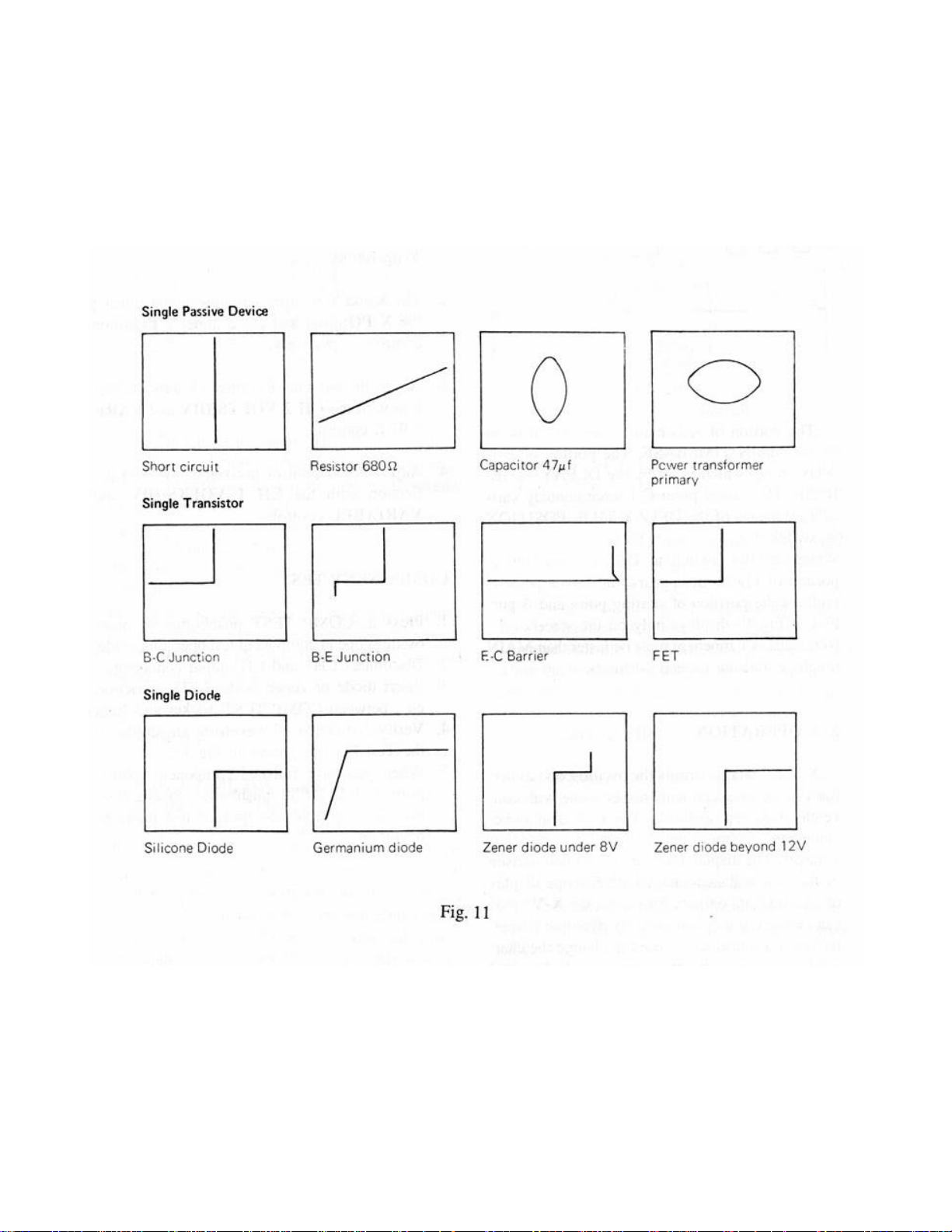

COMPONENT TEST OPERATION

(Model 2160A)

Do not apply an external voltage to the

COMP TEST jacks. Only non-powered

circuits should be tested with this unit.

Testing powered circuits could damage

the instrument and increase the risk of

electrical shock.

The component test function produces a component “signature” on the CRT by applying an ac signal across the

device and measuring the resulting ac current. The display

represents a graph of voltage (X) versus current (Y). The

component test function can be used to view the signatures

of resistors, capacitors, inductors, diodes, and other semiconductor devices. Devices may be analyzed in-circuit or

out-of-circuit and combinations of two or more devicesmay

be displayed simultaneously. Each component produces a

different signature and the components can be analyzed as

outlined below.

Component Test mode is activated by depressing the

COMPonent TEST switch. The SWEEP MODE switch

must not be in the DELAY position.

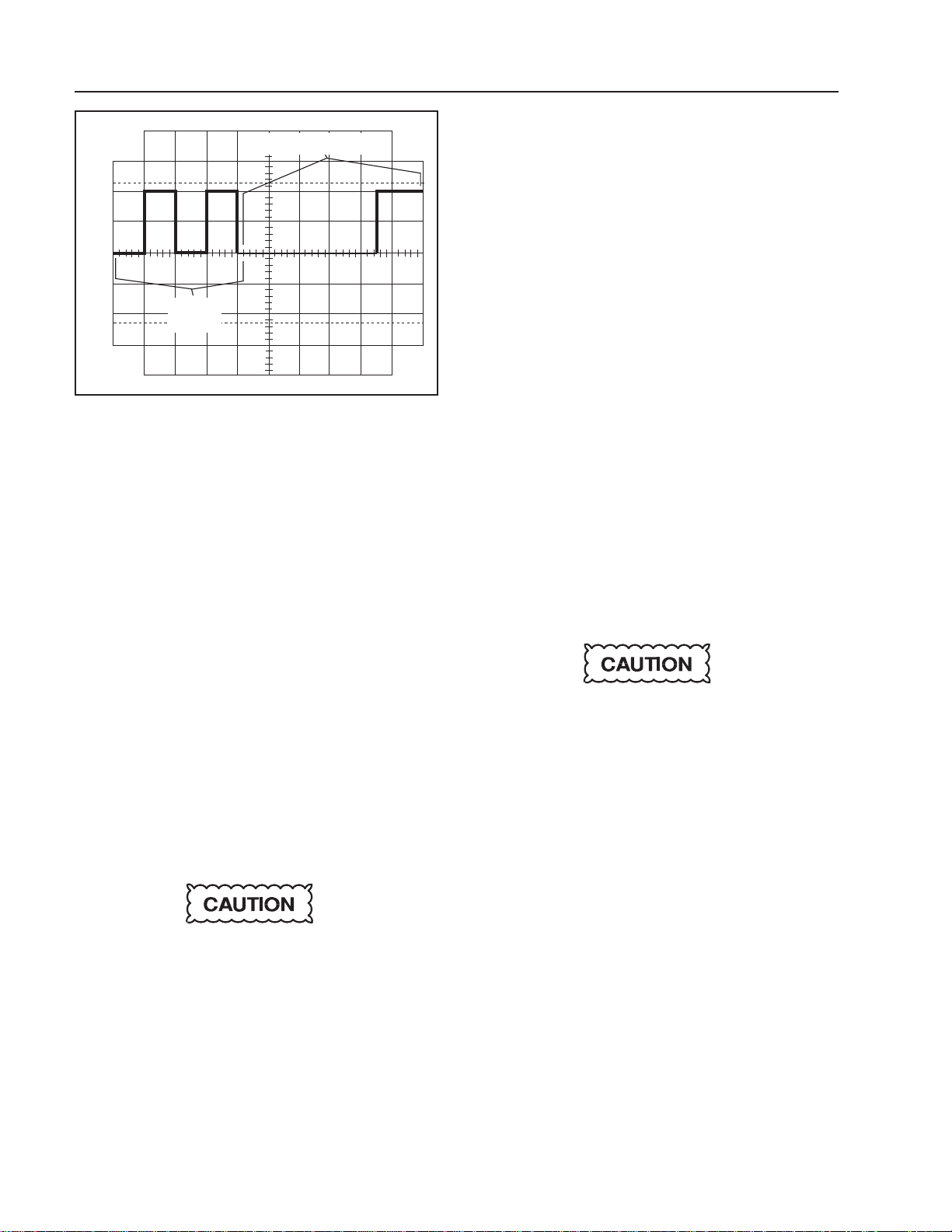

Resistors

A purely resistive impedance produces a signature that is

a straight line. A short circuit produces a vertical line and an

open circuit causes a horizontal line. Therefore, the higher

the resistance, the closer to horizontal the trace will be.

Values from 10 Ω to about 5 kΩ are within measurement

range. Values below 10 Ω will appear to be a dead short

while values above 5 kΩ will appear to be an open circuit.

Fig. 6 shows some typical resistance signatures.

To test a resistor,insertone of the resistor’sleads into the

white COMP TEST jack, and the other into the GND jack

(make sure that the leads touch the metal walls inside the

jacks). To test in-circuit, a pair of test leads can be used to

connect the COMP TEST and GND jacks to the component(s).

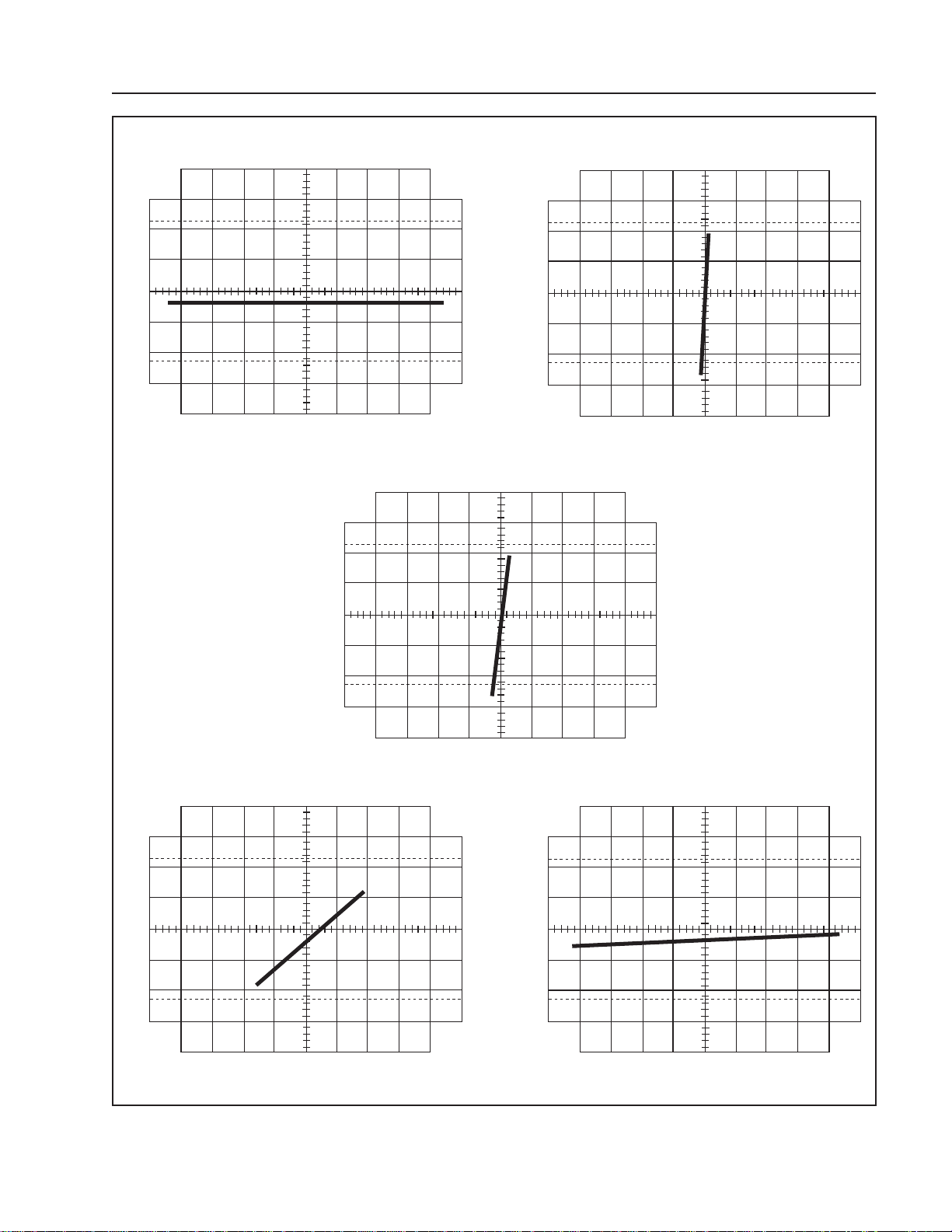

Capacitors

Besureto dischargecapacitors (by shorting the leads together) before connecting

to the COMP TEST jack. Some capacitors can retain a voltage high enough to

damage the instrument.

A purely capacitive impedance produces a signature that

is an ellipse or circle. Value is determined by the size and

shape of the ellipse. A very low capacitance causes the

ellipse to flatten out horizontally and become closer to a

straight horizontal line and a very high capacitance causes

the ellipse to flatten out vertically and become closer to a

straight vertical line. Values from about 0.33 µF to about

330 µF are within measurable range. Values below 0.33 µF

will be hard to distinguish from an open circuit and values

above330 µF will be hard to distinguish from ashort circuit.

Fig. 7 shows several typical capacitance signatures.

To test a capacitor,insert the capacitor’spositive lead into

the white COMP TEST jack, and the negative lead into the

GND jack (make sure that the leads touch the metal walls

inside the jacks). Totest in-circuit or to test a capacitor with

leadsthat aretoo short tofit intotheCOMPTESTand GND

jacks, a pair of test leads can be used to connect the COMP

TEST and GND jacks to the component(s).

16

Page 19

OPERATING INSTRUCTIONS

100

90

10

100

90

10

0

Open Circuit

100

90

0

Short Circuit

100

90

10

10

0

10 Resistor

Ω

100

90

10

0

200 Resistor

Ω

0

5.1 k ResistorΩ

Fig. 6. Typical Resistive Signatures.

17

Page 20

OPERATING INSTRUCTIONS

100

90

10

0

0.33 F Capacitorµ

100

90

Inductors

Like capacitance, a purely inductive impedance produces

asignaturethat is an ellipse or circle and valueis determined

by the size and shape of the ellipse. A very high inductance

causes the ellipse to flatten out horizontally and a very low

inductance causes the ellipse to flatten out vertically.Values

from about 0.05 H to about 5 H are within measurement

range. Values below 0.05 H will be hard to distinguish from

a short circuit and values above 5 H will be hard to distinguish from an open. Fig. 8 shows several typical inductance

signatures.

To test an inductor, insert one of the inductor’s leads into

the white COMP TEST jack, and the other into the GND

jack (make sure that the leads touch the metal walls inside

the jacks). To test in-circuit or to test an inductor with leads

that are too short to be inserted into the COMP TEST and

GND jacks, a pair of test leads can be used to connect the

COMP TEST and GND jacks to the component(s).

100

90

10

100

90

10

0

10

0

4.7 F Capacitorµ

1 Henry Inductor

100

90

0

300 F Capacitorµ

10

0

5 Henry Inductor

Fig. 7. Typical Capacitive Signatures.

Fig. 8. Typical Inductive Signatures.

18

Page 21

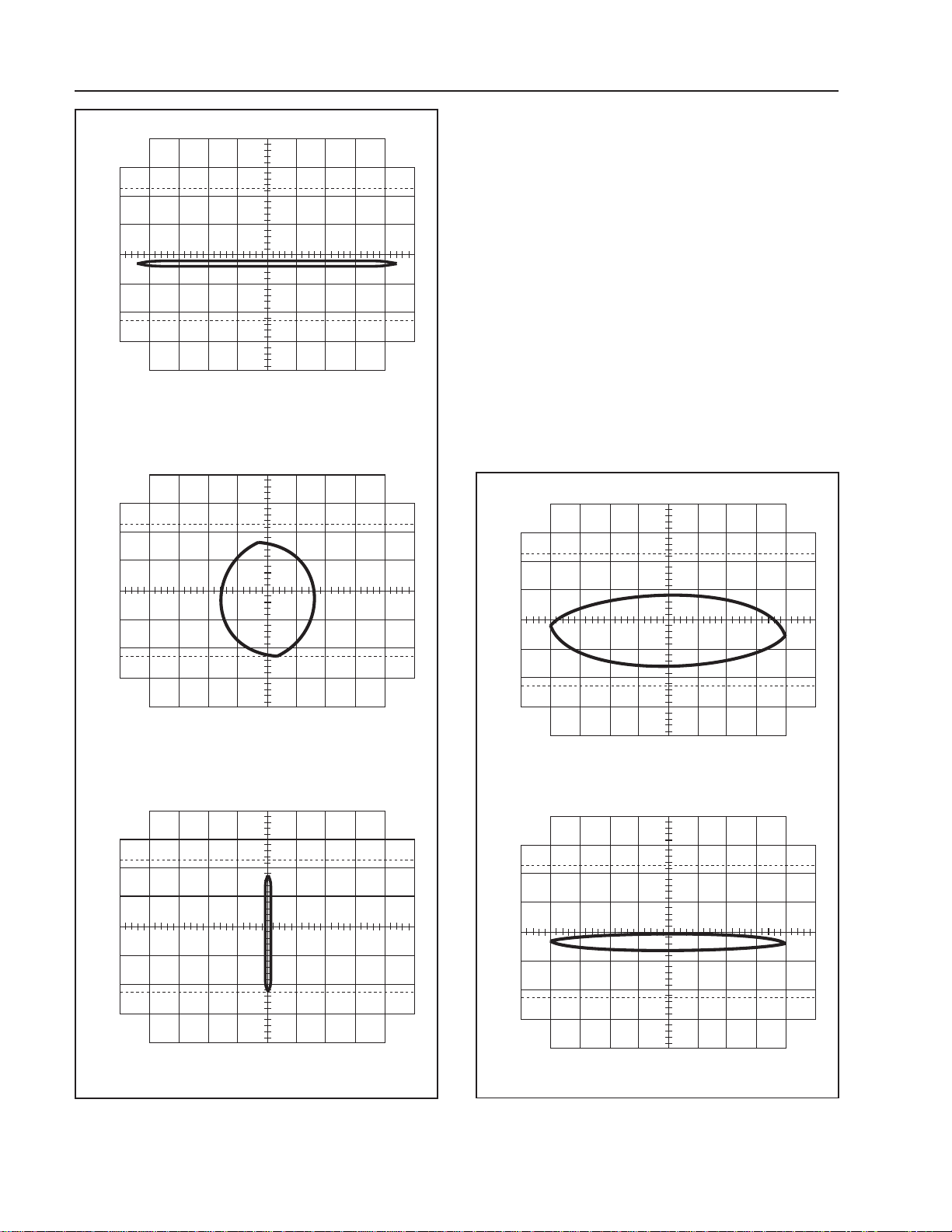

Semiconductors

Purelysemiconductordevices (such as diodes and transistors) will produce signatures with straight lines and bends.

Typical diode junctions produce a single bend with a horizontal and vertical line as shown in Fig. 9. Zener diodes

produce a double bend with two vertical and one horizontal

line as shown in Fig. 10 (value is determined by the distance

of the leftmost vertical component from the center graduation on the CRT). The maximum Zener voltage observable

on this feature is about 15 V. It is also possible to test

transistors and IC’s by testing one pair of pins at a time.

NOTE

When testing diodes it is important to

connect the diode’s cathode to the white

COMP TEST jack and the anode to the

GNDjack.Reversing thepolaritywill not

damage the devicebut the horizontal and

vertical components of the signature will

appear in different quadrants of the

display.

To test semiconductors, insert the diode’s or transistor’s

leads (only two at a time) into the COMP TEST and GND

jacks (make sure that the leads touch the metal walls inside

the jacks). To test in-circuit or to test IC’s or devices with

leads too short to insert into the COMP TESTand GND

jacks, a pair of test leads can be used to connect the COMP

TEST and GND jacks to the component(s).

OPERATING INSTRUCTIONS

100

90

10

0

Silicon Diode

Fig. 9. Typical P-N Junction Signature.

100

90

Combinations of Components

Using the component test feature it is also possible to

observe the signatures of combinations of components.

Combinations cause signatures that are a combination of the

individual signatures for each component. For example, a

signature for a resistor and capacitorin parallel will produce

a signature with the ellipse of the capacitor but the resistor

would cause the ellipse to be at an angle (determined by the

valueof the resistor). When testing combinations of components it is important to make sure that all the components

being connected are within measurement range.

In-CircuitTesting

The component test feature can be very effectivein locating defective components in-circuit, especially if a “known

good” piece of equipment is available for reference. Compare the signatures from the equipment under test with

signatures from identical points in the reference unit. When

10

0

10 V Zener Diode

Fig. 10. Typical Zener Signature.

signaturesare identical orverysimilar,the tested component

is good. When signatures are distinctively different, the

tested component is probably defective.

19

Page 22

MAINTENANCE

n

n

n

WARNING

The following instructions are for use by

qualifiedservice personnel only. Toavoid

electricalshock,do not perform any servicing other than contained in the operating instructions unless you are qualified

to do so.

High voltage up to 12,000 V is present

when covers are removed and the unit is

operating. Remember that high voltage

may be retained indefinitely on high voltage capacitors. Also remember that ac

line voltage is present on line voltage

input circuits any time the instrument is

plugged into an ac outlet, even if turned

off. Unplug the oscilloscope and discharge high voltage capacitors before

performing service procedures.

FUSE REPLACEMENT

If the fuse blows, the “ON” indicator will not light and the

oscilloscope will not operate. The fuse should not normally

open unless a problem has developed in the unit. Try to

determine and correct the cause of the blown fuse, then

replace only with the correct value fuse. For 110/125 V line

voltage operation, use an 800 mA, 250 V fuse. For 220/240

Vline voltage operation, use a 600 mA,250Vfuse. The fuse

is located on the rear panel adjacent to the power cord

receptacle.

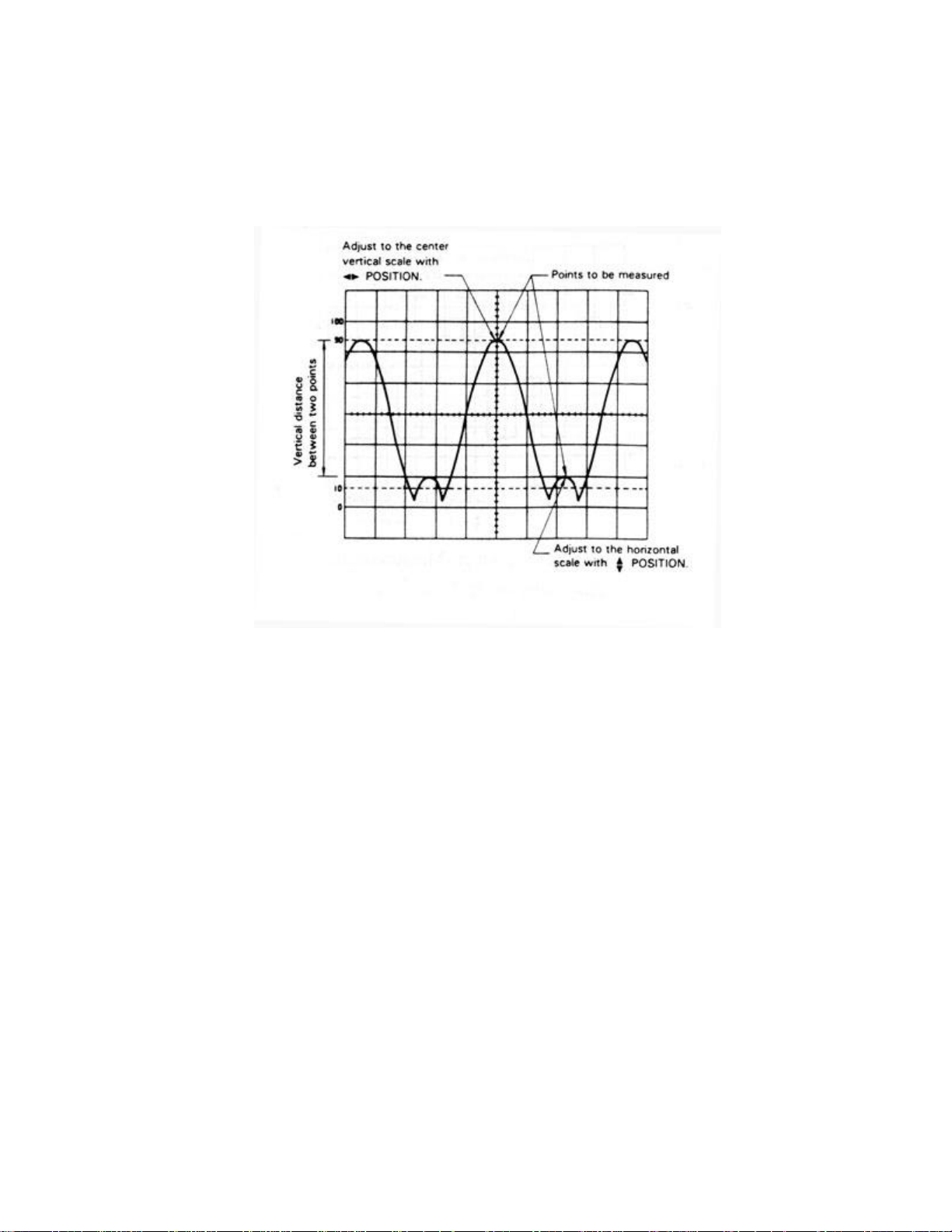

PERIODIC ADJUSTMENTS

Probe compensation and trace rotation adjustments

should be checked periodically and adjusted if required.

These procedures are given below.

Probe Compensation

1. Connectprobes toCH1 andCH2 input jacks.Perform

procedure for each probe, one probe at a time.

2. Set the probe to X10 (compensation adjustment is not

possible in the X1 position).

3. Touch tip of probe to CAL terminal.

4. Adjust oscilloscope controls to display 3 or 4 cycles of

CAL square wave at 5 or 6 divisions amplitude.

5. Adjust compensation trimmer on probe for optimum

square wave (minimum overshoot, rounding off, and

tilt). Refer to Fig. 11.

Correct

Compensatio

Over

Compensatio

Insufficient

Compensatio

Remove the fuseholder assembly as follows:

1. Unplug the power cord from rear of scope.

2. Insert a small screwdriver in fuseholder slot (located

between fuseholder and receptacle). Pry fuseholder

away from receptacle.

3. When reinstalling fuseholder, be sure that the fuse is

installedso that the correct line voltage is selected(see

LINE VOLTAGE SELECTION).

LINE VOLTAGE SELECTION

To select the desired line voltage, simply insert the fuse

and fuse holder so that the appropriate voltage is pointed to

by the arrow. Be sure to use the proper value fuse (see label

on rear panel).

Fig. 11. Probe Compensation Adjustment.

Trace Rotation Adjustment

1. Set oscilloscope controls for a single trace display in

CH 1 mode, and with the channel 1 AC-GND-DC

switch set to GND.

2. Use the channel 1 POSition control to position the

trace over the center horizontal line on the graticule

scale. The trace should be exactly parallel with the

horizontal line.

3. Usethe TRACEROTATIONadjustmenton the front

panel to eliminate any trace tilt.

20

Page 23

MAINTENANCE

CALIBRATION CHECK

A general check of calibration accuracy may be made by

displaying the output of the CAL terminal on the screen.

Thisterminalprovidesa square wave of 2 V p-p. This signal

should produce a displayed waveform amplitude of four

divisions at .5 V/div sensitivity for both channel 1 and 2

(with probes set for direct). With probes set for X10, there

should be four divisions amplitude at 50 mV/div sensitivity.

The VARIABLE controls must be set to CAL during this

check.

NOTE

The CAL signal should be used only as a

general check of calibration accuracy,not

as a signal source for performing recalibration adjustments; a voltage standard

calibrated at several steps and of 0.3% or

better accuracy is required for calibration

adjustments.

The CAL signal should not be used as a

time base standard.

INSTRUMENT REPAIR SERVICE

Because of the specialized skills and test equipment re-

quired for instrument repair and calibration, many customers prefer to rely upon B+K Precision for this service. To

use this service, even if the oscilloscope is no longer under

warranty, follow the instructions given in the SERVICE

INFORMATION portion of this manual. There is a flat rate

charge for instruments out of warranty.

21

Page 24

APPENDIX

IMPORTANT CONSIDERATIONS FOR RISE TIME

AND FALL TIME MEASUREMENTS

Error in Observed Measurement

The observed rise time (or fall time) as seen on the CRT

is actually the cascaded rise time of the pulse being measured and the oscilloscope’sownrisetime. The two rise times

are combined in square law addition as follows:

T

observed

=

2

(T ) +(T )

pulse

scope

2

The effect of the oscilloscope’s rise time is almost negligible when its rise time is at least 3 times as fast as that of

the pulse being measured. Thus, slower rise times may be

measured directly from the CRT. However, for faster rise

time pulses, an error is introduced that increases progressively as the pulse rise time approaches that of the oscilloscope. Accurate measurements can still be obtained by

calculation as described below.

Direct Measurements

TheModel2160A oscilloscope has aratedrisetime of 5.8

ns (8.8 ns for Model 1541D). Thus, pulse rise times of about

17 ns or greater can be measured directly (26 ns for Model

1541D). Most fast rise times are measured at the fastest

sweep speed and using X10 magnification. For the Models

2160A and 1541D, this sweep rate is 10 ns/div. A rise time

of less than about two divisions at this sweep speed should

be calculated for Model 2160A (three divisions for Model

1541D).

Calculated Measurements

Forobserved rise times of lessthan17 ns(26nsforModel

1541D),the pulserisetimeshouldbecaluclated to eliminate

the error introduced by the cascaded oscilloscope rise time.

Calculate pulse rise time as follows:

T

pulse

=

(T ) +(T )

observed

2

scope

2

Limits of Measurement

Measurements of pulse rise times that are faster than the

scope’srated rise time are not recommended because a very

small reading error introduces significant error into the

calculation. This limit is reached when the “observed” rise

time is about 1.3 times greater than the scope’s rated rise

time, about 7.5 ns minimum for the Model 2160A and 12 ns

for Model 1541D.

Probe Considerations

Forfast rise timemeasurementswhich approach the limits

of measurement, direct connection via 50 Ω coaxial cable

and 50 Ω termination is recommended where possible.

When a probe is used, its rise time is also cascaded in square

law addition. Thus the probe rating should be considerably

faster than the oscilloscope if it is to be disregarded in the

measurement.

22

Page 25

Service Information

Warranty Service: Please return the product in the original packaging with proof of purchase to the address below.

Clearly state in writing the performance problem and return any leads, probes, connectors and accessories that you are

using with the device.

Non-Warranty Service: Return the product in the original packaging to the address below. Clearly state in writing the

performance problem and return any leads, probes, connectors and accessories that you are using with the device.

Customers not on open account must include payment in the form of a money order or credit card. For the most current

repair charges please visit www.bkprecision.com and click on “service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty

Service does not include return shipping. Return shipping to locations in North American is included for Warranty

Service. For overnight shipments and non-North American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number and

description of problem.

23

Page 26

Limited Three-Year Warranty

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be free

from defects in workmanship and materials for a period of three years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts.

Returned product must be accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration form

on www.bkprecision.com within fifteen (15) days of purchase.

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of

unauthorized alterations or repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting

from loss of use. Some states do not allow limitations of incidental or consequential damages. So the above limitation

or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

24

Page 27

B+K Precision

OSCILOSCOPIOS

Models

2120B – 30 MHz

2125A – 30 MHz

1541D – 40 MHz

2160A – 60 MHz

2190B – 100 MHz

25

Page 28

=============================================================================

DESCRIPCION

Los Osciloscopios B&K Precision de la serie PS comprenden 5 modelos con ancho de banda de 30;

40; 60 y 100 MHz ( para una atenuación de 3 dB ), con diferentes prestaciones en cada modelo.

Aparte de las diferencias de ancho de banda, los modelos presentan diferencias funcionales entre sí,

indicándose algunas de ellas en la tabla siguiente. Para facilitar el uso de este manual, la tabla

incorpora una guía rápida para ubicar la página correspondiente a los textos relevantes para las

funciones adicionales de cada modelo.

Modelo

Pag.

2120B 30 MHz Simple 150 mm - Interna

2125A 30 MHz Demorada 150 mm - Interna

Ancho

Banda

Base de

Tiempo

Tubo / Retícula Multímetro

Digital

No No No No

No Si No Si

Salida

Canal 2

Readout

en TRC

Probador

Comp.

Iluminada

1541D 40 MHz Simple 150 mm - Interna

2160A 60 MHz Demorada 150 mm - Interna

No No No No

No Si No Si

Iluminada

2190B 100 MHz Demorada 150 mm - Interna

No Si No Si

=============================================================================

CARACTERISTICAS DESTACADAS DE LA SERIE

Facilidad de operación: los controles y el panel frontal han sido diseñados teniendo en cuenta el

agrupar convenientemente los controles relacionados entre sí por su función, facilitando su ubicación

y uso. El panel posee varias áreas codificadas en diferentes colores para facilitar al usuario la

identificación, ubicación y uso de los distintos comandos disponibles.

Alta impedancia de entrada: la impedancia de entrada de ambos canales es, en todos los modelos,

de 1 M Ω +/- 2 % en paralelo con 25 pF +/- 10 pF.

Alta sensibilidad : 1 mV / Div. Máximo en todos los modelos.

Hold-off variable: disponible en todos los modelos, permite inhibir la generación de pulsos de

disparo de la base de tiempo por un tiempo variable a voluntad, en condición de señales complejas,

permitiendo lograr un display estable y repetible.

Operación X – Y : seleccionando este modo, el canal 1 se convierte en canal X y el canal 2 en Y

permitiendo graficar señales relacionadas entre sí.

Disparo de TV: la serie posee separadores de sincronismo para disparo sobre las señales de TV –V

y TV -H.

Barrido mezclado (modelos 2125A, 2160A, 2190B): esta función permite ver ambos barridos a

continuación uno de otro.

Salida de canal 2: (modelos 2125A, 2160A, 2190B): conector BNC en el panel posterior para

extracción de señal de canal 2 para lecturas de frecuencia, etc.

Modulación de intensidad (modelos 2125A, 2160A, 2190B): permite modular la intensidad del haz

mediante una señal externa de nivel TTL.

Comprobador de componentes (modelos 2125A, 2160A, 2190B): permite determinar su condición

en base a la generación y presentación de una curva característica de corriente en función de la

tensión aplicada.

Localizador de haz: (modelos 2125A, 2160A, 2190B): permite ubicar el haz dentro de la pantalla

irrespectivamente de la posición de los controles de posición, reduciendo el rango de actuación de

estos.

Retícula iluminada: (modelos 2125A, 2160A, 2190B): facilita la observación de formas de onda en

lugares con iluminación pobre. La intensidad es ajustable a conveniencia del usuario.

26

Page 29

Barrido de alta velocidad : hasta 10 nSeg / Div ( con magnificador x 10 ) Mod. 2190B: hasta 2 ns /

div. con magnificador x 10.

Exactitud : ±3% para sensibilidad , y barrido.

Display : rectangular de 150 mm de diagonal, lo que asegura excelente observación de formas de

onda ; aceleración: 2 KV ( 2120B y 2125A ); 8,5 KV ( 1541D ); 12 KV ( 2160A ) y 16 KV ( 2190B ).

27

Page 30

=========================================================================

ESPECIFICACIONES

MODELOS

2120B; 2125A; 1541D; 2160A; 2190B

PANTALLA

Tubo rectangular de 150 mm de diagonal, aluminizado. Retícula interna de 8 x 10 div. de 10 mm de

lado. Marcas de referencia para 0; 10 %; 90 % y 100 % para verificación de tiempos de

establecimiento y atenuación. Ejes centrales con marcas cada 0,2 div. ( 2 mm ). Aceleración simple

en mod. 20 y 25 MHz. Modelos de 40; 60 y 100 MHz con posaceleración.

MODELO ACEL. / POSACELERACION

2120B y 2125A 2 KV

1541D 2 KV / 8,5 KV

2160A 2 KV / 12 KV

2190B 2 KV / 16 KV

VERTICAL

Dos canales idénticos; conectores BNC en la entrada. Acoplamiento seleccionable de CA ó CC;

posibilidad de conectar a masa la entrada.