Page 1

INSTRUCTION

MANUAL

MODELS: 1760A, 1761, 1762

Triple Output

DC POWER SUPPLY

With Dual 4-Digit LED Displays

Page 2

2

TEST INSTRUMENT SAFETY

WARNING

Normal use of test equipment exposes you to a certain amount of danger from electrical shock because testing must sometimes be

performed where exposed high voltage is present. An electrical shock causing 10 milliamps of current to pass through the heart will

stop most human heartbeats. Voltage as low as 35 volts DC or AC rms should be considered dangerous and hazardous since it can

produce a lethal current under certain conditions. Higher voltages are even more dangerous. Your normal work habits should

include all accepted practices to prevent cont act with exposed high voltage, and to steer current away from your heart in case of

accidental contact with a high voltage. Observe the following safety precautions:

1. There is little danger of electrical shock from the DC output of this power supply. H owever, there are severa l other possible

test con ditions usin g this power supply that can create a high voltage shock hazard:

a. If the equipment under test is the “hot chassis” type, a serious shock hazard exists unless the equipment is unplugged (just

turning off the equipment does not remove the hazard), or an isolation transformer is used.

b. If the equipment under test is “powered up” (and that equipment uses high voltage in any of its circuits), the power supply

outputs may be floated to the potential at the point of connection. Remember that high voltage may appear at unexpected

points in defective equipment. Do not float the power supply output to more than 100 volts peak with respect to chassis or

earth ground.

c. If the equipment under test is “off” (and that equipment uses high voltage in any of its circuits under normal operation),

discharge high-voltage capacitors before making connections or tests. Some circuits retain high voltage long after the

equipment is turned off.

2. Use only a polarized 3-wire AC outlet. This assures that the power supply chassis, case, and ground terminal are connected to a

good earth ground and reduces danger from electrical shock.

3. Don’t expose high voltage needlessly. Remove housings and covers only when necessary. Turn off equipment while making

test connections in high-voltage circuits. Discharge high-voltage capacitors after removing power.

(continued on inside back cover)

Page 3

3

Instruction Manual

For Models

1760A, 1761, 1762

Triple Output DC Power Supplies

With Dual 4-Digit LED Displays

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

Page 4

4

TABLE OF CONTENTS

page

Page

TEST INSTRUM E NT S AF ETY ------------- inside front cover

INTRODUCTION ------------------------------------------------ 5

FEATURES ------------------------------------------------------- 7

SPECIFICATIONS ---------------------------------------------- 8

CONTROLS AND INDICATORS ---------------------------- 10

General Controls and Indicators ------------------------------- 10

4-6.5 V Supply Controls and Indicators ---------------------- 10

“A” Supply Controls and Indicators--------------------------- 12

“B” Supply Controls and Indicators --------------------------- 12

Rear Panel Controls --------------------------------------------- 13

OPERATIN G IN S TRU CTI ONS ------------------------------- 14

Safety Precautions ----------------------------------------------- 14

Equipment Precautions ----------------------------------------- 14

Independent Use of “A” or “B” Supply ----------------------- 14

Hook-up ---------------------------------------------------------- 15

Typical Constant Voltage Operation -------------------------- 18

Setting Current Limit ------------------------------------------- 19

Typical Constant Cu r r ent Operat i on -------------------------- 20

Constant Voltage/Current Characteristic --------------------- 21

Series Tracking Operation -------------------------------------- 22

Parallel Tracking Operation ------------------------------------ 26

4-6.5 V Po wer Sup ply O peration ------------------------------ 29

APPLICATION ---------------------------------------------------- 33

General -------------------------------------------------------------- 33

Electronics Servicing ---------------------------------------------- 33

Electronics Manufacturing ---------------------------------------- 33

Electronics Design Lab -------------------------------------------- 34

Electronics Education --------------------------------------------- 34

Battery Charging --------------------------------------------------- 34

Split Supply --------------------------------------------------------- 34

MAINTENANCE -------------------------------------------------- 41

Fuse Replacement -------------------------------------------------- 41

Line Voltage Conversion ------------------------------------------ 41

Adjustments -------------------------------------------------------- 42

“A” Supply and “A” Metering Adjustments -------------------- 42

4-6.5 V Supply and 6.5 V Metering Adjustments -------------- 44

“B” Supply and Metering Adjustments -------------------------- 44

“B” Series Tracking Adjustment --------------------------------- 45

Instrument Repair Service ---------------------------------------- 45

WARRANTY SERVICE INSTRUCTIONS -------------------- 46

LIMITED TWO-YEAR WARR ANT Y -------------------------- 47

Page 5

5

INTRODUCTION

These B+K Precision Triple Output DC Power Supplies are high

The two “main” volt supplies can be operated independently or in

tracks from 5% to 100% of the voltage of the “A” Supply. Maximum

. In the parallel tracking mode, the two supplies are

Both “main” volt supplies may be used in constant voltage or

constant current applications. The crossover from constant voltage to

constant current modes is smooth and automatic. LED’s indicate the

In constant voltage applications, a current limit may be preset. When

In constant current ap plicatio ns, the maximu m voltage ma y

limits the current output to a maximum of 5 amps. An

permits full flexibility of connections. When needed, the (+)

itive, or one positive, one

negative, and a common. All of these configurations can be

used with either matching (tracking) or differing

quality, general purpose DC power sources. They provide two “main”

supplies and a “third” auxiliary output with a 4-6.5V (2-6.5V for

models 1761 & 1762) DC output. The “main” V su ppli es are ad ju stabl e

with both coarse an d fin e vol tage co nt rol s for p recis e settab il ity an d are

capable of current output of 0-2A (0-3A for model 1761). The “third”

supply has a current output of 0-5A, allowing it to handle extensive

digital logic circuitry. Two large panel-mounted LED meter displays

can monitor either the output current or output voltage of each supply.

one of two tracking modes. In the series tracking mode, the “B” Supply

current setting of the two supplies can still be set independently when

in the series tracking o perating mode. In the series tr acking mode the

“A” and “B” supplies are con nected in series, allowing for double the

voltage setting

connected together in parallel, allowing for double the current setting.

“CV” (constant voltage) or “CC” (constant current) mode of operation.

load variations cau se the current to reach the pres et limit, the un it then

regulates output current rather than output voltage. Current limits are

adjustable from 5% to 100% of maximum.

be preset. When load variations cause current to drop below

the regulated value, the unit reverts to regulated voltage

operation at the preset value.

The “third” V supply is ideal for powering digital logic

circuitry. The 0-5 amp capacity allows the supply to be used

for large circuits. Built-in overload protection automatically

indicator lights when the supply is overloaded.

These models exhibit excellent regulation and low ripple

characteristics. The circuit design i ncorporates a pre-regulator,

which greatly reduces internal power dissipation at low output

voltages.

Reverse polarity prot ection prevents accidental damage to

the power supply from improper connection to an external

voltage, and current limiting protects the equipment being

powered, as well as the power supply.

The output is isolated from chassis and earth ground, which

or (-) polarity may be strapped to ground, or either polarity

may be floated to an external voltage. Additionally, the two

“main” volt supplies can be used as a “split supply” with two

positive voltages and a common negative, two negative

voltages and a common pos

(independent) voltages.

Page 6

6

The features and versatility of the unit, especially the triple output

supply for engineering lab applications. It can serve as a single or

voltage power source, including the bias supply, for

breadboard and prototype circuits and equipment. It can provide

amplifiers. It may be used as a battery eliminator, or to power

an be evaluated while powering a breadboard or

prototype circuit to determine the circuit’s power supply

The same features that make the Model 1760A a good

for school laboratories, and home use by electronic

and tracking features, make it an ideal general purpose power

multi-

single or simultaneously varying voltages for circuit evaluation. It

can provide trackin g (+) and (-) voltages for evaluating differential

individual circuit boards or cards while removed from the system.

Its output c

requirements. Its laboratory quality specifications will meet most

engineering laboratory requirements.

choice for an engineering lab also make it a good choice for

most other solid state electronic applications. These

applications include service shops; industrial production

testing of components, assemblies, and complete equipment;

hobbyists.

Page 7

7

TRIPLE OUTPUT

tracks the “A” supply. Outputs can be strapped for two positive

doubles output voltage capability and

CONSTANT VOLTAGE OR CONSTANT CURRENT

output voltage or output current of all three supplies. Use of

Limits internal dissipation for higher reliability and

Fully adjustable current limiting (from 5% to 100% of

reverse polarity.

Operates as three separate power supplies. Each has floating

output and is completely isolated from the other two.

ONE 4-6.5 V (1760A) or 2-6.5 V (1761 & 1762) SUPPLY

Durable 0-to-5 amp supply is ideal for use with most digital

logic circuitry. Adequat e current capacity for ext ensive circuitry.

TWO 0-30V (model 1760A), 0-35V (model 1761), or 0-60V

(model 1762) SUPPLIES

“A” and “B” supply are continuously variable over their

respective voltage ranges with coarse and fine controls. Each

supply has a 2A (3A model 1761) current capacity.

UNIQUE TRACKING FEATURE

The “A” and “B” supplies can be operated so that the “B” supply

voltages with a common negative, two negative voltages with a

common positive, or one positive and one negative with a neutral

common.

SINGLE 0-60V (model 1760A), 0-70V (model 1761), or 0120V (model 1762) SUPPLY

Series tracking feature

allows use of “A” and “B” supplies combined as one supply.

SINGLE 0-30V, 4A (model 1760A), 0-35V, 6A (model

1761), or 0-60V, 4A (model 1762) SUPPLY

Parallel tracking feature doubles output current capability and

allows use of “A” and “B” supplies combined as one supply.

FEATURES

The “A” and “B” supplies provide regulated DC voltage

output or regulated DC current output. Crossover is smooth

and automatic.

LED DISPLAY

Two large, easy-to-read LED 4-digit displays monitor

two meters allows simultaneous current and voltage metering

when using “A” and “B” supplies in tracking operation. Good

visibility in bright or low light.

LABORATORY QUALITY

Excellent regulation, low ripple.

PRE-REGULATOR

efficiency.

ISOLATED OUTPUT

Either polarity may be floated or grounded.

OVERLOAD PROTECTION

maximum output current) for “A” and “B” supplies protects

circuit under test and the power supply.

REVERSE POLARITY PROTECTION

Prevents damage to power supply from external voltage of

Page 8

8

“A” AND “B” SUPPLIES

Tracking Series, “B” trac ks “A”:

Output Voltage Range:

0V to 30V (model 1760A)

0V to 35V (model 1761)

0V to 60V (model 1762)

Output Current Limit Range:

0.1A to 2A (model 1760A and 1762)

0.1A to 3A (model 1761)

Load Regulation (Constant Voltage):

≤0.01% + 3 mV

Line Regulation 108 - 132 V (Constant Volta ge ):

≤0.01% + 3 mV

Ripple (Constant Voltage):

≤1 mV RMS

Recovery Time (Constan t Voltage):

≤100 uS

Temp. Coefficient (Constant Voltage):

<300 ppm/°C

Load Regulation (Constant Current):

≤0.2% + 3mA

Line Regulation 108 - 132 V (Constant Current):

≤0.2% + 3mA

Ripple Current (at 108 V for Constant Current):

≤3mA RMS

Tracking (Series) Accuracy:

±0.2% + 10mV

SPECIFICATIONS

5% to 100%

Panel Meter Accuracy (Volts):

±0.5% + 9 digits.*

Panel Meter Accuracy (Current):

±0.5% + 9 digits.*

(* see note 1)

“Third” SUPPLY

Output Voltage Range:

4V to 6.5V (2V to 6.5V model 1761)

Load Regulation (Constant Voltage):

≤10mV (0 to 5A load)

Line Regulation 108 - 132V (Constant Voltage):

≤10mV

Ripple and Noise:

≤2mV RMS

Over Voltage Protection Threshold:

6.8V to 7.3V

Panel Meter Accuracy:

Same as “A” Supply Meter.

Page 9

9

SPECIFICATIONS

GENERAL

Dimensions (H x W x D):

Power Requirements:

Domestic: 120 VAC + 10%, 60 Hz

International: 120/220/230/ 24 0 V AC -* 10%, 50/60 Hz

Power Consumption (Fully Loaded):

Approximately 350 W

Protection:

Reverse polarity protection and current limiting.

NOTE: Specifications and information are subject to change without notice. Please visit www.bkprecision.com

information.

Note 1:

Important: Even with noticeable Thermal Drift, this high resolution power supply will be considerably more accurate than any standard three

digit display bench power supply.

Thermal Drift: Since this power supply has greater resolution than standard bench power supplies they are more su sceptible to Thermal

Drift. Thermal Drift occurs on almost every type of power supply but is more apparent on high resolution types. Thermal Drift results in the

metering of the power supp ly to either slo wly increase or decr ease with the change in the power supply’s internal temperature. As the power

supply outputs more power its internal temperature will increase causing the metering (primarily the current) to slowly increase. As the power

demand is deceased the power supply will cool causing the metering (primarily the current) to slowly decrease. If the power supply remains

with a constant output of power for more than fifteen minutes the power supply metering will remain constant and should not continue to

drift.

5.7" x 10.5" x 15" (145 mm x 267 mm x 381 mm)

Weight:

10 kg (21 lbs)

Accessories Supplied:

Two earth ground bus straps.

for the most current product

Page 10

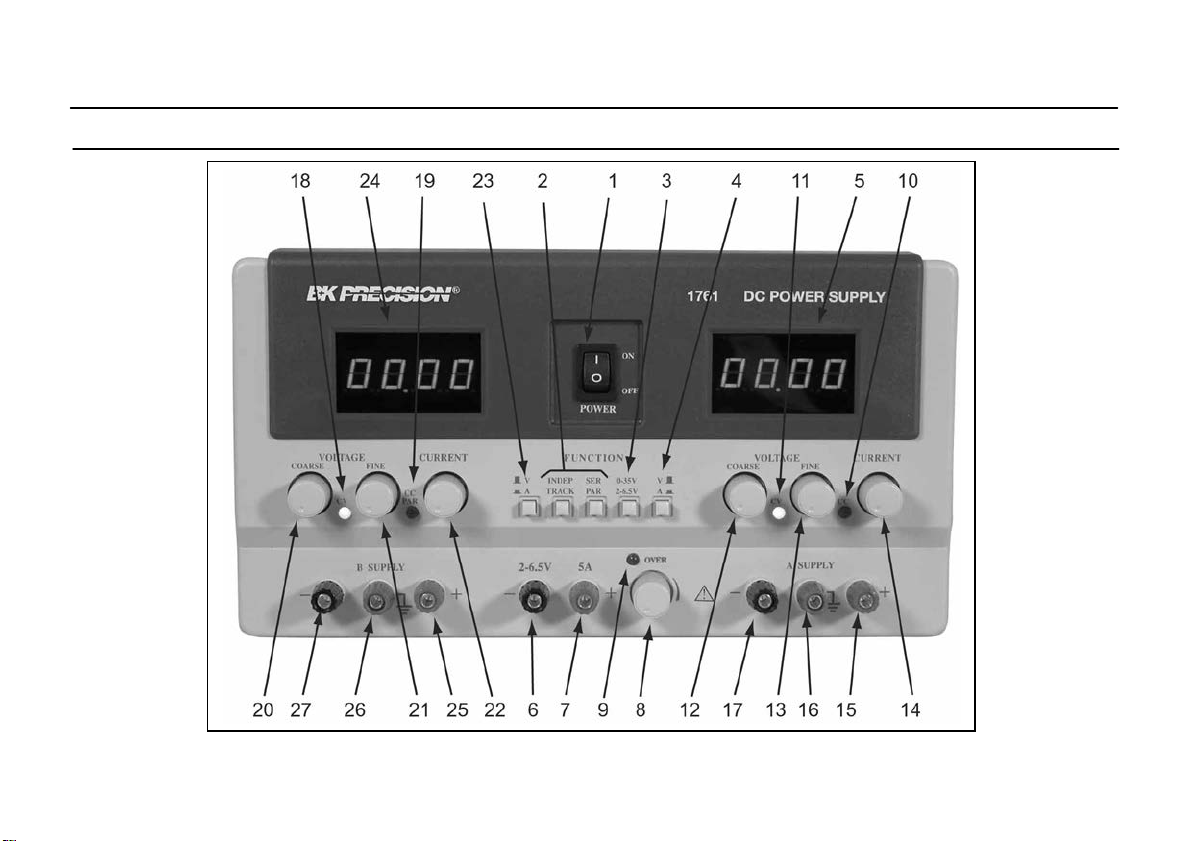

10

GENERAL CONTROLS AND INDICATORS

TRACKING Mode Switches. Two pushbutton switches that

1. 0-30V/4-6.5V Switch. Controls “A”/4-6.5V LED

(amps) position (in), current is read from the

. Digital display indicates

CONTROLS AND INDICATORS

8. POWER Switch. Turns power on and off.

9.

select INDEPendent mode, SERies trackin g mode, or PARallel

tracking mode as follows:

a. When INDEP/TRACK switch is disengaged (out), the unit

is in the INDEPendent mode and the “A” and “B” power

supplies are completely independent from one another.

b. When the INDEP/TRACK switch is engaged (in) and the

SER/PAR switch is disengaged (out), the unit is in the

TRACKing SERies mode. In this mode, maximum voltage

of both supplies is set using the “A” VOLTAGE controls

(voltage at output terminals of the “B” supply tracks the

voltage at the output terminals of the “A” supply). Also, in

this mode of operation the positive terminal (red) of the “B”

supply is internally connected to the negative terminal

(black) of the “A” supply. This allows the two supplies to be

used as one 0-to-60 volt supply.

c. When both INDEP/TRACK and SER/PAR switches are en-

gaged (in), the unit is in the TRACKing PARallel mode. In

this mode the “A” and “B ” supplies are wired together in

parallel and both the maximum cu rrent and voltage are set

using the “A” controls. The “A” and “B” outputs can be

used as two individual (but tracking) power supplies or just

the “A” output can b e used as a 0-to-30 volt supply with a 4

A capability.

Display. When this switch is in the 0-30V position (out),

the LED display monitors the “A” (0-30 V) supply.

When this switch is in the 4-6.5V positi on (in), the LED

display monitors the 4-6.5V supply.

2. Right V/A Sw itch. Selects current or voltage metering

mode for the “A” 0-30 V supply or the 4-6.5 V supply

(depending on setting of 0-30 V/4 -6.5 V switch ). When

in the A

“A”/4-6.5 V LED Display. When in the V (volts)

position (out), voltage is read from the “A”/ 4-6.5 V

LED Display.

3. “A”/4-6.5 V LED Display

voltage or current at the 0-30 V “A” supply or the 4-6.5

V supply (depending on the setting of the Right V/A and

0-30 V/4 -6.5 V switches).

4-6.5 V SUPPLY CONTROLS AND INDICATORS

4. “-” Terminal (Black). Negative polarity output terminal

for 4-6.5V supply.

5. “+” Terminal (Red). Positive polarity output terminal

for 4-6.5V supply.

6. Voltage Level Control. Adjusts output voltage for 4-

6.5V supply. Fully counterclockwise rotation adjusts

output voltage to 4V. Clockwise rotation increases

voltage to a maximum of 6.5V (full clo c kwi se ro t at ion ).

7. 5 A OVERload Indicator. Lights when load on 4-6.5

Volt supply becomes too large.

Page 11

11

CONTROLS AND INDICATORS

Fig. 1. Front Panel Co ntrols and Indi cator s.

Page 12

12

“A” SUPPLY CONTROLS AND INDICATORS

supply is in the Constant Current mode. The Power

adjustment control for the maximum output voltage of the

Fine adjustment of output

10. CURRENT Control. Adjusts current limit of “A”

stant voltage mode. Adjusts constant

supply in constant current mode.

mode. The Power Supply regulates the output current at

endent modes. Also lights

16. C.C. (Constant Cur rent) Indicator. Red LED lights when

“A”

Supply regulates the output current at the value set by the

“A” CURRENT control. In the Parallel Tracking mode,

when this indicator is lit, both the “A” and “B” sup plies are

in the Constant Current mode.

17. C.V. (Constant Voltage) Indicator. Green LED lights when

the “A” supply is in the Constant Voltage mode. The Power

Supply regulates the output voltage at the value set by the

“A” VOLTAGE controls. In either the Series or Parallel

Tracking mode, when this indicator is lit, both the “A” and

“B” supplies are in the Constant Voltage mod e.

18. Coarse VOLTAGE Control. Coarse adjustment of the

output voltage of the “A” supply. Also functions as coarse

“B” supply when either parallel or series tracking mode is

selected. Read the value on the “A”/4-6.5 V LED Display

when the voltage (V) and master (0-30 V) meterin g modes

are selected.

19. Fine VOLTAGE Control.

voltage of the “A” supply. Also fun ctions as fine adjustment

control for the maximum output voltage of the “B” supply

when either parallel or series tracking mode is selected. Read

the value on the “A”/4-6.5 V LED Display when the voltage

(V) and master (0-30 V) metering modes are selected.

CONTROLS AND INDICATORS

supply in con

current value of “A”

Current can be read from the “A”/4-6.5V LED Display

when the current (A) and master (0-30V) metering

modes are selected.

11. “+” Terminal (Red). Positive polarity output terminal

for the “A” supply. Also serves as the positive polarit y

terminal for 4 A parallel and 0-to-60 V series tracking

operation.

Terminal (Green). Earth and Chassis Ground.

12.

13. “-” Terminal (Black). Negative polarity output terminal

for the “A” supply. Also serves as the negative polarity

terminal for 4 A parallel tracking operation. In series

tracking op eration, this termin al is internally tie d to the

(+) positive terminal of the “B” supply.

“B” SUPPLY CONTROLS AND INDICATORS

14. C.V. (Constant Voltage) Indicator. Green LED lights

when the “B” supply is in the Constant Voltage mode.

The Power Supply regulates the output voltage at the

value s et b y the “B” VOLTAGE controls.

15. C.C. (Constant Current)/PARallel Indicator. Red

LED lights when “B” supply is in the Constant Current

the value set by the “B” CURRENT control when in the

series tracking or INDEP

when the TRACKing PARa llel mo de is selected.

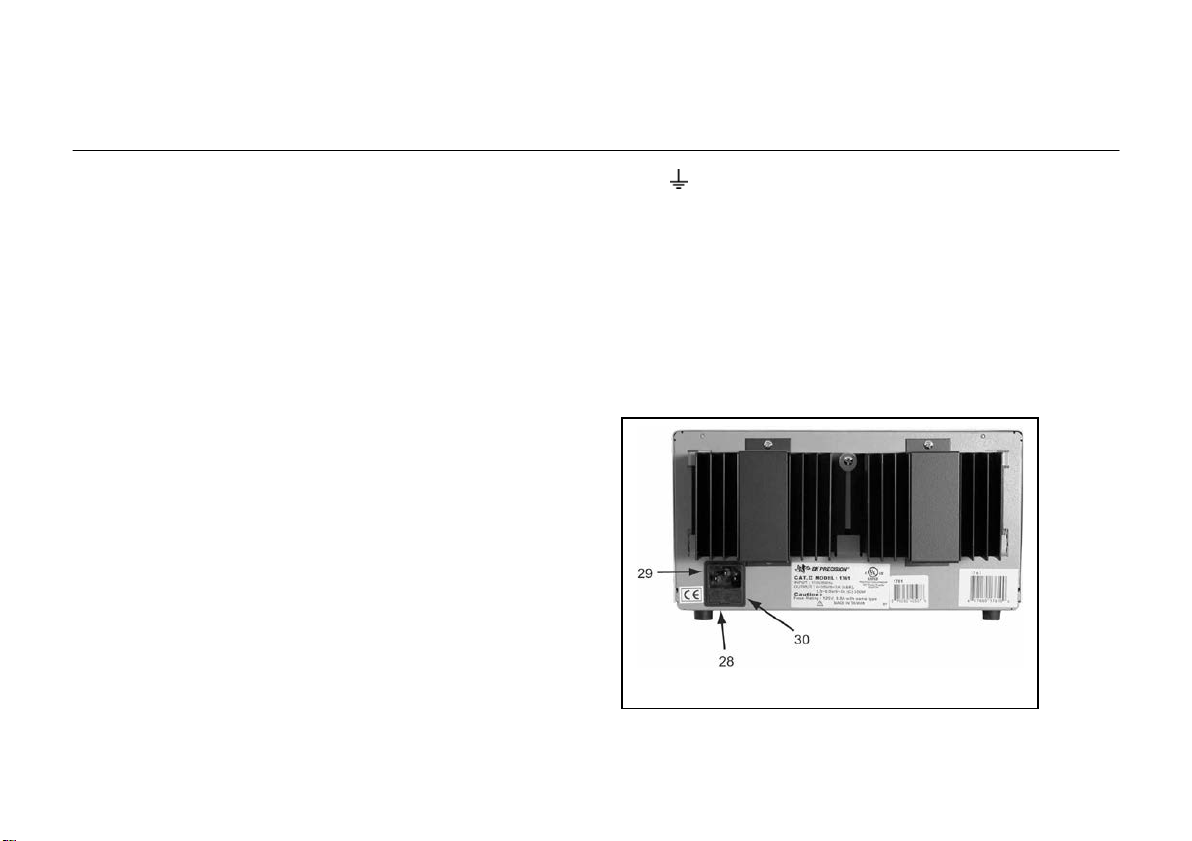

Page 13

13

CONTROLS AND INDICATORS

Fig. 2. Rear Panel Controls.

25. Coarse VOLTAGE Control. Coarse adjustment of the output

this terminal is

connected to the negative terminal of the “A” supply.

voltage of the “B” supply when the INDEPendent mode is

selected. Also sets the 5% to 100% tracking in the SERies

TRACKing mode. Disabled in the PARallel TRACKing mode.

Read the value on the “B” LED Display when the voltage (V)

metering mode is selected.

26. Fine VOLTAGE Control. Fine adjustment of output voltage of

the “B” supply when the INDEPendent mode is selected. Also

sets the 5% to 100% tracking in the SERies TRACKin g mode.

Disabled in the PARallel TRACKing mode. Read the value on

the “B” LED Di splay when the voltage (V) metering mode is

selected.

27. CURRENT Control. Adjusts current limit of “B” supply in

constant voltage mode. Adjusts current value of “B” supp ly in

constant current mode. Current can be read from the “B” LED

Display when the current (A) metering mode is selected.

28. Left V/A Switch. Selects current or voltage metering mode for

the 0-30 V “B” supply. When in the A (amps) position (in),

current is read form the “B” LED Display. When in the V

(volts) position (out), voltage is read form the “B” LED

Display.

29. “B” LED Display. Digital display indicates voltage or current

at the 0-30 V “B” supply (depending on the setting of the A/V

switch).

30. “+” Terminal (Red). Positive polarity output terminal for the

“B” supply. In series tracking operation,

20. Ter minal (Green). E arth and Chas sis Grou nd .

21. “-” Terminal (Black). Negative polarity output terminal

for the “B” supply. Also serves as the negative polarity

terminal for 0-to-60 V series tracking operation.

REAR PANEL CONTROLS

22. Fuse

23. Power Cord

24. 110/220 Line Voltage Conversion Swi tch

Page 14

14

OPERATING INSTRUCTIONS

SAFETY PRECAUTIONS

power supply. When the unit is providing large

heat sink can become very hot. Contacting the

may contain high voltage and present a shock

hazard. Observe caution. If the power supply

output is floated (referenced to a voltage rather

ground.

EQUIPMENT PRECAUTIONS

Avoid using the power supply in ambient temperatures above

There is no need to worry about voltage spikes or overshoot

supplies only when they are used independently from one another.

endent operating mode, the operating

controls of the two power supplies are completely independent and

either supply can be used individually or both can be used

are covered in the APPLICATIONS section of this manual.

Avoid contacting the heat sink at the rear of the

amounts of current at any or all of its outputs, the

heat sink when it is hot could result in skin burns

or damage to the equipment in contact with them.

Use only a polarized 3-wire AC outlet. This as-

sures that the power supply chassis, case, and

ground terminal are connected to a good earth

ground and r educ es dang er fro m el ect ri cal sh ock .

There may be great danger of electrical shock if

the power supply output is connected to an external high voltage. Some equipment being powered

than earth ground) turn off the power supply and

the equipment under test when making connections. Never float the power supply to a potential

greater than 100 volts peak with respect to earth

CAUTION

+40° C. Always allow sufficient air space around the heat sink at

the rear of the power supply for effective radiation to prevent

internal heat build-up.

Although the power supply is protected against reverse polarity

damage, the circuit being powered may not include such protection.

Always carefully observe polarity; incorrect polarity may damage

the equipment under test.

Do not exceed the voltage rating of the circuit being powered.

Many transistors and integrated circuits will not withstand voltage

of 30 volts.

damaging the equipment under test. The voltage between the output

terminals of the power supply never exceeds the preset value as the

POWER switch is turned on or off.

INDEPENDENT USE OF “A” OR “B” SUPPLY

The “A” and “B” supplies each provide a 0-to-30 volt output at

up to 2.0 amps. This procedure covers the use of the “A” and “B”

When used in the INDEP

simultaneously. Basic operation is covered here. Several variations

Page 15

15

Hook-up

mode switch so that the

Turn off the power supply and the equipment to be powered

Connect the positive polarity of the device being powered to

powered is also the chassis or common, it may be

b. Similarly, the positive polarity can be grounded by

in Fig. 3C should also be used where it is not

ered is separate from both the positive and

is not equipped with reverse polarity protection,

1. Disengage the INDEP/TRACK

power supply is in the INDEPendent operating mode.

2.

during hook-up.

3.

the red (+) terminal of the power supply.

4. Connect the negative polarity of the device being powered to

the black (-) terminal of the power supply.

5. Fig. 3 illustrates the grounding possibilities when used in the

INDEPendent mode.

a. If the negative polarity of the equipment or circuit being

grounded to earth by strapping the black (-) terminal to

the green (

) terminal as shown in Fig. 3A.

OPERATING INSTRUCTIONS

strapping the red (+) terminal to the green ( )

terminal as shown in Fig. 3B.

c. If an earth ground reference is not required, the

configuration of Fig. 3C may be used. The scheme

known whether the chassis is common with either

the positive or negative polarity.

d. If the chassis or common of the equipment being

pow

negative polarity power inputs, use the connection

shown in Fig. 3D.

6. Observe proper polarity. If the circu it being powered

damage to the circuit can result from reverse polarity.

Use color coded hook-up leads, for convenience in

identifying polarity, red for (+) and black for (-).

7. Make sure that the hook-up leads offer sufficient

current capability and low resistance between the

power supply and the circuits being powered.

Page 16

16

OPERATING INSTRUCTIONS

Fig. 3. Independent Ope rati on Groundi ng Po ssibili ties.

Page 17

17

OPERATING INSTRUCTIONS

Fig. 3. Independent Ope rati on Groundi ng Po ssibili ties.

Page 18

18

Fig. 4. Typical Cons tant Volt age O peratio n.

Typical Constant Voltage Operation

Before connecting the device to be powered to the power

afe load current for the

and connect it to the device to be

current metering mode and note the load current on the

1.

supply, determine the maximum s

device to be powered and set the current limit value (see

“Setting Current Limit” procedure in this section).

2. Set Fine VOLTAGE control to center and Coarse

VOLTAGE control to minimum (fully counterclo ckwise).

3. Turn off power supply

powered (see “Hook-Up” procedure in this section).

4. Turn on POWER switch. The CV indic ator should l ight.

5. Set the meter selection switch to the V position to select the

voltage metering mode.

6. Increase the VOLTAGE setting until the LED display reads

the desired value. The Fine control permits easier setting to a

specific value.

7. Set the meter selection switch to the A position to select the

display.

8. If the load current exceeds the preset current limit, the CV

indicator will go off and the CC indicator will light. In this

case, the power supply automatically switches to the constant

current mode and further rotation of the VOLTAGE control

will not increase the output voltage.

OPERATING INSTRUCTIONS

Page 19

19

OPERATING INSTRUCTIONS

Fig. 5. Setti ng Cur rent Li mit.

Setting Current Limit

control away from zero

control for the desired current limit.

The current limit (overload protection) has now been preset.

1. Determine the maximum safe current for the device to be

powered.

2. Temporarily short the (+) and (-) terminals of the power

supply together with a test lead.

3. Rotate the Coarse VOLTAGE

sufficiently for the CC indicator to light.

4. Set the meter selection switch to the A position to select the

current metering mode.

5. Adjust the CURRENT

Read the current value on the LED display.

6.

Do not change the CURRENT control setting after this step.

7. Remove the short between the (+) and (-) terminals and hook

up for constant voltage operation.

Page 20

20

Fig. 6. Typi cal C onstant C urrent Oper atio n.

Typical Constant Current Operation

Turn off the power supply and connect it to the device to be

The CC indicator will not light if the load is less than 5% of

advance (before connecting the load) as prescribed earlier in the

increa se th e ou tp ut cur ren t.

1. Before connecting the device to be powered to the power suppl y,

determine the maximum safe voltage to be applied, set the meter

selection switch to the V position, and set the VOLTAGE

controls to obta in tha t voltag e readin g on the LED display.

2. Determine the desired constant current value.

3. Set the CURRENT control to minimum (fully counterclockwise).

4.

powered.

5. Turn on the power supply. The CC indicator should light if the

load is greater than 5% of full scale.

full scale or approximately 0.1A.

6. Set the meter selection switch to the A position to obtain the

current metering mode.

7. Increase the CURRENT con trol sett ing until th e desire d constant

current value is read on the display, or set the current limit in

“Setting Current Limit” procedure.

8. If the load current drops below the constant current value, the CC

indicator will go off and the CV indicator will light. In this case,

the power supply automatically switches to the constant voltage

mode, and further rotation of the CURRENT control will not

NOTE

OPERATING INSTRUCTIONS

Page 21

21

OPERATING INSTRUCTIONS

Figure 7. Constant Vol tag e/Constant Curre nt

Constant Voltage/Constant Current Characteristic

The working characteristic of this power supply is called a constant

sponse to the load change. The intersection of constant voltage and

constant current modes is called the crossover point. Fig. 7 shows the

the constant voltage mode, a regulated output voltage is provided. The

output voltage remains constant as the load increases, up until the point

current becomes constant and the output voltage drops in proportion to

further increases in load. The crossover point is indicated by the front

constant current mode, which may be adjusted for a 1 amp charging

oad decreases to the point where it no longer demands the full

l amp charging rate. This is the crossover point where the power supply

voltage/constant current automatic crossover type. This permits continuous transition from constant current to constant voltage modes in re-

relationship between this crossover point and the load.

For example, if the load is s uch that the power supply is op erating in

where the preset current limit is reached. At that point, the output

panel LED indicators. The crossover point is reached when the CV

indicator goes off and the CC indicator comes on.

Similarly, crossover from the cons tant current to the constant voltage

mode automatically occurs from a decrease in load. A good example of

this would be seen when charging a 12-volt battery. Initially, the open

circuit voltage of the power supply may be preset for 13.8 volts. A low

battery will place a heavy load on the supply and it will operate in the

rate. As the battery becomes charged, and its voltage approaches 13.8

volts, its l

goes into the constant voltage mode.

Characteristics.

Page 22

22

SERIES TRACKING OPERATION

supply. This allows the power

In the series tracking mode, the maximum output voltage of both

supplies can be simultaneously varied with one

Simultaneous metering of both current and voltage can be obtained

mode of operation by setting one of the displays for current

switch and releasing the

SER/PAR switch.

1. Set the 0-30 V/4-6.5 V switch to the 0-30 V

control. Follow the instructions for

Turn off the power supply and the equipment to be

Fig. 8 illustrates the grounding possibilities when

being powered is also the chassis or common, it

may be grounded to earth by strapping the black

When the series tracking mode of operation is selected, the positive

(red) terminal of the “B” supply output is internally connected to th e

negative (black) terminal of the “A”

supply to be used as a single 0-to-60 volt power supply simply by

using the negative (black) terminal of the “B” supply and the positive

(red) terminal of the “A” supply.

the “A” and “B”

control. The maximum “B” supply voltage can be set to the same

value of the “A” supply by setting the “B” Coarse and Fine

VOLTAGE controls fully clockwise, so that “B” is set to 100%

tracking.

in this

metering and one for voltage metering. In this case, the output voltage

(across the two supplies) is actually double the displayed value. For

example, if the “B” display is set for voltage metering and the “A”

display for current metering, the output voltage across the “A”

positive (red) terminal and the “B” negative (black) terminal would

be double the reading on the “B” LED Display (since both supplies

are putting out the same voltage). The actual output current would be

the valu e r ead fr o m th e “A” LED Dis pla y.

8. Set the power supplies to the TRACKING SERIES mode by

engaging the INDEP/TRACK

OPERATING INSTRUCTIONS

position, the “B” V/A switch to the V (voltage

metering) position, and the “A” V/A switch to the A

(current met er in g) po s ition .

2. Set the “B” Coarse and Fine Voltage and

CURRENT controls to the fu lly clockwi se pos ition.

The maximum current is set using the “A”

CURRENT

“Setting Cu rrent Limit” (INDEPENDENT USE OF

“A” OR “B” SUPPLY section of this manual) using

the “A” CURRENT control.

3. Adjust the output voltage to the desired level using

the “A” VOLTAGE controls (remember that the

actual output voltage is double the reading on the

“B” LED Display).

4.

powered during hook-up.

5. Connect the positive polarity of the device being

powered to the red (+) terminal of the “A” power

supply.

6. Connect the negative polarity of the device being

powered to the black (-) terminal of the “B” power

supply.

7.

the unit is used as a 0-to-60 volt supply.

a. If the negative polarity of the equipment or circuit

(-) terminal of the “B” supply to the green ( )

terminal of the “B” supply as shown in Fig. 8A.

Page 23

23

OPERATING INSTRUCTIONS

Fig. 8. Series Tracking Operation Grounding Poss ibilities

Page 24

24

OPERATING INSTRUCTIONS

Fig. 8. Series Tracking Operation Grounding Poss ibilities

Page 25

25

OPERATING INSTRUCTIONS

Fig. 8. Series Tracking Operati on Grounding Po ssibili ties

a. Similarly, the positive polarity can be grounded by

If one of the supplied ground straps is to be used,

and negative terminals and load down the power

configuration of Fig. 8D may be used. The scheme in

Fig. 8D should also be used where it is not known

or common of the equipment being

powered is separate from both the positive and

negative polarity power inputs, use the connection

strapping the red (+) terminal of the “A” supply to the

green terminal of the “A” supply as shown in Fig. 8B.

b. If “split supply” operation is desired, a positive and

negative voltage with a center ground can be achieved

by strapping the black (-) terminal of the “A” supply

to the green ( ) of the “A” supply as shown in Fig.

8C. See the APPLICATIONS section of this manual

for more information on “split supply” operation.

NOTE

only use it in one of these three ways. Connecting

two ground straps could ground both the positive

supply, causing improper operation.

c. If an earth ground reference is not required, the

whether the chassis is common with either the positive

or negative polarity.

d. If the chassis

shown in Fig. 8E.

Page 26

26

9. Observe proper polarity. If the circuit being powered is not equipped with

up leads offer sufficient current capability and

In the parallel tracking mode of operation, both supplies are strapped

(because each supply is providing the same amount of

supply output jacks, follow the instructions for “Setting Current

1. Adjust the output voltage to the desired level

being powered to the red (+) terminal of the

Fig. 9 illustrates the grounding possibilities

circuit being powered is also the chassis or

Similarly, the positive polarity can be

the configuration of Fig. 9C may be used.

The scheme in Fig. 9C should also be used

If the chassis or common of the equipment

eing powered is separate from both the

reverse polarity protection, damage to the circuit can result from reverse

polarity. Use color coded hook-up leads, for convenience in identifying

polarity, red for (+) and black for (-).

10. Make sure that the hook-

low resistance between the power supply and the circuits being powered.

PARALLEL TRACKING OPERATION

together (in parallel). This allows for a 0-30 V supply with a 4 amp current

capability. Only the “A” output terminals are used for parallel tracking

operation. In the parallel tracking mode, the “B” supply output voltage and

current track the “A” supply output voltage and current.

6. Set the power supplies to the TRACKING PARALLEL mode by

engaging both TRACKING switches (INDEP/TRACK and SER/PAR

switches).

7. Set the 0-30V/4-6.5V switch to the 0-30V position, the “A” V/A switch to

the V (voltage metering) position, and the “B” V/A switch to the A

(current metering) position. Output voltage will now be read from the “A”

LED Display. Output current is exactly double the value read from the

“B” LED Display

current).

8. Because both voltage and current of the “B” supply track the “A” supply,

the maximum current and voltage are set using the “A” controls. Using

the “A”

Limit” (INDEPENDENT USE OF “A” OR “B” SUPPLY paragraph of this

section). Remember that the actual current output at the “A” supply

output jacks is double th e re ading on the “B” LED Display.

OPERATING INSTRUCTIONS

using the “A” VOLTAGE controls.

2. Turn off the power supply and the equipment to

be powered during hook-up.

3. Connect the positive polarity of the device

“A” po wer supply.

4. Connect the negative polarity of the device

being powered to the black (-) terminal of the

“A” po wer supply.

5.

when used in the TRACKing PARallel mode.

a. If the negative polarity of the equipment or

common, it may be grounded to earth by

strapping the black (-) terminal to the green

(

) terminal as shown in Fi g. 9A.

b.

grounded by strapping the red (+) terminal to

the gre en (

c. If an earth ground reference is not required,

where it is not known whether the chassis is

common with either the positive or negative

polarity.

d.

b

positive and negative polarity power inputs,

use the connection shown in Fig. 9D.

) terminal as shown in Fig. 9B.

Page 27

27

OPERATING INSTRUCTIONS

Fig. 9. Parallel Tracking Operation Grounding Possibilities

Page 28

28

OPERATING INSTRUCTIONS

Fig. 9. Parallel Tracking Operation Grounding Possibilities

Page 29

29

OPERATING INSTRUCTIONS

9. Observe proper polarity. If the circuit being powered is not

1. Fig. 10 illustrates the grounding possibilities of the 4-6.5V

If an earth ground reference is not required, the

equipped with revers e polarity protection, damage to t he circuit

can result from revers e polarity. Use color coded hook-up leads,

for convenience in i dentifying polarity, red f or (+) and black for

(-).

10. Make sure that the hook-up leads offer sufficient current

capability and low res istance between the p ower supply and t he

circuits being powered. 10-amp test leads are available as an

optional accessory.

4-6.5 V POWER SUPPLY OPERATION

The 4-6.5V s upply provides a 4 .0 to 6.5V DC output with a 5 amp

current capacity. The supp ly is idea l for us e with TTL circ uits.

5. Set the 0-30V/4-6.5V switch to the 4-6.5V position a nd the Right

V/A swi tch to the V p osition. This sets the “A”/4-6.5V Display

to show output voltage of the 4-6.5V supply.

6. Using the Voltage Level C ontrol to adjust the outp ut voltage of

the 4-6.5 V supply to the desir ed level.

7. Turn off the power supply and the equipment to be powered

during hook-up.

8. Connect the positive polar ity of the device being powered to the

red (+) terminal of the 4-6.5V supply.

9. Connect the negative polarity of the devic e being powered t o the

black (-) terminal of the 4-6.5V supply.

supply.

a. If the negative polarity of the equipment or circuit being

powered is also the chassis or com mon, it may grounded to

earth by connecting a jumper from the black (-) terminal to

either green (

b. Similarly, the positive polarity can be grounded by

connecting a jumper between the r ed (+) terminal and either

green (

c.

configuration of Fi g. 10C may be used. The scheme in Fig.

10C should also be used where i t is not known whether the

chassis is common with either the positive or negative

polarity.

d. If the chassis or common of the e quipment bei ng powered i s

separate from both the posi tive and negative polarity power

inputs, use the connection shown in Fi g. 10D.

2. Observe proper polarity. If the circuit being powered is not

equipped with reverse polar ity protec tion, damage t o the circuit

can result from reverse polarity. Use color coded hook-up

leads, for conven ience in identifying polari ty, red for (+) and

black for (-).

3. Make sure that the hook-up leads offer sufficient current

capability and low res ist a nce bet ween the p ower sup pl y and the

circuits being powered. 10-amp hook-up leads are a vailable as

an optional accessory.

4. Set the Right V/A switch to the A pos ition to moni tor the l oad

current.

) terminal as shown in Fig. 10A.

) terminal as shown in Fig. 10B.

Page 30

30

OPERATING INSTRUCTIONS

Fig. 10. Grounding Possibilities for 4-6.5 V Power Supply

Page 31

31

OPERATING INSTRUCTIONS

Fig. 10. Gr o unding Possibilities for 4-6.5 V Power Supply

Page 32

32

10. If the red OVERload indicator lights, too much load has been placed

on the supply. This will cause voltage and current to drop and

situation, the load on the supply must be decreased so that no more

NOTE

to normal operation, the output

prevent proper operation of the 4-6.5V supply. To correct this

than 5 amps of current are required.

OPERATING INSTRUCTIONS

If decreasing the load d oes not cause

the overload indicator to turn off, the

overvoltage protection circuitry has

activated. In order to return the supply

voltage must be decreased (or the

external voltage source must be removed) and the power must be

momentarily shut of f.

Page 33

33

APPLICATIONS

GENERAL

power supply has a very wide

facturing and testing facilities,

schools, and home hobbying. The “A” and “B” power supply

operate a module or circuit board on the test bench when it is

removed from its parent equipment. It can be used to power

players, auto sound systems, CB radios, etc. on the test bench.

volt electrical

Some servicing applications require the injection of a

equipment being tested may contain its own power supply

present in the circuit. One polarity of the power supply

output is floated to an appropriate point in the circuit, such as

the emitter of a transistor. The other polarity of the power

such as the base of that transistor. Varying the power supply

modules, subassemblies, and complete units in the

power source for testing purchased components and

This power supply is particularly well suited for

will cause the CC indicator to light, and the unit can be

The Model 1760A/1761/1762

variety of applications in electrical and electronics servicing,

engineering laboratories, manu

outputs are fully adjustable from 0-30V (1760A), 0-35V (1761), or

0-60V (1762) and 0-2A (1760A and 1762) or 0-3A (1761) and the

4-6.5V (1760A) or 2-6.5V (1761 & 1762) supply is fully adjustable

with a current capability of 0-5A. This flexibility makes it suitable

for most applications requiring a DC power source.

ELECTRONICS SERVICING

Most electronics trou blesho oting and repair is performed on a test

bench. This power supply can provide the DC power source to

portable, battery-operated equipment and check the effect of low

battery voltage. It can power vehicular equipment such as tape

Parallel tracking supplies up to 4 amps, adequ ate surge current for

most vehicular equipment.

Most automobiles and other vehicles use 12systems. Although the electrical system is normally referred to as a

12-volt system, actual battery voltage when fully charged is

approximately 14 volts. The power supply may be set to 14 volts for

servicing equipment from vehicles with 12-volt electrical systems.

Some trucks use a 24-volt electrical system; bench testing of

equipment from these systems should be performed at 28 volts.

variable DC voltage for certain tests, such as checking the

effect of AGC bias in a television receiver. This requires an

isolated DC power supply, such as the Model 1760A. The

and operate from AC power. A DC vol tage may already be

supply output is then applied to another point in the circuit,

voltage then varies the DC bias on the stage, and the effects

may be noted. A series limiting resistor is often used to

protect the circuits from overdissipation.

ELECTRONICS MANUFACTURING

In electronics manufacturing facilities, the power supply is

often used as a DC power source while testing and adjusting

production and assembly area or in the quality control ar ea.

The instrument can be used in incoming inspection as a DC

subassemblies.

manufacturing applications because of its ease of operation

and its continuous duty rating. When load current or total

power dissipation are among the main characteristics to be

measured, the total load current and voltage are easily

displayed on the LED display. The current limit can be set so

that all units which do not meet the load current specification

Page 34

34

ELECTRONICS DESIGN LAB

The technician or engineer working in an engineering laboratory

power supply to power breadboard and prototype

Use of the instrument in an engineering laboratory is very similar

except that lower currents may be prevalent when powering

individual circuits. The current limiting feature is very valuable in

this application because it can protect unproven circuits from

The student in an electronics curriculum may use the power supply

for powering equipment and circuits as previously described for all

other applications. In addition, the power supply can be used in the

nts in fundamental

specifications for proper voltage and current settings.

Charging information is sometimes printed on the batteries.

current mode of operation. Before connecting the power

than the power supply’s maximum load current, set the

he power supply output and the

charging current will taper off. The power supply may

When this occurs, the power supply will continue to provide

er supplies” are required for

ideally suited for “split power supply” operation. This

supply can be configured to provide two positive voltages

common positive, or one positive and one negative with a

common ground. In addition, each of these configurations

requires a DC

circuits. This power supply is ideal because it monitors output

current and voltage, limits current to protect the circuit, is adjustable

over a wide range, and has excellent regulation and very low ripple.

to that described for servicing electronics equipment and modules,

damage.

ELECTRONICS EDUCATION

classroom laboratory to conduct experime

electronics. In learning Ohm’s law, for example, the relationships of

resistance, current, and voltage are easily d emonstrated by the u se of

a power supply.

BATTERY CHARGING

charge in rechargeable batteries such as lead-acid, nickel-cadmium,

and some alkaline types. Refer to the battery manufacturer’s charging

The power supply can be used as a battery charger to restore the

APPLICATIONS

Battery charging, at least initially, requires the constant

supply to the battery, preset the VOLTAGE controls to the

fully charged terminal voltage specified by the battery

manufacturer. Turn off the power supply while connecting

the battery. Observe proper polarity and connect as for

constant current operation. Adjust the CURRENT control

for the maximum charging current specified by the battery

manufacturer (If the maximum charging current is greater

CURRENT control to maximum). The CC indicator will

light and the battery will charge at the preset current limit.

As the battery approaches full charge, its terminal voltage

will approach that of t

automatically switch to CV (constant voltage) operation.

a trickle charge.

SPLIT SUPPLY

Frequently, “split pow

amplifier and other electronic circuits. The Model 1760 A is

with a common negative, two negative voltages with a

can be obtained with identical or differing voltages.

Page 35

35

APPLICATIONS

Fig. 11. Typical Hook-Up Using Tw o Identi cal

Positive Voltages and a Common Negative.

Two Identical Positive Voltages With a Common

voltages with a common negative. A good example of this would

common negative. Using both supplies in the parallel tracking

Turn off the power supply and the equipment to be powered

Connect the positive polarity inputs of the circuit to be

powered to the positive (red) terminals of the supplies and

Negative (Refer To Fig. 11)

Some electronic equipment requires two identical positive

be a digital car clock where there are two +12 volt inputs and a

mode would provide the simplest hook-up and operation. This

type of “split supply” operation is obtained as follows:

1. Connect a ground strap between the “A” supply’s ne gative

terminal and ground.

2. Set the desired voltage and maximum current using the “A”

VOLTAGE and CURRENT controls.

3.

during hook-up.

4.

connect the common negative input of the circuit to be

powered to the “A” supply’s negative (black) or ground

(green) terminal.

Page 36

36

Fig. 12. Typical Hook-Up Using Tw o Diff erent

Positive Voltages and a Common Negative.

Two Differing Positive Voltages With a Common Negative

with a common negative. A typical example of this would be a

endent operating mode and set up the LED

Turn off the power supply and the equipment to be powered

s of the circuit to be

powered to the positive (red) terminal of the supply. Connect

the common negative input of the circuit to be powered to

(Refer To Fig. 12)

Many electronic circuits require two different positive voltages

device that uses both TTL (+5 V) and analog (typically +15 V)

circuitry. Using both suppli es, two differing positive volta ges with

a common negative a re ob t ain ed as fol lo ws:

1. Select the INDEP

displays so that both displays monitor voltage.

2. Connect the ground straps between each supplies’ negative

terminal and ground.

3. Independently set the desired voltage and maximum current

for the “A” and “B” supplie s using the “A” VOL TAGE and

CURRENT controls and the “B” VOLTAGE and

CURRENT contro ls r esp ectively.

4.

during hook-up.

5. Connect the positive polarity input

either the supply’s negative (black) or ground (green)

terminal.

6. If desired, set the LED displays to monitor current.

APPLICATIONS

Page 37

37

APPLICATIONS

Fig. 13. Typical Hook-Up Using Two Identical

Two Identical Negative Voltages With a Common Positive

(Refer To Fig. 13)

When the same negative voltage i s required at two point s in the

same circuit and a common positive is needed, perform the

following:

1. Connect the ground strap between the positive terminal and

the ground of the “A” supply.

2. Set the desired voltage and maximum current using the “A”

VOLTAGE and CURRENT controls.

3. Turn off the power supply and the equipment to be powered

during hook-up.

4. Connect the negative polarity inputs of the circuit to be

powered to the negative (black) terminals of the supplies.

Connect the common positive input of the circuit to be

powered to the “A” suppl y’s positive (red) or ground (green)

terminal.

Negative Voltages and a Common Positive.

Page 38

38

Fig. 14. Typical Hook-Up Using Tw o Diff erent

Two Differin g Ne gati ve Vol tage s Wi th a Posi tive C ommon

endent operating mode and set up the LED

ired voltage and maximum current

Turn off the power supply and the equipment to be powered

polarity inputs of the circuit to be

Connect the common positive input of the circuit to be

(Refer To Fig. 14 )

Using both supplies, two differing negative voltages with a

common positive are obtained as follows:

1. Select the INDEP

displays so that both displays monitor voltage.

2. Connect the ground straps between each supplies’ positive

terminal and ground.

3. Independently set the des

for the “A” and “B” supplies using the “A” VOLTAGE and

CURRENT controls and the “B” VOLTAGE and CURRENT

controls respectively.

4.

during hook-up.

5. Connect the negative

powered to the negative (black) terminals of the supplies.

powered to either supplies’ positive (red) or ground (green)

terminal.

6. If desired, set the LED displays to monitor current.

APPLICATIONS

Negative Voltages and a Common Positive.

Page 39

39

APPLICATIONS

Fig. 15. Typical Hook-Up Using I denti cal Positi ve

and Negative Voltages with a Sep ar at e C ommo n .

Identical Positive and Negative Voltages With a Separate

Turn off the power supply and the equipment to be powered

Common (Refer To Fig. 15)

Another typical “split supply” application is when a circuit uses

operational amplifiers (op-amps). Typically, identical positive and

negative voltages are required to power op-amp circuits. Using both

supplies and the series tracking mode of operation, identical positive

and negative voltages with a separate common are obtained as follows:

1. Select the TRACKing SERies operating mode and set A/B

Metering switch to monitor the “A” sup ply.

2. Set the desired voltage using the “A” VOLTAGE controls.

3. Connect a ground wire between the “A” supply negative terminal

and the GND (green ) ter mi na l.

4.

during hook-up.

5. Connect the positive polarity input of the circuit to be powered to

the positive (red) terminal of the “A” supply and connect the

negative polarity of the circuit to the negative terminal of the “B”

supply. Connect the circuit ground to the ground terminal of the

“A” supply, the positive terminal of the “B” supply, or the GND

(green) terminal.

Page 40

40

Fig. 16. Typical Hook-Up Using Different Positive

Differing Positive and Negative Voltages With a Separate

Using both supplies and the series tracking mode of operation,

current will usually be different for each of the supplies in this

supply will

automatically vary the same percentage.

Common (Refer To Fig. 16)

different positive and negative voltages with a separate common

utilizing th e variable “B tracks A” mode of operation are obtained

as follows:

1. Select the TRACKing SERies operating mode and set up the

LED displays to monitor voltage.

2. Connect one ground strap between the ground terminal and

the negative terminal of the “A” supply and the other between

the ground terminal and the positive terminal of the “B”

supply.

3. Set the desired voltage for each supply using the VOLTAGE

controls. Set the maximum current using the CURRENT

controls.

4. Turn off the power supply and the equipment to be powered

during hook-up.

5. Connect the positive polarity input of the circuit to be

powered to the positive (red) terminal of the “A” supply and

connect the negative polarity of the circuit to the negative

terminal of the “B” supply. Conn ect the circuit ground to the

ground terminal of either the “A” or “B” supply.

6. If desired, set th e LED displays to monitor curr ent. The load

configuration.

7. The advantage of this con figuration over the independent on e

is that if the +12 V “A” supply is varied to simulate a -10% to

+10% voltage variation, the -5 V “B”

APPLICATIONS

and Negative Voltages and a Separate Common.

Page 41

41

WARNING

The following instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing

supply will not operate. The fuse should not normally open unless

a problem has developed in the unit. Try to determine and correct

120 V

3.5A

Slow Blow

LINE VOLTAGE CONVERSION, INTERNATIONAL UNITS

supply can be switched from 110VAC to

other than contained in the operating instructions unless you are

qualified to do so.

Line voltage is exposed when the top cover is removed from the

power supply, and is present on the fuseholder and power switch

even when the unit is turned off.

FUSE REPLACEMENT

If the fuse blows, the LED indicator will not light and the power

the cause of the blown fuse, then replace only with a fuse of the

correct rating as listed in Table 1. The fuse is located on the rear

panel (see Fig. 2).

OPERATION FUSE VALUE TYPE

220/230/240 V 1.5A Slow Blow

Table 1. Fuse Val ues

MAINTENANCE

This power

220/230/240VAC by a switch locat ed o n th e rear p anel . To select

the desired line voltage, si mply insert the fuse and fuse h older so

that the appropriate voltage is pointed to by the arrow. Be sure to

use the proper vale fuse (see l abel on rear panel).

Page 42

42

MAINTENANCE

ADJUSTMENTS

This unit was accurately adjusted at the factory before

eadjustment is recommended only if repairs have

1/2 digit

If readjustment is required, use the following procedure. All

l/2 digit

Table 2. Functions of Cali bration Adj ustment s

ADJ

FUNCTION OF ADJ

LOCATION OF A DJ

R6

“A” SUPPLY +5 V REF.

MAIN BO ARD

R10

“B” SUPP LY +5 V RE F.

MAIN BO ARD

R119

“B” SUPP LY S ERI ES

TRACKING

MAIN BO ARD

R122

4-6.5V A METER & A

LIMIT

MAIN BO ARD

R133

4-6.5V V METER

MAIN BO ARD

R134

4-6.5V 3.9V REF.

MAIN BO ARD

R159

4-6.5V 6.8V REF.

MAIN BO ARD

R163

“A” S UPP LY A ME TE R

MAIN BO ARD

R164

“B” SUPP LY A M ETE R

MAIN BO ARD

R304L

“B” SUPPLY V ME TE R

“B” PANEL M E TER

R304R

“A” SUPPLY V METER

“A” P ANEL METER

shipment. R

been made in a circuit affecting adjustment accuracy, or if you

have a reason to believe the unit is out of adjustment. However,

adjustments should be attempted only if a 4multimeter with an accuracy of ±0.1% dcv or better is available

(B+K Precision Model 391A or equivalent).

references to left and right are correct when facing the front of

the supply. The functions of the adjustments are shown in Table

2 and their locations are shown in F i g. 18.

I. “A” SUPPLY AND “A” METERING ADJUSTMENTS

1. Connect an accurate (±0.1%) external 4-

multimeter to measure the DC voltage at the output

terminals of the “A” SUPP LY.

2. Disengage the INDEP/TRACK mode switch (out) so that

the power supply is in the INDEPendent operating mode .

3. Set the “A” VOL TAGE controls (both Coarse and Fine)

to maximum (fully clockwise).

4. Adjust R6 (“A” SUPPLY +5 V REF) on the main circuit

board (located on the right rear side of the supply) for a

reading as close to 30.40 volts (on the multimeter) as

possible.

5. Set the 0-30 V/4-6.5V switch to the 0-30V position and the

Right V/A switch to the V position.

1. Adjust R304 (“A” SUPPLY V METER ADJ) on

the “A” panel meter board (located on the right side

of the supply behind the “A”/4-6.5V LED Display)

for a reading of 30.4 volts on the “A”/4-6 .5V LED

Display.

2. Set the “A” Coarse VOLTAGE control for a

reading of approximately 05.0 volts on the “A”/4-

6.5V LED Dis play.

Page 43

43

MAINTENANCE

Fig. 18. Location of Adjustments (Main Circuit Board).

Page 44

44

MAINTENANCE

3. Set the Right V/ A switch to th e A position.

output terminals to read the output current (so that the meter

6.5V METERING

1. Connect a 1 Ω load (rated at 30W or more) and the

1/2 digit

panel board (located on the left side of the supply

4. Connect the external multimeter across the “A” SUPPLY

causes a short circuit across the terminals) and adjust the “A”

CURRENT control so that 2.00 amps is read on the “A”/4-

6.5V LED Dis play.

5. Adjust R163 (“A” SUPPLY A METER ADJ) so that the

multimeter also reads 2.00 amps.

II. 4-6.5V SUPPLY AND 4ADJUSTMENTS

5. Set the 0-30V/4-6.5V switch to the 4-6.5V position and the

Right V/A switch to the V position.

6. Connect an accurate (±0.1%) external 4-1/2 digit multimeter

across the output terminals of the 4-6.5V SUPPLY to read

output voltage and adjust the 4-6.5V front panel voltage level

control to minimum (4V, fully counterclockwise).

7. Adjust R134 (4-6.5V 3.9V REF) located on the main board

for a reading of 3.90 volts on the external multimeter.

8. Adjust R133 (4-6.5V V M ETER ADJ) located on the main

board so that the “A”/4-6.5 V LED Dis play reads 3.90 volts.

9. Set the Right V/ A switch to th e A position.

10. Turn R122 (4-6.5V A METER & A LIMIT ADJ) and

R159 (4-6.5V 6.8V REF) located on the main board fully

clockwise.

multimeter in series across the output terminals of the 4-

6.5V SUPPLY to read the output current.

2. Adjust the 4-6.5V voltage level control to obtain an

output of 5.30 amp s (r ead on the multimeter).

3. Adjust R122 (4-6.5V A METER & A LIMIT ADJ) so

that the “A”/4-6.5 V LE D Di spla y also reads 5.30 amps.

4. Slowly Adjust R159 (4-6.5V 6.8V REF)

counterclockwise until the OVER indicator on the

1760 Front Panel just light s.

III. “B” S UPPL Y AN D M ETER ING ADJ USTM ENTS

1. Connect an accurate (±0.1%) external 4-

multimeter to measure the DC voltage at the output

terminals of the “B” SUPPLY.

2. Disengage the INDEP/TRACK mode switch (out) so

that the power supply is in the INDEPendent operating

mode.

3. Set the “B” VOLTAGE controls (both Coarse and

Fine) to maximum (fully clockwise).

4. Adjust R10 (“B” SUPPLY +5V REF) on the main

board for as close to 30.70 volts (on the multimeter) as

possible.

5. Set the Left V/ A switch to the V position.

6. Adjust R304 (“B” SUPPLY V METER ADJ) on the

“B”

behind the “B” LED Display) for a reading of 30.7

volts on the “B” LED Di spl ay.

Page 45

45

7. Set the “B” Coarse VOLTAGE control for a reading of

1. Connect the multimeter to the “A” SUPPLY outputs

output terminals and verify that the

Because of the specialized skills and test equipment

required for instrument repair and calibration, many

cies for this purpose. To use this

approximately 05.0 volts on the “B” LED D ispl ay.

8. Set the Left V/ A switch to the A position.

9. Connect the external multimeter across the “B” SUPPLY

output terminals to read the output current (so that the meter

causes a short circuit across the terminals) and adjust the “B”

CURRENT control so that 2.00 amps is read on the “B” LED

Display.

10. Adjust R164 (“B” SUPPLY A METER ADJ) so that the

multimeter also reads 2.00 amps.

IV. “B” SERIES TRACKING ADJUSTMENT

4. Set the supply to the TRACKing SERies mode by engaging

the INDEP/TRACK switch and releasing the SER/PAR

switch.

5. Set the “B” VOLTAGE controls (both Coarse and Fine) to

maximum (fully clockwise).

6. Set the “A” VOLTAGE controls (both Coarse and Fine) to

maximu m (fu l l y clockwise).

MAINTENANCE

and measure the voltage.

2. Disconnect the multimeter from the “A” SUPPLY

outputs and connect it to the “B” SUPPLY outputs.

3. Adjust R119 (SERIES TRACKING ADJ) (lo cated on

the MAIN board) until the voltage read from the

multimeter is the same as it was across the “A”

SUPPLY output terminals. Return the multimeter to

the “A” SUPPLY

output voltage is identi cal. If not, repea t this step.

INSTRUMENT REPAIR SERVICE

customers prefer to rely upon B+K Precision for this

service. We maintain a network of B+K Precision

authorized service agen

service, even if the instrument is no longer under warranty,

follow the instructions given in the WARRANTY

SERVICE INSTRUCTION section of this manual. There

is a nominal charge for instruments out of warranty.

Page 46

46

Service Information

Warranty Servic e: Please return the product in the original packaging with proof of purchase to the address below.

Clearly state in writing the performance problem and return any leads, probes, connectors and accessories that you

are using with the device.

Non-Warranty Service: Return the product in the original packaging to the address below. Clearly state in writing

the performance problem and return any leads, probes, connectors and accessories that you are using with the

device. Customers not on open account must include payment in the form of a money order or credit card. For the

most current repair charges please visit www.bkprecision.com

and click on “service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat-rate repair charge for Non-Warranty

Service does not include return shipping. Return shipping to locations in North American is included for Warranty

Service. For overnight shipments and non-North American shipping fees please contact B&K Precision Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number

and description of problem.

Page 47

47

Limited Two-Year Warranty

Model Number: ______________

Date Purchased: _______________ _

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be

free from defects in workmanship and materials for a period of two years from date of purchase.

B&K Precision Corp. will, without charg e, repair or repl ac e, at its opti on, def ec tive product or component parts.

Returned product must be accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration

form online at www.bkprecision.com

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of

unauthorized alterations or repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages

resulting from loss of use. Some states do not allow limitations of incidental or consequential damages. So the

above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

within fifteen (15) days of purchase.

Page 48

48

TEST INSTRUMENT SAFETY

(continued from inside front cover)

4. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However, remember

that high voltage may appear at unexpected points in defective equipmen t.

5. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to place

equipment; and make certain such surfaces are not damp or wet.

6. When testing AC powered equipment, the AC line voltage is usually present on some power input circuits such as the on-off

switch, fuses, power transformer, etc. “any time” the equipment is connected to an AC outlet.

7. B+K Precision products are not authorized for use in any application involving direct contact between our product and the

human body, or for use as a critical component in a life support device or system. Here, “direct contact” refers to any

connection from or to our equipment via any cabling or switching means. A ”critical component” is any component of a life

support device or system whose failure to perform can be reasonably expected to cause failure of that device or system, or to

affect its safety or effectiveness.

8. Never work alone. Someone should be nearby to render aid if necessary. Training in CPR (cardio-pulmonary resuscitation) first

aid is highly recommended.

Page 49

49

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

© 2012 B&K Precision Corp.

V042313

Printed in Taiwan

Loading...

Loading...