Page 1

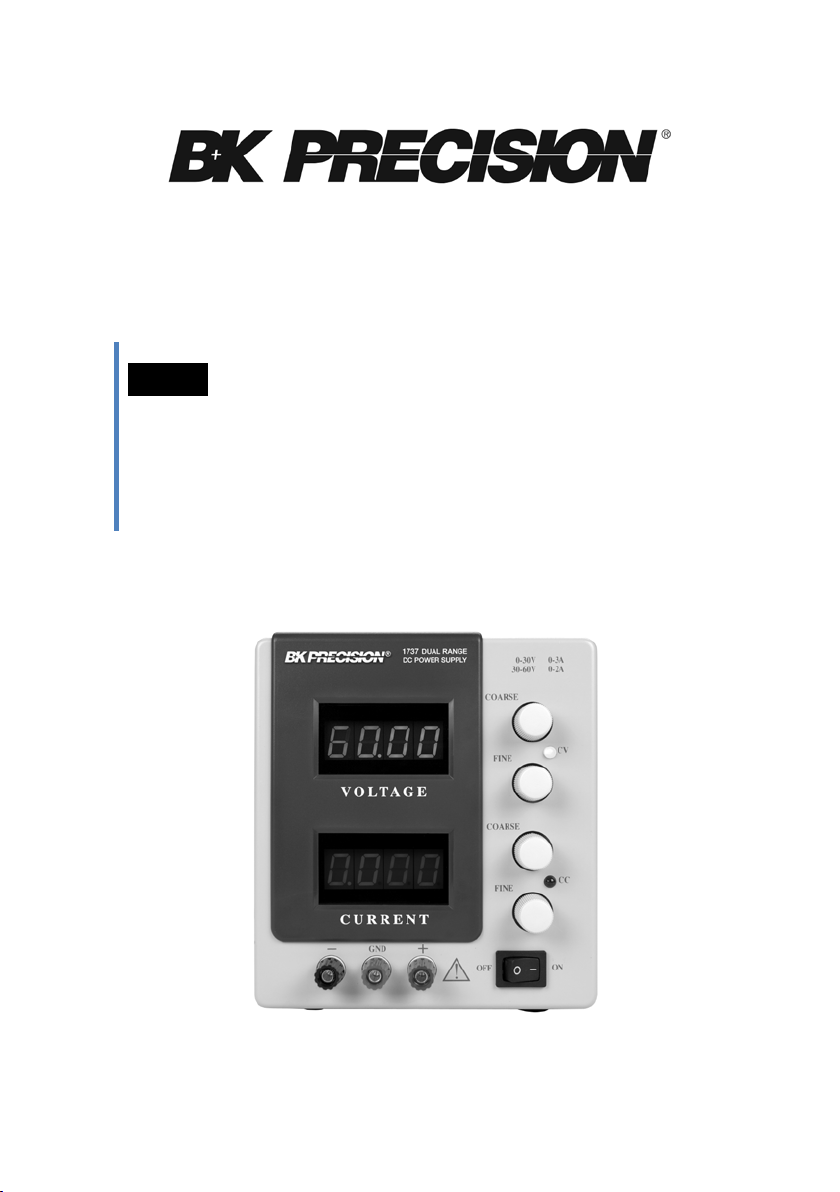

Model 1737

Dual Range DC Power Supply

INSTRUCTION MANUAL

Page 2

Page 3

1 Safety Summary

The following safety precautions apply to both operating and maintenance personnel and

must be observed during all phases of operation, service, and repair of this instrument.

Before applying power, follow the installation instructions and become familiar with the

operating instructions for this instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical ground. This instrument is grounded through the

ground conductor of the supplied, three-conductor ac power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. Do not

alter the ground connection. Without the protective ground connection, all

accessible conductive parts (including control knobs) can render an electric

shock. The power jack and mating plug of the power cable meet IEC safety

standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component

replacement and internal adjustments must be made by qualified maintenance

personnel. Disconnect the power cord before removing the instrument covers

and replacing components. Under certain conditions, even with the power cable

removed, dangerous voltages may exist. To avoid injuries, always disconnect

power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications to this

instrument. Return the instrument to B&K Precision for service and repair to

ensure that safety features are maintained.

1

Page 4

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples, denote a

hazard and appear throughout this manual. Follow all instructions contained in

these statements.

A WARNING statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in injury or death to

personnel.

A CAUTION statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in damage to or

destruction of parts or the entire product.

WARNING:

WARNING:

CAUTION:

CAUTION:

Do not alter the ground connection. Without the protective

ground connection, all accessible conductive parts (including

control knobs) can render an electric shock. The power jack and

mating plug of the power cable meet IEC safety standards.

To avoid electrical shock hazard, disconnect power cord before

removing covers. Refer servicing to qualified personnel.

Before connecting the line cord to the AC mains, check the rear

panel AC line voltage indicator. Applying a line voltage other

than the indicated voltage can destroy the AC line fuses. For

continued fire protection, replace fuses only with those of the

specified voltage and current ratings.

This product uses components which can be damaged by electrostatic discharge (ESD). To avoid damage, be sure to follow

proper procedures for handling, storing and transporting parts

and subassemblies which contain ESD-sensitive components.

SAFETY SYMBOLS

Connect to safety earth ground using the wire recommended in the user

manual.

This symbol on an instrument indicates that the user should refer to the

operating instructions located in the manual.

Certification

We certify that this product met its published specifications at time of shipment from the

factory.

2

Page 5

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and

other European countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste

electrical and electronic equipment (WEEE), and in jurisdictions

adopting that Directive, is marked as being put on the market

after August 13, 2005, and should not be disposed of as

unsorted municipal waste. Please utilize your local WEEE

collection facilities in the disposition of this product and

otherwise observe all applicable requirements.

3

Page 6

Contents

1

Safety Summary .......................................................... 1

2 Introduction ................................................................ 5

3 Quick Reference .......................................................... 6

3.1 Front Panel ......................................................................................... 6

3.2 Rear Panel .......................................................................................... 7

4 Operating Instructions ................................................. 8

4.1 Instrument Hook-Up .......................................................................... 9

4.2 Typical Constant Voltage Operation ................................................. 11

4.3 Setting Current Limit ........................................................................ 12

4.4 Typical Constant Current Operation ................................................ 13

4.5 Constant Voltage/Constant Current Characteristic .......................... 14

4.6 Saving the Power Supply’s Current State ......................................... 15

4.7 Connecting Two Power Supplies in Series ....................................... 15

4.8 Connecting Two Power Supplies in Parallel ..................................... 16

5 Remote Operation ...................................................... 17

5.1 RS232 Configuration Overview ........................................................ 18

5.2 RS232 Commands ............................................................................ 18

5.3 Application Software ....................................................................... 19

6 Maintenance .............................................................. 20

6.1 Fuse Replacement............................................................................ 20

6.2 Adjustments ..................................................................................... 20

6.3 Calibration ....................................................................................... 21

6.4 Instrument Repair Service ............................................................... 26

7 Error Messages ........................................................... 27

7.1 Self-Test Errors ................................................................................. 27

7.2 Calibration Errors ............................................................................. 27

7.3 Command Errors .............................................................................. 28

8 Specifications ............................................................. 29

9 Service Information .................................................... 31

10 Limited Two-Year Warranty ........................................ 32

4

Page 7

2 Introduction

Description

The B&K Precision model 1737 is a general purpose dual range DC power source.

This power supply can output more voltage at a lower current or more current at

a lower voltage. The 1737 provides 0-60 V DC output, adjustable with both

coarse and fine voltage controls for precise setting. The current output for the

1737 is 0-3 A for the 0-30 V range, and 0-2 A for the 30-60 V range, adjustable

with both coarse and fine current controls.

The 1737 exhibits excellent regulation and low ripple characteristics. Its

mechanical configuration conserves bench space and allows for easy portability.

Additionally, the power supply can be operated locally from the front panel or

remotely through the RS-232 interface.

This power supply is well suited for a wide variety of electrical and electronics

applications in service shops, engineering labs, production facilities, school

laboratories, and home use.

Features

• Low ripple and noise

• Excellent regulation

• Constant voltage (CV) and constant current (CC) operation

• Two 4-digit LED displays provide good visibility in bright or low light

• LED indication for CV and CC modes

• Automatic recall of last settings on power up

• RS-232 interface

• Isolated output

• Overload protection

• Reverse polarity protection

5

Page 8

3 Quick Reference

7 8 6 5 9 1 2

3 4 10

11

12

3.1 Front Panel

Figure 1 - Front Panel

INDICATORS

Either the CV or CC LED indicators will be lit whenever the unit is operating. The unit

automatically changes from CV to CC operation when the preset current limit is

reached.

1) CV (Constant Voltage) Indicator. The green LED is lit in constant voltage mode.

Unit regulates output voltage at the value set by voltage controls.

2) CC (Constant Current) Indicator. The red LED is lit in constant current mode. Unit

regulates output current at the value set by current controls.

3) Green LED Display. 4-digit display continuously monitors voltage.

4) Red LED Display. 4-digit display continuously monitors current.

VOLTAGE CONTROLS

5) Voltage Coarse Control. Coarse adjustment of output voltage. Read value on the

green LED display.

6) Voltage Fine Control. Fine adjustment of output voltage. Read value on the

green LED display.

6

Page 9

CURRENT CONTROL

15

14

13

7) Current Coarse Control. Coarse adjustment of current limit. Read value on the

red LED display.

8) Current Fine Control. Fine adjustment of current limit. Read value on the red LED

display.

POWER CONTROLS

9) Power ON-OFF Switch.

OUTPUT TERMINALS

10) “-” Terminal (Black). Negative polarity output terminal.

11) GND Terminal. Earth and chassis ground.

12) “+” Terminal (Red). Positive polarity output terminal.

3.2 Rear Panel

Figure 2 - Rear Panel

13) Power Cord

14) Fuse

15) RS-232 Interface Connector

7

Page 10

4 Operating Instructions

Safety Precautions

Use only a polarized 3-wire AC outlet. This assures that the power supply chassis,

case, and ground terminal are connected to a good earth ground and reduces

danger from electrical shock.

There is little danger of electrical shock from the power supply output, which

produces a maximum of 60 volts dc. However, there may be great danger of

electrical shock if the power supply output is connected to an external high

voltage. Some equipment being powered may contain high voltage and present a

shock hazard. Observe caution. If the power supply output is floated (referenced

to a voltage rather than earth ground) turn off the power supply and the

equipment under test when making connections. Never float the power supply to

a potential greater than 100 volts peak with respect to earth ground.

Equipment Precautions

Avoid using the power supply in ambient temperatures above +40° C. Always

allow sufficient air space around the heat sink at the rear of the power supply for

effective radiation to prevent internal heat build-up.

Although the power supply is protected against reverse polarity damage, the

circuit being powered may not include such protection. Always carefully observe

polarity; incorrect polarity may damage the equipment under test.

Do not exceed the voltage rating of the circuit being powered. Many transistors

and integrated circuits will not withstand voltage of 60 volts.

There is no need to worry about voltage spikes or overshoot damaging the

equipment under test. The voltage between the output terminals of the power

supply never exceeds the preset value as the POWER switch is turned on or off.

8

Page 11

4.1 Instrument Hook-Up

1. Turn off the power supply and the equipment to be powered during hook-

up.

2. Connect the positive polarity of the device being powered to the red (+)

terminal of the power supply.

3. Connect the negative polarity of the device being powered to the black (-)

terminal of the power supply.

Figure 3 illustrates the grounding possibilities.

4.

a. If the negative polarity of the equipment or circuit being powered is also

the chassis or common, it may be grounded to earth by strapping the black

(-) terminal to the green (

b. Similarly, the positive polarity can be grounded by strapping the red (+)

terminal to the green (

c. If an earth ground reference is not required, the configuration of

may be used. The scheme in

known whether the chassis is common with either the positive or negative

polarity.

d. If the chassis or common of the equipment being powered is separate

from both the positive and negative polarity power inputs, use the

connection shown in

6. Observe proper polarity. If the circuit being powered is not equipped with

reverse polarity protection, damage to the circuit can result from reverse

polarity. Use color coded hook-up leads, for convenience in identifying

polarity, red for (+) and black for (-).

7. Make sure that the hook-up leads offer sufficient current capability and low

resistance between the power supply and the circuits being powered.

) terminal as shown in Figure 3A.

) terminal as shown in Figure 3B.

Figure 3C

Figure 3C should also be used where it is not

Figure 3D.

9

Page 12

Figure 3 (A and B) - Grounding Possibilities

Figure 3 (C and D) - Grounding Possibilities

10

Page 13

4.2 Typical Constant Voltage Operation

1. Before connecting the device to be powered to the power supply, determine

the maximum safe load current for the device to be powered and set the

current limit value (see Setting Current Limit procedure in this section).

2. The output voltage can be set using the voltage coarse knob (with a 1 V

resolution) and voltage fine knob (with a 10 mV resolution). After the last

adjustment you must wait 3 seconds until the state is saved.

3. Turn off power supply and connect it to the device to be powered (see

Instrument Hook-Up procedure in this section).

4. Turn on the power switch. The CV indicator should light.

5. Increase the voltage setting until the voltage LED display reads the desired

value. The fine control permits easier setting to a specific value.

6. Note the load current on the current LED display.

7. If the load current exceeds the preset current limit, the CV indicator will go

off and the CC indicator will light. In this case, the power supply

automatically switches to the constant current mode, and further rotation of

the voltage control will not increase the output voltage.

Figure 4 - Typical Constant Voltage Operation

11

Page 14

4.3 Setting Current Limit

1. Determine the maximum safe current for the device to be powered.

2. Temporarily short the (+) and (-) terminals of the power supply together

with a test lead.

3. Adjust the coarse and fine current control for the desired current limit. Read

the current value on the current LED display.

4. The current limit (overload protection) has now been preset. Do not change

the current controls settings after this step.

5. Remove the short between the (+) and (-) terminals and hook up for constant

voltage operation.

Figure 5 - Setting Current Limit

12

Page 15

4.4 Typical Constant Current Operation

1. Before connecting the device to be powered to the power supply, determine the

maximum safe voltage to be applied, and set the voltage controls to obtain that

voltage reading on the voltage LED display.

2. Determine the desired constant current value.

3. Set the coarse and fine current control to minimum (1 mA). Wait 3 seconds.

4. Turn off the power supply and connect it to the device to be powered.

5. Turn on the power supply. The CC indicator should light.

6. Increase the coarse and fine current control setting until the desired constant

current value is read on the display, or set the current limit in advance (before

connecting the load) as described earlier in the Setting Current Limit procedure.

7. If the load current drops below the constant current value, the CC indicator will go

off and the CV indicator will light. In this case, the power supply automatically

switches to the constant voltage mode, and further rotation of the current

controls will not increase the output current.

Figure 6 - Typical Constant Current Operation

13

Page 16

4.5 Constant Voltage/Constant Current Characteristic

The working characteristic of this power supply is called a constant voltage/constant

current automatic crossover type. This permits continuous transition from constant

current to constant voltage modes in response to the load change. The intersection

of constant voltage and constant current modes is called the crossover point.

7

shows the relationship between this crossover point and the load.

For example, if the load is such that the power supply is operating in the constant

voltage mode, a regulated output voltage is provided. The output voltage remains

constant as the load decreases, up until the point where the preset current limit is

reached. At that point, the output current becomes constant and the output voltage

drops in proportion to further decreases in load. The crossover point is indicated by

the front panel LED indicators. The crossover point is reached when the CV indicator

goes off and the CC indicator comes on.

Similarly, crossover from the constant current to the constant voltage mode

automatically occurs from an increase in load. A good example of this would be seen

when charging a 12-volt battery. Initially, the open circuit voltage of the power

supply may be preset for 13.8 volts. A low battery will have a low load on the supply

and it will operate in the constant current mode, which may be adjusted for a 1 amp

charging rate. As the battery becomes charged, and its voltage approaches 13.8 volts,

its load increases to the point where it no longer demands the full 1 amp charging

rate. This is the crossover point where the power supply goes into the constant

voltage mode.

Figure

Figure 7 - Constant Voltage/Constant Current Characteristic

14

Page 17

4.6 Saving the Power Supply’s Current State

The current state of the power supply is saved after 2 seconds from the last

adjustment or after the “SAVE” command is received through the RS232 interface.

4.7 Connecting Two Power Supplies in Series

Two power supplies may be connected in series to provide a variable 0-120 V output.

In this configuration, the two power supplies can supply up to 60 V-3 A or 120 V-2 A.

Figure 8 for the connection scheme.

See

When connected in series, the voltage controls of each power supply exercise control

over a 0-60 V range. Add the LED display readings together or connect an external

voltmeter across the load to determine the total output voltage.

Load current may be monitored from either supply; the readings will be identical

since they are connected in series. Also, since the supplies are connected in series, it

is only necessary to set the current limit on one of the supplies; the other may be set

for maximum.

Figure 8 - Connecting Two Power Supplies in Series

15

Page 18

4.8 Connecting Two Power Supplies in Parallel

Two power supplies may be connected in parallel to double the maximum load

current. In this configuration, the two power supplies will provide 0-60 V output

at up to 4 A or 0-30 V at 6 A (heavier gauge hook-up leads are advisable). Current

equalizing resistors must be used as shown in

current limiting feature will prevent damage if current is temporarily unbalanced

during set-up.

When connected in parallel and operating in the constant voltage mode,

determine the total load current limit and preset the current limiting for each

power supply to half the total load current value. Then when the load is

connected, set the voltage controls on the two power supplies for equal voltage

readings. This should also provide approximately equal current from each supply.

Add the two current meter readings together for total load current, or connect

an external ammeter in series with the load.

Figure 9. However, the protective

Figure 9 - Connecting Two Power Supplies in Parallel

16

Page 19

If the current equalizing resistors are not well matched, it is preferable that the

2

3

5

RX

TX

GND

DB-9

connector

Instrument

2

3

5

RX

TX

GND

PC

DB-9

connector

voltages be slightly unbalanced to achieve current balance. Be sure that the

supplies are adequately balanced so that both remain in the CV mode.

When connected in parallel and operating in the constant current mode, the

voltage controls of both supplies should be preset to the same value. Then when

the load is connected, the current controls of the two supplies should be

adjusted for approximately equal current from each unit. Be sure that both

supplies remain in the CC mode.

5 Remote Operation

The power supply can be connected to the RS232 interface using the 9-pin (DB-9)

serial connector on the rear panel. The 1737 uses a null modem RS232 cable. The

cable pin diagram for the DB-9 connector is shown in the picture below:

Figure 10 - RS232 Cable Pin Diagram

For all communications over the RS232 interface, the power supply uses Xon/Xoff

protocol.

NOTE: If using HyperTerminal, make sure you properly configure the “ASCII Setup”. In

“ASCII Setup”, do not append line feeds to “ASCII Sending”. “Echo typed characters

locally” can be checked, but “Send line ends with line feeds” should be left

unchecked. In “ASCII Receiving”, “Append line feeds to incoming line ends” can also

be checked.

17

Page 20

5.1 RS232 Configuration Overview

Baud Rate 9600 bps

Parity Bits none

Data Bits 8

Start Bits 1

Stop Bits 1

Flow Control Xon / Xoff

Termination Character \r

Table 1 - RS232 Configuration

5.2 RS232 Commands

1.VOLT xx.xx<CR>

This command sets the output voltage value. The output voltage takes the

programmed value only if the power supply is in Constant Voltage mode.

Example: The output voltage is set at 5 V.

VOLT 05.00<CR>

2. CURR x.xxx<CR>

This command sets the output current value. The output current takes the

programmed value only if the power supply is in Constant Current mode.

Example: The output current is set at 300 mA.

CURR 0.300<CR>

18

Page 21

3. SAVE<CR>

The programmed values of the output current and voltage are saved. If the

power supply is restarted, the values of the output current and voltage will

be those previously saved.

4. VOLT?<CR>

This command returns the voltage measured to the output terminals of the

power supply: xx.xxV<CR>

The voltage value returned is the same as the one displayed on the voltage

display.

5. CURR?<CR>

This command returns the current measured to the output terminals of the

power supply: x.xxxA<CR>

The current value returned is the same as the one displayed on the current

display.

6. STAT?<CR>

The power supply responds to this command with one of the following

messages:

CV<CR> if the power supply is in Constant Voltage mode

CC<CR> if the power supply is in Constant Current mode

5.3 Application Software

Remotely control your 1737 using B&K Precision’s application software, available for

download at

a simple data logging function to store and log data to a text or CSV file. RS232

commands can also be sent through the software.

www.bkprecision.com. This software provides a virtual front panel and

19

Loading...

Loading...