Page 1

User’s Manual

SRP-500

Inkjet Printer

Rev. 1.08

http://www.bixolon.com

Page 2

- 2 -

SRP-500

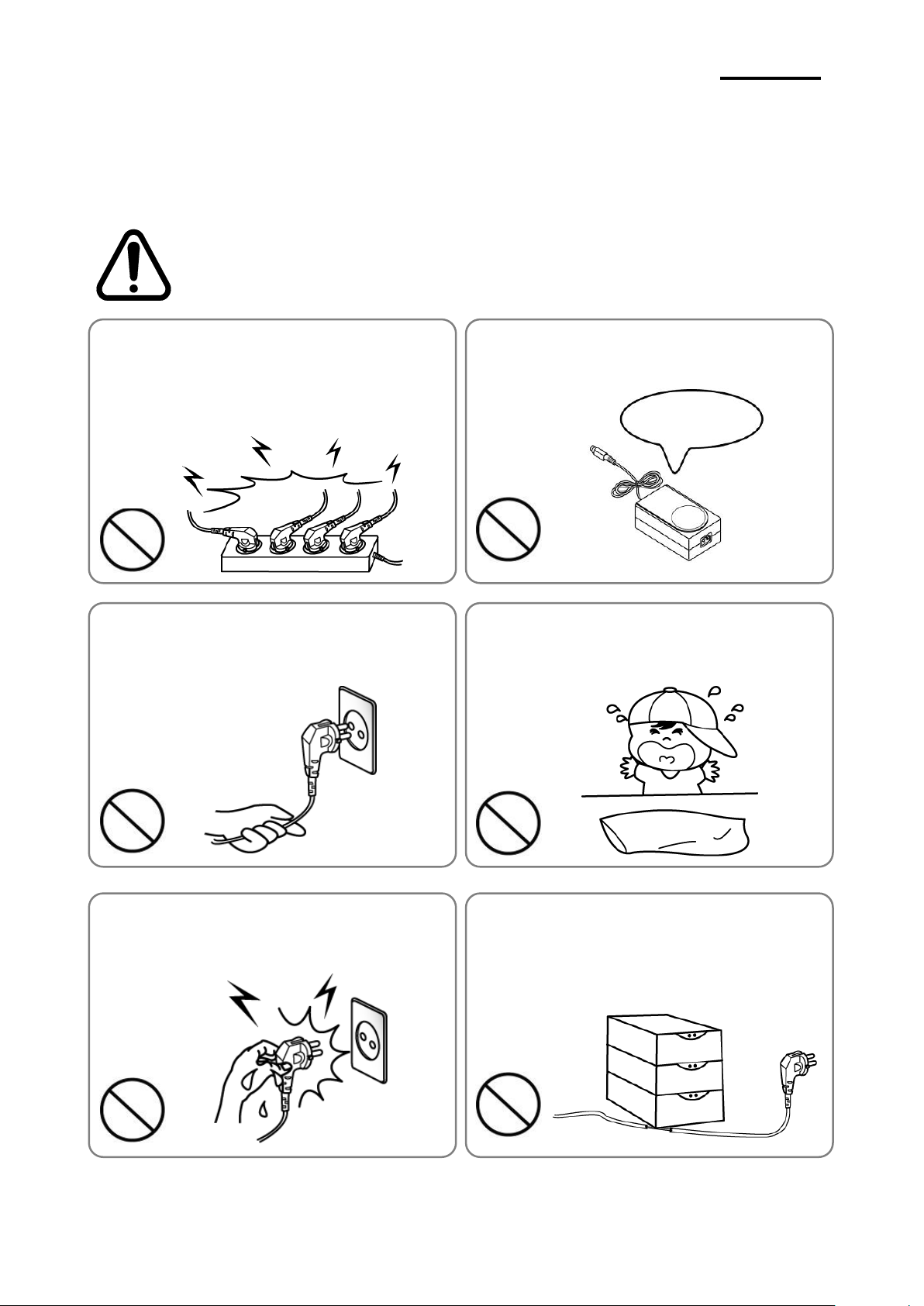

■ Safety Precautions

WARNING

Violating following instructions can cause serious injury or death.

Do not bend the cable by force or leave it under any

heavy object.

• A damaged cable can cause a fire.

Do not plug in or unplug with your hands wet.

• You can be electrocuted.

Keep the plastic bag out of children’s reach.

• If not, a child may put the bag on his head.

Do not pull the cable to unplug.

• This can damage the cable, which is the origin of a fire or a

breakdown of the printer.

You must use only the supplied adapter.

• It is dangerous to use other adapters.

Do not plug several products in one multi-outlet.

• This can provoke over-heating and a fire.

• If the plug is wet or dirty, dry or wipe it before usage.

• If the plug does not fit perfectly with the outlet, do not plug in.

• Be sure to use only standardized multi-outlets.

PROHIBITED

PROHIBITED

PROHIBITED

PROHIBITED

PROHIBITED

ONLY SUPPLIED ADAPTER

PROHIBITED

In using the present appliance, please keep the following safety regulations in order to

prevent any hazard or material damage.

Rev. 1.08

Page 3

- 3 -

SRP-500

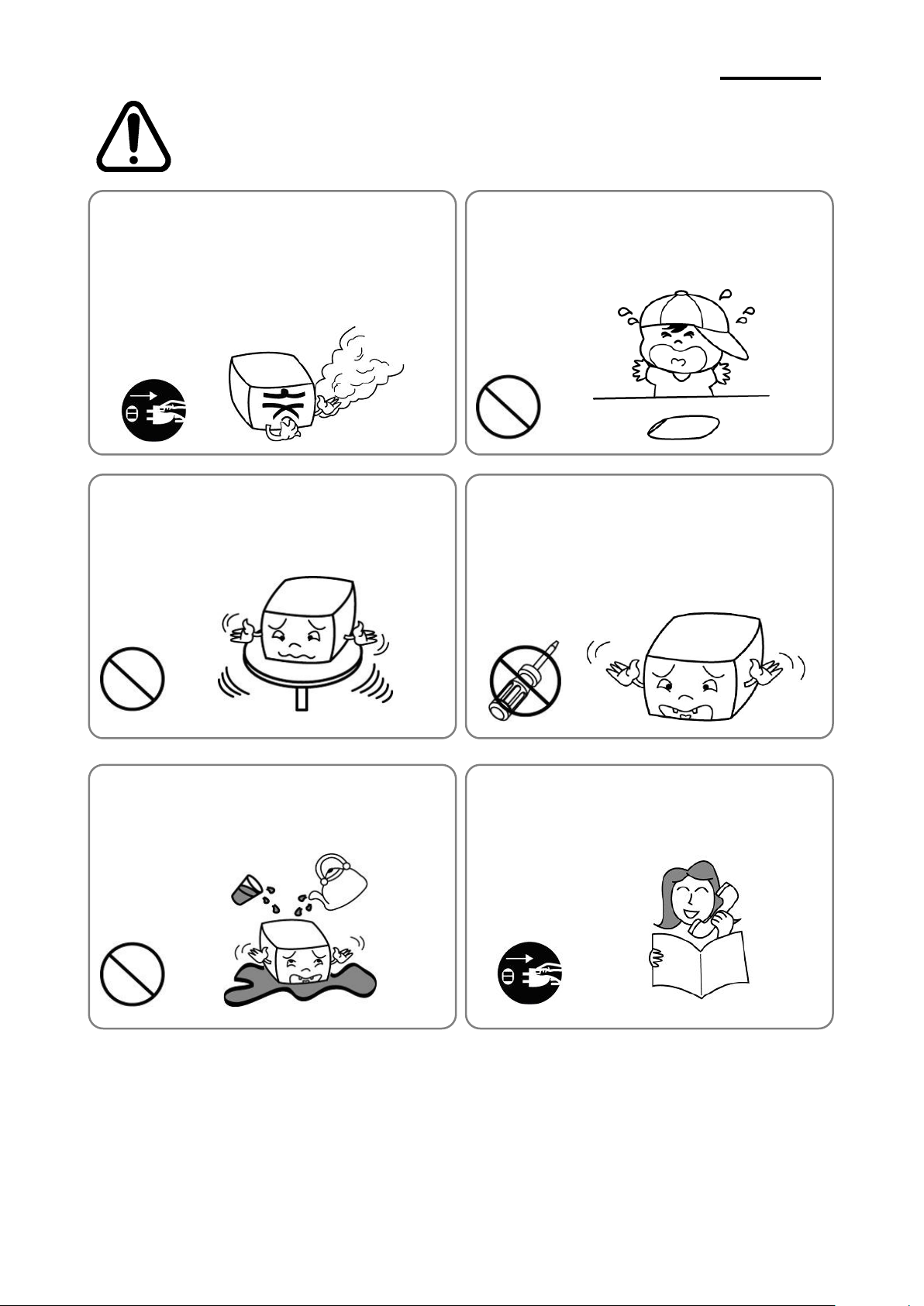

CAUTION

Violating following instructions can cause slight wound or damage the appliance.

Do not use the printer when it is out of order. This

can cause a fire or an electrocution.

• Switch off and unplug the printer before calling your dealer.

Do not let water or other foreign objects in the

printer.

• If this happened, switch off and unplug the printer before

calling your dealer.

Use only approved accessories and do not try to

disassemble, repair or remodel it for yourself.

• Call your dealer when you need these services.

• Do not touch the blade of auto cutter.

Install the printer on the stable surface.

• If the printer falls down, it can be broken and you can hurt

yourself.

Keep the desiccant out of children’s reach.

• If not, they may eat it.

If you observe a strange smoke, odor or noise from

the printer, unplug it before taking following

measures.

• Switch off the printer and unplug the set from the mains.

• After the disappearance of the smoke, call your dealer to

repair it.

TO UNPLUG

PROHIBITED

DISASSEMBLING

PROHIBITED

PROHIBITED

PROHIBITED

TO UNPLUG

PRINTER

PRINTER

PRINTER

PRINTER

DEALER

PRINTER

Rev. 1.08

Page 4

- 4 -

SRP-500

All rights reserved. No part of this publication may reproduced, stored in a retrieval, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording,

or otherwise, without the prior written permission of BIXOLON.

No patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, BIXOLON assumed

no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained herein.

Neither BIXOLON nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a

result of : accident, misuse, or abuse of this product or unauthorized modifications, repairs,

or alterations to this product, or (excluding the U.S) failure to strictly comply with

BIXOLON’ s operating and maintenance instructions.

BIXOLON shall not be liable against any damages or problems arising from the use of any

options or ant consumable products other than those designated as Original BIXOLON

products.

■ Notice

We at BIXOLON maintain ongoing efforts to enhance and upgrade the functions and

quality of all our products. In following, product specifications and/or user manual content

may be changed without prior notice.

Rev. 1.08

Page 5

- 5 -

SRP-500

■ EMC and Safety standards Applied

Product Name : SRP-500

The following standards are applied only to the printers that are so labeled.

Europe : CE marking, TUV/GS : EN60950 ; 1999

North America : EMI : FCC Class A

Safety standards : UL / C-UL : UL60950-3rd.

National : CB-scheme : IEC 60950 ; 1999

■ Warning

The connection of a non-shielded printer interface cable to this printer will invalidate the

EMC standards of this device.

You are cautioned that changes or modifications not expressly approved by the party

responsible for compliance could void your authority to operate the equipment.

■ CE Marking

The printer conforms to the following Directive and Norms

Directive 89/336/EEC EN 55022 Class A :1998

EN 55024 : 1998

(EN 61000-4-2 : 1995+A1 : 1998)

(EN 61000-4-3 : 1996)

(EN 61000-4-4 : 1995)

(EN 61000-4-5 : 1995)

(EN 61000-4-6 : 1996)

(EN 61000-4-11 : 1994)

EN 61000-3-2 : 1995+A1 : 1998+A2 : 1998)

EN 61000-3-3 : 1995

Directive 73/23/EEC Safety : EN 60950 ; 1999

■ Waste Electrical and Electric Equipment (WEEE)

This marking shown on the product or its literature, indicates that is should not

be disposed with other household wastes at the end of its working life, To

prevent possible harm to the environment or human health from uncontrolled

waste disposal, please separate this from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources. Household

users should contact either the retailer where they purchased this product, or their local

government office, for details of where and how they can take this item for environmentally

safe recycling. Business users should contact their supplier and check the terms and

conditions of the purchase contract. This product should not be mixed with other

commercial wastes for disposal.

■ Rating Label Symbol Information

DC (Direct current)

■ Label Material

* Control Label: PC

* Other Labels: PET

Rev. 1.08

Page 6

- 6 -

SRP-500

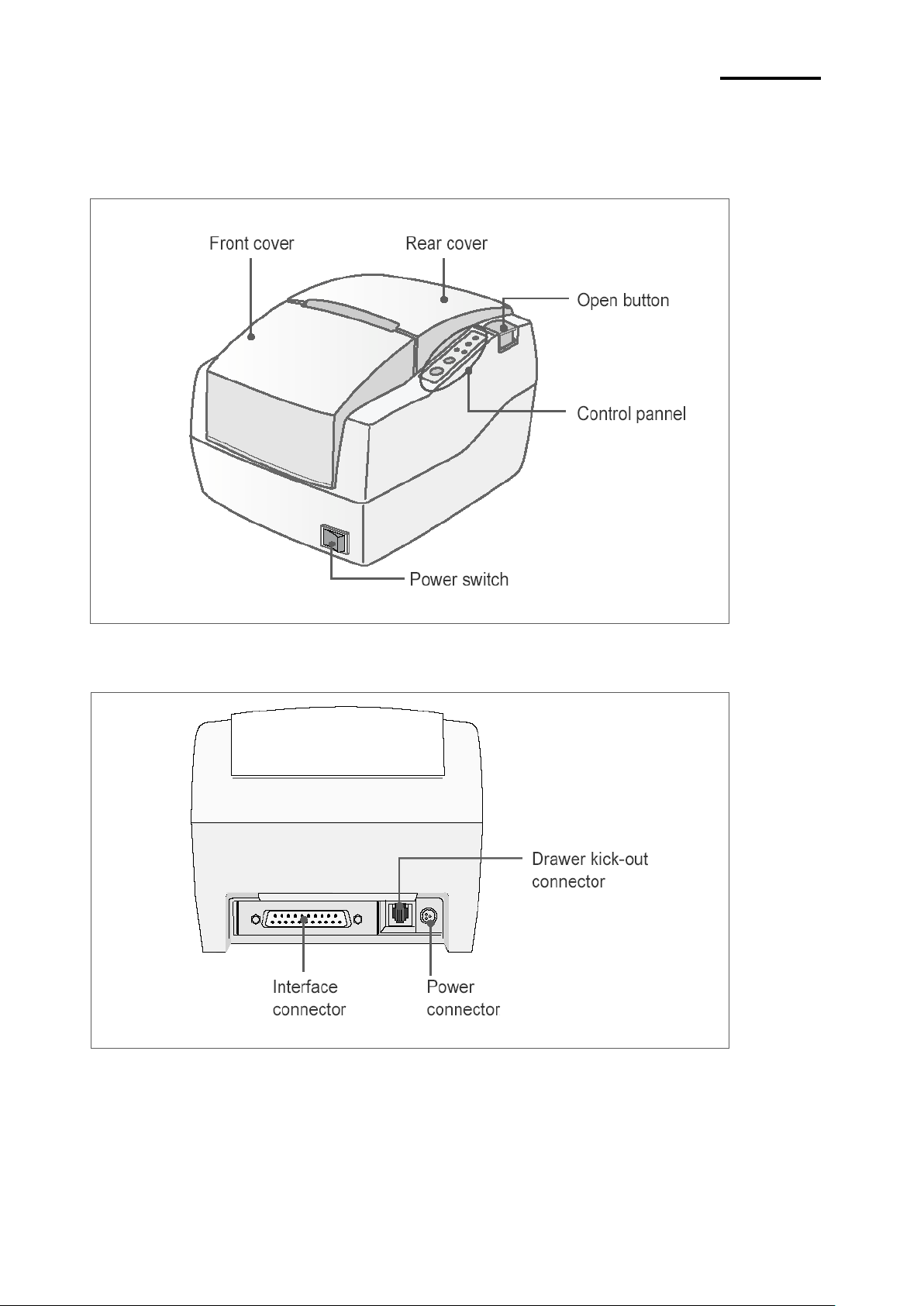

■ Introduction

* Front view

* Rear view

Rev. 1.08

Page 7

- 7 -

SRP-500

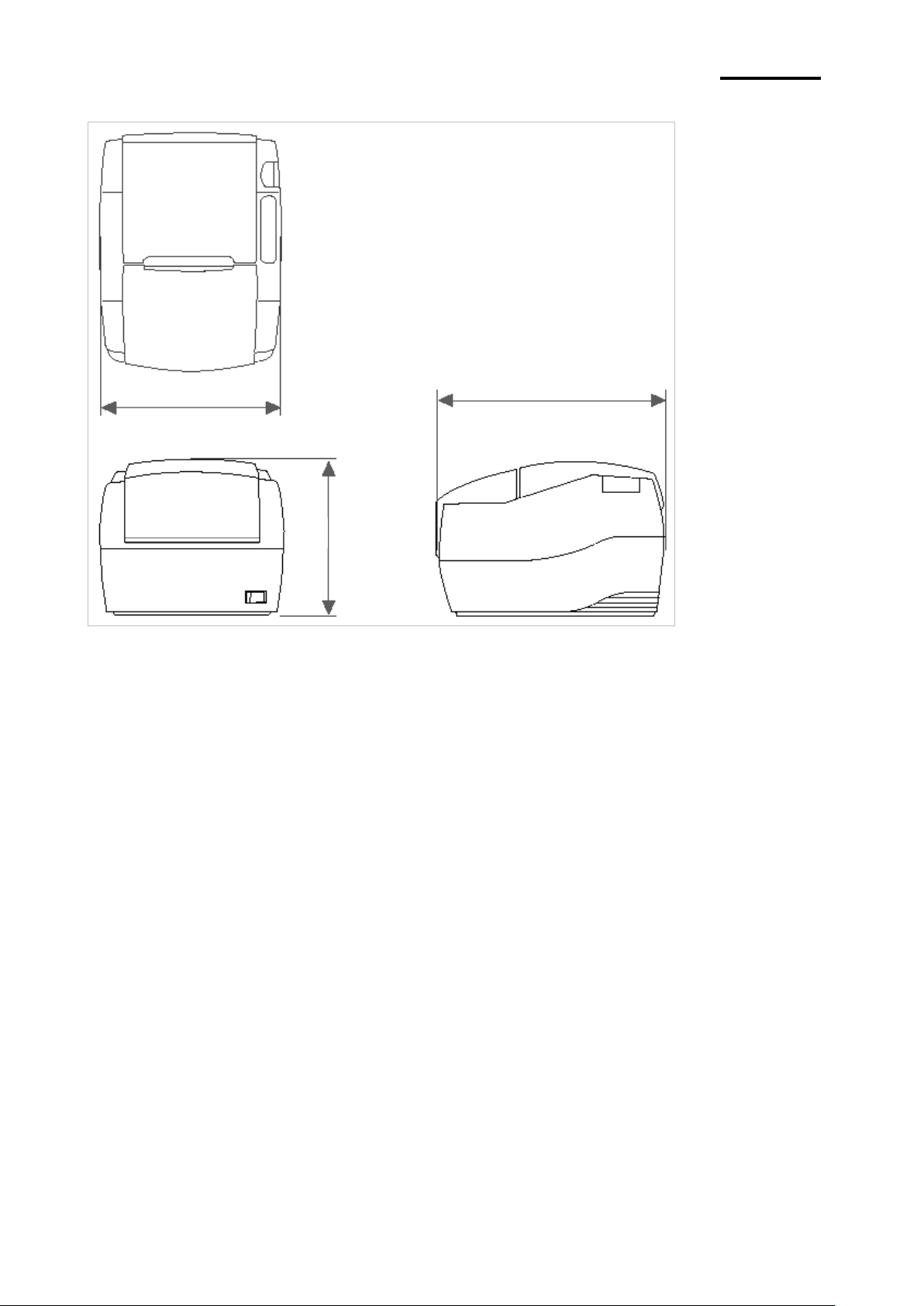

* Dimension

172

152

226

The SRP-500 is a high-quality inkjet POS printer.

This one-station printer has the following features.

1. Compact design and light-weight.

2. High-speed printing using logic-seeking.

3. Easy to use : clamshell mechanism.

4. High reliability and long life due to the use of stepping motors for both carriage return

and paper feeding.

5. Two color printing (red/black/blue/green) available.

6. Various formats are possible because the paper feeding pitch is selectable.

7. 2 drawers can be driven due to the internal drawer interface.

8. Character font (12X12, 12X14) is selectable.

9. The auto cutter uses a circular method with a high-quality blade and a long life.

(Approximately 1,000,000 cuts)

10. Paper near end sensor is standard.

Please be sure to read the instructions in this manual carefully before using your new

printer

Rev. 1.08

Page 8

- 8 -

SRP-500

■ Table of Contents

1. Setting Up the Printer ................................................................................................... 9

1-1 Unpacking .................................................................................................................. 9

1-2 Choosing a place for the printer ............................................................................... 10

1-3 Using the control panel ............................................................................................ 11

2. Connecting the cables ................................................................................................ 12

2-1 Connect the AC adapter according to the following procedure ................................ 12

2-2 Connecting the interface cable ................................................................................ 13

3. Setting the Dip Switches ............................................................................................ 14

3-1 Serial Interface (RS232C) ........................................................................................ 15

3-2 Parallel / USB Interface (Parallel-IEEE1284) ........................................................... 16

4. Setting the memory switches .................................................................................... 17

4-1 Setting methods ....................................................................................................... 17

4-2 Memory switch description ...................................................................................... 17

4-3 Star emulation.......................................................................................................... 18

5. Installing new Ink cartridge(s) ................................................................................... 21

6. Installing or replacing paper roll ............................................................................... 23

7. Self Test ....................................................................................................................... 25

8. Hexadecimal Dumping ............................................................................................... 26

9. Specification ............................................................................................................... 27

10. Appendix - Troubleshooting .................................................................................... 28

10-1 The printer does not start printing .......................................................................... 28

10-2 The printer stops printing ....................................................................................... 28

10-3 You want to check the operation of the printer by itself ......................................... 29

10-4 Printing is poor ....................................................................................................... 29

Rev. 1.08

Page 9

- 9 -

SRP-500

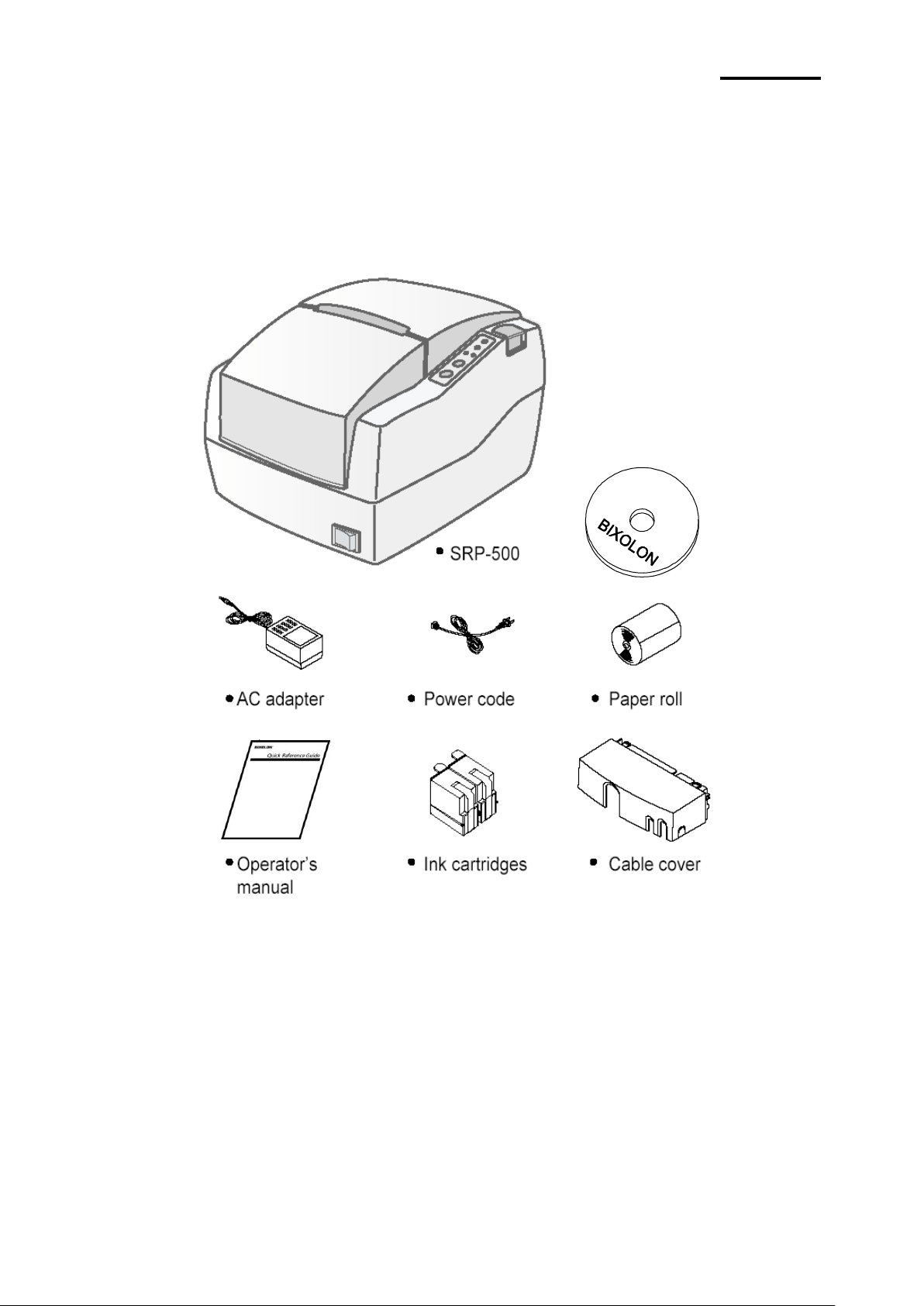

1. Setting Up the Printer

1-1 Unpacking

Your printer box should include the items shown in the illustration below.

If any items are damaged or missing, please contact your dealer.

CD

Rev. 1.08

Page 10

- 10 -

SRP-500

1-2 Choosing a place for the printer

1-2-1 Avoid locations that are subject to direct sunlight or excessive heat.

1-2-2 Avoid using or storing the printer in a place subject to excessive temperature or

moisture.

1-2-3 Do not use or store the printer in a dirty location.

1-2-4 When setting up the printer, choose a stable, horizontal location.

1-2-5 Intense vibration or shock may damage the printer.

1-2-6 Ensure the printer has enough space to be used easily.

Rev. 1.08

Page 11

- 11 -

SRP-500

1-3 Using the control panel

Most of the functions of this printer are governed by software, but you can monitor the

printer’s status by looking at the lights on the control panel and for some procedures you

will use the buttons.

● Power (LED)

This indicator light is on when the power is turned on. It blinks when the printer is in the

self test printing standby state. Always wait until this indicator light stops blinking before

you start using the printer and before you turn it off.

● Error (LED)

When this indicator light is on(but not blinking), it means that the printer is out of paper or

almost out of paper or the printer covers are open. When this light blinking, there is an

error. If you see this light blinking, turn off the printer for a few seconds and then turn it

black on. If the light is still blinking, call your supervisor or a service person.

● Cartridge (LED)

The right indicator is for the right cartridge and the left indicator for the left cartridge. If the

printer is a single color printer, the left cartridge indicator will be used. In most cases, the

left cartridge is black, and the right is a color.

● Clean (BUTTON)

Use this button to clean the printer head.

● Feed (BUTTON)

Use this button to feed paper or to start self test and for hexadecimal dump mode.

Rev. 1.08

Page 12

- 12 -

SRP-500

2. Connecting the cables

※ CAUTION

Before connecting the printer to the power supply, make sure that the voltage and power

specifications match the printer's requirements. Using an incorrect power supply can

cause serious damage to the printer.

2-1 Connect the AC adapter according to the following procedure

2-1-1 Make sure the printer is turned off.

2-1-2 Plug the AC adapter cable into the printer's power connector.

2-1-3 Plug the power cord into the outlet, and turn on the power.

Rev. 1.08

Page 13

- 13 -

SRP-500

2-2 Connecting the interface cable

Connect the printer to the host ECR (host computer) though an interface cable matching

the specification of the printer and the host ECR (host computer).

Be sure to use a drawer that matches the printer's specification.

Depending on the interface your system uses, either connect the serial, parallel or USB

communication cable to the appropriate connector on the back of the printer. Cables are

provided by your dealer or system installer.

Connect the interface cable according to the following procedure.

2-2-1 Turn off printer and the ECR (host computer) host.

2-2-2 Plug the interface cable into the interface connector on the printer then fasten the

screw on both sides of the connector.

2-2-3 Plug the drawer kick-out cable into the drawer kick-out connector on the printer.

(When removing the drawer kick-out cable, press on the connector's clip while pulling

out.)

Rev. 1.08

Page 14

- 14 -

SRP-500

3. Setting the Dip Switches

Although the factory settings are best for almost all users, if you have special requirements,

you can change the DIP switch. If you need to change settings, follow the steps below to

make your changes.

- Make sure the printer is turned off.

- Remove the screw from the DIP switch cover. Then take off the DIP switch cover,

which is shown in the illustration below.

- Set the switches using a pointed tool, such as tweezers or a small screwdriver.

- Replace the DIP switch cover. Then secure it with the screw.

- The new settings take effect when you turn on the printer.

※ NOTE

Turn off the printer before removing the DIP switch cover to prevent an electric short,

which can damage the printer.

Rev. 1.08

Page 15

- 15 -

SRP-500

3-1 Serial Interface (RS232C)

Switch

Function

ON

OFF

Default

1-1

Emulation Selection

Refer to the following table

OFF

1-2

OFF

1-3

Auto cutter

Enable

Disable

ON

1-4

Cartridge

one cartridge

two cartridges

OFF

1-5

Density

*1)

Bold

Normal

OFF

1-6

Special Function

*2)

Enable

Disable

OFF

1-7

Near end sensor

Enable

Disable

ON

1-8

Undefined

OFF

Emulation

1-1

1-2

BXL/POS

OFF

OFF

STAR

OFF

ON

BXL/POS-KP

*3)

ON

ON

Switch

Function

ON

OFF

Default

2-1

Data receive error

Print “?”

Ignore

OFF

2-2

Reserved

OFF

2-3

Hand Shaking

DTR/DSR

XON/XOFF

OFF

2-4

Word length

7bit

8bit

OFF

2-5

Parity check

Enable

Disable

OFF

2-6

Parity selection

EVEN

ODD

OFF

2-7

Baud rate selection

Refer to the following table

OFF

2-8

OFF

Transmission

2-7

2-8

2400 baud

ON

ON

4800 baud

OFF

ON

9600 baud

OFF

OFF

19200 baud

ON

OFF

DIP switch Setting 1 Function

Emulation Selection

DIP switch Setting 2 Function

Baud Rate selection

*1) : It may use in dark area. (like a restaurant). But printing speed to be slow down.

*2) : Enable = Automatically print NV bit image #1 after cutting.

*3) : Kitchen Printer mode : A alarm is generated by printer after auto-cutting and

in paper-end error. (It needs buzzer accessory)

Rev. 1.08

Page 16

- 16 -

SRP-500

3-2 Parallel / USB Interface (Parallel-IEEE1284)

Switch

Function

ON

OFF

Default

1-1

Emulation Selection

Refer to the following table

OFF

1-2

OFF

1-3

Auto cutter

Enable

Disable

ON

1-4

Cartridge

one cartridge

two cartridges

OFF

1-5

Density

*1)

Bold

Normal

OFF

1-6

Special Function

*2)

Enable

Disable

OFF

1-7

Near end sensor

Enable

Disable

ON

1-8

Undefined

OFF

Emulation

1-1

1-2

BXL/POS

OFF

OFF

STAR

OFF

ON

BXL/POS-KP

*3)

ON

ON

Switch

Function

ON

OFF

Default

2-1

Auto Line Feed

Enable

Disable

OFF

2-2

Undefined

OFF

2-3

OFF

2-4

OFF

2-5

OFF

2-6

OFF

2-7

OFF

2-8

OFF

DIP switch Setting 1 Function

Emulation Selection

DIP switch Setting 2 Function

*1) : It may use in dark area. (like a restaurant). But printing speed to be slow down.

*2) : Enable = Automatically print NV bit image #1 after cutting.

*3) : Kitchen Printer mode : A alarm is generated by printer after auto-cutting and

in paper-end error. (It needs buzzer accessory)

※ NOTE

Changes in DIP switch settings are recognized only when the printer power is turned on or

when the printer is reset by using the interface. If the DIP switch setting is changed after

the printer power is turned on, the change does not take effect until the printer is turned on

again or is reset.

Rev. 1.08

Page 17

- 17 -

SRP-500

4. Setting the memory switches

SW no.

Description

remark

MSW1

Selection for the default code page

MSW2

Reserved

MSW3

Reserved

MSW4

Reserved

MSW5

Reserved

MSW6

Reserved

MSW7

Reserved

MSW8

Reserved

1-5

1-4

1-3

1-2

1-1

1-0

Character Table

0 0 0 0 0

0

Page 0 (PC437 : U.S.A)

0 0 0 0 1

0

Page 2 (PC850 : Multilingual)

0 0 0 0 1

1

Page 3 (PC860 : Portuguese)

0 0 0 1 0

0

Page 4 (PC863 : Canadian-French)

0 0 0 1 0

1

Page 5 (PC865 : Nordic)

0 1 0 0 0

0

Page 16 (WPC1252 : Latin I)

0 1 0 0 0

1

Page 17 (PC866 : Cyrillic #2)

0 1 0 0 1

0

Page 18 (PC852 : Latin II)

0 1 0 0 1

1

Page 19 (PC858 : Euro)

0 1 0 1 0

1

Page 21 (PC862 : Hebrew DOS code)

0 1 0 1 1

0

Page 22 (PC864 : Arabic)

0 1 0 1 1

1

Page 23 (Thai character code 42)

0 1 1 0 0

0

Page 24 (WPC1253 : Greek)

0 1 1 0 1

0

Page 26 (WPC1257 : Baltic)

0 1 1 0 1

1

Page 27 (Farsi)

*1)

0 1 1 1 0

1

Page 29 (PC737 : Greek)

0 1 1 1 1

1

Page 31 (Thai character code 14)

1 0 0 0 1

0

Page 34 (Thai character code 11)

1 0 0 0 1

1

Page 35 (Thai character code 18)

1 0 0 1 1

0

Page 38 (PC928 : Greek)

4-1 Setting methods

1) Memory switch setting utility (Please check out our bundle CD)

2) Control from emulation command (refer to command manual)

4-2 Memory switch description

MSW1 details

*1) Only Font B available

Rev. 1.08

Page 18

- 18 -

SRP-500

4-3 Star emulation

Function

Class

m

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data Definition (Data Specification)

Definition

","

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data definition (set specified bit)

Definition

"+"

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data definition (clear specified bit)

Definition

"-"

{n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8

Data Definition (clear all data)

Definition

"@"

Fixed at "0000"

Definition data write and reset

Write

"W"

Fixed at "0000"

Definition data write and reset and test print

Write

"T"

Fixed at "0000"

4-3-1 Setting methods

1) Memory switch setting utility (Please check out our bundle CD)

2) Control from emulation command (refer to command manual)

Memory Switches are from MSW 0 to MSW 8. They are stored in non-volatile memory

(flash memory). To change the settings, send the following commands from the host.

[Name] Set Memory Switch

[Code] ASCII ESC GS # m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}

Hexadecimal 1B 1D 23 m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8 0A 00

Decimal 27 29 35 m {n1 n2 n3 0n4}0 ... {n1 n2 n3 n4}8 10 0

[Defined Region] m = "W", "T", ",", "+", "-", "@"

"0" ≤ n1,n2,n3,n4 ≤ "9",

"A" ≤ n1,n2,n3,n4 ≤ "F"

[Function] Sends command to write after defining Memory Switch using the definition command

specified by the following classes to set the Memory Switch. The printer is automatically

reset after writing the setting defined by that command to the non-volatile memory.

Do not turn off the power to the printer while sending commands to the non volatile

memory. Doing so will destroy the Memory Switch setting. It is also possible for all Memory

Switch settings to become offset to their initial, default settings.

Consider the life of the non-volatile memory and avoid over-use of this command.

LF NUL

8

(Ex) Memory Switch 1-8 = 0; Memory Switch 2-7 = 1: Memory Switch 2-A =1 for a test print:

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2D); ' <ESC><GS> # -

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H31);CHR$(&H30);CHR$(&H30); ' 0100

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H0A);CHR$(0); ' 0000 <LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H2B); ' <ESC><GS> # +

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H34);CHR$(&H38);CHR$(&H30); ' 0480

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); ' 0000

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30); CHR$(&H0A);CHR$(0); ' 0000<LF><NUL>

PRINT #1, CHR$(&H1B);CHR$(&H1D);CHR$(&H23);CHR$(&H54); ' <ESC><GS> # T

PRINT #1, CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H30);CHR$(&H0A);CHR$(&H0); ' 0000 <LF><NUL>

Rev. 1.08

Page 19

- 19 -

SRP-500

4-3-2 Memory switch description

SW no.

Description

remark

MSW0

Selection for the default code page

MSW1

Reserved

MSW2

Reserved

MSW3

Reserved

MSW4

Selection for Carriage return

MSW5

Reserved

MSW6

Reserved

MSW7

Reserved

MSW8

Reserved

SW no.

Factory Setting (n1 n2 n3 n4)

MSW 0

“0000”

MSW 1

“0000”

MSW 2

“0000”

MSW 3

“0000”

MSW 4

“0000”

MSW 5

“0000”

MSW 6

“0000”

MSW 7

“0000”

MSW 8

“0000”

Default

Rev. 1.08

Page 20

- 20 -

SRP-500

MSW1 details

1-5

1-4

1-3

1-2

1-1

1-0

Character Table

0 0 0 0 0

0

Page 0 (PC437 : U.S.A)

0 0 0 0 1

0

Page 2 (PC850 : Multilingual)

0 0 0 0 1

1

Page 3 (PC860 : Portuguese)

0 0 0 1 0

0

Page 4 (PC863 : Canadian-French)

0 0 0 1 0

1

Page 5 (PC865 : Nordic)

0 1 0 0 0

0

Page 16 (WPC1252 : Latin I)

0 1 0 0 0

1

Page 17 (PC866 : Cyrillic #2)

0 1 0 0 1

0

Page 18 (PC852 : Latin II)

0 1 0 0 1

1

Page 19 (PC858 : Euro)

0 1 0 1 0

1

Page 21 (PC862 : Hebrew DOS code)

0 1 0 1 1

0

Page 22 (PC864 : Arabic)

0 1 0 1 1

1

Page 23 (Thai character code 42)

0 1 1 0 0

0

Page 24 (WPC1253 : Greek)

0 1 1 0 1

0

Page 26 (WPC1257 : Baltic)

0 1 1 0 1

1

Page 27 (Farsi)

*1)

0 1 1 1 0

1

Page 29 (PC737 : Greek)

0 1 1 1 1

1

Page 31 (Thai character code 14)

1 0 0 0 1

0

Page 34 (Thai character code 11)

1 0 0 0 1

1

Page 35 (Thai character code 18)

1 0 0 1 1

0

Page 38 (PC928 : Greek)

4-3

4-2

4-1

4-0

Function

0 0 0

0

<CR>Command : Ignore, <LF>Command : CR+LF

0 0 0

1

<CR>Command : CR, <LF>Command : LF

0 0 1

0

<CR>Command : CR+LF, <LF>Command : Ignore

0 0 1

1

<CR>Command : CR+LF, <LF>Command : LF

0 1 0

0

<CR>Command : CR, <LF>Command : CR+LF

0 1 0

1

<CR>Command : CR+LF, <LF>Command : CR+LF

*1) Only Font B available.

MSW4 details

Rev. 1.08

Page 21

- 21 -

SRP-500

5. Installing new Ink cartridge(s)

5-1 Remove new ink cartridge from sealed pouch.

(Hold cartridge by round plastic tab to avoid

contamination)

5-2 Remove Mylar from face of new cartridge.

※ CAUTION

Do not touch ink cartridge's metallic connector

surface with your fingers. Doing so will

contaminate the connector and produce bad print

quality.

5-3 Turn the printer on and open the front

cover of printer.

5-4 Pull down cartridge holder.

Rev. 1.08

Page 22

- 22 -

SRP-500

5-5 Take out old ink cartridge(s). Place new

cartridge(s) into carriage. Hold plastic

tab to ensure clean installation. Black

cartridge goes into the left carriage. The

color cartridge goes into right carriage.

(tab faces front of printer.)

5-6 Close cartridge holder.

5-7 Close front cover of printer.

Rev. 1.08

Page 23

- 23 -

SRP-500

6. Installing or replacing paper roll

※ CAUTION

Notice the caution label and do not touch the auto cutter blade when you open rear cover.

6-1 To prevent data loss, make sure that the printer is not receiving data.

6-2 Open the rear cover by pressing the open button and push the arrow mark back.

Rev. 1.08

Page 24

- 24 -

SRP-500

6-3 Remove the used paper roll core if

there is one.

6-4 Insert the paper roll as shown.

6-5 Be sure to note the correct

direction that the paper should

come off the paper roll.

6-6 Pull out small amount of paper as

shown. Then close the cover and

tear off the extra paper by pulling it

toward the front of the printer.

Rev. 1.08

Page 25

- 25 -

SRP-500

7. Self Test

The self test lets you know if your printer is operating properly.

It checks the control circuits, printer mechanisms, print quality, ROM version, and DIP

switch settings.

The test is independent of any other equipment or software, so it is a good idea to run it

when you first set up the printer or if you have any trouble. If the self test works correctly,

the problem is in the other equipment or the software, not the printer.

7-1 Make sure the printer is turned off and the printer cover is closed properly.

7-2 While holding down the Feed button, turn on the printer and continue to hold until the

paper begins to feed. The self test prints the printer settings and cuts the paper and

pauses. (The power light blinks.).

7-3 Press the Feed button to continue printing the rolling ASCII pattern. Repeat for the

nozzle pattern, NV bit image(s).

7-4 The self test mode terminates after printing NV bit image(s) automatically.

Rev. 1.08

Page 26

- 26 -

SRP-500

8. Hexadecimal Dumping

This feature allows experienced users to see exactly what data is coming to the printer.

This can be useful in finding software problems. When you turn on the hexadecimal dump

function, the printer prints all commands and other data in hexadecimal format along with a

guide section to help you find specific commands.

To use the hexadecimal dump feature, follow these steps:

8-1 After you make sure that the printer is off, open the front cover of the printer.

8-2 Hold down the Feed button while you turn on the printer.

8-3 Close the front cover.

8-4 Run any software program that sends data to the printer. The printer prints

"Hexadecimal Dump" and then all the codes it receives in a two-column format. The

first column contains the hexadecimal codes and the second column gives the ASCII

characters that correspond to the codes.

- A period(.) is printed for each code that has no ASCII equivalent

8-5 When the printing finishes, turn off the printer.

Rev. 1.08

Page 27

- 27 -

SRP-500

9. Specification

Printing

Printing method

Serial ink jet matrix method

Printing direction

Bidirectional(logic seeking) with friction feed

Resolution

104 x 96(dpi): Text

208 x 96(dpi): Graphic

Characters per line

Max 42(characters)

Printing speed

6.5 LPS (Lines Per Second) at 40 columns

Printing Width

61.5mm

Line Interval

4.233mm (1/6”)

Character sets

Alphanumeric characters: 95

International characters: 32

Extended graphics : 128 x 12 pages

Character font

14 x 12 / 12 x 12

(24 x 12 ; for Korea, 20 x 24 ; for GB2312)

Paper roll

Type

Normal paper

Size

Width : 76 ± 0.5(mm)

Thickness

0.06 to 0.085(mm)

Maximum outside diameter

ø 83mm

Paper core inside diameter

ø 10 to 12.5(mm)

Ink cartridge

Model

RIC-500B,R (HP 6602a,r)

Firing frequency

3.0KHz – low density printing(Text)

1.5KHz – high density printing(Graphic)

Operating Voltage

19.9 ± 0.5V

Resistance

60 Ω

Operating Temperature

0~45 °C

Date of expiration

2 years after production (at normal temperature)

※ NOTE : Follow the laws or regulations of your country or community for

disposing of used ink cartridges.

Electrical

characteristics

Supply voltage

24VDC

Current consumption

(at 24V,except for drawer

kick-out driving)

Operating Mean : Approximately 0.5A

Peak : Approximately 1.5A

Standby Mean : Approximately 0.3A

※ NOTE : Maximum 1A for drawer kick-out driving.

Reliability

Life

Firing frequency

Mechanism : 18,000,000 lines

Auto cutter : 1,500,000 cuts

(End of Life is defined as the point at which the

printer reaches the beginning of the Wear out

Period.)

MTBF

30,000 hours

Environmental

condition

Operating

0 ° to 45 °C

Storage

-20 ° to 60 °C

Shipping

-40 ° to 70 °C

Relative Humidity

Operating : 10 to 80% RH (non-condensing)

Storage : 10 to 90% RH (non-condensing)

Shipping : 5 to 90% RH (non-condensing)

※ NOTE : Exposure to high or low temperatures for periods of greater than

48 hours will lead to significantly reduced cartridge life.

Printer

Weight

Approx. Wt : 2.7Kg

Shipping. Wt : 3.5Kg

* This equipment is indooruse and all the communication hiring are limited to inside of the building.

* The switch is the disconnecting device. Turn off switch from any hazard.

Rev. 1.08

Page 28

- 28 -

SRP-500

10. Appendix - Troubleshooting

This chapter gives solutions to some printer problems you may have.

10-1 The printer does not start printing

10-1-1 Are any of the control panel lights on?

If no control panel lights are on, check the following:

- Make sure that the printer is turned on.

- Make sure that the power supply cable is correctly plugged into the printer and

to the power outlet.

10-1-2 If any of the lights are on, please check the following:

- If the Power light is blinking, the printer is not yet ready. Wait until the light quits

blinking and the printer is ready to use.

- If the Error light is on (but not blinking), the printer is off line. Check to see that the

covers are closed and check the paper state. See Chapter 6 for instructions on

installing or replacing the paper roll.

- If the Error light is blinking, there is an error. In this case, turn off the printer for a

few seconds and then turn it back on. If the light is still blinking, call your

supervisor or service person.

- If the Cartridge lights (LH/RH) is on, check the cartridges in the printer. See

chapter 5 for instruction on installing new ink cartridges.

10-2 The printer stops printing

- If the Error light is on (but not blinking), the printer is off line. Check to see that the covers

are closed and check the paper state. See Chapter 6 for instructions on installing or

replacing the paper roll.

- If the Error light is blinking, there is an error. In this case, turn off the printer for a few

seconds and then turn it back on. If the light is still blinking, call your supervisor or a

service person.

- Turn off the printer and check for a paper jam.

To clear paper jam, follow the steps below:

1) Turn off the printer and open the rear cover of the printer.

2) Remove the jammed paper and reload the paper roll as described in Chapter 6.

3) Close the rear cover

4) Turn on the printer.

Rev. 1.08

Page 29

- 29 -

SRP-500

10-3 You want to check the operation of the printer by itself

Try to run the self test to check that the printer works properly.

See the self test instructions in Chapter 7 to run the self test.

If the self test does not work, contact your supervisor or a service person.

If the self test works properly, check the following:

- Check the connection at both ends of the interface cable between the printer and

the computer. Also make sure that this cable meets the specifications for both the

printer and the computer.

- The data transmission settings may be different between the printer and computer.

Make sure that the printer’s DIP switch settings for data transmission are the

same as the computer’s. You can see the printer’s interface settings on your self

test printout.

If the printer still does not print, contact your dealer or a qualified service person.

10-4 Printing is poor

Obstructed ink nozzles in the print head will lower the print quality.

Try cleaning the print head as described below:

- Make sure that the printer is turned on.

- Press the Clean button.

The printer begins its self cleaning process, which takes less than 5 seconds.

- When the cleaning action is finished (Power light is ON), resume printing or run a

self test (as described in Chapter 7).

- If the printing quality has not improved, repeat this process 2~3 more times. If the

printing quality still has not improved, replace the ink cartridge. If, after the new

ink cartridge has been installed, the printing quality has not improved, call your

supervisor or a service person.

Rev. 1.08

Loading...

Loading...