Page 1

Service Manual

SRP-270

Impact Printer

Rev. 3.02

http://www.samsungminiprinters.com

Page 2

SRP-270

■ Table of Contents

1. Precaution Segment....................................................................................................................................6

1-1 Safety Precautions................................................................................................................................... 6

1-2 Servicing Precaution................................................................................................................................7

1-3 Precaution for Electrostatically Sensitive Devices (ESDs) ......................................................................8

2. Installation and Operation ..........................................................................................................................9

2-1 Installation................................................................................................................................................9

2-1-1 AC Adapter Installation .....................................................................................................................9

2-1-2 Interface Cable Installation ...............................................................................................................9

2-1-3 Cash Drawer Cable Installation ........................................................................................................9

2-1-4 Ribbon Cartridge Installation.............................................................................................................9

2-1-5 Paper Roll Installation ..................................................................................................................... 10

2-2 Operation ...............................................................................................................................................11

2-2-1 Setting the DIP switches .................................................................................................................11

2-2-2 Setting the DIP switch (RS-232C Serial Interface) ......................................................................... 11

2-2-3 Setting the DIP switch (IEEE1284 Parallel, USB Interface) ...........................................................12

2-2-4 Hexadecimal Dumping....................................................................................................................13

2-2-5 The self Test Mode .........................................................................................................................13

3. Product Specifications.............................................................................................................................. 16

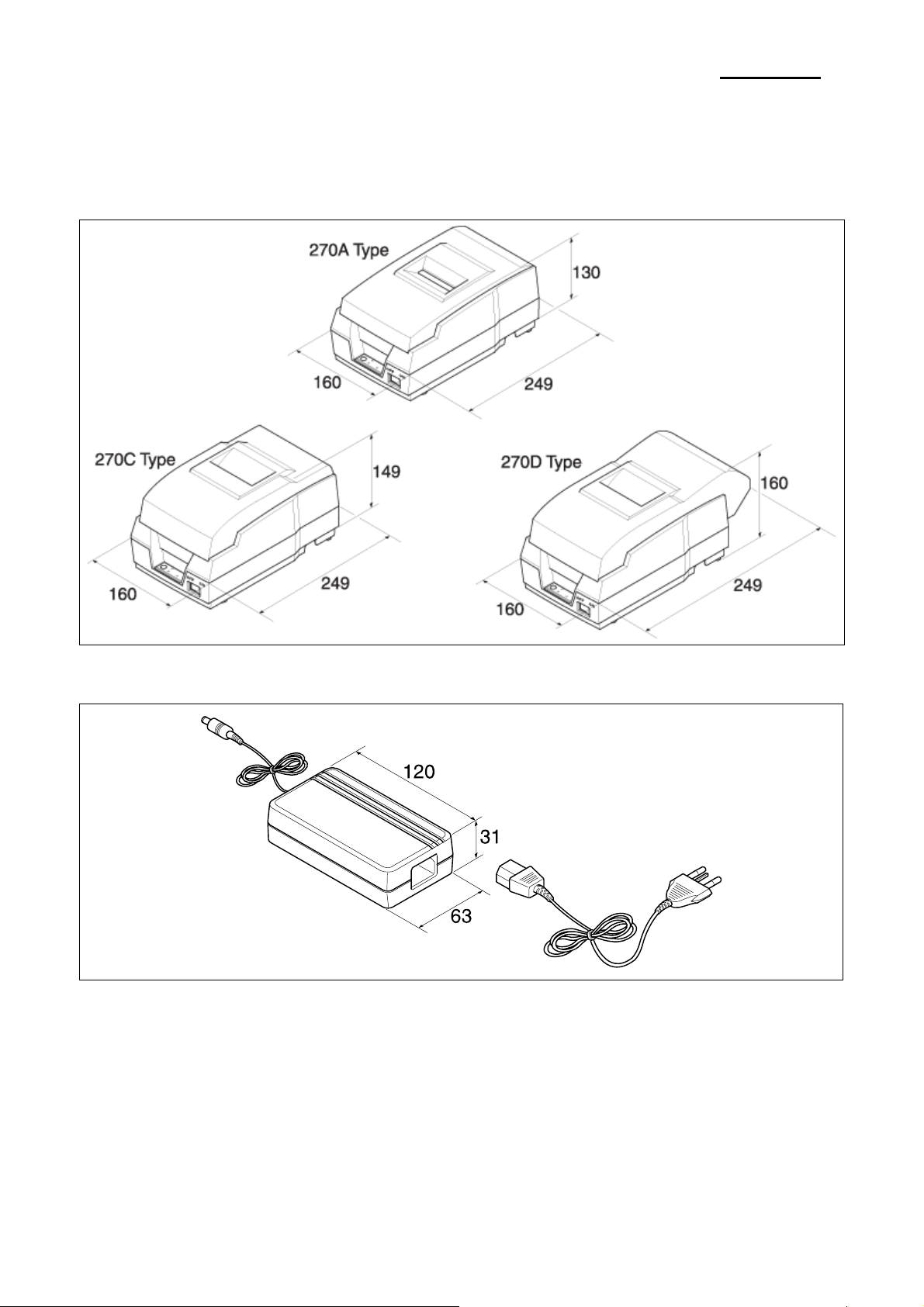

3-1 Appearance............................................................................................................................................16

3-1-1 Printer Dimensions (mm) ................................................................................................................16

3-1-2 AC Adapter Dimensions (mm) ........................................................................................................16

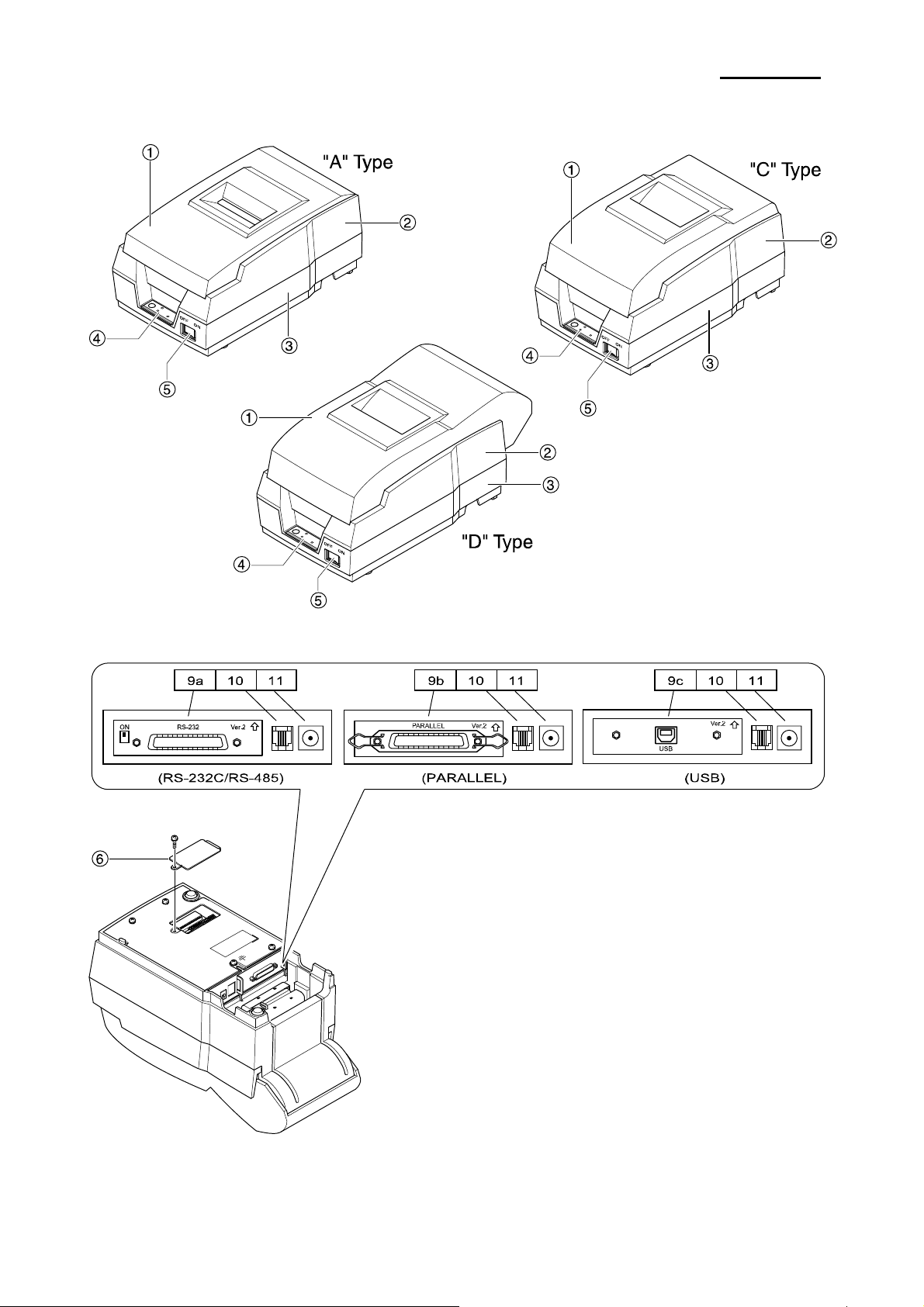

3-1-3 Feature Locations ...........................................................................................................................17

3-2 General Specifications...........................................................................................................................18

3-3 Printer Mecha Specifications .................................................................................................................18

3-3-1 Printer Mecha Specification ............................................................................................................18

3-3-2 Character Specification...................................................................................................................19

3-3-3 Printer (SMP-710/SMP-710N) Pin Description...............................................................................19

3-3-4 Printer Head Specification ..............................................................................................................20

3-3-5 Printer Head Thermistor Specification ............................................................................................20

3-3-6 Feed & Carriage Motor Specification..............................................................................................20

3-3-7 Auto cutter specification..................................................................................................................20

3-3-8 Paper Specification ......................................................................................................................... 20

3-3-9 Ribbon Cassette Specification........................................................................................................21

3-3-10 Other Component Specification....................................................................................................21

3-4 SMPS Specifications .............................................................................................................................21

3-4-1 SMPS (Switching Mode Power Supply) Specification ....................................................................21

3-4-2 SMPS Output Connector ................................................................................................................21

3-5 Interface Specifications.......................................................................................................................... 22

3-5-1 RS-232C Serial Interface................................................................................................................22

3-5-2 RS-485 Serial Interface................................................................................................................... 24

3-5-3 IEEE1284 Parallel Interface............................................................................................................ 25

3-5-4 USB2.0 Interface............................................................................................................................. 27

3-6 Cash Drawer Specifications................................................................................................................... 28

3-6-1 Cash Drawer Cable......................................................................................................................... 28

3-6-2 Cable Connection ...........................................................................................................................28

Rev. 3.02

- 2 -

Page 3

SRP-270

4. Hardware ....................................................................................................................................................29

4-1 Wiring Diagram ......................................................................................................................................29

4-2 Block Diagram........................................................................................................................................30

4-3 Special Circuit Descriptions ................................................................................................................... 31

4-3-1 Power Circuit................................................................................................................................... 31

4-3-2 RESET Circuit.................................................................................................................................32

4-3-3 Cash Drawer Circuits ...................................................................................................................... 33

4-3-4 I/F PBA Detect Block Diagram........................................................................................................34

4-3-5 RS-232C Communication Block Diagram....................................................................................... 35

4-3-6 RS-485 Communication Block Diagram .........................................................................................36

4-3-7 Parallel Communication Block Diagram .........................................................................................37

4-3-8 USB Communication Block Diagram .............................................................................................. 37

4-3-9 DIP Switch Circuit ...........................................................................................................................38

5. Disassembly and Assembly .....................................................................................................................39

5-1 General Precautions on Disassembly....................................................................................................39

5-2 Plate Bottom ..........................................................................................................................................39

5-3 Cover Assy (SRP-270D Type)............................................................................................................... 40

5-4 Cover Assy (SRP-270A & SRP-270C Type) .........................................................................................40

5-5 Case Upper Assy (SRP-270A & SRP-270C Type)................................................................................41

5-6 Case Upper Assy (SRP-270D Type) ..................................................................................................... 42

5-7 Printer Assy (SRP-270A & SRP-270C Type) ........................................................................................42

5-8 Printer Assy (SRP-270D Type).............................................................................................................. 43

5-9 Auto Cutter Assy....................................................................................................................................43

5-10 Main PCB.............................................................................................................................................44

5-11 Interface Board Assy ...........................................................................................................................44

6. Alignment and Adjustments.....................................................................................................................45

6-1 Printer Adjustment .................................................................................................................................45

7. Troubleshooting ........................................................................................................................................46

7-1 Power Problem ......................................................................................................................................46

7-2 System Problem.....................................................................................................................................46

7-3 Printer Problem......................................................................................................................................46

7-4 Cash Drawer Problem ...........................................................................................................................46

7-5 DIP S/W Problem................................................................................................................................... 46

7-6 RS232 Problem......................................................................................................................................46

7-7 RS485 Problem......................................................................................................................................46

7-8 IEEE 1284 Problem ...............................................................................................................................47

7-9 USB Problem .........................................................................................................................................47

8. Appendix (Spec of SMP-710/710N) .......................................................................................................... 48

8-1 Specifications......................................................................................................................................... 48

8-1-1 Printing specifications .....................................................................................................................48

8-1-2 Character specifications.................................................................................................................. 49

8-1-3 Paper specifications........................................................................................................................50

8-1-4 Ribbon Cassette specifications....................................................................................................... 50

8-1-4 Ribbon Cassette specifications....................................................................................................... 51

8-1-5 Environmental specifications ..........................................................................................................51

8-1-6 Reliability.........................................................................................................................................52

8-1-7 Main Unit specifications ..................................................................................................................52

8-1-8 Electrical specifications...................................................................................................................53

8-1-9 Mechanisms specifications ............................................................................................................. 53

8-1-10 Principle of Movement ..................................................................................................................54

Rev. 3.02

- 3 -

Page 4

SRP-270

8-2 Handling the Printer ............................................................................................................................... 61

8-2-1 Precautions on Printer Handling .....................................................................................................61

8-2-2 Paper Setting Procedures (Insertion/Removal) ..............................................................................62

8-2-3 Ribbon Cassette Installation ........................................................................................................... 64

8-3 Maintenance ..........................................................................................................................................65

8-3-1 Cleaning..........................................................................................................................................65

8-3-2 Inspection........................................................................................................................................65

8-4 Lubricants and Adhesive Application..................................................................................................... 66

8-4-1 Lubricant Requirements.................................................................................................................. 66

8-4-2 Lubricant Types ..............................................................................................................................66

8-4-3 Lubrication Points ...........................................................................................................................66

8-4-4 Adhesive Application Requirements ............................................................................................... 66

8-4-5 Adhesive types................................................................................................................................ 66

8-4-6 Adhesive Application Points............................................................................................................66

8-5 Tools, Lubricants and Adhesives........................................................................................................... 67

8-5-1 List of Tools..................................................................................................................................... 67

8-5-2 List of Lubricants and Adhesives .................................................................................................... 67

8-6 Repair ....................................................................................................................................................67

8-6-1 Repair Levels .................................................................................................................................. 67

8-6-2 Repair Procedures .......................................................................................................................... 67

8-6-3 Repair Guidelines ...........................................................................................................................68

8-6-4 Assignment Connector Pin .............................................................................................................73

8-7 Disassembly...........................................................................................................................................74

8-8 Assembly ...............................................................................................................................................74

8-8-1 Sub-assemblies ..............................................................................................................................75

8-8-2 Main-assemblies ............................................................................................................................. 78

8-8-3 Adjustment ...................................................................................................................................... 85

Rev. 3.02

- 4 -

Page 5

SRP-270

■ About

About this Manual

This Service Manual describes how to perform hardware service maintenance for the BIXOLON SRP-270

Receipt Printer.

Notes

Notes may appear anywhere in the manual. They draw your attention to additional information about the item.

Precaution symbols

Indicates a Safety Precaution that applies to this part component.

Indicates the part or component is an electro-statically sensitive device. Use caution when handling

these parts.

Copyright

ⓒ 2008 by BIXOLON Co., Ltd. All right reserved.

This Manual may not, in whole or in part, be copied, photocopied, reproduced, translated or converted to any

electronic or machine readable from without prior written permission or BIXOLON Co., Ltd.

■ Overview of this Receipt Printer

This System Receipt Printer is a microprocessor-based system, using a 16 bit-microprocessor.

This Service Manual provides the technical information for many individual component systems, circuits and

gives an analysis of the operations performed by the circuits. If you need more technical information, please

contact our service branch or R&D center. Schematics and specifications provide the needed information for

the accurate troubleshooting.

All information in this manual is subject to change without prior notice. Therefore, you must check the

correspondence of your manual with your machine. No part of this manual may be copied or reproduced in

any form or by any means, without the prior written consent of BIXOLON Co., Ltd.

Rev. 3.02

- 5 -

Page 6

SRP-270

1. Precaution Segment

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential

hazards such as electrical shock.

1-1 Safety Precautions

1. Be sure that all of the built-in protective devices are replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices, including

nonmetallic control knobs and compartment covers.

3. Make sure that there are no cabinet openings through which people - particularly children - might

insert fingers and contact dangerous voltages. Such openings include excessively wide cabinet

ventilation slots and improperly fitted covers and drawers.

4. Leakage Current Hot Check:

WARING: Do not use an isolation transformer during this test.

Use a leakage-current tester or a metering system that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for Applications), and Underwriters Laboratories (UL Publications

UL1410, 59.7)

With the unit completely reassembled, plug the AC line cord directly into a 100VAC or 240VAC outlet of the

Adaptor.

With the unit’s AC switch first in the ON position and then OFF, measure the current between a

known Earth ground (metal water pipe, conduit, etc.) and all exposed metal part, including: metal cabinet,

frame, and screw-heads and printer. The current measure should not exceed 0.1 milliamp. Reverse the

power-plug prong in the AC outlet and repeat the test.

5. Design Alteration Warning:

Never alter or add to the mechanical or electrical design of the Receipt Printer. Unauthorized alterations

might create a safety hazard. Also any design changes or additions will void the manufacture’s warranty.

6. Components, parts and wiring that appear to have overhead or that are otherwise damaged should be

replaced with parts that meet the original specifications. Always determine the cause of damaged or

overheating and correct any potential hazards.

7. Observe the original lead dress, especially near the following areas: sharp edges, and especially the AC

and high voltage supplies. Always inspect for pinched, out-of-place, or frayed wiring.

Do not change the spacing between components and the printed circuit board. Check the AC power cord

for damage. Make sure that leads and components do not touch thermally hot parts.

8. Product Safety Notice:

Some electrical and mechanical parts have special safety-related characteristics, which might not be

obvious from visual inspection. These safety features and the protection they give might be lost if the

replacement component differs from the original-even if the replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are indicated in the circuit diagram by shading,

( )or ( ). Use replacement components that have the same ratings, especially for flame resistance

and dielectric strength specifications. A replacement part that does not have the same safety

characteristics as the original might create shock, fire or other hazards.

Rev. 3.02

- 6 -

Page 7

SRP-270

1-2 Servicing Precaution

WARNING 1: First read the Safety Precaution section of this manual. If some unforeseen

circumstance creates a conflict between the servicing and safety precautions,

always follow the safety precaution.

WARNING 2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Always unplug the unit’s AC power cord from the AC power source or the Power Switch off before

attempting to:

(a) Remove or reinstall any component or assembly,

(b) Disconnect an electrical plug or connector,

(c) Connect a test component in parallel with an electrolytic capacitor.

2. Some components are raised above the printed circuit board for safety.

An insulation tube or tape is sometime used. The internal wiring is sometimes clamped to prevent contact

with thermally hot components. Reinstall all such elements to their original position.

3. After servicing, always check that the screws, components and wiring have been correctly reinstalled.

Make sure that the portion around the serviced part has not been damaged.

4. Check the insulation between the blades of the AC plug and accessible conductive parts.

(example: metal panels and input terminals).

5. Insulation Checking Procedure:

Disconnect the power cord from the AC source and turn the power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC plug. The insulation resistance between each blade of the

AC plug and accessible conductive parts (see above) should be greater than 1 mega-ohm.

6. Never defeat any of the B+ voltage interlock. Do not apply AC power to the unit (or any of its assemblies)

unless all solid-state heat sinks are correctly installed.

7. Always connect an instrument’s ground lead to the instrument chassis ground before connecting the

positive lead; always remove the instrument’s ground lead last.

Rev. 3.02

- 7 -

Page 8

SRP-270

1-3 Precaution for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor (solid state) devices are easily damaged by static electricity. Such components are

called Electrostatically Sensitive Devices (ESDs); examples include integrated circuits and some field-

effect transistors. The following techniques will reduce the occurrence of component damaged caused by

static electricity.

2. Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge

from your body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device.

(Be sure to remove it prior to applying power-this is an Electric shock precaution.)

3. After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to

prevent accumulation of electrostatic charge.

4. Do not use freon-propelled chemical. These can generate electrical charges that damage ESDs.

5. Use only a grounded-tip soldering iron when soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device. Many solder removal devices are not rated as anti-static;

these can accumulate sufficient electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its protective package until you are ready to install it.

Most replacement ESDs are packaged with leads that are electrically shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective material from the leads of a replacement ESD, touch the

protective material to the device will be installed.

9. Minimize body motions when handling unpacked replacement ESDs. Motions such as brushing clothes

together, or lifting a foot from a carpeted floor can generate enough static electricity to damaged an ESD.

Rev. 3.02

- 8 -

Page 9

2. Installation and Operation

2-1 Installation

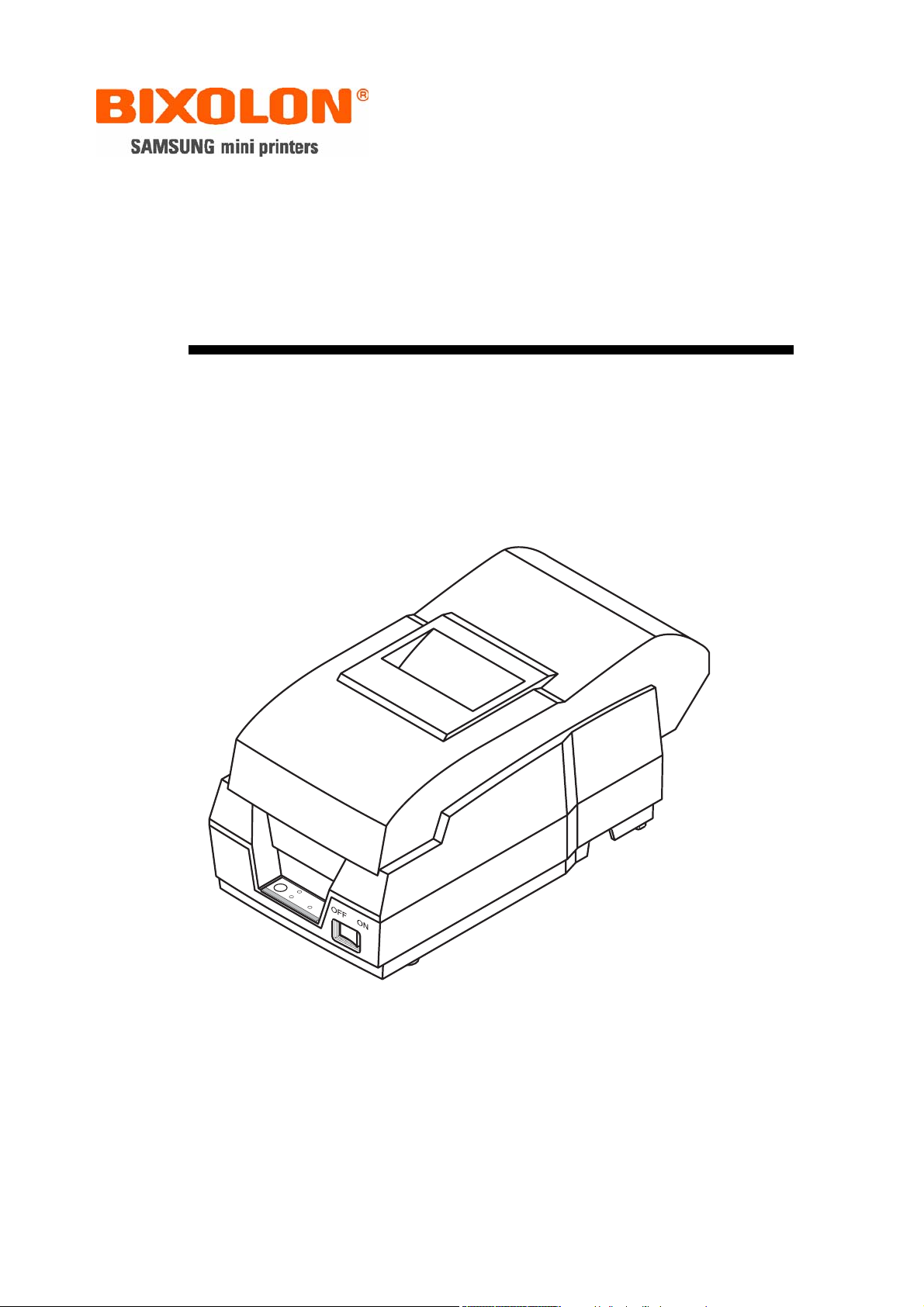

2-1-1 AC Adapter Installation

2-1-2 Interface Cable Installation

SRP-270

1. Mack sure the printer is turned off with the “Off”

side of the switch is pressed down.

2. Check the label on the AC Adapter to make sure the

voltage required by the AC Adapter matches that of the

electrical outlet.

3. Plug the DC cord connector into the power jack on the

printer.

4. Plug the AC Adapter power cord into the wall outlet.

2-1-3 Cash Drawer Cable Installation

Cash Drawer Connector

1. Turn off the printer, host ECR and Computer.

2. Plug RS-232, RS-485, USB or Parallel Cable

connector into the I/F connector on the printer.

3. Tighten the screws on both sides of the connector.

4. Turn on the printer, host ECR and Computer.

2-1-4 Ribbon Cartridge Installation

Cash Drawer Cable

1. Turn the printer off.

2. Plug the Cash Drawer cable connector into the

connector on the printer. (To remove the Cash Drawer

cable, press the clip on the connector, grasp the

connector and pull it out.)

3. Secure the Shield Wire on the bottom of the printer.\

Rev. 3.02

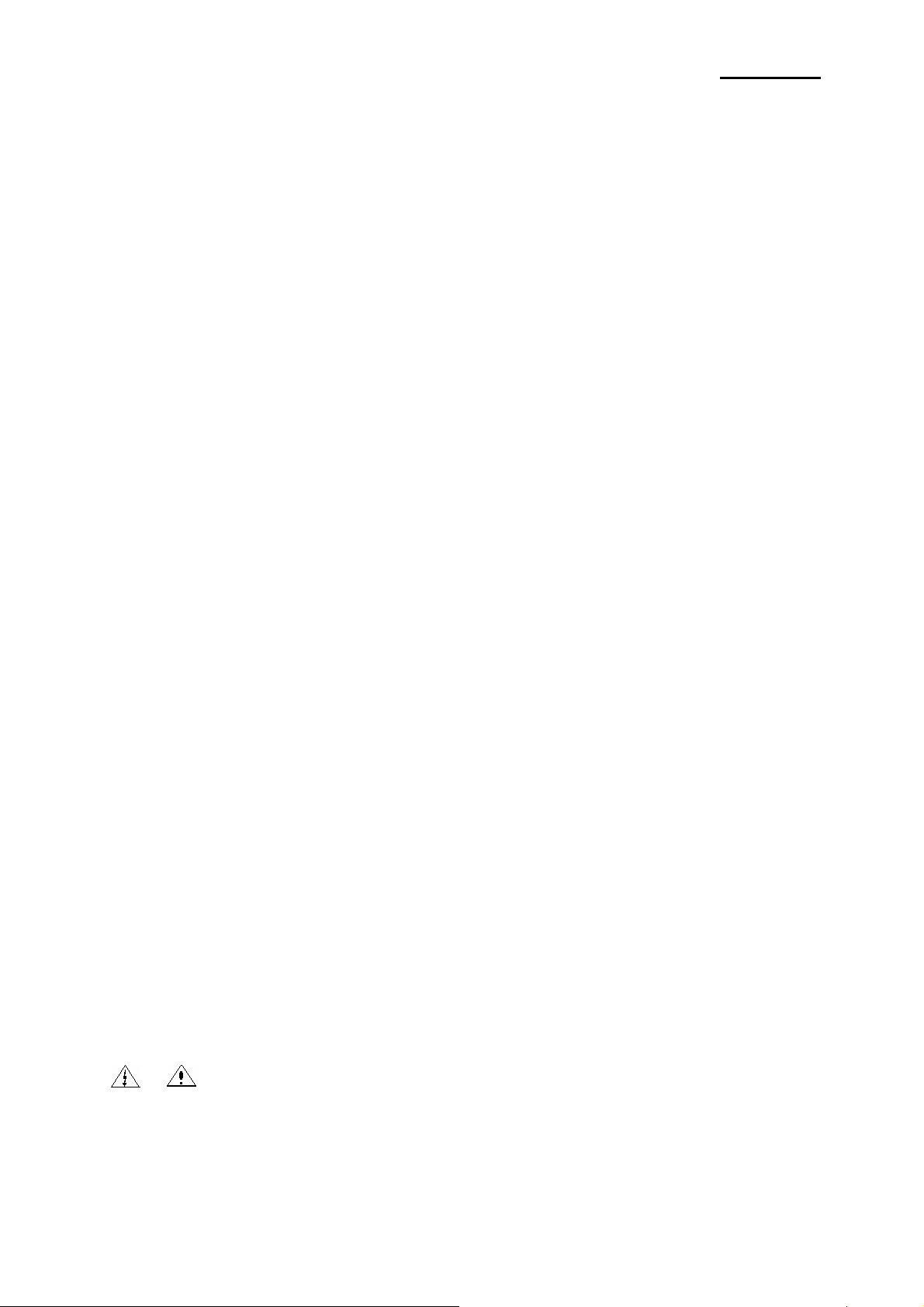

1. Before inserting the ribbon cartridge, turn the Knob.

2. Insert the ribbon cartridge. Pay particular attention to

the placement of the ribbon behind the Print Head.

3. After inserting the ribbon cartridge, turn the knob

clockwise again to make sure the ribbon moves freely

in the cartridge.

- 9 -

Page 10

SRP-270

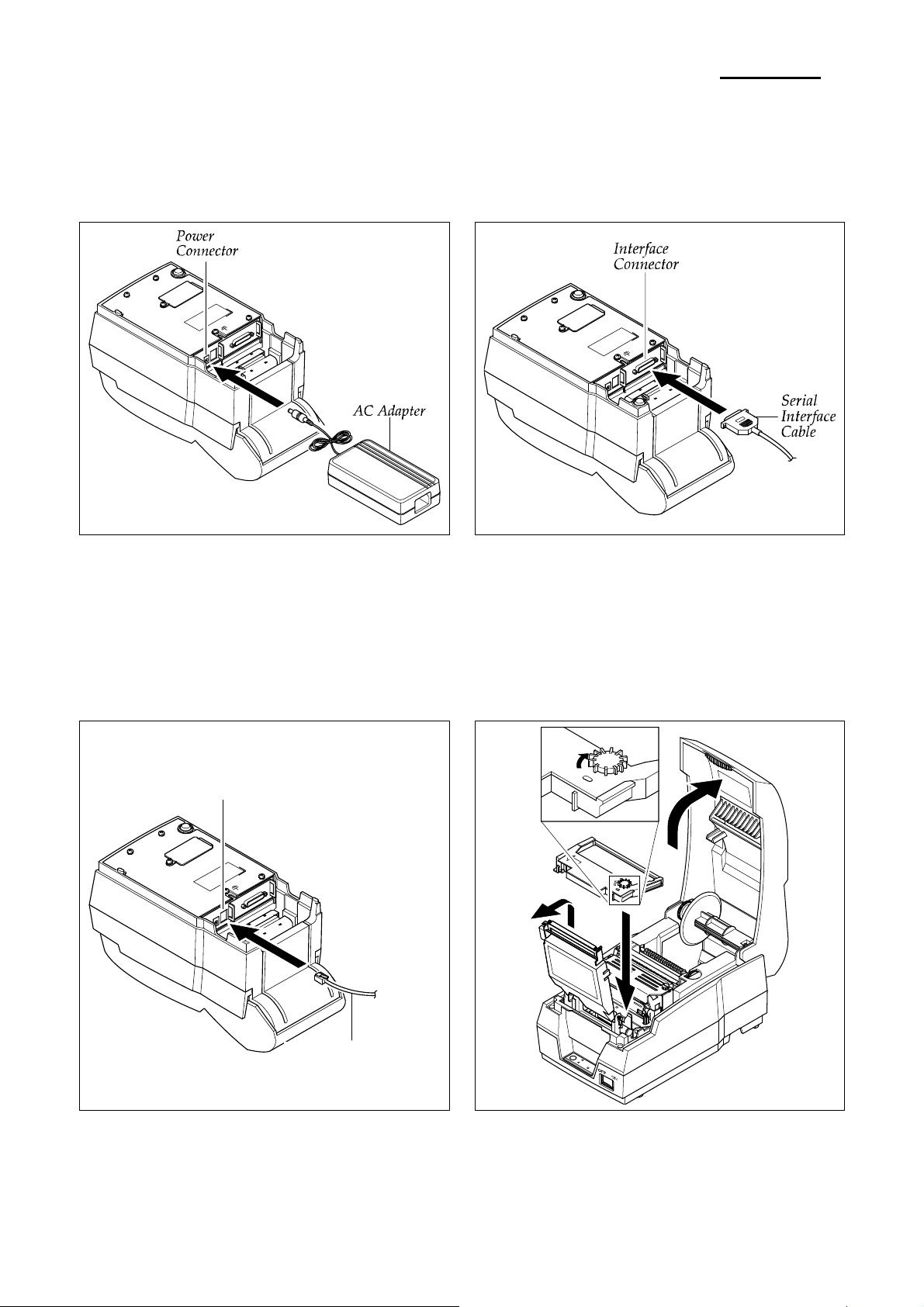

2-1-5 Paper Roll Installation

1. Using a new roll paper, unroll the paper and cut the end

as shown.

6. If the paper is loose, wind the Rewind Spindle to tighten

the paper.

2. In case of Model 270C/D, open Auto Cutter on the

power ON.

3. Auto feeding one paper.

4. Put first paper into Auto Cutter, set second paper rolling

Spool Winding to Lower Case.

5. Setting Auto Cutter, then put first paper to the middle of

guide for cover Printer and pull it out close cover.

7. Release the holder after fitting the Roll Paper Core onto

the Holder. Make sure to load the paper roll so that it

rotates in the correct direction.

Rev. 3.02

- 10 -

Page 11

SRP-270

2-2 Operation

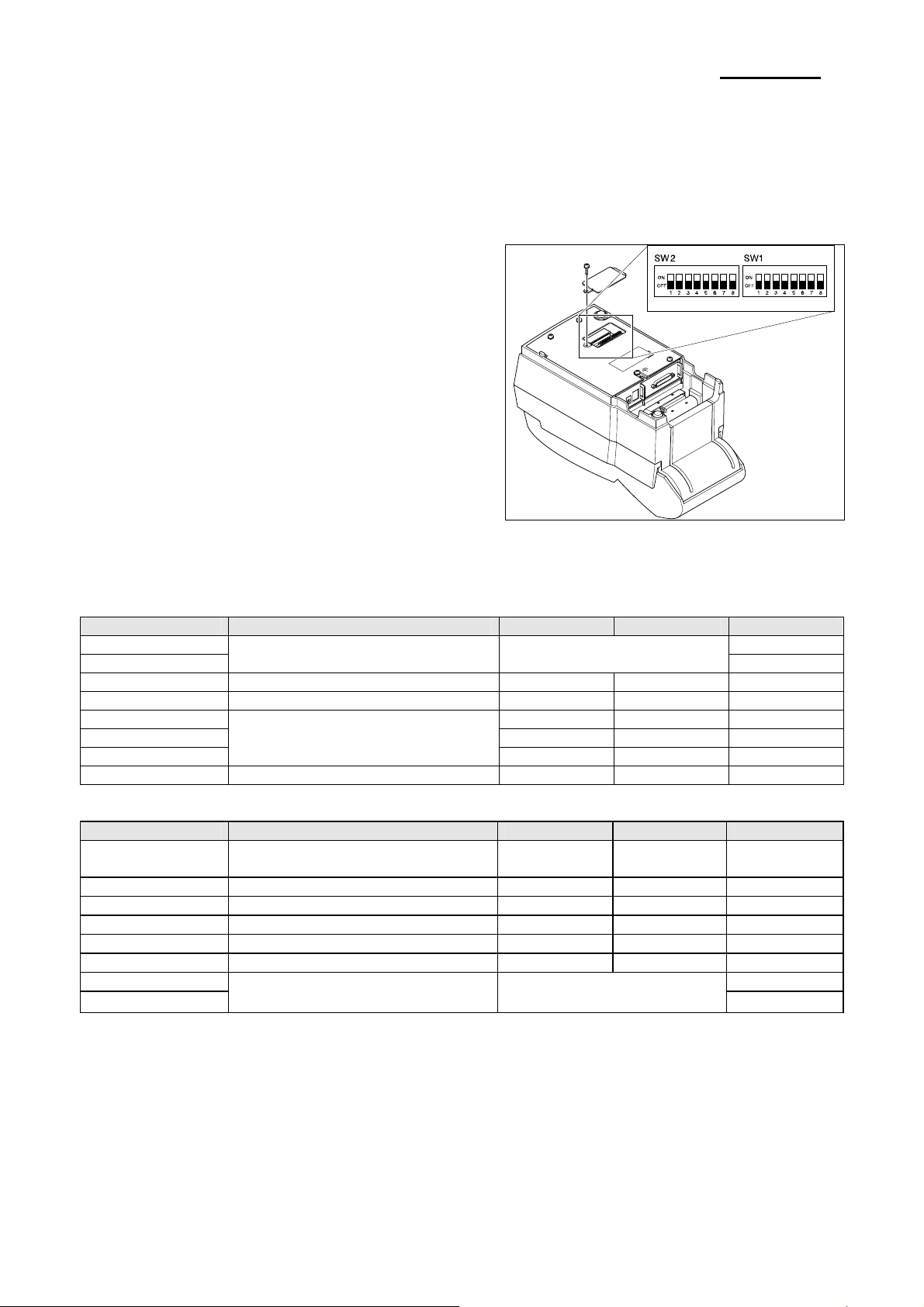

2-2-1 Setting the DIP switches

The DIP switches are located on the bottom of the printer. The DIP switches are used to set the printer to perform various

functions. Follow these when changing DIP switches setting :

1. Turn the printer power switch off.

2. Remove the screw on the bottom of the printer and

open the bracket.

3. Flip the DIP switches using tweezers or another narrowended tool. Switches are on when up and off when off

down.

4. The new setting takes effect when you turn on the

printer.

※ Note : Always change DIP switch settings only when the

printer is turned off. Change made with the power

on have no effect and then on again.

2-2-2 Setting the DIP switch (RS-232C Serial Interface)

• DIP Switch 1

SW FUNCTION ON OFF DEFAULT

1 OFF

2

Emulation Selection Refer to the following Table 1

3 Auto-Cutter Enable Disable OFF

4 FONT SPACE 2 3 OFF

5 6 -

Function for Service Engineer

7

8 Korean Type Selection Unified Complete OFF

• DIP Switch 2

SW FUNCTION ON OFF DEFAULT

1 Auto Line Feed

Always

Enabled

2 Hexadecimal dump YES NO OFF

3 Hand Shaking XON/OFF DTR/DSR OFF

4 Word length 7 bits 8 bits OFF

5 Parity check Enable Disable OFF

6 Parity selection EVEN ODD OFF

7 OFF

8

Baud Rate selection Refer to the following Table 2

NOTE※

When the word length is 7 bits, you can not parity check OFF status.

OFF

OFF

Always

Disabled

OFF

OFF

Rev. 3.02

- 11 -

Page 12

SRP-270

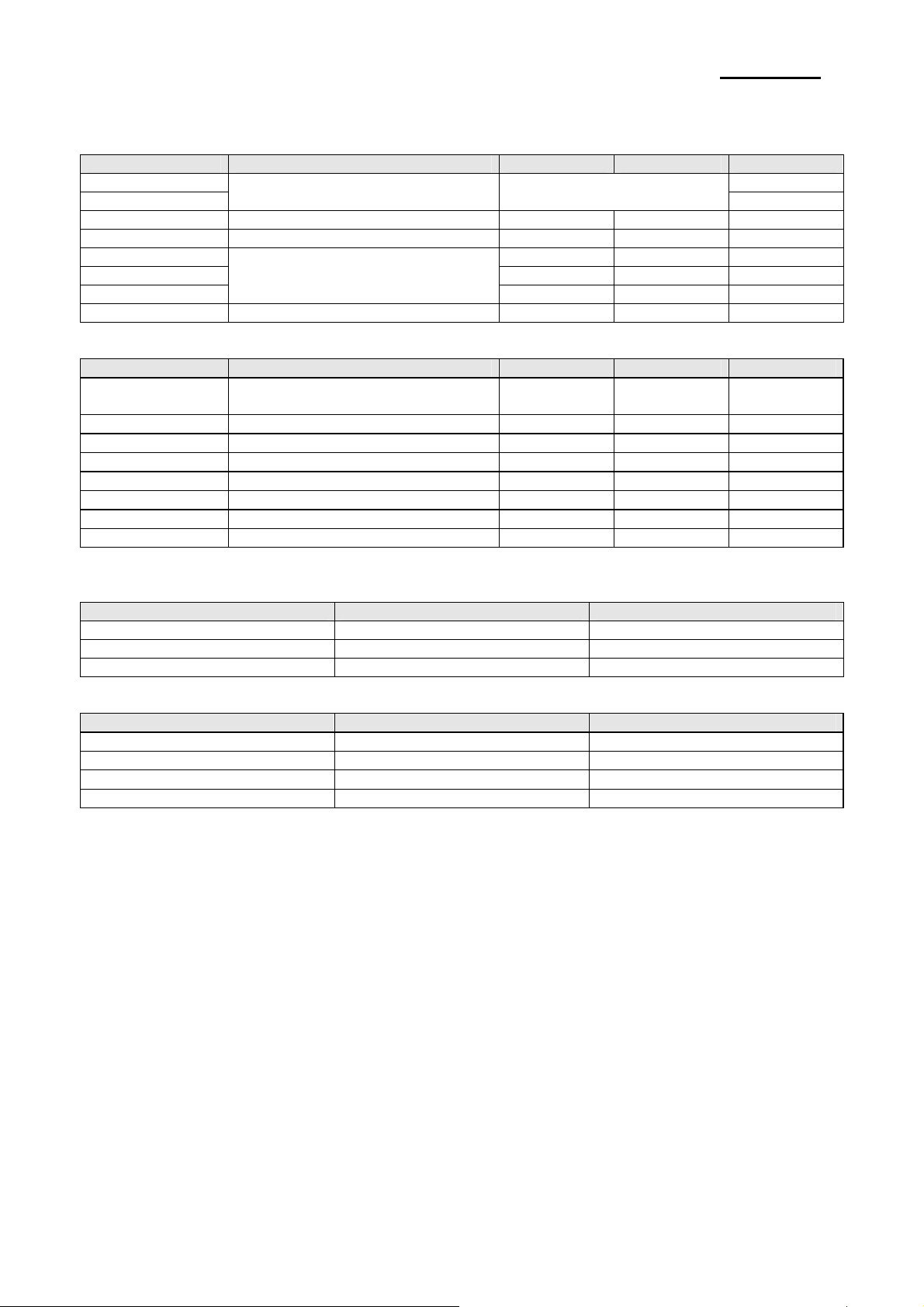

2-2-3 Setting the DIP switch (IEEE1284 Parallel, USB Interface)

• DIP Switch 1

SW FUNCTION ON OFF DEFAULT

1 OFF

2

3 Auto-Cutter Enable Disable OFF

4 FONT SPACE 2 3 OFF

5 6 7

8 Korean Type Selection Unified Complete OFF

• DIP Switch 2

SW FUNCTION ON OFF DEFAULT

1

2 Hex Dump YES NO OFF

3 Reserved - - OFF

4 Reserved - - OFF

5 Reserved - - OFF

6 Reserved - - OFF

7 Reserved - - OFF

8 Reserved - - OFF

• Table 1 – Emulation Selection

SW – 1 SW – 2 MODE

OFF OFF Epson

OFF ON Citizen

ON OFF Star

• Table 2 – Baud rate (bps) Selection

Transmission speed SW – 7 SW – 8

19200 baud ON ON

2400 baud OFF ON

4800 baud ON OFF

9600 baud OFF OFF

Emulation Selection Refer to the following Table 1

Function for Service Engineer

Auto Line Feed

Always

Enabled

OFF

OFF

Always

Disabled

OFF

Rev. 3.02

- 12 -

Page 13

SRP-270

2-2-4 Hexadecimal Dumping

This feature allows experienced users to see exactly what data is coming to the printer. This can be useful in

finding software problems. When you turn on the hexadecimal dump function, the printer prints all commands

and data in hexadecimal format along with a guide section the help you find specification commands.

To use hexadecimal dump mode, please follow these steps:

1. After you make sure that the printer is off.

2. Set DIP-switch 2-2to ON.

3. Turn on the printer, and then the printer enters the hexadecimal dump mode.

4. Run any software program to send data to the printer. The printer will print all the codes it receives in a

two-column format. The first column contains the hexadecimal codes and the second column gives the

ASCII characters corresponding to the codes.

1B 21 00 1B 26 02 40 40 .! . . & . @ @

02 0D 1B 44 OA 14 1E 28 ...D...(

00 01 0A 41 OD 42 OA 43 .. . A . B . C .

Note 1 : A period(.)is printed for each code that no ASCII equivalent.

Note 2 : During the hex dump all the commands except DLE EOT and DLE ENQ are disabled.

5. When the printing finishes, turn off the printer, and change DIP-switch 2-2 to OFF.

6. Turn on the printer and then the hexadecimal mode is off.

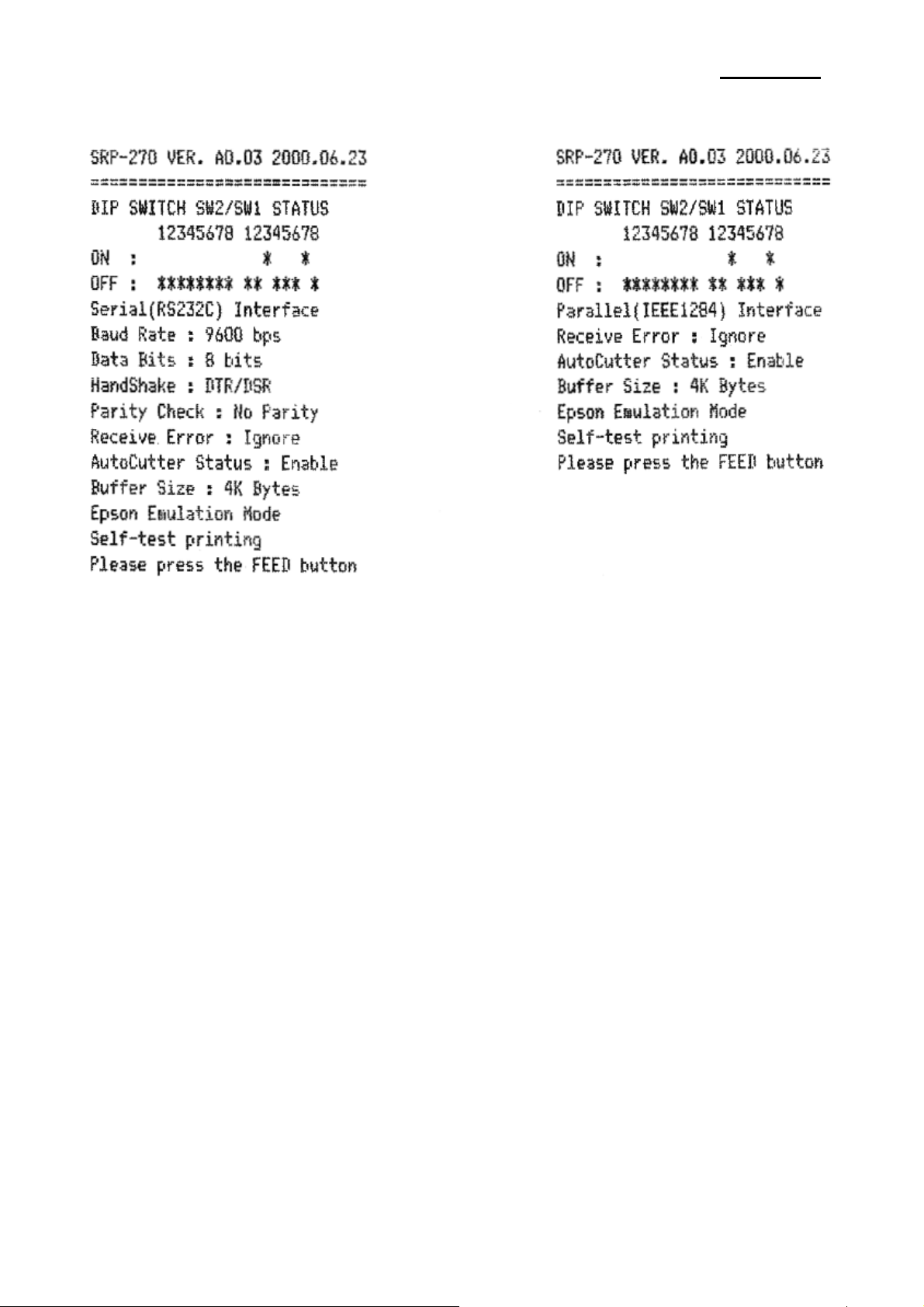

2-2-5 The self Test Mode

The self-test checks whether the printer has any problem. If the printer does not function properly, contact

your dealer. The self-test checks the following.

1. Make sure paper roll has been installed properly.

2. Turn on the printer power while holding down the FEED button so that the self-test begins.

3. The self-test prints the current printer status, which provides the control ROM version and the DIP switch

setting.

4. After printing the current printer status self-test printing will print the following and pause.

(The PAPER OUT and ERROR LED’s light blinks.)

Please press the button

5. Press the FEED button to continue printing. The printer prints a pattern using the built-in character set.

6. The character test sheet to be printed is that four lines are printed as BLACK color and the next four lines

are printed as RED color in turn. Total 20 character lines will be printed.

7. The self-test automatically ends and cuts the paper after printing the following.

** Character Test Completed **

8. Back-Lash printing is possible when the DIP switch 1-7 is ON, or the printing is skipped when the DIP

switch 1-7 is OFF.

9. The printer is ready to receive data as soon as it completes the self-test.

Rev. 3.02

- 13 -

Page 14

SRP-270

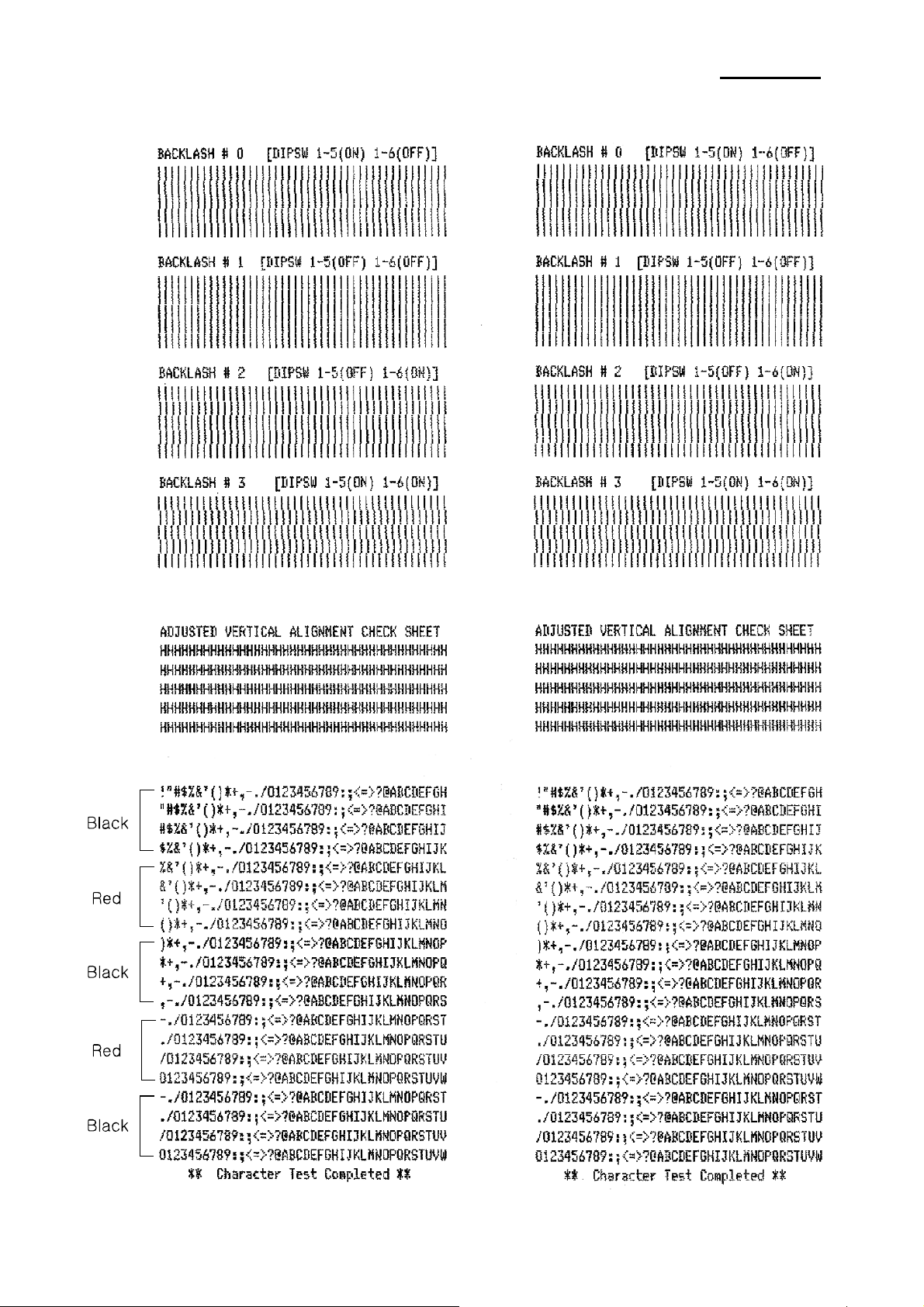

(A) Serial Self-Test Sheet (B) Parallel Self-Test Sheet

Rev. 3.02

- 14 -

Page 15

SRP-270

(A) Serial Self-Test Sheet (B) Parallel Self-Test Sheet

Rev. 3.02

- 15 -

Page 16

3. Product Specifications

3-1 Appearance

3-1-1 Printer Dimensions (mm)

SRP-270

3-1-2 AC Adapter Dimensions (mm)

Figure 3-1 Printer Dimension

Figure 3-2 Adapter Dimension

Rev. 3.02

- 16 -

Page 17

SRP-270

3-1-3 Feature Locations

Rev. 3.02

1. Cover, A/C/D

2. Case-Upper, A/C/D

3. Case-Lower, A/C/D

4. Label-Control

5. Power Switch

6. Bracket DIP Switch

9a.RS-232C/RS-485 (Serial I/F Connector)

9b.IEEE-1284(Parallel I/F Connector)

9c.USB(USB I/F Connector)

10. Drawer Kick-Out Connector

11. DC Power Jack

Figure 3-3 Feature Location

- 17 -

Page 18

SRP-270

3-2 General Specifications

Item Description Remark

• SRP-270 : RS-232 Serial Communication

Product

Processor

Memory

Interface Serial

(RS-232C / RS-485)

Interface Parallel

USB

Printer

Auto Cutter

Power Consumption • Approx. 24W

AC Adapter

Environment

Condition

Weight

Dimensions(mm)

Reliability

3-3 Printer Mecha Specifications

3-3-1 Printer Mecha Specification

Item Description Remark

Model • SMP-710/SMP-710N

Print Method • Serial Impact Dot Matrix type (9-Pin Dot)

Printing Direction • Bi-Direction

Printing Speed • 4.6 Lines / Sec (9 x 7 Font 40 Columns)

Printing Resolution • 160(W) x 144(L) DPI

Paper Feeding • Performed by Step Motor

Paper • Rolled Paper : W 76±0.5 x Max ø 83mm

Supply Voltage • 24V ± 10% : Step Motor, Head

Connector • 30P (Dot Head, Sensor Signal, Motor Control and Power Input)

Head Life • Approx. 300 million Dots / Wire

Weight • Under 650g (Excluding Ribbon Cassette, Auto Cutter)

• SRP-270S : RS-485 Serial Communication

• SRP-270P : IEEE1284 Parallel Communication

• SRP-270U : USB Communication

• MITSUBISHI M16C/62 Group M30622 SFP (16 Bit)

Internal RAM Size : 3K Byte

• EPROM : 1Mbits (M27C010)

• SRAM : 256Kbits (KM62256)

• Flow Control :

1) DTR / DSR (H/W Flow Control)

2) XON / XOFF (S/W Flow Control)

• Baud Rate : 1200 / 2400 / 4800 / 9600 Bps

• Receive Buffer : 4 Kbytes

• Connector : DB25P Female (I/F PBA Side)

• Mode :

1) Forward Mode : Compatibility Mode

2) Reverse Mode : Nibble / Byte Mode

• Connector : Self-Powered

• Transfer Type : BULK

• Speed : 12 Mbps (Full-Speed)

• Power : Self-Powered

• Printing Method : 9pins Impact Serial Dot

• Printing Speed : 4.6 Line/Sec

• Type : Guillotine

• Cutting Method : 1 Point Partial Cutting

• Input : AC 100V ~ 240V, 50Hz/60Hz

• Output : DC 24V±5%, 1.5A

• Temperature : 0℃ ~ 40℃

• Humidity : 30% ~ 80% RH

• 3.2 Kg (A Type) / 3.5 Kg (C Type) / 3.6 Kg (D Type)

• 2.2 Kg (A Type) / 2.5 Kg (C Type) / 2.6 Kg (D Type)

• A Type : 160 X 249 X 130

• C Type : 160 X 249 X 149

• D Type : 160 X 249 X 160

• Head: 300 million dots

• Printer: 18 million lines (MCBF)

• Auto Cutter: 1 million cuts

• 5V ± 10% : Home Sensor, Motor Driver IC

• LIFE : Approx.20 Million Print Lines

External ROM Version

The Flow Control, Baud

Rate, Stop Bit and Parity

are determined by DIP

S/W position.

Packing

Unpacking

Rev. 3.02

- 18 -

Page 19

SRP-270

3-3-2 Character Specification

Item Description Remark

Dot Interval

Font Type ASCII Chinese

Print Font 9 x 9 7 x 9 16 x 16

Printing Columns 33 40 -

Character Size (mm) 3.2 x 1.7 3.2 x 1.4 5.7 x 3.0

Column Interval (mm) 2.13 1.59 3.19

Line Interval 1/6“ 1/6“ 1/3“

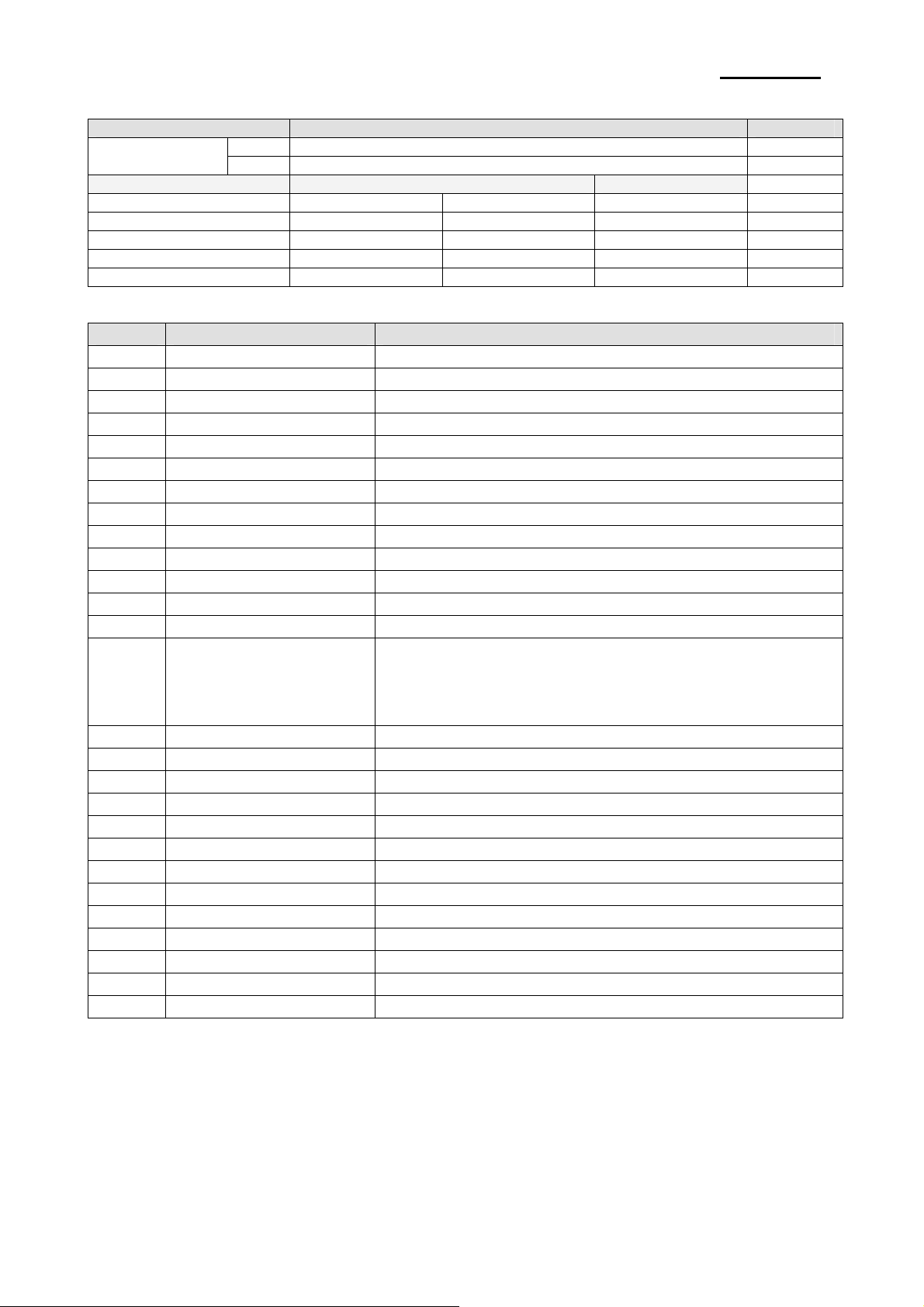

3-3-3 Printer (SMP-710/SMP-710N) Pin Description

Pin No. Pin Name Descriptions

1 Printer Head Head #6

2 Printer Head Head #8

3 Printer Head Head #4

4 Printer Head Head #9

5 Printer Head Head #2

6 +24Vdc The Voltage for Driving Print Heads

7 +24Vdc The Voltage for Driving Print Heads

8 +24Vdc The Voltage for Driving Print Heads

9 Print Head Head #3

10 Printer Head Head #5

11 Printer Head Head #1

12 Printer Head Head #7

13 Thermistor Thermistor Output Value in Printer Head

14

15

16

17

18 Carriage Motor ON/OFF Control Driving voltage or Holding Voltage Of Carriage Motor

19 Carriage Motor A Phase A of the Carriage Motor

20 Carriage Motor B Phase B of the Carriage Motor

21 Vcc (+5 Vdc) 22 Vcc 23 Feed Motor ON/OFF Control, Driving Voltage or Holding Voltage of Feed Motor

24 Feed Moter A Phase A of the Feed Motor

25 Feed Moter B Phase B of the Feed Motor

26 H/S Output 27 P/E Output 28 +24 Vdc The Voltage for Driving Motors

29 +24 Vdc The Voltage for Driving Motors

30 Sol- -

GND -

H 0.3175 mm

V 0.3528 mm

Rev. 3.02

- 19 -

Page 20

SRP-270

3-3-4 Printer Head Specification

Item Description Remark

Model • DH400-G10

Specification

Solenoid Coil

Driver Circuit

Performance

Temperature

3-3-5 Printer Head Thermistor Specification

Item Description Remark

Type

Electronic

Characteristics

Max Operating Limit

Rx Formula • RX = R25 x Exp {B x (1/TX -1/T25) ]} T : Absolute Temperature

3-3-6 Feed & Carriage Motor Specification

Item Description Remark

Model • PM42S-048-SYM4 (NMB Electronic Co., Ltd)

Voltage • 24 VDC ± 10%

Current • 500 mA / Phase (Peak)

Resistance • 10 W

Step Angle • 7.5°

Pull Out Torque • 1200 PPS 200 g/cm

3-3-7 Auto cutter specification

Item Description Remark

Model • ORC-RUG80-2 (OHYANERIKI MFG. Co., Ltd)

Type • Guillotine Type

Motor • DC Brush Motor Fk-180SH-12280 Mabuchi Motor

Voltage • 24VDC ± 10%

Current • 400 mA (Average), 1.6 A (Peak)

3-3-8 Paper Specification

Item Description Remark

Paper Type • Roll Paper

Paper Roll Width • W76 ± 0.5 mm (2.99” ± 0.00200”)

Paper Roll Diameter • Max x ø 83mm (3.26”)

Normal Paper

• Type: Ballistic Type (Free Fight)

• Number of Wire: 9Pin

• Resistance: 10W ± 15%

• Inductance: 4.5mH ± 15% (Open Circuit)

• Temperature Rate: 155 Deg.C

• Insulation Resistance: 10MW

• Type: constant Voltage

• voltage: 24VDC ± 5% (Normal ) (At Printer Head)

• Current: 1.3 A

• Pulse: 330μ Sec (Head On Time)

• Fly Back Voltage: 48VDC (Min)

• Platen Gap: 0.51 ± 0.1 mm

• Max Frequency: 1500 Hz

• Forms Capability: Original + 2 Copies

• Max Operating Temp: 65°C

• Max Transient Temp: 140°C (For 5 Minutes)

• LP310-1J (Tama Elec. Co., Ltd) or

Correspond to it correspond to it

• Resistance R25: 17.3 KW (At 25°C)

• B Value: 3950K ± 2

• Operating Temp: 120°C ~ 150°C

• Time Constant: Max 30 sec (In the air)

• Thickness: 1 Sheet 0.06~0.085mm

(0.0028 ~ 0.0034”)

• Weight: 52.3 ~64 g/m2 (0.115 ~ 0.1411 lb)

Any thermistor which

correspond to it

Rev. 3.02

- 20 -

Page 21

SRP-270

3-3-9 Ribbon Cassette Specification

Item Description Remark

Standard • ERC-38 (Black / Red)

Color • Black & Red

Size • 13 mm (W) x 6 mm (L)

• ERC-38 (B/P): 1,500,000 Characters (Black)

Life

3-3-10 Other Component Specification

Item Description Remark

Paper End Sensor • Reflection Type Micro Switch

Paper Roll Near End

Sensor

750,000 Character (Red)

(Continuous Printing 7 x 9 Font / ASCII / 25 )℃

• Micro Switch Factory option

3-4 SMPS Specifications

3-4-1 SMPS (Switching Mode Power Supply) Specification

Item Description Remark

Input Voltage • 100VAC ~ 240VAC

Input Current • 1.5A (Max)

Line Regulation • +24V ± 1%

Load Regulation • +24V ± 5%

Ripple Noise • Peak 300mV

O.C.P • 2.3A ~ 2.5A (Over Current Protect)

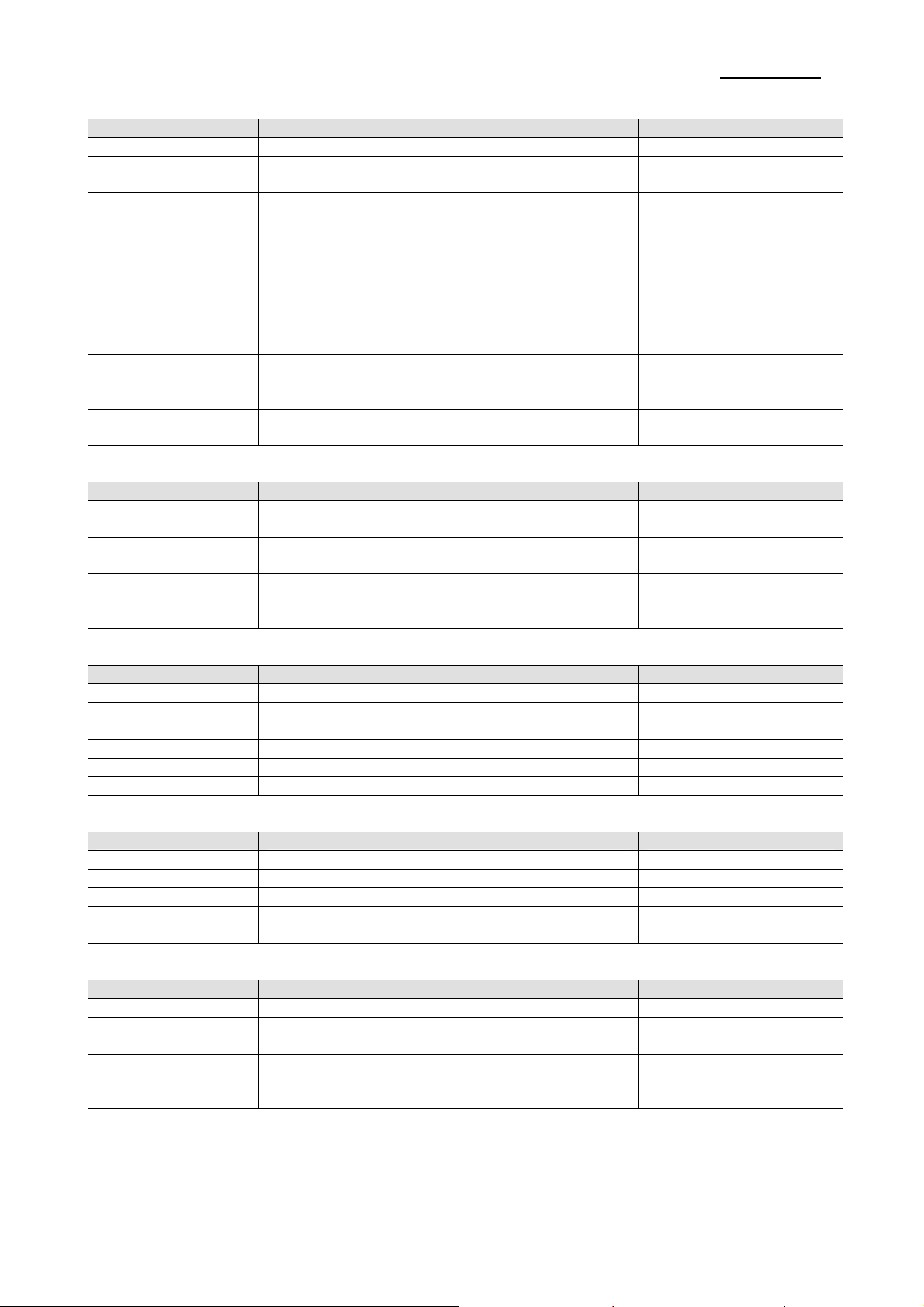

3-4-2 SMPS Output Connector

Pin Number Signal Name

1 +24 VDC

2 GND

Power Connector

Rev. 3.02

- 21 -

Page 22

SRP-270

3-5 Interface Specifications

3-5-1 RS-232C Serial Interface

3-5-1(a) Specification

Item Description Remark

Data Transmission • Serial

Synchronization • Asynchronous

HandShaking

(Flow Control)

Signal Level

Baud Rate • 19200 / 2400 / 4800 / 9600 Bps

Data Word Length • 7 Bit / 8 Bit

Parity • None / Even / Odd

Connector • DB25P Female (I/F PBA)

※ Note: The HandShaking (Flow Control) / Data Word Length / Baud Rate / Parity functions depend

on the DIP Switch settings. Refer to the User’s Manual.

3-5-1(b) RS-232C I/F Cable

• H/W : DTR / DSR

• S/W : XON / XOFF

• Logic”1” (MARK) : -3V ~ -15V

• Logic”0” (SPACE) : +3V ~ +15V

Table 3-14 RS-232C Specification

XON: ASC Code 11h

XOFF: ASC Code 13h

Printer Side: D-SUB25P-Male

Ferrite Core : 1 Turn (OP-118E : 18.2 x 12.5 x 25.5)

Figure 3-6 RS-232C Cable

CONN : User Spec

In Case PC : D-SUB25P-Female or

D-SUB9P-Female

Rev. 3.02

- 22 -

Page 23

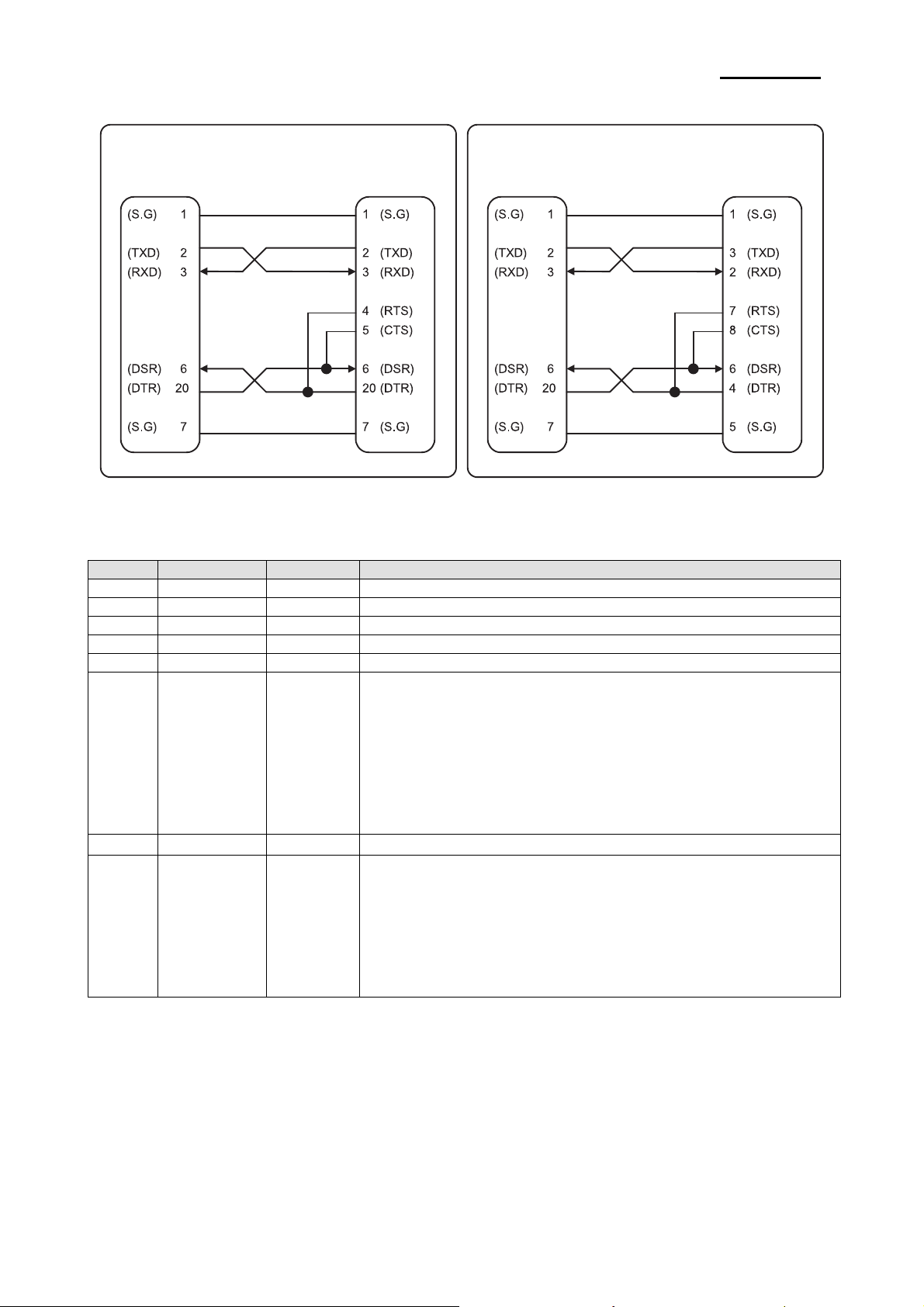

3-5-1(c) Cable Connection

SRP-270

PRINTER

SIDE (25P)

3-5-1(d) Signal Description

Pin No. Signal name Direction Function

1 FG - Frame Ground

2 TxD Output Transmit Data

3 RxD Input Receive Data

4 RTS Output Ready To Send

5 CTS Input Clear To Send

6 DSR Input

7 SG -

20 DTR Output

3-5-1(e) H/W Flow Control

When DTR/DSR flow control is select, before transmitting a data, the Printer checks whether the host is

BUSY or not. If the host is BUSY, the Printer does not transmit a data to the host. If the host is not BUSY, the

Printer transmits a data to the Host. The host is the same. Refer to the Interface Part of Chapter 4-3 Special

Circuit Diagrams.

HOST

SIDE (25P)

Figure 3-7 RS-232C Cable Connection

This signal indicates whether the host computer can receive data.

(H/W flow control)

1) MARK(Logic1) : The host can receive a data.

2) SPACE(Logic0) : The host can not receive a data.

3) The printer transmits a data to the host, after confirming

this signal.

4) When XON/XOFF flow control is selected, the printer does

not check this signal.

Signal Ground

This signal indicates whether the printer is busy. (H/W flow control)

1) MARK(Logic1) : The printer is busy.

2) SPACE(Logic0) : The printer is not busy.

3) The host transmits a data to the printer, after confirming

this signal.

4) When XON/XOFF flow control is selected, the host does not

check this signal.

Table 3-15 RS-232C Pin Description

PRINTER

SIDE (25P)

HOST

SIDE (9P)

Rev. 3.02

- 23 -

Page 24

SRP-270

3-5-1(f) S/W Flow Control

When XON/XOFF flow control is selected, the printer transmits XON(ACSII 11h) or XOFF(ASCII 13h) signal

through the TXD line. If the Printer is BUSY, the Printer transmits XOFF(ASCII 13h) to host through the TXD

line. Then the host recognize that the Printer is BUSY. So, the host does not transmit a data to the Printer. If

the Printer is released from BUSY, the Printer transmits XON(ASCII 11h) to host through the TXD line. Then

the host recognize that the Printer is not BUSY. And the host transmit a data to the Printer.

※ Note : Refer to the Operation Manual about XON/XOFF flow control.

3-5-2 RS-485 Serial Interface

3-5-2(a) Specification

Item Description Remark

Data Transmission • Serial

Synchronization • Asynchronous

HandShaking

(Flow Control)

Signal Level

Baud Rate • 19200 / 2400 / 4800 / 9600 Bps

Data Word Length • 7 Bit / 8 Bit

Parity • None / Even / Odd

Connector • DB25P Female (I/F PBA)

※ Note : The HandShaking (Flow Control) / Data Word Length / Baud Rate / Parity functions depend

on the DIP Switch settings. Refer to the User’s Manual.

3-5-2(b) RS-232C I/F Cable

Same as the appearance of RS-232C Cable

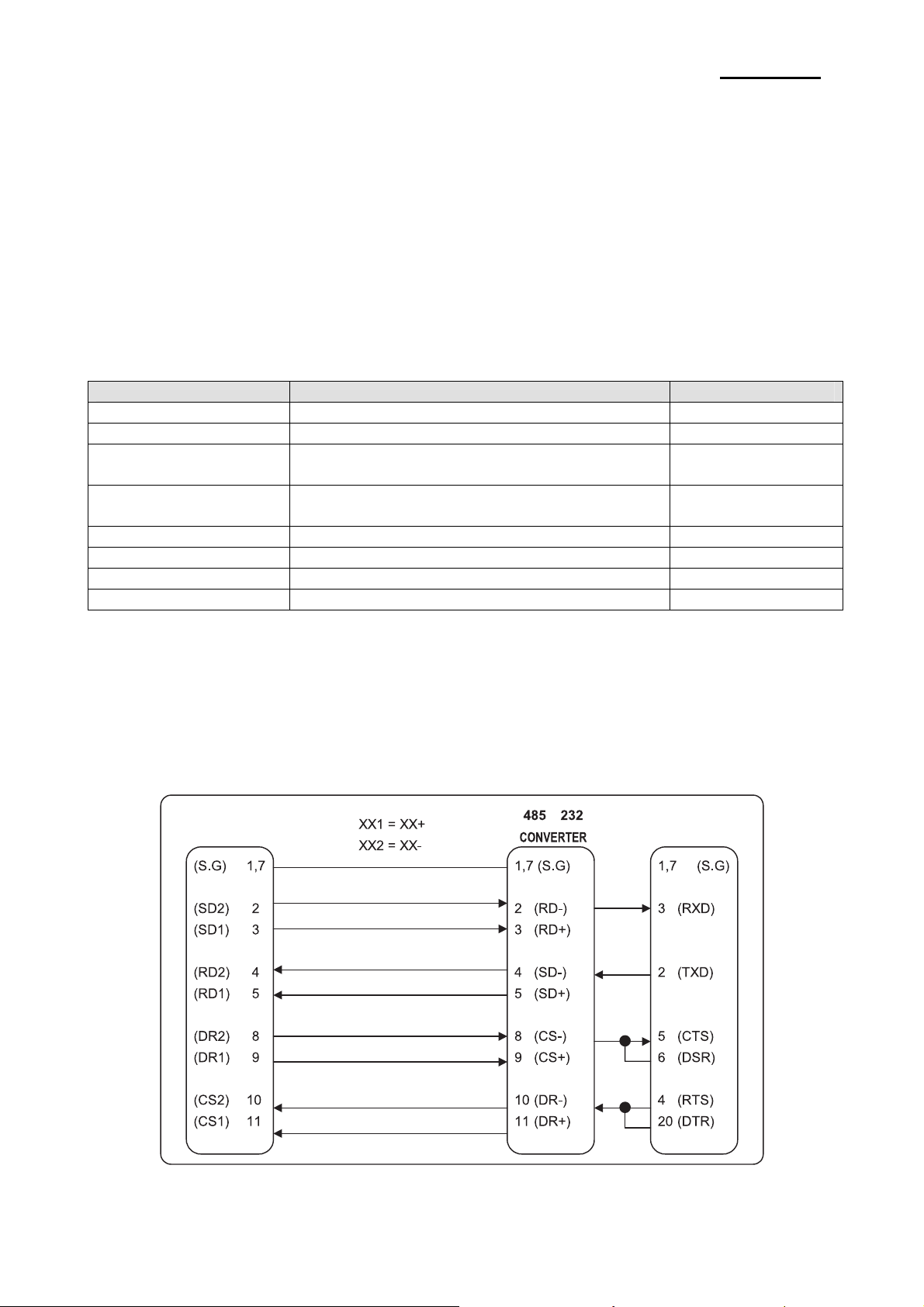

3-5-2(c) Cable Connection

• H/W : DTR / CTS (Same as DSR)

• S/W : XON / XOFF

• Logic”1” : SD1-SD2 ≥ 0.2V, RD1-RD2 ≥ 0.2V

• Logic”0” : SD1-SD2 ≤ 0.2V, RD1-RD2 ≤ 0.2V

Table 3-16 RS-485 Specification

XON: ASC Code 11h

XOFF: ASC Code 13h

Rev. 3.02

PRINTER

SIDE

Figure 3-8 RS-485 Cable Connection

- 24 -

HOST

SIDE

Page 25

SRP-270

3-5-2(d) Signal Description

Pin No. Signal name Direction Function

1 Frame GND - Frame Ground

2 SD2 Output

3 SD1 Output

4 RD2 Input

5

7 SGND - Signal Ground

8

9

10

11

※ Note : BUSY condition and other information refer to the User’s Manual.

※ Note : This format is used when the UART for RS-232C is connected to the RS-485 driver.

3-5-2(e) H/W Flow Control

When DR1,2/CR1,2 flow control is select, before transmitting a data, the Printer checks whether the host is

BUSY or not. If the host is BUSY, the Printer does not transmit a data to the host. If the host is not BUSY, the

Printer transmits a data to the Host. The host is the same. Refer to the Interface Part of Chapter 4-3 Special

Circuit Diagrams.

3-5-2(f) S/W Flow Control

When XON/XOFF flow control is selected, the printer transmits XON(ACSII 11h) or XOFF(ASCII 13h) signal

through the TXD line. If the Printer is BUSY, the Printer transmits XOFF(ASCII 13h) to host through the TXD

line. Then the host recognize that the Printer is BUSY. So, the host does not transmit a data to the Printer. If

the Printer is released from BUSY, the Printer transmits XON(ASCII 11h) to host through the TXD line. Then

the host recognize that the Printer is not BUSY. And the host transmit a data to the Printer.

※ Note : Refer to the Operation Manual about XON/XOFF flow control.

3-5-3 IEEE1284 Parallel Interface

Bidirectional parallel interface : in accordance with the IEEE1284 Nibble/Byte mode.

3-5-3(a) Forward Mode Specification (Compatibility mode)

Data transmission from host computer to printer : Centronics compatiable

Data Transmission • 8-bit Parallel

Synchronization • External supplied nStrobe signals

HandShaking • nACK and Busy signals

Signal Level • TTL compatiable

Connector • Centronics 36P

RD1 Input

DR2

DR1

CS2

CS1

Item Description Remark

Output

Input

Send Data

”H” : SD1 > SD2 , “L” : SD1 < SD2

Receive Data

”H” : RD1 > RD2 (RD1-RD2 ≥ 0.2V)

“L” : RD1 < RD2 (RD1-RD2 ≤ 0.2V)

When DTR/DSR is selected, this signal indicates whether the printer is

BUSY or READY. (H/W flow control)

1) DR1 > DR2 (H) : The printer is BUSY.

2) DR1 < DR2 (H) : The printer is READY.

3) The host computer transmits a data to the host,

after confirming this signal.

When DTR/DSR is selected, this signal indicates whether the host

computer is BUSY or READY. (H/W flow control)

1) CS1 > CS2 (H) : The host computer is BUSY.

2) CS1 < CS2 (H) : The host computer is READY.

3) The printer transmits a data to the host, after confirming this signal.

Table 3-17 RS-485 Pin Description

Table 3-18 IEEE1284 Specification

Rev. 3.02

- 25 -

Page 26

SRP-270

3-5-3(b) Reverse Mode Specification (Nibble / Byte mode)

Data transmission from the printer to the host computer.

The STATUS data transmission from the printer to the host computer is accomplished in the Nibble or Byte

mode. This mode allows data transmission from the asynchronous printer under the control of the host

computer. Data transmission in the Nibble mode are made via the existing control lines in units of for bits

(Nibble). In the Byte mode, data transmission in accomplished by making the 8-bit data lines bidirectional.

Neither mode can operate at the same time as the compatibility mode, so switching is always required.

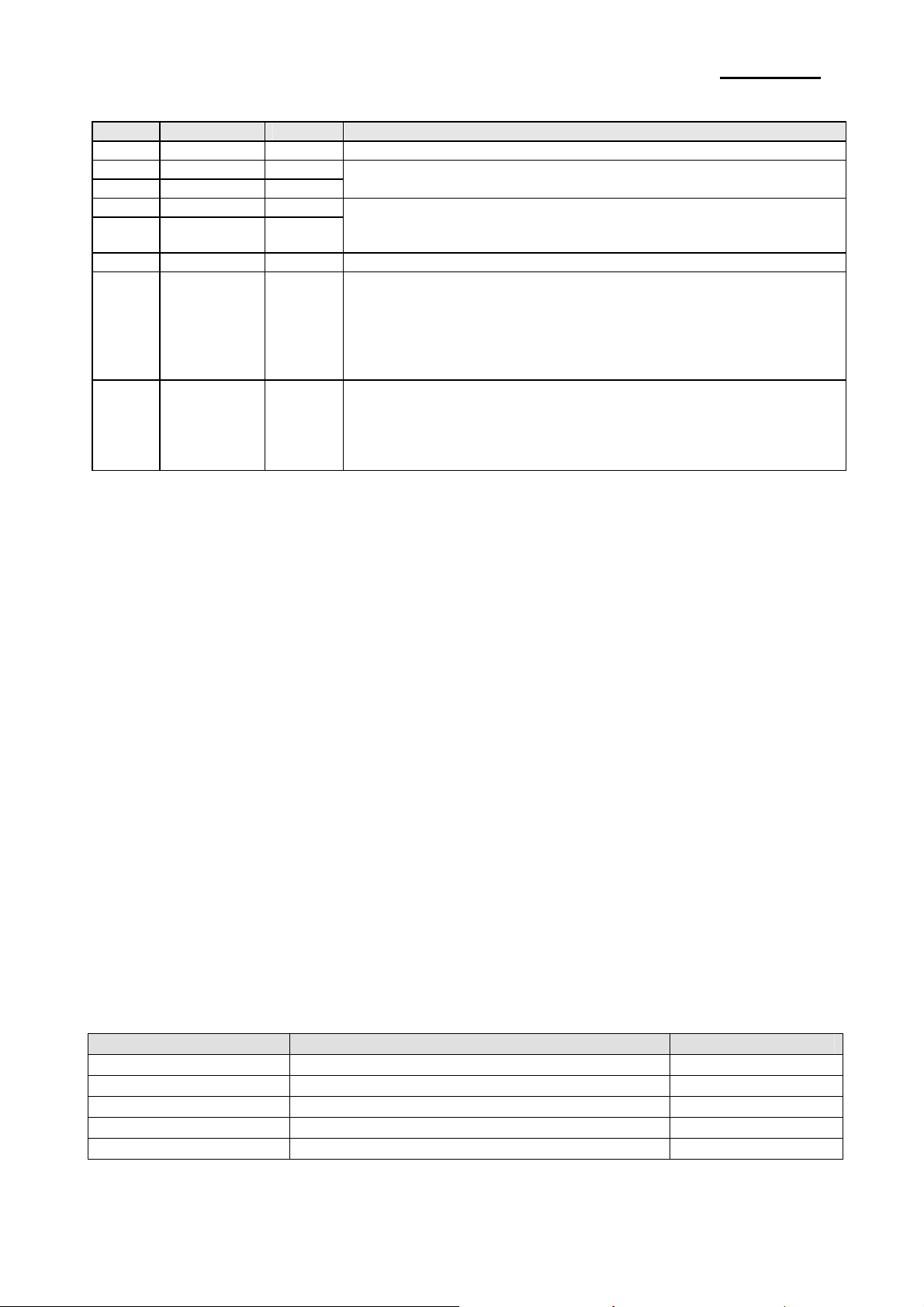

3-5-3(c) Signal Specification (Compatibility/Nibble/Byte mode)

Pin No. Source Compatibility Mode Nibble Mode Byte Mode

1 Host nStrobe HostClk HostClk

2 Host / Printer Data 0 (LSB) - Data 0 (LSB)

3 Host / Printer Data 1 - Data 1

4 Host / Printer Data 2 - Data 2

5 Host / Printer Data 3 - Data 3

6 Host / Printer Data 4 - Data 4

7 Host / Printer Data 5 - Data 5

8 Host / Printer Data 6 - Data 6

9 Host / Printer Data 7 (MSB) - Data 7 (MSB)

10 Printer nAck PtrClk PtrClk

11 Printer Busy PtrBusy/Data3,7 PtrBusy

12 Printer Perror AckDataReq /Data2,6 AckDataReq

13 Printer Select Xflag/Data1,5 Xflag

14 Host nAutoFeed HostBusy HostBusy

15 NC ND ND

16 GND GND GND

17 FG FG FG

18 Printer Logic-H Logic-H Logic-H

19~30 GND GND GND

31 Host nlnit nInit nlnit

32 Printer nFault nDataAvail /Data0,4 nDataAvail

33 GND ND ND

34 Printer DK_Status ND ND

35 Printer +5V ND ND

36 Host nSelectln 1284-Active 1284-Active

Table 3-19 IEEE1284 Pin Description

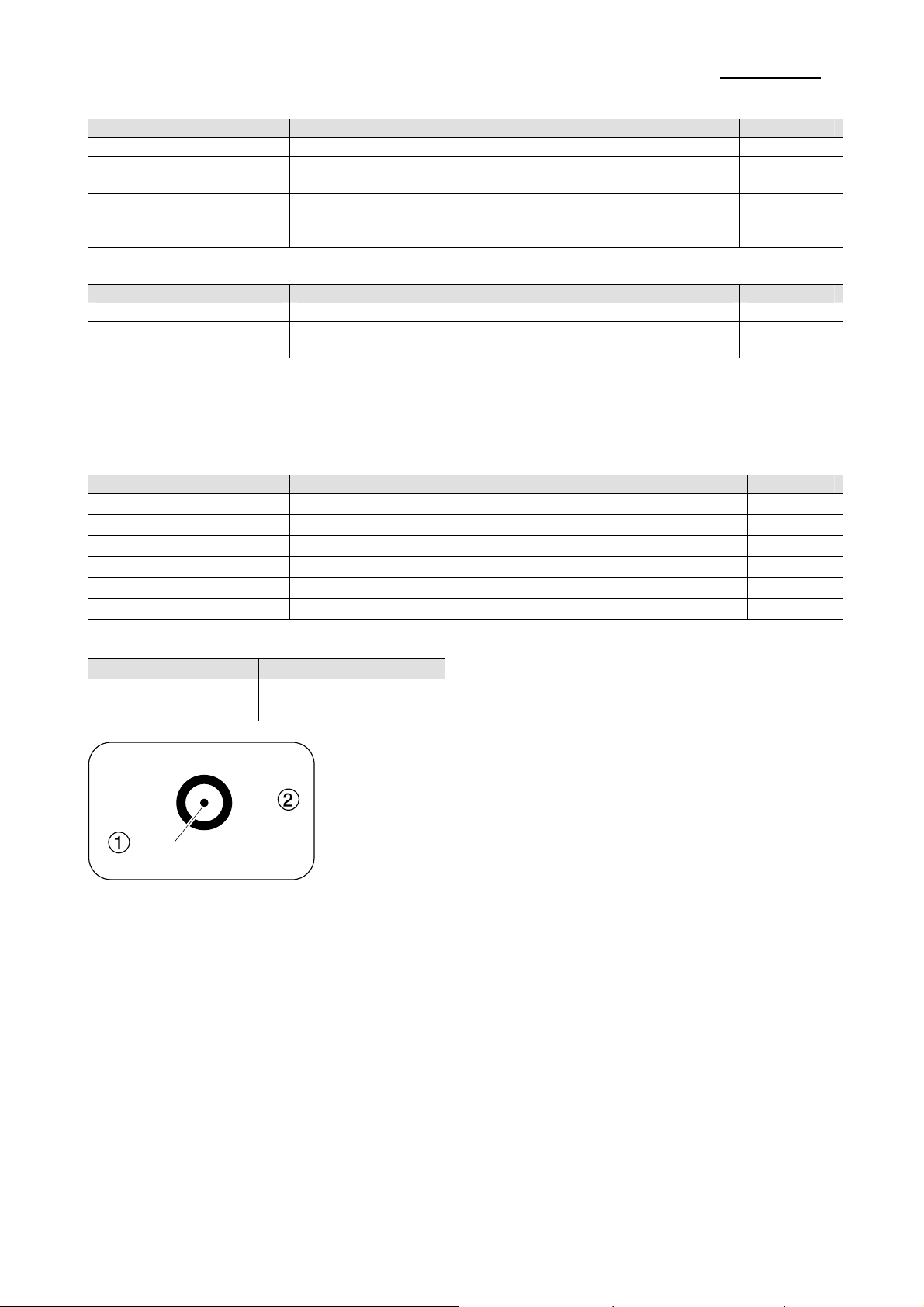

3-5-3(c) IEEE1284 I/F Cable

Rev. 3.02

Host

Side

Printer Centronics

Side 36P

Figure 3-9 IEEE1284 Cable

- 26 -

Page 27

SRP-270

3-5-4 USB2.0 Interface

SRP-270 support the USB (Universal Serial Bus) Serial Communication.

3-5-4(a) Specification

Item Description Remark

Transfer Type • BULK

Data Signal

Data Format

Transceiver

Speed • 12 Mbps

Power • Self-Powered

Cable & Connector

Other • Support USB SPEC V1.1

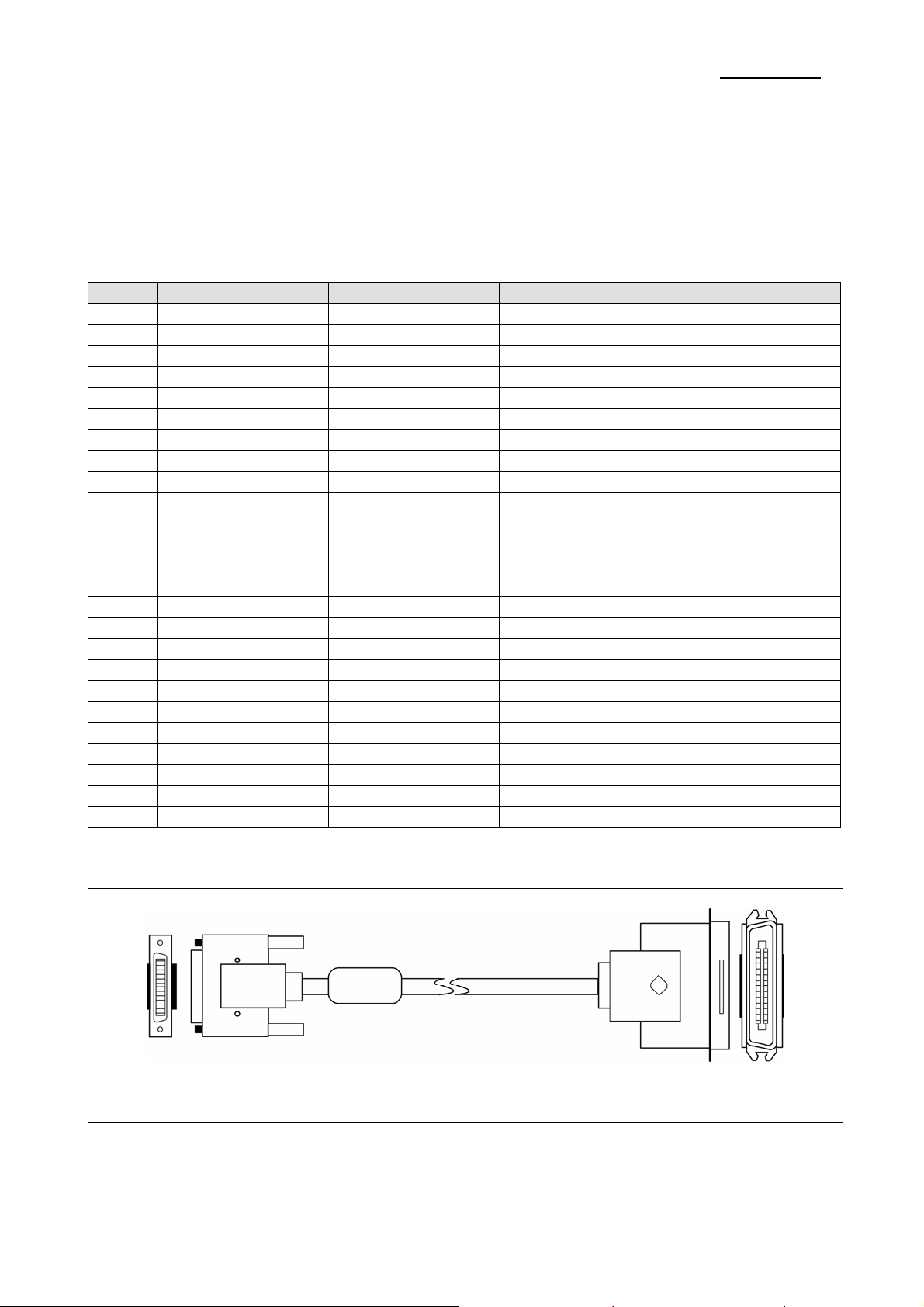

3-5-4(b) Signal Description

Pin No. Signal Name Assignment(Color) Function

Shell Shield Drain Wire Frame Ground

1 VBUS Red Host Power : DC5[V] / 500[mA]

2 D- White Differential Data Line

3 D+ Green Differential Data Line

4 GND Black Signal Ground

3-5-4(c) USB I/F Cable

• Bi-direction, Half-Duplex

• Differential Signal Pair (D+ / D-)

• NRZI Format

• Zero Bit Stuffing after 6 ones

• Differential Receive Sensitivity : 200[mV]

• Differential common Mode Range : 0.8 ~ 2.5[V]

• Single-End Receiver Threshold : 0.8 ~ 2.0[V]

• Cable : 5m / 2m

• Connector : B Type

Table 3-20 USB Specification

Table 3-21 USB Pin Description

Rev. 3.02

Figure 3-10 USB A-B Type Cable

- 27 -

Page 28

SRP-270

3-6 Cash Drawer Specifications

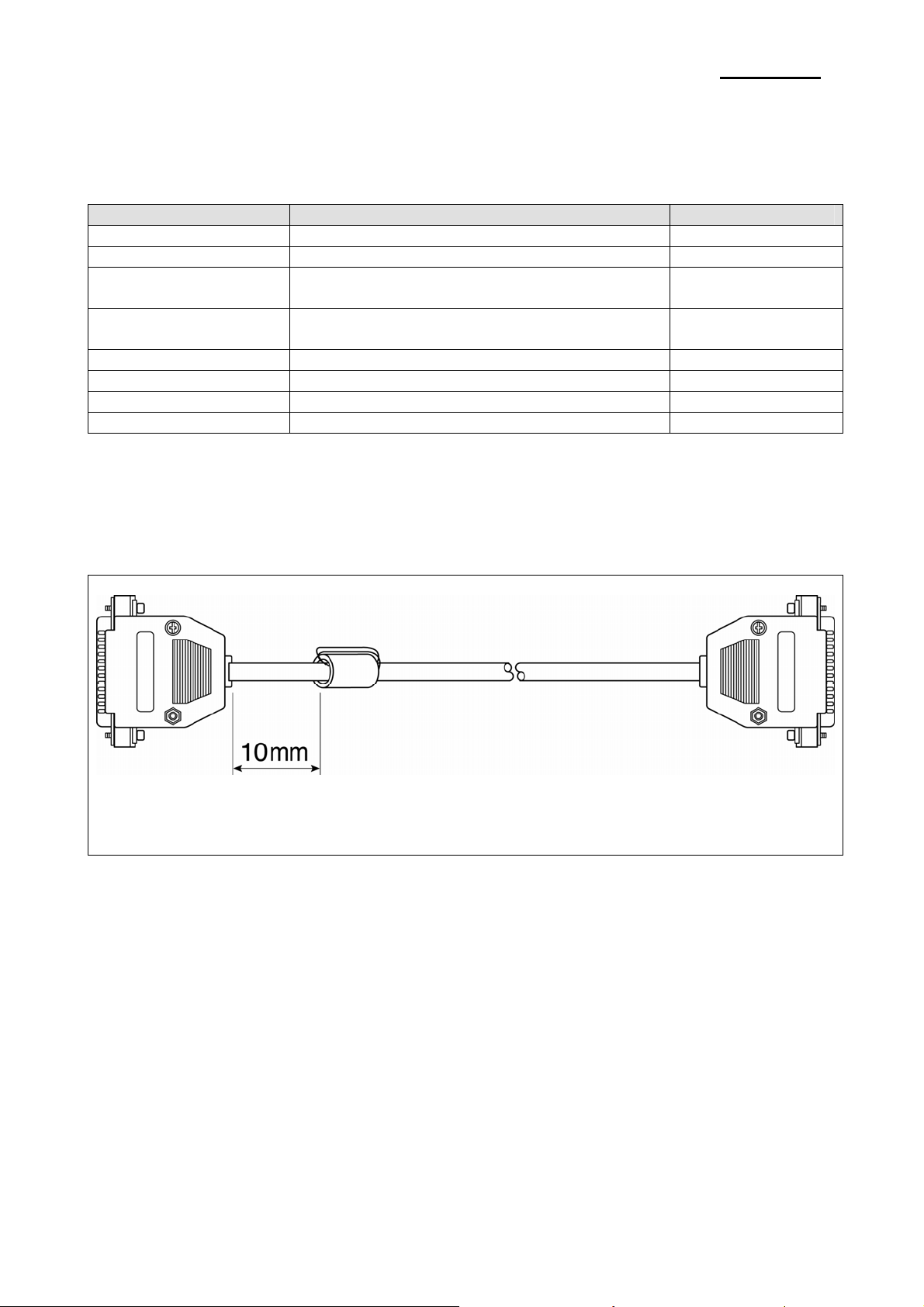

3-6-1 Cash Drawer Cable

Ferrite Core : 1 turn (OP-18E : 18.2 x 12.5 x 25.5)

Figure 3-12 Cash Drawer Cable

3-6-2 Cable Connection

Pin No. Description Direction

1 Frame GND 2 Cash Drawer Driver Signal #1 Output

3 Drawer Open / Close Signal Input

4 +24V 5 Cash Drawer Driver Signal #2 Output

6 Signal GND -

Table 3-23 Cash Drawer Cable Connection

※ Note : +24V is always output through pin 4 during power on.

Rev. 3.02

- 28 -

Page 29

4. Hardware

4-1 Wiring Diagram

SRP-270

Rev. 3.02

[Figure 4-1 Board Wiring Diagram]

- 29 -

Page 30

4-2 Block Diagram

SRP-270

Rev. 3.02

[Figure 4-2 Block Diagram]

- 30 -

Page 31

SRP-270

4-3 Special Circuit Descriptions

4-3-1 Power Circuit

This system is operated under 110Vac or 230Vac. The power circuit supplies the three differential DC voltage

sources.

[Figure 4-3 Power Block Diagram]

No. VOLTAGE DESCRIPTION

1 +24VDC Cash Drawer Solenoid Driving / Step Motor Voltage

2 +5VDC Logic IC Driving Voltage / Sensor

1) Drawer Driving and Feed, Auto Cutter Motor Voltage : +24Vdc

+24VDC is supplied from SMPS. This Voltage is smoothed by capacitors (C1,6,39).

This voltage is used as a Printer Head, Printer Motor, Cash Drawer Solenoid Driving voltage and a source

voltage of the +5V voltage sources.

2) Logic IC Driving Voltage: +5V

+5Vdc Logic driving voltage is produced by the step-down dc-dc converter U1(34063A). That is, U1 produces

rectangular wave. This makes D2 (EK04) and L6 store energy. The voltage is smoothed by C8 (470uF) and

then +5Vdc Logic voltage is produced.

Rev. 3.02

- 31 -

Page 32

SRP-270

4-3-2 RESET Circuit

Reset signal is a signal in order to start-up CPU under Power-on. Reset circuit uses a reset ICTL7705ACD

(U5). When +5Vdc is fallen under 4.3Vdc by Power-off, reset signal prohibits the system from misoperating

by lowering down to 0V.

[Figure 4-4 Reset Block Diagram]

5ms

[Figure 4-5 Reset Waveform]

Rev. 3.02

- 32 -

Page 33

SRP-270

4-3-3 Cash Drawer Circuits

The circuit is used for opening cash drawer and driven by the Q8 (STA471). When its state is high level

signal, Q8 (STA471) drive the solenoid to open the cash drawer. As an optional item, we provide sensor

switch (we call it a compulsory switch) which checks the drawer whether it is opened or not. This sensor

switch turns on for the drawer open condition, and turns off for the other.

Caution: make sure that the Cash Drawer solenoid resistance is more than 20Ω.※

[Figure 4-6 Cash Drawer Block Diagram]

Rev. 3.02

- 33 -

Page 34

SRP-270

4-3-4 I/F PBA Detect Block Diagram

When the printer is ON, the printer checks what kind of the I/F PBA is installed. After detection, the CPU

specify the I/O port properly. The following is the method of I/F PBA detection.

First, The CPU sends a “I/F Sel “ signal (P7.3) to I/F PBA. The I/F PBA has the three return Signal

(DIPC1~C3).

The CPU recognize the I/F PBA by the value of the three return signal.

I/F PBA DIP_C1 DIP_C2 DIP_C3

RS-232C L L H

RS-485 L H L

IEEE1284 H L L

USB2.0 H H L

No Connection L L L

Rev. 3.02

- 34 -

Page 35

SRP-270

4-3-5 RS-232C Communication Block Diagram

The CPU is used for serial communication.

And also RS-232C Driver (MAX232), is used to serial communication.

Show following block diagram.

M30622SFP

[Figure 4-8 RS-232C Communication Block Diagram]

Rev. 3.02

[Figure 4-9 RS-232C Communication Waveform]

- 35 -

Page 36

SRP-270

4-3-6 RS-485 Communication Block Diagram

The CPU is used for serial communication.

And also RS-485 Driver (MAX488), is used to serial communication.

Show following block diagram.

M30622SFP

[Figure 4-10 RS-485 Communication Block Diagram]

Rev. 3.02

[Figure 4-11 RS-485 Communication Waveform]

- 36 -

Page 37

SRP-270

4-3-7 Parallel Communication Block Diagram

The printer support the bidirectional Parallel Interface with Centronics, Nibble, Byte Mode.

The Centronics is Forward and the Nibble, Byte are reverse Mode.

M30622SFP

[Figure 4-10 IEEE1284 Communication Block Diagram]

4-3-8 USB Communication Block Diagram

The printer support the USB (Universal Serial Bus). The transfer type of the printer is the BULK.

USBN9602

M30622SFP

48[MHz]

Rev. 3.02

[Figure 4-11 USB2.0 Communication Block Diagram]

- 37 -

Page 38

SRP-270

4-3-9 DIP Switch Circuit

The key Board Circuit consist of the scan signal of 4 lines and the return signal of 4-line. The CPU sends

repeatedly and continuously the scan data R1, 2, 3, 5 through P10.0~10.2, P1.1. The DIP S/W information

input in the return signal if the specific DIP S/W is ON Status during the given time. The CPU reads the data

through C1~C4 and analyzes what DIP S/W is ON and performs the selected function.

M30622SFP

R1~R3,R5

DIODE(MMBD6050L)

R5

[Figure 4-12 DIP Switch Block Diagram]

R5

Rev. 3.02

- 38 -

Page 39

SRP-270

5. Disassembly and Assembly

5-1 General Precautions on Disassembly

This chapter describes the Disassembly and Reassembly procedures for the Printer of SRP-270 Series.

This Printer contains electronically sensitive device. Use caution when handling any component.

Whenever servicing the machine, you must perform as follows:

1. Disconnect the DC power jack of Adapter from the Printer before Disassembling.

2. Use a flat and clean surface.

3. Replace only with authorized components.

4. Do not force to remove plastic-material components.

5. Make sure all components are in their proper position.

5-2 Plate Bottom

1. Remove four screws securing the Plate Bottom.

Separate the Plate Bottom from the Lower Case.

3. Unplug Auto Cutter wire and FPC Cable from

the Main PCB.

2. If you want to remove the PCB Cover, remove

screw securing, as shown below.

Rev. 3.02

- 39 -

Page 40

5-3 Cover Assy (SRP-270D Type)

1. Open the Cover Assy and take out the Spool

Winding, as shown below.

SRP-270

2. Push the locking lib to the direction of arrow

and remove the Cover Assy, as shown below.

5-4 Cover Assy (SRP-270A & SRP-270C Type)

1. Open the Cover Assy. 2. Pull the Cover Assy upward and remove it.

Rev. 3.02

- 40 -

Page 41

SRP-270

5-5 Case Upper Assy (SRP-270A & SRP-270C Type)

1. Open the cover Assy. 3. Separate the Case Upper from the Case

Lower.

2. Remove four screws.

Rev. 3.02

- 41 -

Page 42

5-6 Case Upper Assy (SRP-270D Type)

1. Push the locking lib to the direction of arrow and

remove the Cover Assy, as shown below.

SRP-270

2. Remove four screws securing the Case Upper.

Separate the Case Upper from the Case Lower.

5-7 Printer Assy (SRP-270A & SRP-270C Type)

1. Before you disassembly the Printer

Assy, you should remove :

- Plate Bottom (see Chapter 4-2)

- Cover Assy (see Chapter 4-3 & 4-4)

- Case Upper Assy (see Chapter 4-6)

2. Remove two screws securing the Printer Assy.

Separate the Printer Assy from the Case Lower.

Rev. 3.02

- 42 -

Page 43

5-8 Printer Assy (SRP-270D Type)

1. Before you disassembly the Printer Assy, you

should remove :

- Plate Bottom (see Chapter 4-2)

- Cover Assy (see Chapter 4-3 & 4-4)

- Case Upper Assy (see Chapter 4-6)

2. Remove the Spool Gear and Belt, as shown

below.(SRP-270D Type)

SRP-270

3. Remove two screws securing the Printer Assy.

Separate the Printer Assy from the Case Lower.

5-9 Auto Cutter Assy

1. Before you disassembly the Auto Cutter Assy, you

should remove :

- Plate Bottom (see Chapter 4-2)

- Cover Assy (see Chapter 4-3 & 4-4)

- Case Upper Assy (see Chapter 4-6)

- Printer Assy (see Chapter 4-7 & 4-8)

2. Remove two screws securing the Auto Cutter

Assy. Separate the Auto Cutter Assy from the

Printer Assy, as shown below.

Rev. 3.02

3. Before you reassembly the Auto Cutter Assy,

you should set up the Belt and Hinge.

- 43 -

Page 44

5-10 Main PCB

1. Before you disassembly the Main PCB,

you should remove :

- Plate Bottom (see Chapter 4-2)

- Cover Assy (see Chapter 4-3 & 4-4)

- Case Upper Assy (see Chapter 4-6)

- Printer Assy (see Chapter 4-7 & 4-8)

SRP-270

2. Remove four screws securing the Main PCB.

Separate the Main PCB from the Main Frame.

5-11 Interface Board Assy

1. Before you disassembly the Interface Board Assy, you should remove :

- Plate Bottom (see Chapter 4-2)

- Cover Assy (see Chapter 4-3 & 4-4)

- Case Upper Assy (see Chapter 4-6)

- Printer Assy (see Chapter 4-7& 4-8)

2. Remove two screws and take out the Interface Board Assy, as shown below.

Rev. 3.02

- 44 -

Page 45

SRP-270

6. Alignment and Adjustments

6-1 Printer Adjustment

When assembling this printer, be sure to refer to the required adjustment procedure.

To ensure normal operation of the printer after disassembly or replacement of a Component for maintenance

or repair. Be sure to perform along to the required method.

* Adjustment of Head gap

Adjustment

Step

1

2

• Rotate Gear lst Reduction to move the Head unit

to L side.

• Insert the thickness gauge between Head unit and

Platen, then rotate the Ad.

Level L and adjust the gap.

3

4

Follow below steps for replacing Head unit

1. Loosen the Ribbon frame

2. Disassemble the Head unit from the Head Carriage and take out the Head FPC from the connector of

PCB Assy.

4. Replace the Head unit and assemble, according to the order of sub Aassy-1

5. After assembling, adjust the gap as above “Adjustment” indicates.

6. Assemble the Ribbon Frame.

• Move the Head unit then check if the proper

gap from R side center has been achieved.

• If Head gap is not proper, adjust Head gap by

rotating Ad.Lever R.

Description Points in Adjustment

- Appropriate gap: 0.50~0.60mm

- In order to make the gap narrow

(wide), turn Ad.

Lever to mark ’-(+)’

- If gap is not correct, repeat once

more.

(Replacement of Head unit)

Rev. 3.02

- 45 -

Page 46

7. Troubleshooting

7-1 Power Problem

• Check the Power Out on SMPS.

• Check the Fuse.

• Check the related Pattern.

• Check the IC34063.

7-2 System Problem

• Check the Reset part (IC & Pattern)

• Check the Clock on FS741 (14.7456MHz)

• Check the Adr/Data line Pattern

7-3 Printer Problem

• Check the Feed Motor Signal on CPU

• Check the Feed Motor Block on PCB (STA471, Step Motor Connection)

• Check the Carriage Motor Signal on CPU

• Check the Carriage Motor Block on PCB (STA471, Step Motor Connection)

• Check the Ribbon Select Signal on 74HCT574 (U22)

• Check the Ribbon Block on PCB (STA471, Connection)

• Check the Auto Cutter Signal on 74HCT574 (U22)

• Check the Auto Cutter Block on PCB (TA8428K, Connection)

• Check the Near-End, Home Sensing Signal on Main PBA.

• Check the Sensing Block. (Sensor, Harness)

• Check the Head Trigger Signal, Head Signal on CPU.

• Check Dot Printing Block on Main PBA. (STA471, 74HCT05, Connection)

7-4 Cash Drawer Problem

• Check the Drawer Connector & Harness.

• Check the Drawer Signals on 74HCT574.

• Check the Drawer Block on Main PBA (STA471, Connection).

7-5 DIP S/W Problem

• Check the Output Signal (DIP R1~4)

• Check the Diode.

• Check the Input Signal (DIP C1~C4)

• Check the related Circuit & Pattern

7-6 RS232 Problem

• Check the connection of the RS-232C CONN and Other side.

• Check the I/F Cable whether it is open or short.

• Check the Txd, Rxd Pin on CPU.

• Check the MAX232 Driving Chip and related Circuit on I/F PBA.

• Check the connection of the H/W handshaking Line and Other side (DTR/DSR)

7-7 RS485 Problem

• Check the connection of the RS-485 Connector and Other side.

• Check the I/F Cable whether it is open or short.

• Check the TXD, RXD Pin on CPU.

• Check the MAX488 Driving Chip and related Circuit on I/F PBA.

• Check the connection of the H/W handshaking Line and Other side (DR1,2/CS1,2)

• Check the Voltage Level of each Line.

SRP-270

Rev. 3.02

- 46 -

Page 47

7-8 IEEE 1284 Problem

• Check the Control Line (CS3, WR, RD).

• Check the 1284 Control Line and Status Line.

• Check the Signal of ICs (U3, U6, U5)

• Check the related Circuit and Pattern on I/F PBA.

• Check the 1284 Control, Status Data Line.

7-9 USB Problem

• Check the Control Line & Signal. (CS3, RD, WR, INT)

• Check the Data Line & Signal.

• Check the Connector (34P)

• Check the Clock (48MHz)

• Check the related Circuit and Pattern on I/F PBA & Main PBA.

• Check the D+ whether it is Pull up to V3.3.

• Check the USB Cable whether it is open or short.

SRP-270

Rev. 3.02

- 47 -

Page 48

8. Appendix (Spec of SMP-710/710N)

8-1 Specifications

8-1-1 Printing specifications

Item Description

Printing method serial impart dot-matrix

Head wire configuration 9-pin serial type

SRP-270

Dot pitch 0.352mm(1/72")

Dot wire diameter 0.3mm(0.01")

Printing direction Bidirectional with logic seeking

Printing width 63.5mm(2.5")

Line feed 4.233mm(1/6") (default setting)

Paper feed method Friction feed

Paper feed speed Approximately 6.2 inches/second (during continuous paper feeding)

Characters per line See the table on the next page

Characters per inch See the table on the next page

Total dot count

(horizontal direction)

Print speed

NOTE: If the print duty ratio is too high, the operation of the print※ head is stopped by the duty limit.

In such circumstances, the print speeds shown above cannot be guaranteed.

cpi=characters per inch.

7×9 font (400 half-dot positions per line)

9×9 font (400 half-dot positions per line)

Approximately 4.6 lines/second (40 columns, 16cpi)

Approximately 8.4 lines/second (16 columns, 16cpi)

Rev. 3.02

- 48 -

Page 49

SRP-270

8-1-2 Character specifications

8-1-2-1 Character sets

Item Description

Alphanumeric 95

International 32

Graphics 128×7 pages

8-1-2-2 Character structure

* 7×9 with 400 half-dot positions per line.

* 9×9 with 400 half-dot positions per line.

Character structure

Horizontal × Vertical

7 × 9

9 × 9

7 × 9

9 × 9

NOTE: The default font is 7×9; the dot spacing between characters is either 3 half dots or 2 half ※

dots, depending on programming.

Character

structure

Character Set

ANK

Graphics

ANK

Graphics

ANK

Graphics

ANK

Graphics

Character

Dimensions

W x H

1.2×3.1 mm

(.047×.122")

1.7×3.1 mm

(.070××.122")

1.6×3.1 mm

(.063×.122")

2.0×3.1 mm

(.079×.122")

1.2×3.1 mm

(.047×.122")

1.6×3.1 mm

(.063×.122")

1.6×3.1 mm

(.063×.122")

1.9×3.1 mm

(.075×.122")

Dot spacing

Between

Characters

3 half dots 40 16

0 40 16

3 half dots 33 13.3

0 33 13.3

2half dots 42 17.8

0 42 17.8

2half dots 35 14.5

0 35 14.5

Characters Per

Line (cpi)

Characters Per

Inch (cpi)

Rev. 3.02

- 49 -

Page 50

SRP-270

8-1-3 Paper specifications

Item Description

Paper types Paper roll: Platen paper or pressure-sensitive paper

Paper roll width 76±0.5mm (2.99±0.20")

Paper roll maximum diameter Ø83mm(3.27")

Paper roll core

Normal paper

Pressure-sensitive paper

Unless there is an optional near-end detector, you cannot use a paper roll

with the core and paper glued together.

Thickness: 1 sheet: 0.06 to 0.085 mm(.0024 to.0034")

Weight: 52.3 to64g/m2(13.9 to 171b) (45 to 55kg/1000 sheets/1091×788)

Original sheet + up to 1 copy sheet

1 sheet thickness: 0.05 to 0.08mm(.0020to.0031")

Total thickness: 0.2mm(.0078")or less

(*1) This dimension shows the distance from the manual cutter to the print position.

(*2) Values for the printing area are calculated (between dot centers) with the wire diameter{0.29mm(.011")}

Rev. 3.02

- 50 -

Page 51

SRP-270

8-1-4 Ribbon Cassette specifications

Compatible Model Color Ribbon life ("1)

ERC-38 (B) Black 3 million characters {with continuous printing at 25 (77°F)}℃

ERC-38 (B/R) Black and Red

("1) Ribbon life is based on the following conditions:

Character font: 7×9 font (with descenders)

Print pattern: ASCII 96-character rolling pattern. See the specification published by SMP-710/710N

for the print pattern example.

NOTE: Malfunctions and other problems may occur if a ribbon cassette other than the specified ※

one is used.

8-1-5 Environmental specifications

Item Description

Temperature

Black: 1.5million characters {with continuous printing at 25 (77°F)}℃

Red: 750,000 characters {with continuous printing at 25 (77°F)}℃

Operating: 0°to 40 (32°to 1℃ 04°F)

At 34 (93°F)or higher, there are humidity restrictions;℃

See the figure below.

Storage: -5°to 50 (℃ 23°to 122°F), except paper and ribbon

Operating: 30% to 80% RH(non-condensing)

Storage: 10% to 90% RH(non-condensing),except paper and ribbon

Humidity

Vibration resistance

Impact resistance

* When packed

Frequency: 5 to 55Hz

Acceleration: 5G

Sweep: 10 minutes (half cycle)

Duration: 1 hour

Directions: x, y and z

* When packed

Package: SMP-710/710N standard package

Height: 60cm(23.62")

Directions: 1 corner, 3 edges, and 6 surfaces

* When unpacked

Height: 5cm(1.97")

Directions: Lift one edge and release it(for all 4 edges)

Rev. 3.02

- 51 -

Page 52

SRP-270

8-1-6 Reliability

Item Description

MCBF

8-1-7 Main Unit specifications

Paper

Feed

Motor

This is an average failure interval based on failures relating to wear out and random failures up

to the life of 18 million lines.

Item Description

Type 4-phase, 48-polarity, PM-type stepping motor

Drive voltage 24 VDC±10%

Winding resistance 10Ω±1Ω at 25 (77°F), per phase℃

Current consumption Average: 400mA at 24 VDC, 25 (77°F), 570mA maximum℃

Carriage

Motor

Print

Head

Unit

Home

Position

Sensor

Type 4-phase, 48-polarity, PM-type stepping motor

Drive voltage 24 VDC±10%

Winding resistance 10Ω±1Ω at 25 (77°F), per phase℃

Current consumption

Number of solenoids 9

Winding resistance 9.5Ω±10% at 25 (77°F), per phase℃

Drive voltage 24 VDC±10%

Type Photo sensor

Voltage 5 VDC±5%

Output level LOW when the carriage home position is detected.

Peak: 1.5 A in maximum

Average: 400mA at 24 VDC, 25 (77°F), 570mA maximum℃

Rev. 3.02

- 52 -

Page 53

SRP-270

8-1-8 Electrical specifications

8-1-8-1 The explanations of the circuit operations

1) Head Carriage Step Motor

- It rotates and moves the Dot Head by using the several gears and synchronous belt

- Print Speed : 4.6 Line/Sec

- This step motor is control by constant current method.

So, current flows two red line of step motor is Max.560㎃

- This step motor is control by SMA7029M (Recommended)

2) Paper Feed Step Motor

- It is used when the paper is fed.

- The characteristics of step motor is as same as head carriage step motor

3) Home Sensor

- It detects the head position

- It decides the start point of printing

4) Solenoid

- It plays part in exchanging printing color (red → black)

5) Head

-It plays part in printing a character (Axiohn Co.)

8-1-8-2 Circuit Block Diagram

8-1-9 Mechanisms specifications

This printer consists of 5 mechanisms;

Head feeding Mechanism. Printing Mechanism. Paper Feeding Mechanism. Detector Mechanism, Ribbon

Mechanism. How is the external view of SMP-710/710N Impact dot matrix printer

as shown. For details on the

operating principles and handling of each of the mechanisms, refer to "Principle of Movement" in section 8-110 and "Handling, Maintenance and Repair" in 8-2.

Rev. 3.02

- 53 -

Page 54

SRP-270

8-1-10 Principle of Movement

8-1-10-1 Head Feeding Mechanism

This printer is using DC24V PM Type Stepping motor.

As shown in figure the motor section consists of the motor. Motor speed control IC, motor drive/brake circuit

and motor speed interface.

When the carriage motor is driven and the carriage motor gear is moved in the direction of arrow B(forward

rotation), the rotational power is conveyed to the belt drive pulley, then the belt. Next the carriage sub

assembly, which is fixed to the belt, moved in the direction of arrow B.

When the carriage motor gear is rotated in the direction of arrow A (reverse rotation), the carriage sub

assembly is moved in the direction of arrow A.

Rev. 3.02

- 54 -

Page 55

SRP-270

8-1-10-2 Printing Mechanism

When the specified print head drive pulse is input to the drive coil, the iron core is magnetized, and the

actuating plate is pulled in the direction of arrow A.

This action pushed the wire toward the platen, When the wire strike s the ink ribbon and paper against the

platen(*), a single dot is printed.

When the energizing of the drive coil is completed, the wire and actuating plate are re turned to the standby

position by the wire return spring and actuating plate spring.

(*)The "platen" is the portion of the base paper feed Assy being struck by the wires during printing.

8-1-10-3 Detection Mechanism

The detection mechanism unit consists of the home position detection, paper detection.

Rev. 3.02

- 55 -

Page 56

SRP-270

8-1-10-4 Home Position Detection Mechanism

The home position detection mechanism consists of the detection protrusion at the left side of the carriage

sub assembly and the sensor sub assembly at the left side of the base frame. It determines the home

position, identifies the carriage position, and detects carriage sub assembly operation errors.

The sensor sub assembly consists of an LED and photo transistor. When the carriage sub assembly moves,

the detection protrusion passes between the LED and photo transistor and blocks the optical axis of the