Page 1

................................................................................................................................

Profinity

™

Epoxide Resin

Instruction Manual

Please read these instructions prior to using Profinity epoxide resin. If

you have any questions or comments regarding these instructions,

please contact your Bio-Rad Laboratories representative.

Page 2

Table of Contents

Section 1 Product Description ................................................1

Section 2 General Considerations for

Ligand Coupling.......................................................3

Section 3 Column Packing.......................................................5

Section 4 Protein Binding and Elution ..................................7

Section 5 Renaturation of Eluted Proteins...........................8

Section 6 Assessing Protein Purity........................................8

Section 7 Regeneration and Storage.....................................9

Section 8 References................................................................9

Section 9 Ordering Information ..............................................9

Page 3

Section 1

UNOsphere

O

OH

NHR (-SR, -OR)

R-NH2, -SH, -OH

UNOsphere

Product Description

Profinity epoxide is an activated macroporous resin for the immobilization of

various ligands of interest. Ligands containing amino, thiol, or hydroxyl groups can

be coupled to Profinity epoxide through an epoxy ring-opening reaction under mild

conditions.

Profinity epoxide is based on Bio-Rad’s proprietary and innovative UNOsphere

™

technology (US patent 6,423,666). Resins made using this technology have

properties of superb mechanical strength, open pore structure, optimized ligand

density, and low, nonspecific binding effects. These unique features of the

UNOsphere base matrix enable ligand-coupled Profinity resin to exhibit excellent

flow properties and to perform separations at very fast flow rates without

compromising protein binding, recovery, or purity. Profinity resin’s open-pore

structure is particularly useful for the purification of large biomolecules.

The base matrix of Profinity epoxide resin is stable across the entire pH range

(1–14) and is compatible with most reagents commonly used in protein

purification, such as denaturing agents, detergents, and reducing agents. It is

amenable to separations under native or denaturing conditions using liquid

chromatographic instrumentation, gravity flow columns, or sample preparation spin

columns.

The resin is supplied dry and is available in 5 g and 25 g quantities.

Note: UNOsphere support, from which Profinity epoxide is derived, was designed

to achieve the highest productivity possible (as measured in grams of target

molecule per operational hour per liter of support). UNOsphere media may be run

at the highest rates and loading capacities while staying within the pressure limits

of the column and chromatography system.

1

Page 4

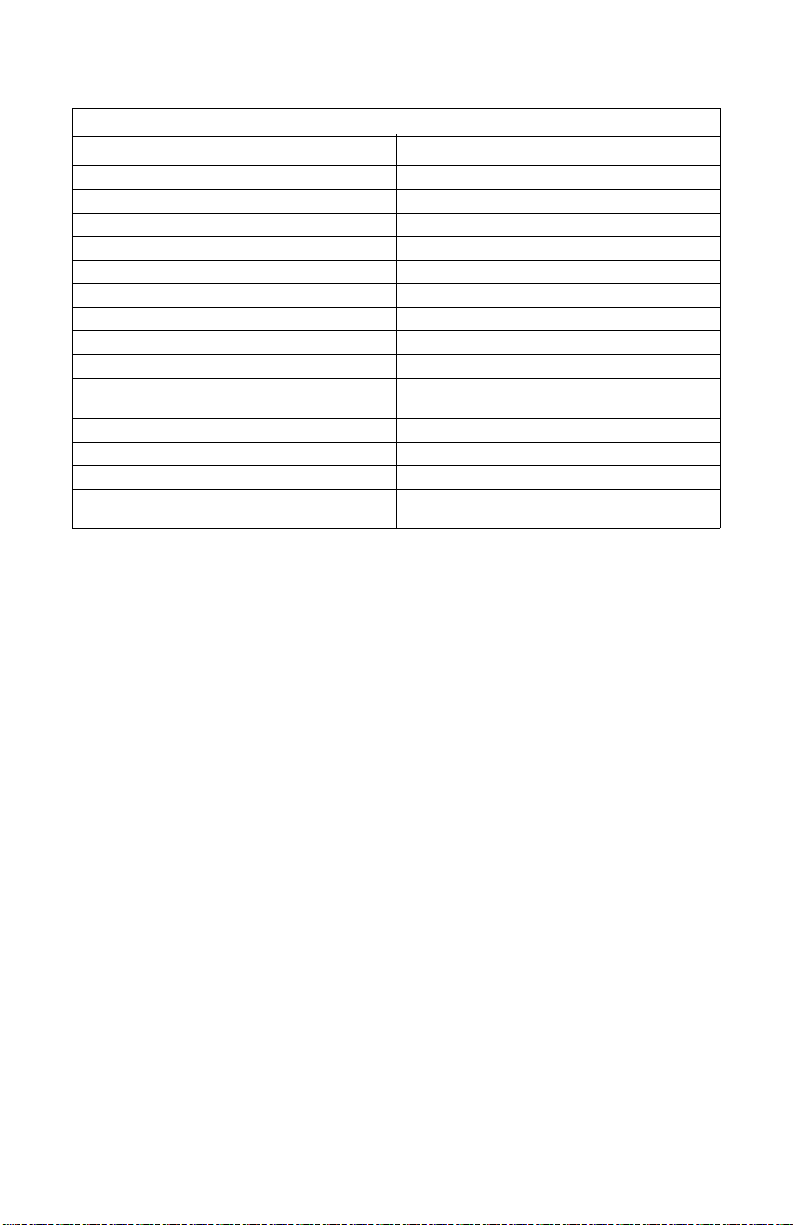

Table 1: Characteristics of Profinity epoxide resin

Profinity epoxide

Functional group Epoxy group

Base matrix UNOsphere base matrix

Form Dry powder

Particle size 45–90 µm

Mean particle size 60 µm

Functional group density 50–132 µmol/g UNOsphere epoxide resin

Swelling factor (ml drained resin/g resin) 5.5–8.0

Recommended linear flow rate <600 cm/hr at 25°C

Maximum operating pressure (net)*

pH stability (base matrix of coupled resin)** 1–14

Chemical compatibility (base matrix

of coupled resin)**

Storage 4°C ambient temperature

Shelf life > 1 year at ambient temperature

Operational temperature 4–40°C

Autoclavability (base matrix

of coupled resin)**

**

Maximum pressure test: Profinity epoxide resin packed in a 1.1 x 30 cm Amicon column to a bed height

of 20 cm with 20 mM sodium phosphate buffer up to 43 psi (3 bar). Flow rates were increased stepwise

to 200 cm/h and held for 2 min at each step. The pressure-low curve for Profinity epoxide becomes

nonlinear at pressures above 80 psi.

****

Refers to base matrix of coupled resin. The stability of coupled ligands may be a limitation of an affinity

resin’s stability.

≥ 80 psi

Compatible with common buffers

and aqueous solutions

0.1 M sodium acetate at 120°C for 30 min

2

Page 5

3

Section 2

General Considerations for Ligand Coupling

Removal of fines

Fine particles in resin may clog the column screen or filter membrane and increase

the column backpressure. Before Profinity epoxide resin is bottled, fines in the

medium have already been removed, so removal of fines is not necessary for most

applications. If necessary for a particular application, the very small amount of

remaining fines may be removed by decanting. Weigh out required amount of dry

resin in a hood (1 g of dry resin gives 5.5–8.0 ml of settled resin bed). Slurry resin

in 3 column volumes (CV) distilled water or buffer by agitation or mixing with a

paddle. Do not use magnetic stirrers, since magnetic stirbars will grind the resin

and more fines will be generated. Let resin settle for 25–40 min, and then carefully

decant the supernatant. The decanting process may be repeated a couple of

times if needed.

General protocols

Profinity epoxide resin can be used for coupling of a variety of ligands, such as

protein A, StrepTactin, subtilisin, and immunoglobulins. Since Profinity epoxide is

based on the UNOsphere platform, it has large pores. The medium’s open pore

structure is particularly useful for coupling large ligands and for purifying large targets. The general ligand coupling protocol is as follows:

1. Weigh out appropriate amount of dry resin (1 g dry resin swells to 5.5–8.0 ml

of settled resin in distilled water or buffers). Swell and wash resin with distilled

water or buffer. Do not use buffers containing Tris, glycine, or thiols since

these nucleophiles will compete with ligands for the resin’s active groups.

Removal of fines is not necessary for most applications. See Removal of fines

above.

2. Add protein ligand (5–20 mg per ml settled resin) to coupling solution. A

buffer: resin ratio of 1:1 to 2:1 is suitable for coupling. Salts such as

ammonium or potassium sulfate may be added to facilitate coupling.

3. Rotate the stoppered vessel containing the ligand and resin at ambient

temperature overnight (avoid using magnetic stirbars for mixing since the

resin’s physical properties will be damaged). Wash away unreacted ligand

using an ample amount of coupling buffer.

4. Collect ligand-coupled resin on a frit. Deactivate or block remaining active

groups by mixing resin cake with 1 M ethanolamine, pH 8–9 for at least

4 hours.

5. Wash the product thoroughly with coupling buffer. Additional wash cycles

alternating acidic and basic buffers are recommended. Each cycle should

consist of a wash of a pH 4.0 buffer (100 mM acetate, 500 mM NaCl)

Page 6

followed by a wash of a pH 8.0 buffer (100 mM phosphate, 500 mM NaCl).

The product can now be used for intended applications or stored in the

presence of a bacteriostat at 4–8°C for future use.

General coupling efficiency considerations

Amount of Ligand Used and Monitoring Amount Coupled

While the amount of ligand coupled is, to a certain extent, proportional to the

amount of ligand added to the coupling solution, the efficiency of ligand coupled

(varying with the ligand and conditions of coupling) will generally taper off at a

certain ligand concentration. In most cases, 5–20 mg of ligand per ml settled resin

is a good starting point to study optimal ligand concentration in a coupling

solution.

Soluble (unbound) ligand remaining in the coupling and wash buffers may be

monitored by measuring OD 280 or by using Bio-Rad protein assay kit II (catalog

#500-0002) or DC™ protein assay kit II (catalog #500-0112).

Coupling Buffers and pH

In order to maintain pH control, a minimum buffer strength of 10 mM is

recommended. Suitable buffers include carbonate, borate, and phosphate. Do not

use buffers such as Tris or glycine. They contain primary amino groups that will

couple to the resin, as will any other compounds containing nucleophiles.

Profinity epoxide couples ligands best at a pH range of 9–13. Often the choice of

coupling pH is limited by the stability of ligands in basic buffers. Profinity epoxide

resin’s epoxy groups react faster with ligands at a higher pH; however, competing

hydrolysis reactions of the resin’s epoxy groups also occur more frequently at

higher pH. Coupling of ligands through their hydroxyl groups requires a pH

around 13.

Coupling Temperature and Time

Coupling at 20°C is recommended for most applications. Carrying out the

coupling reaction at a higher temperature, up to 40°C, is normally faster if the

ligand is stable at the selected temperature. A water bath should be used to raise

the reaction temperature to the desired level.

Coupling ligands at ~20°C overnight is recommended for most applications. A

shorter coupling time is needed if both the pH of the coupling buffer and the

reaction temperature are high. A prolonged coupling reaction sometimes leads to

degradation of ligands and should be avoided.

Deactivation (Blocking) of Remaining Active Groups and Washing of

Ligand-Coupled Resin

Active groups remaining on the resin after coupling need to be deactivated or

blocked to avoid undesirable reaction with proteins of interest during affinity

chromatography. They can be deactivated or blocked by mixing the resin cake

with 1 M ethanolamine, pH 8–9 for at least 4 hr.

4

Page 7

After coupling, ligand-coupled resin needs to be washed thoroughly with coupling

buffer to remove excess ligand, but sometimes small amounts of ligand are still

trapped on the resin through ionic interactions. Additional wash cycles alternating

acidic and basic buffers are recommended. Each cycle should consist of a wash

with a pH 4.0 buffer (100 mM acetate, 500 mM NaCl) followed by a wash with a

pH 8.0 buffer (100 mM phosphate, 500 mM NaCl).

Section 3

Column Packing

General handling

Profinity base resin is a rigid support that can operate under high flow rates and

pressures. However, bead damage due to excessive physical force is possible.

Magnetic stirrers or excessive stirring may cause mechanical damage and fracture

of some beads. Fine particles generated in this manner may clog the column and

increase the column backpressure; in addition, they may enter the pores of intact

beads and reduce their binding capacity.

Small column packing — slurry packing

Slurry packing is the preferred packing method for small columns. Use this

method for packing ligand-coupled Profinity epoxide resin into 5–15 mm ID

columns. For best results, a bed height of 5 to 30 cm should be used. Since the

slurry volume may exceed the column volume, a packing reservoir may be

necessary.

1. Make a 50–70% slurry of ligand-coupled Profinity epoxide resin in degassed

binding buffer of choice. Resuspend the slurry by gently swirling or stirring

with a glass or plastic rod. Do not use a magnetic stirrer.

2. Connect the packing reservoir to the column with the outlet valve closed.

3. Fill the column to about 10% of its volume with buffer. Ensure that the bed

support is fully hydrated and free of any bubbles.

4. Pour the slurry into the reservoir and insert the flow adaptor. Allow buffer to

back-flow out of the adaptor to remove trapped air.

5. To pack the column bed, open the column outlet and pump 5–10 CV of

buffer through the column at 125–200% of the selected operating flow rate.

For optimal performance, pack the column at the maximum flow rate allowed

by the column hardware and resin.

6. Turn off the pump and close the column outlet. Reposition the flow adaptor

firmly against the bed. Additional pumping may be required for the final

adjustment of the flow adaptor.

5

Page 8

Recommended Columns

Bio-Rad’s Bio-Scale

™

MT high-resolution columns may be used for the above

column packing procedure. These columns are empty but may be packed with

the support of choice. Bio-Scale MT columns are convenient for use with

Bio-Rad’s BioLogic

™

system or with any medium- or high-pressure system.

• Bio-Scale MT2 column (7 x 52 mm) for bed volumes up to 2 ml

• Bio-Scale MT5 column (10 x 64 mm) for bed volumes up to 5 ml

• Bio-Scale MT10 column (12 x 88 mm) for bed volumes up to 10 ml

• Bio-Scale MT20 column (15 x 113 mm) for bed volumes up to 20 ml

Column packing — sample preparation sized columns

Use this method for packing Profinity resin into small micro spin columns for

sample preparation (such as Bio-Rad’s Micro Bio-Spin

columns, empty, 100, catalog #732-6204).

1. Make a 50% slurry of ligand-coupled Profinity epoxide resin in degassed

binding buffer of choice. Resuspend the slurry by gently swirling or stirring

with a glass or plastic rod. Do not use a magnetic stirrer.

2. Place the column into an appropriate collection vessel (for example, a 2 ml

capless collection tube), and spin.

3. Using a pipet, transfer enough Profinity resin to a microcentrifuge tube. If

using Bio-Rad’s Micro Bio-Spin column, transfer ~0.2 ml slurried Profinity

resin to a Micro Bio-Spin column. This is equivalent to ~100 µl of a packed

resin bed.

™

chromatography

4. Remove excess binding buffer by centrifugation. Centrifuge at 1,000 x g for

15 sec to pack resin. The column is now ready for separation.

Recommended columns for gravity-flow chromatography

The following Bio-Rad columns may be used for gravity-flow chromatography.

They are empty and can be filled with Profinity resin.

• Poly-Prep

sample

• Econo-Pac

• Glass Econo-Column

diameter

®

columns, for up to 2 ml chromatography support and 10 ml

®

columns, for up to 20 ml

®

columns, from 5–170 cm long and 0.5–5.0 cm in

6

Page 9

Section 4

Protein Binding and Elution

General strategies are listed below. Refer to textbooks (Gagnon 1996, Hermanson

et al. 1992, Matejtschuk 1997) and literature articles for additional information and

guidance.

Binding

Use only the required amount of Profinity support. If excess support is used,

sample elution becomes more difficult because the sample continues to bind and

elute as it passes down the column. Stronger elution conditions become

necessary, residence time is longer, the eluted peak is broader, and there is a

greater risk of denaturation and poor recovery. One method to ensure that only the

required amount of Profinity resin is used is to apply the sample to the top of the

column and elute using reverse flow. Another method is to titrate the resin with

sample, checking the supernatant for unbound sample after each addition.

Continue until the resin is saturated. This method can be used with a small

amount of resin and sample to determine the resin capacity and the amount of

resin required for the purification.

Removal of unbound solutes

Proteins or other solutes that are not bound, or are weakly bound by nonspecific

interactions, must be washed off prior to elution. This can be done by washing

with binding or equilibration buffers, with salts (1 M NaCl), or with detergents

(0.5% Triton X-100). In many cases, the elution buffer can be used, but at a lower

concentration. This frequently neglected wash step eliminates proteins that may

complicate final elution and helps yield a more highly purified product.

Elution

Elution is usually the most demanding step in affinity chromatography. Often the

objective is to obtain high purity and high recovery of a stable and active product.

In attempting to maximize yields, elution conditions that denature the proteins are

often chosen.

Antigens and antibodies are bound to each other by a combination of ionic

bonding, hydrogen bonding, and hydrophobic interactions (Frost et al. 1981). The

strength of different antigen-antibody complexes varies widely. Other parameters

such as ligand density, steric orientation, and nonspecific interactions can be

important.

Acid elution is the most commonly employed desorption method and is

frequently very effective. Eluants such as glycine-HCl (pH 2.5), 20 mM HCl, and

sodium citrate (pH 2.5) can be used to disrupt antigen-antibody interactions. Acid

elution can give low recoveries due to hydrophobic interactions between the

antigen and the antibody. An eluant such as 1 M propionic acid, or the addition of

10% ethylene glycol to an acidic eluant, is more effective in dissociating such

complexes.

7

Page 10

Base elution is less frequently used than acid elution, but, in some cases, it is

more effective. Elution with 1 M NH

effective with membrane glycoproteins and certain antigens that precipitate in acid

but are stable in base (Izuta and Saneyoshi 1988). Organic solvents can also be

added to basic eluants as described above with acid elution.

Chaotropic agents disrupt the tertiary structure of proteins and, therefore, can be

used to dissociate antigen-antibody complexes. Chaotropic salts disrupt ionic

interactions, hydrogen bonding, and sometimes hydrophobic interactions.

Chaotropic anions are effective in the order SCN->ClO

cations are effective in the order guanidine>Mg

(up to 8 M), guanidine-HCl (up to 6 M), and NaSCN (up to 6 M) are effective in

disrupting most protein-protein interactions. However, these strong chaotropic

agents may destroy the activity of the antigen, the antibody, or both. Conditions as

mild as possible should always be used.

It is important to remove the eluted antigen or antibody from eluant as quickly as

possible to minimize the chance of denaturation. If acid or base is used, the

samples should be neutralized immediately following elution. If a chaotropic agent

is used for elution, it can be rapidly removed by desalting (Econo-Pac desalting

columns, Econo-Pac P6 desalting cartridges, Bio-Gel

very small volumes, Micro Bio-Spin columns).

OH or with 50 mM diethylamine, pH 11.5, is

4

->I>Br->Cl-. Chaotropic

4

+>K+

2

>Na+. Eluants such as urea

®

P-6 desalting gel, or for

Section 5

Renaturation of Eluted Proteins

Proteins that have been denatured during elution can often be renatured by the

addition of a chaotropic agent such as guanidine-HCl, followed by stepwise

dialysis against decreasing concentrations of the chaotrope. The high

concentration of guanidine-HCl puts the protein into a random coil configuration.

As the chaotrope is slowly removed, the protein will return to its native form.

Section 6

Assessing Protein Purity

Check the integrity of purified protein by SDS-PAGE analysis (such as on

Criterion

cannot be run directly on these gels due to precipitation of protein. First remove

the guanidine by desalting using Bio-Gel P-6 (or -30) spin columns.

™

or Criterion™XT precast midi gels). Samples containing guanidine-HCl

8

Page 11

9

Section 7

Regeneration and Storage

Regeneration conditions depend on which type of ligand or protein is used in the

coupling and chromatography process. Refer to textbooks and literature articles

for guidance. In general, 2–4 wash cycles alternating acidic and basic buffers are

useful. Each cycle should consist of a wash of a pH 4.0 buffer (100 mM acetate,

500 mM NaCl) followed by a wash of a pH 8.0 buffer (100 mM phosphate,

500 mM NaCl).

Profinity epoxide resin should be stored dry between 4°C and ambient temperature. Ligand-coupled Profinity resin should be stored at 4–8°C in an appropriate

buffer that contains a bacteriostat.

Section 8

References

Frost RG et al., Covalent immobilization of proteins to N-hydroxysuccinimide ester

derivative of agarose. Effect of protein charge on immobilization, Biochim Biophys

Acta 670, 163–169 (1981)

Gagnon P, Purification Tools for Monoclonal Antibodies, Validated Biosystems,

Inc., Tuscon (1996)

Hermanson GT et al., Immobilized Affinity Ligand Techniques, Academic Press,

New York (1992)

Izuta S and Saneyoshi M, AraUTP-Affi-Gel 10: a novel affinity absorbent for the

specific purification of DNA polymerase alpha-primase, Anal Biochem 174,

318–324 (1988)

Matejtschuk P (ed), Affinity Separations — A Practical Approach, Oxford University

Press, Oxford (1997)

Section 9

Ordering Information

Ordering Information

Catalog # Description

156-0200 Profinity Epoxide Resin, 5 g

156-0201 Profinity Epoxide Resin, 25 g

Streptactin is a trademark of Institut für Bioanalytik GmbH. Triton is a trademark of Union Carbide.

Page 12

Bio-Rad Laboratories, Inc.

2000 Alfred Nobel Dr., Hercules, CA 94547 USA

510-741-1000

10003245 Rev A

Loading...

Loading...