Page 1

Operating Manual

Translation of the original operating manual

MKF (E3.2)

Alternating climate chambers with program control

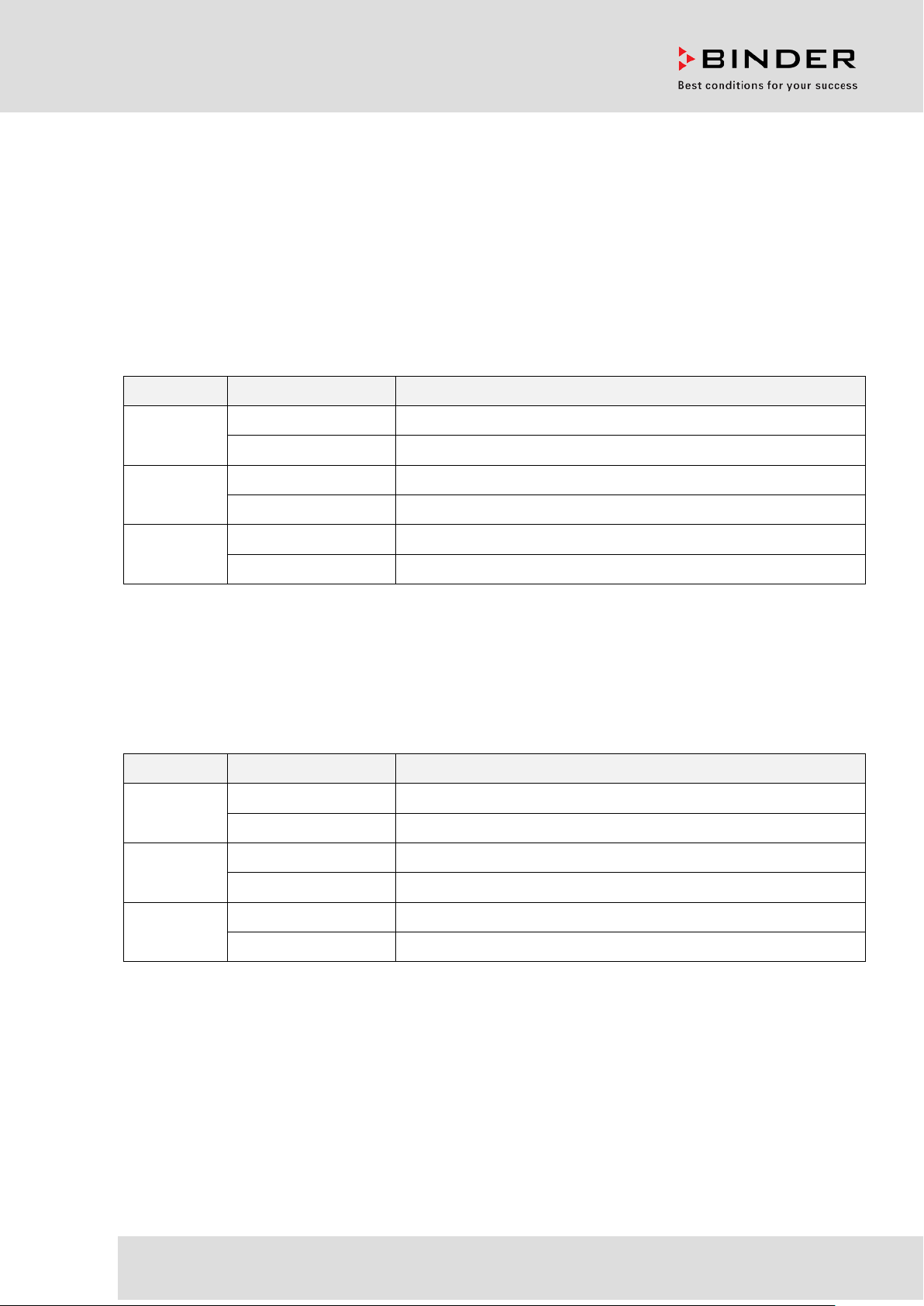

Model Model version

MKF 115

MKF 240

MKF 720

MKF115-400V

MKF115-400V-C 9020-0291 (with voltage and frequency changer)

MKF240-400V

MKF240-400V-C 9020-0295 (with voltage and frequency changer)

MKF720-400V

MKF720-400V-C

Art. No.

9020-0283, 9120-0283

9020-0285, 9120-0285

9020-0287, 9120-0287

9020-0299 (with voltage and frequency changer)

MKFT (E3.2)

Alternating climate chambers with deep temperature

with program control

Model Model version Art. No.

MKFT 115

MKFT115-400V

MKFT115-400V-C

9020-0284, 9120-0284

9020-0293 (with voltage and frequency changer)

MKFT 240 MKFT240-400V 9020-0286, 9120-0286

MKFT240-400V-C

MKFT 720 MKFT720-400V 9020-0288, 9120-0288

MKFT720-400V-C

9020-0297 (with voltage and frequency changer)

9020-0301 (with voltage and frequency changer)

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.b ind er -world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacif ic: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 07/2017 Art. No. 7001-0287

Page 2

CONTENTS

1. SAFETY .................................................................................................................. 5

1.1 Legal considerations ........................................................................................................................... 5

1.2 Structure of the safety instructions ...................................................................................................... 5

1.2.1 Signal word panel ..................................................................................................................... 5

1.2.2 Safety alert symbol ................................................................................................................... 6

1.2.3 Pictograms ................................................................................................................................ 6

1.2.4 Word message panel structure ................................................................................................. 7

1.3 Localization / position of safety labels on the chamber ...................................................................... 7

1.4 Type plate............................................................................................................................................ 9

1.5 General safety instructions on installing and operating the chamber ............................................... 10

1.6 Intended use ..................................................................................................................................... 12

1.7 Operating instructions ....................................................................................................................... 12

1.8 Measures to prevent accidents ......................................................................................................... 13

1.9 Resistance of the humidity sensor against harmful substances ....................................................... 14

2. CHAMBER DESCRIPTION .................................................................................. 15

2.1 Chamber overview ............................................................................................................................ 16

2.2 Lateral control panel .......................................................................................................................... 17

2.3 Instrument panel ............................................................................................................................... 18

2.4 Rear power switch ............................................................................................................................. 18

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 19

3.1 Unpacking, and checking equipment and completeness of delivery ................................................ 19

3.2 Guidelines for safe lifting and transportation ..................................................................................... 20

3.3 Storage .............................................................................................................................................. 20

3.4 Location of installation and ambient conditions ................................................................................ 21

4. INSTALLATION AND CONNECTIONS ............................................................... 23

4.1 Wastewater connection for humidifying system ................................................................................ 24

4.2 Freshwater supply for humidifying system ........................................................................................ 24

4.2.1 Automatic fresh water supply for humidifying system via water pipe ..................................... 25

4.2.2 Manual fresh water supply for humidifying system via internal freshwater can...................... 25

4.2.3 Water circle: lever for condensate recycling (option) .............................................................. 26

4.3 Connection of cooling water outlet for water cooling (option) ........................................................... 27

4.4 Connection of cooling water inlet for water cooling (option) ............................................................. 27

4.5 Connection kit for connecting the chamber’s freshwater connection to a water pipe ....................... 28

4.6 Safety kit: Hose burst protection device with reflux protection device for the chamber’s freshwater

connection (available via BINDER INDIVIDUAL customized solutions) ........................................... 29

4.7 Installation of the voltage and frequency changer (chambers with voltage and frequency changer)30

4.8 Electrical connection ......................................................................................................................... 31

4.8.1 Information on connecting the alternating climate chamber ................................................... 31

4.8.2 Connecting the voltage and frequency changer (for chambers equipped with a voltage and

frequency changer) ................................................................................................................. 32

5. START UP ............................................................................................................ 33

5.1 Function overview of display program controller MB1 ...................................................................... 33

5.2 Operating modes ............................................................................................................................... 34

5.3 Behavior after power failure .............................................................................................................. 34

5.4 Behavior when opening the door ...................................................................................................... 34

5.5 Turning on the chamber .................................................................................................................... 35

MKF+ MKFT (E3.2) 07/2017 page 2/115

Page 3

6. CONTROLLER MB1 SETTINGS .......................................................................... 36

6.1 Selection of the menu language ....................................................................................................... 36

6.2 Function overview program controller MB1 ...................................................................................... 37

6.3 Menu settings in the “User-settings” menu ....................................................................................... 38

6.4 Menu settings in the “User Level” menu ........................................................................................... 39

7. GRAPHIC REPRESENTATION OF THE HISTORICAL MEASUREMENT

(CHART RECORDER FUNCTION) ...................................................................... 40

7.1 Setting the storage rate ..................................................................................................................... 42

8. MANUAL MODE ................................................................................................... 43

8.1 Set-point entry ................................................................................................................................... 43

8.2 Performance after power failure in Manual Mode ............................................................................. 45

9. PROGRAM OPERATION ..................................................................................... 45

9.1 Menu-based program entry ............................................................................................................... 45

9.2 Entering the temperature values and the switching states of the operation lines............................. 46

9.3 Entering the humidity values ............................................................................................................. 48

9.4 Selecting between set-point ramp and set-point step ....................................................................... 49

9.5 Program entry as set-point ramp or as set-point step ....................................................................... 49

9.6 Information on programming different temperature or humidity transitions ...................................... 54

9.7 Repetition of a section or several sections within a program ............................................................ 55

9.8 Performance after power failure in Program Mode ........................................................................... 55

9.9 Starting a previously entered program .............................................................................................. 56

9.10 Deleting a program ............................................................................................................................ 56

9.11 Temperature profile and operation lines template ............................................................................ 57

9.12 Humidity profile template ................................................................................................................... 58

9.13 Program table template for temperature and operation lines ........................................................... 59

9.14 Program table template for humidity ................................................................................................. 60

10. BEDEW PROTECTION FACILITY (OPERATION LINE 1) .................................. 61

11. ZERO-VOLTAGE RELAY OUTPUTS VIA OPERATION LINES 2 TO 5 .............. 62

12. TEMPERATURE SAFETY DEVICES ................................................................... 63

12.1 Over temperature protective device (class 1) ................................................................................... 63

12.2 Safety controller (over-temperature safety device class 2) ............................................................... 63

12.3 Over/under temperature safety device class 2 (option) .................................................................... 65

13. NOTIFICATION AND ALARM FUNCTIONS ........................................................ 66

13.1 Notification and alarm system overview (auto diagnosis system) .................................................... 66

13.2 Resetting the notification or alarm messages ................................................................................... 67

14. HUMIDITY SYSTEM ............................................................................................. 68

14.1 Function of the humidifying and dehumidifying system .................................................................... 69

15. DEFROSTING AT REFRIGERATING OPERATION ............................................ 71

16. OPTIONS .............................................................................................................. 72

16.1 Communication software APT-COM™ 3 DataControlSystem (option) ............................................ 72

16.2 Interface RS 422 (option) .................................................................................................................. 72

16.3 Analog outputs for temperature and humidity (option) ...................................................................... 72

16.4 Data logger kits ................................................................................................................................. 73

16.5 Keyboard locking (option) ................................................................................................................. 73

16.6 BINDER Pure Aqua Service (opt ion) ................................................................................................ 73

MKF+ MKFT (E3.2) 07/2017 page 3/115

Page 4

Compressed air dryer (option) .......................................................................................................... 74

16.7

16.8 Water cooling (option) ....................................................................................................................... 75

16.9 Additional measuring channel for digital object temperature indicator with flexible temperature

sensor Pt 100 (option) ....................................................................................................................... 75

17. MAINTENANCE, CLEANING, AND SERVICE .................................................... 76

17.1 Maintenance intervals, service .......................................................................................................... 76

17.2 Cleaning and decontamination ......................................................................................................... 77

17.2.1 Cleaning .................................................................................................................................. 77

17.2.2 Decontamination ..................................................................................................................... 78

17.3 Sending the chamber back to BINDER GmbH ................................................................................. 79

18. DISPOSAL............................................................................................................ 80

18.1 Disposal of the transport packing ...................................................................................................... 80

18.2 Decommissioning .............................................................................................................................. 80

18.3 Disposal of the chamber in the Federal Republic of Germany ......................................................... 80

18.4 Disposal of the chamber in the member states of the EU except for the Federal Republic of

Germany............................................................................................................................................ 82

18.5 Disposal of the chamber in non-member states of the EU ............................................................... 83

19. TROUBLESHOOTING ......................................................................................... 84

20. TECHNICAL DESCRIPTION ................................................................................ 87

20.1 Factory calibration and adjustment ................................................................................................... 87

20.2 Over current protection ..................................................................................................................... 87

20.3 Definition of usable volume ............................................................................................................... 87

20.4 MKF (E3.2) technical data ................................................................................................................. 88

20.5 MKFT (E3.2) technical data .............................................................................................................. 90

20.6 Equipment and options (extract) ....................................................................................................... 92

20.7 Accessories and spare parts (extract) .............................................................................................. 93

20.8 Heating-up and cooling-down graphs MKF....................................................................................... 95

20.9 Heating-up and cooling-down graphs MKFT .................................................................................... 96

20.10 Dimensions MKF 115 / MKFT 115 .................................................................................................... 97

20.11 Dimensions MKF 240 ........................................................................................................................ 98

20.12 Dimensions MKFT 240 ...................................................................................................................... 99

20.13 Dimensions MKF 720 / MKFT 720 .................................................................................................. 100

21. CERTIFICATES AND DECLARATIONS OF CONFORMITY ............................. 101

21.1 EU Declaration of Conformity for MKF ............................................................................................ 101

21.2 EU Declaration of Conformity for MKFT ......................................................................................... 104

21.3 Certificate for the GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V.“

(German Social Accident Insurance) DGUV ................................................................................... 107

22. PRODUCT REGISTRATION .............................................................................. 109

23. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 110

23.1 For chambers located outside the USA and Canada ..................................................................... 110

23.2 For chambers located in the USA and Canada .............................................................................. 113

MKF+ MKFT (E3.2) 07/2017 page 4/115

Page 5

Dear customer,

For the correct oper ation of the chamber, it is important that you read this operating m anual completely

and carefully and obser ve all instr uctions as indicate d. Failur e to rea d, underst and and f ollow the ins tructions may result in personal injury. It can also lead to damage to the chamber and/or poor equipment

performance.

1. Safety

This operating manual is part of the components of delivery. Always keep it handy for reference. The

device should only be ope rated by laboratory personnel especiall y trained for this purpos e and familiar

with all precautionar y measures requir ed for work ing in a laborator y. Observe th e national regu lations on

minimum age of laboratory personnel. To avoid injuries and damage observe the safety instructions of the

operating manual.

WARNING

Failure to observe the safety instructions.

Serious injuries and chamber damage.

Observe the safety instructions in this operating manual.

Carefully read the complete operating instructions of the chamber.

1.1 Legal considerations

This operating m anual is for informational purposes only. It contains information for ins talling, start-up,

operation and mainte nance of the product. Note: the contents and the pr oduct described are subj ect to

change without notice.

Understanding and obs erving the instructions in this operat ing manual are prerequisites for hazard-free

use and safety durin g operation a nd maintena nce. In no e vent shall BIN DER be held l iable f or any damages, direct or incidental arising out of or related to the use of this manual.

This operating manual ca nnot cover all conc eivable applicati ons. If you would lik e additional infor mation,

or if special problem s arise that are not suff iciently addressed in this manual, please ask your dealer or

contact us directly by phone at the number located on page one of this manual

Furthermore, we emphas ize that the contents of this operating manual are not p art of an earlier or exis ting agreement, descripti on, or legal relat ionship, n or do the y modif y such a relatio nship. All oblig ations on

the part of BINDER deriv e from the respec tive purchase contrac t, which also con tains the entire and exclusively valid statem ent of warranty administration. The statem ents in this manual neither augment nor

restrict the contractual warranty provisions.

1.2 Structure of the safety instructions

In this operating manual, t he following safety definitions and symbols indicate dangerous situations following the harmonization of ISO 3864-2 and ANSI Z535.6.

1.2.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal

word, the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious (irreversible) injury.

MKF+ MKFT (E3.2) 07/2017 page 5/115

Page 6

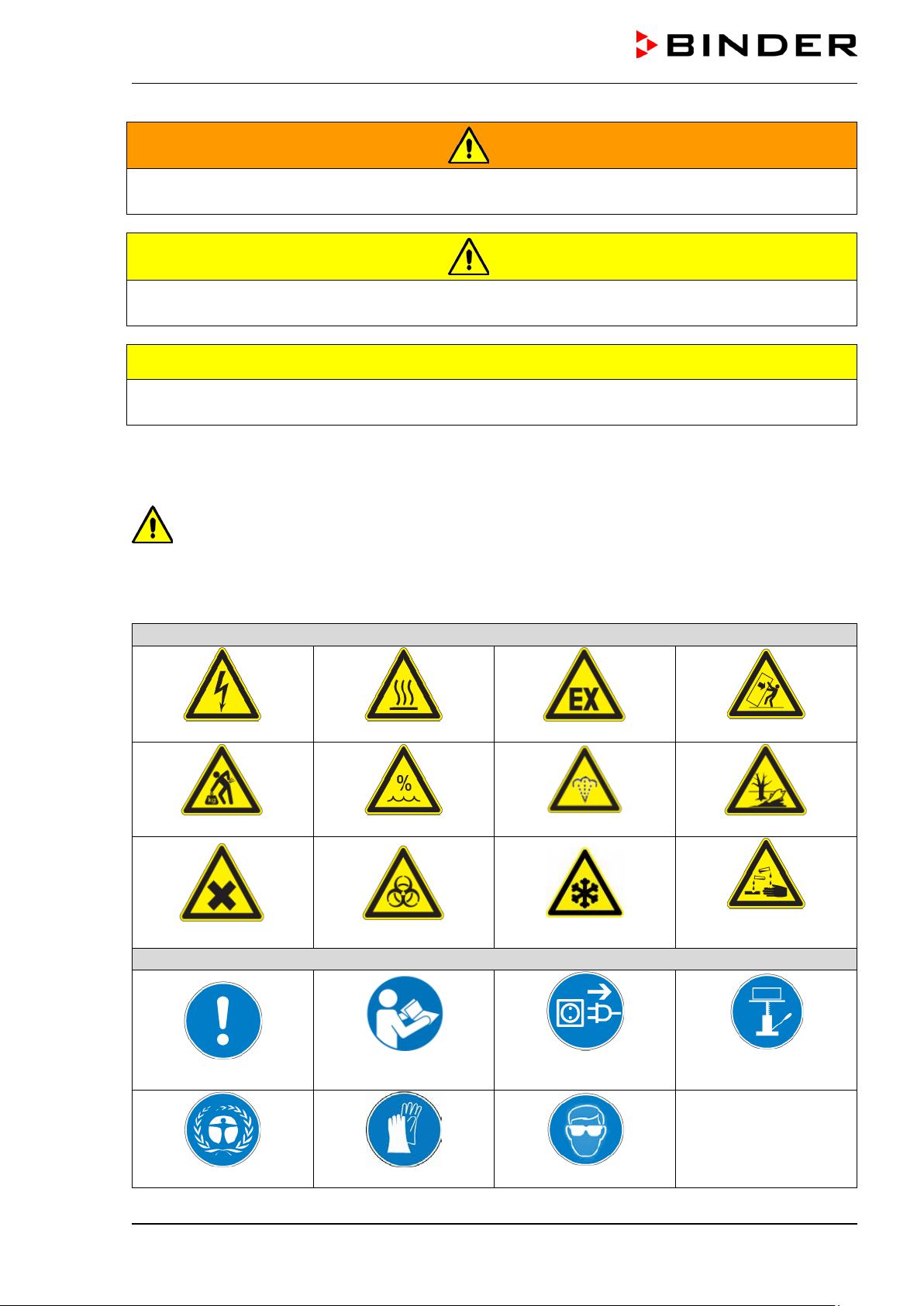

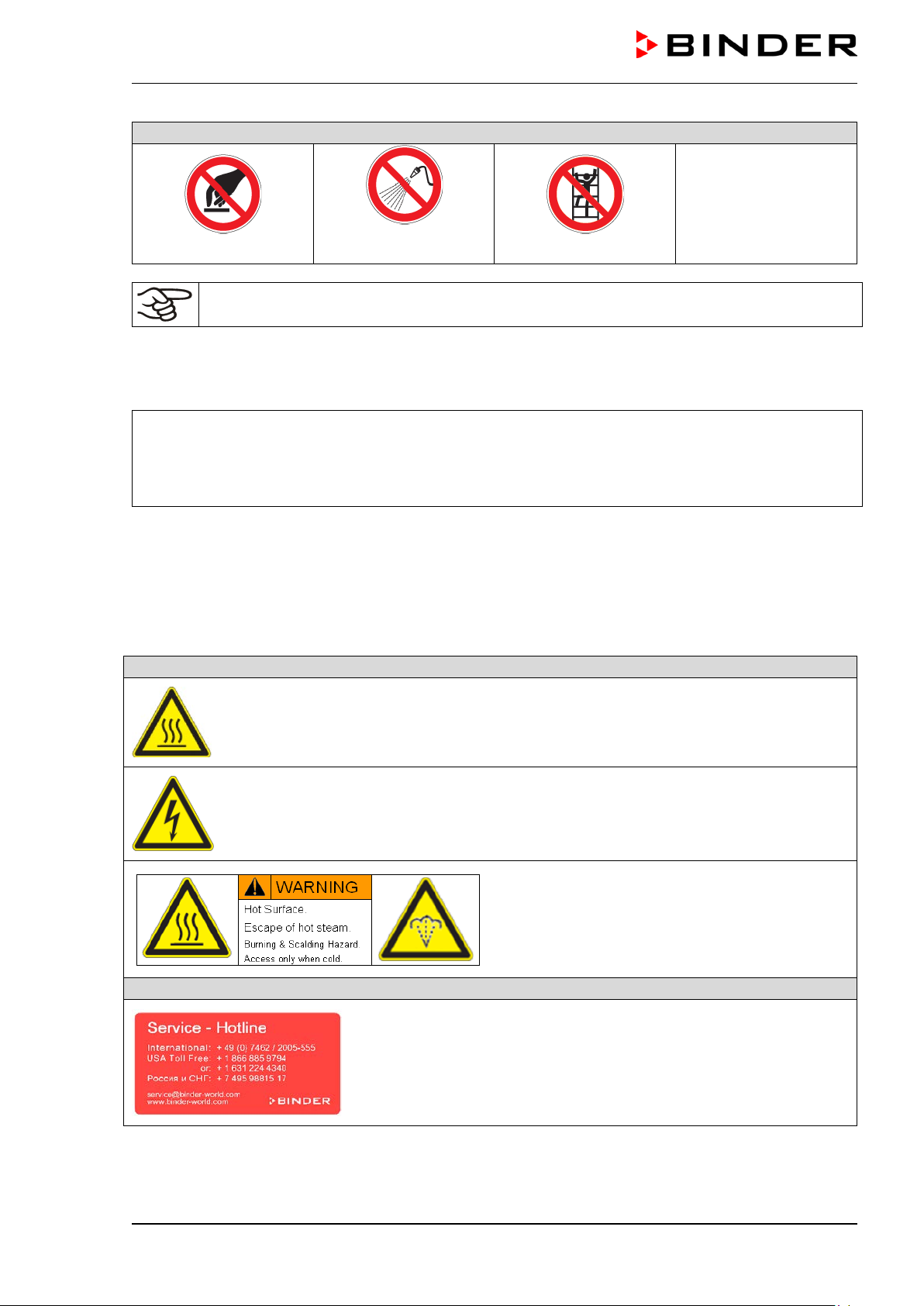

Warning signs

Electrical hazard

Hot surface

Explosive atmosphere

Lifting hazard

High humidity

Pollution hzard

or chemical burns

Mandatory action signs

instructions

plug

Environment protection

Wear protective gloves

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious (irreversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in damage to the product

and/or its functions or of a property in its proximity.

1.2.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

1.2.3 Pictograms

Harmful substances

Biohazard

Scalding hazard

Danger of frost

Stability hazard

Risk of corrosion and /

Mandatory regulation

MKF+ MKFT (E3.2) 07/2017 page 6/115

Read operating

Disconnect the power

Wear safety goggles

Lift with mechanical

assistance

Page 7

Prohibition signs

water

Pictograms (Warning signs)

Service label

Do NOT touch

Information to be observed in order to ensure optimum function of the product.

Do NOT spray with

Do NOT climb

1.2.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

∅ Instruction how to avoid the hazard: prohibition

Instruction how to avoid the hazard: mandatory action

Observe all other notes and inf ormation not necessarily emphasi zed in the same way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

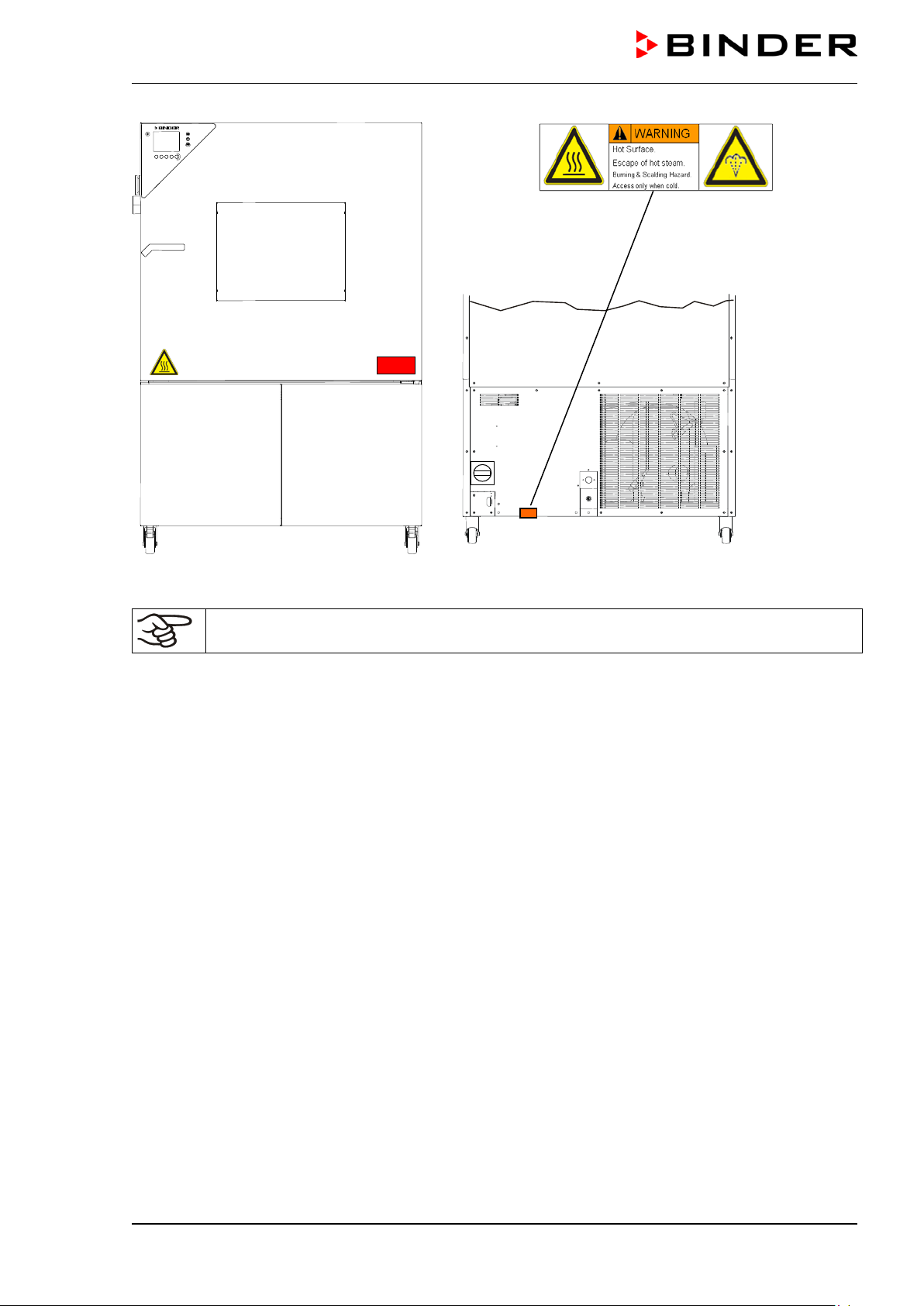

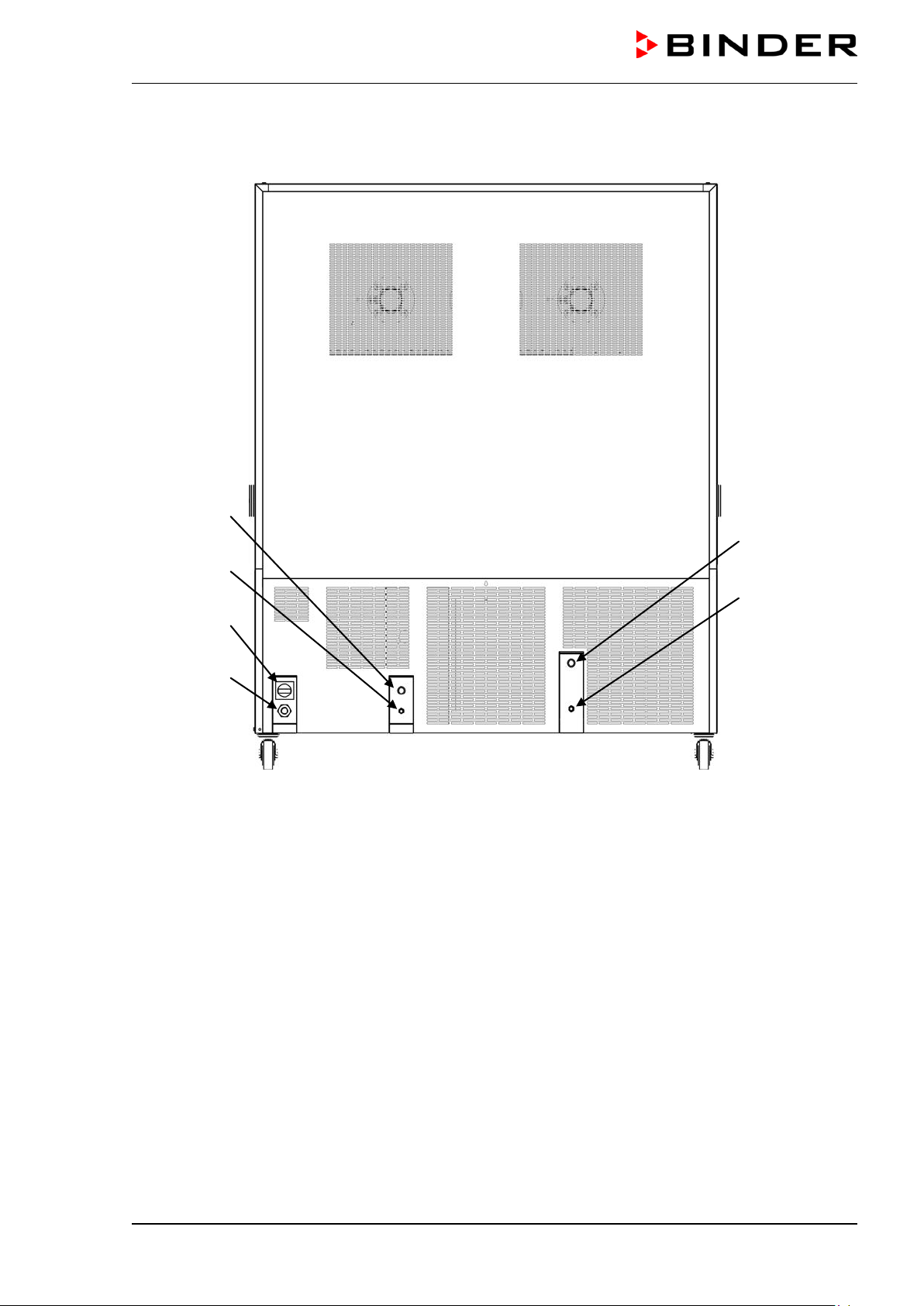

1.3 Localization / position of safety labels on the chamber

The following labels are located on the chamber:

Hot surface (on outer chamber door)

Electrical hazard

(chamber with voltage and frequency changer : on the voltage and frequency changer)

Burning and scalding hazard

(on chamber rear)

MKF+ MKFT (E3.2) 07/2017 page 7/115

Page 8

Figure 1: Position of labels on the chamber

Keep safety labels complete and legible.

Replace safety labels that are no longer legible. Contact BINDER service for these replacements.

MKF+ MKFT (E3.2) 07/2017 page 8/115

Page 9

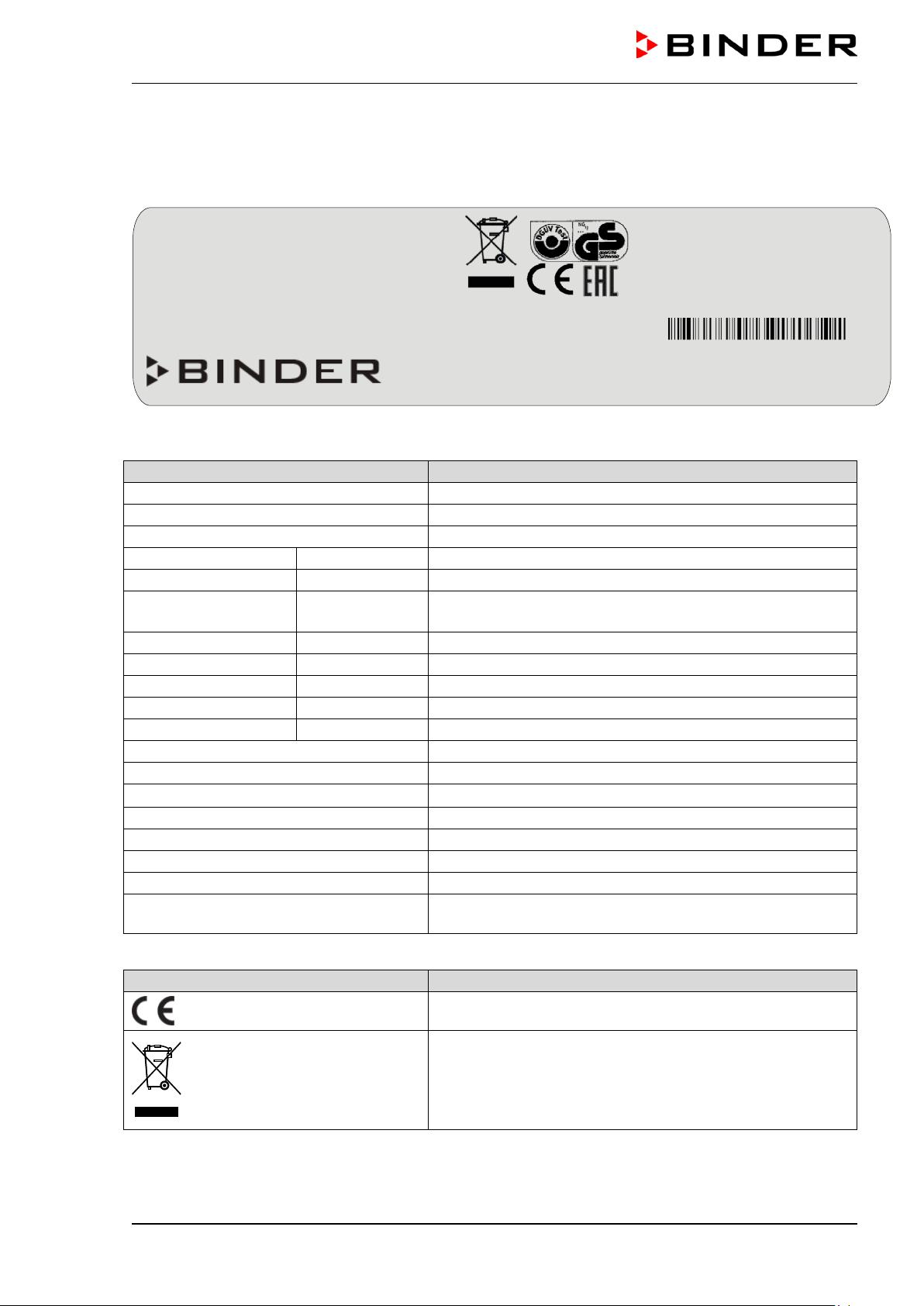

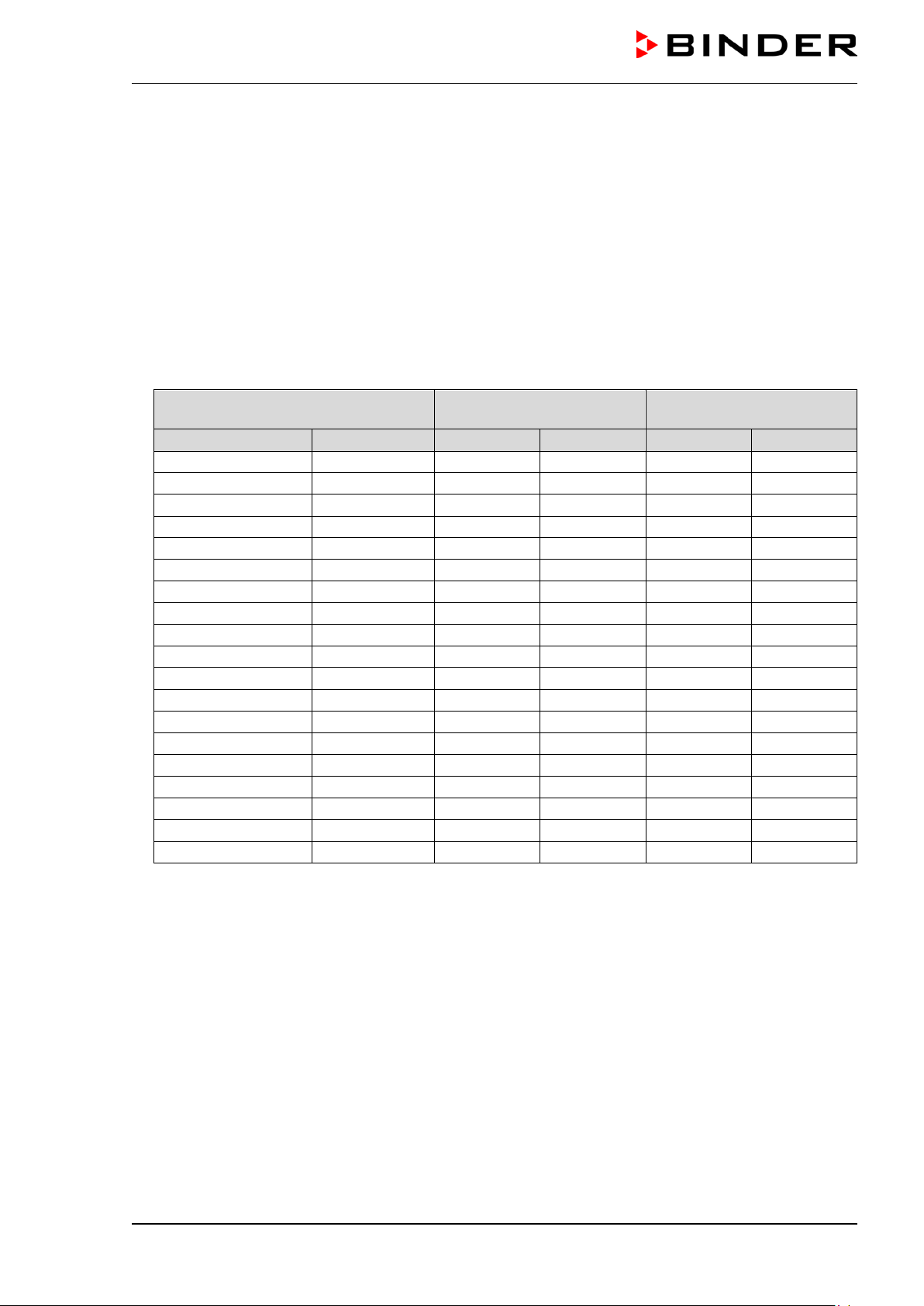

Indications of the type plate (example)

Information

BINDER

Manufacturer: BINDER GmbH

MKFT 240

Model designation

Alternating climate chamber

Device name

Serial No.

000000000000

Serial no. of the chamber

Built

2017

Year of construction

180 °C

356°F

IP protection

20

IP type of protection acc. to standard EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880

Class

2.0

Class of temperature safety device

Art. No.

9020-0286

Art. no. of the chamber

Project No.

---

Optional: Special application acc. to project no.

6,50 kW

Nominal power

12,0 A

Nominal current

400 V / 50 Hz

Nominal voltage ± 10% at the indicated power frequency

3 N ~

Current type

Max operating pressure 29 bar

Max operating pressure in the refrigerating system

Stage 1: R 404A – 2,20 kg

Cooling 1st stage: Refrigerant type, filling weight

Stage 2: R 23 – 0,40 kg

Cooling 2nd stage: Refrigerant type, filling weight

covered by the Kyoto Protocol

Kyoto Protocol

Symbol on the type plate

Information

Nominal temp.

180 °C

6,50 kW / 12,0 A

Max. operating pre s sure 29 bar

356 °F

400 V / 50 Hz

Stage 1: R 404 A – 2,20 kg

IP protection

20

Stage 2: R 23 - 0,40 kg

Safety device

DIN 12880

3 N ~

Contains fluorinated greenhouse gases

Class

2.0 covered by the Kyoto Protocol

Art. No.

9020-0286

Project No.

Built

2017

Alternating climate chamber

BINDER GmbH

www.binder-world.com

MKFT 240

Serial No. 00000000000000

1.4 Type plate

The type plate stick s to the left side of the chamber, bottom right-hand, above the refrigerating and humidity module.

Im Mittleren Ösch 5

78532 Tuttlingen / Germany

E3.2

Figure 2: Type plate (example of MKFT 240 regular unit)

Made in Germany

Nominal temperature

Contains fluorinated green hous e gas es

Nominal temperature

Contains fluorinated green hous e gas es cover ed b y the

CE conformity marking

Electrical and electronic equipment manufactured / placed

on the market in the EU after 13 August 2005 and be disposed of in separate collection according to Directive

2012/19/EU on waste electrical and electronic equipment

(WEEE).

MKF+ MKFT (E3.2) 07/2017 page 9/115

Page 10

Symbol on the type plate

Information

GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV), Prüf- und Zertifizierungsstelle

Nahrungsmittel und Verpackung im DGUV Test“ (German

Social Accident Insurance (DGUV), Testing and Certification Body for Foodstuffs and Packaging Industry in DGUV

Test).

The equipment is certified according to Customs Union

Technical Regulation (CU TR) for the Eurasian Economic

Union (Russia, Belarus, Armenia, Kazakhstan Kyrgyzstan).

1.5 General safety instructions on installing and operating the chamber

With regard to operating th e chamber and to the installation location, please observe the DGUV guidelines 213-850 on safe working in laborator ies (formerly BGI/GUV-I 850-0, BGR/GUV-R 120 or ZH 1/119,

issued by the employers’ liability insurance association) (for Germany).

BINDER GmbH is only respons ible for the safety feat ures of the chamber provided sk illed electricians or

qualified personnel authorized by BIND ER perform all m aintenance and repair, and if com ponents relating to chamber safety are replaced in the event of failure with original spare parts.

To operate the chamber, use only original BINDER ac cessories or ac cessories f rom third-par ty suppliers

authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

CAUTION

Danger of overheating.

Damage to the chamber.

∅ Do NOT install the chamber in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

Do not operate the chamber in hazardous locat ions .

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the chamber in potentially explosive areas.

∅ KEEP explosive dust or air-solvent mixtures AWAY from the chamber.

The alternating chamber does not dispose of any measures of explosion pr otec t ion .

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT introduce any substance combustible or explosive at working temperature into

the alternating climate chamber.

∅ NO explosive dust or air-solvent mixture in the inner chamber.

Any so lvent contained in the c harging material m ust not be explosive or inflamm able. I.e., irrespecti ve of

the solvent concentrati on in the steam room, NO explosi ve mixture with air must f orm. The temperature

inside the chamber mus t lie below the flash point or b elow the sublim ation point of the charging m aterial.

Familiarize yourself with the physical and chemical properties of the charging material, as well as the

contained moisture constituent and its behavior with the addition of heat energy and humidity.

MKF+ MKFT (E3.2) 07/2017 page 10/115

Page 11

Familiarize yourself with a ny potential health ris ks caused by the chargi ng material, a possibl y contained

moisture constituent or by reaction products that ma y arise during the con ditioning process. Take adequate measures to exclude such risks prior to putting the chamber into operation.

DANGER

Electrical hazard.

Danger of death.

∅ The chamber must NOT become wet during operation or maintenance.

The chambers were produ ced in accordance with VDE regu lations and were routinel y tested in accordance to VDE 0411-1 (IEC 61010-1).

CAUTION

The window, the access ports and the inner chamber will become hot during operation.

Danger of burning.

∅ Do NOT touch the window, the access ports, the inner surfaces or the charging material

during operation.

WARNING

Stability hazard.

Danger of injury.

Damage to the chamber and the charging material.

Housing cover breakaway.

∅ Do NOT climb on the lower housing cover.

∅ Do NOT load the lower housing cover with heavy objects while the chamber door is

open.

MKF+ MKFT (E3.2) 07/2017 page 11/115

Page 12

1.6 Intended use

Alternating climate c hambers series MKF / MKFT are suitable for temper ature drying and heat treatm ent

of solid or pulverized c hargi ng m aterial, as well as bu lk m aterial, usi ng the s uppl y of heat. T he y are su itable for harmless materials . A mixture of any component of the charging m aterial with air must NOT be

explosive. The operat ing tem perature mus t lie below the flas h point or b elow the sublim ation point of the

charging material. Any component of the charging material must NOT be able to release toxic gases.

Other applications are not approved.

The cham bers ar e specially d esign ed for s olving all th e problem s which occ ur du ring m aterial an d age ing

tests.

The chambers are not cl assified as medical devices as defined b y the Medical Dev ice Directive

93/42/EEC.

Due to the special demands of the Medical Device Directive (MDD), these ovens are not qualified for sterilization of medical devices as defined by the directive 93/42/EWG.

Following the instructions in this operating manual and conducting regular maintenance work

(chap. 17) is part of the intended use.

The chambers do not dispose of any measures of explosion protection.

DANGER

Explosion or implosion hazard.

Danger of poisoning.

Danger of death.

∅ Do NOT introduce any subs tance com bustible or ex plosiv e at work ing temper ature into

the chamber, in particular no energy sources such as batteries or lithium-ion batteries

∅ NO explosive dust or air-solvent mixture in the inner chamber.

∅ Do NOT introduce any substance which could lead to release of toxic gases.

The charging material shall not contain any corrosive ingredients that may damage the machine components made of stainless steel, aluminum, and copper. Such ingredients include in

particular acids and halides. Any corrosive damage caused by such ingredients is excluded

from liability by BINDER GmbH.

In case of foreseeable use of the chamber there is no risk for the user through the integration of the

chamber into systems or by special environmental or operating conditions in the sense of EN 610101:2010. For this, the intended use of the chamber and all its connections must be observed.

1.7 Operating instructions

Depending on the applicati on and l ocation of the chamber, the operator of the chamber m ust provide the

relevant information for safe operation of the chamber in a set of operating instructions.

Keep these operating instructions with the chamber at all times in a place where they are

clearly visible. They must be comprehensible and written in the language of the employees.

MKF+ MKFT (E3.2) 07/2017 page 12/115

Page 13

1.8 Measures to prevent accidents

The operator of the chamber must observe the following rule: “Betreiben von Arbeitsmitteln. Betreiben

von Kälteanlagen, W ärmepumpen und Kühleinrichtungen“ (Operation of work equipment. Operation of

refrigeration systems, heat pumps and refrigeration equipment) (GUV-R 500 chap. 2.35) (for Germany).

The manufacturer took the following measures to prevent ign iti on and ex plos io ns :

• Indications on the type plate

See operating manual chap. 1.4.

• Operating manual

An operating manual is available for each chamber.

• Overtemperature monitoring

The chamber is equipped with a temperature display, which can be read from outside.

The chamber is equipped with an additional safety controller (temperature safety device class 2 acc. to

DIN 12880:2007). Visual and audible (buzzer) signals indicate temperature exceeding.

• Safety, measurement, and control equipment

The safety, measuring, and control equipment is easily accessible.

• Electrostatic ch arg e

The interior parts are grounded.

• Non-ionizing radiation

Non-ionizing radiatio n is not intentionall y produced, but release d only for technica l reasons by electr ical equipment (e.g. electric motors, power c ables, solenoids). The m achine has no permanent m agnets. If persons with active im plants (e.g. pac emaker s, defibrillators ) keep a s afe distance (distanc e of

field source to implant) of 30 cm, an influence of these implants can be excluded with high probability.

• Protection against touchable surfaces

Tested according to EN ISO 13732-1:2008.

• Floors

See operating manual chap. 3.4 for correct installation

• Cleaning

See operating manual chap. 17.2.

• Examinations

The chamber has been inspected by the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV)

(German Social Accident Insurance (DGUV)” (German Social Accident Insurance (DGUV), Testing

and Certification Body for Foodstuffs and Packaging Industry in DGUV Test) and bears the GS mark.

MKF+ MKFT (E3.2) 07/2017 page 13/115

Page 14

Maximum work place

threshold limit value

Tolerated concentration

with permanent load

Substance

Formula

ppm

mg/m3

ppm

mg/m3

Ammonia

NH3

20

14

5500

4000

Acetone

CH3COCH3

500

1200

3300

8000

Benzene

300

1200

150000

Chlorine

Cl2

0.5

1.5

0.7

2

Acetic acid

CH3COOH

10

25

800

2000

Ethyl acetate

CH3COOC2H5

400

1400

4000

15000

Ethanol

C2H5OH

500

960

3500

6000

Ethylene glycol

HOCH2CH2OH

10

26

1200

3000

Formaldehyde

HCHO

0.3

0.37

2400

3000

Isopropanol

(CH3)2CHOH

200

500

4800

12000

Methanol

CH3OH

200

260

3500

6000

Methyl ethyl ketone

C2H5COCH3

200

590

3300

8000

Ozone

O3

0.1

0.2

0.5

1

Hydrochloric acid

HCl 2 3

300

500

Hydrogen sulphide

H2S

10

15

350

500

Nitrogen oxides

NOx 5 9 5 9

Sulphur dioxide

SO2 5 13 5 13

Toluol

C6H5CH3

100

380

1300

5000

Xylene

C6H4(CH3)2

100

440

1300

5000

1.9 Resistance of the humidity sensor against harmful substances

The following list of har mf ul substanc es ref ers onl y to the hum idit y sensor a nd do es not i nclu de an y other

materials incorporated in the chamber or prohibited substances in relation to explosion protection.

Some gases - especially clean gases - do not have an y influe nce on th e hum idity sensor . Others do have

a very small influence, whereas others may influence the sensor to a larger extent.

• The following g ases do not influence the sensor and the humidity measurem ent: Arg on (Ar), carbon

dioxide (CO

• The following gases do not , or to a m inor extent inf luence the sensor and the hu midity measurement:

Butane (C

• The following gases do not , or to a m inor extent inf luence the sensor and the hu midity measur ement,

provided that the indicated loads are not exceeded:

),helium (He), hydrogen (H2), neon (Ne), nitrogen (N2), nitrous oxide (N2O), oxygen (O2)

2

), ethane (C2H6), methane (CH4), natural gas propane (C3H8)

4H10

These values are to be considered only as approximate values. The sensor resistance largely depends on the temperatur e and hum idity conditio ns during t he time of exposure to harm ful substanc es.

Avoid simultaneous condensation. Tolerated error of measurement: ± 2 % r.H. The maximum work

place threshold limit value is the one that can be regarded as harmless for humans.

• Vapors of oil and fat are dangerous for the sens or because they may condensate at t he sensor and

thus prevent its function (insulating la yer). For similar reasons it is not possible to measure smoke

gases.

MKF+ MKFT (E3.2) 07/2017 page 14/115

Page 15

2. Chamber description

The alternat ing clim ate cham ber MKF / MKFT is a special ly developed pr ecision c ooling/ warming cabi net

for the domain of industrial material testing and environment simulation, with an unrivalled c ap acity, which

far exceeds the capabil ities of normal test cabinets, prov iding the ideal facilities for solving all the problems which occur during material as well as ageing and stress tests.

The chambers ar e equipped with a m ultifunctional microproces sor displa y controller with 2-channe l technology for temperature and humidity plus a digital display accurate to on e-tenth of a degree resp. 0.1%

r.H. With its com prehensive program control functions, the d isplay program controller MB1 permits the

high precision perfor mance of temperature and h umidity cycles with rapid he ating up and cooling do wn

phases.

With its micropr ocessor c ontrolled hum idifying and dehum idifying s ystem the chamber is a high-precision

climatic test cham ber . It c o vers th e r e gu lar t es t s pecif i c ations for temperature and c lim ates c orr es pon ding

to DIN und IEC stan dards. Furthermore, it permits simulat ing exac tl y and o ver lon g periods const ant co nditions for other app lications such as sam ple conditioning for m aterial testing of paper, tex tiles, plastics,

building materials, etc.

The patented APT .line™ prehea ting cham ber and a ir conduc tion tech nolog y guarante es excellent spatia l

temperature and hum idity values for the tota l working area. The chamber provides a power ful refrigerating system with rapid coo ling-down spee ds. In addition, the chamber provides almost unlim ited possibilities for adaptation to individual customer requirements based upon extensive programming options.

A resistance hum idifying system hum idifies the air. For this purpose, use deionized (dem ineralized) water. The option BINDER Pur e Aqua Service permits using the chamber with an y degree of water hardness.

The high-quality hous ing insulat ion guarante es both a lo w noise mode of operation an d a c o nsis te ntly low

housing temperature. T he inner chamber, the pre-heating cham ber and the interi or side of the doors are

all made of stainless steel V2A (German m aterial no. 1.4301, US equivalent AISI 304). W hen operating

the chamber at tem per atur es abo ve 150 °C / 302°F, the impac t of the oxygen in the air may cause discoloration of the metallic s urfaces (yellowish-brown or blue) b y natural oxidation processes . These colorations are harmless and will in no way impair the function or qualit y of the chamber. The housing is RA L

7035 powder-coated. All corners and edges are completely coated.

The efficient program controller is equipped with a m ultitude of oper ating f unctions , in additio n to recorder

and alarm functions. Programm ing of tes t cycles is easily accomplished via the modern c olor-display controller MB1 and is also possible directly with a computer via Intranet in connection with the communication

software APT-COM™ 3 DataCo ntrolSystem (option, c hap. 16.1). The chamber comes equipp ed with an

Ethernet serial interf ace for computer comm unication. In addition, th e BINDER communic ation software

APT-COM (option) perm its networking up to 30 chambers and connec ting them to a PC for controlling

and programming, as wel l as recording and repr esenting temper ature and humidity data. F or further options, see chap. 20.6.

The chambers ar e equipped with

brakes.

Temperature ranges:

• MKF without hum idity: -40 °C / 104 °F up to +180 ºC / 356 °F,

four castors . Both front castors can be easi ly locked via the attached

• MKF in climatic operation: + 10 °C / 50 °F up to +95 °C / 203 °F

• MKFT without humidity: -70 °C / -94 °F up to +180 ºC / 356 °F

• MKFT in climatic operation: + 10 °C / 50 °F up to +95 °C / 203 °F

• MKF / MKFT in climatic operation with optional compressed air dryer:

0 °C / 32 °F up to +95 °C / 203°F

Humidity ranges:

• MKF / MKFT: 10% up to 98% r.H.

• MKF / MKFT with optional compressed air dryer: 5 % r.H. up to 98% r.H.

MKF+ MKFT (E3.2) 07/2017 page 15/115

Page 16

(A)

(F)

2.1 Chamber overview

(B)

(C)

(D)

(E)

Figure 3: Alternating climate chamber MKF / MKFT

(A) Instrument panel

(B) Door handle

(C) Window

(D) Door

(E) Refrigeration machine

(F) Access to fill the water can and to the humidity generation module

MKF+ MKFT (E3.2) 07/2017 page 16/115

Page 17

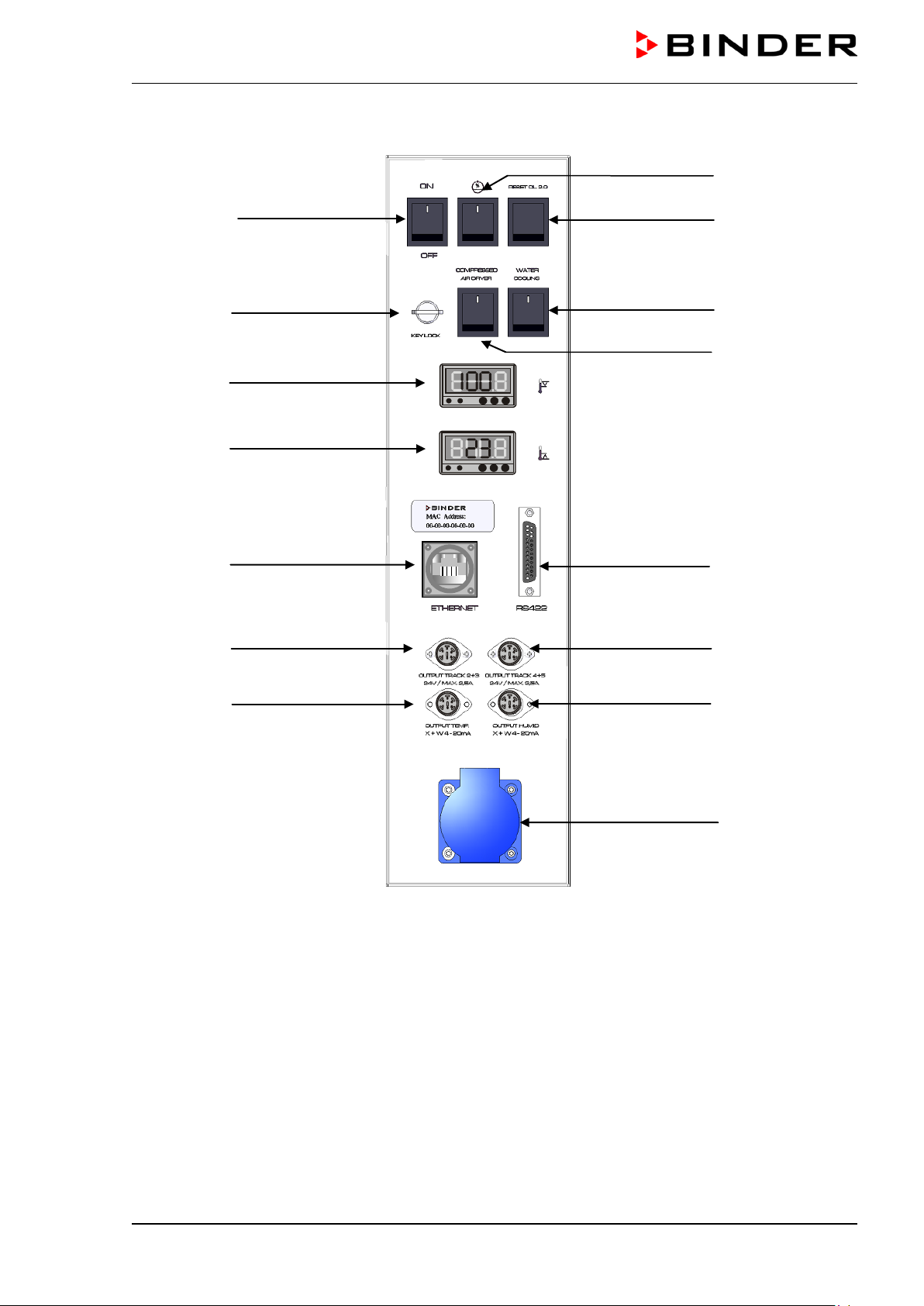

2.2 Lateral control panel

(3)

(6)

(9a)

(9b)

(10a)

(11)

(13)

(4)

(5)

(7)

(8)

(10b)

(12)

(14)

(15)

Figure 4: Lateral control panel MKF / MKFT at the right side of the humidity module with options

(3) Main power switch ON/OFF

(4) Humidity switch ON/OFF

(5) Reset switch for over and under temperature safety device class 2 (option)

(6) Key switch for keyboard locking (option)

(7) Switch for water cooling (only with MKF / MKFT 115 and 240) (option)

(8) Switch for compressed air dryer (option)

(9) Temperature safety device class 2 for over and under temperature (option):

Entry displays for upper (9a) and lower (9b) temperature limit

(10a) Ethernet interface for computer communication

(10b) RS422 interface for computer communication (option)

(11) 2 zero-voltage relay outputs via operation lines 2 and 3

(12) 2 zero-voltage relay outputs via operation lines 4 and 5

(13) Analog output temperature (option)

(14) Analog output humidity (option)

(15) Socket 230 V AC, max. 500 W

MKF+ MKFT (E3.2) 07/2017 page 17/115

Page 18

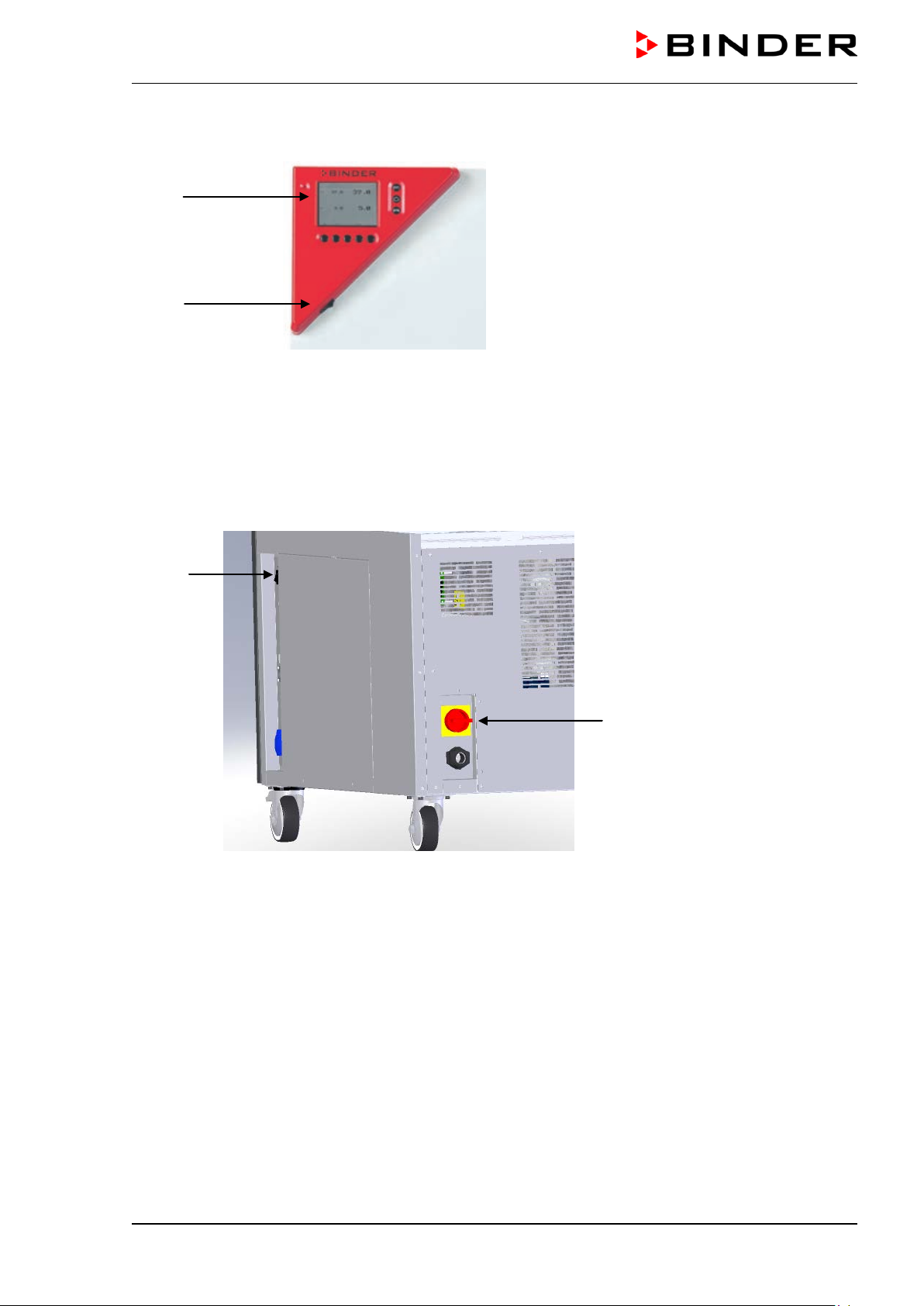

2.3 Instrument panel

(1)

(2)

(1) Microprocessor program controller MB1 with 2-channel technology for temperature and humidity

(2) Switch for interior chamber light

Figure 5: Triangle instrument panel

2.4 Rear power switch

(3)

(20)

Figure 6: Rear view of the chamber

(3) Main power switch

(20) Rear power switch

MKF+ MKFT (E3.2) 07/2017 page 18/115

Page 19

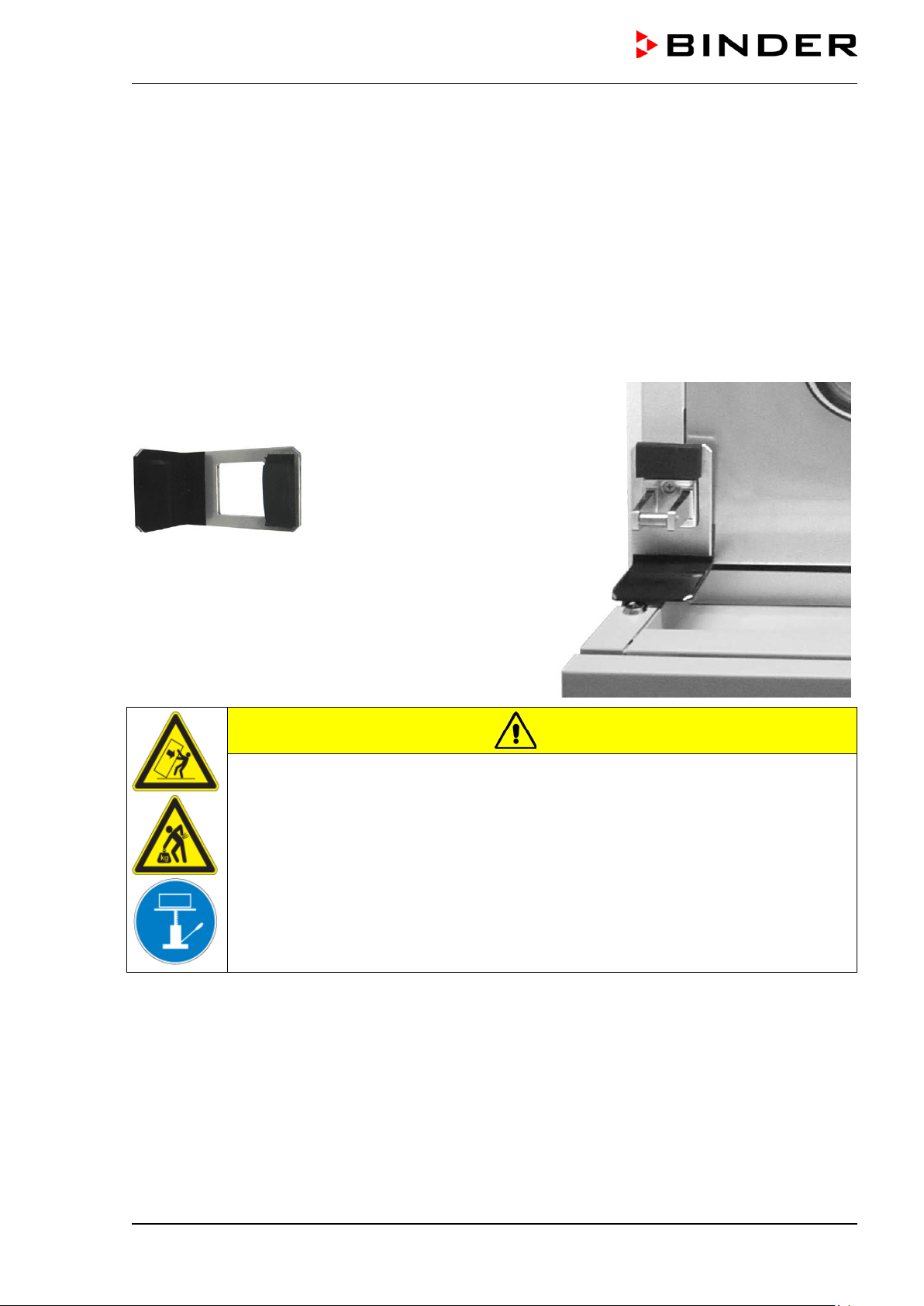

Remove the upholstered transport piece (L-type profile)

3. Completeness of delivery, transportation, storage, and installa-

tion

3.1 Unpacking, and checking equipment and completeness of delivery

After unpacking, p lease check the chamber and its o ptional accessories, if any, base d on the delivery

receipt for completenes s and for transportation damage. I nform the carrier immediately if transportation

damage has occurred.

The final tests of the manufactur er m a y have caused t rac es of the s helves on the i nner s urfaces. This has

no impact on the function and performance of the chamber.

Please remove an y transportation protection de vices and adh esives in/on th e chamber and on th e doors

and take out the operating manuals and accessory equipment.

from the lower door locking and keep it for possible later

transportation.

Figure 7:

Door locking with transport piece (state of delivery)

CAUTION

Sliding or tilting of the chamber.

Damage to the chamber.

Risk of injury by lifting heavy loads.

∅ Do NOT lift or transport the chamber using the door handle, the door or the lower

housing.

∅ Do NOT lift the chamber by hand.

Keep the chamber in upright position.

Lift the chamber from the pallet using technical devices (fork lifter). Set the fork lifter

only from the rear in the middle of the chamber. Make sure to place all the lateral supports of the chamber on the forks.

If you need to return the chamber, please use the original packing and observe the guidelines for s afe

lifting and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 18.1.

Note on second-hand units (Ex-Demo-Units)

Second-hand units ar e chambers that have been used for a short time for tests or ex hibitions. They are

thoroughly tested before resale. BINDER ensures that the chamber is technically sound and will work

flawlessly.

Second-hand units are marked with a sticker on the chamber door. Please remove the sticker before

commissioning the chamber.

MKF+ MKFT (E3.2) 07/2017 page 19/115

Page 20

3.2 Guidelines for safe lifting and trans por ta tion

The front castors of the cham ber c an be block ed by b rak es. Please m ove the chambers with cas tors on ly

when empty and on an even surface, otherwise the castors may be damaged. Mount the upholstered

steel L-type profile at t he lo wer do or loc king. After operation p lease obs erve the guidelines for t emporarily

decommissioning the chamber (chap. 18.2).

CAUTION

Sliding or tilting of the chamber.

Damage to the chamber.

Risk of injury by lifting heavy loads.

Do NOT lift or transport the chamber using the door handle, the door or at the lower

housing.

Do NOT lift the chamber by hand.

Transport the chamber only in its original packaging.

Secure the chamber with transport straps for transport.

Keep the chamber in upright position.

Place the chamber using technical devices (fork lifter) on the transport pallet. Set the

fork lifter only from the rear in the middle of the chamber. Make sure to place all the

lateral supports of the chamber on the forks.

Transport the chamber with the original transport pallet. Set the fork lifter ONLY to the

pallet. Without the pallet the chamber is in imminent danger of overturning.

You can order transport packing and pallets for transportation purposes from BINDER service.

Permissible ambient temperature range during transport:

• If the steam humidifying system has NOT been emptied: +3 °C / 37.4 °F to +60 °C / 140 °F.

• After BINDER Service has emptied the steam humidifying system: -10 °C / 14 °F to +60 °C / 140 °F.

With temperatures below +3 °C / 37.4°F, water must be completely removed from the humidifying system.

CAUTION

Transport below +3 °C / 37.4°F with filled steam humidifying system.

Freezing in the steam generator.

Damage to the chamber.

Contact BINDER Service bef or e any transp ortat ion be l o w +3 °C / 37.4°F.

3.3 Storage

Intermediate storage of the chamber is possible in a closed and dr y room. Observe the guidelines for

temporary decommissioning (chap. 18.2).

Permissible ambient temperature range during storage:

• If the steam humidifying system has NOT been emptied: +3 °C / 37.4 °F to +60 °C / 140 °F.

• After BINDER Service has emptied the steam humidifying system: -10 °C / 14 °F to +60 °C / 140 °F.

MKF+ MKFT (E3.2) 07/2017 page 20/115

Page 21

CAUTION

With temperatures below +3 °C / 37.4 °F, water must be complet ely removed from the humidifying system.

Storage below +3 °C / 37.4 °F with filled steam humidifying system.

Freezing in the steam generator.

Damage to the chamber.

Contact BINDER Service before any storage below +3 °C / 37.4 °F.

• Permissible ambient humidity: max. 70 % r.H., non-condensing

CAUTION

Condensation by excess humidity.

Danger of corrosion on the housing after operating at humidity values > 70 % r.H.

for a long period.

Dry the appliance completely before shut-down:

• Set the humidity to 0 % r.H. or turn off humidity switch (4).

• Set the tem perature set point to 150 °C / 302 °F (Manual m ode). Let the chamber

operate for approx. 2-3 hours with closed door. Remove the access port plugs.

• Only then, shut do w n th e chamber at the main p o wer s witc h (3) an d c lose the tap of

the water supply.

After drying the chamber for decommissioning, the humidity value will approximate ambient

humidity.

When after storage in a co ld location you transfer the chamber to its warmer ins tallation site, condensation may form. Before s tart-up, wait at least two hour s until the chamber has att ained ambient temper ature and is completely dry and the oil in the compressors has warmed up.

In case of a prolonged temporal d ecommissioning: Leave the chamber door open or remove the ac cess

port plugs.

3.4 Location of installation and ambient conditions

Set up the chamber on a flat, even and non-flammable surface, free from vibration, and in a wellventilated, dry locatio n and align it using a spir it level. The site of installation m ust be capa ble of s upporting the chamber’s weight (s ee technical data, chap. 20.4). T he chambers are designed f or setting up inside a building (indoor use).

When after storage in a co ld location you transfer the chamber to its warmer ins tallation site, condensation may form. Before s tart-up, wait at least two hour s until the chamber has att ained ambient temper ature and is completely dry and the oil in the compressors has warmed up.

CAUTION

Danger of overheating.

Damage to the chamber.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

MKF+ MKFT (E3.2) 07/2017 page 21/115

Page 22

• Permissible ambient temperature range during operation: +18 °C / 64. 4 °F to +32 °C / 89.6 °F. At

elevated ambient temperature values, fluctuations in temperature can occur.

The ambient temperature should not be substantially higher than the indicated ambient temperature of +25 °C / 77°F to which the specified technical data relate. For other ambient conditions, deviations from the indicated data are possible.

• Permissible ambient humidity: 70 % r.H. max., non-condensing.

When operating the cham ber at tem perature s et-po ints belo w am bient tem peratu re, hig h am bient hum idity may lead to condensation on the chamber.

• Installation height: max. 2000 m / 6.6 ft. above sea level.

A water tap (1 bar to 10 bar) is neces sary for the installation of the hum idification system. If no suitable

house water connection is available, you can manually supply water by filling the water can (chap. 4.2).

To avoid any possible water damage, provide a floor drain at the location of the device. Select

a suitable installation site to avoid any consequential damage by splashing water.

When placing several chambers of the same size sid e by side, m ainta in a m inimum distance of 250 m m /

9.84 in betwee n each chamber. Wall distances: r ear 300 mm / 11.81 in, sides 200 mm / 7.87 in. Spac ing

above the chamber of at least 200 mm / 7.87 in must also be maintained.

• With optiona l compressed air dryer: Wall distance r ear approx. 1 m / 3.28 ft so that it is possible to

read the status display of the compressed air dryer on the chamber rear.

• Chambers with v oltage and freque ncy changer: rear w all distance of the a lternating clim ate chamber

approx. 1 m / 3.28 ft to set up the voltage and frequency changer

CAUTION

Danger by stacking.

Damage to the chambers.

∅ Do NOT place the alternating climate chambers on top of each other.

To completely separat e the chamber f rom the power supp ly, you mus t disconnect the power plug . Install

the chamber in a way that the power plug is easily accessible and can be easily pulled in case of danger.

With an increased amount of dust in the ambient air, clean the cond enser fan several times a year. We

recommend check ing the fan grid (behind the lef t maintenance access flap) every week. In case of v is ible

dirt accumulation, disconnect the chamber and clean the fan grid by suction.

Avoid any conducti ve dust in the ambiance accor ding to th e chamber layout com plying with pollution degree 2 (IEC 61010-1).

The chamber must not be installed and operated in potentially explosive areas.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT operate the chamber in potentially explosive areas.

∅ KEEP explosive dust or air-solvent mixtures AWAY from the vicinity of the chamber.

MKF+ MKFT (E3.2) 07/2017 page 22/115

Page 23

4. Installation and connecti ons

(18)

(17)

(20)

(21)

(22)

(16)

Figure 8: Rear view of the chamber with water connections and optional water cooling

(16) Power cable

(17) Wastewater connection “OUT” with hose olive for hose ½“

(18) Freshwater connection “IN” with screw thread ¾’’ for hose ½“, with union nut

(20) Rear power switch

(21) Connection “OUT ” for cooling water ou tlet with s crew thread ¾ ’’ for hose ½“, with union nut (option

water cooling)

(22) Connection “IN” for cooling water inlet with screw thread ¾’’ for hose ½“, with union nut (option

water cooling)

MKF+ MKFT (E3.2) 07/2017 page 23/115

Page 24

4.1 Wastewater connection for humidifying system

Fasten the wastewater h ose to th e waste water c onnec tion “OU T” (17) ( Figure 8) on the rear of the chamber (olive ∅ 14 mm). Observe the following points:

• You can use a part of the supplied tap water hose as a drainage hose. In case another hose is us ed , it

has to be permanently resistant against at least 95 °C / 203 °F.

• Mount the waste water hose with a m axim um pos itive inclinat ion of 1 m and a m ax im um total length of

3 m.

• Protect both ends of the drainage hose with two of the four supplied hose clamps.

Wastewater is collected in an internal can with a volume of approx. 0.5 liters. It is pumped off

only when required, thus there is no continuous wastewater flow.

Protect the wastewater supply at both sides with the supplied hose clamps.

4.2 Freshwater supply for humidifying system

Connect the wastewater pipe before connecting the chamber to a freshwater pipe or filling the

water can.

You can supply the chamber with freshwater via a wat er pipe or b y manua ll y filling the int ernal water can.

It is not necessary to switch between both poss ibilit ies . When connecting to a wat er pip e, th e wa ter c an is

automatically filled.

Water intake temperature NOT below +5 °C / 41 °F and not exceeding 40 °C / 104 °F.

CAUTION

Calcification of the humidifying system.

Damage to the chamber.

Operate the chamber with deionized (demineralized) water only.

Types of suitable water quality

• Deionized water from a water treatment installation alr ead y existin g at the c ustom er's s ite. Con duct iv ity from 1 µS /cm up to a max im um of 20 µS/c m . (Water, which is in equilibrium with the CO

and has a conductivity below 1 µS/cm (ultrapure water), may cause acid corrosion due to its low pH.)

• Water treated by the optional water treatment system BINDER Pure Aqua Service (disposable system). A reusable measuring equipment to assess the water quality is included (chap. 16.6).

in the air,

2

BINDER GmbH is NOT responsible for the water quality at the user’s site.

Any problems and malfunctions that might arise following use of water of deviating quality is

excluded from liability by BINDER GmbH.

The warranty becomes void in the event of use of water of deviating quality.

MKF+ MKFT (E3.2) 07/2017 page 24/115

Page 25

the rear of

4.2.1 Automatic fresh water supply for humidifying system via water pipe

An enclosure inside the chamber contains the conn ection kit for water suppl y and wastewater. I nstall the

water supply connect ion using either the e nclosed water hos e or another pressur e-resistant one. T o accomplish this, remove the c over of the fres hwater c onnection “ IN” (18) (Figure 8) on the rear of the chamber. Protect both ends of the hose with two of the four supplied hose clamps. Before turning on the

chamber, check the c onnection for leaks. W ater supply is automaticall y effected via the freshwater c onnection “IN” (18).

As the chamber only lets in water when required, there is no continuous water flow.

• Supply pressure 1 to 10 bar when connecting to a water pipe.

• Water type: deionized (demineralized) water

• Water intake temperature NOT below +5 °C / 41 °F and not exceeding 40 °C / 104 °F.

• The water intake shall be provided with a shut-off slide or water-tap.

• For the water sup ply, fix the delivered adapter with hose olive on the thread at

the chamber.

• Protect the water supply at one side with the supplied hose clamp.

4.2.2 Manual fresh water supply for humidifying system via internal freshwater can

If no house water connec tion with s uitab le water is av ailable, you ca n m anua lly s upply wat er b y fi lling th e

freshwater can (total volume: 19 liters / 0.67 cu.ft. up to the maximum level mark), which is located behind

the right door of the humidity generation module.

The cover of the water inl et va lve must be screwed on the fres hwater c on nection “IN” (18). Open the do or

(F) (Figure 3) to access the filler neck of one of the water can. You cannot totally tak e out the water can

because of its fix c onnec t io ns . Fil l t he water ca n o nly up to ¾, up to the m axim um level mark. When filling

it too much with the chamber turn ed on, the alarm message “

controller (chap. 13.1). Manually suck off the wat er, or operate the chamber with high temperature and

humidity values until the ex cess water is consum ed. W hen filling it too muc h with the cham ber turned of f,

water can escape from the chamber. Thus, ensure not to f ill the can by more than the maximum level

mark.

To guarantee humidification during 24 hours even at high humidity set-points with manual

water supply, we recommend filling the freshwater can (option) daily at the end of the day.

WATER LEVEL TOO HIGH” is displayed on the

MKF+ MKFT (E3.2) 07/2017 page 25/115

Page 26

(19)

4.2.3 Water circle: lever for condensate recycling (option)

Figure 9: Lever for condensate recycling (open position)

next to the freshwater can behind the maintenance access door

The lever (19) for c ondensate rec ycling is located behind the m aintenanc e access door next to t he freshwater can.

• Open lever (ver tica l position): the condensate f r om the interi or is c onducted to the freshwater can. Use

only with clean interior!

• Closed lever (horizontal position): the condensate is conducted to the wast e water connection. Use this

position in case of soiling / contamination of the interior.

CAUTION

Soiling of the vapor humidification system.

Damage to the chamber.

Conduct the condensate to the wastewater connection in case of soiling / contamina-

tion of the interior (horizontal lever position).

MKF+ MKFT (E3.2) 07/2017 page 26/115

Page 27

4.3 Connection of cooling water outlet for water cooling (option)

An enclosure inside the chamber contains the connection kit for the cooling water inlet and outlet.

• Fasten the coo ling hose to the connection “O UT” (21) (Figure 8) on the rear of the chamber (screw

thread ¾’’).

• You can use a part of the supplied tap water hose as a drainage hose. In case another hose is us e d , it

has to be permanently resistant against max. 50 °C / 122 °F.

• Protect both ends of the drainage hose with two of the f our supplied hose clamps. Befor e turning on

the chamber, check the connection for leaks.

4.4 Connection of cooling water inlet for water cooling (option)

Connect the cooling wat er outl et before connecting the cooling water inlet.

Type of suitable water quality:

• Water intake temperature: max. 10 °C / 50 °F.

• pH value 4-7

• connection pressure: 4 to 10 bar

BINDER GmbH is NOT responsible for the water quality at the user’s site.

Any problems and malfunctions that might arise following use of water of deviating quality is

excluded from liability by BINDER GmbH.

The warranty becomes void in the event of use of water of deviating quality.

An enclosure inside the chamber contains the connection kit for the cooling water inlet and outlet.

• Fasten the cooling water hos e to t he c o nnec t ion “I N” ( 22) (Figure 8) on the re ar o f the chamber (screw

thread ¾’’).

• Install the water supply connec tion using eit her the en closed water hose or anoth er press ure-resistant

one. To acc om plish this, re move the cover of the freshwater conn ec tio n “ IN” (22) ( Figure 8) on the rear

of the chamber.

• Protect both ends of the hose with t wo of the four suppli ed hose clam ps. Before turnin g on the chamber, check the connection for leaks.

MKF+ MKFT (E3.2) 07/2017 page 27/115

Page 28

4.5 Connection kit for connecting the chamber’s freshwater connection to a

water pipe

A safety kit against f looding c aused by bur st water h oses is enclosed with the chamber. It consists of the

following:

• Hose burst protection device

• Hose nozzle with screwing

• 4 hose clamps

• 6m water hose, divisible for the feed hose and drain

Protection principle of hose burst protection:

Whenever a strong water flow of approx. 18 l / min. occurs, e.g. c aused by a burst water h ose, a valve

automatically cuts off the water supply, which can be heard as a clic king noise. The water supply now

remains shut until it is manually released.

Assembly:

Screw the hose burst protec tion device onto a water tap with a G¾ inch right turning thread connec tion.

The connection is self -sealing. Establish the connecti on between the safety kit and the cham ber with a

part of the supplied hose. Protect both ends of the hose by the supplied hose clamps.

We recommend connectin g t he hose as th e las t s te p in order to a void twisting the hose while scre wing o n

the safety kit.

Open the water tap slowly in order to avoid actuating the hose burst protection device.

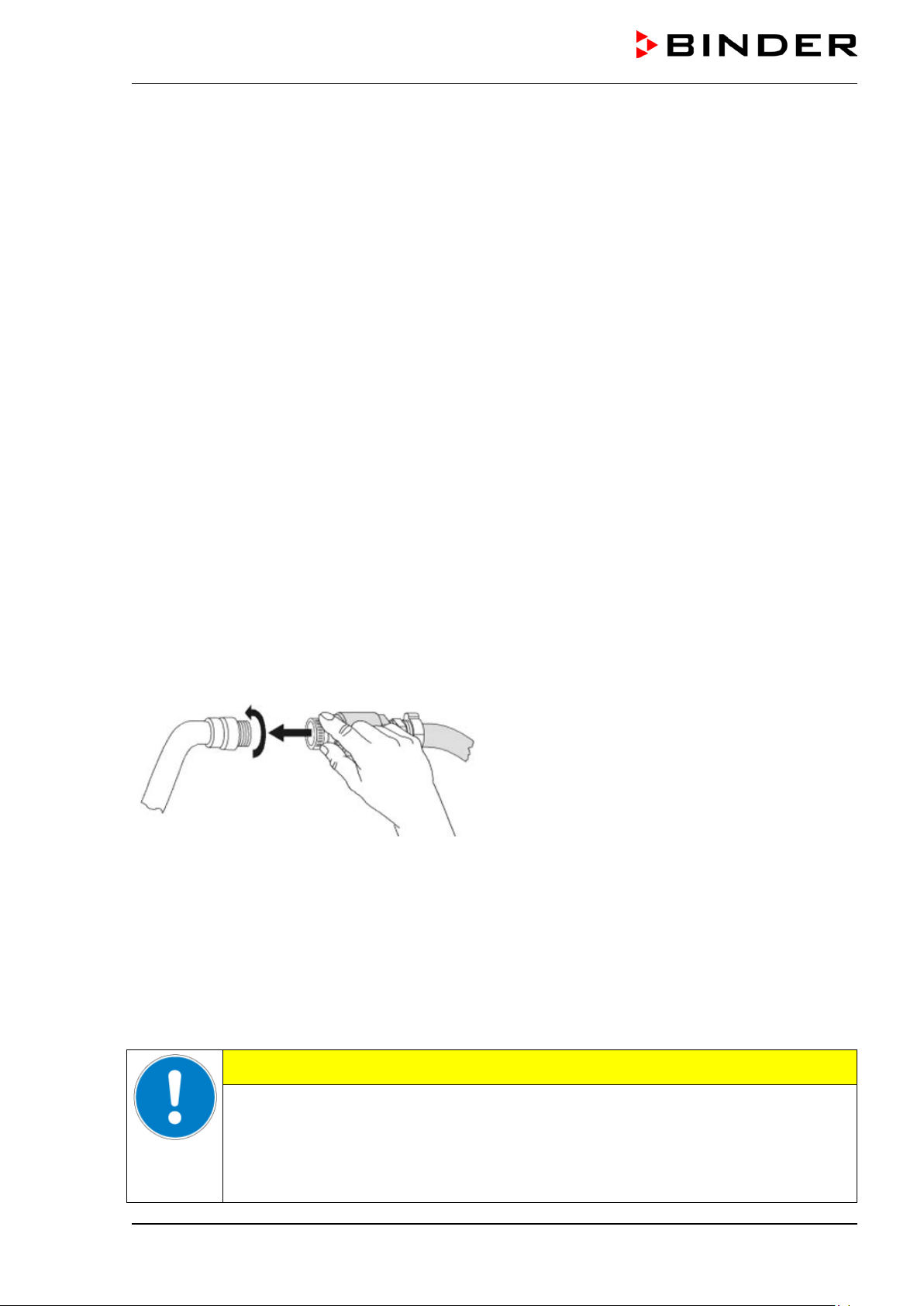

Figure 10: Assembly of the connection kit

Release of the reflux protection device:

In case the burst protection device has interru pted the water supp ly, firs t find the r eason and r em ove it as

necessary. Close the wate r tap. Release the valve by a half lef t-turn of the upper knurled part. You can

hear the release of the valve as a c lick ing noise. T ighten the burs t prot ection de vice agai nst the water tap

by a right turn. Open the water tap slowly afterwards.

Maintenance of the assembly of the hose burst protection device:

Calcification can im pair valve function. We recommend an a nnual inspection by a skilled plum ber. The

plumber should rem ove the safety kit to check the valve b y hand for proper function and calc ification or

blockage.

CAUTION

Danger of calcification.

Impairment of valve function.

Have a plumber inspect the valve annually.

Remove calcifications by citric acid or acetic acid solutions.

Continue by testing the function and tightness of the mounted unit.

Check: Quickl y open the water tap while there is n o chamber connected – the valve should cut off the

water flux without any delay.

MKF+ MKFT (E3.2) 07/2017 page 28/115

Page 29

4.6 Safety kit: Hose burst protection device with reflux protection device for

the chamber’s freshwater connection (available via BINDER INDIVIDUAL

customized solutions)

A safety kit with a reflux protec tion device is available for protecti on of the dri nking water system against

flooding caused by burst water hoses.

Protection principles:

Whenever a strong water flow of approx. 18 l / min. occurs, e.g. cause d by a burst water hose, a valve

automatically cuts off the water supply, which can be heard as a clic king noise. The water supply now

remains shut until it is manually released.

A possible endang erin g of the dr inking water system d epen ds o n t he r is k potential of the chargi ng material. Under unfavorable conditions (e.g. decreasing pressure inside the tap water system), drained off

charging material coul d be suck ed out of the cham ber via the steam generator i nto the tap water system

and therefore contaminate the drinking water . The safety kit with a reflux protection device pro vi des s ecurity in case of short-term utilization of s ubstances with low risk potential. W hen using substanc es bearing

a higher risk potent ial, install a pip e disconnector to assure absolute protection. It is the user’s respons ibility to prevent (acc ording to national standards) an y reflux of contaminated water f rom getting into the

drinking water system.

Assembly:

The standard supplied parts – hose burst protection device, hose nozzle with screwing – are not needed.

Screw the pre-mounted as sembly of the hose burst p rotection and ref lux protection de vices onto a water

tap with a G¾ inch right tu rning thread connec tion. The connect ion is self-seal ing. Establish the co nnection between the safety kit and the c hamber with a part of the supplied hose. Protect both ends of the

hose with the supplied hose clamps.

We recommend connectin g the hose as the last step in order to avoid twisting it while s crewing on the

safety kit.

Open the water tap slowly in order to avoid actuating the hose burst pr otec ti on de vice.

Figure 11: Assembly of the safety kit: hose burst

protection and reflux protection devices (option)

Release of the reflux protection device:

In case the hose burst prot ection device interru pts the water supp ly, firs t find th e reason an d rem ove it as

necessary. Close the wate r tap. Release the valve by a half lef t-turn of the upper knurled part. You can

hear the release of the valve as a c lick ing noise. T ighten the burs t prot ection de vice agai nst the water tap

by a right turn. Open the water tap slowly afterwards.

Maintenance of the assembly of hose burst protection and reflux protection devices:

Calcification can impair the function of both valves. We recommend an annual inspection by a skilled

plumber. The plumber should remove the safety kit with the reflux protection device to check the two

valves by hand for proper function and calcification or blockage.

CAUTION

Danger of calcification.

Impairment of valve function.

Have a plumber inspect the two valves annually.

Remove calcifications by citric acid or acetic acid solutions.

Continue by testing the function and tightness of the mounted unit.

MKF+ MKFT (E3.2) 07/2017 page 29/115

Page 30

(a)

(b)

(a)

(b)

Check: Quickl y open the water tap while there is n o chamber connected – the valve should cut off the

water flux without any delay.

4.7 Installation of the voltage and fre quency changer

(chambers with voltage and frequenc y changer )

The voltage and frequency changer is supplied packed separately together with the chamber.

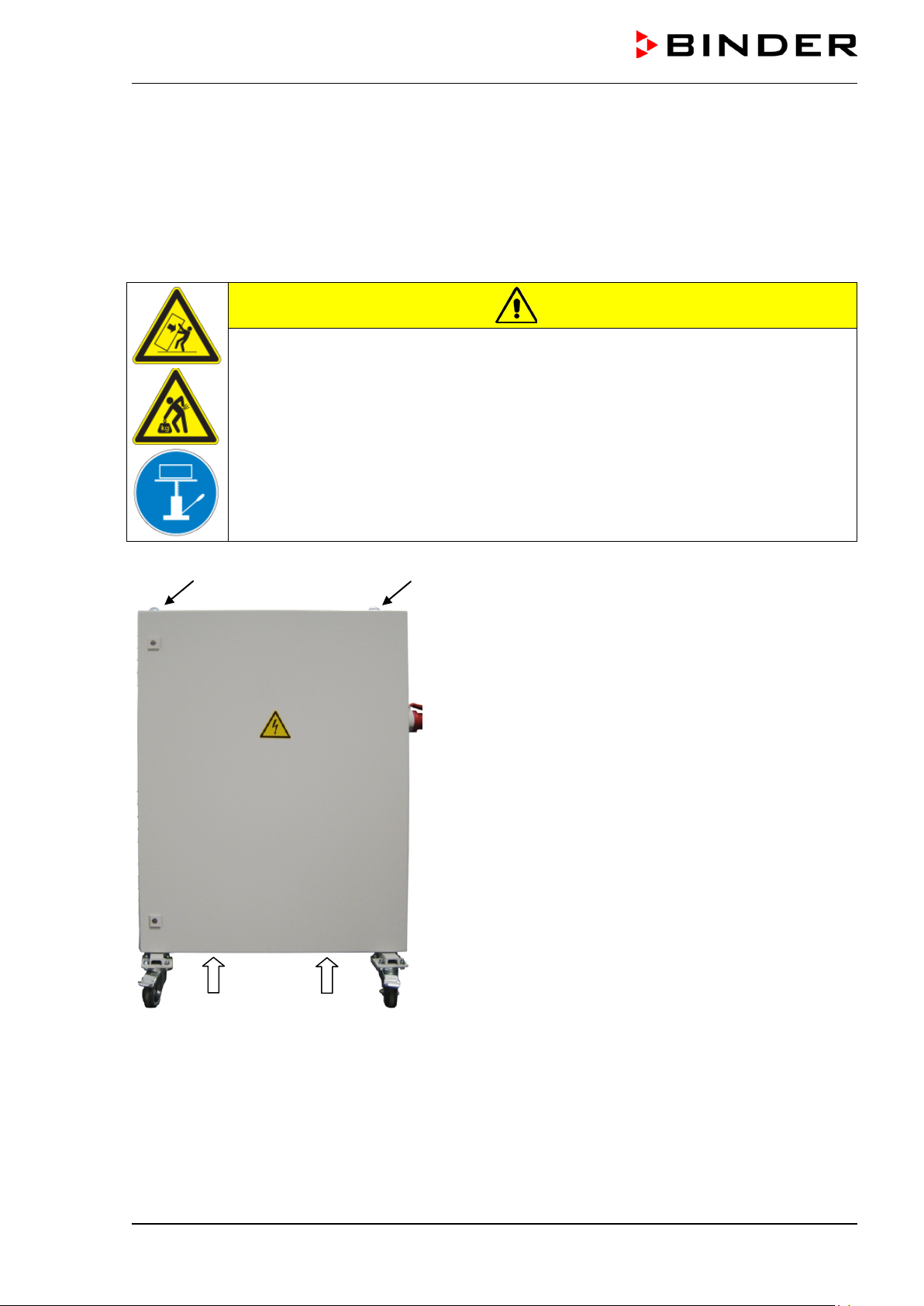

CAUTION

Sliding or tilting of the voltage an d fre q u ency changer.

Damage to the voltage and frequency changer.

Risk of injury by lifting heavy loads.

∅ Do NOT lift the voltage and frequency changer by hand.

Lift the voltage and frequency changer from the pallet using technical devices (for k

lifter). Set the fork lifter only from the rear in the middle of the chamber.

Alternatively, the voltage and frequency changer can also be lifted at the eyelets on

the top by means of a lift truck

(a) Eyelets for lifting with a lift truck

(b) Positions for a forklift

Figure 12: Positioning of aids for lifting the voltage

and frequency changer

For the installation of the voltage and frequenc y changer behind the chamber, pr ovide a rear wall distance of the chamber of approx. 1 m / 3.3 ft.

If possible, fix the volta ge a nd f requenc y changer at the chamber . For this purpose, an Allen k e y size 4 is

required. Connect t he slots at the e nd of the chassis with two M6 scr ews to the threads provided below

on the rear panel of the chamber (see Figure 13).

MKF+ MKFT (E3.2) 07/2017 page 30/115

Page 31

MKF 115

MKF 240

16 Amp

3 x internal

MKF 720

MKFT 720

25 Amp

CAUTION

Danger of overheating.

Damage to the voltage and frequency changer.

∅ Do NOT install the voltage and frequency changer in unventilated recesses.

Ensure sufficient ventilation for dispersal of the heat.

The voltage and frequenc y changer is equipped with four castors. The r ear castors can be easily lock ed

via the attached brakes

4.8 Electrical connection

4.8.1 Information on connecting the alternating climate chamber

The chambers are suppli ed r ead y for c onnection. They come with a fixed p o wer c onnec t ion ca bl e of 2700

mm / 8.9 ft in length and are equipped with3 internal overload releases against excess-current.

Model Power plug

MKFT 115

MKFT 240 CEE plug 5-poles, 16 Amp 400 V at 50 Hz 3 N~

• The domes tic socket must also prov ide a protective conduct or. Make sure that the connection of the

protective conductor of the domes tic installatio ns to th e cham ber ’s protective co nductor meets the latest technology. The protective conductors of the socket and plug must be compatible!

• Prior to con nect ion and s tar t-up, chec k the po wer su ppl y voltag e. Com par e the v alues to the s pecif ied

data located on the chamber’s type plate (left chamber side, bottom right-hand, chap. 1.4)

• When connecting, please observe the regulations specified by the local electricity supply company and

as well as the VDE directives (for Germany). We recommend the use of a residual current circuit

breaker.

• Pollution degree (acc. to IEC 61010-1): 2

• Over-voltage category (acc. to IEC 61010-1): II

CEE plug 5-poles, 16 Amp

CEE plug 5-poles, 32 Amp

Nominal voltage ± 10% at the

indicated power frequency

400 V at 50 Hz

400 V at 50 Hz

Current

type

3 N~

3 N~

Chamber

fuse

16 Amp

3 x internal

3 x internal

CAUTION

Danger of incorrect power supply voltage.

Damage to the equipment.

Check the power supply voltage before connection and start-up.

Compare the power supply voltage with the data indicated on the type plate.

See also electrical data (chap. 20.4).

To completely separate the chamber from the power supply, you must disconnect the power

plug. Install the chamber in a way that the power plug is easily accessible and can be easily

pulled in case of danger.

MKF+ MKFT (E3.2) 07/2017 page 31/115

Page 32

chamber

(H)

(I)

(G)

4.8.2 Connecting the voltage and frequency changer (for chambers equipped with a

voltage and frequency changer)

The voltage and frequenc y changer is supplied with a fixed power connec tion cable without a p lug. It is

protected against exc ess-current with 3 internal overload releases. The connection is m ade by the customer.

The socket must provide a protective conductor.

Electrical connection data:

• Input side: 480 V, 60 Hz, 4-wire

• Output side (to the chamber): 400 V, 50 Hz, 5-wire

To establish the elec trical connection of the alternating climate cham ber with the volta ge and frequency

changer, proceed in the following order:

1. Connect the chamber to the connection socket (G) of the voltage and frequency changer

2. Establish the power connection of the voltage and frequency changer using the power cable (I)

3. Turn on the voltage and frequency changer at the power switch (H) (position “ON”)

4. Turn on the chamber with the main power switch (3) in the lateral control panel

Left side of the voltage and frequency changer

with connection socket (G) for the alternating climate

Figure 13: Voltage and frequency changer, mounted

MKF+ MKFT (E3.2) 07/2017 page 32/115

Right side of the voltage and frequency changer

with power switch (H) and power cable (I)

Page 33

Pilot lamp: Ready for operation

Figure 14: Power switch (H) of the voltage and frequency changer in position “ON”

In position “OFF” the switch can be locked, e.g. with a padlock.

5. Start up

After connecting the supply lines (chap. 4), you can start up the chamber.

• Turn on the rear power switch (20) at least one hour before operating the chamber.

• Turn on the chamber by the main power switch (3) in the lateral control panel.

• Open the water-tap for supply. Alternatively, fill the freshwater can (chap. 4).

• Turn on the humidifying and dehumidifying system with switch (4) (humidity switch ON/OFF).

After the first turn ing on of the hum idity or after an interruption of the po wer supply the re lative humidit y

will increase after a de lay of approx. 20 m inutes. During this period, the r elative humidity can dr op considerably.

The refrigerating and dehu m idification f unctions are a vaila ble onl y one hour af ter turning o n the rear po wer switch (20). This is in dicated by the notific ation “1H PREHEAT PHASE” i n the control ler displa y (chap.

13.1). After 1 minute the m essage “WATER TANK EMPTY” appears on the c ontroller display. You can

reset this message only after the 1-hour prehe ati ng ph ase.

Warming chambers may release odors in t he first few da ys after comm issioning. T his is not a quality de-

fect. To reduce odors quickl y we recommend heating up the chamber to its nom inal temperature for one

day and in a well-ventilated location.

5.1 Function overview of display program controlle r MB1

EXIT button (to exit a menu point)

MKF+ MKFT (E3.2) 07/2017 page 33/115

AUTOMATIC button (to start a previously entered program)

ENTER button (to confirm a selection)

Navigation buttons (functions are assigned by the menu)

Switch for interior chamber light (2)