Page 1

CB (E2) Service Manual

state: 01/2002 created: 03/2002 / Jochen Tussinger

CB (E2) Service Manual

08:43:55 20.11.01

W

X

4.9

25.2

36.8

EXIT

°C

%

%

TEMP

TEMP

37.0

C2O

5.0

O2

25.0

CONFIG W MENUE VIEW->

RESET

Version of the described Chamber :

Standard equipped CB CO2 Incubator E2

with

FPI Sensor System

and

MB1 Controller

SERIAL-NO. 01-27954 à

Order-No. 9040-0012 / CB 150

Order-No. 9040-0013 / CB 210

Page 2

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Contents

1 Modification levels...................................................................................................................3

2 Unit overview..........................................................................................................................4

2.1 The Controller MB1...........................................................................................................5

2.2 Short description of the MB1 Controller..............................................................................6

3 Function ...............................................................................................................................12

3.1 The CO2-measuring principle........................................................................................... 12

3.2 Function of the Heating System....................................................................................... 12

3.3 Flow-Chart of the heating function (basis CB 150 wiring diagram) ......................................13

3.4 Controller MB1 PIN description (Input / Output)................................................................ 14

3.5 Function of the CO2 System ............................................................................................15

3.6 Flow Chart of the CO2 System (basis CB wiring diagram) ..................................................15

3.7 Function of the Permadry® system.................................................................................. 16

3.8 Flow Chart of the Permadry® system (basis CB wiring diagram)........................................ 17

3.9 Description of the Function of the Fan Control ..................................................................17

3.10 Sterilization Mode ........................................................................................................18

3.11 Hot-air sterilization .......................................................................................................18

3.12 Hot-air sterilization with inner chamber contaminated with highly infective material ..........20

4 Trouble Shooting................................................................................................................... 22

5 Most common service work.................................................................................................... 25

5.1 Changeing of the fan....................................................................................................... 26

5.2 Take out of the electronic component board .....................................................................28

5.3 Opening of the rear service lid to achieve the area of the air jacket ....................................29

5.4 Setting of the door heating ...............................................................................................31

5.5 CO2-Reference Measurement.......................................................................................... 32

5.5.1 Measuring of CO2 indirectly via the pH of the cell medium ..........................................33

5.5.2 Measuring of CO2 directly via chemical indicator tubes............................................... 34

5.5.3 Measuring of CO2 directly via a electronic measuring device....................................... 35

6 Calibration............................................................................................................................ 36

6.1 Definition of calibration.................................................................................................... 36

6.2 References for calibration ................................................................................................36

6.3 Tolerance of the adjustment ............................................................................................36

Calibration instructions for CO2 incubator CB with screen controller MB1........................................37

Temperature / CO2 / O2 controller ................................................................................................37

Temperature calibration ............................................................................................................37

Calibration (alignment) of the temperatur e controller ...................................................................38

Reading out of the actual values:............................................................................................... 39

Entries: ....................................................................................................................................39

Result Calibration (alignment) of the temperature controller......................................................... 39

CO2 calibration (alignment)........................................................................................................ 40

O2 calibration (alignment).......................................................................................................... 41

7 Maintenance......................................................................................................................... 48

8 Explosion Drawings of the CB /E2 ..........................................................................................51

8.1 CB Component Board .....................................................................................................51

8.2 CB Kettle / Sensors / Heaters / Permadry......................................................................... 52

8.3 CB Door / Sealing / Inner parts ........................................................................................53

2

Page 3

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

1 Modification levels

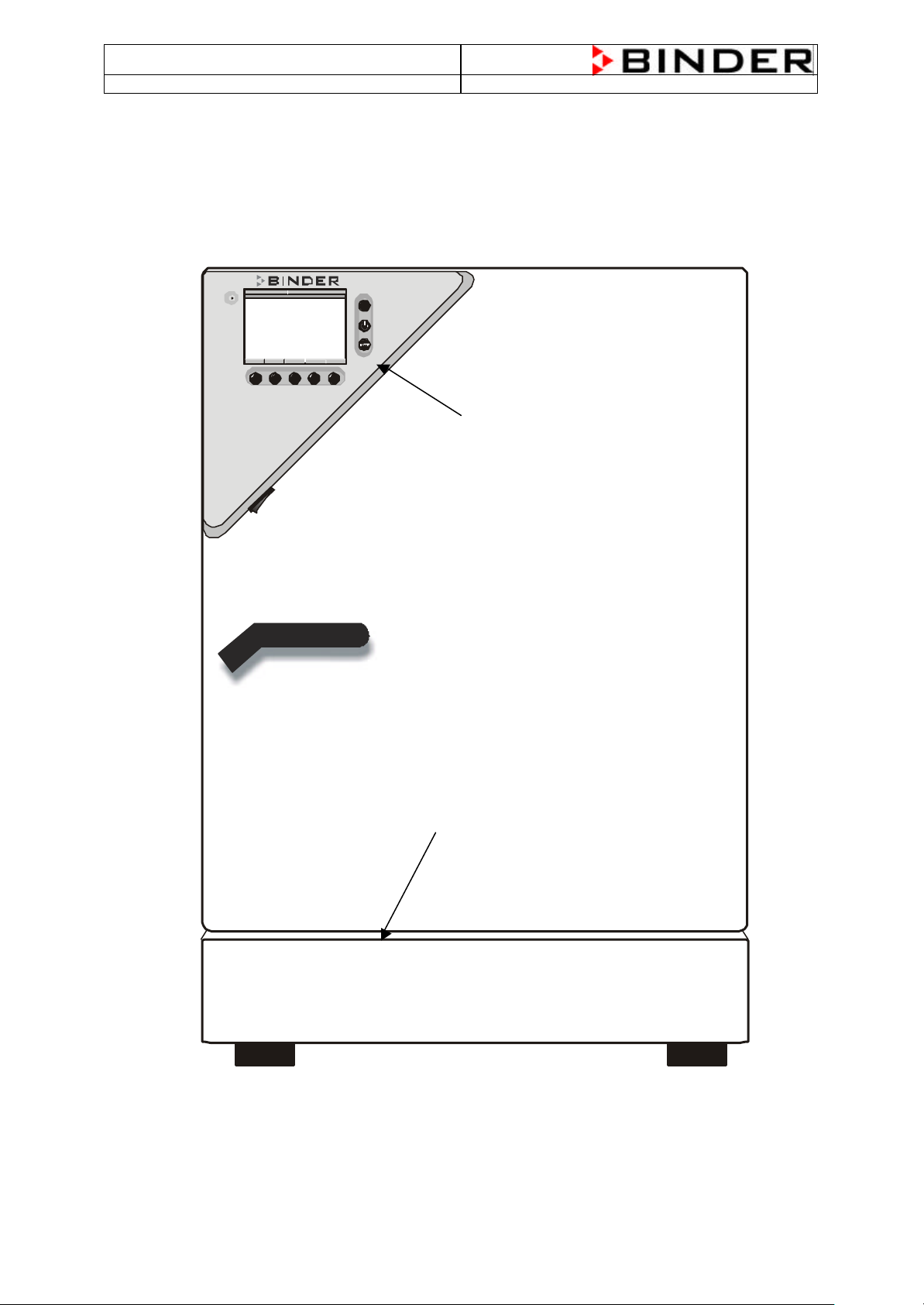

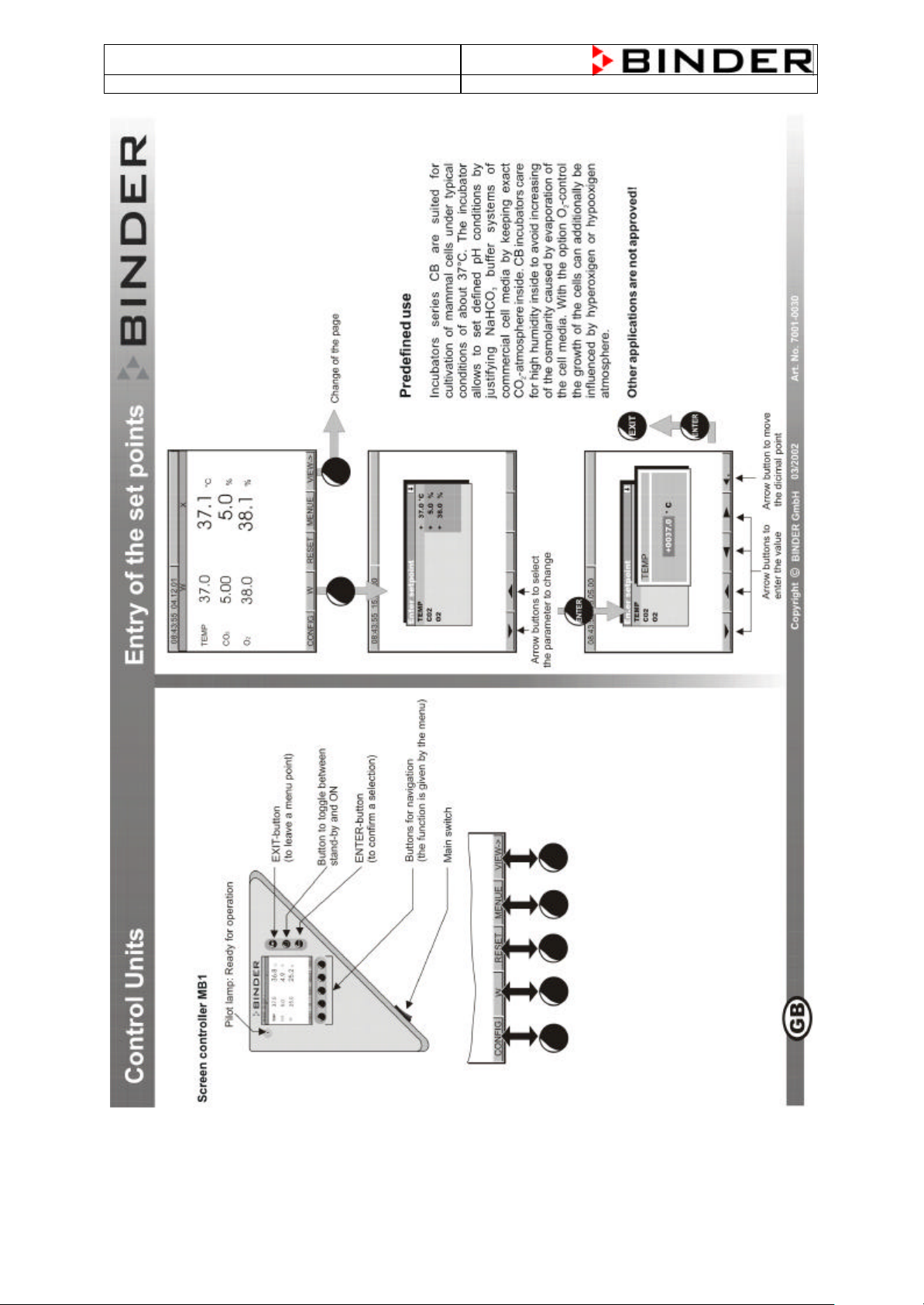

The CB CO2 Incubator E2 is a further development of CB CO2 Incubator E1. Especially the Display

controller MB1 inside the red triangle is conspicuous.

The whole electronic is placed inside the lower part of the CB CO2 Incubator (Front Access

Maintenance). Theres no I-box as at the CB CO2 Incubator E1 at the top of the chamber.

08:43:55 20.11.01

W X

TEMP

TEMP

37.0

5.0

25.0

36.8

4.9

25.2

RESET

C2O

O2

CONFIG W MENUE VIEW->

EXIT

°C

%

%

Display Controller MB1

Display controller MB1

Machine Room with all electronic parts

3

Page 4

CB (E2) Service Manual

Machine room with all

(M)

(F) (K)

state: 01/2002 created: 03/2002/ Jochen Tussinger

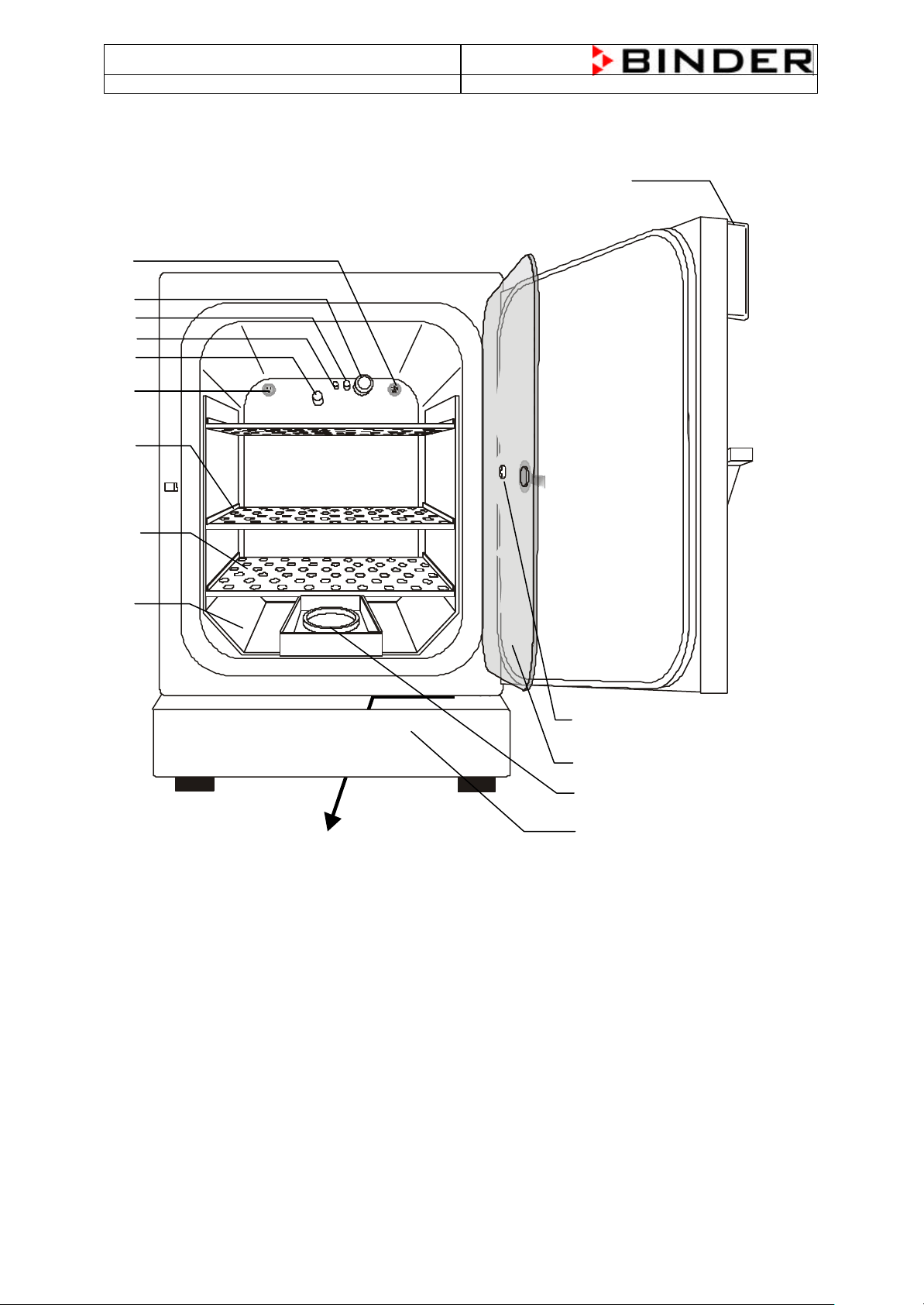

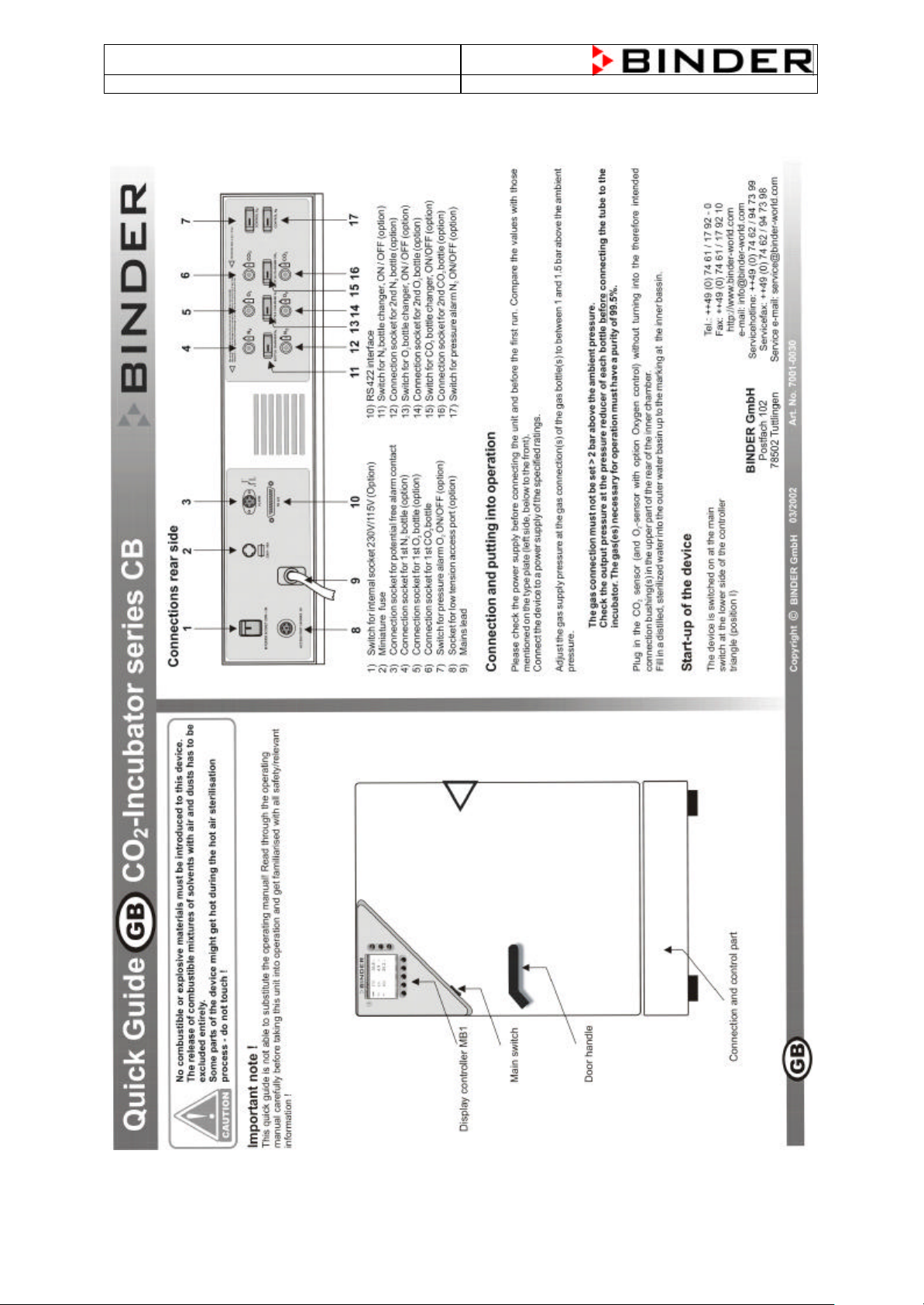

2 Unit overview

(B)

(C)

(D)

(E)

(G)

(H)

(I)

(J)

(A)

FRONT

electronic parts

(N)

(L)

A) Display controller MB1 for temperature and CO2 as well as O2 (option)

B) Connection socket for low tension supply (option)

C) CO2 sensor

D) Gas mixing head

E) PT 100 temperature probe

F) O2 sensor (option)

G) Internal socket 230V (max. 3 A) (option)

H) Shelf holder bar

I) Shelves

J) Shelf holder

K) Lower housing cover

L) Permadry® water basins

M) Inner glass door

N) Measuring access port

4

Page 5

CB (E2) Service Manual

5.0

VIEW->

Display Controller MB1

state: 01/2002 created: 03/2002/ Jochen Tussinger

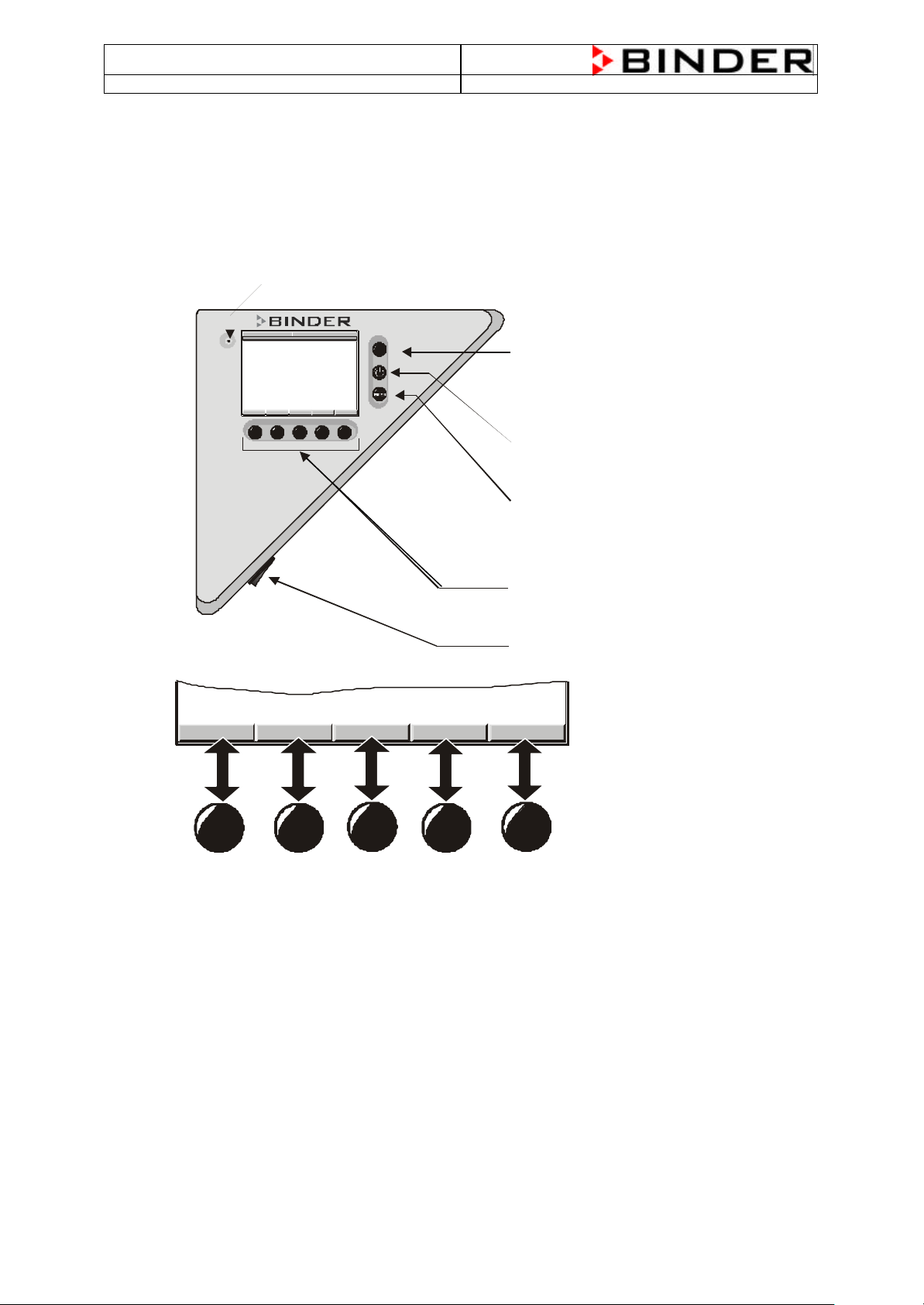

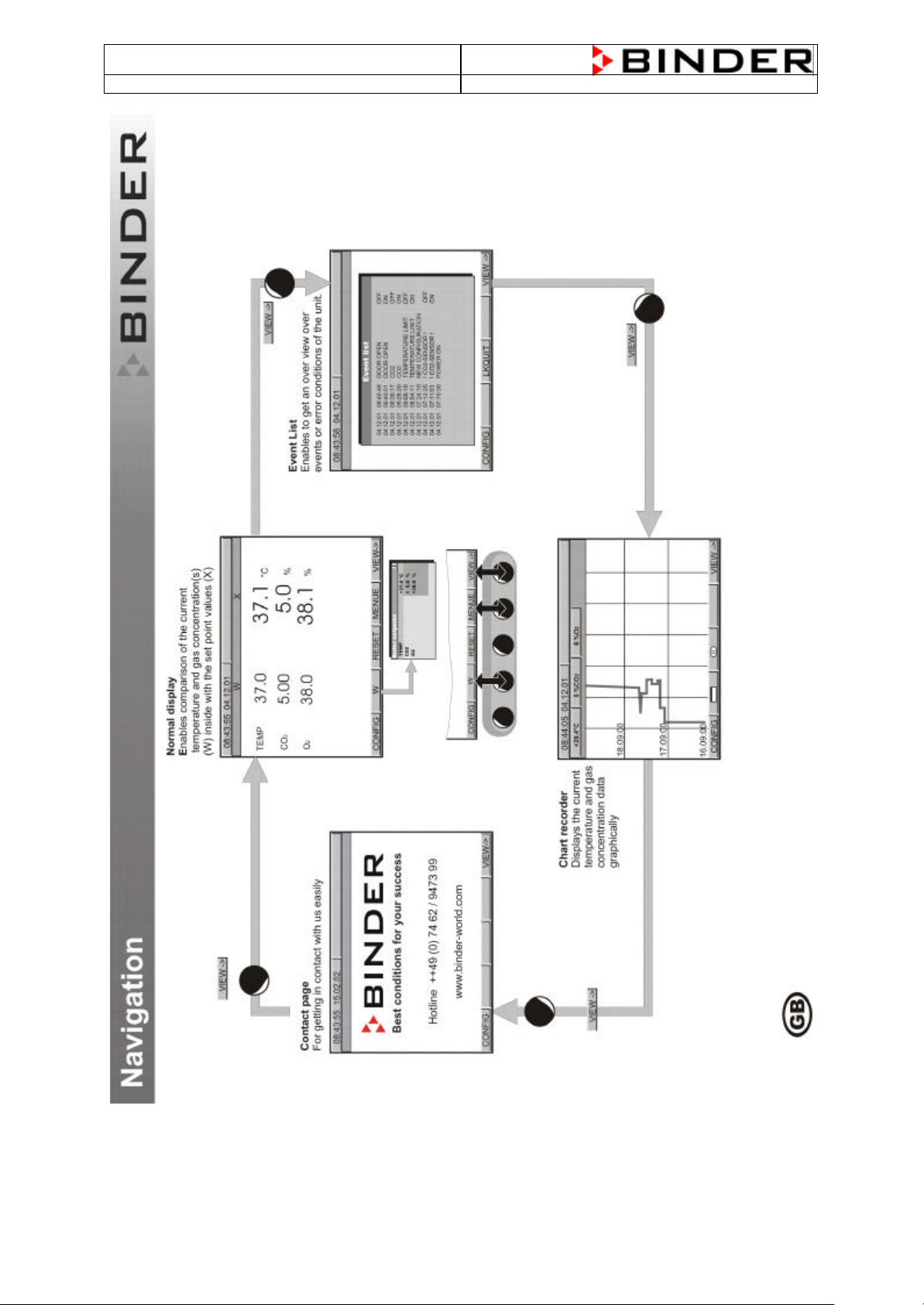

2.1 The Controller MB1

Operating Light

08:43:55 20.11.01

W X

TEMP

37.0

TEMP

C2O

O2

25.0

36.8

4.9

25.2

EXIT

°C

%

%

EXIT-Button

(to leave a

Menue)

CONFIG W MENUE VIEW->

RESET

ON / OFF Button

(Stand-by)

ENTER-Button

((to confirm a

selection)

Navigation buttons

(corresponding function

will be assigned)

Mainswitch

CONFIG

W

RESET

For the controller MB1, it is possible to show all setpoints an d actual values at the same time.

It is also possible to display the actual values portrary.

MENUE

5

Page 6

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

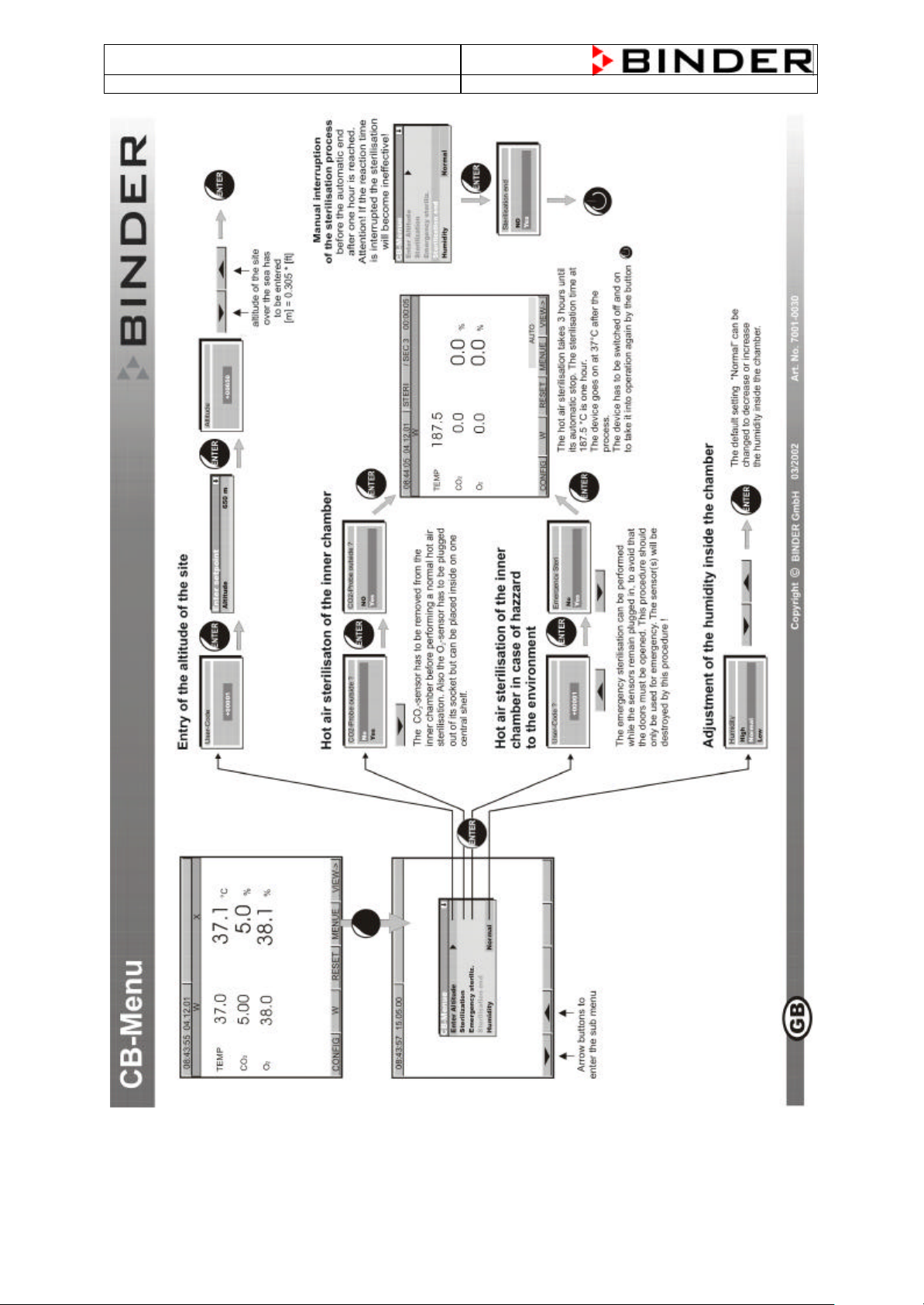

2.2 Short description of the MB1 Controller

6

Page 7

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

7

Page 8

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

8

Page 9

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

9

Page 10

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

10

Page 11

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

,,

11

Page 12

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

3 Function

Incubators series CB are suited for cultivation of mammal cells under typical conditions of about 37°C.

The incubator allows the set defined pH conditions by justifying NaHCO3 buffer systems of commercial

cell media by keeping exact CO2-atmosphere inside. CB incubators care for high humidity inside to

avoid increasing of the osmolarity caused by evaporation of the cell media. To reach this, the different

functions heating, sterilization and CO2 injection have to work as a perfect team. This know-how is as

Firmware inside the controller type MB1.

3.1 The CO2-measuring principle

The CO2-measuring procedure of the incubator series CB is characterized by fast reaction times, as

well as the highest accuracy and selectivity. The accuracy of the CO2 measuring system bases on a

single-beam infrared measuring cell, which measures in di fferential mode, with permanently

alternating transmission characteristic of its semi-conductor filter. Due to this highly developed single beam principle with Fabry -Perot interferometer (FPI), disturbance variables and aging phenomena in

the measuring system are almost completely eliminated, so that this measuring system, in contrast to

other measuring procedures, remains practically drift -free between calibrations and is absolutely

selective for CO2.

The CO2–measuring cell contains a measuring section ins ide in which the absorption of infrared light

depends on the number of CO2-molecules in the beam path. This number of CO2 –molecules changes

with the ambient pressure in relation to a constant volume. The distances between the molecules are

consequently pr essure-dependent. The collision frequency of the IR-beam with CO2-molecules

increases therefore by increasing pressure.

For this reason, the ambient pressure must be compensated in order to correct the display reading of

the CO2-concentration in VOL. -%. This is achieved by entering the altitude of the site above the sea

which is described in this manual.

3.2 Function of the Heating System

The temperature measurement is realized by a PT100 temperature probe which changes his resistance

at different temperatures . For example: 37°C = 114,380 Ω (see following chart).

The CB is equipped with a double PT100, one part is for the measurement inside the chamber, the

other part is connected to the safety device class 3.1.

The measured value is evaluated in the controller MB1. The controller MB1 compares the set -value

and the now measured value and decides to give a signal-current to the solid state relay –4K3 to

activate the heating.

12

Page 13

CB (E2) Service Manual

Measuring of the Pt100 resistance between the white

state: 01/2002 created: 03/2002/ Jochen Tussinger

3.3 Flow-Chart of the heating function (basis CB 150 wiring diagram)

The Pt100 temperature probe is equipped with 3 cables, two red and one white cable.

The white cable is connected to pin 1 at E1 – Pt100, the two red cables at pin’s 2 and 3 at E1 – Pt100.

To measure the resistance disconnect all three cables from the controller an measure between the

white cable and one of the red cables, do not measure between both red cables.

Ω

cable PIN 1 and one of the two red cables PIN 2 or 3

13

Page 14

CB (E2) Service Manual

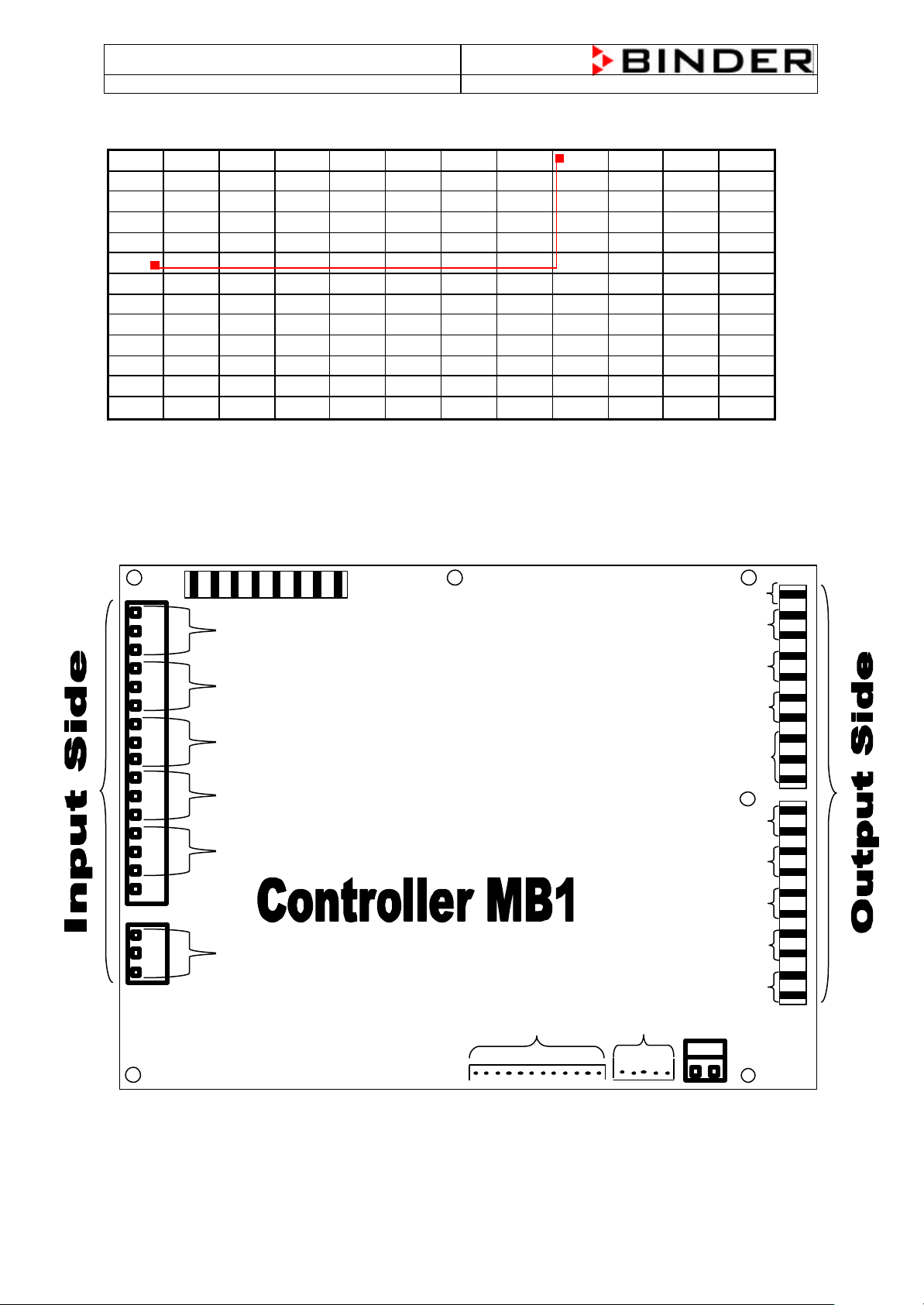

BE1 BE2 BE3 BE4

Output Phase

-

controll

3A / 115

-

230V AC

Heater air

-

duct

BA2 – 1A / 115

-

230V AC

Door Heater

BA3 – 1A / 115

-

230V AC

Collection Alarm

BA1 – 3A / 115

-

230V AC

Ground TE

Heater Kettle

BA4 – 60mA / 5V DC

CO2 Solenoid valve

BA5 – 60mA / 5V DC

Safety device Cl 3.1

BA6 – 60mA / 5V DC

Fan Cold water bassin

0(2)-10V / 0(4)

-

20mA

Volatge output

45mA / 24VDC

state: 01/2002 created: 03/2002/ Jochen Tussinger

Pt100 temperature probe (Temperature in °C / Resistance in Ω)

T (°C) 0 1 2 3 4 5 6 7 8 9 10

-10

0

10

20

30

40

50

60

70

80

90

100

96,086 96,478 96,870 97,262 97,653 98,045 98,436 98,827 99,218 99,609 100,000

100,000 100,391 100,781 101,172 101,562 101,953 102,343 102,733 103,123 103,513 103,902

103,902 104,292 104,681 105,071 105,460 105,849 106,238 106,627 107,016 107,404 107,793

107,793 108,181 108,570 108,958 109,346 109,734 110,122 110,509 110,897 111,284 111,672

111,672 112,059 112,446 112,833 113,220 113,607 113,994 114,380 114,767 115,153 115,539

115,539 115,925 116,311 116,697 117,083 117,469 117,854 118,240 118,625 119,010 119,395

119,395 119,780 120,165 120,550 120,934 121,319 121,703 122,087 122,471 122,855 123,239

123,239 123,623 124,007 124,390 124,774 125,157 125,540 125,923 126,306 126,689 127,072

127,072 127,454 127,837 128,219 128,602 128,984 129,366 129,748 130,130 130,511 130,893

130,893 131,274 131,656 132,037 132,418 132,799 133,180 133,561 133,941 134,322 134,702

134,702 135,083 135,463 135,843 136,223 136,603 136,982 137,362 137,741 138,121 138,500

138,500 138,879 139,258 139,637 140,016 140,395 140,773 141,152 141,530 141,908 142,286

For Example: Your resistance measurement system shows you 114,380 Ω this corresponds to 37°C.

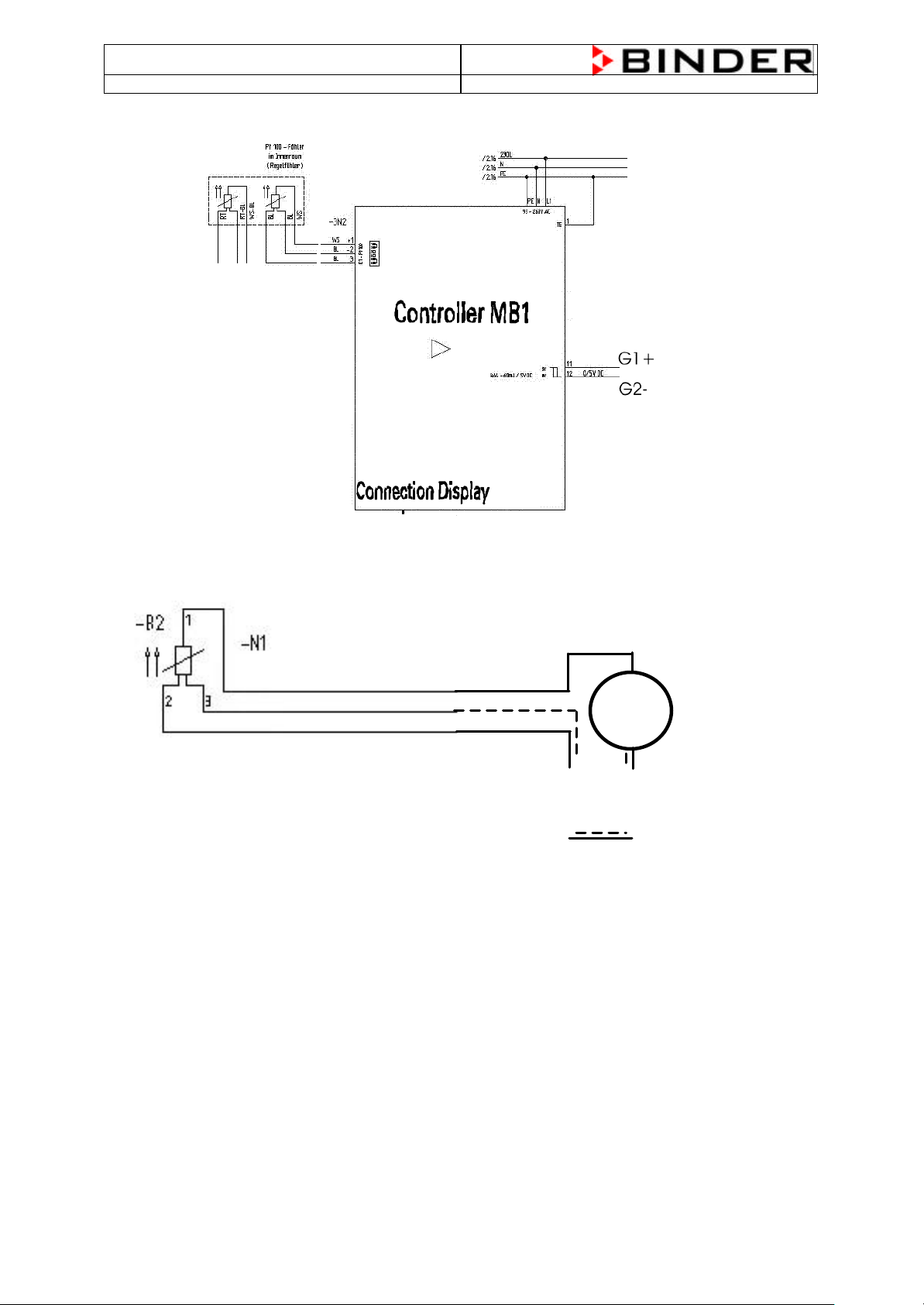

3.4 Controller MB1 PIN description (Input / Output)

E1 – Pt100

E2 – Pt100

E3 – Pt100

E4 – 4 - 20mA

E2 – Pt100

E – Safety device class 3.1

Display connection

RS422

14

Page 15

CB (E2) Service Manual

To A1+ / A2

-

1 – white

state: 01/2002 created: 03/2002/ Jochen Tussinger

3.5 Function of the CO2 System

The CO2 System measures the CO2 concentration inside the chamber. This information is supplied by

the FPI Sensor Head. The Controller MB1 compares the engaged value with the now measured value

and decides to open the solenoid valve of the CO2 gas inlet.

3.6 Flow Chart of the CO2 System (basis CB wiring diagram)

FPI-Sensor à FPI Sensor Board à Controller MB1 à Solenoid Valve à Gas Injection Nozzle

2 – grey

3 – green

4 – yellow

5 – blue

6 – red

7 – brown

8 - pink

To Power supply at the Transformer

H1+

Solenoid Valve CO

2

1

-5Y1

2

H2-

15

Page 16

CB (E2) Service Manual

Lettering

state: 01/2002 created: 03/2002/ Jochen Tussinger

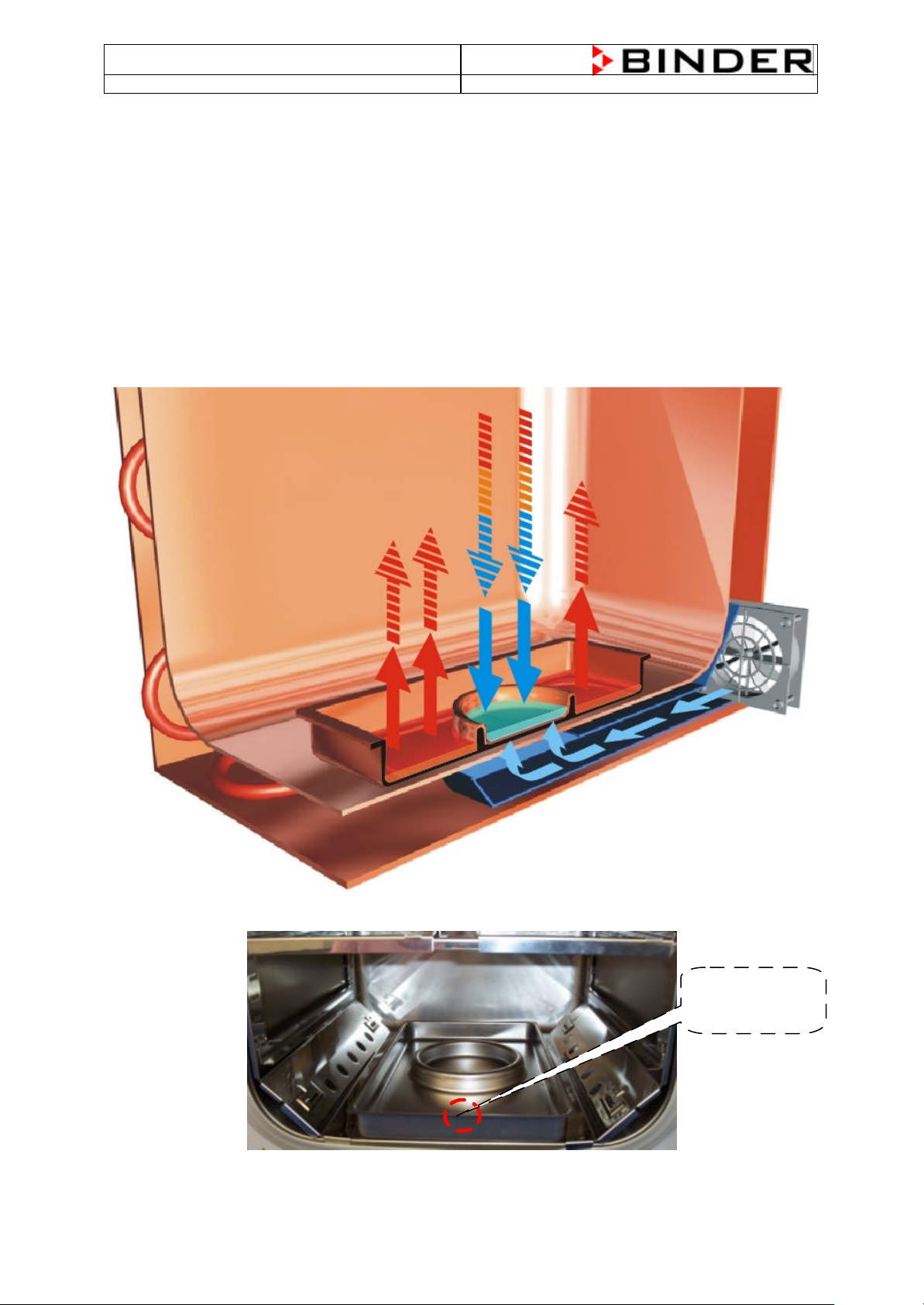

3.7 Function of the Permadry® system

Isotonic osmotic pressure ratios, essential for the growth of cells, are basically maintained in CO2

incubators by a maximum humidity content in the inner chamber. During this process care must be

taken to ensure the best possible protection against contamination.

The patented Permadry® system guarantees a humidity performance of up to 98% relative humidity

with completely dry inner walls. The principle hereof is totally easy. The double basin system consists

of a large-surface warm water basin an a cold water basin as defined condensation point. The

temperatures of both basins are in that way controlled that the humidification and the dehumidification

are permanently balanced. The Permadry® system works completely free of disturbances or

maintenance. The handling of the Permadry® system is the easiest thing and as safe as a coffee cup.

The basin is easily removable and can be refilled in or at the unit at any time.

Cold air, produced by the Permadry® -fan, streams through the air -channel and cools the round cold

water basin. The condensation point is fixed by this.

The Permadry® water basin must be placed correctly. There is a description „FRONT“ impressed.

„FRONT“

16

Page 17

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

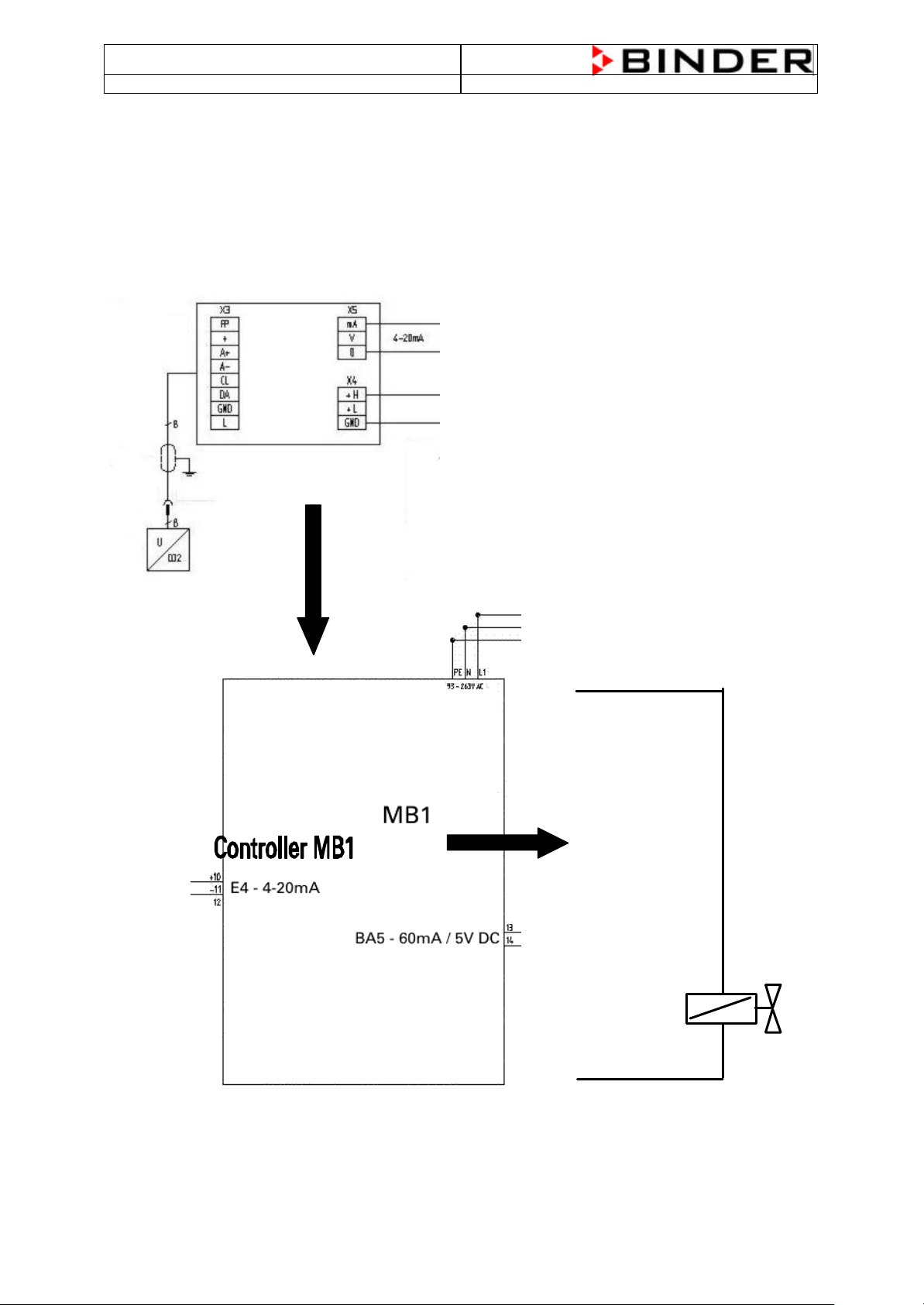

3.8 Flow Chart of the Permadry® system (basis CB wiring diagram)

Controller MB1 à Permadry® fan

3.9 Description of the Function of the Fan Control

The CB heats up to the engaged set -value (°C), just before the chamber reaches the set -value the

controller MB1 starts to pulse the heating signal. The ON/OFF rate is assigned by the regulation ration

of the controller MB1.

The higher the regulation ratio, the higher is the fan speed. If the chamber doesn’t heat (regulation

ratio = 0) the fan is working with his minimal speed. If the chamber heats continuing (regulation ratio =

100%) the fan is working with his maximum speed. The speed of the fan is reduced to avoid kinetic

influence of heating

The rotation of the Permadry®-Fan is reverse proportional to the rotation of the Mainfan.

The only difference is: The Mainfan is controlled constant with the help of a phase control level, the

Permadry®-Fan is in interval mode which is given by a solid state relay.

17

Page 18

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

3.10 Sterilization Mode

Depending on the resistance level of the germs, attention must be paid to the quality of the sterilizat ion

procedure. The lower the sterilization temperature the higher the risk of remaining germs and the

longer the sterilization time is. With the standard hot air sterilization at 187,5°C it is absolutely

guaranteed that all germs are reliably eliminated an d, furthermore also time is saved.

All unit parts in the inner chamber are auto sterilized at a temperature of 187,5°C. The precision IR

sensor is separately treated in a desinfectant bath. This ensures that the measuring quality does not

suffer from the high temperature, as it may happen with other systems.

3.11 Hot-air sterilization

The hot -air sterilization gets activated in the CB Menu. The sterilization temperature of

187,5° C is adjusted by the manufacturer. It may not be changed.

The CO2 sensor is temperature resistant up to a maximum temperature of 60° C.

By no means it can be sterilized or autoclaved.

The CO2-sensor head is especially adjusted for a specific chamber that it belongs to. It cannot

be operated in another chamber. There is an adhesive label with a number on the sensor head

to avoid any mixing up.

Effect the hot -air sterilization as following:

1. Switch off the unit.

2. Pull out the CO2 sensor (without rotating) from the connection bushing in the upper part of the rear

and remove it from the inner chamber.

3. Only with option Oxygen control: Remove the oxygen sensor from the connection bushing without

rotating and put it on the middle shelf.

4. Before starting the sterilization, please remove the water from the basin.

5. Shut the outer and the inner door of the unit.

6. Ensure that the water basins, the shelf holder and the shelves are in the inner chamber.

7. Switch on the unit.

8. Unlock the keypad of the controller MB1 with the key switch (option)

(unlocked = horizontal position, key is removable).

9. Activate the sterilization procedure in the CB Menu as following:

18

Page 19

CB (E2) Service Manual

TEMP

187.5

HANDHANDHANDAUTO

Sollwert Art

Offset

CO2-Probe outside ?

No

Yes

Sollwert Art

NO

Yes

CB-Menue

Enforced steriliz.

Normal

CB-Menue

Emergency steriliz.

Normal

Display during the

state: 01/2002 created: 03/2002/ Jochen Tussinger

Enter Altitude

Enter Altitude

Sterilization

Sterilization

Sterilization end

Sterilization end

Humidity

Humidity

08:44:05 04.12.01

CO

2

O

2

CONFIG

W

0.0

0.0

W RESET

STERI / SEC 3 00:00:05

0.0

0.0

%

%

MENUE VIEW->

sterilization process

Caution: Never open the two unit doors during the sterilization process, as the temperature

reaction time will be interrupted and the sterilization will become ineffective.

10. The hot-air sterilization is automatically finished after 3 hours.

11. Switch off the unit and open the outer door.

The temperature of the glass door handle is about 150°C. Use gloves or a tool (e. g. pincers)

for opening the glass door, or let the unit cool down as follows: with opened front door for at least

1 hour, with closed front door at least 4 hours. Please make sure that the unit has cooled down

to ambient temperature, but down to at least 60° C before plugging in the CO2 sensor. In case of

doubt, please wait at least 2 hours.

12. Befor putting into operation, please plug in the CO2 sensor. Optional also the O2 Sensor.

Due to the sterilization, units in copper version change their colour. This does not have any negative

effect on the function and quality of the unit.

Caution danger of burning !

Due to the increased temperature performances there is the risk of burnings at the marked unit

parts and especially at the inner glass door.

Do not touch !

19

Page 20

CB (E2) Service Manual

TEMP

187.5

08:44:05 04.12.01

HANDHANDHANDAUTO

STERI / SEC 3 00:00:05

Sollwert Art

User-Code ?

+00001

Sollwert Art

Offset

Emergency Steri

No

Yes

Enforced steriliz.

Normal

Emergency steriliz.

Normal

Sollwert Art

User-Code ?

+00000

Display during the

emergency sterilization

state: 01/2002 created: 03/2002/ Jochen Tussinger

3.12 Hot-air sterilization with inner chamber

contaminated with highly infective material

If it is not possible to discharge the unit and to remove all necessary parts for safety reason, the hot -air

sterilization can exceptionally be done nonetheless.

Attention! Note that this procedure destroys the CO2 and the O2 sensor (option)!

1. Shut the outer and the inner door of the unit.

2. Switch on the unit.

3. Unlock the keypad of the controller MB1 with the key switch (option)

(unlocked = horizontal position, key is removable).

4. Activate the emergency sterilization procedure in the CB Menu as following:

CB-Menue

CB-Menue

Enter Altitude

Enter Altitude

Sterilization

Sterilization

Sterilization end

Sterilization end

Humidity

Humidity

Grenzwert

Offset

Grenzwert

Offset

W

CO

2

0.0

O

2

0.0

CONFIG MENUE VIEW->

W RESET

0.0

0.0

%

%

process

20

Page 21

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Caution: Never open the two unit doors during the emergency sterilization process, as the

temperature reaction time will be interrupted and the sterilization will become ineffective.

5. The emergency hot-air sterilization is automatically finished after 3 hours.

6. The incubator is no longer ready for operation. Contact the BINDER service for repair.

(As CO2 Sensor and/or O2 Sensordestroyed)

Due to the sterilization, units in copper version change their colour. This does not have any negative

effect on the function and quality of the unit.

Caution danger of burning !

Due to the increased temperature performances there is the risk of burnings at the marked unit

parts and especially at the inner glass door.

Do not touch !

21

Page 22

CB (E2) Service Manual

too high inside the

Sensor System is defect. The Sensor outputsignal of the

0,24mA you can

roller as described in chap.

state: 01/2002 created: 03/2002/ Jochen Tussinger

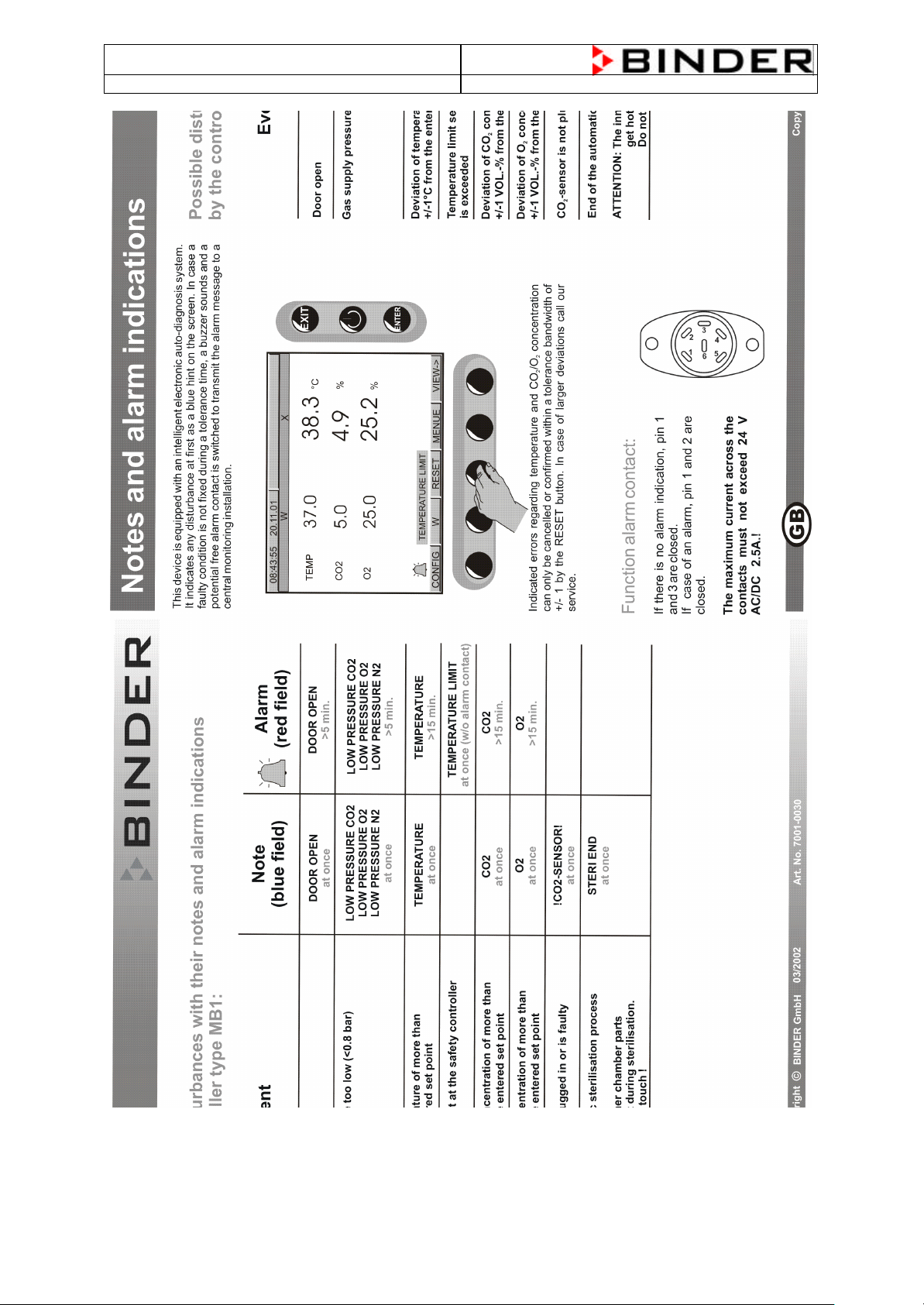

4 Trouble Shooting

Safety hints: Do never unplug the CO2 sensor head while the chamber is switched on.

This could result in sensor destruction or initiation problems.

Hint: The tradename of the controller is MB1

Fault description Fault cause

High CO2 consumpt ion

CO

2

chamber

par example cell-medium is

colored yellow = CO2 too high

• If when the CO2 is connected the max. pressure of 1,5 bar is

exceeded, this can lead to a defect in the pressure switch.

The pressure switch becomes leaky as a result and loses gas.

The controller MB1 shows also a too high concentration of CO2:

• MB1 controller output which controlls the gas inlet valve is defect.

There are continually 5V DC at controller output BA5.

• The solenoid valvet is mechanically defect, it doesn’t close.

• The controller MB1 doesn’t show a too high concentration of

CO2:

The FPIFPI-Sensor board could be checked according the following chart.

Binder offers a calibration kit for this purpose with analyzed test gas

with a CO2-concentration of 5 Vol.-%. Because the atmospheric

pressure influences the measurement result of the CO2 sensor system,

the altitude of the site has to be taken into consideration.

Expected results during exposing the sensor head to 5% test gas:

Sea Level Sensor Current

0 m 8,00 mA

100 m 7,93 mA

200 m 7,86 mA

300 m 7,79 mA

400 m 7,72 mA

500 m 7,66 mA

600 m 7,60 mA

700 m 7,55 mA

800 m 7,49 mA

900 m 7,44 mA

1000m 7,39 mA

If this values are not reached with a tolerance of +/- 0,24mA

(corresponds to 0,3 Vol % CO2) between the signal output of the FPI

sensor board and the MB1 controller input from the sensor system is

faulty.

• Replace the FPI sensor head and check the sensor current against

the expected value again during exposing the sensor head to test

gas.

If the deviation is now within the tolerance of +/proceed a re-calibration at the MB1 cont

re-calibration to achieve maximum accuracy.

• If this values are reached with a tolerance of +/- 0,24mA at the

signal output of the FPI sensor board and yet the MB1 controller

shows not a reading between 4,8 or 5,2 Vol.-% the MB1 is not

calibrated correctly or it is faulty. Check the correct setting of the

altitude above see level which is essentially for correct CO2 values

displayed on MB1-controller display (see CB operating manual). Try

a re -calibration (see chapter re-calibration) with the correct altitude

setting set before.

22

Page 23

CB (E2) Service Manual

also when there is no

state: 01/2002 created: 03/2002/ Jochen Tussinger

MB1 controller display shows

CO2 readings of 19 to 20 Vol.% CO

2

CO2 inside the chamber e.g.

with open door.

FPI sensor board:

Red and green error LED flash

alternately

FPI sensor board:

Green LED flashes and lights

alternately.

FPI sensor board:

Red LED is continuously on or

flashes (green remains off)

during normal operation

CO2 too low inside the

chamber

par example cell -medium is

colored violet = CO2 too low

• This means the new plugged CO2 sensor head is not initialized

successfully.

• Try a restart of the chamber by switching OFF and after 10 s ON an

the main switch.

• If this worse reading still remains the sensor board has to be

replaced and a re-calibration must be carried out.

• This means no connection between sensor head and the FPI

sensor board.

• The sensor head is not plugged correctly – try to plug it again.

• The red silicone wire between the Lemo socket for the sensor head

and the FPI sensor board is faulty.

• The soldered contacts of the Lemo socket might be unfixed.

• Normal function, no defect.

• Sensor system is faulty. The sensor head and may be the sensor

board must be replaced. The system must be re-calibrated (see

chap. re -calibration)

The controller MB1 shows also a to low CO2 concentration:

• Check the pressure of the CO2 bottle (max.1.5 bar, min. 1.0 bar)

• Sterilization process has to be off

• Check gas inlet valve. When the door is closed the valve has to

open with a clicking noise.

• The door switch has to be in closed position when the door is

closed. If it is not closed no CO2 can flow inside the chamber. Press

the door switch by hand and check on the inlet tube whether CO2 is

flowing in

• Check CO2 connection (rear), and the 1mm drill hole of the gas

mixing head. May be there is something jammed.

The controller MB1 doesn’t show a to low CO2 concentration:

The CO2 Sensor System is defect. The Sensor Outputsignal of the

FPI-Sensor board to the controller MB1 could be checked according

the following chart.

Binder offers a calibration kit for this purpose with analyzed test gas

with a CO2-concentration of 5 Vol.-%. Because the atmospheric

pressure influences the measurement result of the CO2 sensor system,

the altitude of the site has to be taken into consideration.

Expected results during exposing the sensor head to 5% test gas:

Sea Level Sensor current

0 m 8,00 mA

100 m 7,93 mA

200 m 7,86 mA

300 m 7,79 mA

400 m 7,72 mA

500 m 7,66 mA

600 m 7,60 mA

700 m 7,55 mA

800 m 7,49 mA

900 m 7,44 mA

1000m 7,39 mA

If this values are not reached with a tolerance of +/- 0,24mA

(corresponds to 0,3 Vol % CO2) between the signal output of the FPI

sensor board and the MB1 controller input from the sensor system is

faulty.

23

Page 24

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

• Change the FPI Sensor Head and check the Sensorcurrent against

the table above during exposing with 5% CO2 Testgas

• If the deviation is within the tolerance of +/- 0,24mA, please make a

re-calibration.

• If the value with the tolerance of +/- 0,24mA at the signal output of

the FPI Sensor board is reached but the controller doesn’t show a

value between 4,8 and 5,2 Vol.-% CO2, there was a wrong

calibration done. Check the correct setting of the altitude and make

a re-calibration.

• Make sure, that you have reset the old calibration.

The CO2 concentration doesn’t

go down after a door opening

of approx. 20s to 0 Vol.-% CO

• Check the altitude setting at the MB1 controller

• The Sensor system is defective or wrongley calibrated

2

• Make a re -calibration and check if the value is now ok.

• If not, you have to change the sensor system. Change first only the

FPI sensor head and make a re-calibration.

The CO2 concentration drifts

during exposing with 5% Testgas

CO2 Controller shows „-1999“.

There’s also a red alarm-bell

blinking

• If the signal doesn’t reach a stable value, you have to change the

sensor system, first only the FPI sensor head, after that you have to

make a re -calibration

Means measurement value underrange:

• The Sensor signal between the Sensor Board and the Sensorinput

E4 at the controller MB1 is low. (under 4mA)

• Check if the sensor head puts correctly

• Check the cable between the Sensor Board and the controller MB1

looking for a break or a faulty contact.

• Check the cable between the Sensor Board and the sensor

• If the controller gets the correct signal, but shows still –1999, the

input at the controller is defect. The controller must be changed.

• There’s no current from the transformer (24VDC). Check the power

supply for the FPI sensor. Possibly, the fuse is blown (T500mA).

CO2 controller shows ”9999” Means measurement value exceeding

• The sensor signal between the FPI sensor board and the sensor

input at the controller MB1 at Pin E4 is to high (over 20mA) or

there’s a initialization error – try a restart.

• If the red LED of the sensor board is lit permanent, you have to

change the sensor board.

• If not, check the sensor current and the sensor output of the sensor

board.

• Try a re-calibration with analyzed testgas

• If the error reshows, you have to change the controller

To low humidity inside the

chamber

Humidity to high inside the

chamber

• The stpoint of the door heating is to high. (This is a internal setting

of the controller. Please see description in chapter 4.4)

• The Permadry® fan doesn’t run. This fan is for blowing cold air

throgh the air chanel to the cold water basin

Condensation inside

Condensation at the glass

door

• Check the outer door and the inner door fits not tightly

• Check the two door sealing.

• Adjust the door keepi ng

• The door heating element is faulty – Check the resistance (normally

278 Ω).

24

Page 25

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

5 Most common service work

Please note:

Please unplug when servicing or working on electronic part

It’s for your own protection

25

Page 26

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.1 Changeing of the fan

If it is possible for the intended service work the

mains plug should be pulled.

Note:

The fan motor turns when the chamber is

switched on.

Remove the rear wall of the chamber by use of a

plus driver.

You have to cut the aluminium tape around the

fan mounting plate.

Remove the two connectors to the fan motor.

Removed the 4 screws of the plate of the fan

motor (sheet metal frame).

26

Page 27

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Unscrew the axis nut of the fan wheel (left turning

thread !) with a spanner size 13. Remove fan

Assemble the ne w fan motor in reversed order.

Replace Aluminium Tape.

27

Page 28

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.2 Take out of the electronic component board

Open the glass door and then the two screws at

the cover.

After unscrew you have to press down the cover

to take it off.

Now you can change the steri filter.

The cover plate is fixed by 4 screws.

Before you can take out the complete component

board, please check that the power supply is

disconnect.

Please remove the drawn part of the air chanel of

the Permadry® system before you take out the

component board.

Now lift the component board and take them out

forwards.

Now it is possible to change all electronic parts.

If you plug in the power supply to measure some

parts, be carefull, there could be 230V AC.

28

Page 29

CB (E2) Service Manual

1

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.3 Opening of the rear service lid to achieve the area of the air jacket

This is necessary for following service works.

♦ To replace the temperature probe of the air jacket

♦ To replace the socket of the FPI-sensor head

♦ To replace the gas mixing head

♦ To replace the double temperature probe for inn er temperature and safety device

If it is possible for the intended service work the

mains plug should be pulled out.

Note:

The fan motor turns when the chamber is

switched on.

Remove the rear wall of the chamber by use of a

plus driver.

Cut the aluminum foil with a sharp knife at the

upper area as shown.

Note that it should not be cut up all around. Cut

only the top line and the two sides

29

Page 30

CB (E2) Service Manual

3

4

state: 01/2002 created: 03/2002/ Jochen Tussinger

Fold up the insulation as shown beside.

Remove the parker screws which fix the metal

cover.

Remove the metal cover sheet.

Now you have access to following parts:

♦ socket of the FPI-sensor head gas mixing

head double temperature probe for inner

temperature and safety device

Inner view:

♦ left: double temperature probe for inner

temperature and safety de vice

♦ middle: gas mixing head

♦ socket of the FPI-sensor head

30

Page 31

CB (E2) Service Manual

°C % W X CO

08:43:55 04.12.01

.00

Feuchte

Feuchte

08:43:57 15.05.00

08:43:57 15.05.00

System

-

Code ?

08:43:57 15.05.00

System

-

Code ?

08:43:57 15.05.00

SW-Offset Tür

+ 4.0°C

Press the Button up to SW

-

Offset door press

CAUTION:

state: 01/2002 created: 03/2002/ Jochen Tussinger

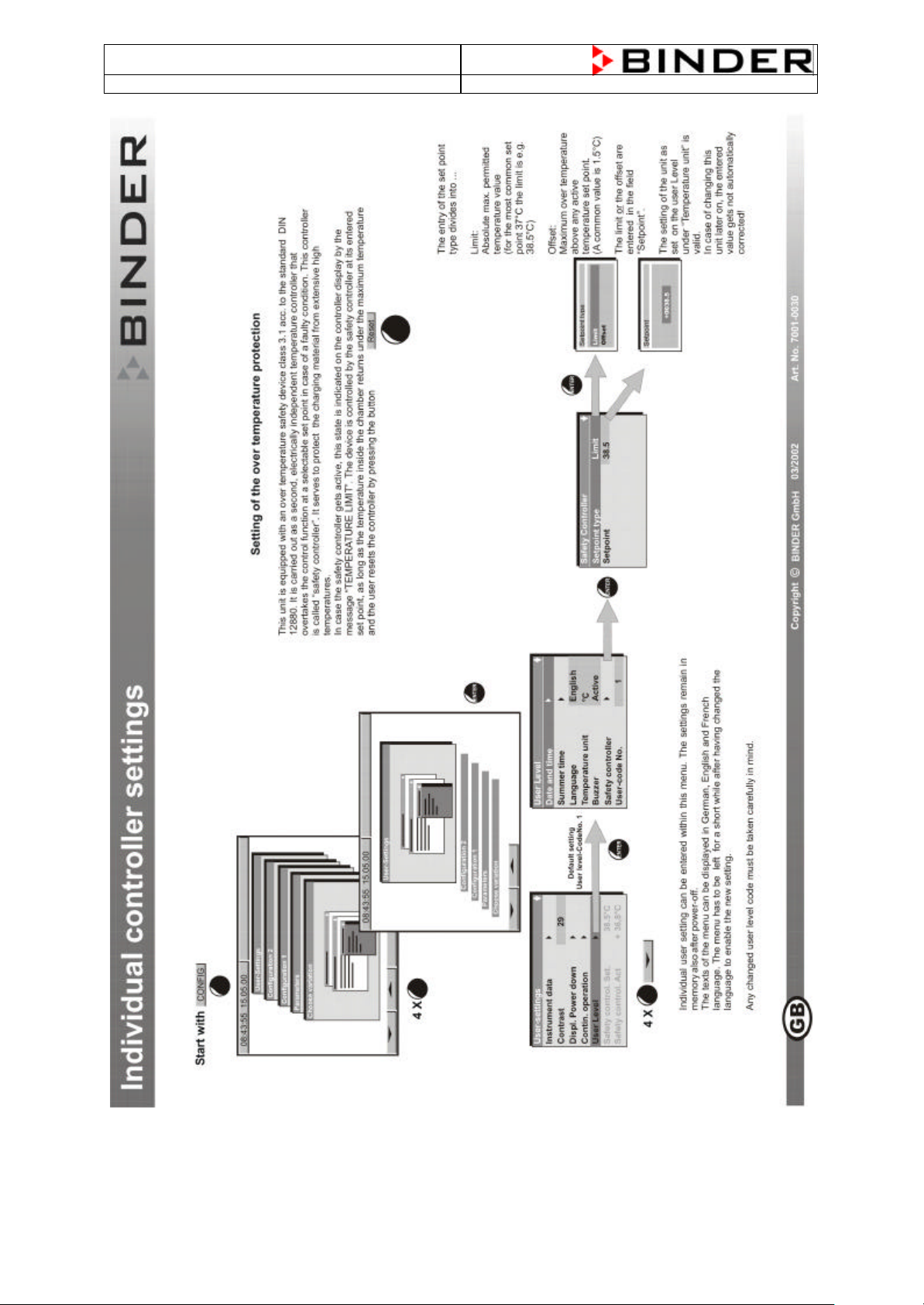

5.4 Setting of the door heating

This function is needed, to stop condensation at the glass door.

Make sure that the outer and inner door seal tightly

Parametrierung ∇

TEMP

37.0

2

5.00

37.1

5.0

1. 5.

CONFIG

W RESET

MENUE VIEW->

08:43:57 15.05

2. 6.

Benutzer-Daten

Konfiguration 2

Not-Sterilisation

Konfiguration 1

Steri Abbruch

Not-Sterilisation

Parametrierung

Feuchte

Steri Abbruch

Not-Sterilisation

Wahl der Variante

Feuchte

Steri Abbruch

Not-Sterilisation

Steri Abbruch

3.

Benutzer-Daten

Konfiguration 2

Not-Sterilisation

Konfiguration 1

Steri Abbruch

Not-Sterilisation

Parametrierung

Feuchte

Steri Abbruch

Not-Sterilisation

Feuchte

Steri Abbruch

Feuchte

Wahl der Variante

EXIT

ENTER

Now you are at the System-Code input field

4.

+00000

just type 2802 and confrim with ENTER

5.

+02802

ENTER to confirm. Now you can set the desired

value.

Then press EXIT to come back to standard display

The System-Code is only for Service Engineers. Don’t give the System-Code

to the customer, it is possibl eto

change also the parameters, so that the

chamber couldn’t work

31

Page 32

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.5 CO2-Reference Measurement

The CO2-measuring procedure of the incubator series CB is characterised by fast reaction times, as

well as the highest accuracy and selectivity. The accuracy of the CO2 measuring system bases on a

single-beam infrared measuring cell, which measures in differential mode, with permanently

alternating transmission characteristic of its semi-conductor filter. Due to this highly developed single beam principle with Fabry -Perot interferometer (FPI), disturbance variables and aging phenomena in

the measuring system are almost completely eliminated, so that this measuring system, in contrast to

other measuring procedures, remains practically drift -free between calibrations and is absolutely

selective for CO2.

The CO2–measuring cell contains a measuring section inside in which the absorption of infrared light

depends on the number of CO2-molecules in the beam path. This number of CO2 –molecules changes

with the ambient pressure in relation to a constant volume. The distances between the molecules are

consequently pressure -dependent. The collision frequency of the IR-beam with CO2-molecules

increases therefore by increasing pressure.

For this reason, the ambient pressure must be compensated in order to correct the display reading of

the CO2-concentration in VOL. -%. This is achieved by entering the altitude of the site above the sea

which is described in the CB operating manual.

It is a common desire of customers to make test-measurements between the re-calibrations

implemented as a part of the recommended annual maintenance work.

In principal there are 3 possibilities to test CO2-concentration inside a incubator which are described

later on.

32

Page 33

CB (E2) Service Manual

7.4

7.6

pH-value

Trade names of common

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.5.1 Measuring of CO2 indirectly via the pH of the cell medium

By use of the indirect determination of CO2 concentration via the pH-value of the nutrient it is possible

to check the CO2-concentration inside the chamber. This method can not be used for re -calibration of

the sensor system but it is a simple method to test for the correct CO2 concentration without any

special CO2-measuring equipment. Only a accurate pH indicator or a pH measuring electrode is

necessary, but this is standard equipment in cell culture laboratories.

This method bases on the acid base equilibrium of the buffer system in the nutrient.

The most common media are buffered by NaHCO3. With the help of the pH-value in the medium, a

conclusion can thus be drawn about the concentration of CO2.

This conclusion is directly possible using the diagram below, which expresses the interrelationship

between CO2 concentration in vol. % and the pH of different NaHCO3 buffered media.

We recommend the incubation of an empty sample with medium for 1/2 day under the same

conditions as the cells. The incubation can be performed in a cell culture bottle or in a 50 ml Falcon

tube with open lid.

After gassing, remove the empty sample from the incubator and within 5 minutes measure the pH1value with a glass electrode. During the measurement the medium should have the least possible

surface contact with the ambient air, so that the CO2 can only diffuse out slightly. Therefore,

transfusing should be avoided. A significant downward movement will only be observed after 5

minutes, allowing sufficient time for measurement. Naturally, pH -test strips can also be used (pH6-8

range not bleeding).

Following graph shows the pH-value of NaHCO3 buffered media as function of the CO2-concentration:

Vol.% CO2

18

3,70

16

media:

NaHCO3

14

12

10

8

6

4

2

6.8 7.0

2,20

1,20

0,85

0,35

7.2

[g/l]

DMEM 3,70

BME 2,20

MEM 2,20

Medium 199 2,20

Mc Coy 2,20

F10 1,20

F12 1,20

Example:

If a pH of 7,2 is measured in a medium which is buffered with 2,20 g NaHC03 per liter there must be 8

Vol.-% CO2 in the surrounding of this medium.

33

Page 34

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

5.5.2 Measuring of CO2 directly via chemical indicator tubes

This is a common do it yourself test of the users. A chemical color reaction in a glass tube shows the

CO2-concentration. A standardized volume of air from the inside of the incubator has to be sucked

through this glass tube to get a quantitative test result. Therefor a special hand pump must be used

with a standardized suction volume.

Example for such a procedure:

1) Break off both ends of such a glass tube or

remove the plugs.

2) Pin that end with the higher end of the scale

on the adapter of the hand pump which

belongs to that test system.

3) Pin the other end trough the silicon plugged

access port of the inner chamber door (4) of

the CB incubator.

4) Take one sample volume out of the inner

camber volume by pressing the pump entirely

together and releasing it afterwards.

5) The standardized volume is sucked trough the

glass tube and the chemical indicator changes

its color beginning from the side pinned into

the chamber in direction to the hand pump.

6) The more CO2 is inside the chamber the vast

the chemical reaction will cause a change of

the color of the chemical reactor.

7) The CO2 concentration can be read off by the

scale directly printed on the glass tube or a

delivered reference reading rule.

It is necessary to correct the result with the

current ambient pressure. The necessary

formula is printed on the instruction sheet of

such systems.

Notes:

All the necessary equipment must be delivered by

only one manufacturer and one defined test

system.

This test systems are nor very accurate.

A typical accuracy is around 10% of the full scale

value!

Therefor this system should not be used for re calibrating the BINDER FPI-sensor system.

Example for chemical indicator tubes

Example for hand pump (foreground) or a

electrical pump (background)

34

Page 35

CB (E2) Service Manual

Ž Œ

state: 01/2002 created: 03/2002/ Jochen Tussinger

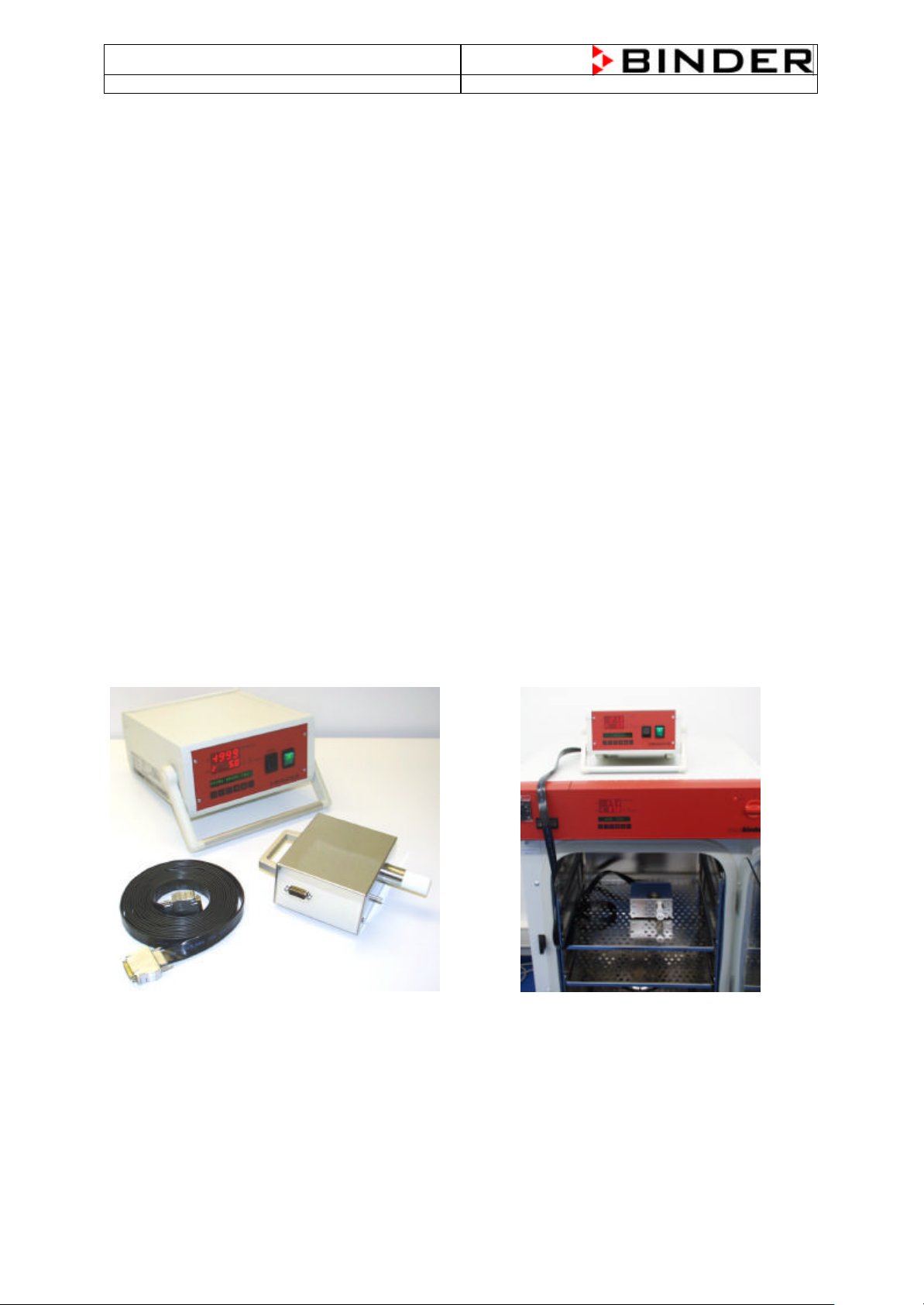

5.5.3 Measuring of CO2 directly via a electronic measuring device

The easiest way to measure CO2 concentration are electronic sensor systems. BINDER offers the

portable measuring device model CTM 01 which were specially designed to measure CO2

concentration and temperature inside of CO2 incubators. The CTM 01 can be used both for reference

measurements in certified laboratories, as well as for service purposes.

Description of CTM01:

• The measuring system consists of 2 parts: The measuring station, which remains outside the CO

incubator, and the sensor housing, which is put in the center of the usable volume of the

incubator. Both parts are connected by a ribbon cable, which can be laid across the door gasket of

the incubator without causing leakage.

• The measuring cell is placed directly in the atmosphere to be measured. This means that there is

no requirement for gas pumps, whose inconstant flow rates can cause inaccuracies. When

converting the measured variable, partial pressure CO2, to the display value, VOL. -% CO2, the

respective altitude above sea level is entered and taken into account, so that the display value

always corresponds immediately to the real concentration in VOL. -% CO2 , irrespective of the

place of use.

• The temperature is determined via a PT100 temperature sensor and is displayed on the large LED

display in 10 seconds alternation with the CO2 - concentration.

• The measured data of temperature and CO2 -concentration are output to an RS 422 interface.

Thus the measured data can be simple recorded, stored and graphically represented via PC using

the APT-COM communication software developed by BINDER.

• For monitoring, the nominal values set in the incubator can be entered into the mobile measuring

system. If these nominal values are exceeded or fallen below by permanent ly set tolerances, this

is reported by the unit optically and acoustically, as well as via a potential-free alarm contact. The

alarm function only becomes active if both measured values were previously within the tolerance

limits.

2

ΠMeasuring station

• Sensor housing

Ž Ribbon cable

•

Measuring in a BINDER incubator type CB

(door is normally closed during measurement)

35

Page 36

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

6 Calibration

6.1 Definition of calibration

In this service manual the word “calibration” means to adjust the actual value readings of the MB1

controller for the two controlled values of the CB incubator which are CO2 concentration and

temperature to accurate references of known value. Other words e.g. “alignment” are also customary

for the same procedure.

6.2 References for calibration

Reference for temperature:

A electronic measuring- and display device for temperature which

is traceable to a acknowledged standards/calibration institution

(DKD , PTB for Germany) with valid calibration certificate.

The cable to the sensor probe must be thin to cause no leakage

when it is laid between via the door sealing.

Reference for CO2 concentration

Two test gases with analyzed concentration are used to which the

FPI sensor head is exposed directly.

BINDER offers a calibration kit with all necessary gases and

accessories. The third bottle is only needed for option O2-control..

6.3 Tolerance of the adjustment

Binder calibrates each chamber before it is dispatched to the

customer. High-quality measuring systems are used for this, whose

accuracy is tested annually. To guarantee best possible quality of results which are worked out by use

of the CB incubator the controlled values should be checked annually and re -calibrated if necessary.

When is it worth to correct a deviation between the value measured and the value displayed on the

MB1 controller?

The following table gives you the conditions for an ideal adjustment of a temperature deviation,

Measured value Measured range 2 points adjustment Adjustment if deviation

is higher than:

Temperature

CO2 volume in %

Deviations which are smaller than this deviations do not require an adjustment.

Important:

The values on the above chart can only be used if the value of measurement uncertainty on the

calibration certificate of the measuring instrument is smaller than the values of the chart.

When this is not the case, then you must take as limit value for an adjustment the measurement

uncertainty va lue of the calibration certificate.

Up to 60°C

CO2 volume in %

37°C (2nd point not used)

0 Vol.-% and 5 Vol.-%CO2

+/- 0,3K

+/- 0,3 Vol.-% CO

2

36

Page 37

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Calibration instructions for CO2 incubator CB

with screen controller MB1

Temperature / CO2 / O2 controller

Measurement device for temperature

Type:

Identification No.:

Traceability:

Date of calibration:

Measuring uncertainty

of the measuring device:

Temperature calibration

The temperature calibration is effected in one single procedure at the most common working

temperature (mostly used 37°C) in thermal stationary condition. The unit is checked in empty

condition with one central shelf.

The reference sensor for temperature is led into the empty inner chamber through the door

sealing and is positioned in the middle of the usable volume on one central shelf. Both unit

doors remain closed during the calibration. The incubator has to be pre-heated at the

calibration temperature for at least one hour.

The adjustment of the temperature controller is only necessary in case there is a deviation between

the temperature, measured in centre of the useful vol ume and the reading of the actual temperature

displayed on the controller MB1 or its safety controller of more than +/-0.2 K. In case the reference

instrument has a measuring uncertainty larger than +/-0.2 K (see its calibration certificate), this is the

confidence criteria.

Test for the necessity of a temperature calibration (adjustment of the controller)

Temperature set -point W

______________°C

Display reading of the controller

______________°C

Display reading X of the safety controller in menu “user-settings”

______________°C

Display reading of the reference instrument

______________°C

Divergence actual temperature - Reading reference instrument

______________°C

Divergence actual temperature of the safety controller -

Reading reference instrument

______________°C

37

Page 38

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Measuring uncertainty of the reference instrument

______________°C

Yes No

Calibration (adjustment) of the temperature controller

o o

necessary

In case of “No” chap. 3 can be skipped.

Notes: Repeated calibrations are recommended in periods of 12 months.

Calibration (alignment) of the temperature controller

Overview :

First of all the former calibration is reset (see chap. reset of the calibration). The input value

correction is deactivated afterwards (set the state of the input val. correction to Off). Then

return to the normal operation mode and let adjust the incubator for 1 hour to the calibration

temperature.

The display reading values of the inner chamber temperature (Analogue input 1), of the preheating

chamber temperature (Analogue input 2) and of the safety controller are set to the display reading

value of the reference instrument. This is done by entering the display value of the reference

instrument to the menu “Input value correction” of analogue input 1, analogue input 2, and of the

safety controller.

Finally the input value correction is activated (set the state of the input val. correction to On).

Reset of former calibrations

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 1

Enter the value 0 to Start Value X.

Enter the value 0 to Start Value W.

Enter the value 1000 to End Value X.

Enter the value 1000 to End Value W.

Set State to Off

→ EXIT → Analogue input 2

Enter the value 0 to Start Value X.

Enter the value 0 to Start Value W.

Enter the value 1000 to End Value X.

Enter the value 1000 to End Value W.

Set State to Off

→ EXIT → Safety controller

Enter the value 0 to Start Value X.

Enter the value 0 to Start Value W.

Enter the value 1000 to End Value X.

Enter the value 1000 to End Value W.

Set State to Off

→ leave menu with 4 x EXIT.

38

Page 39

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Entry of the reference temperature

Starting Situation:

During 1 hour without door opening the incubator is adjusted stable to the calibration

temperature (e.g. X = W = 37°C).

The reference instrument shows e.g. 36.5°C.

Reading out of the actual values:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Analogue Inputs → read out and note 1. and 2.

→ leave the menu with 3 x EXIT

Normal Display → User-Settings → read out and note “Safety control.Act.”

→ leave the menu with EXIT

Example:

Reference device Analogue Input 1.

equals

Analogue Input 2. Safety control.Act

value X = value W in

Normal display

36.5°C 37.0 °C 36.7°C 36.9°C

Entries:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 1

Enter the display value of the controller (e.g. 37.0°C) to End Value X.

Enter the display value of the reference instrument (e.g. 36.5°C) to End Value W.

Set State to On

→ EXIT → Inp. Val. correct. → Analogue input 2

Enter the display value of analogue input 2. (e.g. 36.7°C) to End Value X.

Enter the display value of the reference device (e.g. 36.5°C) to End Value W.

Set State to On.

→ EXIT → Inp. Val. correct. → Safety controller

Enter the value Safety control.Act (e.g. 36.9°C) to Start Value X.

Enter the display value of the reference instrument (e.g. 36.5°C) to Start Value W.

Check and enter if needed the fix value 187° C to End Value X.

Check and enter the fix value 175°C to End Value W.

Set State to On

→ leave the menu with 4 x EXIT.

The corrected value appears on the controller display after 5 seconds.

Result Calibration (alignment) of the temperature controller

After the adjustment of the controller the temperature display reading of the reference

instrument is compared with the display reading of the controller MB1 again:

Temperature set point of the

controller

______________°C

Actual value shown on the test

equipment

______________°C

Confidence criteria fulfilled

Yes No

o o

39

Page 40

CB (E2) Service Manual

The calibration is carried out in two individual

exposed to pure

nitrogen and afterwards it is exposed to analysed

concentration. The

litre pressure gas bottles

(10bar) have to be used. The test gas bottles are

connected via the original BINDER pressure

ucer with flow meter and a plastic tube with the

calibration cup. The flow rate has to be situated

between 600 and 900 ml/min. This is equal to the

two highest graduations of the flow meter in

state: 01/2002 created: 03/2002/ Jochen Tussinger

CO2 calibration (alignment)

Reset of former calibrations

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 4

Enter the value 0 to Start Value X.

Enter the value 0 to Start Value W.

Enter the value 1000 to End Value X.

Enter the value 1000 to End Value W.

Set State to Off

→ leave menu with 4 x EXIT.

Determination and entry of the calibration values

The incubator has to be pre-heated at the working temperature (common value 37°C) for at

least half an hour. The altitude of the site above the sea level has to be entered to the

temperature/CO2-controller. The procedure is described in chapter 7.3 of the operation manual.

Afterwards the incubator is switched off at the main switch (1) and the CO2 sensor is pulled out

of the incubator. The unit doors can now remain open during the calibration. The white filter of

the CO2 sensor is removed and the original BINDER calibration cap is pushed on the sensor

tip. The sensor with the calibration cup is put into the socket of the incubator again and the

incubator is switch on at the main switch (1).

steps. At first the sensor is

CO2 test gas with known CO

2

original BINDER one-

red

upright position.

Note: The BINDER service uses larger pressure gas bottles with analysed test gases and an other

flow meter. But the procedure remains as described.

After 5 minutes exposing of the sensor to each test gas the CO2-concentration of the gas is

entered to the MB1 controller according to the following description.

Exposion to Nitrogen (0 vol.-% CO2) for 5 minutes:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 4

Enter the display value of the controller (e.g. –0.2 Vol.-%) to Start Value X.

Enter the CO2 concentration of Nitrogen (0 Vol.-%) to Start Value W.

→ leave menu with 4 x EXIT and stop exposure with Nitrogen.

40

Page 41

CB (E2) Service Manual

first the sensor is exposed to ambient air and

test gas with

connected via the original BINDER pressure reducer

calibration

cup. The flow rate has to be situated between 600 and

state: 01/2002 created: 03/2002/ Jochen Tussinger

Exposition to test gas (5 vol.-% CO2 ) for 5 minutes:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 4

Enter the display value of the controller (e.g. 4.7 Vol.-%) to End Value X.

Enter the CO2 concentration of the CO2 test gas (5.0 Vol.-%) to End Value W.

Set State to On

→ leave menu with 4 x EXIT.

The corrected value 5 Vol.-% appears on the controller display after 5 seconds.

Afterwards the exposure with test gas is stopped.

Result CO2-Adjustment:

Yes No

The analysis result of the test gas acc. to the label of the gas bottle is reached.

o o

O2 calibration (alignment)

Reset of former calibrations

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 5

Enter the value 0 to Start Value X.

Enter the value 0 to Start Value W.

Enter the value 1000 to End Value X.

Enter the value 1000 to End Value W.

Set State to Off

→ leave menu with 4 x EXIT.

Determination and entry of the calibration values

The incubator has to be pre-heated at the working temperature (common value 37°C) for at

least half an hour.

The altitude of the site above the sea level has to be entered to the temperature/ CO2 /O2controller. The procedure is described in chapter 7.3 of the operation manual.

The chamber doors can be opened during the calibration procedure. The original BINDER

calibration cap is pushed on the O2-sensor tip only when exposed to the test gas, not when

exposed to ambient air.

The calibration is carried out in two individual steps. At

afterwards it is exposed to analysed O

known O2 concentration. Use the original BINDER onelitre pressure gas bottle (10 bar). The test gas bottle is

with flow meter and a plastic tube with the

900 ml/min. This is equal to the two highest

graduations of the flow meter in upright position.

2

41

Page 42

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Note: The BINDER service uses a larger pressure gas bottle with analysed test gas and an other flow

meter. But the procedure remains as described.

After 5 minutes exposing of the sensor to ambient air or to the test gas the entrance signal of

the O2 sensor is corrected according to the table below and is entered to the MB1 controller

according to the following description.

Correcting table for O2- calibration (alignment of controller display)

The connection between the oxygen concentration of the test gas or the ambient air and the expected

entrance signal to the MB1 controller is presented in the table below.

O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV]

20 198.8 79 1390.5

20.1 199.9 79.1 1394.8

20.2 201.1 79.2 1399.1

20.3 202.2 79.3 1403.4

20.4 203.3 79.4 1407.7

20.5 204.4 79.5 1412.0

20.6 205.5 79.6 1416.4

20.7 206.7 79.7 1420.7

20.8 207.8 79.8 1425.1

20.9 208.9 79.9 1429.6

21 210.0 Reference value for air 80 1434.0

21.1 211.2 80.1 1438.5

21.2 212.3 80.2 1443.0

21.3 213.4 80.3 1447.5

21.4 214.6 80.4 1452.0

21.5 215.7 80.5 1456.6

21.6 216.8 80.6 1461.1

21.7 218.0 80.7 1465.8

21.8 219.1 80.8 1470.4

21.9 220.2 80.9 1475.0

22 221.4 81 1479.7

81.1 1484.4

81.2 1489.1

81.3 1493.9

81.4 1498.7

81.5 1503.5

Reference value

for BINDER test gas

If other test gases are used, see table in appendix for according tension values.

The measuring value correcting in the following description is carried out according this table by

entering the expected voltage value (W) and the voltage value (X) that corresponds to the actual

controller display.

42

Page 43

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Procedure of O2- calibration (alignment of controller display)

Sensor without calibration cap, unit door open, unit in normal operation.

Exposition to ambient air (21 vol.-% O2) for 5 minutes

Comparison of table values:

With ambie nt air the MB1 controller display shows e.g., 20.3 Vol.-% O2. According to the above table

this corresponds to a voltage of 202.2 mV.

With ambient air the MB1 controller display should display 21 Vol.-%. According to the above table this

corresponds to a voltage of 210 mV.

Setting:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 5

For Start Value X enter the voltage value that corresponds to the controller display (e.g.,

202.2).

For Start Value W enter the reference voltage value of the O2 concentration of the

ambient air (210).

→ leave menu with 4 x EXIT.

Sensor with pushed -on calibration cap, unit door open, unit in normal operation.

Sensor exposition to test gas 80 vol.-% O2 for 5 minutes:

Comparison of table values:

With sensor exposition to test gas (80 Vol. -% O2) the MB1 controller display shows e.g., 80.9 Vol.-%.

According to the above table this corresponds to a voltage of 1475mV.

With sensor exposition to test gas (80 Vol.-% O2) the MB1 controller display should display 80 Vol.-%.

According to the above table this corresponds to a voltage of 1434mV.

End value setting:

Normal Display → Config → Configuration 2 → System-Code 2802 → Service Level →

Inp. Val. correct. → Analogue input 5

For End Value X enter the voltage value that corresponds to the controller display (e.g.,

1475).

For End Value W enter the reference voltage value of the O2 test gas (80 vol.-%) (1434).

Set State to On

→ leave menu with 4 x EXIT.

The corrected value 80 vol.-% appears on the controller display after 5 seconds.

Afterwards the exposure with test gas is stopped.

Result O2-Adjustment:

Yes No

The analysis result of the test gas acc. to the label of the gas bottle is reached.

o o

43

Page 44

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

Appendix : Conversion table VOL.-% O2 – mV

O2 [Vol.-%] U [mV] O2 [Vol.-%]U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV]

0 0.0 5 45.7 10 93.9 15 144.8 20 198.8

0.1 0.9 5.1 46.6 10.1 94.9 15.1 145.9 20.1 199.9

0.2 1.8 5.2 47.6 10.2 95.9 15.2 146.9 20.2 201.1

0.3 2.7 5.3 48.5 10.3 96.9 15.3 148.0 20.3 202.2

0.4 3.6 5.4 49.5 10.4 97.8 15.4 149.0 20.4 203.3

0.5 4.5 5.5 50.4 10.5 98.8 15.5 150.1 20.5 204.4

0.6 5.4 5.6 51.3 10.6 99.8 15.6 151.1 20.6 205.5

0.7 6.3 5.7 52.3 10.7 100.8 15.7 152.2 20.7 206.7

0.8 7.2 5.8 53.2 10.8 101.8 15.8 153.2 20.8 207.8

0.9 8.1 5.9 54.2 10.9 102.8 15.9 154.3 20.9 208.9

1 9.0 6 55.1 11 103.8 16 155.3 21 210.0

1.1 9.9 6.1 56.1 11.1 104.8 16.1 156.4 21.1 211.2

1.2 10.8 6.2 57.0 11.2 105.8 16.2 157.5 21.2 212.3

1.3 11.7 6.3 58.0 11.3 106.8 16.3 158.5 21.3 213.4

1.4 12.6 6.4 58.9 11.4 107.8 16.4 159.6 21.4 214.6

1.5 13.5 6.5 59.9 11.5 108.9 16.5 160.7 21.5 215.7

1.6 14.4 6.6 60.8 11.6 109.9 16.6 161.7 21.6 216.8

1.7 15.3 6.7 61.8 11.7 110.9 16.7 162.8 21.7 218.0

1.8 16.2 6.8 62.7 11.8 111.9 16.8 163.9 21.8 219.1

1.9 17.1 6.9 63.7 11.9 112.9 16.9 164.9 21.9 220.2

2 18.0 7 64.7 12 113.9 17 166.0 22 221.4

2.1 18.9 7.1 65.6 12.1 114.9 17.1 167.1 22.1 222.5

2.2 19.8 7.2 66.6 12.2 115.9 17.2 168.2 22.2 223.7

2.3 20.7 7.3 67.5 12.3 116.9 17.3 169.2 22.3 224.8

2.4 21.6 7.4 68.5 12.4 118.0 17.4 170.3 22.4 226.0

2.5 22.6 7.5 69.5 12.5 119.0 17.5 171.4 22.5 227.1

2.6 23.5 7.6 70.4 12.6 120.0 17.6 172.5 22.6 228.3

2.7 24.4 7.7 71.4 12.7 121.0 17.7 173.6 22.7 229.4

2.8 25.3 7.8 72.4 12.8 122.0 17.8 174.6 22.8 230.6

2.9 26.2 7.9 73.3 12.9 123.1 17.9 175.7 22.9 231.7

3 27.1 8 74.3 13 124.1 18 176.8 23 232.9

3.1 28.1 8.1 75.3 13.1 125.1 18.1 177.9 23.1 234.0

3.2 29.0 8.2 76.2 13.2 126.1 18.2 179.0 23.2 235.2

3.3 29.9 8.3 77.2 13.3 127.2 18.3 180.1 23.3 236.4

3.4 30.8 8.4 78.2 13.4 128.2 18.4 181.2 23.4 237.5

3.5 31.7 8.5 79.1 13.5 129.2 18.5 182.3 23.5 238.7

3.6 32.7 8.6 80.1 13.6 130.2 18.6 183.4 23.6 239.8

3.7 33.6 8.7 81.1 13.7 131.3 18.7 184.5 23.7 241.0

3.8 34.5 8.8 82.1 13.8 132.3 18.8 185.6 23.8 242.2

3.9 35.4 8.9 83.1 13.9 133.3 18.9 186.7 23.9 243.4

4 36.4 9 84.0 14 134.4 19 187.8 24 244.5

4.1 37.3 9.1 85.0 14.1 135.4 19.1 188.9 24.1 245.7

4.2 38.2 9.2 86.0 14.2 136.5 19.2 190.0 24.2 246.9

4.3 39.2 9.3 87.0 14.3 137.5 19.3 191.1 24.3 248.0

4.4 40.1 9.4 88.0 14.4 138.5 19.4 192.2 24.4 249.2

4.5 41.0 9.5 88.9 14.5 139.6 19.5 193.3 24.5 250.4

4.6 42.0 9.6 89.9 14.6 140.6 19.6 194.4 24.6 251.6

4.7 42.9 9.7 90.9 14.7 141.7 19.7 195.5 24.7 252.8

4.8 43.8 9.8 91.9 14.8 142.7 19.8 196.6 24.8 254.0

4.9 44.8 9.9 92.9 14.9 143.8 19.9 197.7 24.9 255.1

44

Page 45

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

O2 [Vol.-%] U [mV] O2 [Vol.-%]U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV]

25 256.3 30 317.8 35 383.8 40 455.1 45 532.7

25.1 257.5 30.1 319.1 35.1 385.2 40.1 456.6 45.1 534.3

25.2 258.7 30.2 320.3 35.2 386.6 40.2 458.1 45.2 535.9

25.3 259.9 30.3 321.6 35.3 387.9 40.3 459.6 45.3 537.5

25.4 261.1 30.4 322.9 35.4 389.3 40.4 461.1 45.4 539.2

25.5 262.3 30.5 324.2 35.5 390.7 40.5 462.6 45.5 540.8

25.6 263.5 30.6 325.5 35.6 392.1 40.6 464.1 45.6 542.4

25.7 264.7 30.7 326.8 35.7 393.5 40.7 465.6 45.7 544.1

25.8 265.9 30.8 328.0 35.8 394.9 40.8 467.1 45.8 545.7

25.9 267.1 30.9 329.3 35.9 396.3 40.9 468.6 45.9 547.4

26 268.3 31 330.6 36 397.6 41 470.1 46 549.0

26.1 269.5 31.1 331.9 36.1 399.0 41.1 471.6 46.1 550.7

26.2 270.7 31.2 333.2 36.2 400.4 41.2 473.1 46.2 552.3

26.3 271.9 31.3 334.5 36.3 401.8 41.3 474.7 46.3 554.0

26.4 273.1 31.4 335.8 36.4 403.2 41.4 476.2 46.4 555.6

26.5 274.3 31.5 337.1 36.5 404.6 41.5 477.7 46.5 557.3

26.6 275.5 31.6 338.4 36.6 406.0 41.6 479.2 46.6 559.0

26.7 276.8 31.7 339.7 36.7 407.4 41.7 480.8 46.7 560.6

26.8 278.0 31.8 341.0 36.8 408.8 41.8 482.3 46.8 562.3

26.9 279.2 31.9 342.3 36.9 410.3 41.9 483.8 46.9 564.0

27 280.4 32 343.6 37 411.7 42 485.4 47 565.7

27.1 281.6 32.1 344.9 37.1 413.1 42.1 486.9 47.1 567.4

27.2 282.9 32.2 346.2 37.2 414.5 42.2 488.4 47.2 569.0

27.3 284.1 32.3 347.6 37.3 415.9 42.3 490.0 47.3 570.7

27.4 285.3 32.4 348.9 37.4 417.3 42.4 491.5 47.4 572.4

27.5 286.5 32.5 350.2 37.5 418.8 42.5 493.1 47.5 574.1

27.6 287.8 32.6 351.5 37.6 420.2 42.6 494.6 47.6 575.8

27.7 289.0 32.7 352.8 37.7 421.6 42.7 496.2 47.7 577.5

27.8 290.2 32.8 354.2 37.8 423.1 42.8 497.7 47.8 579.2

27.9 291.5 32.9 355.5 37.9 424.5 42.9 499.3 47.9 580.9

28 292.7 33 356.8 38 425.9 43 500.8 48 582.6

28.1 293.9 33.1 358.2 38.1 427.4 43.1 502.4 48.1 584.4

28.2 295.2 33.2 359.5 38.2 428.8 43.2 504.0 48.2 586.1

28.3 296.4 33.3 360.8 38.3 430.3 43.3 505.5 48.3 587.8

28.4 297.7 33.4 362.2 38.4 431.7 43.4 507.1 48.4 589.5

28.5 298.9 33.5 363.5 38.5 433.1 43.5 508.7 48.5 591.3

28.6 300.2 33.6 364.8 38.6 434.6 43.6 510.3 48.6 593.0

28.7 301.4 33.7 366.2 38.7 436.0 43.7 511.9 48.7 594.7

28.8 302.7 33.8 367.5 38.8 437.5 43.8 513.4 48.8 596.5

28.9 303.9 33.9 368.9 38.9 439.0 43.9 515.0 48.9 598.2

29 305.2 34 370.2 39 440.4 44 516.6 49 599.9

29.1 306.4 34.1 371.6 39.1 441.9 44.1 518.2 49.1 601.7

29.2 307.7 34.2 372.9 39.2 443.3 44.2 519.8 49.2 603.5

29.3 308.9 34.3 374.3 39.3 444.8 44.3 521.4 49.3 605.2

29.4 310.2 34.4 375.6 39.4 446.3 44.4 523.0 49.4 607.0

29.5 311.5 34.5 377.0 39.5 447.8 44.5 524.6 49.5 608.7

29.6 312.7 34.6 378.4 39.6 449.2 44.6 526.2 49.6 610.5

29.7 314.0 34.7 379.7 39.7 450.7 44.7 527.8 49.7 612.3

29.8 315.3 34.8 381.1 39.8 452.2 44.8 529.4 49.8 614.0

29.9 316.5 34.9 382.5 39.9 453.7 44.9 531.1 49.9 615.8

45

Page 46

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

O2 [Vol.-%] U [mV] O2 [Vol.-%]U [mV] O2 [Vol.-%]U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV]

50 617.6 55 711.5 60 816.4 65 935.4 70 1072.7

50.1 619.4 55.1 713.5 60.1 818.6 65.1 937.9 70.1 1075.7

50.2 621.2 55.2 715.4 60.2 820.9 65.2 940.5 70.2 1078.7

50.3 623.0 55.3 717.4 60.3 823.1 65.3 943.1 70.3 1081.7

50.4 624.8 55.4 719.4 60.4 825.4 65.4 945.6 70.4 1084.7

50.5 626.5 55.5 721.4 60.5 827.6 65.5 948.2 70.5 1087.7

50.6 628.4 55.6 723.4 60.6 829.9 65.6 950.8 70.6 1090.7

50.7 630.2 55.7 725.4 60.7 832.1 65.7 953.4 70.7 1093.8

50.8 632.0 55.8 727.5 60.8 834.4 65.8 956.0 70.8 1096.8

50.9 633.8 55.9 729.5 60.9 836.7 65.9 958.6 70.9 1099.9

51 635.6 56 731.5 61 839.0 66 961.2 71 1102.9

51.1 637.4 56.1 733.5 61.1 841.3 66.1 963.8 71.1 1106.0

51.2 639.2 56.2 735.6 61.2 843.6 66.2 966.5 71.2 1109.1

51.3 641.1 56.3 737.6 61.3 845.9 66.3 969.1 71.3 1112.2

51.4 642.9 56.4 739.6 61.4 848.2 66.4 971.8 71.4 1115.3

51.5 644.7 56.5 741.7 61.5 850.5 66.5 974.4 71.5 1118.4

51.6 646.6 56.6 743.7 61.6 852.8 66.6 977.1 71.6 1121.6

51.7 648.4 56.7 745.8 61.7 855.1 66.7 979.8 71.7 1124.7

51.8 650.3 56.8 747.8 61.8 857.4 66.8 982.4 71.8 1127.9

51.9 652.1 56.9 749.9 61.9 859.8 66.9 985.1 71.9 1131.0

52 654.0 57 752.0 62 862.1 67 987.8 72 1134.2

52.1 655.8 57.1 754.1 62.1 864.5 67.1 990.5 72.1 1137.4

52.2 657.7 57.2 756.1 62.2 866.8 67.2 993.2 72.2 1140.6

52.3 659.6 57.3 758.2 62.3 869.2 67.3 996.0 72.3 1143.8

52.4 661.4 57.4 760.3 62.4 871.5 67.4 998.7 72.4 1147.0

52.5 663.3 57.5 762.4 62.5 873.9 67.5 1001.4 72.5 1150.3

52.6 665.2 57.6 764.5 62.6 876.3 67.6 1004.2 72.6 1153.5

52.7 667.1 57.7 766.6 62.7 878.7 67.7 1006.9 72.7 1156.8

52.8 668.9 57.8 768.7 62.8 881.1 67.8 1009.7 72.8 1160.0

52.9 670.8 57.9 770.8 62.9 883.5 67.9 1012.5 72.9 1163.3

53 672.7 58 772.9 63 885.9 68 1015.2 73 1166.6

53.1 674.6 58.1 775.1 63.1 888.3 68.1 1018.0 73.1 1169.9

53.2 676.5 58.2 777.2 63.2 890.7 68.2 1020.8 73.2 1173.2

53.3 678.4 58.3 779.3 63.3 893.1 68.3 1023.6 73.3 1176.6

53.4 680.3 58.4 781.5 63.4 895.6 68.4 1026.4 73.4 1179.9

53.5 682.3 58.5 783.6 63.5 898.0 68.5 1029.3 73.5 1183.3

53.6 684.2 58.6 785.8 63.6 900.4 68.6 1032.1 73.6 1186.6

53.7 686.1 58.7 787.9 63.7 902.9 68.7 1034.9 73.7 1190.0

53.8 688.0 58.8 790.1 63.8 905.4 68.8 1037.8 73.8 1193.4

53.9 690.0 58.9 792.2 63.9 907.8 68.9 1040.7 73.9 1196.8

54 691.9 59 794.4 64 910.3 69 1043.5 74 1200.2

54.1 693.8 59.1 796.6 64.1 912.8 69.1 1046.4 74.1 1203.7

54.2 695.8 59.2 798.8 64.2 915.3 69.2 1049.3 74.2 1207.1

54.3 697.7 59.3 801.0 64.3 917.7 69.3 1052.2 74.3 1210.6

54.4 699.7 59.4 803.1 64.4 920.2 69.4 1055.1 74.4 1214.1

54.5 701.6 59.5 805.3 64.5 922.8 69.5 1058.0 74.5 1217.5

54.6 703.6 59.6 807.5 64.6 925.3 69.6 1060.9 74.6 1221.0

54.7 705.6 59.7 809.8 64.7 927.8 69.7 1063.9 74.7 1224.6

54.8 707.5 59.8 812.0 64.8 930.3 69.8 1066.8 74.8 1228.1

54.9 709.5 59.9 814.2 64.9 932.8 69.9 1069.8 74.9 1231.6

46

Page 47

CB (E2) Service Manual

state: 01/2002 created: 03/2002/ Jochen Tussinger

O2 [Vol.-%] U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%]U [mV] O2 [Vol.-%] U [mV] O2 [Vol.-%]U [mV]

75 1235.2 80 1434.0 85 1690.3 90 2051.6 95 2669.2

75.1 1238.8 80.1 1438.5 85.1 1696.3 90.1 2060.6 95.1 2687.2

75.2 1242.3 80.2 1443.0 85.2 1702.3 90.2 2069.6 95.2 2705.6

75.3 1245.9 80.3 1447.5 85.3 1708.3 90.3 2078.7 95.3 2724.3

75.4 1249.6 80.4 1452.0 85.4 1714.4 90.4 2088.0 95.4 2743.5

75.5 1253.2 80.5 1456.6 85.5 1720.5 90.5 2097.3 95.5 2763.1

75.6 1256.8 80.6 1461.1 85.6 1726.7 90.6 2106.7 95.6 2783.1

75.7 1260.5 80.7 1465.8 85.7 1732.9 90.7 2116.3 95.7 2803.6

75.8 1264.2 80.8 1470.4 85.8 1739.2 90.8 2125.9 95.8 2824.5

75.9 1267.9 80.9 1475.0 85.9 1745.5 90.9 2135.6 95.9 2846.0

76 1271.6 81 1479.7 86 1751.8 91 2145.5 96 2868.0

76.1 1275.3 81.1 1484.4 86.1 1758.2 91.1 2155.4 96.1 2890.6

76.2 1279.0 81.2 1489.1 86.2 1764.6 91.2 2165.5 96.2 2913.7

76.3 1282.8 81.3 1493.9 86.3 1771.1 91.3 2175.7 96.3 2937.5