Bertazzoni PROF366RTBXT, PROF365CTXV, PROF366QBXT, PROF305CTXV, PROF304QXE Design Guide

...Page 1

WALL OVENS

SPECIALTY OVENS

GAS RANGETOPS & COOKTOPS

INDUCTION & ELECTRIC COOKTOPS

DESIGN GUIDE

1.2

Page 2

BUILT-IN COOKING DESIGN GUIDE

Bertazzoni appliances are designed to work together

and create harmony in the kitchen.

The products in our built-in cooking program can

be combined with numerous installation options to

create the ideal setup that suits the kitchen layout

and cooking style of the homeowner.

Versatility is key, with a choice of technologies and

designs that work together seamlessly.

This guide contains up-to-date technical

specifications and dimensions necessary to prepare

the installation of Bertazzoni built-in cooking products

in a kitchen.

All these details are also available online at

bertazzoni.com.

Page 3

INDEX

INTRODUCTION 3

WALL OVENS 4

30” Electric Convection Single Ovens 6

30” Electric Convection Double Ovens 11

24” Electric Convection Oven 15

SPECIALTY OVENS 19

30” Convection Speed Ovens 21

30” Convection Steam Ovens 26

30” Warming Drawer 31

30” Microwave Oven 34

24” Convection Speed Ovens 38

24” Microwave Drawer 43

INDUCTION & ELECTRIC COOKTOPS 72

36” Induction Cooktop 74

30” Induction Cooktop 77

30” Electric Ceramic Cooktop 80

24” Electric Ceramic Cooktop 83

MULTIPLE INSTALLATIONS 86

30” Oven - Wall Configurations 88

24” Oven - Wall Configurations 100

30” Oven and Cooktop - Undercounter Configurations 104

24” Oven and Cooktop - Undercounter Configurations 123

GAS RANGETOPS & COOKTOPS 46

48” Rangetops 48

36” Rangetops 51

36” Drop-in Cooktops 6 burners 54

36” Drop-in Cooktops 5 burners 57

30” Drop-in Cooktops 60

36” Gas Cooktop Front Control 63

30” Gas Cooktop Front Control 66

24” Gas Cooktop Front Control 69

3bertazzoni.com

Page 4

WALL OVENS

Built-in ovens offer an excellent alternative – or

even complementary choice – to freestanding range,

offering simple elegance. For some, the ability to fit

an oven easily into a compact space makes built-in

ovens their first choice. For others it is the attraction

of flexible design with the option to install the ovens

on top of each other or side-by-side, at eye-level or

undercounter.

All Bertazzoni built-in ovens can be installed proud

or perfectly flush to align with matching convection

steam, speed and microwave ovens as well as

warming drawers.

30” Electric Convection

Single Ovens

30” Electric Convection

Double Ovens

24” Electric Convection

Single Ovens

4 bertazzoni.com

Page 5

Page 6

WALL OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

30” Electric Convection Single Ovens

Dimensions

PROF30FSEXT

PROF30FSEXV

MAST30FSEXT

MAST30FSEXV

28"

712

CONDUIT

CHANNEL

17 1/8"

436

1"

26

23 1/2"

596

1 7/8"

47

29 7/8"

758

28 5/8"

726

1/2"

13

3 3/8"

86

22 5/8"

575

28 1/8"

715

2"

52

CONDUIT

CHANNEL

3 3/8"

86

21 5/8"

550

6 bertazzoni.com

Page 7

CONVECTION OVENS

FRONT VIEW

30” Electric Convection Single Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C).

Installation of the appliance must be performed in accordance

with the provisions of applicable legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

5"

127

E

4"

102

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

275lb (125kg )

Electrical supply

120/240 V

120/208 V

60 Hz

60 Hz

5500 W

4400 W

Service 30 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

7bertazzoni.com

Page 8

WALL OVENS

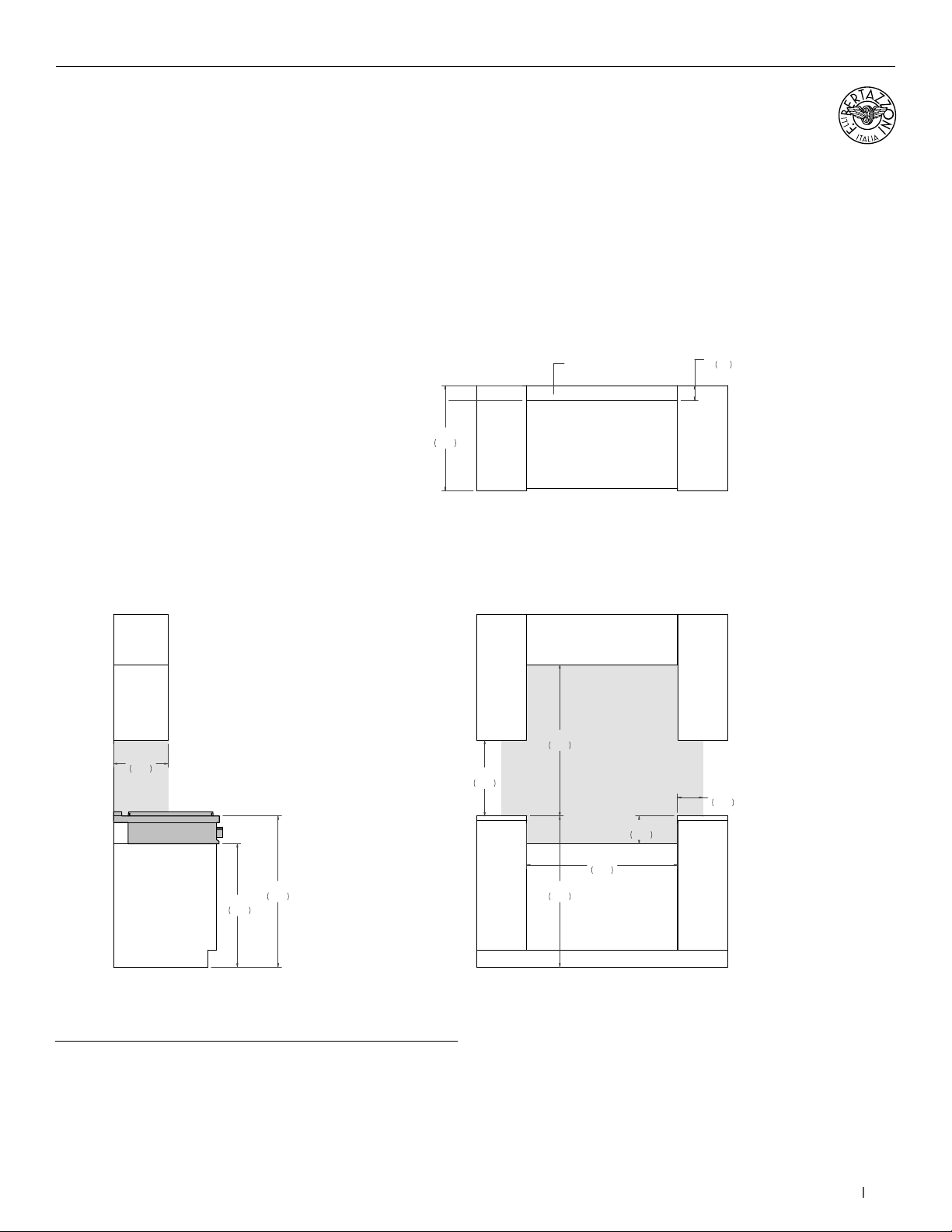

30” Electric Convection Single Ovens

Proud installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a a

23"

584

DEPTH

SIDE VIEW

FRONT VIEW

28 3/8"

720

HEIGHT

28 1/2"

724

WIDTH

(a) Spacers - Included with appliance

8 bertazzoni.com

Page 9

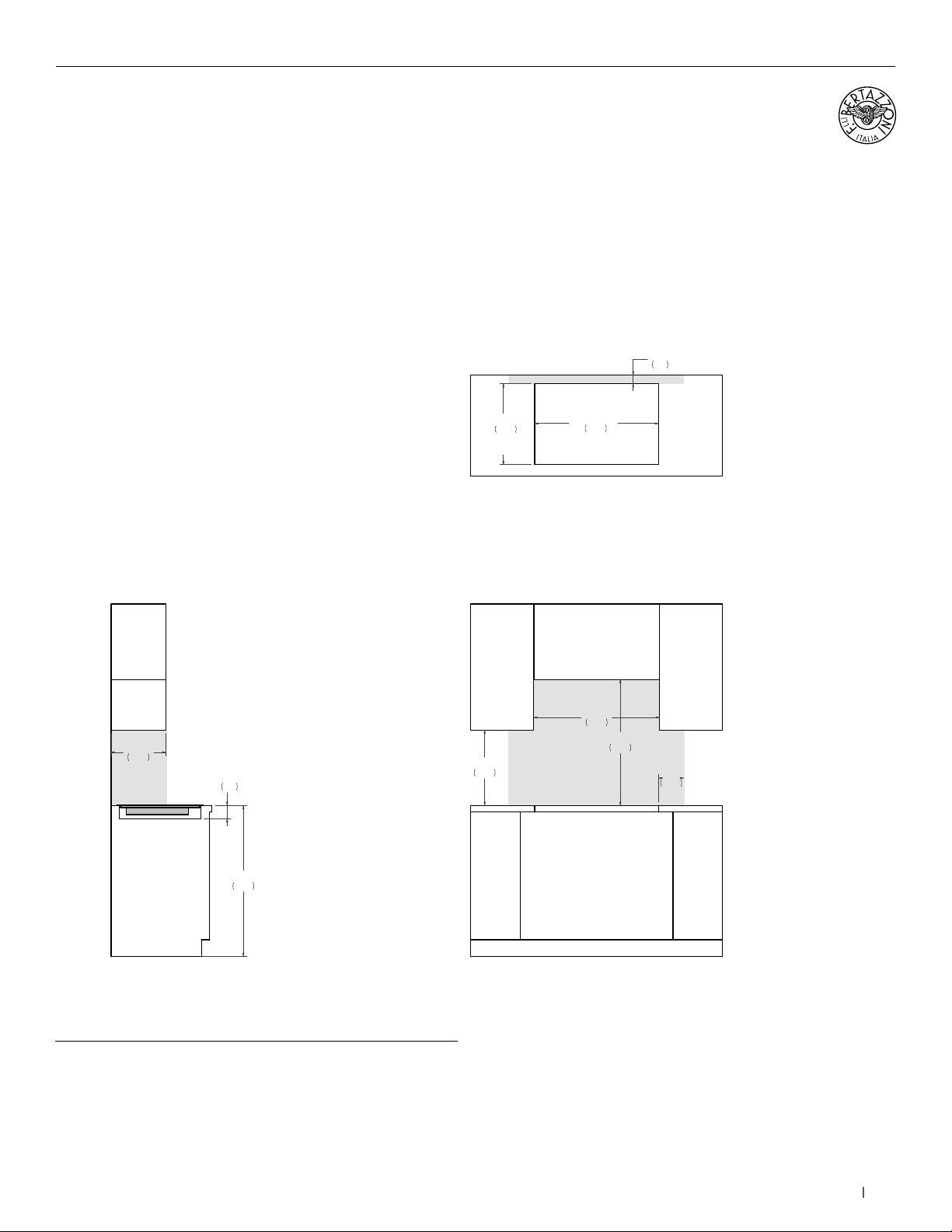

WALL OVENS

30” Electric Convection Single Ovens

Flush installation non vented

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a a

23 5/8"

600

FLUSH INSET

DEPTH

1"

25

SIDE VIEW

FRONT VIEW

29 3/8"

746

FLUSH INSET

HEIGHT

28 3/8"

720

b

30 7/8"

784

FLUSH INSET

WIDTH

28 1/2"

724

7/8"

1 1/8"301 1/8"

30

1/8"

23

3

b

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

9bertazzoni.com

Page 10

WALL OVENS

30” Electric Convection Single Ovens

Flush installation vented

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a a

23 5/8"

600

FLUSH INSET

DEPTH

1"

25

SIDE VIEW

AIR INTAKE

FRONT VIEW

29 1/8"

741

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

28 3/8"

720

30 1/2"

774

FLUSH INSET

WIDTH

28 1/2"

724

3/4"

18

1"

25

b

1"

25

1/8"

3

b

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

10 bertazzoni.com

Page 11

WALL OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

30” Electric Convection Double Ovens

Dimensions

PROF30FDEXT

PROF30FDEXV

MAST30FDEXT

MAST30FDEXV

1"

26

52 3/4"

1338

CONDUIT

CHANNEL

53 1/4"

1352

3 3/8"

86

23"

585

28 1/8"

715

2 3/8"

CONDUIT

CHANNEL

62

22"

560

17 1/8"

436

1 7/8"

47

23 1/2"

596

29 7/8"

758

1/2"

13

3 3/8"

86

11bertazzoni.com

Page 12

WALL OVENS

FRONT VIEW

30” Electric Convection Double Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes. A properly-grounded horizontally- mounted

electrical receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

5"

127

E

4"

102

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

12 bertazzoni.com

485lb (220kg)

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Electrical supply

120/240 V

120/208 V

60 Hz

60 Hz

11000 W

8800 W

Service 50 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

Page 13

WALL OVENS

30” Electric Convection Double Ovens

Proud installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a a

23 5/8"

600

DEPTH

SIDE VIEW

FRONT VIEW

53"

1346

HEIGHT

28 1/2"

724

WIDTH

(a) Spacers - Included with appliance

13bertazzoni.com

Page 14

WALL OVENS

30” Electric Convection Double Ovens

Flush installation vented

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a

23 7/8"

606

FLUSH INSET

DEPTH

25

1"

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

53 7/8"

1367

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

53"

1346

30 1/2"

774

FLUSH INSET

WIDTH

28 1/2"

724

b

3/4"

18

1"

25

b

1/8"

1"

25

AIR INTAKE

b

3

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

14 bertazzoni.com

Page 15

WALL OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

24” Electric Convection Single Ovens

Dimensions

PROF24FSEXV

22 7/8"

581

CONDUIT

OUTPUT

3/4"

20

19 1/8"

485

1 3/8"

33

23 1/2"

598

23 3/8"

595

1/2"

13

2 3/8"

61

21 5/8"

550

21 7/8"

556

CONDUIT

OUTPUT

15bertazzoni.com

Page 16

WALL OVENS

FRONT VIEW

24” Electric Convection Single Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed in

accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

5"

127

E

4"

102

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

16 bertazzoni.com

155lb (70kg)

Electrical supply

120/240 V

120/208 V

60 Hz

60 Hz

2800 W

2100 W

Service 16 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

Page 17

WALL OVENS

24” Electric Convection Single Ovens

Proud installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a

23"

585

DEPTH

a

SIDE VIEW

FRONT VIEW

23"

585

22"

560

(a) Spacers - Included with appliance

17bertazzoni.com

Page 18

WALL OVENS

24” Electric Convection Single Ovens

Flush installation non vented

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a

23 3/4"

603

FLUSH INSET

DEPTH

3/4"

a

20

SIDE VIEW

FRONT VIEW

24 1/8"

614

FLUSH INSET

HEIGHT

FLUSH INSET

WIDTH

23"

585

1"

26

b b

3/8"

24"

611

22"

560

9

3/4"

20

1"

26

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

18 bertazzoni.com

Page 19

SPECIALTY OVENS

Bertazzoni has perfected cooking appliances for

over 100 years. As a result, we understand that

today’s home chefs want a variety of technologies

at their disposal. That means lifestyle-driven speed

cooking without sacrificing flavor, texture or aroma.

Or cooking with steam to retain the food’s natural

nutrients, vitamins and minerals. Bertazzoni built-in

specialty ovens include convection, steam, speed

and powerful microwave technology, along with a

practical warming drawer. Engineered to integrate

perfectly into the vertical and horizontal lines of your

kitchen cabinets, they can be installed stacked or

side by side to create perfect symmetry.

30” Convection

Speed Ovens

30” Convection

Steam Ovens

30” Microwave Oven

24” Convection

Speed Oven

30” Warming Drawers

24” Microwave Drawer

19bertazzoni.com

Page 20

20 bertazzoni.com

Page 21

SPECIALTY OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

30” Convection Speed Ovens

Dimensions

PROF30SOEX

MAST30SOEX

17 1/2"

446

CONDUIT

OUTPUT

1"

26

14 1/8"

359

2 3/8"

61

29 7/8"

758

18 3/4"

475

1/16"

2

20 3/8"

517

3 3/8"

86

21 1/4"

541

CONDUIT

OUTPUT

21 3/8"

543

21bertazzoni.com

Page 22

SPECIALTY OVENS

FRONT VIEW

30” Convection Speed Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

5"

127

E

4"

102

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

22 bertazzoni.com

110lb (50kg) Electrical supply 120/240 V 60 Hz 3850 W

Service 16 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

Page 23

SPECIALTY OVENS

30” Convection Speed Ovens

Proud installation

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a

23"

585

FLUSH INSET

DEPTH

4 1/4"

107

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

18 1/4"

464

AIR INTAKE

4" x 15"

(102 x 380)

28 1/2"

724

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

23bertazzoni.com

Page 24

SPECIALTY OVENS

30” Convection Speed Ovens

Flush installation

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a

23 3/4"

603

FLUSH INSET

DEPTH

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

19 1/8"

485

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

18 1/4"

464

4 1/4"

107

30 1/2"

774

FLUSH INSET

WIDTH

28 1/2"

724

1"

25

b

1"

25

1/8"

3

1"

25

3/4"

18

b

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

24 bertazzoni.com

Page 25

SPECIALTY OVENS

30” Convection Speed Ovens

Undercounter installation

SIDE VIEW

2 1/2"

62

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

FRONT VIEW

23 3/4"

603

FLUSH INSET

DEPTH

a

30 1/2"

774

FLUSH INSET

WIDTH

4 1/4"

107

a

1"

25

FLUSH INSET

AIR INTAKE

36"

914

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

19 1/8"

485

HEIGHT

AIR INTAKE

(102 x 380)

4" x 15"

18 1/4"

464

3/4"

28 1/2"

724

1/8"

3

18

1"

25

bb

AIR INTAKE

4" x 15"

(102 x 380)

1"

25

25bertazzoni.com

Page 26

SPECIALTY OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

30” Convection Steam Ovens

Dimensions

PROF30CSEX

MAST30CSEX

17 1/2"

446

CONDUIT

OUTPUT

1"

26

14 1/8"

359

2 3/8"

61

29 7/8"

758

18 3/4"

475

1/16"

2

20 3/8"

517

3 3/8"

86

21 1/4"

541

CONDUIT

OUTPUT

21 3/8"

543

26 bertazzoni.com

Page 27

SPECIALTY OVENS

FRONT VIEW

30” Convection Steam Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

5"

127

E

4"

102

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

110lb (50kg) Electrical supply 120/240 V 60 Hz 3200 W

Service 16 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

27bertazzoni.com

Page 28

SPECIALTY OVENS

30” Convection Steam Ovens

Proud installation

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a

23"

585

FLUSH INSET

DEPTH

4 1/4"

107

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

18 1/4"

464

AIR INTAKE

4" x 15"

(102 x 380)

28 1/2"

724

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

28 bertazzoni.com

Page 29

SPECIALTY OVENS

30” Convection Steam Ovens

Flush installation

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

a

23 3/4"

603

FLUSH INSET

DEPTH

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

19 1/8"

485

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

18 1/4"

464

4 1/4"

107

30 1/2"

774

FLUSH INSET

WIDTH

28 1/2"

724

1"

25

b

1"

25

1/8"

3

1"

25

3/4"

18

b

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

29bertazzoni.com

Page 30

SPECIALTY OVENS

30” Convection Steam Ovens

Undercounter installation

SIDE VIEW

2 1/2"

62

TOP VIEW

4" x 28 1/2"

(102 x 724)

AIR INTAKE

FRONT VIEW

23 3/4"

603

FLUSH INSET

DEPTH

a

30 1/2"

774

FLUSH INSET

WIDTH

4 1/4"

107

a

1"

25

AIR INTAKE

30 bertazzoni.com

36"

914

19 1/8"

485

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

18 1/4"

464

3/4"

28 1/2"

724

1/8"

3

18

1"

25

bb

AIR INTAKE

4" x 15"

(102 x 380)

1"

25

Page 31

SPECIALTY OVENS

SIDE VIEW FRONT VIEW

TOP VIEW

30” Warming Drawers

Dimensions

PROF30WDEX

MAST30WDEX

1"

26

POWER CORD

OUTPUT

28 1/8"

713

9 7/8"

251

19 1/8"

487

21 1/2"

547

5/8"

15

9 1/8"

231

29 7/8"

758

21"

532

3 3/8"

86

31bertazzoni.com

Page 32

SPECIALTY OVENS

FRONT VIEW

30” Warming Drawer

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

4"

102

5"

127

E

E

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

32 bertazzoni.com

110lb (50kg) Electrical supply 120 V 60 Hz 550 W

Service 5 Amp

Power Connection NEMA 5-15P

Page 33

SPECIALTY OVENS

30” Warming Drawer

Flush installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

a a

23 3/4"

604

FLUSH INSET

DEPTH

1"

25

SIDE VIEW

FRONT VIEW

10 1/8"

256

b

30 1/2"

774

FLUSH INSET

WIDTH

28 1/2"

724

1"

25

1"

25

b

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

33bertazzoni.com

Page 34

SPECIALTY OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

30” Microwave Oven

Dimensions

MO30STANE with frame FR30PROX

13 1/4"

338

14 5/8"

372

1 3/8"

35

24"

609

12 1/2"

318

1"

26

18 1/8"

460

29 7/8"

760

FRAME

FR30PROX

18 3/4"

476

24"

609

17 7/8"

453

34 bertazzoni.com

Page 35

SPECIALTY OVENS

FRONT VIEW

30” Microwave Oven

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

4"

102

E

5"

127

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

110lb (50kg) Electrical supply 120 V 60 Hz 1100 W

Service 10 Amp dedicated circuit

Power Connection NEMA 5-15P plug with 59” cord

35bertazzoni.com

Page 36

SPECIALTY OVENS

30” Microwave Oven

Proud installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

23"

585

FLUSH INSET

DEPTH

SIDE VIEW

FRONT VIEW

16 7/8"

428

28 1/2"

724

36 bertazzoni.com

Page 37

SPECIALTY OVENS

30” Microwave Oven

Flush installation

TOP VIEW

4" x 4"

(102 x 102)

CUT OUT SLOT

FOR POWER CORD

23"

585

FLUSH INSET

DEPTH

1"

25

SIDE VIEW

FRONT VIEW

18 1/2"

470

FLUSH INSET

HEIGHT

16 7/8"

428

30 1/2"

776

FLUSH INSET

WIDTH

1"

3/4"

26

20

28 1/2"

724

7/8"

22

a

1"

26

a

(a) Visible Area - Match finish to outside cabinet panels

37bertazzoni.com

Page 38

SPECIALTY OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

24” Convection Speed Ovens

Dimensions

PROF24SOEX

17 1/2"

446

CONDUIT

OUTPUT

3/4"

20

13 3/4"

349

1 5/8"

41

17 7/8"

455

23 3/8"

595

20 5/8"

523

2 3/8"

61

21 1/4"

541

CONDUIT

OUTPUT

21 3/8"

543

38 bertazzoni.com

Page 39

SPECIALTY OVENS

FRONT VIEW

24” Convection Speed Ovens

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

5"

127

E

4"

102

E

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

110lb (50kg) Electrical supply 120/240 V 60 Hz 3850 W

Service 16 Amp dedicated circuit

Power Connection METAL CONDUIT – 59” cord

39bertazzoni.com

Page 40

SPECIALTY OVENS

24” Convection Speed Ovens

Proud installation

TOP VIEW

(102 x 560)

AIR INTAKE

4" x 22"

a

23"

585

DEPTH

a

SIDE VIEW

AIR INTAKE

FRONT VIEW

17 7/8"

455

AIR INTAKE

4" x 15"

(102 x 380)

22"

560

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

40 bertazzoni.com

Page 41

SPECIALTY OVENS

24” Convection Speed Ovens

Flush installation

TOP VIEW

(102 x 560)

AIR INTAKE

4" x 22"

a

23 3/4"

603

FLUSH INSET

DEPTH

a

3/4"

20

SIDE VIEW

AIR INTAKE

FRONT VIEW

18 1/2"

470

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

FLUSH INSET

1"

17 7/8"

455

25

b b

24"

610

WIDTH

22"

560

1"

25

1/8"

1/2"

12

3

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

41bertazzoni.com

Page 42

SPECIALTY OVENS

24” Convection Speed Ovens

Undercounter installation

TOP VIEW

4" x 22"

(102 x 560)

AIR INTAKE

23 3/4"

603

FLUSH INSET

DEPTH

a

a

3/4"

19

SIDE VIEW

AIR INTAKE

36"

914

FRONT VIEW

2 5/8"

68

18 1/2"

470

FLUSH INSET

HEIGHT

AIR INTAKE

4" x 15"

(102 x 380)

17 7/8"

455

24"

610

FLUSH INSET

WIDTH

1/2"

12

1"

1"

25

25

22"

560

1/8"

3

bb

AIR INTAKE

4" x 15"

(102 x 380)

(a) Spacers - Included with appliance

(b) Visible Area - Match finish to outside cabinet panels

42 bertazzoni.com

Page 43

SPECIALTY OVENS

SIDE VIEW

FRONT VIEW TOP VIEW

24” Microwave Drawer

Dimensions

MD24X

14 5/8"

370

POWERCORD

OUTPUT

1 1/8"

29

23 7/8"

606

15 7/8"

403

POWERCORD

OUTPUT

21 7/8"

555

21 5/8"

550

4 5/8"

119

4"

102

16 1/8"

410

43bertazzoni.com

Page 44

SPECIALTY OVENS

FRONT VIEW

24” Microwave Drawer

Installation requirements

INSTALLATION

The oven can be installed in a proud or flush application.

Finish the edges of the opening because they may be visible

when the door is open.

The clearance between the oven and the kitchen units

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

use only materials and finishes that will not discolor or

delaminate and will withstand temperatures up to 195°F

(90°C). Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

BE SURE that support for this appliance is perpendicular to

the front facing of the wall or cabinet before you perform the

installation.

The cabinet base must be flat and capable of

supporting the weight of the oven when in use.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable

electrical codes.

A properly-grounded horizontally- mounted electrical

receptacle should be installed.

Place the electrical supply flush with the back

wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional

cabinet depth.

4"

102

E

5"

127

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

44 bertazzoni.com

110lb (50kg) Electrical supply 120/240 V 60 Hz 1500 W

Service 15 Amp

Power Connection NEMA 5-15P plug with 47” cord

Page 45

SPECIALTY OVENS

24” Microwave Drawer

Flush installation

TOP VIEW

23 1/2"

597

FLUSH INSET

DEPTH

1 1/8"

28

SIDE VIEW

ANTI TIP

FRONT VIEW

15 7/8"

404

FLUSH INSET

HEIGHT

7/8"

23

23 7/8"

608

FLUSH INSET

WIDTH

22 1/8"

562

15 1/2"

395

1/8"

4

aa

1/4"

6

7/8"

23

(a) Visible Area - Match finish to outside cabinet panels

45bertazzoni.com

Page 46

GAS RANGETOPS & COOKTOPS

Bertazzoni rangetops and cooktops offer amazing

versatility and feature a maximized cooking surface.

Available in 24”, 30”, 36” and 48” versions, together

with a variety of versatile burner configurations,

these powerful models are the perfect pairing any

Bertazzoni built-in oven.

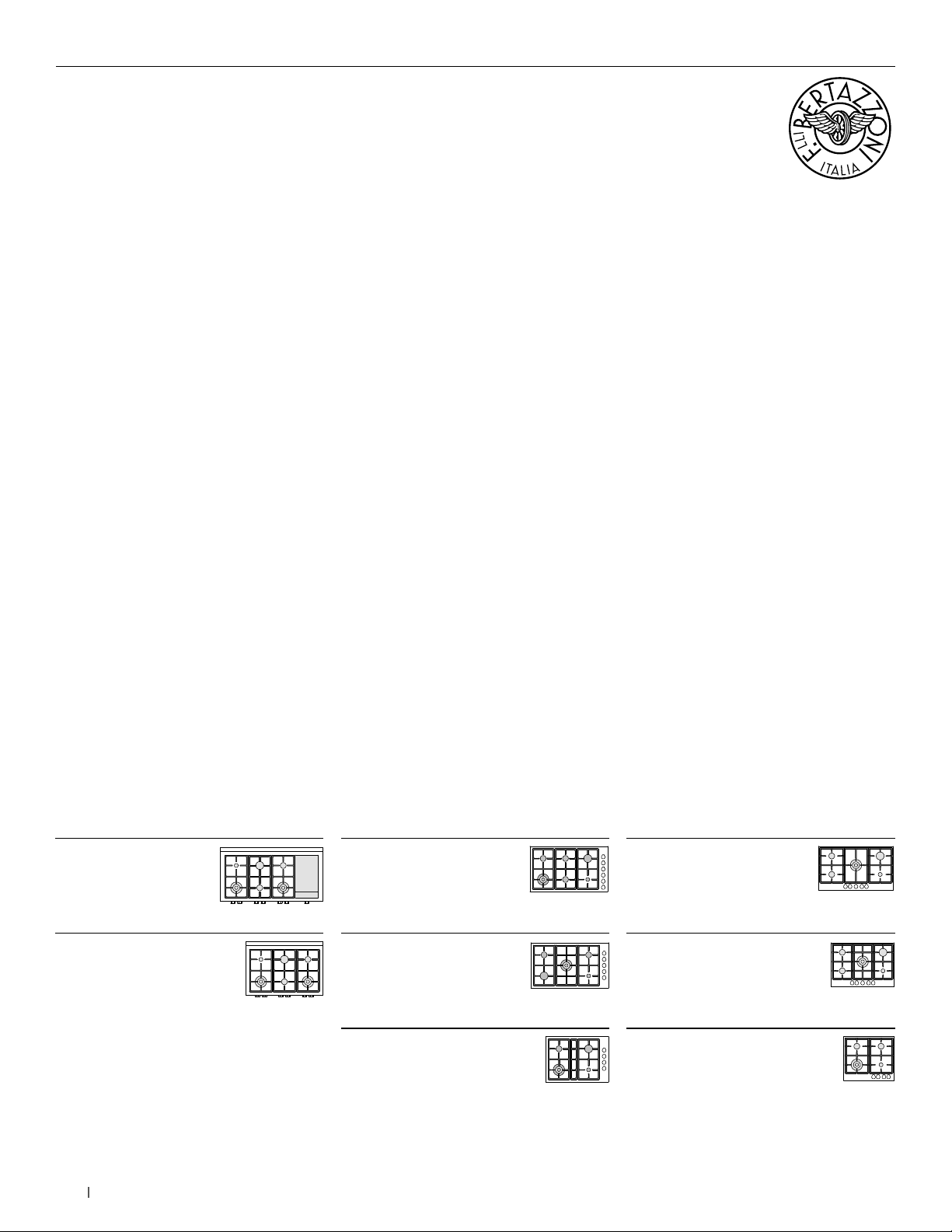

Rangetops Side control drop-in cooktops Front control built-in cooktops

48” Rangetops

36” Rangetops

46 bertazzoni.com

36” Drop-in Cooktops

6 burners

36” Drop-in Cooktops

5 burners

30” Drop-in Cooktops

4 burners

36” Cooktops

5 burners

30” Cooktops

5 burners

24” Cooktops

4 burners

Page 47

Page 48

GAS RANGETOPS & COOKTOPS

48” Rangetops

Dimensions

PROF486GRTBXT

MAST486GRTBXT

TOP VIEW

25 1/4"

641

47 7/8"

1216

FRONT VIEW

7 5/8"

194

SIDE VIEW

1"

26

6 5/8"

168

21 5/8"

550

1 5/8"

40

48 bertazzoni.com

Page 49

EG

FRONT VIEW

GAS RANGETOPS & COOKTOPS

48” Rangetops

Installation requirements

INSTALLATION

The gas rangetops can be mounted in a standard installation

sitting on top of the countertop surface.

If a drawer is placed under the appliance, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood, refer to the

hood manufacturer’s installation requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

187lb (85kg)

COUNTERTOP

10 5/8"

270

15"

381

15"

381

Electrical supply 120 V 60 Hz 1100 W

Service 10 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas rangetops can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

For detailed installation specifications consult the installation manual.

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

49bertazzoni.com

Page 50

GAS RANGETOPS & COOKTOPS

48” Rangetops

Installation

SIDE VIEW

13"

330

29 3/8"

746

36"

914

TOP VIEW

25"

635

FRONT VIEW

18"

457

AREA FOR ELECTRIC

AND GAS CONNECTION

36"

915

36"

914

48"

1218

6 5/8"

168

3 1/2"

90

6"

152

Combustible material cannot be located within shaded area.

50 bertazzoni.com

Page 51

GAS RANGETOPS & COOKTOPS

36” Rangetops

Dimensions

PROF366RTBXT

MAST366RTBXT

MAST366RTXE

TOP VIEW

25 1/4"

641

35 3/4"

909

FRONT VIEW

7 5/8"

194

SIDE VIEW

1"

26

6 5/8"

168

21 5/8"

550

1 5/8"

40

51bertazzoni.com

Page 52

EG

FRONT VIEW

GAS RANGETOPS & COOKTOPS

36” Rangetops

Installation requirements

INSTALLATION

The gas rangetops can be mounted in a standard installation

sitting on top of the countertop surface.

If a drawer is placed under the appliance, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood, refer to the

hood manufacturer’s installation requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

165lb (75kg)

COUNTERTOP

10 5/8"

270

15"

381

15"

381

Electrical supply 120 V 60 Hz 1 W

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas rangetops can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

For detailed installation specifications consult the installation manual.

52 bertazzoni.com

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

Page 53

GAS RANGETOPS & COOKTOPS

36” Rangetops

Installation

SIDE VIEW

13"

330

29 3/8"

746

36"

915

TOP VIEW

25"

635

FRONT VIEW

18"

457

AREA FOR ELECTRIC

AND GAS CONNECTION

36"

915

36"

913

36"

914

6 5/8"

168

3 1/2"

90

6"

152

Combustible material cannot be located within shaded area.

53bertazzoni.com

Page 54

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 6 burners

Dimensions

PROF366QBXT

MAST366QBXT

TOP VIEW

21 1/4"

540

36 3/8"

925

FRONT VIEW

1/8"

4

3/4"

19

3/8"

11

2 5/8"

68

SIDE VIEW

3/4"

18

3/4"

18

54 bertazzoni.com

Page 55

EG

FRONT VIEW

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 6 burners

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

4"

15"

381

102

COUNTERTOP

15"

381

Electrical supply 120 V 60 Hz 1 W

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

132lb (60kg)

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas cooktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

For detailed installation specifications consult the installation manual.

55bertazzoni.com

Page 56

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 6 burners

Installation

SIDE VIEW

13"

330

3 1/8"

80

TOP VIEW

20 1/2"

520

CUT-OUT

DEPTH

FRONT VIEW

18"

457

36"

915

35 5/8"

905

CUT-OUT

WIDTH

36 3/8"

925

35 5/8"

905

1 3/4"

45

1 3/4"

45

6"

152

36"

914

Combustible material cannot be installed within shaded area.

56 bertazzoni.com

Page 57

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 5 burners

Dimensions

PROF365QBXT

PROF365QXE

MAST365QBXT

MAST365QXE

21 1/4"

540

36 3/8"

925

FRONT VIEW

1/8"

4

3/4"

19

3/8"

11

2 5/8"

68

SIDE VIEW

3/4"

18

3/4"

18

57bertazzoni.com

Page 58

EG

FRONT VIEW

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 5 burners

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

4"

15"

381

102

COUNTERTOP

15"

381

Electrical supply 120 V 60 Hz 1 W

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

125lb (57kg)

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas cooktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

For detailed installation specifications consult the installation manual.

58 bertazzoni.com

Page 59

GAS RANGETOPS & COOKTOPS

36” Drop-in Cooktops 5 burners

Installation

SIDE VIEW

13"

330

3 1/8"

80

TOP VIEW

20 1/2"

520

CUT-OUT

DEPTH

FRONT VIEW

18"

457

36"

915

35 5/8"

905

CUT-OUT

WIDTH

36 3/8"

925

35 5/8"

905

1 3/4"

45

1 3/4"

45

6"

152

36"

914

Combustible material cannot be installed within shaded area.

59bertazzoni.com

Page 60

GAS RANGETOPS & COOKTOPS

30” Drop-in Cooktops

Dimensions

PROF304QBXT

PROF304QXE

MAST304QBXT

MAST304QXE

21 1/4"

540

29 1/2"

748

FRONT VIEW

1/8"

SIDE VIEW

2 5/8"

3/8"

11

68

3/4"

18

3/4"

18

4

1/2"

12

60 bertazzoni.com

Page 61

EG

FRONT VIEW

GAS RANGETOPS & COOKTOPS

30” Drop-in Cooktops

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

4"

10"

254

102

COUNTERTOP

10"

254

Electrical supply 120 V 60 Hz 1 W

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

110lb (50kg)

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas coopktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

For detailed installation specifications consult the installation manual.

61bertazzoni.com

Page 62

GAS RANGETOPS & COOKTOPS

30” Drop-in Cooktops

Installation

SIDE VIEW

13"

330

3 1/8"

80

TOP VIEW

20 1/2"

CUT-OUT

DEPTH

FRONT VIEW

18"

457

520

CUT-OUT

36"

915

28 7/8"

735

WIDTH

30"

762

1 3/4"

45

1 3/4"

45

6"

152

36"

914

Combustible material cannot be installed within shaded area.

62 bertazzoni.com

Page 63

GAS RANGETOPS & COOKTOPS

TO

36” Gas Cooktop Front Control

Dimensions

PROF365CTXV

P VIEW

20 1/2"

522

35"

890

FRONT VIEW

3/8"

8

1"

24

SIDE VIEW

1"

24

2"

50

1 1/2"

38

3/8"

10

63bertazzoni.com

Page 64

4"

FRONT VIEW

GAS RANGETOPS & COOKTOPS

36” Gas Cooktop Front Control

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

88lb (40kg)

102

COUNTERTOP

EG

10"

254

Electrical supply 120 V 60 Hz 1 W

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas cooktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

10"

254

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

For detailed installation specifications consult the installation manual.

64 bertazzoni.com

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

Page 65

GAS RANGETOPS & COOKTOPS

36” Gas Cooktop Front Control

Installation

TOP VIEW

3 3/8"

85

SIDE VIEW

13"

330

2 1/2"

62

18 7/8"

480

CUT-OUT

DEPTH

FRONT VIEW

18"

457

36"

915

33 1/2"

850

CUT-OUT

WIDTH

36 3/8"

925

6"

152

36"

914

Combustible material cannot be installed within shaded area.

65bertazzoni.com

Page 66

GAS RANGETOPS & COOKTOPS

30” Gas Cooktop Front Control

Dimensions

PROF305CTXV

TOP VIEW

20 1/2"

522

29 5/8"

752

FRONT VIEW

3/8"

8

3 7/8"

99

3 7/8"

99

2"

50

SIDE VIEW

1 1/2"

38

3/8"

10

66 bertazzoni.com

Page 67

4"

FRONT VIEW

GAS RANGETOPS & COOKTOPS

30” Gas Cooktop Front Control

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

81lb (37kg)

102

COUNTERTOP

EG

10"

254

Electrical supply 120 V 60 Hz 1 W

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas cooktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

10"

254

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

For detailed installation specifications consult the installation manual.

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

67bertazzoni.com

Page 68

GAS RANGETOPS & COOKTOPS

30” Gas Cooktop Front Control

Installation

SIDE VIEW

13"

330

2 1/2"

62

TOP VIEW

CUT-OUT

FRONT VIEW

18"

457

18 7/8"

480

DEPTH

36"

915

22"

560

CUT-OUT

WIDTH

30"

762

3 3/8"

85

6"

152

36"

914

Combustible material cannot be installed within shaded area.

68 bertazzoni.com

Page 69

GAS RANGETOPS & COOKTOPS

24” Gas Cooktop Front Control

Dimensions

PROF244CTXV

TOP VIEW

20 1/2"

522

23 3/4"

602

FRONT VIEW

3/8"

1"

24

SIDE VIEW

8

1"

24

2"

50

1 1/2"

38

3/8"

10

69bertazzoni.com

Page 70

4"

FRONT VIEW

GAS RANGETOPS & COOKTOPS

24” Gas Cooktop Front Control

Installation requirements

INSTALLATION

The gas cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the work, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For installation with an updraft or downdraft hood as well as

any OTR, refer to the hood/OTR manufacturer’s installation

requirements.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C). Installation of the appliance must be performed

in accordance with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation. The cabinet base must be flat and

capable of supporting the weight of the oven when in use.

Minimum Suggested Load on

Cabinet Base Board

84lb (38kg)

102

COUNTERTOP

EG

10"

254

Electrical supply 120 V 60 Hz 1 W

Service 1 Amp

Power Connection NEMA 5-15P plug with 59” cord

GAS CONNECTION

The gas cooktop can be used with Natural or LP/Propane

gas. An agency-approved, properly-sized manual shutoff

valve should be installed. To connect gas between shut-off

valve and regulator, use agency-approved, properly sized

flexible or rigid pipe. Check all local code requirements.

10"

254

ELECTRICAL REQUIREMENT

The installation must comply with all applicable electrical codes.

A properly-grounded horizontally- mounted electrical receptacle

should be installed. Place the electrical supply flush with the

back wall and within the shaded area shown in the illustrations.

Placement within the opening may require additional cabinet

depth.

For detailed installation specifications consult the installation manual.

70 bertazzoni.com

Gas Inlet 1/2” NPT

Natural Gas 4” iwc (1.00 kPa)

LPG Gas 10” iwc (2.50 kPa)

Since service pressure may fluctuate with local demand, every

gas cooktop must be equipped with the supplied pressure

regulator on the incoming service line for safe and efficient

operation.

Page 71

GAS RANGETOPS & COOKTOPS

24” Gas Cooktop Front Control

Installation

SIDE VIEW

13"

330

2 1/2"

62

TOP VIEW

FRONT VIEW

18"

457

18 7/8"

480

CUT-OUT

DEPTH

CUT-OUT

36"

915

22"

560

WIDTH

24"

610

3 3/8"

85

152

6"

36"

914

Combustible material cannot be installed within shaded area.

71bertazzoni.com

Page 72

INDUCTION & ELECTRIC COOKTOPS

Electric induction and electric CERAN® cooktops

add an elegant and clean look to your kitchen, with

the added advantage of faster induction heating.

On the induction models, precision touch controls

and digital timed cooking functions let you

automatically manage the entire cooking process;

sensor controlled cookware detection means all the

energy is used to heat the exact space instantly from

the moment you turn them on. They make preparing

a wide variety of dishes effortless, with 5 or

4 zones for cooking. And when you’ve finished

cooking, cleaning up is equally straightforward.

Induction CERAN

36” Induction Cooktop

30” Induction Cooktop

30” Electric Ceramic

Cooktop

24” Electric Ceramic

Cooktop

®

72 bertazzoni.com

Page 73

Page 74

INDUCTION & ELECTRIC COOKTOPS

36” Induction Cooktop

Dimensions

P365IAE

TOP VIEW

20 1/2"

520

34 5/8"

880

FRONT VIEW

1/2"

13

1 5/8"

40

2 1/4"

1 5/8"

40

58

SIDE VIEW

2 3/8"

62

1/8"

4

3/4"

20

3/4"

20

74 bertazzoni.com

Page 75

FRONT VIEW

INDUCTION & ELECTRIC COOKTOPS

36” Induction Cooktop

Installation requirement

INSTALLATION

The induction cooktop can be mounted in a standard

installation sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture or

other installed appliances must be enough to ensure sufficient

cooling air ventilation. For installation with an updraft or

downdraft hood as well as any OTR, refer to thr hood/OTR

manufacturer’s installation requirements.If a drawer is placed

under the worktop, avoid to put into this drawer flammable

objects or not heat-resistant objects.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C).

Installation of the appliance must be performed in accordance

with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

A properly-grounded horizontally- mounted electrical receptacle

should be installed.

The installation must comply with all applicable electrical codes.

Place the electrical supply flush with the back wall and within

the shaded area shown in the illustrations. Placement within the

opening may require additional cabinet depth.

5"

COUNTERTOP

127

E

15"

381

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Electrical supply 208/240 V 60 Hz 11100 W

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

110 lb (50kg)

Service 55 Amp dedicated circuit

Power Connection METAL CONDUIT - 54” cord

75bertazzoni.com

Page 76

INDUCTION & ELECTRIC COOKTOPS

36” Induction Cooktop

Installation

SIDE VIEW

13"

330

3 1/8"

80

TOP VIEW

19 1/4"

490

CUT-OUT

DEPTH

FRONT VIEW

18"

457

31 7/8"

810

CUT-OUT

WIDTH

36 3/8"

925

30"

763

2"

51

6"

152

36"

914

Combustible material cannot be installed within shaded area.

76 bertazzoni.com

Page 77

INDUCTION & ELECTRIC COOKTOPS

30” Induction Cooktop

Dimensions

P304IAE

TOP VIEW

20 1/2"

520

30 3/4"

780

FRONT VIEW

1/2"

12

3/4"

20

2 1/8"

54

3/4"

20

SIDE VIEW

2 1/4"

58

3/16"

4

3/4"

20

3/4"

20

77bertazzoni.com

Page 78

INDUCTION & ELECTRIC COOKTOPS

FRONT VIEW

30” Induction Cooktop

Installation requirements

INSTALLATION

The induction cooktop can be mounted in a standard

installation sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture or

other installed appliances must be enough to ensure sufficient

cooling air ventilation. For installation with an updraft or

downdraft hood as well as any OTR, refer to thr hood/OTR

manufacturer’s installation requirements.If a drawer is placed

under the worktop, avoid to put into this drawer flammable

objects or not heat-resistant objects.

For instructions and clearance of product combinations

please see the Multiple Installation Sections (page 86).

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C).

Installation of the appliance must be performed in accordance

with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

A properly-grounded horizontally- mounted electrical receptacle

should be installed.

The installation must comply with all applicable electrical codes.

Place the electrical supply flush with the back wall and within

the shaded area shown in the illustrations. Placement within the

opening may require additional cabinet depth.

5"

COUNTERTOP

127

E

15"

381

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Electrical supply 208/240 V 60 Hz 7400 W

Minimum Suggested Load on

Cabinet Base Board

78 bertazzoni.com

88lb (40kg)

Service 40 Amp dedicated circuit

Power Connection METAL CONDUIT - 54” cord

Page 79

INDUCTION & ELECTRIC COOKTOPS

30” Induction Cooktop

Installation

SIDE VIEW

13"

330

3 1/8"

80

TOP VIEW

19 1/4"

490

CUT-OUT

DEPTH

FRONT VIEW

18"

457

29 1/2"

750

CUT-OUT

WIDTH

30"

762

30"

763

2"

51

6"

152

36"

914

Combustible material cannot be installed within shaded area.

79bertazzoni.com

Page 80

INDUCTION & ELECTRIC COOKTOPS

30” Electric Ceramic Cooktop

Dimensions

PE304CER

TOP VIEW

20 1/2"

520

30"

762

FRONT VIEW

1 3/4"

45

1/2"

14

14"

355

1/2"

14

SIDE VIEW

1/8"

4

3 1/8"

80

3/4"

20

3/4"

20

80 bertazzoni.com

Page 81

FRONT VIEW

INDUCTION & ELECTRIC COOKTOPS

30” Electric Ceramic Cooktop

Installation requirements

INSTALLATION

The electric cooktop can be mounted in a standard installation

sitting on top of the countertop surface.

The clearance between the hob and the kitchen furniture

or other installed appliances must be enough to ensure

sufficient cooling air ventilation.

If a drawer is placed under the worktop, avoid to put into this

drawer flammable objects or not heat-resistant objects.

For instructions and clearance of product combinations

please see the Multiple Installation Sections.

CABINET REQUIREMENT

To prevent possible damage to cabinets and cabinet finishes,

the countertop must be able to withstand temperatures up to

300°F (149°C).

Installation of the appliance must be performed in accordance

with the provisions of applicable legislation.

BE SURE that support for this appliance is horizontale before

you perform the installation.

The cabinet base must be flat and capable of supporting the

weight of the oven when in use.

ELECTRICAL REQUIREMENT

A properly-grounded horizontally- mounted electrical receptacle

should be installed.

The installation must comply with all applicable electrical codes.

Place the electrical supply flush with the back wall and within

the shaded area shown in the illustrations. Placement within the

opening may require additional cabinet depth.

5"

COUNTERTOP

127

E

15"

381

A separate circuit and a circuit breaker servicing only this

appliance is reccomended

Minimum Suggested Load on

Cabinet Base Board

For detailed installation specifications consult the installation manual.

88lb (40kg))

Electrical supply

Service 35 Amp dedicated circuit

Power Connection METAL CONDUIT - 54” cord

240 V

208 V 31 A