Bertazzoni MAST244GASXB, MAST244GASNEE, MAST244GASBIE, MAST244GASXELP, MAST244GASXE Installation Guide

...Page 1

BERTAZZONI

INSTALLATION MANUAL

FREESTANDING FULL GAS RANGES

3100427

WWW.BERTAZZONI.COM

Page 2

/ Table of contents

TABLE OF CONTENTS

WARNINGS ___________________________________________________________________

DATA RATING LABEL ___________________________________________________________

BEFORE INSTALLATION ________________________________________________________

VENTILATION PREPARATION ____________________________________________________

SPECIFICATIONS ______________________________________________________________

CLEARENCE DIMENSIONS ______________________________________________________

INSTALLATION REQUIREMENTS _________________________________________________

Electrical ___________________________________________________________________

Gas ________________________________________________________________________

ELECTRICAL CONNECTION _____________________________________________________

WIRING DIAGRAM _____________________________________________________________

GAS CONNECTION _____________________________________________________________

Manual shut-off valve _________________________________________________________

Flexible connections __________________________________________________________

Pressure test-point stopper valve _______________________________________________

Pressure regulator ____________________________________________________________

INSTALLATION ________________________________________________________________

Unpackaging the range ________________________________________________________

Removing the oven door _______________________________________________________

Installing the legs _____________________________________________________________

Installing the worktop frontguard ________________________________________________

Installing the island trim _______________________________________________________

Installing backguard (optional) __________________________________________________

INSTALLING THE ANTI-TIP DEVICES ______________________________________________

Anti-tip brackets ______________________________________________________________

Anti-tilt chain ________________________________________________________________

GAS CONVERSION _____________________________________________________________

INSTALLATION CHECKLIST ______________________________________________________

FINAL PREPARATION ___________________________________________________________

BERTAZZONI SERVICE _________________________________________________________

4

6

6

7

7

9

10

10

10

10

11

12

12

12

12

13

14

14

14

15

15

16

16

17

17

17

18

22

22

23

2

Page 3

/ Models

Models

MAST244GASXB

MAST244GASNEE

MAST244GASBIE

MAST244GASXELP

MAST244GASXE

PROF244GASXELP

PROF244GASXE

Models

PROF244GASXELP

PROF244GASXE

3

Page 4

/ Warnings

WARNINGS

To ensure proper and safe operation, the appliance must be properly installed and grounded by a

qualifi ed technician. DO NOT attempt to adjust,

repair, service, or replace any part of your appliance unless it is specifi cally recommended in

this manual. All other servicing should be referred

to a qualifi ed servicer. Have the installer show you

the location of the gas shutoff valve and how to

shut it off in an emergency. A certifi ed technician

is required for any adjustments or conversions to

Natural or LP gas.

FOR THE INSTALLER: Before installing the Bertazzoni appliance, please read these instructions

carefully. This appliance shall be installed in accordance with the manufacturer’s installation instructions.

IMPORTANT:

owner, who should save them for local inspector’s

use and for future reference. DO NOT remove

permanently affi xed labels, warnings, or plates

from product. This may void the warranty.

Installation must conform with all local codes. In

the absence of codes:

Leave these instructions with the

• United States: installation must conform with

the National Fuel Gas Code ANSI Z223.1

INFPA54

• Massachusetts: All gas products must be

installed by a “Massachusetts” licensed plumber or gasfi tter. A “T” type handle manual valve

must be installed in the gas supply line to the

appliance.

• Canada: Installation must be in accordance

with the current CAN/CGA B149.1 & 2 Gas

Installation codes and/or local codes. Electrical installation must be in accordance with the

current CSA C22.1 Canadian Electrical Codes

Part 1 and/or local codes.

This range is NOT designed for installation in

manufactured (mobile) homes or recreational

park trailers.

DO NOT install this range outdoors.

WARNING!

If the information in these instructions is

not followed exactly, a fi re or explosion may

result causing property damage, personal

injury or death.

- Do not store or use gasoline or other fl ammable

vapors and liquid in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electrical switch.

•Do not use any phone in your building.

•Immediately call your gas supplier from a

neghbor’s phone. Follow the gas supplier’s

instructions.

•If you cannot reach your gas suppliers, call

the fi re department.

- Installation and service must be performed by

a qualifi ed installer, service agency or the gas

supplier

DANGER!!! ELECTRIC SHOCK HAZARD!!!

To avoid risk of electrical shock, personal injury

or death, verify that the appliance has been properly grounded in accordance with local codes or

in absence of codes, with the National Electrical

Code (NEC). ANSI/NFPA 70- latest edition.

DANGER!!! GAS LEAK HAZARD!!!

To avoid risk of personal injury or death, leak-testing of the appliance must be conducted according to the manufacturer’s instructions. Before

placing appliance in operation, always check for

gas leaks with water and soap solution.

DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS.

This appliance must be properly grounded.

Grounding reduces the risk of electric shock by

providing a safe pathway for electric current in the

event of a short circuit.

Warning!

To avoid risk of property damage, personal

injury or death; follow information in this manual exactly to prevent a fi re or explosion.

4

Warning - tipping hazard

A child or adult can tip over the range and be killed.

Install the anti-tip device to the structure and/or

the range. Verify the anti-tip device has been properly installed and engaged.

Page 5

Engage the range to the anti-tip device by anti-tip

brackets or anti-tip chain (see installing the anti-tip device chapter). Ensure the anti-tip device is

re-engaged when the range is moved.

Re-engage the anti-tip device if the range is moved. Do not operate the range without te anti-tipdevice in place and engaged.

See anti-tip device installation instructions for

details.

Failure to do so can result in death or serious

burns to children or adults.

DO NOT lift the range by the oven door’s handle,

as this may damage the door hinges and cause

the door to fi t incorrectly.

DO NOT lift the appliance by the range’s control

panel.

The unit is heavy and should be handled accordingly. Proper safety equipment such as gloves

and adequate manpower of at least two people

must be used in moving the range to avoid injury

and to avoid damage to the unit or the fl oor.

Rings, watches, and any other loose items that

may damage the unit or otherwise might become

entangled with the unit should be removed.

Hidden surfaces may have sharp edges. Use caution when reaching behind or under appliance.

DO NOT use a hand truck or appliance dolly on

the back or front of the unit. Handle from the side

only.

/ Warnings

WARNING:

Cancer and Reproductiv Harm www.P65Warnings.ca.gov

.

5

Page 6

/ Data rating label / Before installation

DATA RATING LABEL

The data rating label shows the model and serial

number of the range. It is located under the con-

trol panel and in the last page of this manual.

BEFORE INSTALLATION

• This appliance shall only be installed by an au-

thorized professional.

• This appliance shall be installed in accordance

with the manufacturer’s installation instructions.

• This appliance must be installed in accordance

with the norms & standards of the country where it will be installed.

• The installation of this appliance must conform

to local codes and ordinances. In the absence

of local codes, Installations must conforms to

American National Standards, National Fuel

Gas Code ANSI Z223.1 – latest edition/NFPA

54 or B149.1.

• The appliance, when installed, must be electri-

cally grounded in accordance with local codes

or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

If local codes permit, a fl exible metal appliance

connection conduit with the new AGA or CGA certifi ed design, max. 5 feet (1,5 m) long, ½” I.D. is

recommended for connecting this appliance to the

gas supply line. Do not bend or damage the fl exible connector when moving the appliance.

This appliance must be used with the pressure

regulator provided.

The regulator shall be properly installed in order to

be accessible when the appliance is installed in its

fi nal location. The pressure regulator must be set

for the type of gas to be used. The pressure regulator has ½” female pipe thread. The appropriate

fi tting must be determined based on the size of

your gas supply line, the fl exible metal connector

and the shutoff valve.

The appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 PSI (13,8” w.c. or 3,5 kPa).

A manual valve shall be installed in an accessible

location in the gas line external to the appliance

for the purpose of turning on or shutting off gas to

the appliance.

Type of gas

This range can be used with Natural or LP/Propane gas. The range is shipped from the factory

for use with the gas indicated on the rating label

positioned on the lower face of the control panel

and in the last page of this manual. A step by step

conversion procedure is also included in this manual and in each conversion kit.

Gas pressure

The maximum inlet gas supply pressure incoming to the gas appliance pressure regulator is

1/2 PSI (13,8’’ iwc or 3,5 kPa). The minimum gas

supply pressure for checking the regulator setting

shall be at least 1“ iwc (249 Pa) above the inlet

specifi ed manifold pressure to the appliance; this

operating pressure is 4” iwc (1.00 kPa) for Natural

Gas and 10” iwc (2.50 kPa) for LP Gas.

Room ventilation

An exhaust fan may be used with the appliance;

in each case it shall be installed in conformity

with the appropriate national and local standards.

Exhaust hood operation may aff ect other vented

appliances; in each case it shall be installed in

conformity with the appropriate national and local

standards.

Warning

This appliance should not be installed with a

ventilation system that directs air in a downward

direction toward the range. This type of ventilation system may cause ignition and combustion

problems with the appliance resulting in personal

injury, property damage, or unintended operation.

Ventilating systems that direct the air upwards do

not have any restriction.

Do not use aerosol sprays in the vicinity of

this appliance while it is in operation.

All opening and holes in the wall and fl oor, back

and under the appliance shall be sealed before

installation of the appliance.

6

Page 7

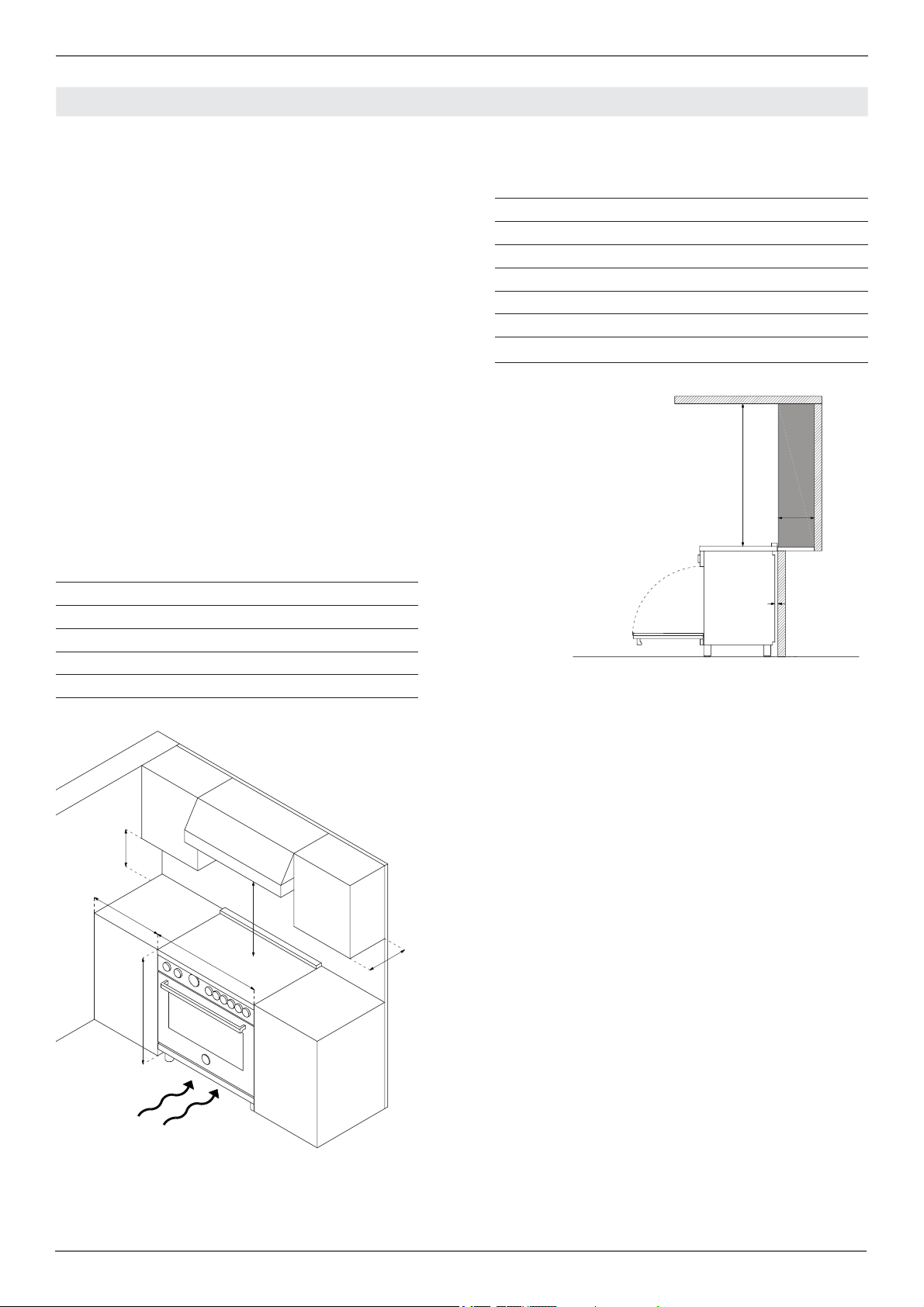

VENTILATION PREPARATION

m

m

/ Ventilation preparation / Specifi cations

This range will best perform when installed with

Bertazzoni exhaust hoods. These hoods have

been designed to work in conjunction with the

Bertazzoni range and have the same fi nish for a

perfect look.

Before installation of the exhaust hood, consult local or regional building and installation codes for

additional specifi c clearance requirements.

Refer to the range hood installation instructions

provided by the manufacturer for additional information.

Select Hood and Blower Models:

• For wall installations, the hood should be equal

or larger width than the range. Where space

permits, a hood larger than the range may be

desirable for improved ventilation performance.

• For island installations, the hood width should

overhang the range by a minimum of 3” (76

mm) on each side.

Hood Placement:

• For best removal of smoke and odors, the

lower edge of the hood should be installed

between 25 1/2” (65 cm) and 31 1/2” (80 cm)

above the range cooking surface.

• If the hood contains any combustible materials

(i.e. a wood covering), it must be installed at a

minimum of 36” (914 mm) above the cooking

surface.

Consider Make-Up Air:

Due to the high volume of ventilation air, a source of outside replacement air is recommended.

This is particularly important for tightly sealed

and insulated homes. A qualifi ed heating and

ventilating contractor should be consulted.

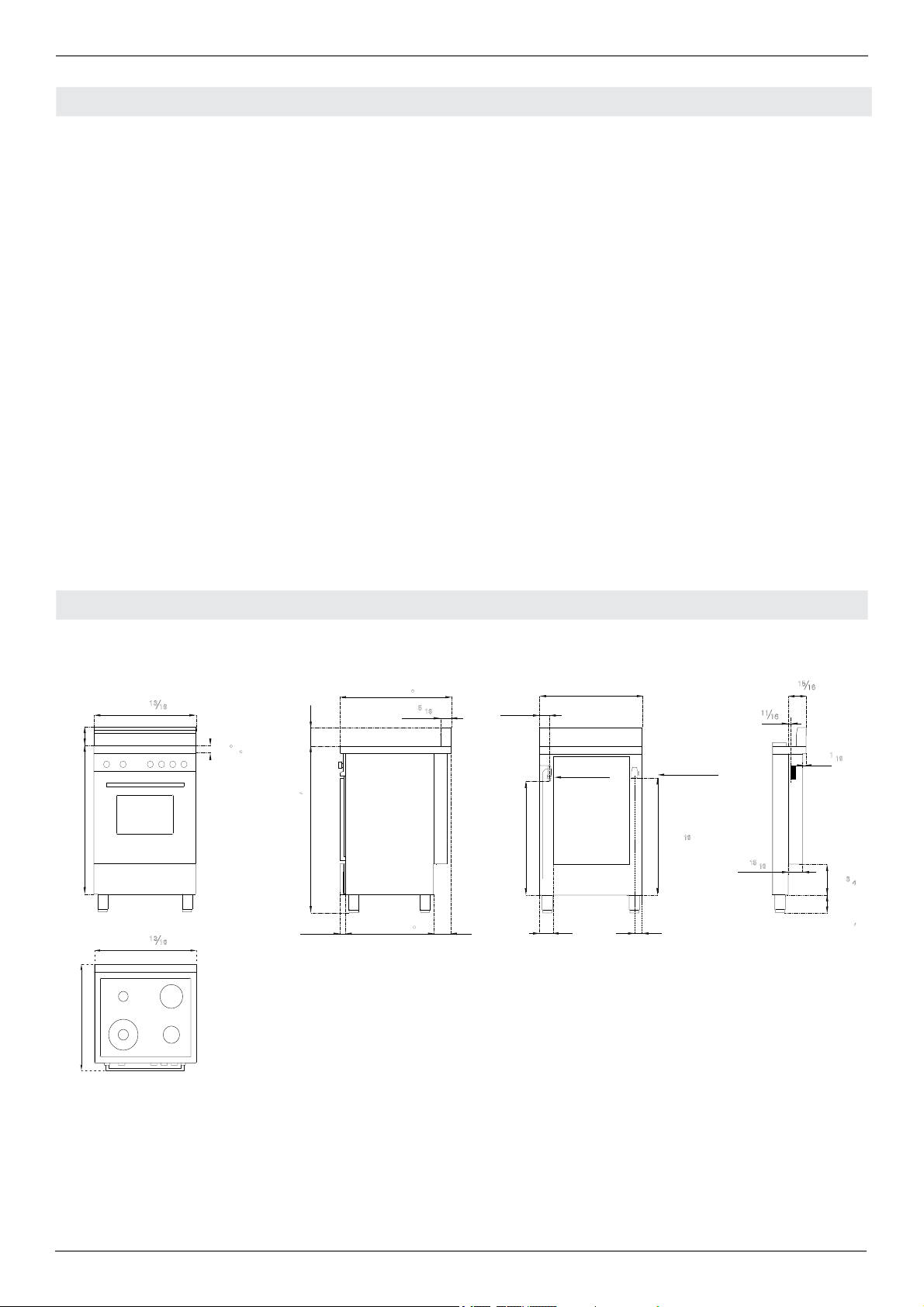

SPECIFICATIONS

13

23"

⁄

16

1"

32"

3

23" 13⁄

16

8

⁄

27"

1"

13

⁄

16

25 " 3⁄

16

5

1" ⁄

16

9

⁄

16

1"

max

4

⁄

1

37"

min -

2

⁄

1

35"

1" 5⁄

15

⁄

16

19 "

16

4"

23"

1" ⁄

9

3

10

⁄

23"

4

GAS

3"

ELECTRIC

24"

3

2" ⁄

7

⁄

6

1

15

1" ⁄

8

15

⁄

16

2"

11

⁄

16

"

1

2" ⁄

16

16

1" ⁄

3" 1⁄

5" 1⁄

3

4

2

4

7

Page 8

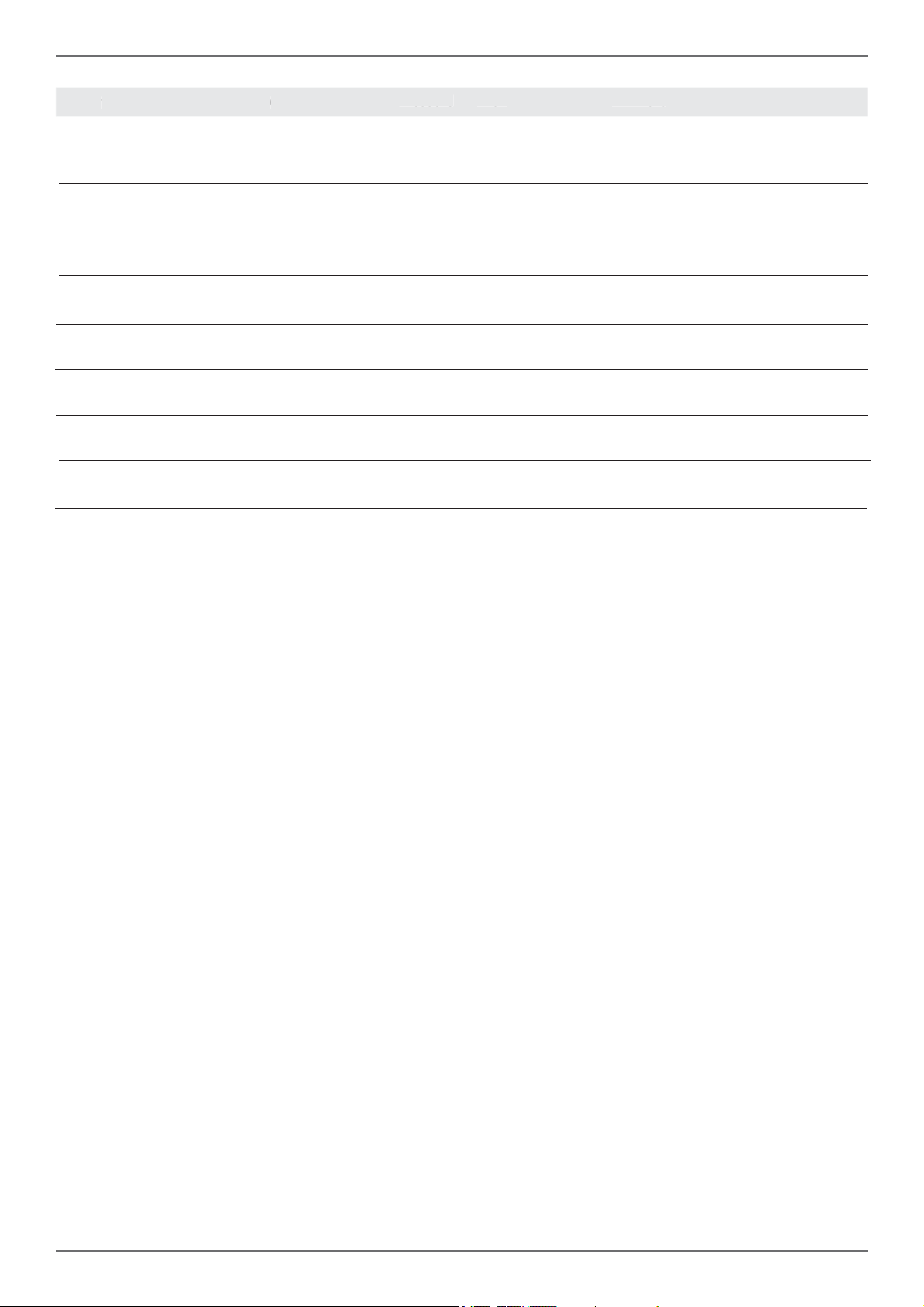

/ Specifi cations

s

Burner

urner Injector

Injector

diam.[mm]

Auxiliary

0.90

0.54

Semi-rapid

1.18

0.70

Rapid

1.55

0.92

Wok burner

1.80

1.02

Dual burner

0.80+2.10

0.50+1.20

Oven

1.70

1.02

Broiler

1.35

0.90

Gas

as

Type

NG

LP (Propane)

NG

LP (Propane)

NG

LP (Propane)

NG

LP (Propane)

NG

LP (Propane)

NG

LP (Propane)

NG

LP (Propane)

Pressure

Pressure Max Min Rate

Max

Min Rate

Rate

[iwc]

[W]

[Btu/hr]

[Btu/hr]

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

3,500

3,300

5,900

5,500

10,400

9,500

13,600

13,600

19,000

19,000

12,000

12,000

8,500

8,500

1,025

967

1,729

1,611

3,047

2,783

4,000

4,000

5,567

5,567

3,516

3,516

2,491

2,491

900

900

1,500

1,500

2,500

2,500

5,200

5,200

1,300

1,300

2,800

2,800

only max

only max

[W]

264

264

439

439

732

732

1,520

1,520

381

381

820

820

only max

only max

By-pass

-pas

diam.[mm]

Regulated

0.29

Regulated

0.36

Regulated

0.47

Regulated

0.65

Regulated

0.34/0.65

Regulated

0.48

No by-pass

No by-pass

See use and care manual for the layout of the surface burners of your range

8

Page 9

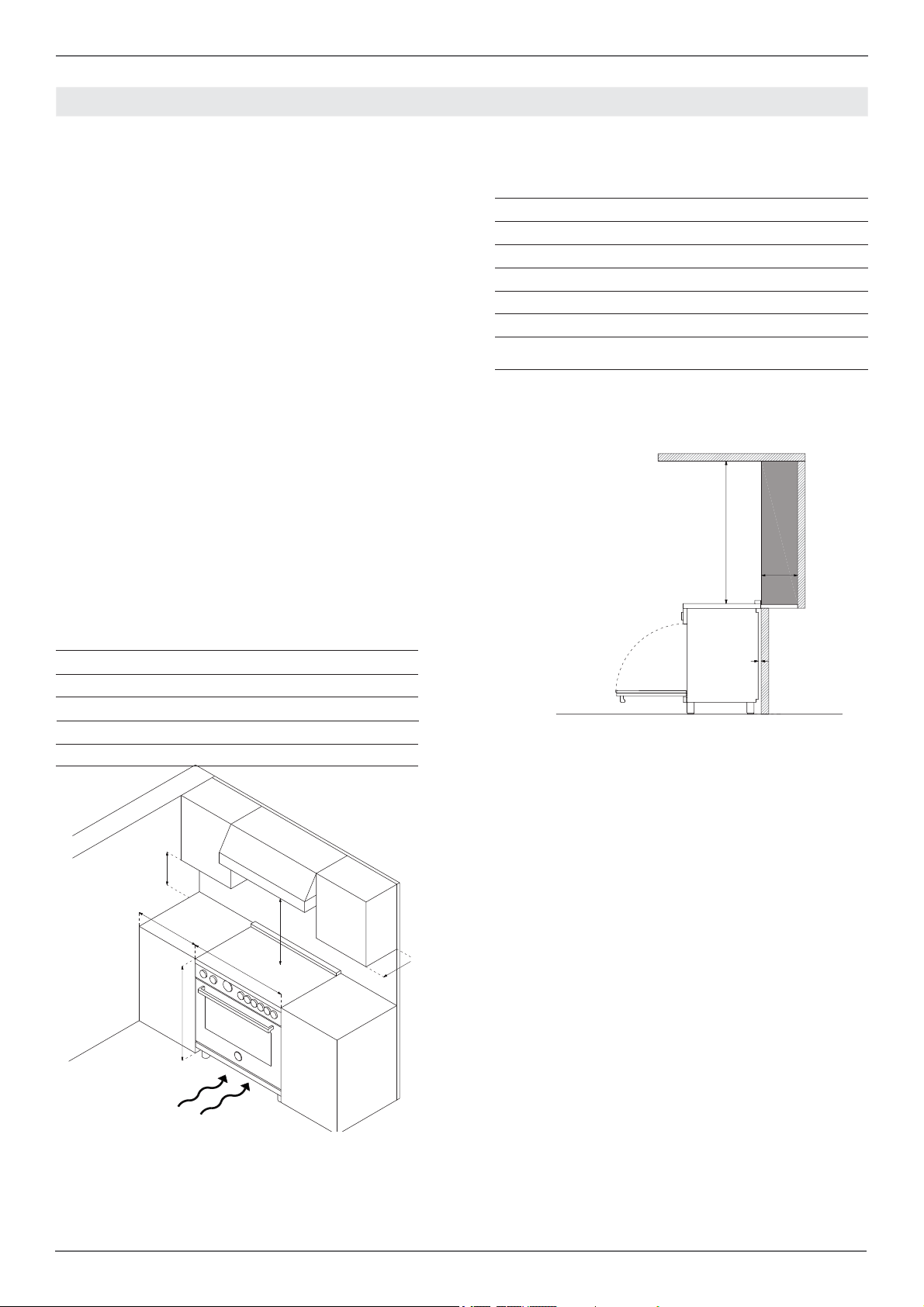

CLEARENCES DIMENSIONS

/ Clearence dimensions

Installation adjacent to kitchen cabinets

This range may be installed directly adjacent to

existing countertop high cabinets (36” or 91.5 cm

from the fl oor).

For the best look, the worktop should be level with

the cabinet countertop. This can be accomplished

by raising the unit using the adjustment spindles

on the legs.

ATTENTION: the range CANNOT be installed directly adjacent to kitchen walls, tall cabinets, tall

appliances, or other vertical surfaces above 36”

(91.4 cm) high. The minimum side clearance in

such cases is 6” (15.2 cm).

Wall cabinets with minimum side clearance must

be installed 18” (45.7 cm) above the countertop

with countertop height between 35 ½” (90.2 cm)

and 37 ¼” (94.6 cm). The maximum depth of wall

cabinets above the range shall be 13” (33.0 cm).

Cabinet

24’’ (60,4 cm)

A

36’’ (91,5 cm) hood with combustible materials

B

13’’ (33,0 cm)

C

18’’ (45,7 cm)

D

35’’ 1/2(90,2 cm) / 37”

E

F

6’ (15,2 cm)

G

12”(30,50 cm)

1/4

(94,6 cm)

Metal hood

A

24’’ (60,4 cm)

B

25 1/2’’(65 cm) and 31 1/2’’ (80 cm)

C

13’’ (33,0 cm)

D

18’’ (45,7 cm)

E

35’’ 1/2(90,2 cm) / 37”

F

6’ (15,2 cm)

G

12”(30,50 cm)

H

1” 9/16(4 cm)

Shaded area behind range indicates minimum

clearance to combustible surfaces, combustible

materials cannot be located within this area.

12” (305 mm) min. to combustible surface with

Flush Island Trim

1/4

(94,6 cm)

B

G

H

D

F

B

A

C

E

/

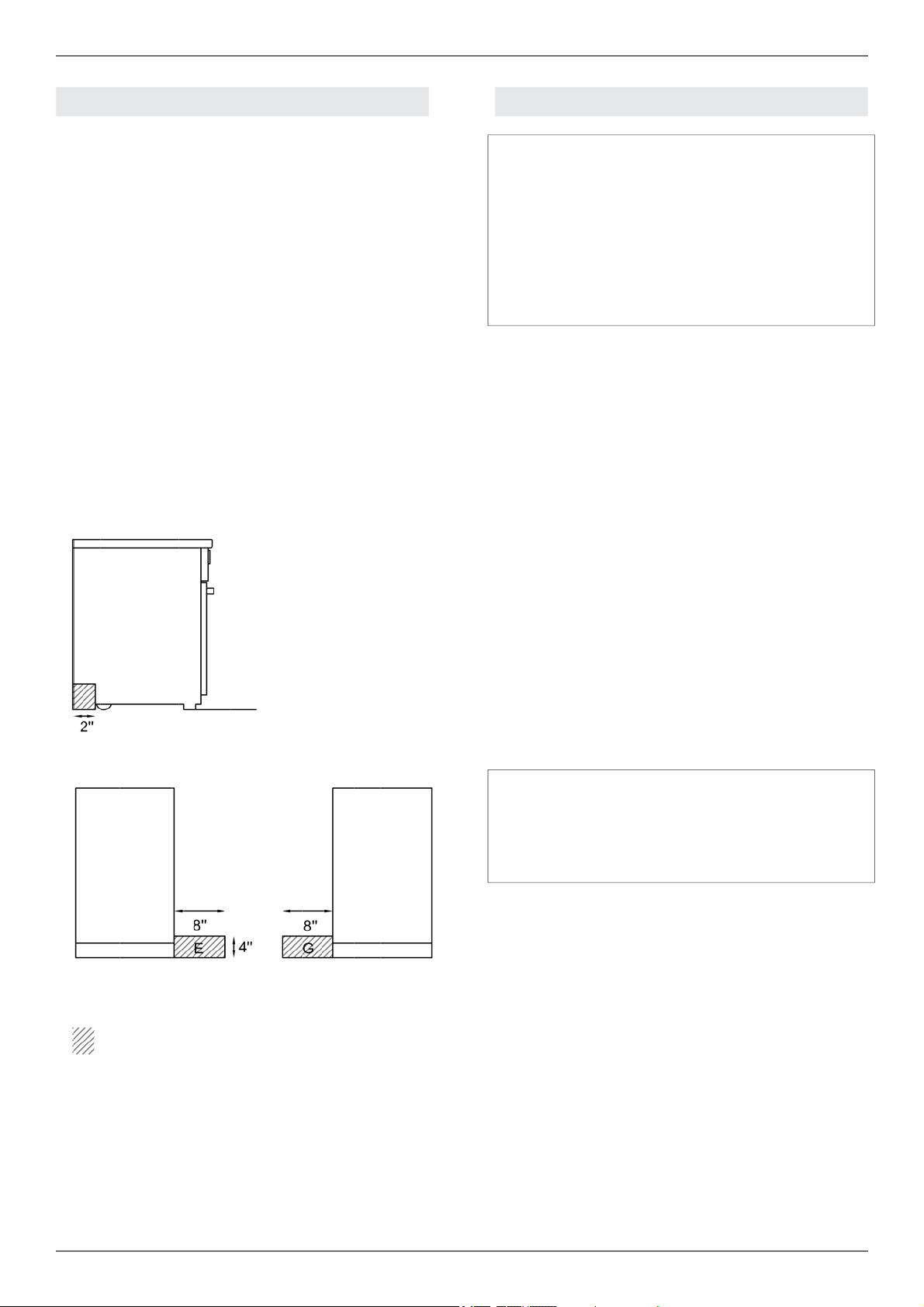

If installing toekick, verify that the sum of the cutout areas equal the recommended ventilation (L)

24” area 29 sq. inches ( 18765 mm2)

For Flush Island installations, counter surface

should have a cantilever edge meeting the back

section of the Flush Island Trim accessory.

As defi ned in the “National Fuel Gas Code” (ANSI

Z223.1, Current Edition).

Clearances from non-combustible materials are

not part of the ANSI Z21.1

scope and are not certifi ed by CSA. Clearances of

less than 12” (305 mm)

must be approved by the local codes and/or by

the local authority having jurisdiction.

9

Page 10

/ Installation requirements / Electrical connection

INSTALLATION REQUIREMENTS ELECTRICAL CONNECTION

ELECTRICAL

A properly-grounded horizontally- mounted electrical receptacle should be installed no higher than

3” (7.6 cm) above the fl oor, no less than 2” (5 cm)

and no more than 8” (20,3 cm) from the left side

(facing product).

Check all local code requirements.

GAS

An agency-approved, properly-sized manual

shut-off valve should be installed no higher than

3” (7.6 cm) above the fl oor and no less than 2” (5

cm) and no more than 8” (20.3 cm) from the right

side (facing product).

To connect gas between shut-off valve and regulator, use agency-approved, properly sized fl exible

or rigid pipe. Check all local code requirements.

Warning!

ELECTRICAL SHOCK HAZARD

Disconnect electrical power at the circuit breaker box or fuse box before installing the appliance.

Provide appropriate ground for the appliance.

Use copper conductors only.

Failure to follow these instructions could result in serious injury or death.

This unit is manufactured for a polarized, grounded 120 volt/60 Hz, 16 amp system.

Electric power consumption is about 2.5A.

The minimum of 102 VAC is required for proper

operation of gas ignition systems.

The circuit must be grounded and properly polarized.

The unit is equipped with a SJT power cord and

a NEMA 5-15P plug. In case of replacement, the

power cord shall be replaced with one of the same

type, size and length.

installation area for the connection

Warning!

Electrical grounding

This appliance is equipped with a three-prong

plug for your protection against shock hazard and

should be plugged directly into a properly grounded socket. Do not cut or remove the grounding

prong from this plug.

Caution

Label all wires prior to disconnecting when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

10

Page 11

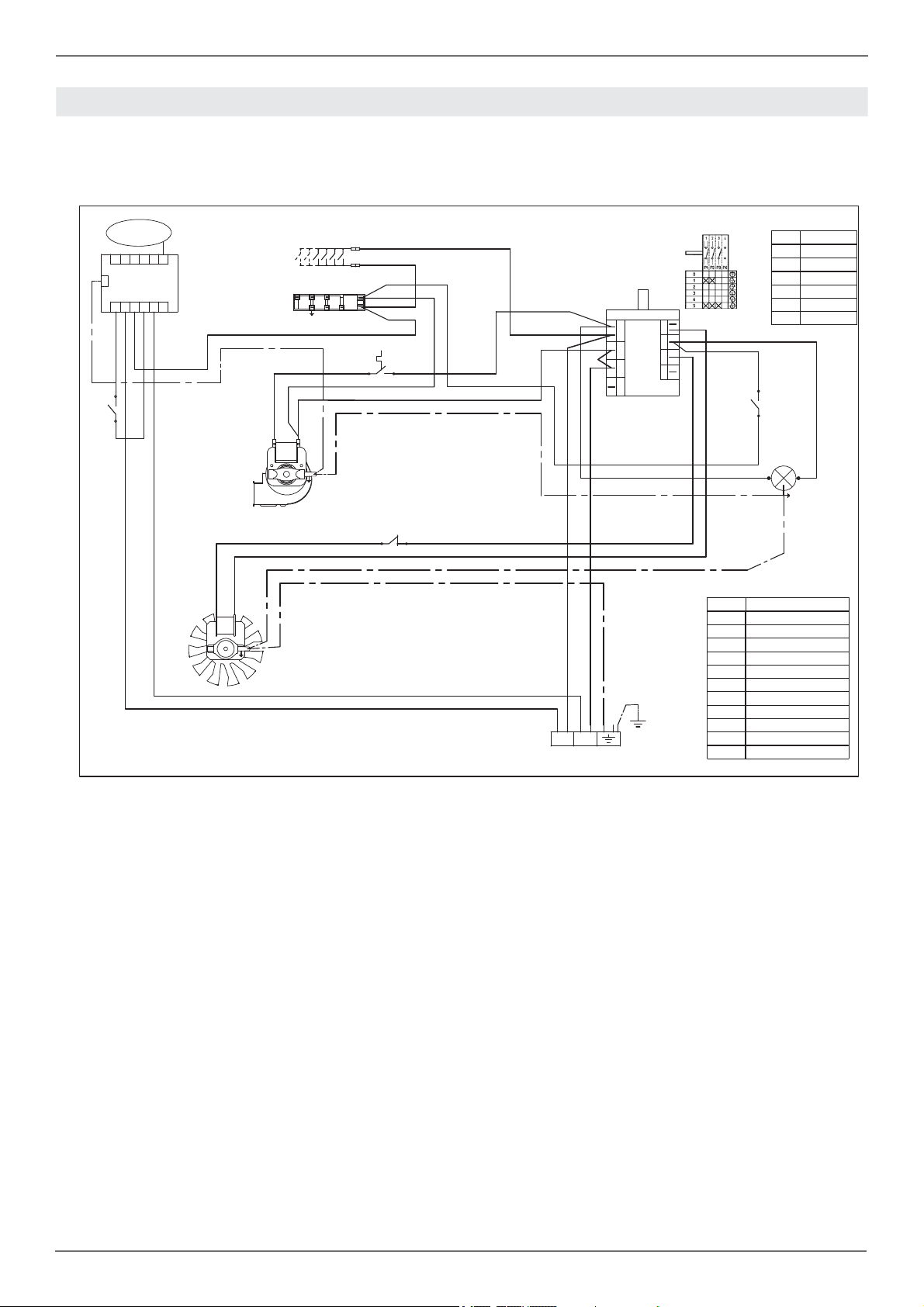

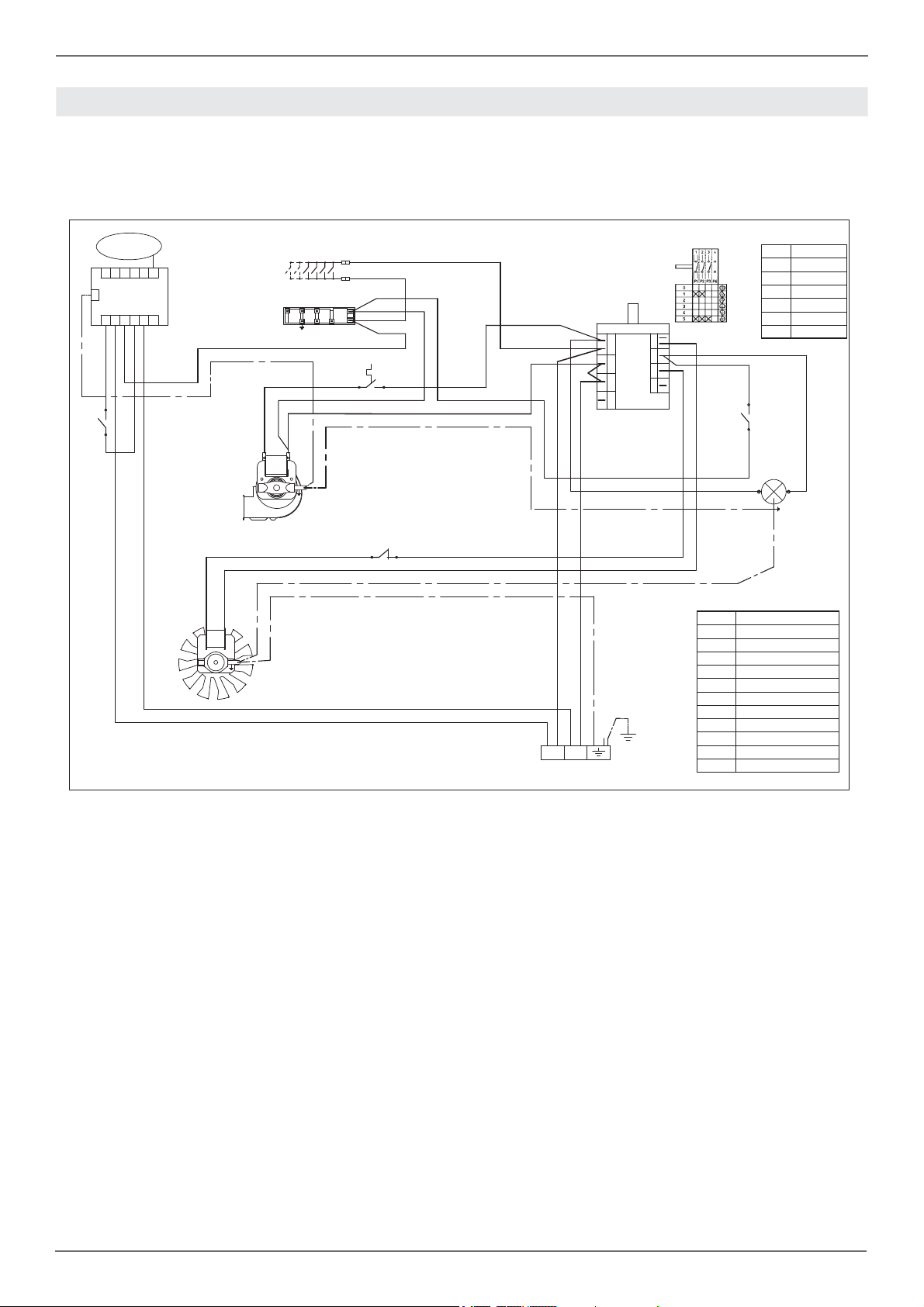

/ Wiring diagram

WIRING DIAGRAM

The electric wiring diagrams and schematics are attached behind the range, and should not be removed

except by a service technician, then replaced after service.

MAGNET UNITS &

TERMOCOUPLES

J12 J11J10 J9 J8 J7

J13

J1 J2 J3 J4 J5 J6

IGN

T-Z

v

MV

MVT

COLOURS

Simb. Descr iption

a

rRed

gr Green (earth)

v Violet

aOrange

n B lack (line)

bi Whit e (neutral)

a

LF

IGN

n

bi

n

G

gv

r

KI

n

bi

n

bi

Comm.2+0

1

P

2

P

3

P

4

P

COM

m

1

2

3

4

ILF

gr

INV

r

r

gv

gv

bi

GV

n

N

L

M

LEGENDA

Simb. Description

IGN Ignition Micro switches

INV Fan Oven Int erloc k

COM Oven Func tion Sel ector

G Spark Generator

ILF Oven lamp swit ch

KI Termal switch

LF Oven lamp

MTerminal Block

MV Fan motor

MVT Cool ing fan mot or

T-Z T-z ero

11

Page 12

/ Gas connection

GAS CONNECTION

Warning!

DO NOT USE AN OPEN FLAME WHEN

CHECKING FOR LEAKS!

Leak testing of the appliance shall be conducted

according to the manufacturer’s instructions. Before placing the oven into operation, always check

for leaks with soapy water solution or other acceptable method.

Check for gas leakage with soapy water solution or

other acceptable methods in all gas connections

installed between inlet gas pipe of the appliance,

gas regulator, till to the manual shut-off valve.

All gas connections must comply with national and

local codes. The gas supply line (service) must be

the same size or greater than the inlet line of the

appliance. This range uses a 1/2” NPT inlet (see

drawing below for details of gas connection). On

all pipe joints use appropriate sealant resistant to

gas to joint the adapter to range manifold use only

the blue gasket supplied.

If necessary, the appliance must be converted by

the dealer, by a factory-trained professional or by

a qualifi ed licensed plumber or gas service company.

FLEXIBLE CONNECTIONS

In case of installation with fl exible couplings and/

or quick-disconnect fi ttings, the installer must use

a heavy-duty, AGA design-certifi ed commercial

fl exible connector of at least 1/2” (1.3 cm) ID NPT

(with suitable strain reliefs) in compliance with

ANSI Z21.41 and Z21.69 standards.

In Massachusetts: The unit must be installed

with a 36” (3-foot) long fl exible gas connector.

In Canada: use CAN 1-6.10-88 metal connec-

tors for gas appliances and CAN 1-6.9 M79 quick

disconnect device for use with gas fuel.

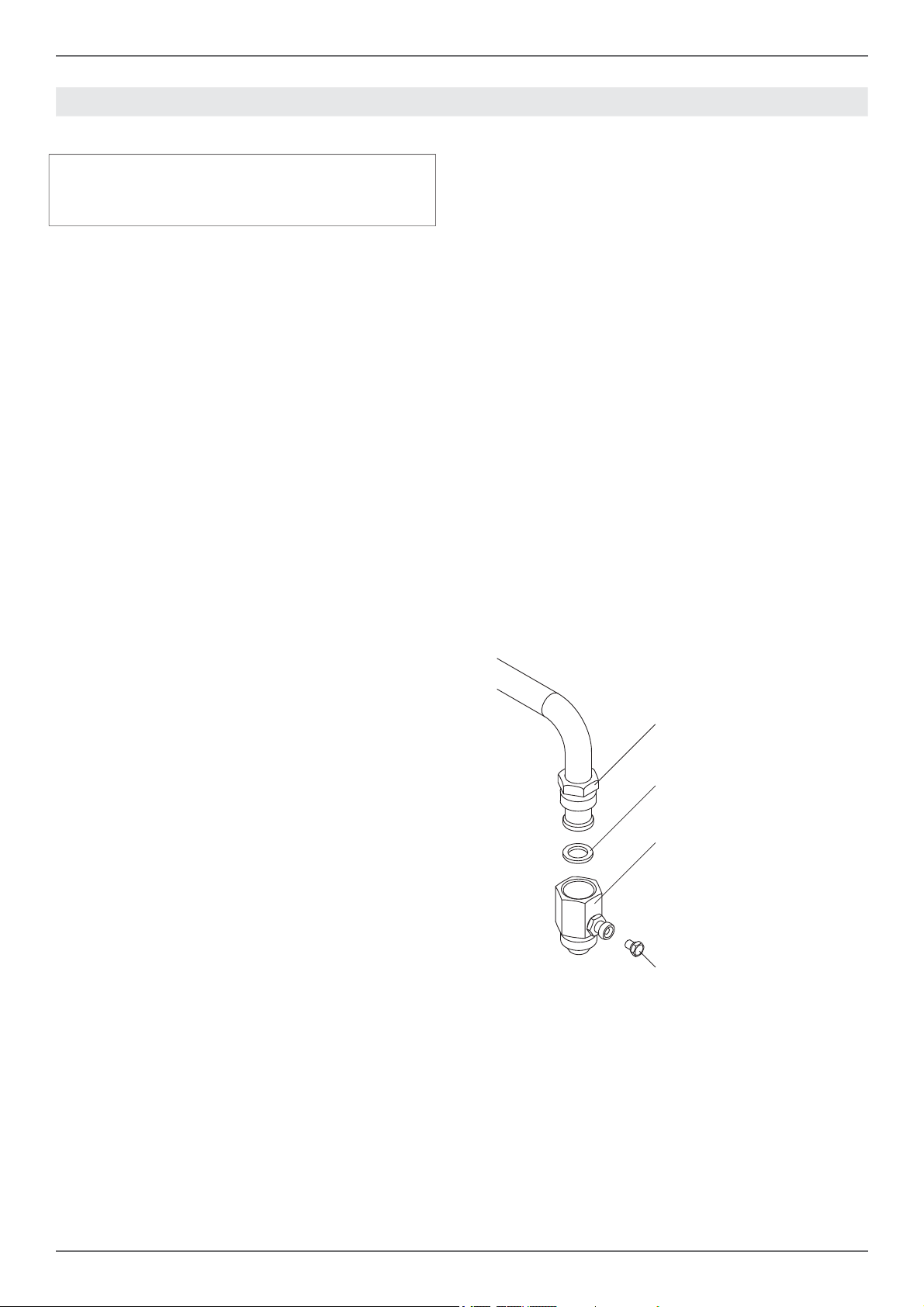

PRESSURE TEST-POINT STOPPER

VALVE

To avoid gas leaks, the pressure test-point stopper valve and gasket supplied with the range must

be installed on the gas fi tting at the back of the

range according to the diagram below.

Gas conversion is important for safe and eff ective use of the appliance. It is the responsibility of

the dealer and the owner of the range to perform

the appropriate gas conversion following the directions of the manufacturer.

THE GAS CONVERSION PROCEDURE IS

DESCRIBED IN THIS MANUAL AND IN THE

PACKAGE CONTAINING THE CONVERSION

NOZZLES SHIPPED WITH EVERY RANGE.

Please provide the service person with this manual before work is started on the range.

MANUAL SHUT-OFF VALVE

THIS VALVE IS NOT SHIPPED WITH THE APPLIANC AND MUST BE SUPPLIED BY THE INSTALLER.

The manual shut-off valve must be installed in the

gas service line between the gas hook-up on the

wall and the appliance inlet, in a position where it

can be reached quickly in the event of an emergency.

GAS PIPE

BASKET

GAS CONNECTION ADAPTOR

1/2’’NPT WITH PRESSURE TEST

POINT 1/8’’ NPT (TO BE FIXED

TOWARD EXTERNAL SIDE OF

THE APPLIANCE)

PRESSURE TEST-POINT

STOPPER

In Massachusetts: A ‘T’ handle type manual

gas valve must be installed in the gas supply line

to this appliance.

12

Page 13

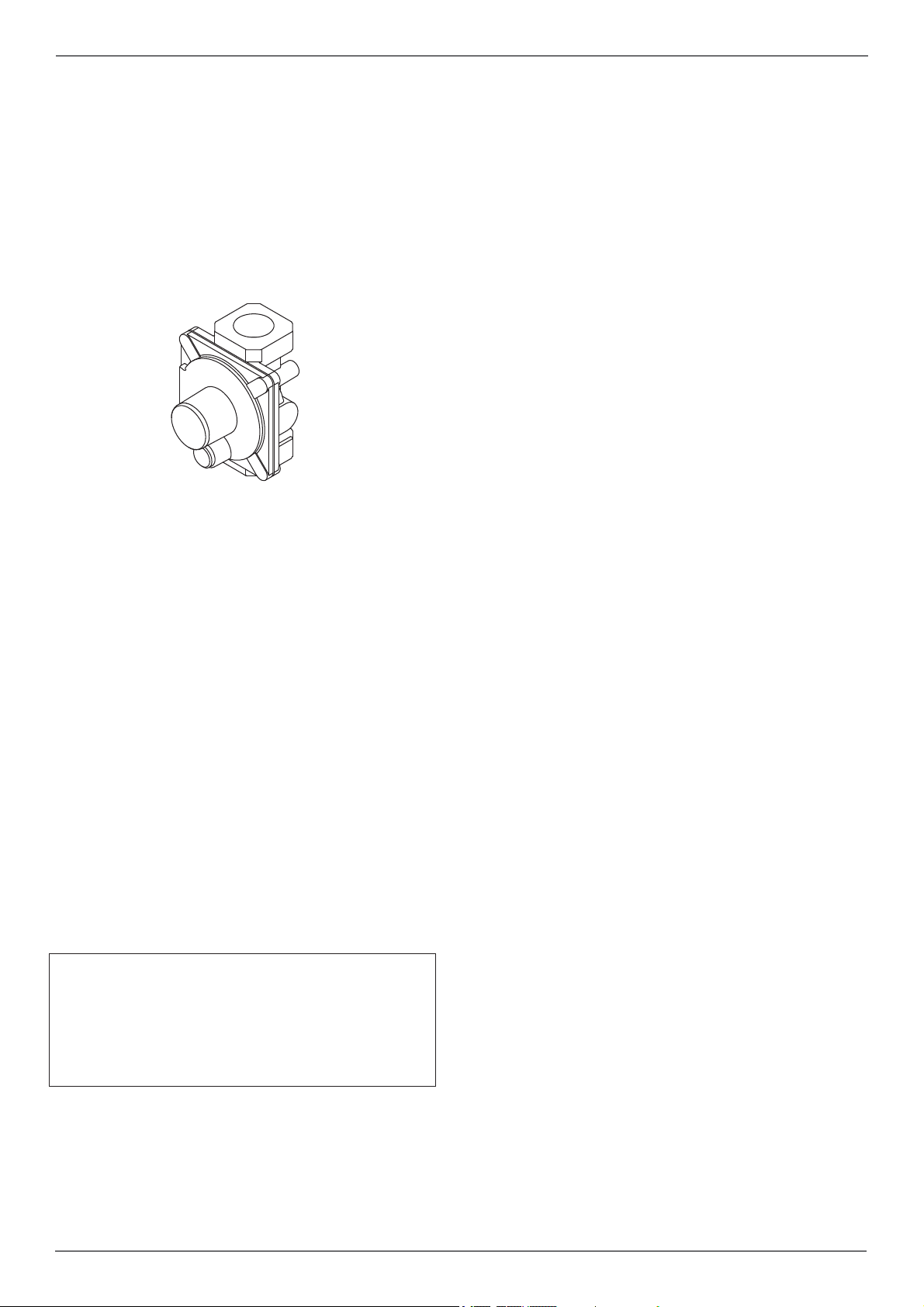

PRESSURE REGULATOR

Since service pressure may fl uctuate with local

demand, every gas cooking appliance must be

equipped with a pressure regulator on the incoming service line for safe and effi cient operation.

The pressure regulator shipped with the appliance has two female threads ½” NPT. The regulator

shall be installed properly in order to be accessible

when the appliance is installed in its fi nal position.

/ Gas connection

Manifold pressure should be checked with a manometer and comply with the values indicated below:

Natural gas 4.0” iwc

LP/Propane 10.0” iwc

Incoming line pressure upstream from the regulator must be 1” iwc higher than the manifold pressure in order to check the regulator.

The regulator used on this range can withstand a

maximum input pressure of 1/2 PSI (13,8” iwc or

3,5 kPa) If the line pressure exceeds that amount,

a stepdown regulator is required.

The appliance, its individual shut-off valve, and

the pressure regulator must be disconnected from

the gas line during any pressure testing of that system at pressures in excess of 1/2 PSI (13,8” iwc

or 3,5 kPa).

The individuaL manual shut-off valve must be in

the OFF position during any pressure testing of

the gas supply piping system at test pressures

equal to or less than 1/2 PSI (13,8” iwc or 3,5 kPa).

Warning

Before carrying out any servicing operation disconnect the appliance from gas and electric

supply and extra appliance from fi nal installation

place in order to have access to the appliance for

proper servicing intervention.

13

Page 14

/ Installation

INSTALLATION

APPLIANCE INSTALLATION

Unpacking the range

• Remove all packing materials from the ship-

ping pallet but leave the adhesive-backed foam

layer over brushed-metal surfaces to protect it

from scratches until the range is installed in its

fi nalposition. Only the fi lm on the side panels

should be removed before inserting the range

between the cabinets.

• Examine the appliance after unpacking it. In the

event of transport damage, do not plug it. Take

pictures of the damage and report it immediately to the freight forwarder.

• Remove the oven door(s). This will reduce the

weight of the range.

• The grates, griddle plate, burner caps, and oven

racks should be removed to facilitate handling.

• Before moving the range, protect the fl oor to

prevent damage.

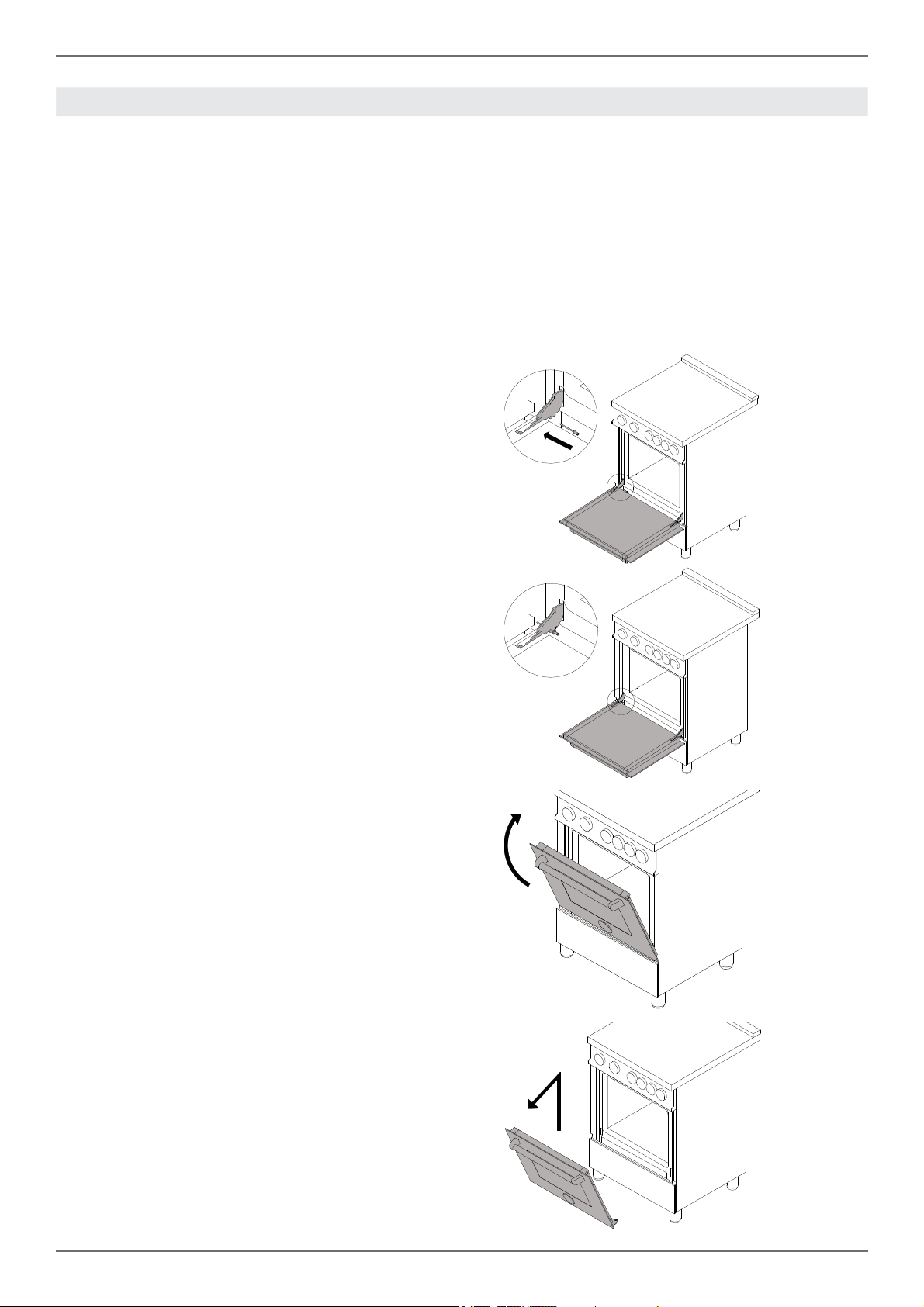

REMOVING THE OVEN DOOR

Prepare the door for removal. Insert the pin into

each hinge. Slowly shut the door until the protruding clamps stop the movement.

Pull oven door upwards and remove.

Do not lift or carry the oven door by its handle!

This may damage the hinges.

3

14

Page 15

/ Installation

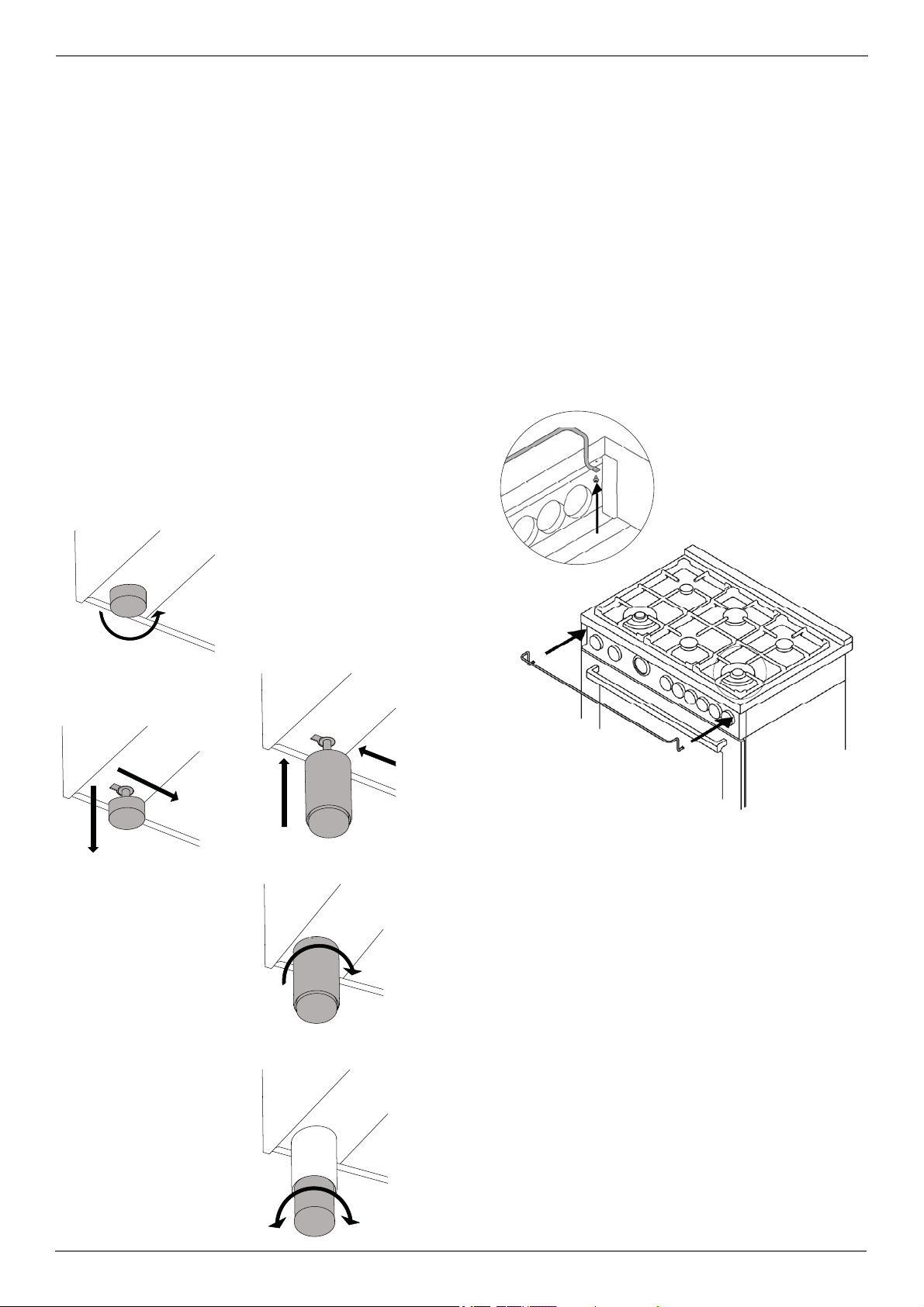

INSTALLING THE LEGS

Bertazzoni ranges must be used only with the legs

properly installed.

Four height-adjustable legs are supplied with the

range in the polysterene container situated over

the appliance.

Before installing the legs, position the appliance

near its fi nal location as the legs are not suitable

for moving the appliance over long distances.

After unpacking the range, raise it enough to insert the legs in the appropriate receptacles situated on the lower part of the appliance. Lower the

range gently to keep any undue strain from legs

and mounting hardware. If possible use a pallet or

lift jack instead of tilting the unit.

Adjust leg height to the desired level by twisting

the inside portion of the leg assembly until the proper height is reached. Check with a level that the

cooktop is perfectly level.

INSTALLING THE WORKTOP

FRONTGUARD

To increase the clearance between the front edge

of the worktop and the burners, it is possible to

install a front guard for the worktop.

To install the front guard,

• Locate the two fi xing holes on the end of the

front guard.

• Locate the two fi xing holes on the bottom facet

of the worktop

• Fix the front guard with it’s two screws

15

Page 16

/ Installation

INSTALLING THE ISLAND TRIM

The island trim must be installed prior to operation

of the appliance for appropriate ventilation of the

oven compartment.

The island trim is only placed on the cooktop, remove all tape and packaging before installing it.

INSTALLING BACKGUARD (OPTIONAL)

The backguard must be installed prior to operation of the appliance for appropriate ventilation of

the oven compartment.

The backguard is an optional contact you dealer

for buying it.

16

Page 17

INSTALLING THE ANTI/TIP DEVICES

/ Installing the anti/tip devices

ANTI-TIP BRACKETS

The anti-tip bracket shipped with the range must

be properly secured to the rear wall as shown in

the picture below.

The height of the bracket from the fl oor must be

determined after the range legs have been adjusted to the desired height and after the range has

been levelled.

• Measure the distance from the fl oor to the

bottom of the anti-tip bracket receptacle on the

back of the appliance.

• Position the anti-tip brackets on the wall at

the desired height plus 1/8” (0.32 cm). The

brackets must be placed at 2”5/16 (6,0 cm)

from the side of the range.

• Secure the brackets to the wall with appropria-

te hardware.

• Slide the range against the wall until the

brackets are fully inserted into their receptacles on the back of the range.

ANTI/TILT CHAIN

The anti-tilt chain shall be installed on right or left

side alternatively according below instructions.

The chain shall be hand pulled and fi xed to open

hook through closed ring.

Disengage the chain prior to moving the appliance

for service.

Attention:

Once servicing operation have been completed

the anti-tilt devices ( brackets and chain) shall be

re-engaged according above instruction/installations.

1

CLOSED RING OPEN HOCK

2

17

Page 18

/ Gas conversion

GAS CONVERSION

Warning!

Before carrying out this operation, disconnect the

appliance from gas and electricity.

Gas conversion shall be conducted by a factory-trained professional.

Call the customer service hotline to identify a fac-

tory-trained professional near your home.

The gas conversion procedure for this range includes 6 steps:

• Pressure regulator

• Surface burners

• Oven burner

• Broiler burner

• Visual checks prior to closure of oven bottom

panel

• Adjustment of minimum setting

LP

The conversion is not completed if all 6 steps have

not been concluded properly.

Before performing the gas conversion, locate the

package containing the replacement nozzle shipped with every range.

IMPORTANT: Each nozzle has a number indicating its fl ow diameter printed on the body. Consult

the table number 1 for matching nozzles to burners.

Save the nozzles removed from the range for future use.

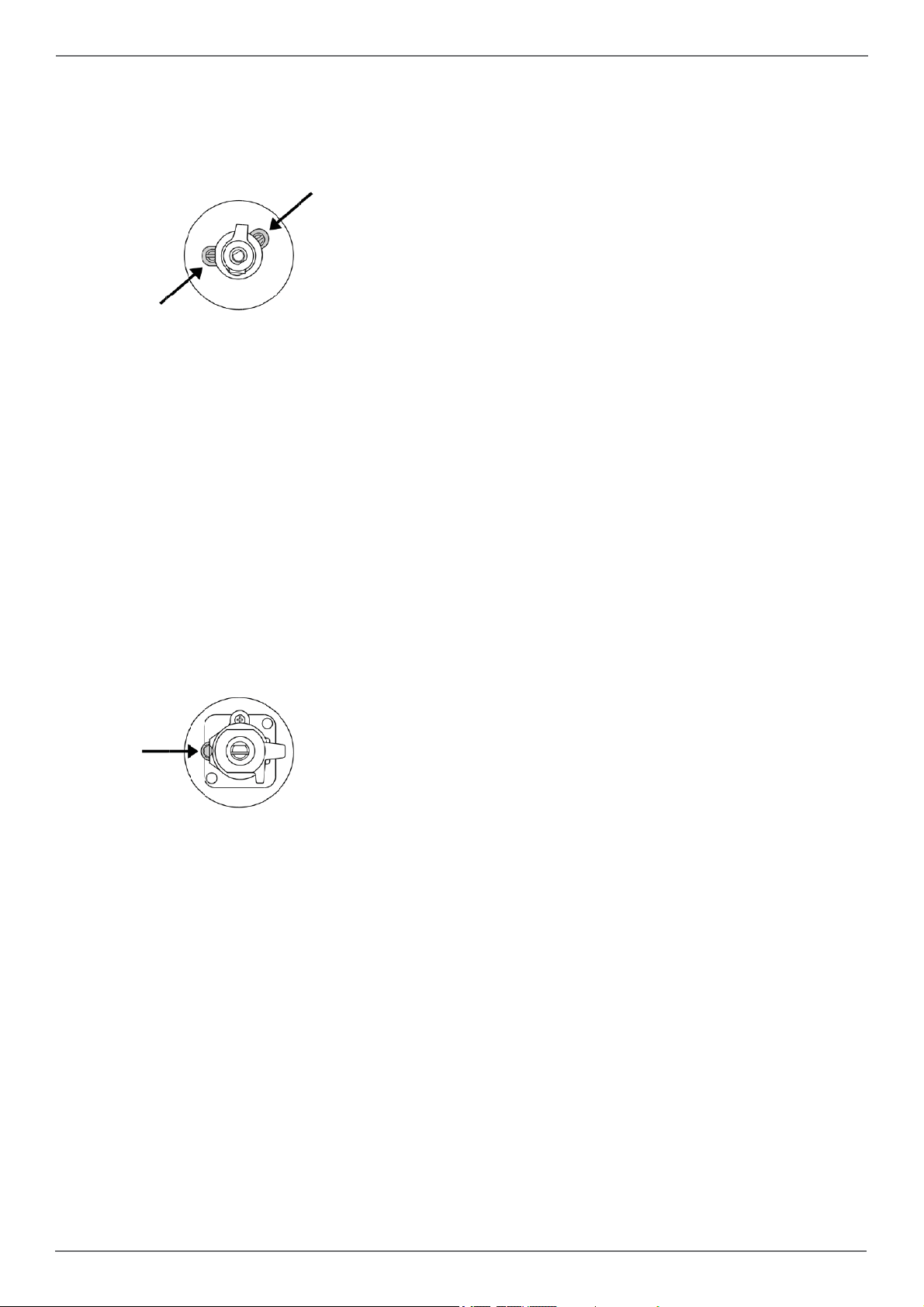

Step 1: pressure regulator

The pressure regulator supplied with the appliance is a convertible type pressure regulator for use

with Natural Gas at a nominal outlet pressure of

4” iwc or LP gas at a nominal outlet pressure of

10”iwc. and it is pre-arranged from the factory to

operate with one of these gas/pressure as indicated in the labels affi xed on the appliance, package

and Instruction booklet.

To convert the regulator for use with the other gas:

Unscrew by hand the upper cap of the regulator, remove the white plastic attachment from the

cap, reverse its direction and screw it again fi rmly against the cap. The white plastic attachment

has arrows indicating the position for natural gas

(NAT) and LP gas (LP).

Screw by hand the metal cap in the original position on the regulator.

NAT

Step 2: surface burners

To replace the nozzles of the surface burners, lift

up the burners and unscrew the nozzles shipped

with the range using a 7 mm (sochet wrench).

Replace nozzles using the conversion set supplied with the range or by a Bertazzoni authorized parts warehouse. Each nozzle has a number

indicating its fl ow diameter printed on the body.

Consult the table number 1 and matching nozzles

to burners.

18

Page 19

/ Gas conversion

Remove the screw located on the right side of the

burner and pull out the burner from its support.

ATTENTION: pay extra attention to avoid damage

to the igniter and thermocouple.

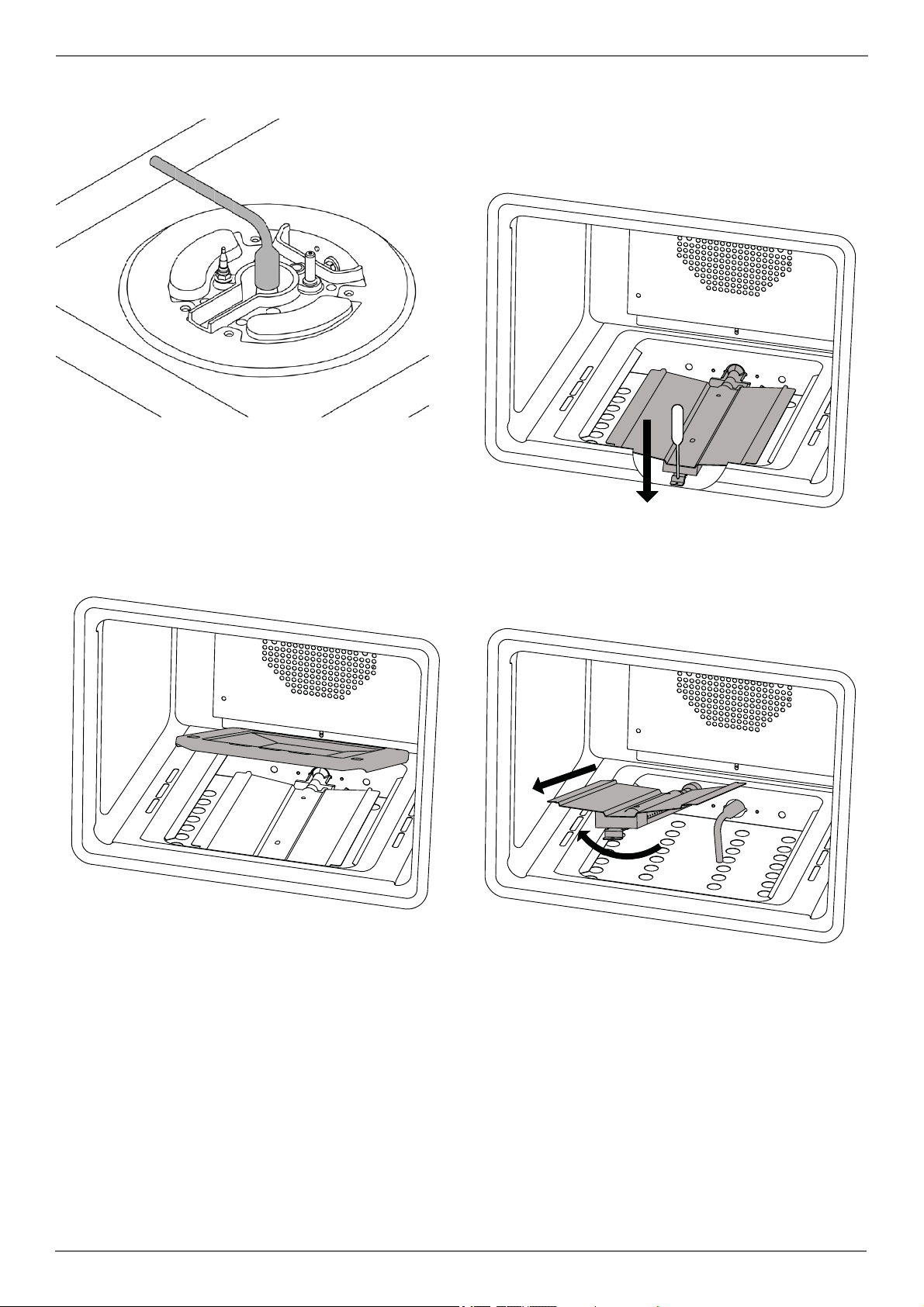

Step 3: oven burner (main or auxiliary)

To replace the nozzles of the main oven burner, start by removing the door and the bottom panel of the oven.

Unscrew the nozzle located inside the gas fi tting

using a 7 mm [ socket wrench].

Replace the nozzle as table number 1.

19

Page 20

/ Gas conversion

Step 4: broiler burner

Remove the screw and pull out the burner from

its support.

ATTENTION: pay extra attention to avoid damage

to the igniter and thermocouple.

Unscrew the nozzle located inside the gas fi tting

using a 7 mm [socket wrench].

Replace the nozzle as table number 1.

primary icone are normal.

The fl ame should burn completely around the burner cap. If it doesn’t, check that the cap is positioned

correctly on the base and that the ports are not

blocked.

The fl ame should be stable with no excessive noise or fl uttering.

yellow fl ames:

further adjustment is required

yellow tips on outer cones:

normal for LP gas

soft blue fl ames:

normal for natural gas

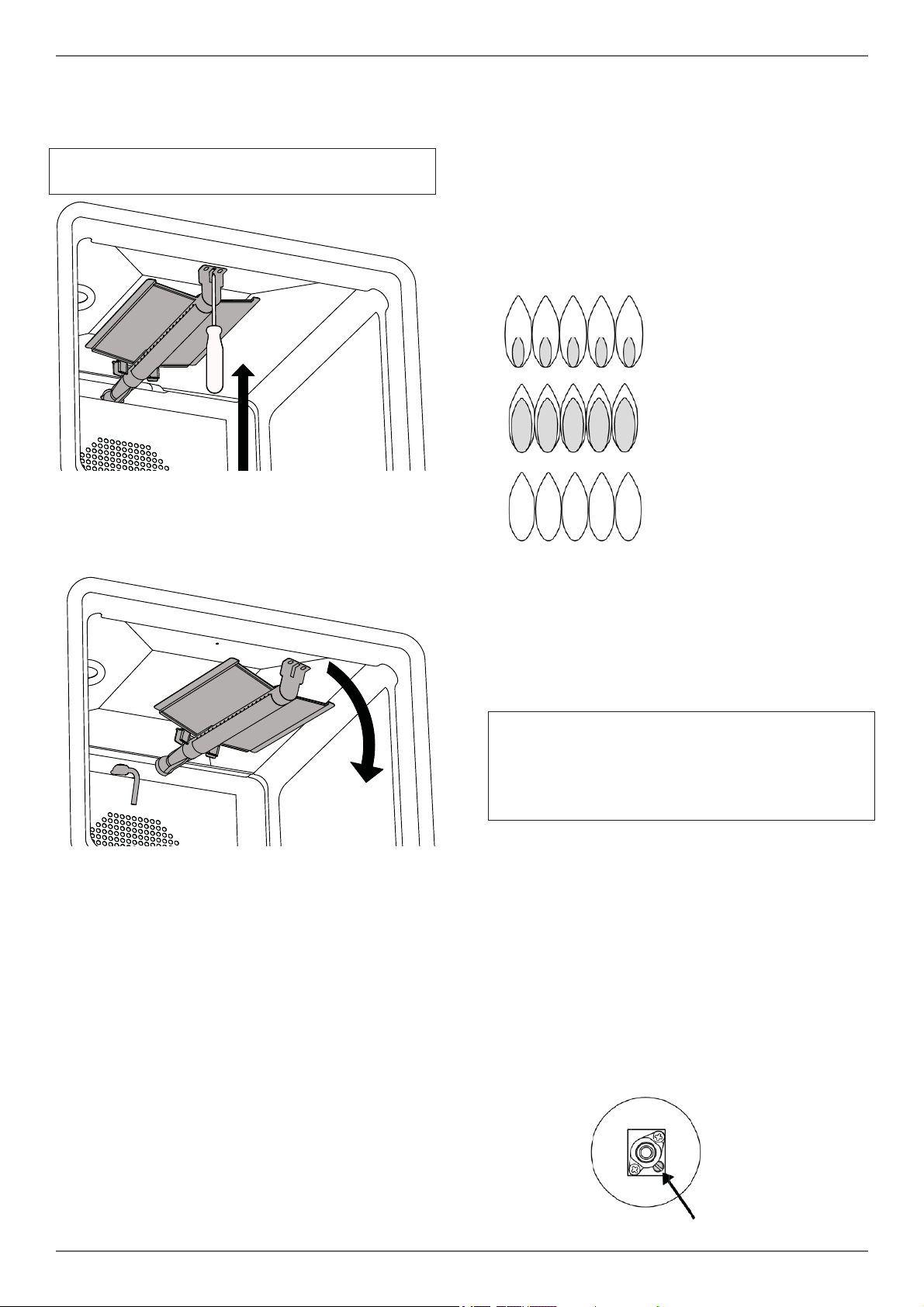

Step 5: visual checks

Oven

Before reinstalling the bottom panel, the following

visual check must be performed to ensure that the

conversion has been carried out properly and without damage to other components of the range.

Verify that the fl ame of the oven/broiler burner be

completely blue and with regular aspect as shown

below.

Surface burners

The burner fl ame color should be blue with no yellow on the tips. It is not uncommon to see orange

in the

fl ame color; this indicates the burning of airborne

impurities in the gas and will disappear with use.

With propane (LP) gas, slight yellow tips on the

After performing all these visual checks, reinstall

the bottom panel of the oven compartment and

proceed to setting the minimum for each burner.

Step 6: minimum fl ame adjustment

WARNING!

These adjustments should be made only for use

of the appliance with natural gas. For use with liquid propane gas, the choke screw must be fully

turned in a clockwise direction.

SURFACE BURNERS

Light one burner at a time and set the knob to the

MINIMUM position (small fl ame).

Remove the knob.

The range is equipped with a safety valve. Using

a small-size slotted screwdriver, locate the choke

valve on the valve body and turn the choke screw

to the right or left until the burner fl ame is adjusted

to desired minimum.

Make sure that the fl ame does not go out when

switching quickly from the MAXIMUM to the MINIMUM position.

20

Page 21

For the gas valve of dual burner the choke valve

is located on the valve body (fi g.20), the A screw

adjust the outer ring, the B screw adjust the inner

ring.

B

A

OVEN BURNER

Reinstall the oven door.

Set the oven temperature control knob to the MAXIMUM setting.

Close the oven door and operate the oven for at

least 10 minutes.

Set the knob to the MINIMUM setting .

Remove the knob.

With a slotted screwdriver turn the choking screw

(by-pass screw at the left side of the thermostat

bar) and, while observing the fl ame at the same

time through the bottom oven porthole, evaluate the consistency of the fl ame so it remains on

when switching quickly from MINIMUM to MAXIMUM setting.

/ Gas conversion

Broiler burner: the broiler burner always opera-

tes at maximum, therefore no minimum adjustment is required.

When gas conversion is complete, complete the

enclosed conversion label and place it

next to the rating label.

21

Page 22

/ Installation checklist / fi nal preparation

INSTALLATION CHECKLIST FINAL PREPARATION

A qualifi ed installer should carry out the following

checks:

Range mounted on its legs

Island trim or Backguard attached according to instruction

Anti-tip device properly installed

Clearance to cabinet surfaces as manufacturer’s guideline

Proper ground connection

Gas service line connected following manufacturer’s guideline

Valves, stoppers and gasket installed

between the range and the service line

Gas connection tested and free of gas

leaks

Range settled for the type of gas available

in the household

Each burner lights satisfactorily, both individually and with other burners operating

Flame appear sharp blue, with no yellow

tipping, shooting or fl ame lifting

Minimum settled for all burners

Oven and broiler lights satisfactorily and

works properly

Oven light works properly

• Before using the oven, remove any protective

wrap from the stainless steel.

• All stainless steel body parts should be wiped

with hot, soapy water and with a liquid stainless

steel cleanser.

• If buildup occurs, do not use steel wool, abrasi-

ve cloths, cleaners, or powders!

• If it is necessary to scrape stainless steel to re-

move encrusted materials, soak with hot, wet

cloths to loosen the material, then use a wood

or nylon scraper.

• Do not use a metal knife, spatula, or any other

metal tool to scrape stainless steel! Scratches

are almost impossible to remove.

• Before using the oven for food preparation,

wash the cavity thoroughly with a warm soap

and water solution to remove fi lm residues and

any dust or debris from installation, then rinse

and wiped dry.

Attention!

When using the oven for the fi rst time it

should be operated for 15-30 minutes at a temperature of about 500°F/260°C (main oven) or

440°F/227°C(auxiliary oven) without cooking

anything inside in order to eliminate any moisture and odours from the internal insulation.

22

Page 23

BERTAZZONI SERVICE

Bertazzoni is committed to providing the best customer and product service. We have a dedicated

team of trained professionals to answer your needs.

If you own a Bertazzoni appliance and need service in the US or Canada please use the following

contact information:

e-mail: aftersaleservice@bertazzoni.com

Telephone - Monday through Friday,

7.30am to 7.30pm EST (except US public holidays).

US 866-905-0010

WESTERN CANADA 866-905-0010 (BC,AB,SK,MB)

EASTERN CANADA 800-561-7265 (ON,QC,NL,NB,NS,PE)

/ Bertazzoni service

23

Page 24

BERTAZZONI

MANUEL D'INSTALLATION

CUISINIÈRES À GAZ AUTONOMES

3100427

WWW.BERTAZZONI.COM

1

Page 25

/ Table des matières

TABLE DES MATIÈRES

AVERTISSEMENTS ____________________________________________________________

ÉTIQUETTE SIGNALÉTIQUE _____________________________________________________

AVANT L'INSTALLATION ________________________________________________________

PRÉPARATION DE LA VENTILATION ______________________________________________

SPÉCIFICATIONS ______________________________________________________________

ESPACE DE DÉGAGEMENT ______________________________________________________

CONDITIONS D'INSTALLATION _________________________________________________

Électricité __________________________________________________________________

Gaz ________________________________________________________________________

RACCORDEMENT ÉLECTRIQUE _________________________________________________

SCHÉMA DE CÂBLAGE ________________________________________________________

RACCORDEMENT AU GAZ ______________________________________________________

Vanne de fermeture manuelle __________________________________________________

Tuyaux fl exibles _____________________________________________________________

Soupape d'arrêt au point consigne de pression ___________________________________

Régulateur de pression _______________________________________________________

INSTALLATION ________________________________________________________________

Déballage de la cuisinière _____________________________________________________

Retrait de la porte du four _____________________________________________________

Installation des pieds _________________________________________________________

Installation de la protection frontale de la surface de cuisson ________________________

Installation de la garniture ____________________________________________________

Installation de la protection arrière (en option) ____________________________________

INSTALLATION DES DISPOSITIFS ANTI-BASCULEMENT _____________________________

Supports anti-basculement ____________________________________________________

Chaîne anti-basculement _____________________________________________________

CONVERSION À UN AUTRE TYPE DE GAZ __________________________________________

LISTE DE CONTRÔLE POUR L'INSTALLATION ______________________________________

PRÉPARATION FINALE __________________________________________________________

ASSISTANCE BERTAZZONI ______________________________________________________

4

6

6

7

7

9

10

10

10

10

11

12

12

12

12

13

14

14

14

15

15

16

16

17

17

17

18

22

22

23

2

Page 26

/ Modèles

Modèles

MAST244GASXB

MAST244GASNEE

MAST244GASBIE

MAST244GASXELP

MAST244GASXE

PROF244GASXELP

PROF244GASXE

Modèles

PROF244GASXELP

PROF244GASXE

3

Page 27

/ Avertissements

AVERTISSEMENTS

Pour un fonctionnement correct et en toute sécurité,

l'appareil doit être correctement installé et mis à la

terre par un technicien qualifi é. NE PAS tenter de

régler, réparer, réviser ou remplacer un composant

de l'appareil à moins que le présent manuel ne

le recommande spécifi quement. Toute autre

intervention doit être réalisée par un opérateur

qualifi é. L'installateur montrera l'emplacement de la

vanne de fermeture du gaz et les modalités d'arrêt en

cas d'urgence. Un technicien certifi é devra intervenir

pour tout réglage ou conversion aux gaz naturel ou

LPG.

POUR L'INSTALLATEUR : Avant d'installer l'appareil

Bertazzoni, veuillez lire attentivement ces instructions.

Cet appareil doit être installé conformément aux

instructions d'installation du fabricant.

IMPORTANT: Ces instructions doivent être laissées

à la disposition du propriétaire, qui les conservera

pour toute consultation future ou en cas de visite

d'un inspecteur. NE PAS retirer les étiquettes, les

avertissements ou les plaques permanentes apposés

sur le produit. Cela risquerait d'annuler la garantie.

AVERTISSEMENT !

Si les informations dans ce manuel ne sont

pas suivies scrupuleusement, un incendie

ou une explosion risque(nt) de survenir et

d’entraîner des dommages matériels, blessures

personnelles ou la mort.

- Ne pas stocker ni utiliser de l’essence ou autres

substances infl ammables à proximité de cet appareil

ou d’autres appareils électroménagers.

- QUE FAIRE SI VOUS SENTEZ LE GAZ

• N’allumer aucun appareil électroménager.

• Ne toucher aucun interrupteur électrique.

• N’utiliser aucun téléphone dans votre immeuble.

• Appeler immédiatement votre fournisseur de gaz

depuis un téléphone voisin. Suivre les instructions du

fournisseur de gaz.

• Si vous ne pouvez pas joindre vos fournisseurs

de gaz, appelez le service incendie.

-L’installation et la maintenance doivent être

entreprises par un installateur qualifi é, agence de

service ou fournisseur de gaz.

L'installation doit être conforme aux règlementations

locales. En l'absence de règlementations :

• États-Unis : l'installation doit être conforme à la

règlementation nationale relative au gaz (National

Fuel Gas Code) ANSI Z223.1 INFPA54.

• Massachusetts : Tout appareil au gaz doit être

installé par un plombier ou un installateur de gaz

agréé par l'état. Une vanne manuelle à poignée

de type « T » doit être installée sur la conduite

d'alimentation en gaz de l'appareil.

• Canada : L'installation doit être réalisée

conformément aux règlementations en matière

d'installation au gaz CAN/CGA B149.1 et CAN/

CGA B149.2 et/ou aux règlementations locales.

L'installation électrique doit être conforme à la

règlementation canadienne en matière d'électricité

CSA C22.1, Partie 1, et/ou aux règlementations

locales.

La cuisinière N'A PAS été conçue pour être installée

dans des maisons préfabriquées (mobiles) ou des

caravanes.

NE PAS installer la cuisinière en extérieur.

DANGER ! RISQUE DE DÉCHARGE ÉLECTRIQUE !

Pour éviter les risques de décharge électrique, de

lésion ou de blessure mortelle, vérifi er que l'appareil

a été correctement mis à la terre, conformément aux

règlementations locales ou, en leur absence, à la

règlementation américaine en matière d'électricité

(NEC). ANSI/NFPA 70 – dernière édition.

DANGER ! RISQUE DE FUITE DE GAZ !

Pour éviter les risques de blessure ou d'accidents

mortels, la détection des fuites sur l'appareil doit

être conforme aux instructions du fabricant. Avant

d'utiliser l'appareil, toujours contrôler l'absence de

fuites à l'aide d'une solution d'eau savonneuse.

NE PAS UTILISER DE FLAMME LIBRE POUR

RECHERCHER LES FUITES DE GAZ.

L'appareil doit être correctement raccordé à la terre. Le

raccordement à la terre réduit le risque de décharge

électrique en fournissant un passage sécurisé au

courant électrique en cas de court-circuit.

Avertissement !

Pour éviter les risques de lésion, de blessure mortelle

ou de dommages aux biens, suivre scrupuleusement

les informations contenues dans ce manuel visant à

prévenir les incendies ou les explosions.

4

Avertissement – risque de basculement

Les enfants et les adultes peuvent faire basculer

la cuisinière si celle-ci n'a pas été fi xée au mur, ce

qui pourrait entraîner des blessures mortelles. Pour

réduire le risque de basculement de l'appareil, celui-ci

doit être fi xé au moyen de dispositifs anti-basculement,

conformément aux instructions d'installation.

Page 28

Remettre en place les dispositifs anti-basculement après tout déplacement de la cuisinière. Ne

pas utiliser la cuisinière si les dispositifs anti-basculement ne sont pas en place et enclenchés.

Ne pas utiliser la cuisinière si les dispositifs

anti-basculement n'ont pas été correctement

installés et enclenchés. Pour plus d'informations,

consulter les instructions d'installation.

Le non-respect des instructions d'installation peut occasionner des blessures

graves, voire mortelles, aux enfants et

aux adultes.

Ne PAS soulever la cuisinière par les poignées du

four, car cela pourrait endommager les charnières

de porte et entraîner une fermeture incorrecte de

la porte.

Ne PAS soulever la cuisinière en la saisissant par

le panneau de commande.

La cuisinière est lourde et doit être manipulée avec

les soins nécessaires. Pour tout déplacement

de la cuisinière, prévoir la présence d’au moins

deux personnes dotées d’équipements adaptés,

notamment des gants, afi n d’éviter de se blesser

ou d’endommager la cuisinière ou le sol.

Les bagues, montres et tout accessoire ample

susceptible d’endommager la cuisinière ou de se

coincer dans la cuisinière doivent être retirés.

Les surfaces cachées peuvent avoir des bords

tranchants. Faire très attention en cas de contact

avec l’arrière ou le dessous de la cuisinière.

Ne PAS positionner de diable ou de chariot sur

l’avant ou l’arrière de la cuisinière. Le positionner

sur le côté uniquement.

/ Avertissements

AVERTISSEMENT:

Cancer et Troubles de l’appareil reproducteurwww.P65Warnings.ca.gov.

5

Page 29

/ Étiquette signalétique / Avant l'installation

ÉTIQUETTE SIGNALÉTIQUE

L’étiquette signalétique indique le modèle et le

numéro de série de la cuisinière. Elle se trouve

sous le panneau de commande et à la dernière

page de ce manuel.

AVANT L'INSTALLATION

• L'appareil doit être installé uniquement par un

professionnel autorisé.

• Cet appareil doit être installé conformément

aux instructions d'installation du fabricant.

• L'appareil doit être installé conformément

aux normes et aux règlementations du pays

d'installation.

• L'installation de cet appareil doit être conforme

aux règlementations locales. En l'absence de

règlementations locales, l'installation doit être

conforme aux normes américaines du National

Fuel Gas Code ANSI Z223.1 – dernière édition/

NFPA 54 ou B149.1.

• Une fois installé, l'appareil doit être raccordé

à la terre conformément aux règlementations

locales ou, en leur absence, à la règlementation

américaine en matière d'électricité (NEC),

ANSI/NFPA 70.

Si les règlementations locales l'autorisent, un

raccord métallique fl exible de nouvelle conception

homologué conformément aux normes AGA ou

CGA, de 5 pieds (1,5 m) max. de longueur, ½”

de diamètre interne (I.D.), est recommandé pour

raccorder l'appareil à la conduite d'alimentation

en gaz. Veiller à ne pas plier ou endommager le

raccord fl exible lors du déplacement de l'appareil.

L'appareil doit être utilisé avec le régulateur

de pression fourni.

Toutes les ouvertures et les trous dans le mur et le

plancher, derrière et sous l'appareil, doivent être

scellés avant l'installation de celui-ci.

Une vanne manuelle doit être installée dans

un emplacement accessible sur la conduite

d'alimentation en gaz, indépendante de l'appareil,

afi n d'ouvrir ou de fermer l'alimentation en gaz.

Type de gaz

Cette cuisinière peut fonctionner avec du gaz

naturel ou du gaz propane/LPG. Cette cuisinière

est expédiée de l'usine pour être utilisée avec le

gaz indiqué sur l'étiquette signalétique se trouvant

sur la face inférieure du panneau de commande et

à la dernière page de ce manuel. Une procédure

de conversion pas à pas est également comprise

dans ce manuel et dans tout kit de conversion.

Pression du gaz

La pression d'alimentation en gaz maximale pour

le régulateur de pression de la cuisinière à gaz est

de 1/2 psi (13,8 inH2O ou 3,5 kPa). La pression

d'alimentation en gaz minimale pour vérifi er le

réglage du régulateur doit être d'au moins 1 inH2O

(249 Pa) au-dessus de la pression d'alimentation

spécifi ée pour le collecteur. Cette pression de

fonctionnement est de 4 inH2O (1,00 kPa) pour

le gaz naturel et de 10 inH2O (2,50 kPa) pour le

gaz LPG.

Ventilation de la pièce

Il convient d'associer un ventilateur extracteur à

l'appareil. Celui-ci doit être installé conformément

aux normes locales et nationales en vigueur. Le

fonctionnement d'une hotte aspirante peut avoir

une incidence sur d'autres appareils de ventilation.

Elle doit être installée conformément aux normes

locales et nationales en vigueur.

Le régulateur doit être correctement installé afi n

d'être accessible une fois l'appareil installé dans

son emplacement fi nal. Le régulateur de pression

doit être réglé conformément au type de gaz

utilisé. Le régulateur de pression dispose d'un

fi letage interne femelle ½”. Une fi xation adaptée

doit être déterminée en fonction des dimensions

de la conduite d'alimentation en gaz, du raccord

métallique fl exible et de la vanne de fermeture.

L'appareil doit être isolé du système d'alimentation

en gaz en fermant la vanne manuelle individuelle

lors de chaque test de pression du système

d'alimentation en gaz à des pressions de test

inférieures ou égales à 1/2 psi (13,8 inH2O ou 3,5

kPa).

6

Avertissement

Cet appareil ne doit pas être installé avec un

système de ventilation qui dirige l'air vers le bas,

en direction de la cuisinière. Ce type de système

de ventilation peut entraîner des incendies

et des problèmes de combustion, avec pour

conséquences des blessures, des dommages aux

biens et un fonctionnement non maîtrisé. Il n'existe

pas de restrictions concernant les systèmes de

ventilation qui dirigent l'air vers le haut.

Ne pas utiliser de sprays aérosols à proximité

de l'appareil en fonctionnement.

Page 30

PRÉPARATION DE LA VENTILATION

m

m

/ Préparation de la ventilation / Spécifi cations

Cette cuisinière a un fonctionnement optimal

en cas d'installation avec une hotte d'extraction

Bertazzoni. Ces hottes, conçues pour être

associées à la gamme Bertazzoni, off rent un

aspect impeccable grâce à leur fi nition identique.

Avant d'installer la hotte d'extraction, consulter les

règlementations locales ou régionales en matière

de construction et d'installation pour connaître les

critères spécifi ques aux espaces de dégagement.

Pour plus d'informations, se reporter aux

instructions d'installation de la hotte fournies par

le fabricant.

Choisir les modèles de hotte et de ventilateur :

• En cas d'installation murale, la hotte doit

présenter une largeur au moins égale à celle de

la cuisinière. Lorsque l'espace le permet, il peut

être souhaitable d'installer une hotte plus large

que la cuisinière, pour une meilleure ventilation.

• En cas d'installations autonomes, la largeur de

la hotte doit dépasser celle de la cuisinière d'au

moins 3” (76 mm) de chaque côté.

Positionnement de la hotte :

• Pour une meilleure extraction des fumées et

des odeurs, le bord inférieur de la hotte doit

se trouver entre 25 1/2” (65 cm) et 31 1/2”

(80 cm) au-dessus de la surface de cuisson de

la cuisinière.

• Si la hotte contient des matériaux

combustibles (par ex. parement en bois), elle

doit être installée à au moins 36” (914 mm) audessus de la surface de cuisson.

Air d'appoint :

En présence d'un volume élevé d'air de

ventilation, il est recommandé de disposer d'une

source d'air de remplacement extérieur. Cela est

particulièrement important pour les habitations

fermées hermétiquement et fortement isolées.

Consulter une entreprise de chauff age et de

ventilation qualifi ée.

SPÉCIFICATIONS

13

23"

⁄

16

1"

32"

8

⁄

3

27"

23" 13⁄

16

1"

13

⁄

16

25 " 3⁄

16

5

1" ⁄

16

9

⁄

16

1"

1" 5⁄

max

4

⁄

1

37"

min -

2

⁄

1

35"

15

⁄

16

19 "

16

4"

23"

1" ⁄

9

3

10

⁄

23"

4

GAS

3"

ELECTRIC

24"

3

2" ⁄

7

⁄

6

1

15

1" ⁄

8

15

⁄

16

2"

11

⁄

16

"

1

2" ⁄

16

16

1" ⁄

3" 1⁄

5" 1⁄

3

4

2

4

7

Page 31

/ Spécifi cations

n

Brûleur

rûleur Injecteur

Auxiliaire

Semi-rapide

Rapide

brûleur couronne

Double brûleur

Four

Grill

Injecteur

diam. [mm]

0.90

0.54

1.18

0.70

1.55

0.92

1.80

1.02

0.80+2.10

0.50+1.20

1.70

1.02

1.35

0.90

Gaz

az

Type

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Gaz naturel

LPG (propane)

Pression

Pression Valeur

[inH2O]

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

4’’

10’’

Valeur

maximale

[Btu/hr]

3,500

3,300

5,900

5,500

10,400

9,500

16,600

13,600

19,000

19,000

12,000

12,000

8,500

8,500

[W]

1,025

967

1,729

1,611

3,047

2,783

4,000

4,000

5,567

5,567

3,516

3,516

2,491

2,491

Valeur minimale

aleur minimale

[Btu/hr]

900

900

1,500

1,500

2,500

2,500

5,200

5,200

1,300

1,300

2,800

2,800

Max. uniquement

Max. uniquement

[W]

264

264

439

439

732

732

1,520

1,520

381

381

820

820

Max. uniquement

Max. uniquement

Dérivation

érivatio

diam. [mm]

Régulé

0.29

Régulé

0.36

Régulé

0.47

Régulé

0.65

Régulé

0.34/0.65

Régulé

048

Sans dérivation

Sans dérivation

Consulter le manuel d'utilisation et d'entretien pour connaître la confi guration des brûleurs

de votre cuisinière.

8

Page 32

ESPACE DE DÉGAGEMENT

C

Installation adjacente à des meubles de cuisine

Cette cuisinière peut être installée à proximité

directe de plans de travail avec meubles intégrés

(36” ou 91,5 cm par rapport au sol).

Pour un aspect optimal, la surface de la cuisinière

doit être au même niveau que celle du plan de

travail avec meuble intégré. Pour ce faire, régler la

hauteur de l'appareil en agissant sur les dispositifs

de réglage des pieds.

ATTENTION : la cuisinière NE DOIT PAS être

installée à proximité directe des murs de la cuisine,

de meubles ou d'appareils hauts, ou d'autres

surfaces verticales de plus de 36” (91,4 cm) de

hauteur. Dans ces cas, l'espace latéral doit être

d'au moins 6” (15,2 cm).

Les meubles muraux présentant cet espace latéral

minimum doivent être installés à 18” (45,7 cm) audessus du plan de travail, avec une hauteur de

plan de travail comprise entre 35 ½” (90,2 cm)

et 37 ¼” (94,6 cm). La profondeur maximale des

meubles muraux au-dessus de la cuisinière doit

être de 13” (33 cm).

Hotte métallique

A

24’’ (60,4 cm)

B

25 1/2’’(65 cm) et 31 1/2’’ (80 cm)

C

13’’ (33,0 cm)

D

18’’ (45,7 cm)

E

35’’ 1/2(90,2 cm) / 37”

F

6” (15,2 cm)

G

12”(30,50 cm)

H

1” 9/16(4 cm)

/ Espace de dégagement

1/4

(94,6 cm)

B

G

Meuble de cuisine

24’’ (60,4 cm)

A

36’’ (91,5 cm) hotte avec matériaux combustibles

B

13’’ (33,0 cm)

C

18’’ (45,7 cm)

D

/

1/4

(94,6 cm)

A

B

35’’ 1/2(90,2 cm) / 37”

E

F

6’ (15,2 cm)

D

F

E

En cas d’installation de toekick, vérifi ez que la

somme des zones de découpe correspond à la

ventilation recommandée (L)

24” surface 29 sq. inches ( 18765 mm2)

H

La zone grisée derrière la cuisinière indique

l'espace minimum à respecter par rapport à la

surface de cuisson. Aucun matériau combustible

ne doit se trouver dans cette zone.

12” (305 mm) min. par rapport aux surfaces

combustibles avec garniture affl eurante.

Pour des installations autonomes, la surface de

travail doit être dotée d'un bord saillant faisant la

jonction avec la partie arrière de la garniture.

Comme indiqué dans la règlementation américaine

en matière de gaz ANSI Z223.1 (édition actuelle).

Le dégagement par rapport aux matériaux non

combustibles ne rentre pas dans le cadre de la

norme ANSI Z21.1

et n'est pas certifi é par l'Association canadienne

de normalisation (CSA). Les dégagements de

moins de 12” (305 mm)

doivent être conformes aux règlementations

locales et/ou être approuvés par l'autorité locale

compétente.

9

Page 33

/ Conditions d'installation / Raccordement électrique

CONDITIONS D'INSTALLATION RACCORDEMENT ÉLECTRIQUE

ÉLECTRICITÉ

Une prise électrique montée horizontalement et

correctement mise à la terre doit être installée à

une hauteur maximale de 3” (7,6 cm) et minimale

de 2” (5 cm) par rapport au sol, et à une distance

maximale de 8” (20,3 cm) par rapport au côté

gauche du produit (en lui faisant face).

Vérifi er les dispositions des règlementations

locales.

GAZ

Une vanne de fermeture manuelle correctement

dimensionnée et approuvée par un organisme

agréé doit être installée à une hauteur maximale

de 3” (7,6 cm) et minimale de 2” (5 cm) par rapport

au sol, et à une distance maximale de 8” (20,3 cm)

par rapport au côté droit du produit (en lui faisant

face).

Pour réaliser le raccordement en gaz entre la

vanne de fermeture et le régulateur, utiliser un

fl exible de dimensions adaptées ou un tuyau

rigide approuvé par un organisme agréé. Vérifi er

les dispositions des règlementations locales.

DANGER !

RISQUE DE DÉCHARGE ÉLECTRIQUE !

Couper l'alimentation électrique au niveau

du disjoncteur ou du tableau à fusibles avant

d'installer l'appareil.

L'appareil doit être correctement mis à la terre.

Utiliser uniquement des conducteurs en

cuivre.

Le non-respect de ces instructions pourrait

entraîner de graves blessures, voire la mort.

Cette cuisinière a été fabriquée pour être branchée

sur un système de 16 A, 120 V / 60 Hz, mis à la

terre et polarisé.

Sa consommation électrique est d'environ 2.5A.

Un minimum de 102 Vca est nécessaire pour un

fonctionnement correct des systèmes d'allumage

du gaz.

Le système doit être mis à la terre et correctement

polarisé.

La cuisinière est dotée d'un câble d'alimentation

de type SJT et d'une prise NEMA 5-15P. Le cas

échéant, le câble d'alimentation doit être remplacé

par un câble de même type, grosseur et longueur.

Attention

Mise à la terre

L'appareil est équipé d'une prise à trois broches

qui garantit une protection contre les décharges

électriques. Elle doit être branchée directement à

une prise murale correctement mise à la terre. Ne

pas couper ou retirer la broche de terre de cette

prise.

Attention

Étiqueter chaque câble avant de les débrancher

pour eff ectuer des contrôles d'entretien.

Des erreurs de câblage peuvent entraîner un

fonctionnement incorrect et dangereux.

Vérifi er le bon fonctionnement de la cuisinière

après l'entretien.

10

zone réservée au branchement

Page 34

/ Schéma de câblage

SCHÉMA DE CÂBLAGE

Les schémas de câblage électrique fi gurent à l'arrière de la cuisinière et ne peuvent être retirés que par un

technicien de maintenance, qui doit les remettre en place une fois l'entretien réalisé.

MAGNET UNITS &

TERMOCOUPLES

J12 J11J10 J9 J8 J7

J13

J1 J2 J3 J4 J5 J6

IGN

T-Z

COLOURS

Simb. Descr iption

a

rRed

gr Green (earth)

v Violet

aOrange

n B lack (line)

bi Whit e (neutral)

a

IGN

n

bi

n

G

gv

r

KI

n

bi

n

Comm.2+0

1

P

2

P

3

P

4

P

COM

1

2

3

4

ILF

v

bi

MVT

m

LF

gr

INV

r

r

gv

LEGENDA

Simb. D escription

IGN Ignition Micro switches

INV Fan Oven Int erloc k

COM Oven Func tion Sel ector

G Spark Generator

ILF Oven lamp swit ch

KI Termal switch

LF Oven lamp

MTerminal Block

MV Fan motor

MVT Cool ing fan mot or

T-Z T-z ero

MV

gv

bi

GV

n

N

L

M

11

Page 35

/ Raccordement au gaz

RACCORDEMENT AU GAZ

Avertissement !

NE PAS UTILISER DE FLAMME LIBRE POUR

RECHERCHER LES FUITES DE GAZ !

La recherche de fuites sur la cuisinière doit

être réalisée conformément aux instructions du

fabricant. Avant d'utiliser le four, toujours réaliser

une recherche de fuites avec une solution d'eau

savonneuse ou toute autre méthode valide.

Vérifi er l'absence de fuites de gaz en utilisant de

l'eau savonneuse ou en ayant recours à d'autres

méthodes valides pour tous les raccords de gaz

installés entre la conduite d'alimentation en gaz

de l'appareil, le régulateur de gaz et la vanne de

fermeture manuelle.

Tous les raccordements au gaz doivent être

conformes aux règlementations locales et

nationales. La conduite d'alimentation en gaz doit

être de dimensions au moins égales à celles du

tuyau d'entrée de l'appareil. Cette cuisinière utilise

un adaptateur NPT 1/2” (voir le dessin ci-après

pour des informations sur le raccordement au

gaz). Pour toutes les jonctions de tuyaux, utiliser

un joint adapté résistant au gaz ; pour joindre

l'adaptateur et le collecteur de la cuisinière, utiliser

uniquement le joint bleu fourni.

Le cas échéant, la conversion de l'appareil doit

être réalisée par le revendeur, un professionnel

formé par le fabricant, un plombier ou une

entreprise spécialisée, qualifi és et agréés.

Massachusetts : Une vanne manuelle de gaz

à poignée de type « T » doit être installée sur la

conduite d'alimentation en gaz de l'appareil.

TUYAUX FLEXIBLES

En cas d'installation avec des tuyaux fl exibles

et/ou à déconnexion rapide, l'installateur doit

utiliser un connecteur fl exible résistant, certifi é

AGA pour une utilisation commerciale, d'au moins

1/2” (1,3 cm) de diamètre interne (I.D.) NPT

(enfi chables) conforme aux normes ANSI Z21.41

et Z21.69.

Massachusetts : Installer la cuisinière avec un

raccord de gaz fl exible d'une longueur de 36” (3

pieds).

Canada : Utiliser des connecteurs métalliques

CAN 1-6.10-88 pour cuisinière à gaz et un

dispositif à déconnexion rapide CAN 1-6.9 M79

en cas d'utilisation avec du gaz.

SOUPAPE D'ARRÊT AU POINT CONSIGNE

DE PRESSION

Pour éviter les fuites de gaz, la soupape d'arrêt au

point consigne de pression et le joint fourni avec

la cuisinière doivent être installés sur le raccord

de gaz à l'arrière de la cuisinière, conformément

au schéma ci-après.

La conversion est importante pour une utilisation

effi cace et sûre de l'appareil. Il incombe au

revendeur et au propriétaire de la cuisinière

de réaliser une conversion au gaz adaptée et

conforme aux instructions du fabricant.

LA PROCÉDURE DE CONVERSION EST

DÉCRITE DANS CE MANUEL ET DANS LE

SACHET CONTENANT LES DIFFÉRENTS

INJECTEURS FOURNI AVEC LA CUISINIÈRE.

Ce manuel doit être fourni à la personne en

charge de l'entretien avant toute intervention sur

la cuisinière.

VANNE DE FERMETURE MANUELLE

CETTEVANNE N'EST PAS EXPÉDIÉE AVEC

LA CUISINIÈRE ET DOIT ÊTRE FOURNIE PAR

L'INSTALLATEUR.

La vanne de fermeture manuelle doit être installée

sur la conduite d'alimentation en gaz, entre le

branchement mural et l'entrée de l'appareil,

dans une position rapidement accessible en cas

d'urgence.

CONDUITE DE GAZ

JOINT

CONNECTEUR DE GAZ 1/2’’NPT

AVEC POINT CONSIGNE

DE PRESSION 1/8’’ NPT (À

FIXER VERS L'EXTÉRIEUR DE

L'APPAREIL)

SOUPAPE D'ARRÊT AU POINT

CONSIGNE DE PRESSION

12

Page 36

RÉGULATEUR DE PRESSION

Dans la mesure où la pression de service peut

fl uctuer en fonction de la demande locale, chaque

appareil de cuisson au gaz doit être équipé

d'un régulateur de pression sur la conduite

d'alimentation, pour garantir un fonctionnement

sûr et effi cace.

Le régulateur de pression fourni avec l'appareil

dispose de deux fi letages femelles ½” NPT. Le

régulateur doit être correctement installé afi n

d'être accessible une fois l'appareil installé dans

son emplacement fi nal.

/ Raccordement au gaz

La pression dans le collecteur doit être contrôlée

au moyen d'un manomètre et être conforme aux

valeurs indiquées ci-après :

Gaz naturel 4,0” inH2O

LPG/Propane 10,0” inH2O

La pression de la conduite d'alimentation en

amont du régulateur doit être supérieure de 1”

inH2O à celle dans le collecteur afi n de pouvoir

contrôler le régulateur.

Le régulateur utilisé avec la cuisinière est adapté

à une pression d'alimentation maximale de 1/2

psi (13,8” inH2O ou 3,5 kPa). Si la pression

d'alimentation dépasse cette valeur, un hacheur

série est nécessaire.

L'appareil, sa vanne de fermeture individuelle et

le régulateur de pression doivent être débranchés

de la conduite de gaz en cas de contrôle de

pression du circuit à des pressions supérieures à

1/2 psi (13,8” inH2O ou 3,5 kPa).

La vanne manuelle de fermeture doit être

FERMÉE lors de chaque test de pression du

circuit d'alimentation en gaz à des pressions de

test inférieures ou égales à 1/2 psi (13,8” inH2O

ou 3,5 kPa).

Avertissement

Avant toute opération d'entretien, débrancher la

cuisinière des sources d'alimentation en gaz et

en électricité, et débrancher tout autre appareil

de la zone d'installation fi nale afi n d'avoir accès

à la cuisinière et de pouvoir réaliser correctement

l'opération d'entretien.

13

Page 37

/ Installation

INSTALLATION

INSTALLATION DE L'APPAREIL

Déballage de la cuisinière

• Retirer tous les matériaux d'emballage de la

paletted'expédition sans toucher à la mousse

postérieure adhésive sur les surfaces en métal

brossé, afi n de protéger la cuisinière des rayures

jusqu'à son installation à son emplacement fi nal.

Ne retirer que le fi lm protégeant les panneaux

latéraux avant de positionner la cuisinière entre

les meubles de cuisine.

• Examiner la cuisinière après l'avoir déballée. En

cas de dommage résultant du transport, ne pas

la brancher. Prendre des photos du dommage

et en informer immédiatement le transporteur.

• Retirer la ou les portes du four. Cela réduira le

poids de la cuisinière.

• Retirer les grilles, plaques et chapeaux des

brûleurs pour faciliter le déplacement de la

cuisinière.

• Avant de la déplacer, protéger le sol pour éviter

tout dommage.

RETRAIT DE LA PORTE DU FOUR

Préparer la porte en vue de son retrait. Insérer la

goupille dans chaque charnière de porte. Fermer

lentement la porte jusqu'à ce que la fi xation

saillante ne bloque le mouvement.

Tirer la porte vers le haut et la retirer.

Ne pas soulever ou tirer la porte par sa poignée !

Cela pourrait endommager les charnières.

14

Page 38

/ Installation

INSTALLATION DES PIEDS

Les cuisinièresBertazzoni ne doivent être utilisées

qu'une fois leurs pieds correctement installés.

Quatre pieds réglables en hauteur sont fournis avec

la cuisinière dans le conteneur en polystyrène placé

sur le dessus de l'appareil.

Avant d'installer les pieds, positionner la cuisinière

à proximité de son emplacement fi nal ; les pieds

ne doivent pas être utilisés pour la déplacer sur de

longues distances.

Après avoir déballé la cuisinière, la soulever

suffi samment afi n de pouvoir insérer les pieds dans

les logements correspondants situés sous l'appareil.

Abaisser lentement la cuisinière pour éviter toute

sollicitation excessive sur les pieds et le matériel de

montage. Si possible, utiliser une palette ou un cric

plutôt que de faire basculer la cuisinière.

Régler la hauteur des pieds au niveau souhaité en

tournant la partie interne du pied. À l'aide d'un niveau,

vérifi er que la surface de cuisson est parfaitement

plane.

INSTALLATION DE LA PROTECTION

FRONTALE DE LA SURFACE DE CUISSON

Afi n d’augmenter l’espace entre le bord frontal de

la surface de cuisson et les brûleurs, il est possible

d’installer une protection frontale pour la surface de

cuisson.

Pour installer la protection frontale:

• Repérer les deux trous de fi xation aux extrémités

de la protection frontale.

• Repérer les deux trous de fi xation sur la face

inférieure de la surface de cuisson.

• Fixer la protection frontale à l’aide de ses deux

vis.

15

Page 39

/ Installation

INSTALLATION DE LA GARNITURE

La garniture doit être installée avant toute

utilisation de la cuisinière afi n de garantir la

ventilation appropriée du compartiment du four.

La garniture est uniquement positionnée sur la

surface de cuisson. Retirer tous les rubans et

matériaux d'emballage avant son installation.

Avant l’installation, portez des gants de sécurité.

INSTALLATION DE LA PROTECTION

ARRIÈRE (EN OPTION)