Bernina L 450 operation manual

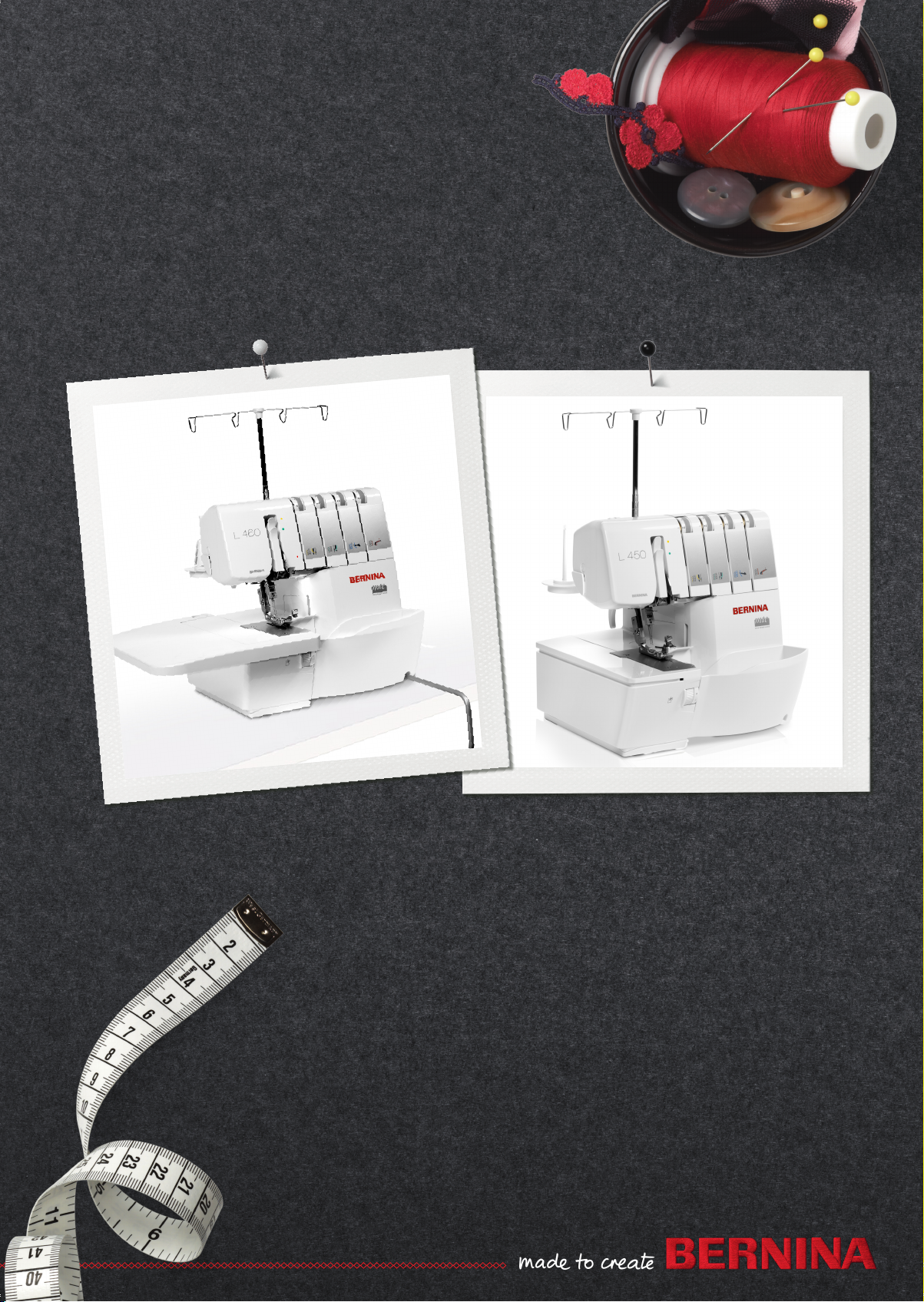

BERNINA L 460 | L 450

Instruction Manual

Safety Instructions 2

Reading Instructions 4

Front view L 450 / L 460 6

Side view L 450 / L460 7

L 450 7

⦁

Accessory 8

Accessory storage in the looper cover 8

Other accessory 8

⦁

Machine Setup 9

Foot control and power cord 9

Cut-offs bin 9

Extension Table (L 450 optional) 10

Retractable Top Thread Guide 10

Spool Stabilizer 11

Operating Instructions 12

⦁

Control elements 12

Power switch 12

Looper cover 12

Sewing table 12

Foot control 13

Needle up/down (L 460) 13

Safety LED L 460 13

Handwheel and handwheel position indicator window 14

Two step presser foot lifter with front foot lift 14

Changing the presser foot 14

FHS Free hand system L 460 15

Changing the needle 15

Needle Inserter 16

Needle Threader 16

Needle pad 16

Knife 17

Thread cutter 17

Seam Guide right 17

⦁

Needle and Thread 18

Needle 18

Needle condition 18

Needle, thread and application table 18

Needle and thread matching 19

Thread selection 19

Adjusting and Setting 20

Stitch length 20

Cutting width 20

Knife suspension 20

mtc Thread control (Micro Thread Control) 21

Presser foot pressure 21

⦁

Differential Feed adjustment 22

Gathering 22

Stretching 22

Threading and Sewing 23

⦁

Stitch overview 23

⦁

Threading - General information 24

Threading preparation 24

Thread pretension 24

Replacing thread spools 24

⦁

4-/3-thread overlock (Stitch No. 1, 3-8, 30) 25

Threading the upper looper (blue) 25

Threading the lower looper (red) 26

Threading the right needle (green) 27

Threading the left needle (yellow) 28

3-thread overlock 29

⦁

Upper looper converter (Stitches 2, 9-15) 29

L 460

L 450

Contents

⦁

Narrow seam, Rolled Hem and Picot stitch

(Stitch 7, 8, 13, 30) 30

recommended thread 30

⦁

Test sewing 31

⦁

Adjusting thread tensions 32

4-/3-thread overlock 32

⦁

Sewing examples 33

Securing a Seam 33

Seam begin 33

Seam end 33

Securing the thread chain 34

Undoing stitches 34

Sewing corners 34

Decorative Effects 35

Differential feed applications 36

Sewing in cord / tape 36

Maintenance 37

⦁

Replacing the upper knife 37

⦁

Cleaning and Oiling 37

⦁

Troubleshooting Guide 38

Optional Accessories 39

⦁

Blind stitch foot 39

⦁

Elasticator Foot 40

⦁

Multi-purpose Foot 41

Piping 41

Pearls along the fabric edge 41

Pearls along a fabric fold. 41

⦁

Gathering foot 42

Appendix 43

⦁

Technical Summary 43

L 450 43

L 460 43

Thread Chart 45

⦁

3-thread overlock (LN) 47

⦁

3-thread overlock (RN) 48

⦁

3-thread flatlock (LN) 49

⦁

3-thread flatlock (RN) 50

⦁

3-thread narrow seam 51

⦁

3-thread rolled hem 52

⦁

2-thread overlock (LN) 53

⦁

2-thread overlock (RN) 54

⦁

2-thread flatlock (LN) 55

⦁

2-thread flatlock (RN) 56

⦁

2-thread rolled hem 57

⦁

2-thread overlock (LN) 58

⦁

2-thread overlock (RN) 59

⦁

3-thread picot stitch 60

1

L 460

L 450

Safety Instructions

Safety Instructions

IMPORTANT INFORMATION

Precautions should always be followed, including

the following:

Read all the instructions before using this machine.

In general when the machine is not in use, it

should be disconnected from the electricity

supply.

DANGER!

As a protection against electrical shock:

1. The machine should never be left unattended

when plugged in.

2. Always unplug this machine from the electrical

outlet after using and before cleaning.

3. LED Radiation. Do not view directly with optical

instruments. Class 1M LED product.

WARNING!

As a protection against burns, fire, electric shock or

injury to persons:

1. Use this machine only for purposes as

described in this manual. Use only attach

ments, accessories and parts recommended

by the manufacturer.

2. Do not allow this machine to be used as a toy.

Close attention is necessary when this machine

is used by or near children. The machine is not

intended for use by persons (and children) with

reduced physical, sensory or mental capabili

ties or lack of experience and knowledge.

Unless they have been given supervision or

instruction concerning use of the machine by a

person responsible for their safety. To ensure

children do not play with the machine they

must be supervised.

Never operate this machine if:

⦁

the cord or the plug are damaged,

⦁

it is not working properly,

⦁

it has been dropped or damaged,

⦁

it has fallen into water.

-

-

3. Return the machine to your local authorized

BERNINA dealer for examination or repair.

4. Never operate the machine with any air open

ings blocked. Keep ventilation openings of the

machine free from the accumulation of lint,

dust and loose cloth.

5. Keep fingers away from all moving parts. Spe

cial care is required around the sewing needle

and the knife.

6. Never insert any objects into any openings on

the machine.

7. Do not use the machine outdoors.

8. Do not operate the machine where aerosol

products (sprays) or oxygen are being used.

9. Do not pull or push the fabric while stitching.

This can result in needle breakage.

10. Switch the machine off «0» when making any

adjustments in the needle area, such as

threading the needle, changing the needle,

threading the looper, or changing the presser

foot.

11. Always unplug the machine from the electrical

outlet when removing covers, when covers are

opened to raise the knife or thread the loopers,

when lubricating or when making any other

user servicing adjustments mentioned in the

instruction manual.

12. Do not use bent needles.

13. Always use the original BERNINA stitch plate.

The wrong stitch plate can cause

needle breakage.

14. This machine is provided with double insula

tion (except for USA and Canada). Use only

original spare parts. See instructions for ser

vicing of double-insulated products.

-

-

-

-

2

Safety Instructions

SERVICING DOUBLEINSULATED PRODUCTS

L 460

L 450

In a double-insulated product two systems of insulation are provided instead of grounding. No

grounding means is provided on a double-insulated

product, nor should a means for grounding be

added to the product. Servicing a double-insulated

product requires extreme care and knowledge of

the system and should be done only by qualified

service personnel. Replacement parts for a dou

ble-insulated product must be identical to the original parts in the product. A double-insulated product

is marked with the words: «Double insulation» or

«Double insulated».

The symbol

may also mark such a product.

-

LIABILITY

No liability will be assumed for any possible damage which arises from misuse of this machine.

This machine is intended for household use only.

This machine meets the European Standard

2004/108/EC concerning the electromagnetic toler

ance.

-

Environmental Protection

BERNINA is committed to the protection

of the environment. We strive to minimize

the environmental impact of our products

by continuously improving product design

and our technology of manufacturing.

When your machine won't be used any

more, dispose this product in an environmentally responsible way according to

the national directive. Do not throw away

this product with your household waste.

In case of doubt, please contact your

local BERNINA dealer.

If the machine is stored in a cold room, it

should be brought to a warm room about

one hour before use.

-

Please find the latest version of your

instruction manual at www.bernina.com

KEEP THESE INSTRUCTIONS SAFE!

3

L 460

L 450

Reading Instructions

DANGER!

Very important!

Risk of injury!

Tips and hints!

L 460

L 450

The tag is not always at the top of the page but

also at the top of the description!

Reading Instructions

Hint for L 450 users

All pictures show the L 460 except for specifically

marked ones.

The operation of the L 450 is identical to the L 460

unless it is specified otherwise.

Hint for US customers

Overlockers as referred to in this manual are widely

called "sergers" in the USA.

All rights reserved

For technical and product improvement reasons, the machine's features, parts and accessory are subject to unannounced

changes and alterations at any time. The included accessories can differ from country to country.

4

L 460

L 450

Welcome

Dear BERNINA customer

Congratulations on your decision to buy the BERNINA overlocker/serger!

It is made to the highest standards and we hope it will give you countless hours of satisfying sewing time. Whether your project is garment sewing, home decoration or even patchwork/quilting, by cutting, sewing and neatening in one fast and smooth operation your

BERNINA overlocker/serger will give your work a professional look.

Your BERNINA L 460 / L 450 is a 4-/3-/2-thread overlocker/serger particularly well suited

for sewing stretch and thin fabrics. Buying a BERNINA overlocker/serger not only allows

you to perform these basic functions to perfection, but furthermore you are supplemented

with many exclusive BERNINA features, making your sewing experience even more joyful. Depending on the actual model such features are the BERNINA Free-Hand System,

electronic motor control for precise sewing, an automatic needle stop and last but not least

the patented "mtc" Micro Thread Control.

Make sure to study this instruction manual in order to get full benefit of all these functions.

Should you require further assistance, your BERNINA dealer will be a good choice to visit.

He also carries a selection of optional accessories, which extends the application range

of your BERNINA overlocker/serger even further. We are happy to welcome you in the

BERNINA sewing family and wish you many hours of happy overlocking/serging and

wonderful sewing experiences with your BERNINA L 460 / L 450.

Peter Horisberger, Product Manager,

BERNINA International AG – CH-8266 Steckborn / Switzerland

5

L 460

L 450

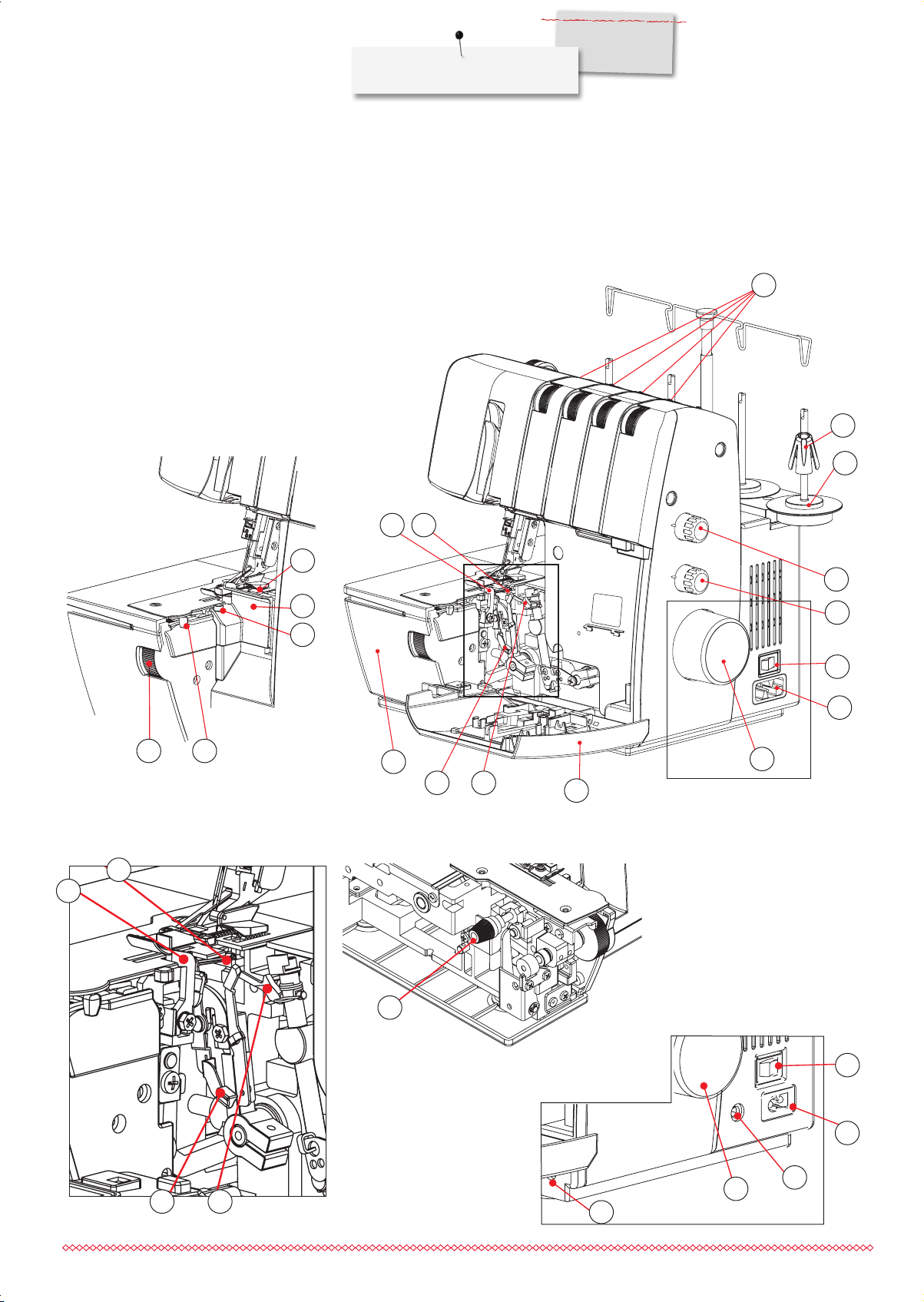

Machine overview

Front view L 450 / L 460

28

25

26

27

987

10

6

5

3

4

3

2

11

12

13

14

15

16

17

1

1 Sewing table

2 Presser foot release lever

3 Needle holder

4 Presser foot lifter

5 Thread Cutter

6 Dual LED Sewing Light

7 Presser foot pressure regulator

8 Retractable Top Thread Guide

9 Thread tension adjustments (yellow)

10 Thread tension adjustments (green)

11 Thread tension adjustments (blue)

12 Thread tension adjustments (red)

13 Thread Guide

14 Threading Chart

15 Thread Guide Looper

16 Handwheel Position Indicator

22

2324

17 Needle Pad

18 Looper Cover

19 Accessories Storage

20 Safety indicator

21 Upper looper

22 Cutting Width dial

23 Presser Foot

24 Stitch Plate

25 Thread Guide Needle Holder

26 Needle Checking Window

27 Set screw

28 Thread Guide

29 Micro Thread Control lever

30 Rolled Hem Selection lever

31 Knife guard

32 Knife

2021

19

33 Lower looper

34 Thread pretension

35 SpoolStabilizer

36 Thread Stand

37 Stitch Length dial

38 Differential dial

39 Power switch

40 Power/Foot Control Socket

41 Handwheel

42 Looper Cover

43 Lower looper threader lever

44 Knife on/off

45 Cutting Width Indicator

46 Power Control Socket

47 Foot Control Socket

48 Kneelifter Socket

18

6

Side view L 450 / L460

L 460

L 450

Machine overview

34

35

36

32

33

22

29

45

31

30

32

33

37

38

39

40

1

2143

42

L 450

41

44

39

L 460

46

2143

48

41

47

7

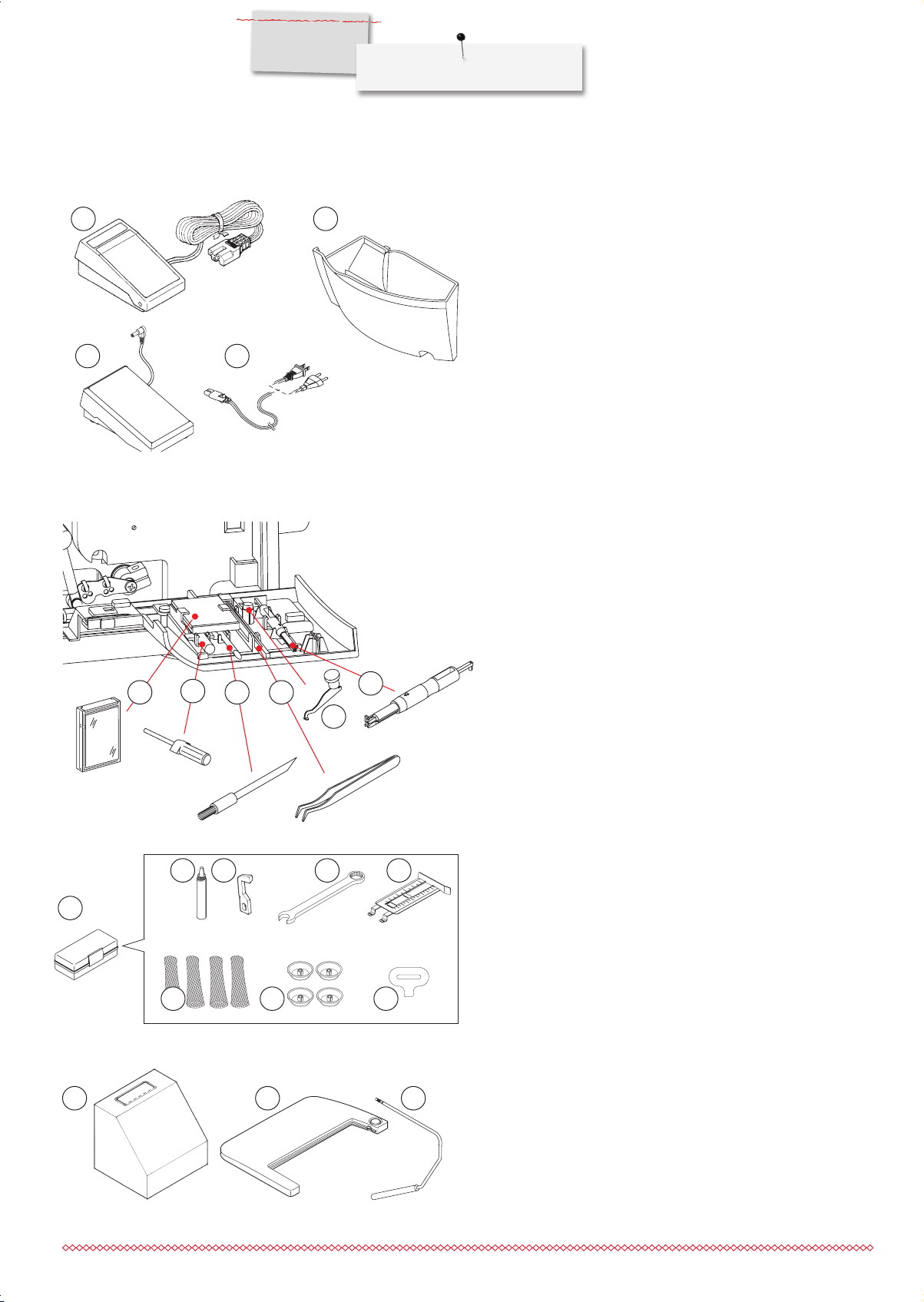

Accessory

L 460

L 450

Machine overview

1

4

1 Foot Control / Power Cord (L 450)

(Typ YC-483N for 230V or YC 482E for 120V)

2 Foot Control (L 460 - BERNINA Typ LV 1)

3 Power Cord (L 460)

4 Cut-offsbin

2

3

Accessory storage in the looper cover

5 Needle set 130/705H (2x No.70, 3x No.80)

6 Hexagon screw driver (1.5 mm)

7 Brush

8 Tweezers

9 Upper looper converter

10 Needle Threader / -Inserter

6

7

5

1312 14

11

16

19 20 21

8

17

10

9

15

18

Other accessory

11 Accessory box

12 Oiler

13 Spare knife

14 Screw driver

15 Seam Guide right

16 Spool net (4x)

17 Thread cap (4x)

18 Screw driver

19 Dust cover

20 Extension Table (L 450 optional)

21 Kneelifter (FHS) (L 460)

8

Machine Setup

Foot control and power cord

L 460

L 460

L 450

Machine Setup

Connection for L 460

⦁

3

2

1

Insert the plug of the foot control into the respective sockets (1).

⦁

Insert the plug of the power cord into the respective sockets (2).

⦁

The power switch (3) turns the machine and the sewing light

on/off.

1 Foot Control Socket

2 Power Control Socket

3 Power switch

L 450

Cut-offs bin

3

Connection for L 450

⦁

Insert the plugs of the foot control / power cord into the respective sockets (4).

⦁

4

Insert the power plug into the wall outlet.

⦁

The power switch (3) turns the machine and the sewing light

on/off.

3 Power switch

4 Power/Foot Control Socket

Polarized plug information (Canada/USA only)

Polarized plug information (Canada/USA only) This appliance has

a polarized plug (one blade wider than the other). This plug will fit

in a polarized outlet only one way to reduce the risk of electrical

shock. If the plug does not fit fully in the outlet, reverse the plug. If

it still does not fit, contact a qualified electrician to install the proper

outlet. Do not modify the plug in any way.

A

Make sure that the looper cover is closed before

you attach the cut-offs bin.

1

Clip the cut-offs bin into the openings on the looper cover. It

catches the cutoff fabric as you sew. This keeps your working area

B

C

2

neat and tidy.

⦁

Position the connection bar (2) in the opening (C). Insert the

two pins (1) into the respective openings (A,B) and let it snap

into place.

⦁

When storing the machine, leave the cut-offs bin attached for

storing the foot control.

1 Upper pins

2 Lower pin

9

L 460

L 450

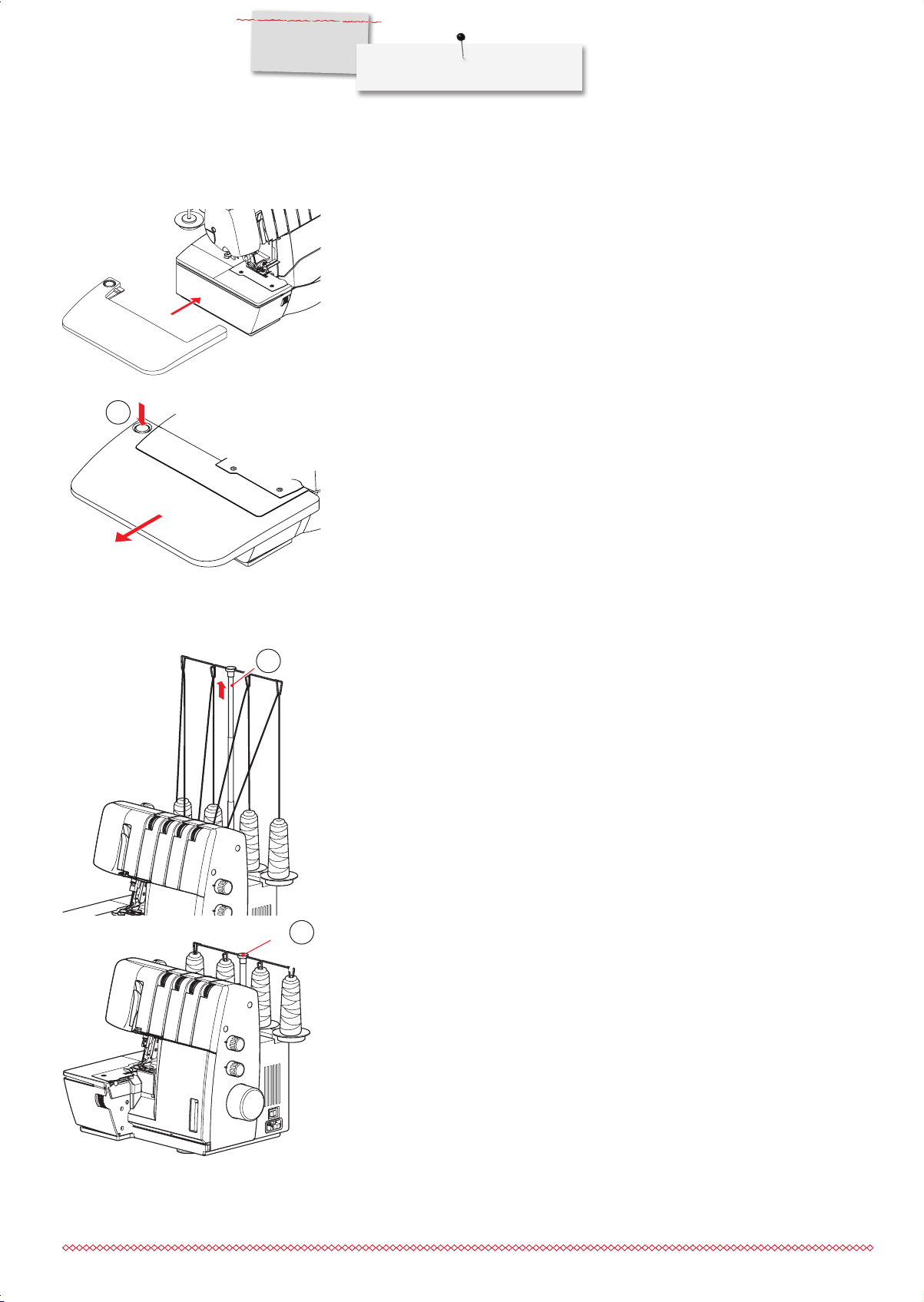

Extension Table (L 450 optional)

1

Machine Setup

The extension table provides a large working surface for your sewing projects.

⦁

To attach, slide the extension table from the left side horizontally along the ditch until

it engages.

⦁

To remove, slide the table to the left side while pushing the release button at the back

of the table.

1 Release button

Retractable Top Thread Guide

1

⦁

⦁

⦁

⦁

1 Thread Guide

1

Pull up the retractable thread stand fully, turning it slightly until the two positioning pins

engage. This will align the Thread Guide (1) parallel to the Thread Stand.

Make sure the lower part of the telescopic support rod (2) is pulled out of the housing

all the way to achieve the optimum height.

When storing the overlock machine, the base of the retractable thread stand can be

pushed back into the housing.

For transportation the thread guides hold the thread spools in place by bringing down

the stand as illustrated.

10

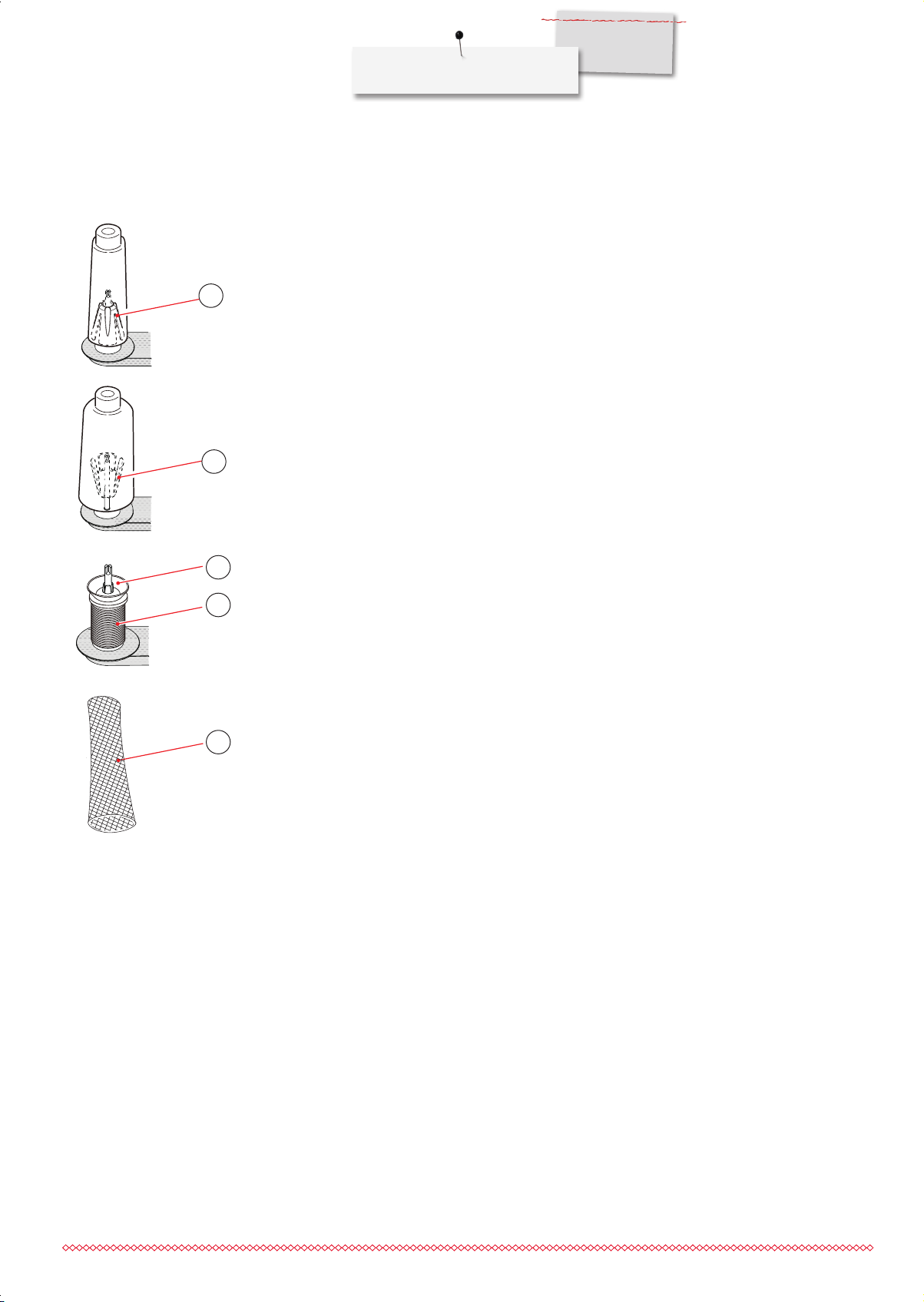

Spool Stabilizer

L 460

L 450

Machine Setup

Spool stabilizer for cones

With small cones the Spool stabilizer (1) is used with the narrow end upwards.

With large cones the Spool stabilizer (2) is used with the narrow end downwards.

1

2

3

4

Spool caps for domestic type spools

For standard type spools, use the spool cap (3).

Spool net

Polyester or bulky nylon threads become loose while unwinding. To keep consistent feeding of such threads, pull the spool net over the spool.

1 small thread cone with Spool stabilizer

2 large cone with Spool stabilizer upside down

3 Spool cap

4 Thread spool

5 Spool net

5

11

L 460

L 450

Operating Instructions

Control elements

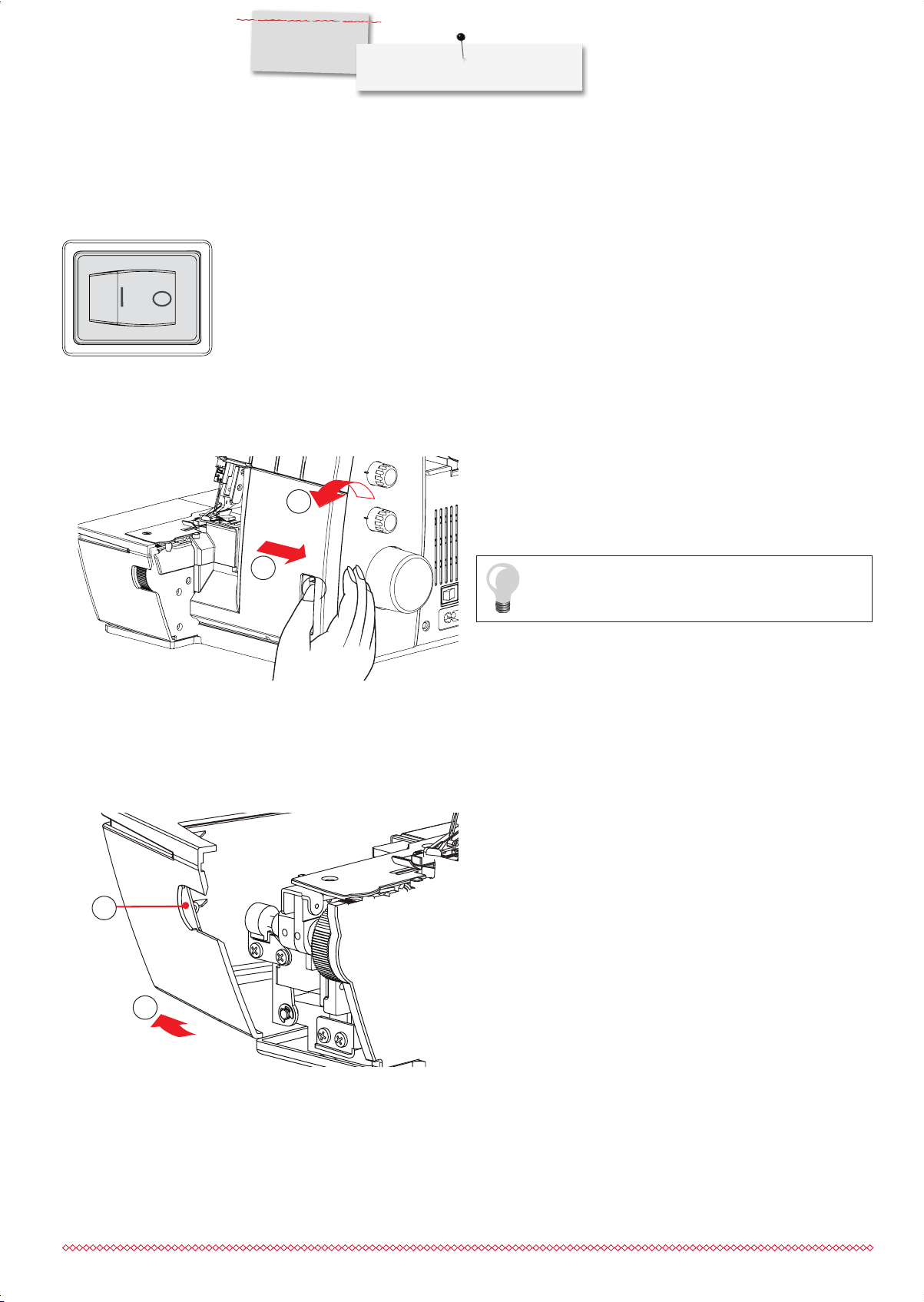

Power switch

Looper cover

Operating Instructions

The power switch controls both the machine power and the sewing light. When leaving the

machine unattended, or servicing the machine, switch the machine off, and remove the

power cord from the wall outlet.

⦁

To open the looper cover, pull it to the right and flip it downwards.

2

⦁

To close the looper cover, flip it upwards and push it to the left.

It engages automatically.

Sewing table

1

2

1

1

1 Grip on the sewing table

2 Opening the sewing table

The cut-offs bin needs to be removed before the looper

cover is opened.

⦁

To open the sewing table, hold onto the grip near the cutting

width dial (1) and push it to the left (2).

⦁

To close the sewing table, swivel it to the right until it engages.

12

Foot control

Needle up/down (L 460)

L 460

L 450

Operating Instructions

⦁

The pressure on the foot control regulates the sewing speed.

L 460

Safety LED L 460

L 460

After sewing, the needle always stops at its highest position.

⦁

Adjust the up/down position of the needle by sinking the heel back on the foot control.

When the Safety LED is activated, the machine will not run.

Reasons and actions:

►

The looper cover is open.

⦁

Make sure that the looper cover is closed properly.

►

The sewing table is open.

⦁

Make sure that the sewing table is closed properly.

►

The presser foot is up

⦁

Make sure that the presser foot is lowered properly. Do not lift the presser foot

while the machine is in operation.

If overheating should occour, the motor will be cut off and the Safety LED will flash.

►

Switch off the machine for 10 - 15 Minutes to cool down. Afterwards sewing can be

continued.

13

L 460

L 450

Operating Instructions

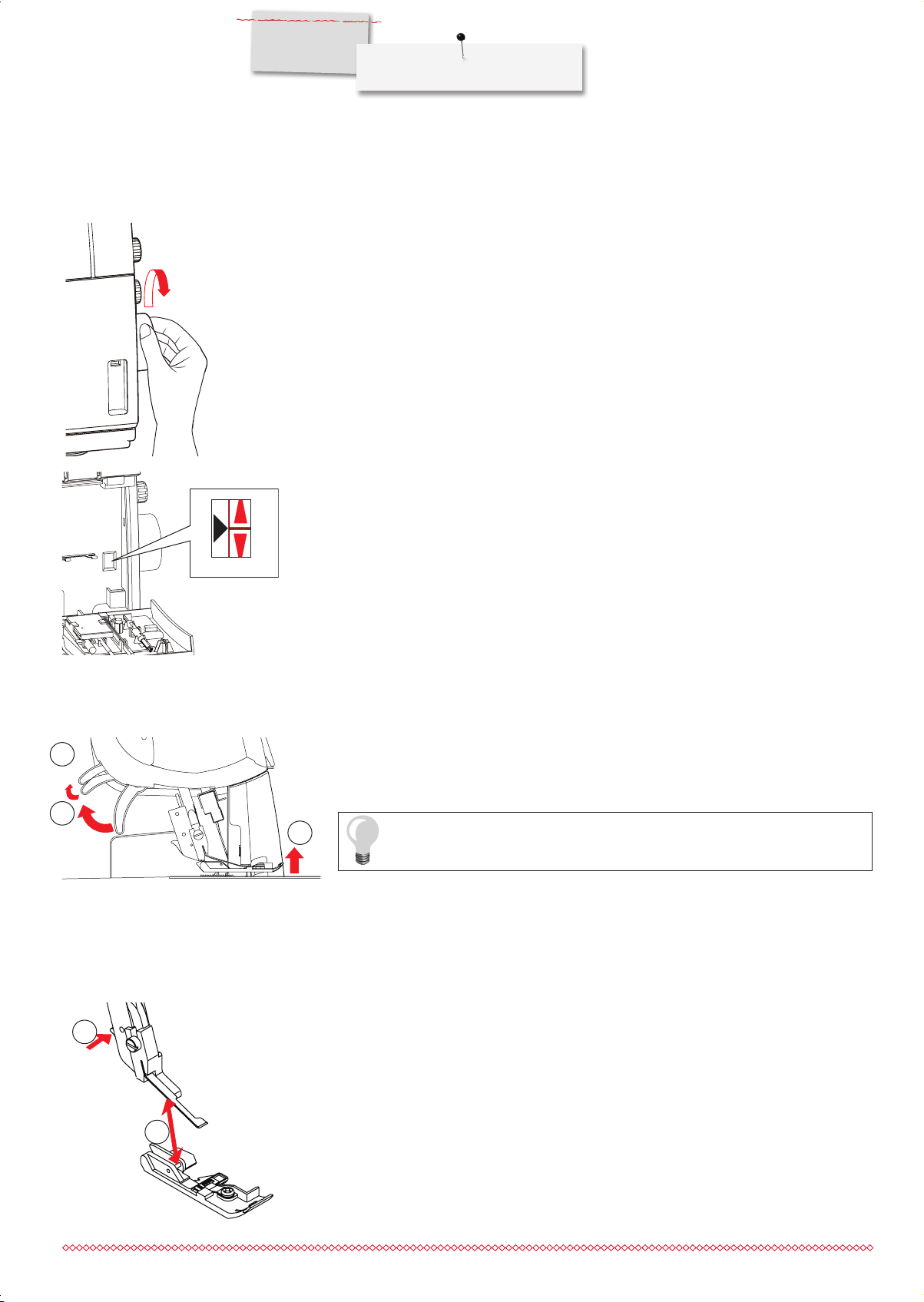

Handwheel and handwheel position indicator window

⦁

The handwheel turns counter-clockwise.

⦁

Open the looper cover to check the handwheel position indicator. Then set the handwheel to threading position.

►

With the L 460, the needle stops at threading position automatically after sewing.

⦁

The needle and the looper are at the threading position (high), when the red bar on

the handwheel is aligned with the black triangle in the handwheel position indicator.

Two step presser foot lifter with front foot lift

⦁

2

1

3

To raise the presser foot, push up the presser foot lifter until it engages (1).

⦁

Press the presser foot lifter even further (2) for an extra raise of the presser foot and

to lift the tip (front foot lift).

1 Lifter position 1

2 Lifter position 2

3 Front foot lift

As soon as the presser foot is lifted, the thread tension discs release automatically and allow safe threading.

Changing the presser foot

4

5

14

Make sure that the needle is in the highest position.

⦁

Raise the presser foot.

⦁

Press the presser foot release lever (4) to release the presser foot and remove it.

⦁

To attach the foot, place it under the shaft.

⦁

The groove in the shaft must line up exactly with the presser foot pin (5).

⦁

Lower the shank and the presser foot engages.

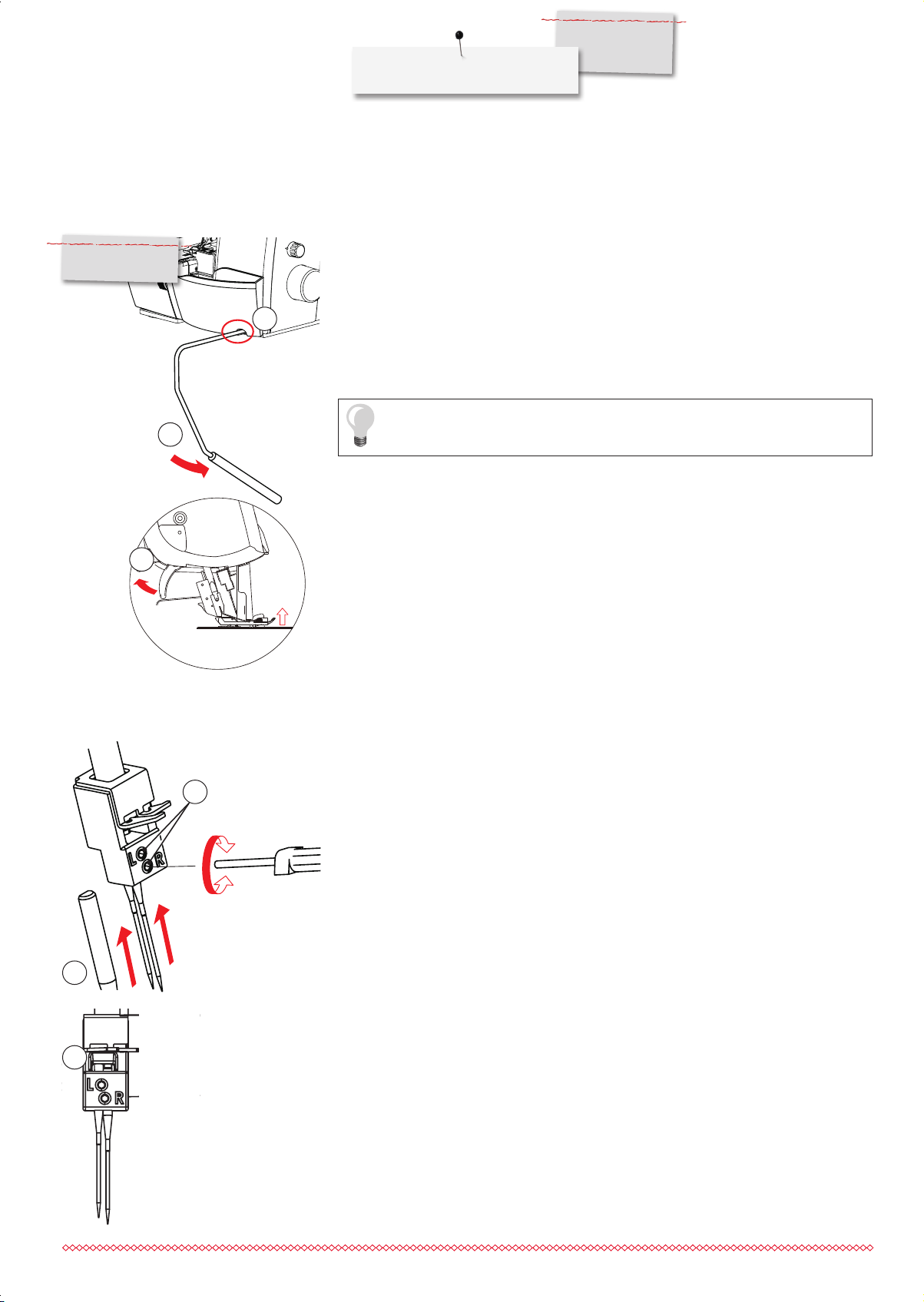

FHS Free hand system L 460

L 460

2

L 460

L 450

Operating Instructions

The Free Hand System lever allows raising the presser foot without using the hands.

⦁

Insert the FHS lever into the FHS Connection (1).

⦁

Pushing the FHS lever to the right with the knee (2) raises the presser foot.

⦁

Wurde der Nähfuss mit dem Nähfussheber angehoben (3), kann er mit dem Kniehebel

gesenkt werden, in dem dieser ganz nach rechts gedrückt und langsam losgelassen

1

wird.

Die seitliche Position des Kniehebels kann durch ein BERNINA-Fachgeschäft

etwas angepasst werden.

3

Changing the needle

1

1 Kneelifter Socket

2 Operating direction

3 Raising the presser foot

⦁

Lower the presser foot.

⦁

Raise the needle bar to its highest position by turning the handwheel counter-clockwise.

⦁

Loosen the needle set screw and remove the needle. In doing so, use the 1.5mm hex

screw driver which is provided in the looper cover.

⦁

Insert the new needle (flat side to the back) into the needle holder and push it all the

way up. Use the needle checking window (3) to check the needle position.

⦁

Tighten the set screw.

1 Set screws

2 Needle (flat side to the back)

3 Needle checking window

2

3

Use needles of the system 130/705H. „Needle and Thread“ see page 18.

15

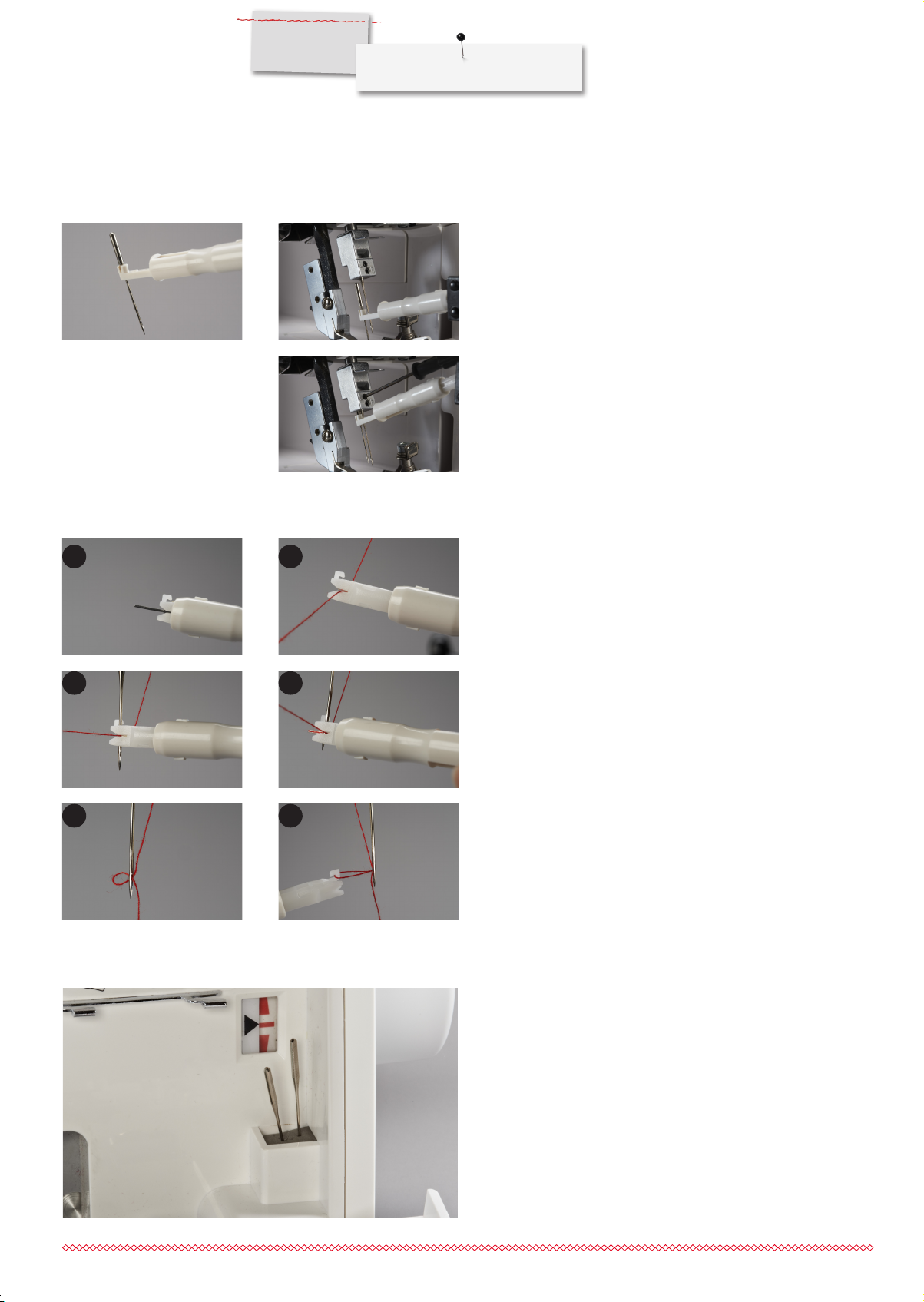

Needle Inserter

L 460

L 450

Operating Instructions

To handle the needle conveniently use the Needle Threader /

-Inserter which is provided in the Accesssories Storage.

⦁

Sliding the Needle Inserter over the needle before loosening

the set screw avoids dropping the needle.

⦁

The new needle is held in place by the Needle Inserter while

inserting and tightening the screw.

Needle Threader

C D

E F

BA

Threading the needle

A Metal rod in Y-shaped threader

B Hold the needle threader with the triangle shaped mark

upwards and guide the thread horizontally through the

Y-shaped slot.

C While gently pulling the thread end, push the nose of the nee-

dle threader onto the needle shaft and start sliding down.

Please Note: Push the Threader only gently towards the needle in order not to damage the metal rod.

D When having reached the needle eye, push, so that the metal

rod slides through the eye, taking along the thread.

E By slowly retracting the needle threader, a thread loop will be

left behind the needle.

F Pull the thread end completely through the eye and place the

thread end under the presser foot.

Needle pad

16

In the convenient needle pad you can store needles temporarily if

only one of them is used or if special needles are inserted.

Knife

1

L 460

L 450

Operating Instructions

Deactivating the knife

⦁

Open the sewing table and the looper cover.

⦁

Press the knife activating knob on/off (1) und turn clockwise (2) until the knife engages

at the lower position.

⦁

Close the sewing table and the looper cover.

2

3

Activating the knife

⦁

Open the sewing table and the looper cover.

⦁

Press the knife activating knob on/off (1) und turn counter-clockwise (2) until the knife

engages at the upper position.

⦁

Close the sewing table and the looper cover.

When working with lowered knife, make sure that the fabric edge is not wider

than the selected cutting width. Otherwise the upper looper and the needle can

be damaged.

Thread cutter

Seam Guide right

⦁

After sewing, bring the thread up and pull it over the cutter from back to front.

⦁

Pull the thread down to cut it.

⦁

The chain of thread will be clamped in the thread cutter to be ready for the next piece

of fabric.

⦁

Open the sewing table.

⦁

Attach the Seam Guide by adjusting the two hooks on the right

side to the Stitch Plate and then push the Seam Guide down to

the left.

⦁

Sliding the fabric along the right side of the guide provides

constant a cutting distance from the raw edge of the fabric.

⦁

The cutout (3) in the center of the lower mounting bar indicates

the position of the left needle. Scales are provided in mm (1)

and inches (2).

1

1 Scale in mm

2 Scale in inches

2

3

3 Cutout

17

Needle and Thread

Needle

Needle condition

L 460

L 450

Operating Instructions

This overlocker is prepared to hold needles of the system 130/705H (standard household

needles, equivalent to HAx1 of the system 15x1 H).

For standard applications use universal needles of the sizes No.70-90 (equivalent to

10-14 in the US).

For fine jersey or delicate stretchy fabric use medium ballpoint needles 130/705 H-S or

SUK (equivalent to HAx1SP, JLx2 or ELx705).

Needles must be in perfect condition to achieve best sewing results. Please check the

needles before each sewing project. Defective needles may not only damage the sewing

project, but can also damage the overlocker.

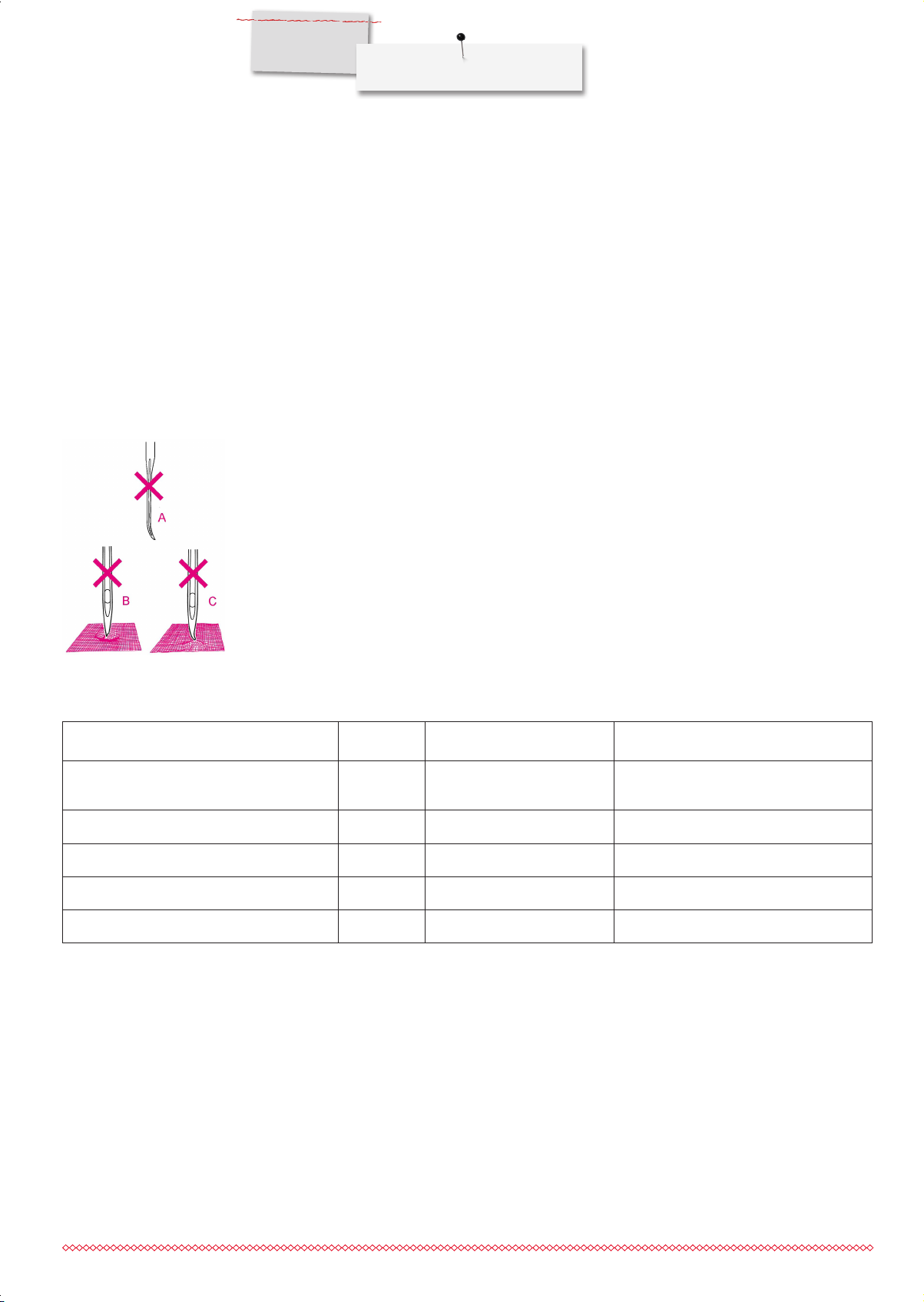

Needles must not be:

A bent or crooked

B damaged or blunt

C have hooked points

Needle, thread and application table

Thread Needle Where Application

All purpose overlock thread

120/2 (polyester)

Polyester sewing thread 80-90 Needles and loopers Seam in all fabrics

Spun polyester Loopers only Neatening edges

Bulked threads (Wooly Nylon) Loopers only Soft seams in knits, rolled hems

Embroidery/darning and decorative threads Loopers only Neatening edges, rolled hems, flatlocks

70-90 Needles and loopers For all overlock stitches

18

Loading...

Loading...