Berkel C32 Manuel de service

SERVICE MANUAL

Food Processer

CC34

B32

C32

A product of Berkel

- NOTICE -

This Manual is prepared for the use of trained Berkel Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Berkel Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Berkel Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Berkel, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

F25264 (0116)

Food Processer

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

SPECIFICATIONS ...................................................................................... 3

CLEANING PROCEDURES ............................................................................. 3

OPERATION ........................................................................................... 3

TOOLS ................................................................................................. 3

LUBRICATION ......................................................................................... 3

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 4

BASE AND TOP HOUSING ............................................................................. 4

MOTOR ................................................................................................ 4

CONTROL BOARD ..................................................................................... 5

KNIFE SHAFT .......................................................................................... 5

MAGNETIC SAFETY SWITCH .......................................................................... 7

SPEED CONTROL SWITCH ............................................................................ 7

ROTARY SWITCH ...................................................................................... 8

MICROSWITCH ........................................................................................ 8

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 10

ELECTRICAL CONTROLS TEST PROCEDURES ...................................................... 10

MOTOR TEST ........................................................................................ 10

ELECTRICAL OPERATION ................................................................................ 11

COMPONENT FUNCTION ............................................................................ 11

COMPONENT LOCATION ............................................................................. 11

WIRING DIAGRAM .................................................................................... 12

TROUBLESHOOTING ..................................................................................... 13

TROUBLESHOOTING ................................................................................. 13

© BERKEL 2016

F25264 (0116) Page 2 of 13

Food Processer - GENERAL

GENERAL

INTRODUCTION

This manual covers Models CC34, B32, and C32

Food Processors.

SPECIFICATIONS

Operating voltage 100-120/50-60/1

Current 10 amps

CLEANING PROCEDURES

Never clean machine with a high pressure hose, with

steam injection equipment or in a dishwasher.

Detailed cleaning procedures are included in

Instruction manual for this model.

OPERATION

Start-up Test

1. With the feeder, any cutting tools, and ejector

plate removed, check that the machine will not

start when variable speed control is in I, II, or P

position.

LUBRICATION

Chevron FM ALC EP - 2 used in bowl drive gear case.

2. With feeder on machine base, check that the

machine stops when feeder handle is raised and

re-starts when feeder handle is lowered, with

variable speed control in I, II, or P position.

3. Check that shaft stops rotating within four

seconds when feeder handle is lifted and variable

speed control is in II position.

Detailed operation procedures are included in the

Instruction manual for this model.

TOOLS

• Standard set of hand tools

• Set of Torx drivers

• VOM with measuring micro amp current tester.

Any VOM with minimum of CAT III 600V, CE

certified. Sensitivity of at least 20,000 ohms per

volt can be used. In addition, meter leads must

also be a minimum of CAT III 600V.

• Loctite® No. 222

Page 3 of 13 F25264 (0116)

Food Processer - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

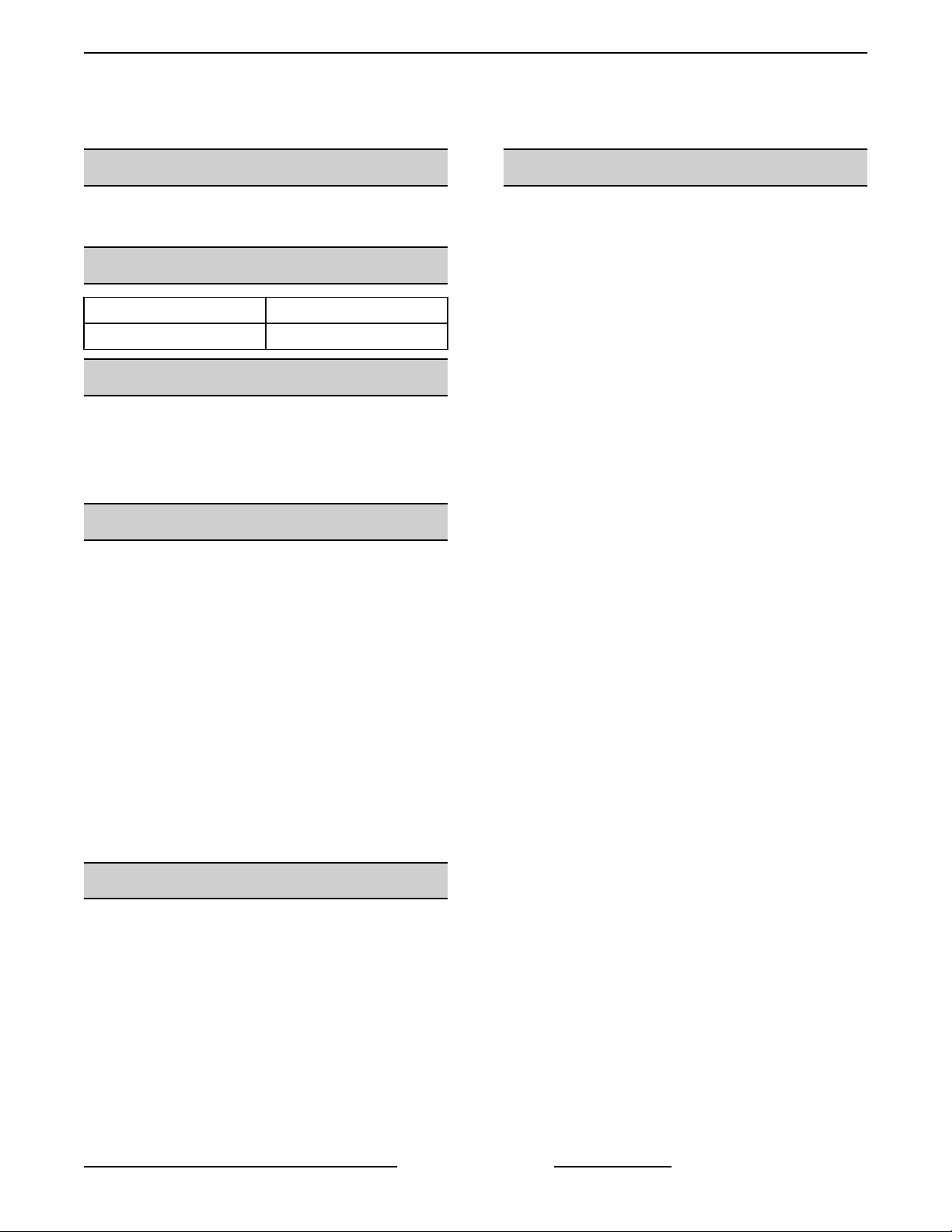

BASE AND TOP HOUSING

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove cutter/mixer bowl or feeder attachment.

2. Position unit on blocks as shown to protect knife

shaft from damage during disassembly.

3. Remove four screws and base housing from top

housing.

Fig. 2

5. Remove screws from motor mounting bracket

and lift motor from housing.

Fig. 1

4. Install in reverse order of removal.

MOTOR

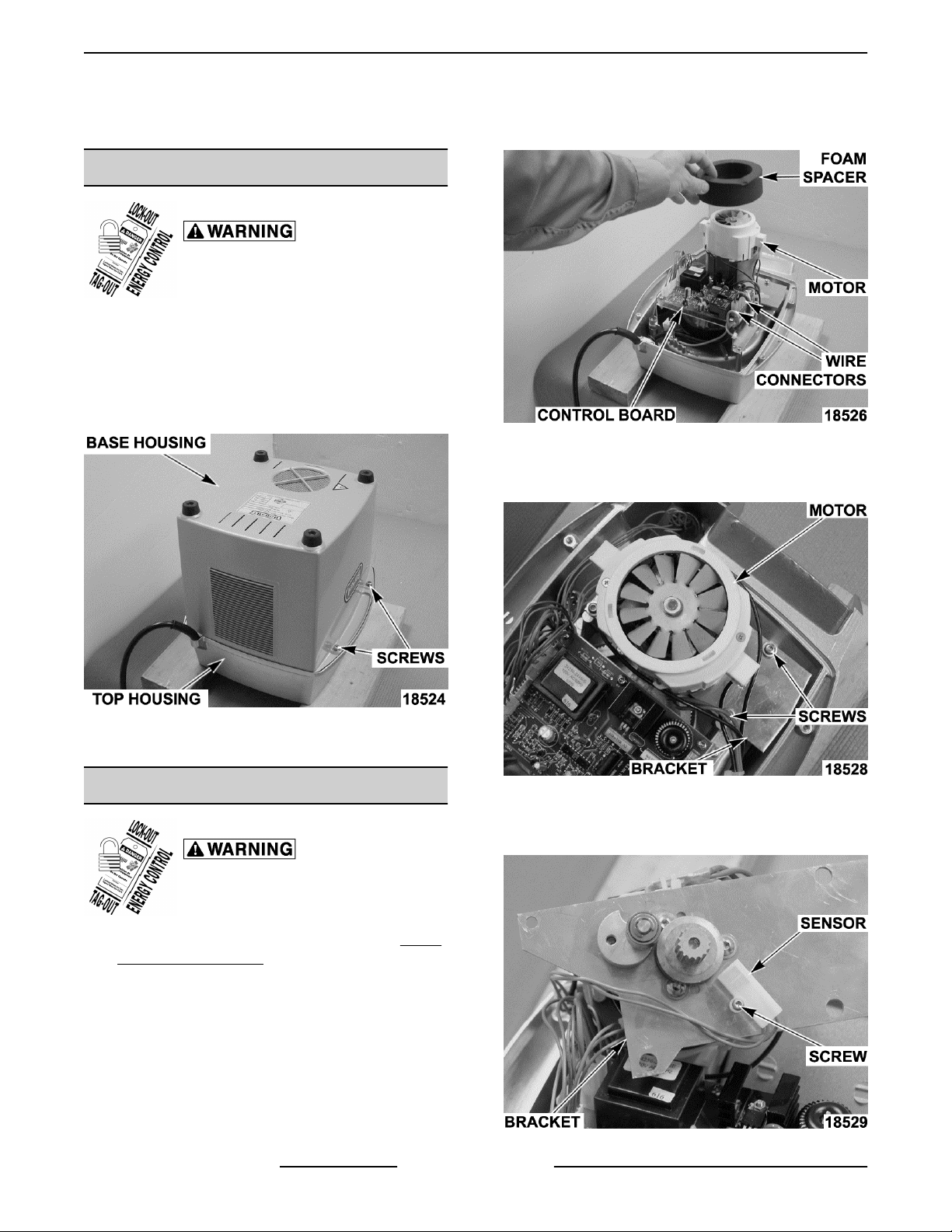

6. Carefully turn motor and bracket over to remove

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove base housing as outlined under BASE

AND TOP HOUSING.

2. Tag and mark all wires.

3. Remove foam spacer from motor.

4. Remove four wire connectors from control board.

F25264 (0116) Page 4 of 13

Fig. 3

the Torx screw and sensor.

Fig. 4

Loading...

Loading...