Berchtold Elektrotom 610 Service manual

ELEKTROTOM® 610

Service Manual

Valid from version 1132

2

ELEKTROTOM® 610 Service Manual

Contents

Page

1. Introduction

5

2. Routine checks following delivery

5

3. Initial installation

5

4. First usage

6

5. Important notes for safe usage

6

6. Surgical indications

6

7. Principles of electrosurgery and techniques

6

8. Function of the ELEKTROTOM® 610

6

- 13

8.1

Current types for 2 cutting modes with differing effects

6

- 7

8.2

Current types for 2 monopolar coagulation modes with differing effects

8

- 10

8.2.1

Forced Coagulation

8 8.2.2

Soft Coagulation

8

- 10

8.3

Bipolar Coagulation

10

- 11

8.4

Safety relevant function

11

- 13

8.4.1

Computer supported safety features

11 8.4.2

Neutral electrode monitoring

11

- 13

8.4.3

Protection against unit malfunction

13

8.4.4

Protection against erroneous unit settings

13

9. Operating of the ELEKTROTOM® 610

14

- 18 9.1

Push buttons and signal lights

14

- 18

9.1.1

The front of the ELEKTROTOM® 610

14 9.1.2

The rear of the ELEKTROTOM® 610

15

9.1.3

Description of the push buttons and symbols

16

- 18

10. Commissioning

18

- 19 10.1

HF currents interference

18

- 19

10.2

Using multiple functions

19

11. Visual and functional checks before each use

19

12. Cleaning, disinfection and sterilisation

20

12.1

Cleaning and disinfection of the unit

20 12.2

Cleaning, disinefection and sterilisation of accessories

20

13. Repairs

20

- 21

13.1

Replace of fuses

21

14. Technical safety controls

21

- 22

15. Guarantee

22

3

ELEKTROTOM® 610 Service Manual

Contents

Page

16. Technical description

22

- 24 16.1

Technical Data

22

- 23

16.1.1

Mains connection

22

16.1.2

HF current output and current characteristics

22

- 23

16.2

Safety relevant data

24 16.3

Provision for man / machine communication

24 16.4

Dimensions and weight

24 16.5

Certification

24

17. Power output diagram

25

- 29 17.1

Power output in relation to resistance (output characteristic)

25

- 27

17.1.1

Current type CUT I

25 17.1.2

Current type CUT II

25 17.1.3

Currents type FORCED COAGULATION

26 17.1.4

Currents type SOFT COAGULATION

26 17.1.5

Current type BIPOLAR COAGULATION

27 17.2

Peak voltage in relation to power regulator

27

- 29

17.2.1

Current type CUT I

27

17.2.2

Current type CUT II

28 17.2.3

Currents type FORCED COAGULATION

28 17.2.4

Currents type SOFT COAGULATION

29 17.2.5

Current type BIPOLAR COAGULATION

29

18. Function and connection diagram

30

- 31

18.1

Block diagram

30

18.2

Circuit diagram

30 18.3

Connection figure

31

19. CPU board

32

- 33 19.1

Circuit diagram

32 19.2

Block diagram

32

19.3

Layout CPU board

33

20. Switch mode power supply (SMPS)

34

- 36 20.1

Block diagram SMPS

34 20.2

Block diagram control board

34 20.3

Layout SMPS

35 20.4

Layout control board

36

21. Key board and LED controller

37

- 38 21.1

Block diagram

37 21.2

Circuit diagram front panel

37 21.3

Layout, components side

38 21.4

Layout,. soldered side

38

4

ELEKTROTOM® 610 Service Manual

Contents

Page

22. Low voltage power supply

39

22.1

Block diagram

39 22.2

Layout

39

23. Self test

40

23.1

Power on test

40

23.2

Stand-by test

40

23.3

Online test

40

24. Trouble shooting and corrective actions

40

- 43 24.1

Error list

40

- 43

24.2

Circuit compensation

43

25. Service adjustments

43

- 44

25.1

Changing the mains voltage

43

- 44

25.1.1

Switch to 110 V

43 25.1.2

Switch to 220 V

44 25.2

Switch mode power supply and power generator

44 25.2.1

Handle and footswitch module

44 25.2.2

NE module

44

26. Switch mode power supply (SPMS) sensor

45

- 46 26.1

Short circuit

45 26.2

SMPS voltage sensor

46

27. Switch mode power supply and power generator

46

- 47

27.1

Adjusting the Impedance sensor

46

27.2

Adjustments in the NE module

46 27.3

Changing the mains voltage 110/220 V

46 27.4

Handle and footswitch adjustments

46 27.5

Adjustments on the switch mode power supply and the power generator

47

28. Switch mode power supply controller

48

- 49

28.1

Checking the switch mode power supply without CPU control

48

28.2

Enabling CPU control – PWM 1kHz signal

48 28.3

Adjusting the “Short circuit” current sensor

48 28.4

Adjusting the SMPS controller

49

5

ELEKTROTOM® 610 Service Manual

1.

Introduction

Electrosurgery belongs to the most important energy applications in surgery. In all surgical disciplines, it remains

the most effective means of combining tissue cutting and haemostasis. The electrosurgical unit, the

ELEKTROTOM® 610 electrosurgical unit is a modern instrument combining economy with a considerable degree of operative flexibility. The unit has the capable output of 100 Watts.

Particularly important features of the ELEKTROTOM® 610 include:

•

Enhanced user simplicity and safety via integrated microprocessor technology

•

Two current types offering excellent cutting qualities combined with simultaneous haemostasis

•

Bipolar coagulation with up to 50 Watts output

•

Effective, contact coagulation with 60 Watts output for both

•

User friendly control panel with foil covered pressure pads and digital read-out display

•

The highest degree of safety using modern, negative electrode monitoring technology, for both single and split

neutral electrodes

•

A malfunction, error code display system, showing user information and offering assistance during service and

repair procedures

These and other advantages of the ELEKTROTOM® 610 will be discovered when studying these instructions for

use and employing the correct accessories and features of the unit in the manor for which they have been developed.

2.

Routine checks following delivery

The product and accessories should be inspected for possible transport damage or other defects immediately on

arrival.

Reclamation regarding damage or defects can only be entertained by the selling organisation (BERCHTOLD

GmbH & Co.) or the delivering agency when they are immediately reported. In case of complaint, the forwarding

agent or the BERCHTOLD sub-agency must immediately be informed, prior to the submission of a damage /

deficiency report to the BERCHTOLD main offices in Germany for further processing by our insurance agents.

When returning a unit or one of its components to BERCHTOLD or to a BERCHTOLD service centre, every

effort should be made to use the original packaging material. The following information/documentation must also

accompany the returned items: Name and address of the owners, product identification number (see plate affixed

to unit), detailed description of the defect.

6

ELEKTROTOM® 610 Service Manual

3.

Initial installation

The unit is intended for use only in a medical environment and connection to the mains must be in accordance

with the IEC 364-710 regulations. Further, connection to the mains should be via a suitably protected socket using

the mains lead and plug provided by the manufacturer or one of an equivalent quality. For safety reasons, extension leads or multi-socket connections should not be used. The mains socket must be protected by a fuse rated at

not less than 10 Amperes.

The ELEKTROTOM® can be placed on any flat surface with a tilt angle not in excess of 10°. The surface itself

should be equivalent in size to that of the unit. Care must be taken not to block the air vents on the underside of

the generator and ensure a free flow of air around the unit. The ELEKTROTOM® should be protected from the

danger of fluids entering the unit.

The generator is at intracardiac interventions supplied with a cable to balance earth potential. This should be connected to the appropriate connector in the operating theatre in order to avoid 'static' shocks when handling various apparatus.

For intracardiac surgery this equipment must be connected to the main power stabiliser in the operating room or

location where it is installed by means of the (yellow/green) power-stabilisation cable supplied.

4.

First usage

Before the unit is first used surgically, the Manufacturer or their official agent shall:

a) have fully tested the unit in the position in which it is to be used;

b) have given full operational instructions for the unit to a responsible person.

5.

Important notes for safe usage

Please see Operating instructions ELEKTROTOM® 610.

6.

Surgical indication

Please see Operating instructions ELEKTROTOM® 610.

7.

Principles of electrosurgery and techniques

Please see Operating instructions ELEKTROTOM® 610.

8.

Functions of the ELEKTROTOM® 610

8.1 Current types for 2 cutting modes with differing effects

The ELEKTROTOM® 610 provides a choice of 2 cut modes (see page 20):

•

Cut I: pure cut with no coagulation (push button 5)

•

Cut II: cut plus coagulation (blend) (push button 6)

7

ELEKTROTOM® 610 Service Manual

The unit output, and subsequent cutting power, can be varied between 5 and 100 Watts, in 5 Watt increments,

using the up/down push buttons 9 and 10. Regardless of the cutting speed, electrode geometry or tissue resistance,

the actual generated power is automatically controlled to be optimal for the procedure being undertaken.

8

ELEKTROTOM® 610 Service Manual

An integrated microprocessor permanently monitors and adjusts, within milliseconds, the unit output to accommodate varying tissue resistance.

The following active electrodes of varying diameter may be used for cutting: Needle electrodes, knife electrodes,

lancet electrodes, wire sling or loop electrodes and the broader, bangle electrodes.

The appropriate active electrode form should be selected to meet the intended cutting function.

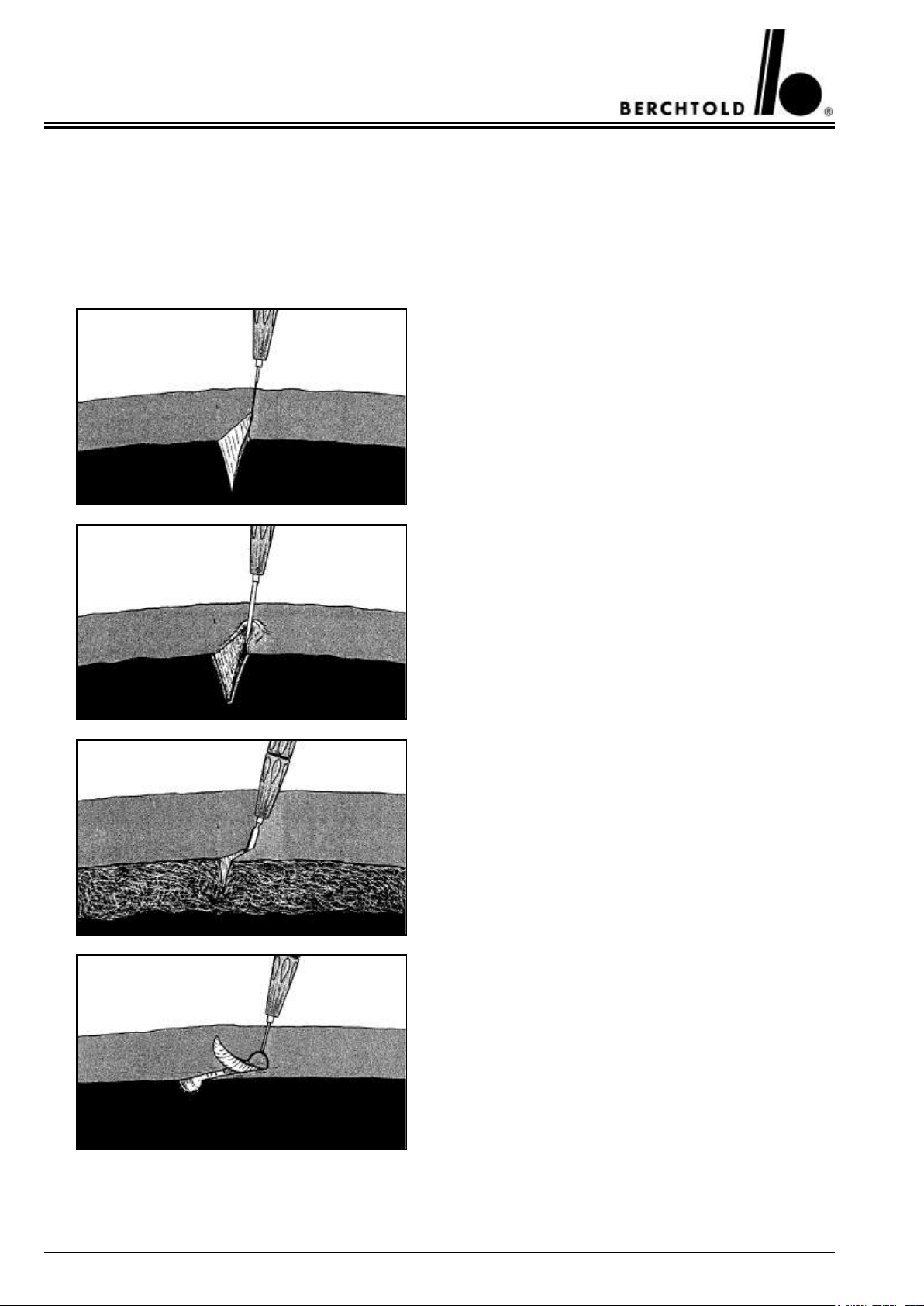

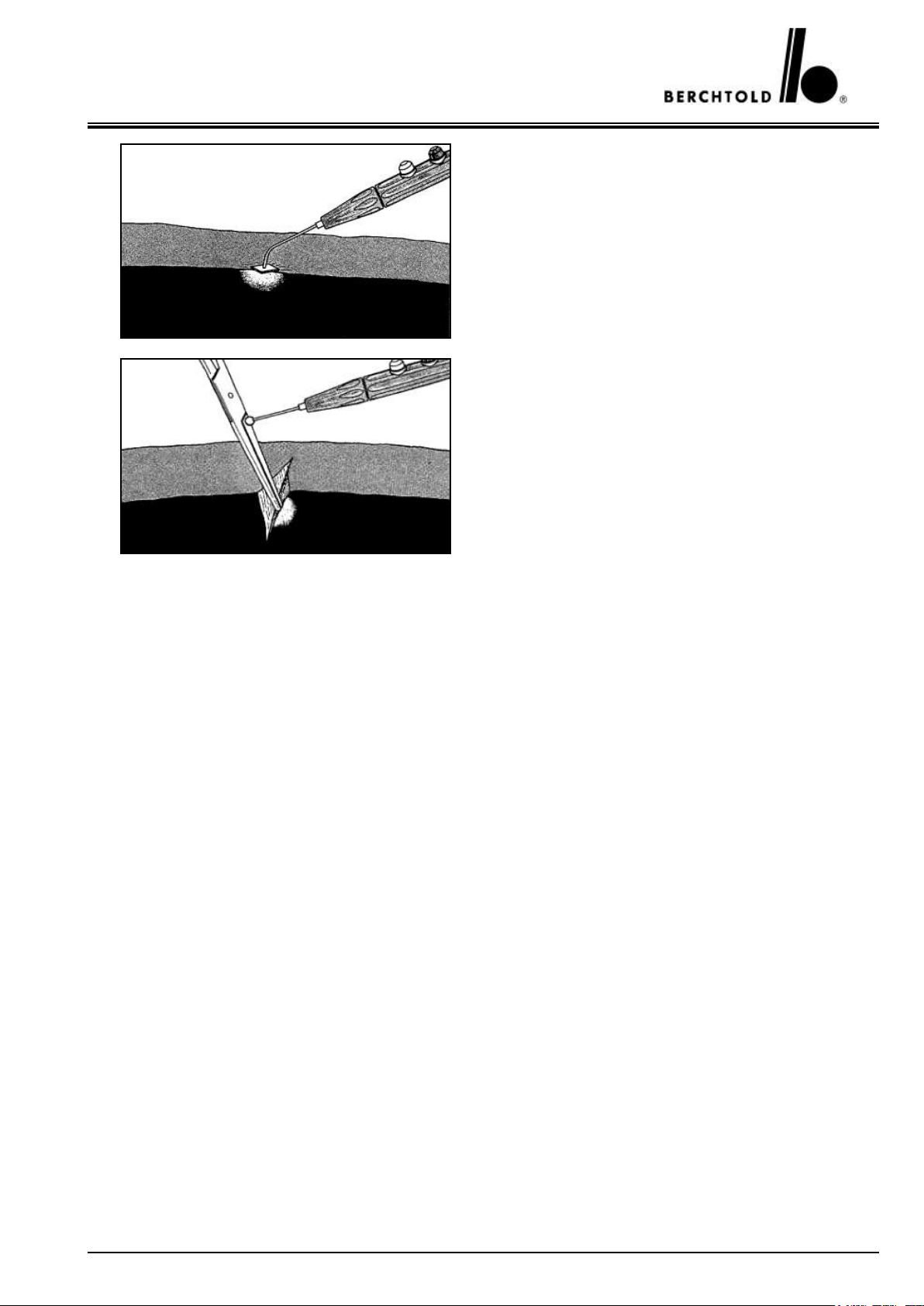

For plain cuts without coagulation (surface necrosis) needle or lancet electrodes with thin cross-section are most

suitable.

A high cutting speed reduces the likelihood of coagulating

the cut surface.

Electrodes with a large cross-section reduce the cut speed

and cause the coagulation of the cut surfaces at the same

time.

Lancet or knife electrodes are best suited when cutting

fat.

Due to the high tissue impedance of fat it is necessary to

select 1-2 steps higher than normal on the output control.

For biopsy excisions and other tissue sampling we recommend the use of loop or conisation electrodes.

9

ELEKTROTOM® 610 Service Manual

Suggested settings for cutting

Function

Suggested setting

(digital display)

Plain cuts with thin needle electrodes

40 W

Blended cuts with knife, lancet or loop electrodes

60 W

Excisions with loop electrodes

60 W

Cutting fat tissue with lancet or knife electrodes

80 W

These setting are recommended from experience. However, electrical conditions may require higher settings than

indicated.

•

8.2 Current types for 2 monopolar coagulation modes with differing effects

The ELEKTROTOM® 610 provides a choice of 2 coagulation modes (see page 20):

•

Contact coagulation (push button 12) high power coagulation (Forced coagulation)

•

Contact coagulation (push button 11) low power coagulation (Soft coagulation)

8.2.1 Forced Coagulation

Forced coagulation is a high voltage coagulation employing micro-arc technology. Further, the current is modulated to give a higher crest factor. The arcing effect is particularly suitable for large area, surface coagulation.

The required coagulation power can be regulated in 5 steps from 5 W to 60 W by means of the up/down pushbuttons 15 and 16.

Forced coagulation is normally carried out using a knife or ball shaped active electrode. The high frequency energy

is discharged directly to the surface tissues via arcing.

Suggested settings for forced coagulation

Function

Suggested setting

(digital display)

Coagulation with knife or ball electrodes

50 W

These setting are recommended from experience. However, electrical conditions may require higher settings than

indicated.

8.2.2 Soft Coagulation

Soft coagulation is a low voltage coagulation whereby the tissue are not excessively over-heated or carbonised.

Ideally, a large active electrode should be selected and the contact area with the tissue should be as great as possible. The unit output, and the subsequent coagulatory power, can be varied using in 5 steps from 5 W to 60 W by

means of the up/down push button 15 and 16. Five, unit output values may be pre-selected, in order to achieve

the required coagulatory effect. Output is selected with considering the electrode geometry (Ball electrode, plate

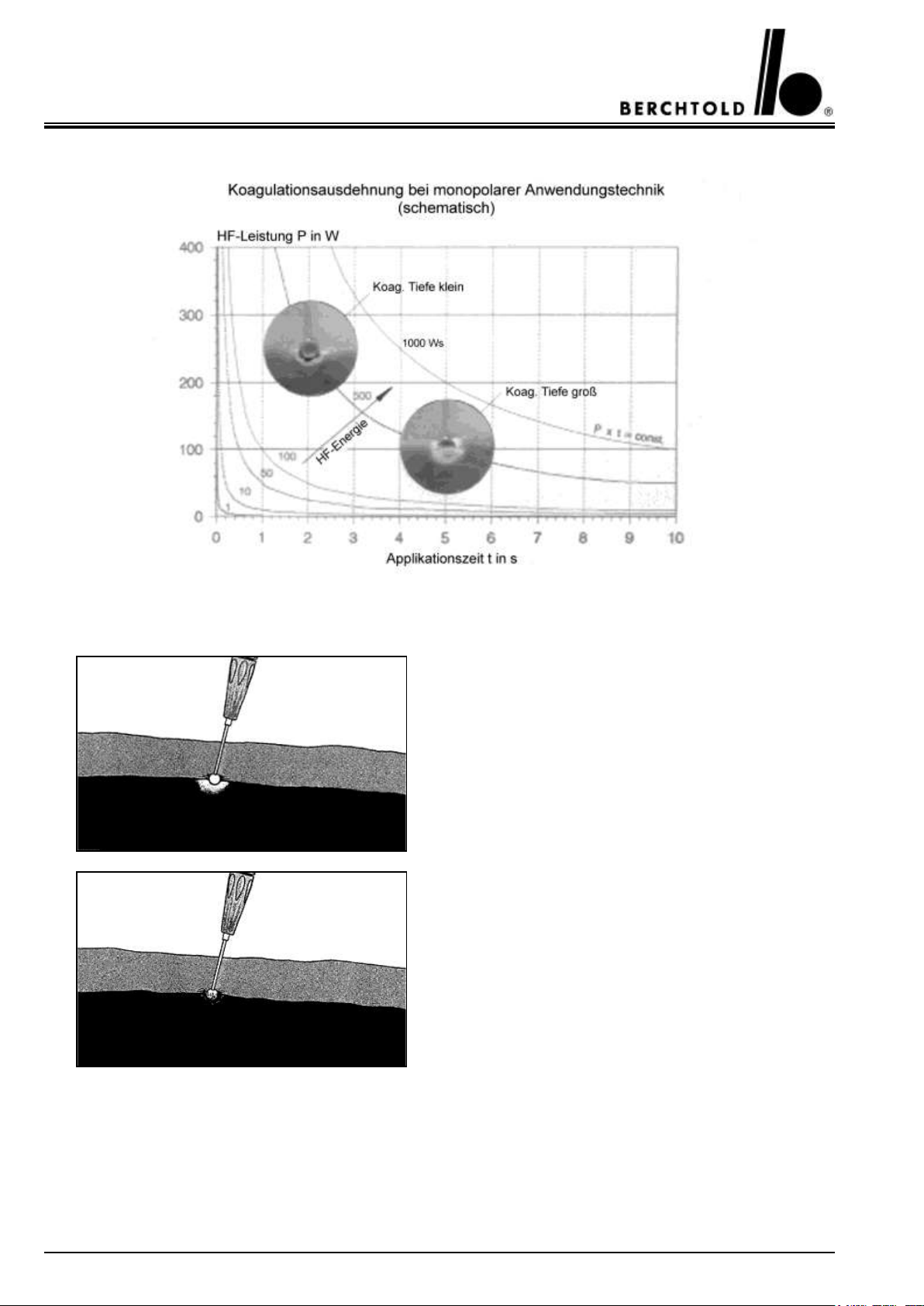

electrode, indirect contact with an artery forceps or tweezers type forceps) and the degree of secondary tissue heating. Lower output levels applied for longer periods of time have a greater, in depth, coagulatory effect and vice

versa.

10

ELEKTROTOM® 610 Service Manual

The special circuitry of the unit automatically controls the generator output to assure a constant coagulatory effect

while taking into account electrode geometry and changing electrical resistance in the tissues.

When high power settings are used, a rapid and narrowly

limited coagulation is achieved. In the area close to the

active electrode the tissue dries out rapidly and the current flow decreases quickly due to the increased resistance.

Please keep active electrodes clean!

Dirty electrodes have an insulating crust of tissue and

blood on their surfaces. This will hinder the flow of current.

11

ELEKTROTOM® 610 Service Manual

In order to staunch bleeding in weeping places and to

desiccate tissue completely in tumour surgery use ball or

plate electrodes.

Bleeding vessels can be closed rapidly and safely by means

of coagulation. The vessel needs to be taken with the

forceps or clamp. Contact of the active electrode to the

instrument conducts current from the active electrode to

the vessel.

Suggested settings for soft coagulation

Function

Suggested setting

(digital display)

Coagulation with plate or ball electrodes

50 W

Coagulation with artery clamp or forceps

50 W

These setting are recommended from experience. However, electrical conditions may require higher settings than

indicated.

8.3 Bipolar coagulation

When using a bipolar forceps or a similar instrument it is possible achieve an accurate coagulation covering a very

small area. In effect, the two tips of the forceps become ‘active’ electrodes and tissue between the tips is subject to

HF current. For example, if a vessel is held between the tips of an insulated bipolar forceps, the resistance set up

by the tissue, between the bare metal tips of the forceps, causes heat production and a subsequent coagulatory

effect.

Activation of the bipolar HF power can be effected by repeatedly pressing key 17 either as

• Automatic start (forceps start) with activation of the membrane key (17)

• Foot pedal start without activation of the automatic start or “MONOPOLAR” procedure. The double pedal foot

switch is connected to socket 25, with the blue pedal activating the bipolar coagulation.

In the case of automatic start, an impedance sensor monitors the contact of the bipolar instrument with the biotissue, so that the HF power is switched on automatically.

The electronically controlled, constant adjustment of unit output allows an automatic adaptation of power to meet

the changing electrical resistance of the tissues being treated. However, output is restricted to the pre-selected

maximum level in Watts. The constant and minimal HF current output avoids sparking and subsequent electrode

sticking.

12

ELEKTROTOM® 610 Service Manual

The constant voltage characteristic curve of the bipolar current type enables automatic power adjustment up to the

preselected maximum output in watts. The constant low HF voltage level avoids sparking and reduces adhesion of

the coagulation electrodes to the biotissue.

Notes on absence of coagulation effects

It can occur that no coagulation effect appears after HF activation. The reason for this failure is always – provided

that there is no defect in the forceps or the connection cable – contaminated forceps tips. The bipolar coagulation

generator provides a relatively low HF voltage. Dried blood or tissue residue are sufficient to insulate the forceps

tips and consequently to interrupt the current. To ensure perfect functioning, the forceps tips must be kept in a

clean, bare-metal and thus conductive condition by frequent wiping.

Suggested settings for bipolar coagulation

Function

Suggested setting

(digital display)

Coagulation with forceps

30 – 40 W

These setting are recommended from experience. However, electrical conditions may require higher settings than

indicated.

8.4 Safety relevant functions

8.4.1 Computer supported safety feature

Considerable safety features are built into the ELEKTROTOM® 610 in order to reduce the dangers of HF electrosurgery to an absolute minimum. Microprocessor control and unit output sensor technology allow the realisation of many, further control functions. Unit, ‘ready for use,’ or otherwise, is indicated both optically and acoustically while HF generation is immediately shut-down when a unit malfunction is detected.

Signals from the various sensors are monitored by the microprocessor. In the case of a microprocessor or software malfunction, HF production is immediately shut-down and an optically displayed error code is shown on the

control panel.

The ELEKTROTOM® 610 is equipped with automatic, self diagnosing circuitry and a malfunction / error code

display feature. A selection of user useful malfunction / error codes is given in the following table.

8.4.2 Neutral electrode monitoring

In the monopolar mode, the negative electrode (patient end-plate) plays a particularly important electrical, and

safety relevant, technical role. It is the second connecting pole in the patient / electrosurgical unit circuit and provides a low Ohm, large surface point of passage for current returning to the HF generator. Opposite to the active

electrode, the site of the negative electrode must remain cool and electrically neutral. Either single or split negative

electrodes made from conductive silicone rubber or disposable, adhesive, metal / plastic electrodes may be used

with this unit.

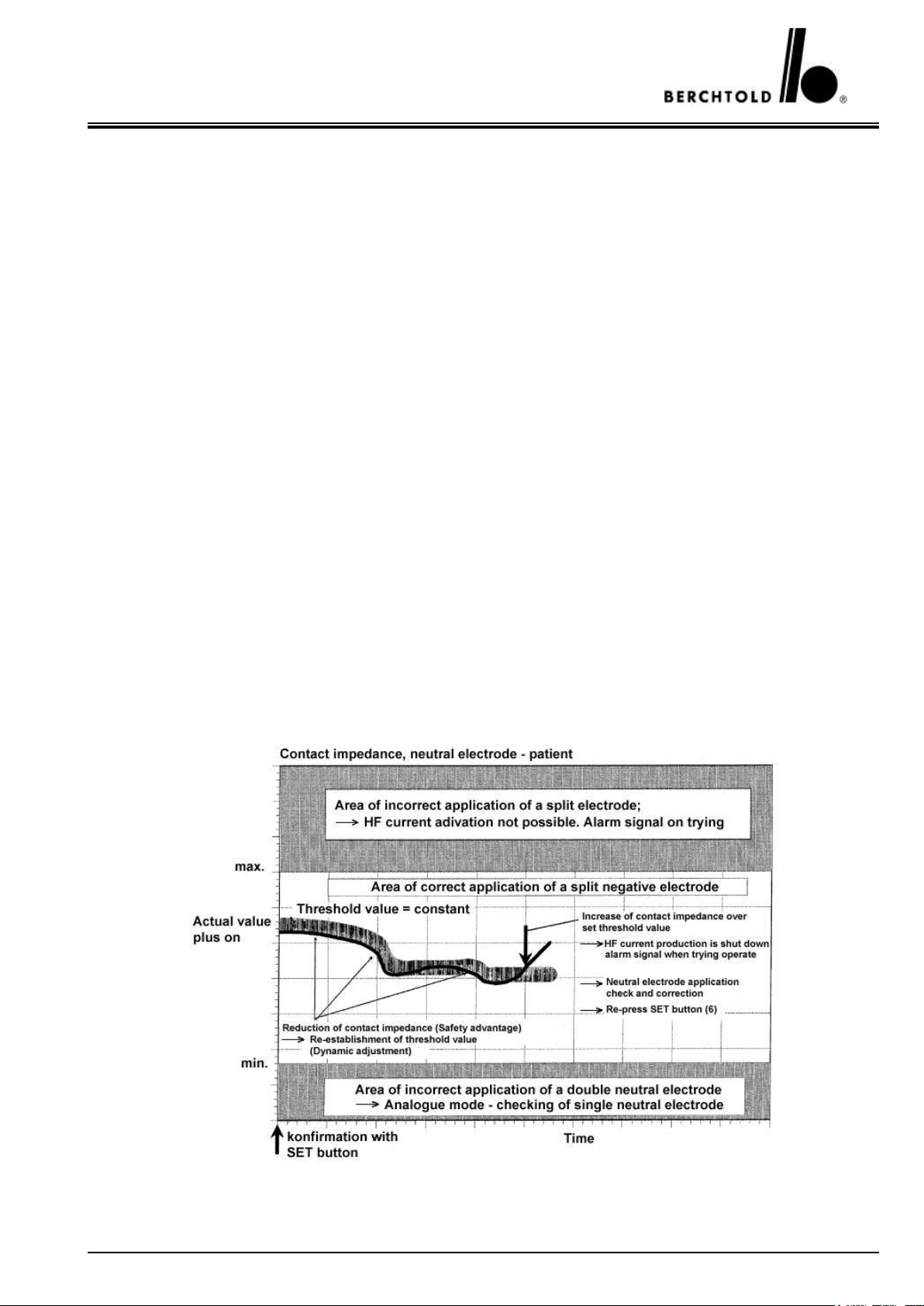

The ELEKTROTOM® 610 is equipped with a new, dynamic neutral electrode monitoring system which is able to

detect the use of either a single or a split negative electrode. The system requires the user to confirm the correct

application of the negative electrode by depressing the SET button.

13

ELEKTROTOM® 610 Service Manual

a) The use of single (Non-split) negative electrodes

When a single negative electrode is used there is only one contact surface, the patient and electrode interface, and

it is only possible for the system to detect and confirm the connection of the cable to the electrosurgical unit together with the integrity of the negative electrode cable. When the connecting cable is attached to the electrosurgical unit (Socket 23), and the SET button (4) depressed, to confirm the correct application of the electrode, the

symbol (2) is illuminated (green) to indicate that a single, negative electrode is applied. Thereafter, all monopolar

functions are available.

Should the negative electrode cable be damaged, or not be plugged correctly into the unit, the signal light (3) is

illuminated and no HF current generation is possible. Attempting to activate HF generation in this situation causes

an optical and acoustic alarm signal together with the malfunction / error code display ”Err 1.” to be activated for

2 seconds.

b) The use of split, negative electrodes

Split negative electrodes have two skin contact surfaces. When such electrodes are used in conjunction with

ELEKTROTOM® 610 not only is the correct connection of the negative electrode lead to the unit and the integrity of the cable checked but there is also a continual monitoring of the electrical contact quality between the patient and the electrosurgical unit.. A permanent signal is passed through the split electrode circuit and continually

compared with pre-establish maximum / minimum parameters. Following application of the negative electrode to

the patient, and connection of the connecting cable to the socket (23) in the electrosurgical unit, the SET button

(4) must be depressed to confirm the correct application of the neutral electrode. When all is correctly connected,

the red signal lamp (3) goes out and the symbol (1) is illuminated green to indicate that a split negative electrode is

applied. Simultaneously, the electrical impedance of the negative electrode circuit is measured and the maximum

and minimum permissible parameters are established.

There is a fully automatic and continual comparison made between the permissible maximum and minimum values and the originally established (or up-dated) permissible parameters.

Should the monitored patient contact impedance fall, there is a automatic re-establishment of the permissible parameters. (Acceptance of a lower impedance measurement is a safety feature of the ELEKTROTOM® 610 and is

referred to as Dynamic Adaptation).

14

ELEKTROTOM® 610 Service Manual

An increase of the monitored impedance, above the established maximum, is potentially dangerous and all HF

generation is immediately shut-down, an acoustic warning given and the error code „Err 1“ is displayed. The

application of the negative electrode, the integrity of the connecting cable and ist connection to the electrosurgical unit must then be investigated. Following the negative electrode investigation, and perhaps its re-application,

the SET button (4) must again be pressed The negative electrode circuit is thereby re-measured and the new,

maximum / minimum operating parameters are re-established. When the newly measured impedance falls within

the acceptable values dictated by the ELEKTROTOM® 610, the new maximum and minimum operating limits

are stored. All monopolar functions may then be safely used.

Should the actual impedance value, measured at any time, exceed the pre-established permissible maximum, the

red signal lamp (3) is illuminated, and the error code „Err 1“ is displayed. Re-pressing SET button (4) will not

cure the problem and the unit will remain inactive until the problem is found and rectified.

If the measured impedance value from a split negative electrode measures less than the pre-established minimum,

the electronics of the ELEKTROTOM® 610 recognise the electrode as a single (non-split) electrode and the

symbol (2), indicating the application of a single negative electrode, is illuminated on the control panel. This

situation can occur, for example, when the two plates are in contact with each other, or are electronically bridged

by a metallic object.

When using monopolar HF electrosurgical equipment, the correct application of a split negative electrode, on a

patients who is correctly isolated on the operating table, offers the highest degree of safety from accidental HF

electrosurgical burns.

8.4.3 Protection against unit malfunction

By monitoring the output current and voltage, the ELEKTROTOM® 610 makes a permanent comparison with

the limits of the selected values on the control panel. Should a disallowable discrepancy occur, HF generation is

immediately shut-down and the following error codes are displayed: Display 7 : „Err“ and on display 13: „8.“

8.4.4 Protection against erroneous unit settings

The control panel of the ELEKTROTOM® 610 has been designed as follows: clear, easy to understand symbols,

foil covered pressure (sensor) pads for unit function selection and three, up/down, pressure sensitive pads, to

pre-select unit output power. In order to offer a clear, over all, picture the panel is divided into four sections:

One concerning operational safety and three concerning unit function.

When selecting „MONO“ or „BI“ functions, the use of a double foot-switch in either monopolar or bipolar

mode is made available.

The following features are to be found just below the control panel: Mains switch (22), sockets (23), (24), 25),

and (26). These connecting sockets are all compatible with the BERCHTOLD range of monopolar and bipolar

accessories and electrosurgical instruments

15

ELEKTROTOM® 610 Service Manual

9.

Operating the ELEKTROTOM® 610

9.1 Puhs buttons, signal lights and symbols

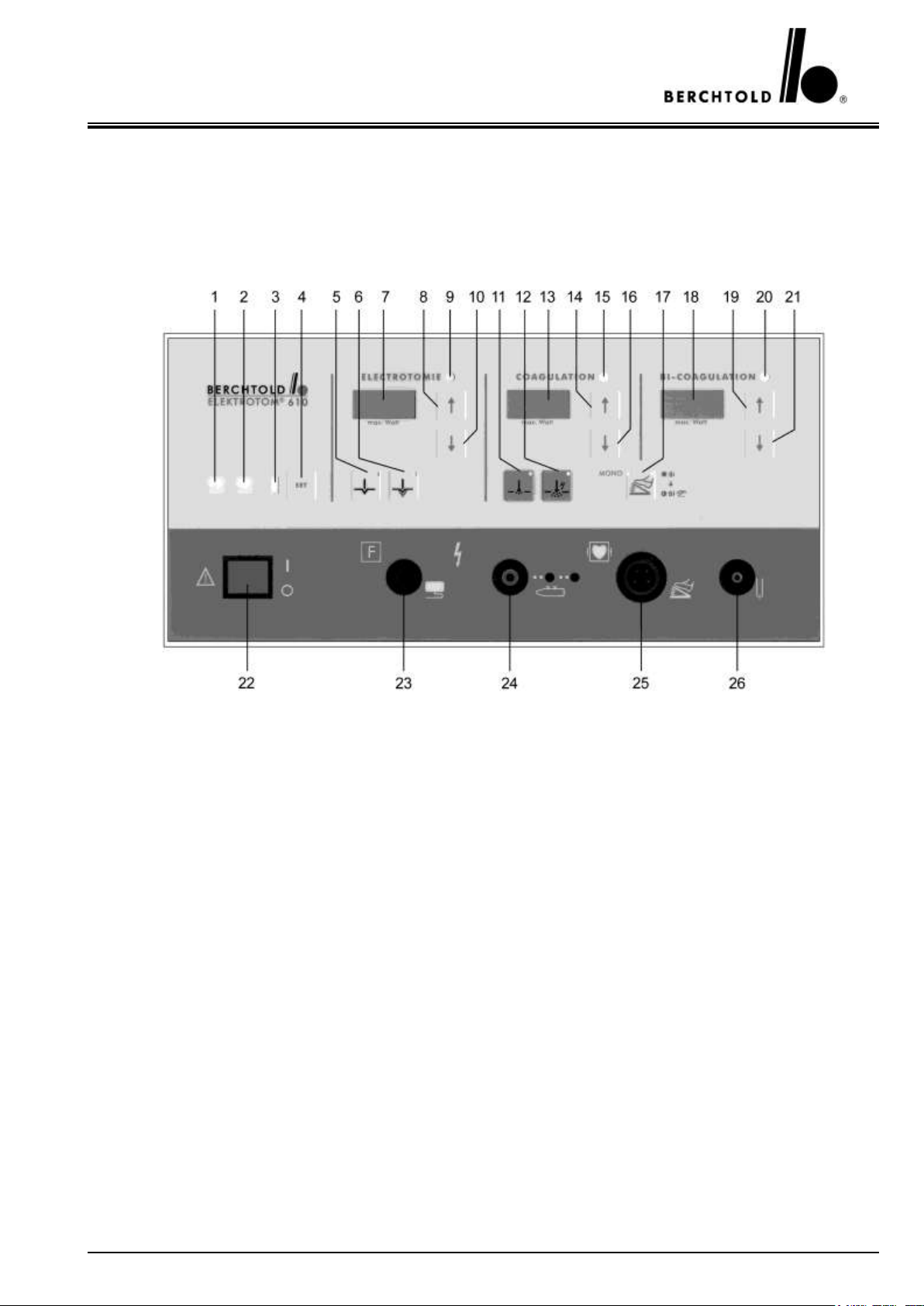

9.1.1 The front of the ELEKTROTOM® 610

1

Symbol indicating „split, negative electrode applied“

2

Symbol indicating „single, negative electrode applied“

3

Signal light red for negative electrode alarm

4

Pushbutton to confirm the correct application of a negative electrode (SET pushbutton)

5

Selection push button for cutting I

6

Selection push button for cutting II

7

Digital output indicator in Watts for cutting power

8

Push button to increase cutting output in 5 Watts steps

9

Signal lamp for cutting

10

Push button to decrease cutting output in 5 Watts steps

11

Selection push button for soft coagulation

12

Selection push button for forced coagulation

13

Digital output indicator in watts for coagulatory power

14

Push button to increase coagulating output in 5 Watts steps

15

Signal lamp for coagulation

16

Push button to decrease coagulating output in 5 Watts steps

17

Selection push button for double foot-switch use in either monopolar or bipolar coagulation

18

Digital output indicator in watts for bipolar coagulatory power

19

Push button to increase bipolar coagulating output in 5 Watts steps

20

Signal lamp for bipolar coagulation

21

Push button to decrease bipolar coagulating output in 5 Watts steps

22

Mains, on/off switch

23

Connecting socket for negative electrode (split or single)

24

Connecting socket for electrode handle (with additional socket for disposable handles)

25

Connecting socket for foot-switch

26

Connecting socket for bipolare coagulations instruments

16

ELEKTROTOM® 610 Service Manual

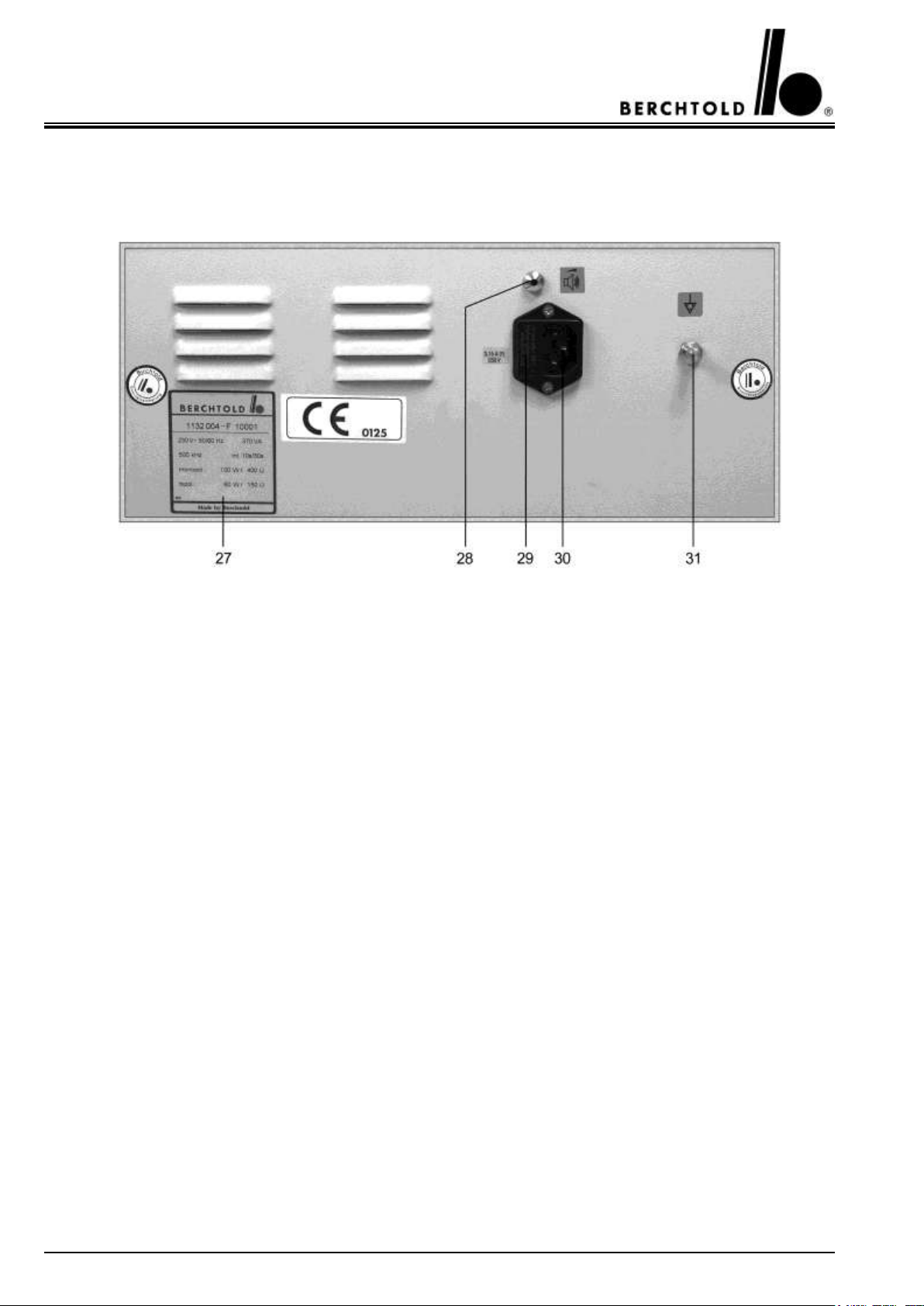

9.1.2 The rear of the ELEKTROTOM® 610

27

Plate showing unit number and mains information

28

Volume control,

recommended tool:

screwdriver with < 3 mm shaft diameter

29

Mains fuses F1 and F2 in removable housing

30

Connecting socket for mains cable

31

Connecting socket for earth potential balancing cable

Loading...

Loading...