Benshaw RDB6 Manual

BENSHAW

REDISTART DIGITAL

RDB6 SERIES

INSTRUCTION MANUAL

The Leader In

Solid State Motor Control

Technology

Publication #: 890001-15-07

QUICK START GUIDE

|

Quick Start |

|

|

General |

This quickstart guide provides the information necessary for the operator to set the |

|

starter for basic operation. This manual should be read in its entirety before the |

|

starter is put into service. |

• Connect the incoming power connections to terminals L1, L2 and L3.

• Connect the motor leads to T1, T2, and T3.

• Connect the control wiring to TB1 on the control card, as shown in the following diagram. USE ONLY THE START/STOP BUTTONS OR THE EXTERNAL AUTO CONTROL.

FU1

.5A

EXTERNAL AUTO

CONTROL

FAULT

UP TO

SPEED

MOTOR

POWER

OPTIONAL

EXTERNAL

FAULT (L)

CUSTOMER EXTERNAL

FIELD TRIPS EXTERNAL

FAULT (N)

•Turn on the power to the starter. The display should show the software release number and then rdy. If not, refer to the starter diagnostics beginning on page 38.

•See the programming chapter beginning on page 20 for a complete description of programming procedures and parameter descriptions. The important parameters to program are P1, P2, P3, P4, and P6.

•Provide a short Start/Stop sequence to the starter to check motor rotation. If the motor rotates backwards, swap any two power leads.

•Give a Start command and allow the motor to accelerate to speed.

•If the motor doesn’t begin accelerating immediately, increase parameter P4. If it takes off too quickly, decrease P4.

•If the motor takes too long to accelerate, decrease P6. If the motor accelerates too quickly, increase P6.

i

TABLE OF CONTENTS

Table of Contents

1.INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1How To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.TECHNICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2Control Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5Solid State Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6Chassis Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7Standard and Heavy Duty Horsepower Ratings . . . . . . . . . . . . . . . . . . . . . . 8

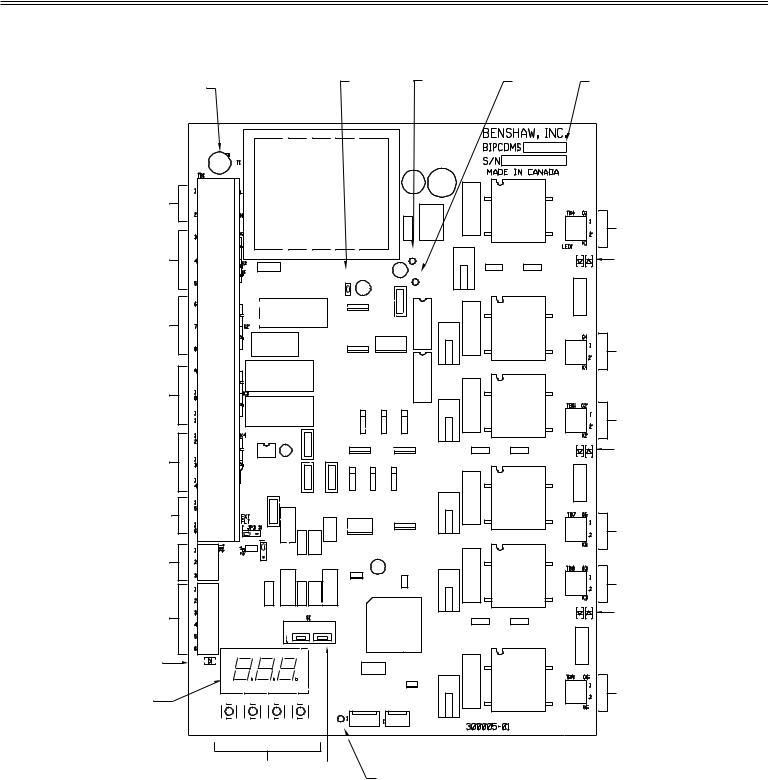

2.8Circuit Card Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1Site Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 |

EMC Installation guidelines |

. . . . . . . . . . . |

. . . . . . . . . . . |

. . . . . . . . . . |

. |

12 |

3.3 |

Installation Procedures . . . |

. . . . . . . . . . . |

. . . . . . . . . . . |

. . . . . . . . . . |

. |

13 |

3.4CT Ratio Scaling Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5Hardware Deceleration Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6Variable Voltage or Current Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.7Door Mounted Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.OPERATING PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1General Operating Parameter Information . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2P1 - Motor Full Load Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 |

P2 |

- Overload Multiplier . . . |

. |

. . . . . . . . . . . |

. . . . . . . . . . . |

. . . . . . . . |

. |

21 |

4.4 |

P3 |

- Motor Thermal Overload |

. |

. . . . . . . . . . . |

. . . . . . . . . . . |

. . . . . . . . |

. |

22 |

4.5P4 - Initial Motor Starting Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6P5 - Maximum Motor Starting Current . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 |

P6 |

- Motor Ramp Time |

. . |

. . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . . . . |

. |

. |

23 |

4.8 |

P7 |

- Motor Stall Time . |

. . |

. . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . . . . |

. |

. |

24 |

4.9P8 - Deceleration Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.10P9 - Deceleration Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.11P10 - Deceleration Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.12 P11 - Overcurrent Trip Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 4.13 P12 - Overcurrent Trip Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ii

TABLE OF CONTENTS

4.14P13 - Undercurrent Trip Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.15P14 - Undercurrent Trip Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.16P15 - Line Phase Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.17P16 - Motor Current Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.18P17 - Current Transformer Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.19P18 - Meter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.20P19 - Meter Dwell Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.21P20 - Passcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.22P21 - 500% Current Kick Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.23 P22 - Starter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.OPERATING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1Pushbutton Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2Starting The Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3Operating Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.5Preventative Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.6Starter Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.7Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6. |

DISPLAY TEMPLATE . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 |

|

6.1 Door Mounted Display Template |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 |

7. |

INSIDE DELTA OPTION . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 |

iii

|

|

|

1. INTRODUCTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.1 |

|

How To Use This Manual |

|

|

|

|

|

|

|

General Information |

The RediStart Digital motor starter operations manual provides the following |

|

|

|

|

information: |

|

|

|

|

• |

Specifications. |

|

|

|

• |

Installation site requirements. |

|

|

|

• |

Installation. |

|

|

|

• |

Programming. |

|

|

|

• |

Operation. |

|

|

|

• |

Diagnostics. |

|

|

How to Use this Manual |

The operations manual is divided into five sections: |

|

|

|

|

• |

Introduction. |

|

|

|

• |

Technical information. |

|

|

|

• |

Installation procedures. |

|

|

|

• |

Operating parameters. |

|

|

|

• |

Operating procedures. |

|

|

|

Each section contains subsections with detailed information on the relative topics. |

|

|

|

|

The subsections contain general information, details and any necessary precautions |

|

|

|

|

about the individual topics. The specific information contained in the subsections can |

|

|

|

|

be found quickly and easily by reviewing the subject headings on the left margin. |

|

|

|

Operations Manual |

The operations manual can be found on-line at: |

|

|

|

On-Line |

|

http://www.benshaw.com |

|

|

|

The manual is available in Adobe Acrobat portable document format (pdf). Adobe and |

|

|

|

|

Acrobat are trademarks of Adobe Systems Incorporated. |

|

|

|

Parameter Chart |

There is a parameter chart on page 41 of the manual. This parameter chart lists each |

|

|

|

|

operating parameter with its name, values and defaults. A space is provided on the |

|

|

chart for the user’s current parameter settings. When the operating parameters are set for the current application, they should be listed on the chart for future reference.

1

1. INTRODUCTION

1.2 |

|

Product Description |

|

|

|

General Information |

The RediStart Digital motor starter is a microprocessor-controlled starter for single or |

|

|

three-phase induction motors. The starter can be custom designed for specific |

|

|

applications. |

|

|

The starter offers: |

|

|

• |

Solid state design. |

|

• Current limited reduced voltage starting. |

|

|

• Closed-loop motor current control. |

|

|

• |

Programmable motor protection. |

|

• |

Programmable operating parameters. |

|

• |

Programmable metering. |

|

Available in NEMA (National Electrical Manufacturers Association) specified frame |

|

|

sizes, the starter may be used in numerous industrial applications. Each starter can |

|

|

operate within applied voltage and frequency values of 100VAC to 600VAC (optional |

|

|

1000VAC) and 23 to 75Hz. This feature enables the RDB6 to be installed in a wide |

|

|

range of sites and countries. |

|

|

The starter can be programmed for any motor FLA and all of the common motor |

|

|

service factors. It enables operators to control both motor acceleration and |

|

|

deceleration. It also protects the motor and its load from damage that could be caused |

|

|

by incorrect phase order wiring. |

|

|

The starter continually monitors the amount of current being delivered to the motor. |

|

|

This protects the motor from overheating or drawing excess current. The starter will |

|

|

automatically stop the motor if the line-to-line current is not within acceptable ranges |

|

|

or if the current is lost in a line. |

|

Features |

The enhanced engineering features of the starter include: |

|

|

• |

Multiple frame sizes. |

|

• |

Universal voltage operation. |

|

• |

Universal frequency operation. |

|

• Programmable motor overload multiplier. |

|

|

• Controlled acceleration and deceleration. |

|

|

• |

Phase rotation protection. |

|

• |

Regulated current control. |

|

• Electronic motor thermal overload protection. |

|

|

• Electronic over/under current protection. |

|

|

• |

Single phase protection. |

|

• Line-to-line current imbalance protection. |

|

|

• |

Stalled motor protection. |

|

• |

Programmable metering. |

|

• |

Passcode protection. |

2

|

|

1. INTRODUCTION |

|

|

|

|

|

|

Optional Features |

Depending on the system configuration and customer specifications, the starter can be |

|

|

customized to include: |

|

|

• |

Door mounted keypad/display. |

|

• Over and under voltage relays. |

|

|

• |

Voltage unbalance sensors. |

|

• Over and under current relays. |

|

|

• Current unbalance sensors that also detect single-phase fault conditions. |

|

|

• |

Ground fault relays. |

|

• |

Motor protection systems. |

|

• Display indicator lights mounted on the cabinet. |

|

|

• |

External overload relays. |

|

• Meters or metering packages. |

|

|

• |

Circuit disconnecting devices. |

Components |

The major components of the starter are: |

|

|

• Customized line and load lugs or pads. |

|

|

• Six (three-phase) or four (single-phase) SCRs with SIOV protection. |

|

|

• Printed circuit assembly control card. |

|

|

• Terminals for two-wire or three-wire 120VAC control. |

|

|

• |

Current feedback transformers. |

|

• An isolated heat sink with dual-SCR flat packs or a live heat sink with |

|

|

|

puck-shaped SCRs. |

LED Display |

A three character, alphanumeric LED display located on the control card (or on the |

|

|

optional door mounted display) displays: |

|

|

• |

Status information. |

|

• |

Operating parameters. |

|

• |

Fault codes. |

|

• |

Thermal Overload Content. |

|

• |

Motor current. |

|

• Motor current imbalance percentage. |

|

Control Relays |

The starter has four control relays: |

|

|

• |

Start/Stop input relay. |

|

• |

Fault output relay. |

• UTS (up to speed) output relay.

• Motor power output relay.

3

2. TECHNICAL INFORMATION

2.1 |

|

|

Physical Specifications |

|

|

|

|

General Information |

The physical specifications of the starter vary depending upon its configuration. The |

||

|

configuration is determined by the applicable motor current and its specific |

||

|

application requirements. |

||

Heat sink |

The starter uses one of two distinct types of heat sinks: |

||

|

• An isolated heat sink with dual SCR flat packs on RDB-27 to RDB-96 models. |

||

|

• A live heat sink with puck-style SCRs on RDB-124 to RDB-720 models. |

||

Dimensions |

The chassis sizes are given in the following chart; |

||

|

|

|

|

|

Catalog # |

Chassis Size |

|

|

( H” x W” x D” ) |

|

|

|

|

|

|

|

RDB-27 |

14 x 10 x 6 |

|

|

RDB-40 |

14 x 10 x 6 |

|

|

RDB-52 |

16 x 10 x 7 |

|

|

RDB-65 |

16 x 10 x 7 |

|

|

RDB-77 |

16 x 10 x 7 |

|

|

RDB-96 |

16 x 10 x 7 |

|

|

RDB-124 |

16 x 12 x 9 |

|

|

RDB-156 |

16 x 12 x 9 |

|

|

RDB-180 |

18 x 12 x 10 |

|

|

RDB-240 |

20 x 14 x 10 |

|

|

RDB-302 |

20 x 14 x 10 |

|

|

RDB-361 |

20 x 14 x 10 |

|

|

RDB-477 |

35 x 16 x 12 |

|

|

RDB-590 |

35 x 16 x 12 |

|

|

RDB-720 |

35 x 16 x 12 |

|

|

|

|

|

2.2 |

Control Power |

|

|

Chassis VA Requirements The power requirements for each starter size is given in the table:

Catalog # |

Transformer |

|

Requirements (VA) |

||

|

||

RDB-27 |

50 |

|

RDB-40 |

50 |

|

RDB-52 |

80 |

|

RDB-65 |

80 |

|

RDB-77 |

80 |

|

RDB-96 |

80 |

|

RDB-124 |

70 |

|

RDB-156 |

70 |

|

RDB-180 |

70 |

|

RDB-240 |

80 |

|

RDB-302 |

125 |

|

RDB-361 |

125 |

|

RDB-477 |

275 |

|

RDB-590 |

275 |

|

RDB-720 |

275 |

4

|

|

2. TECHNICAL INFORMATION |

|

|

|

|

|

|

Total VA Requirements |

The power requirements of the complete starter package also depend on the other |

|

|

devices in the package. The VA requirements of some common devices are: |

|

|

• |

4” fan - 23VA |

|

• |

6” fan - 42VA |

|

• |

Pilot Light - 3VA |

|

• |

Control Relay - 5VA |

|

The VA requirements of the control card and any other devices in the package must be |

|

|

added together. Multiply the total by 1.2 to get the minimum transformer size |

|

|

required. |

|

Control Terminals |

The TB1 terminal block has the following control terminal configuration: |

|

|

• |

TB1-1 |

Control power - Line. |

|

• |

TB1-2 |

Control power - Neutral. |

|

• |

TB1-3 |

Run relay holding contact. |

|

• |

TB1-4 |

Run relay line. |

|

• |

TB1-5 |

Run relay neutral. |

|

• |

TB1-6 |

Fault contact N.O. (not faulted). |

|

• |

TB1-7 |

Fault contact common. |

|

• |

TB1-8 |

Fault contact N.C. (not faulted). |

|

• |

TB1-9 |

Up-to-speed contact N.O. (not at full speed). |

|

• |

TB1-10 |

Up-to-speed contact common. |

|

• |

TB1-11 |

Up-to-speed contact N.C. (not at full speed). |

|

• |

TB1-12 |

Motor power N.O. (When motor is stopped). |

|

• |

TB1-13 |

Motor power common. |

|

• |

TB1-14 |

Motor power N.C. (When motor is stopped). |

|

• |

TB1-15 |

External trip input line (120VAC applied or trip occurs). |

|

• |

TB1-16 |

External trip input neutral. |

|

• |

TB2-1 |

Internal power for potentiometer voltage control. |

|

• |

TB2-2 |

Voltage or current control signal input. |

|

• |

TB2-3 |

Voltage or current control signal common. |

Output Contact Ratings |

Fault Relay: |

|

|

|

2A resistive, 1A inductive, 125VAC |

||

|

Up-to-Speed Relay & Motor Power Relay: |

||

|

16A resistive, 8A inductive, 250VAC |

||

2.3 |

Storage |

|

|

General |

If the starter is to be stored for a significant period of time before being installed, |

|

certain storage environmental conditions must be maintained. |

|

NOTE: The suggested maximum storage length is two years. |

Environmental Conditions |

To protect the starter during the storage period the following environmental |

|

conditions must be maintained: |

• -40 degrees Fahrenheit to 158 degrees Fahrenheit (-40 degrees Centigrade to 70 degrees Centigrade).

• 20% to 95% relative humidity (non-condensing).

The maximum acceptable temperature and humidity changes in 30 minutes are:

•10.8 degrees Fahrenheit (6 degrees Centigrade).

•10% humidity.

5

2. TECHNICAL INFORMATION

2.4 |

EU Declaration of Conformity |

|

|

|

|

2. TECHNICAL INFORMATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.5 |

Solid State Overload |

|

|

|

|

|

|

General |

The starter incorporates an electronic overload which allows the user to select a class |

|

|

|

10, 20, or 30 overload. The following curves serve to define the different overload |

|

|

|

classes. |

|

100000 |

|

|

|

|

|

|

|

|

|

10000 |

|

|

|

|

|

|

|

|

|

1000 |

|

|

|

|

|

|

|

|

|

(Seconds) |

|

|

|

|

|

|

|

|

|

Time |

|

|

|

|

|

|

Class 30 |

|

|

|

|

|

|

|

|

Class 20 |

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Class 10 |

|

|

10 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

Current (Multiples of FLA)

The thermal overload trip time will be lowered once the motor has been operated. See page 33 for a compete description of the overload operation.

7

2. TECHNICAL INFORMATION

2.6 |

|

|

|

|

|

Chassis Rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

115% |

Unit |

Fuse/Circuit Breaker Protected Rating |

||

|

|

Nominal |

Fuse Class |

Max Fuse |

|

||

|

Catalog |

Current |

Withstand |

|

|||

|

Current |

/Circuit |

Current |

Short Circuit |

|||

|

Number |

Rating |

Rating |

||||

|

(A) |

Breaker |

Rating/Trip |

Rating, KA |

|||

|

|

(A) |

(KA) |

||||

|

|

|

Cat.No. |

Plug, A |

|

||

|

|

|

|

|

|

||

|

RDB-27 |

27 |

31 |

5 |

Class J/T |

|

5 |

|

RDB-40 |

40 |

46 |

5 |

Class J/T |

|

5 |

|

RDB-52 |

52 |

59.8 |

5 |

Class J/T |

|

5 |

|

RDB-65 |

65 |

75 |

5 |

Class J/T |

|

5 |

|

RDB-77 |

77 |

89 |

5 |

Class J/T |

|

5 |

|

RDB-96 |

96 |

110 |

10 |

Class J/T |

|

10 |

|

RDB-124 |

124 |

179 |

10 |

Class J/T |

|

10 |

|

RDB-156 |

156 |

143 |

10 |

Class J/T |

|

10 |

|

RDB-180 |

180 |

207 |

10 |

Class J/T |

|

10 |

|

RDB-240 |

240 |

276 |

10 |

Class J/T |

|

10 |

|

RDB-302 |

302 |

347 |

18 |

Class J/T |

|

18 |

|

RDB-361 |

361 |

415 |

18 |

Class J/T |

|

18 |

|

RDB-477 |

477 |

549 |

30 |

Class J/T |

|

30 |

|

RDB-590 |

590 |

679 |

30 |

Class J/T |

|

30 |

|

RDB-720 |

720 |

828 |

30 |

Class J/T |

|

30 |

2.7 |

|

|

Standard and Heavy Duty Horsepower Ratings |

|||||

|

|

|

|

|

|

|

|

|

General |

There are 15 different RDB chassis sizes. Each frame size has two different |

|||||||

|

horsepower ratings depending on the application. |

|

|

|

||||

Standard Duty Rating |

The standard duty horsepower rating is for normal motor starting. The standard duty |

|||||||

|

rating is a motor current that is 350% (3.5 times) of the full-load current for 30 |

|||||||

|

seconds. The standard duty rating table lists the maximum size of motor that can be |

|||||||

|

started by each RDB unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Catalog # |

Nominal |

|

Horsepower Rating (hp for listed VAC) |

|

|||

|

Current (A) |

208 |

220-240 |

440-480 |

600 |

|

||

|

|

|

||||||

|

RDB-27 |

27 |

|

7.5 |

10 |

20 |

25 |

|

|

RDB-40 |

40 |

|

10 |

15 |

30 |

40 |

|

|

RDB-52 |

52 |

|

15 |

20 |

40 |

50 |

|

|

RDB-65 |

65 |

|

20 |

25 |

50 |

60 |

|

|

RDB-77 |

77 |

|

25 |

30 |

60 |

75 |

|

|

RDB-96 |

96 |

|

30 |

40 |

75 |

100 |

|

|

RDB-124 |

124 |

|

40 |

50 |

100 |

125 |

|

|

RDB-156 |

156 |

|

50 |

60 |

125 |

150 |

|

|

RDB-180 |

180 |

|

60 |

75 |

150 |

200 |

|

|

RDB-240 |

240 |

|

75 |

100 |

200 |

250 |

|

|

RDB-302 |

302 |

|

100 |

125 |

250 |

300 |

|

|

RDB-361 |

361 |

|

125 |

150 |

300 |

400 |

|

|

RDB-477 |

477 |

|

150 |

200 |

400 |

500 |

|

|

RDB-590 |

590 |

|

200 |

250 |

500 |

600 |

|

|

RDB-720 |

720 |

|

250 |

300 |

600 |

700 |

|

8

|

|

|

|

2. TECHNICAL INFORMATION |

||||

|

|

|||||||

|

|

|

|

|

|

|

|

|

Heavy Duty Rating |

The heavy duty rating is for heavy duty motor starting. The heavy duty rating is a |

|||||||

|

starting current that is up to 500% (5 times) of the full-load current for 30 seconds. |

|||||||

|

The heavy duty rating table lists the maximum size of motor that can be started by |

|||||||

|

each RDB unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Catalog # |

|

Nominal |

Horsepower Rating (hp for listed VAC) |

|

|||

|

|

Current (A) |

208 |

220-240 |

440-480 |

600 |

|

|

|

|

|

|

|||||

|

RDB-27 |

|

27 |

7.5 |

10 |

20 |

25 |

|

|

RDB-40 |

|

40 |

10 |

10 |

25 |

30 |

|

|

RDB-52 |

|

52 |

10 |

15 |

30 |

40 |

|

|

RDB-65 |

|

65 |

10 |

15 |

30 |

40 |

|

|

RDB-77 |

|

77 |

10 |

15 |

30 |

40 |

|

|

RDB-96 |

|

96 |

25 |

30 |

60 |

75 |

|

|

RDB-124 |

|

124 |

30 |

40 |

75 |

100 |

|

|

RDB-156 |

|

156 |

30 |

40 |

75 |

100 |

|

|

RDB-180 |

|

180 |

60 |

75 |

150 |

200 |

|

|

RDB-240 |

|

240 |

75 |

100 |

200 |

250 |

|

|

RDB-302 |

|

302 |

75 |

100 |

200 |

250 |

|

|

RDB-361 |

|

361 |

75 |

100 |

200 |

250 |

|

|

RDB-477 |

|

477 |

100 |

125 |

250 |

300 |

|

|

RDB-590 |

|

590 |

150 |

200 |

400 |

500 |

|

|

RDB-720 |

|

720 |

200 |

250 |

500 |

600 |

|

9

2. TECHNICAL INFORMATION

2.8 |

|

|

|

Circuit Card Layout |

|

|

|

|

|

|

|

|

JP1 DECEL |

TB2 +24VDC |

TP3 GROUND |

ASSEMBLY |

|

FU1 CONTROL |

OVERRIDE |

NUMBER |

|||

|

|

||||

FUSE |

|

|

|

|

FU1

TB1

CONTROL

POWER

TB4

SCR1

TB1 |

|

|

|

|

|

|

|

+VDC |

LED1,2 |

START/ |

|

|

|

|

|

|

|

|

SCR |

STOP |

|

|

|

|

|

DECEL |

|

GND |

STATUS |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

OVERRIDE |

|

|

|

TB1 |

|

|

|

|

|

|

|

|

|

FAULT |

|

|

|

|

|

|

|

|

|

RELAY |

|

|

|

K2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TB5 |

|

|

|

|

|

|

|

|

|

SCR4 |

TB1 |

|

|

|

|

K3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UP TO |

|

|

|

|

|

|

|

|

|

SPEED |

|

|

|

|

|

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

TB6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCR2 |

|

|

|

K4 |

|

|

|

|

|

|

TB1 |

|

|

|

|

|

|

|

|

LED3,4 |

|

|

|

|

|

|

|

|

SCR |

|

MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STATUS |

|

POWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

|

TB1 |

|

|

|

|

|

|

|

|

|

EXTERNAL |

|

|

|

|

|

|

|

|

|

FAULT |

|

|

|

|

|

|

|

|

TB7 |

|

|

|

|

|

|

|

|

|

SCR5 |

TB2 |

|

|

|

|

|

|

|

|

|

ANALOG |

|

|

|

|

|

|

|

|

|

INPUT |

|

|

|

|

|

|

|

|

TB8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCR3 |

TB3 |

|

|

|

|

|

|

|

|

LED5,6 |

|

|

|

|

|

|

|

|

SCR |

|

CT |

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

STATUS |

|

INPUTS |

|

|

|

|

|

|

|

||

|

|

1 |

2 |

|

|

|

|

||

|

|

N |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

DISP1 |

|

|

|

|

|

|

|

|

LED7 |

PWR |

|

|

|

|

|

|

|

|

POWER |

|

|

|

|

|

|

|

|

|

GOOD |

|

|

|

|

|

|

|

|

|

GOOD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TB9 |

DISP1 |

SW1 |

SW2 |

SW3 |

SW4 |

|

|

|

|

SCR6 |

LED |

|

|

|

|

|

CON1 |

|

|

|

|

|

|

THERMAL RESET |

|

|

CON2 |

|

||

|

PARAMETER |

UP |

DOWN |

ENTER |

|

DIAGNOSTICS |

UART |

|

|

|

|

SW1-SW4 |

|

S1 |

|

|

|

|

|

|

|

PUSHBUTTON |

DIP |

|

TP1 |

|

|||

|

|

SWITCHES |

SWITCH |

|

|||||

|

|

+5VDC |

|

||||||

|

|

|

|

|

|

|

|

||

10

2. TECHNICAL INFORMATION

2.9 |

|

|

Spare Parts |

|

|

|

|

General |

The following lists the spare parts for the different starter sizes: |

|

|

|

|

|

|

Part Number |

Description |

Used On |

Quantity |

|

|

|

|

BIPCDMS |

control card |

all |

1 |

BI-M-FU1 |

control card fuse |

all |

1 |

BISCR5012X |

50 amp dual flat pack SCR |

RDB-27, RDB-40 |

3 |

BISCR10012X |

100 amp dual flat pack SCR |

RDB-52, RDB-65, RDB-77 |

3 |

BISCR13212X |

132 amp dual flat pack SCR |

RDB-96 |

3 |

BISCR????? |

218 amp puck style SCR |

RDB-124, RDB-156 |

6 |

BISCR6601218 |

660 amp puck style SCR |

RDB-180, RDB-240 |

6 |

|

|

RDB-302, RDB-361 |

|

BISCR15001850 |

1500 amp puck style SCR |

RDB-477, RDB-590, RDB-720 |

6 |

BICT2881M |

288:1 ratio current transformer |

RDB-27, RDB-40 |

3 |

|

|

RDB-52, RDB-65 |

|

BICT8641M |

864:1 ratio current transformer |

RDB-77, RDB-96 |

3 |

|

|

RDB-124, RDB-156 |

|

BICT26401M |

2640:1 ratio current transformer |

RDB-180, RDB-240 |

3 |

|

|

RDB-302, RDB-361 |

|

BICT57601M |

5760:1 ratio current transformer |

RDB-477, RDB-590, RDB-720 |

3 |

RSC-18 |

30A AC-1 rated bypass contactor |

RDB-27 |

1 |

RSC-32 |

45A AC-1 rated bypass contactor |

RDB-40 |

1 |

RSC-50 |

70A AC-1 rated bypass contactor |

RDB-52, RDB-65 |

1 |

RSC-65 |

80A AC-1 rated bypass contactor |

RDB-77 |

1 |

RSC-85 |

100A AC-1 rated bypass contactor |

RDB-96 |

1 |

RSC-100 |

150A AC-1 rated bypass contactor |

RDB-124 |

1 |

RSC-125 |

160A AC-1 rated bypass contactor |

RDB-156 |

1 |

RSC-150 |

210A AC-1 rated bypass contactor |

RDB-180 |

1 |

RSC-220 |

275A AC-1 rated bypass contactor |

RDB-240 |

1 |

RSC-300 |

350A AC-1 rated bypass contactor |

RDB-302 |

1 |

RSC-400 |

450A AC-1 rated bypass contactor |

RDB-361 |

1 |

RSC-600 |

660A AC-1 rated bypass contactor |

RDB-477, RDB-590 |

1 |

RSC-800 |

840A AC-1 rated bypass contactor |

RDB-720 |

1 |

BIOT |

Over temperature Switch |

all |

1 |

|

|

|

|

11

3. INSTALLATION

3.1 |

Site Preparation |

|

|

General Information |

Before the starter can be installed, the installation site must be prepared. The |

|

customer is responsible for: |

|

• Providing the correct power source. |

|

• Selecting the control mechanism. |

|

• Obtaining the connection cables. |

|

• Ensuring the installation site meets all environmental specifications for the |

|

enclosure NEMA rating. |

|

• Installing the motor. |

Connection Cables |

The connection cables for the starter must have the correct current NEC/CSA rating |

|

for the unit being installed. Depending upon the model, the connection cables can |

|

range from a single #14 AWG conductor to four 750 MCM cables. |

Site Requirements |

The installation site must adhere to the applicable starter NEMA/CEMA rating. For |

|

optimal performance, the installation site must meet the following specifications: |

|

• Temperature: 32 degrees Fahrenheit to 104 degrees Fahrenheit (0 degrees |

|

Centigrade to 40 degrees Centigrade). |

|

• Humidity: 20% to 95% non-condensing. |

|

• Airways: Clearances are provided around all heat sinks. |

|

• Altitude: Less than 3300 feet (1000 meters) above sea level. |

|

NOTE: At altitudes greater than 3300 feet (1000 meters) above sea level, the starter |

|

size must be derated 1% for every 330 feet (100 meters) above this level. |

Mounting |

The starter must be mounted so the heat sink fins are vertically oriented in an area |

|

that does not experience excessive shock or vibration. All models require airway |

|

passages around the heat sink. During normal operation the heat sink may reach 194 |

|

degrees Fahrenheit (90 degrees Centigrade). Do not install the starter in direct |

|

contact with any materials that cannot withstand these temperatures. |

3.2 |

EMC Installation guidelines |

|

|

General |

In order to help our customers comply with European electromagnetic compatability |

|

standards, Benshaw Inc. has developed the following guidelines. |

|

Attention: This product has been designed for Class A equipment. Use of the product |

|

in domestic environments may cause radio interference, in which case the installer |

|

may need to use additional mitigation methods. |

Enclosure |

Install the product in a grounded metal enclosure. |

Grounding |

Connect a grounding conductor to the screw or terminal provided as standard on each |

|

controller. Refer to layout/power wiring schematic for grounding provision location. |

Wiring |

Wire in an industrial application can be divided into three groups: power control and |

|

signal. The following recommendations for physical separation between these groups |

|

are provided to reduce the coupling effect; |

|

• Different wire groups should cross at 90 degrees inside an enclosure. |

|

• Minimum spacing between different wiring groups in the same tray should be |

|

six inches. |

|

• Wire runs outside an enclosure should be run in conduit or have shielding/armor |

|

with equivalent attenuation. |

|

• Different wire groups should be run in separate conduits. |

|

• Minimum spacing between conduits containing different wire groups should be |

|

three inches (8cm). |

Filtering |

To comply with Conducted Voltage Limits a 0.33 uF L-G capacitor should be |

|

connected to each line at point nearest to the incoming power. |

12

Loading...

Loading...