Benshaw MVRSM12, MVRSM18 Manual

BENSHAW

REDISTART MICRO II

INSTRUCTION MANUAL

MVRSM12/18 SERIES

The Leader In

Solid State Motor Control

Technology

Publication #: 890015-01-08

TABLE OF CONTENTS

Table of Contents

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using This manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Benshaw Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CT (Current Transformer) Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Voltage Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Real Time Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Output Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Control Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

Storage and Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

DeviceNet (Embedded) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

Modbus (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Overload Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Overload Curve Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

RediStart Micro II Computer Card Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Computer Card JC11 Header Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Old RediStart Micro II Power Card Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

3. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 EMC Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Remote RTD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 CT Ratio Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 RediStart Micro II Computer Card Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

i

TABLE OF CONTENTS

4. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Main Display Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

Meter Display Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

Starter Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

Current Ramp Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Programming A Kick Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

Tachometer Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

Programming The Motor Deceleration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

PORT (Power Outage Ride Through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

TruTorque Acceleration Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

TruTorque Deceleration Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

How Fault Classes Work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

Use of Overcurrent and Undercurrent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

Performing an Emergency Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

5. PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 PROGRAMMING: How To Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Menu Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Viewing a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Changing a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 PROGRAMMING: Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 |

|

Motor FLA. . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 45 |

Serv. Fact (service factor) . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 45 |

Start Mode . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 45 |

Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 45 |

Int. Curr. (initial current) . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 46 |

Max. Curr. (maximum current) . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 46 |

Ramp Time . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 46 |

Overload . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 47 |

Phase Order . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 47 |

5.3 PROGRAMMING: Motor Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 |

|

Motor FLA. . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 48 |

Serv. Fact (service factor) . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 48 |

Motor RPMs . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 48 |

5.4 PROGRAMMING: Starter Setup - Starter Modes |

. . . . . . . . . . . . . . . . . . . . . 49 |

Start Mode . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 49 |

Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 49 |

5.5 PROGRAMMING: Starter Setup - Forward1 Profile . . . . . . . . . . . . . . . . . . . . 50 |

|

Int. Curr. (initial current) . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 50 |

Max. Curr. (maximum current) . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 50 |

Ramp Time . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 50 |

Kick Curr. (kick current) . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 51 |

Kick Time . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . 51 |

ii

TABLE OF CONTENTS

5.6 PROGRAMMING: Starter Setup - Forward2 Profile . . . . . . . . . . . . . . . . . . . . 52

Forward #2 Ramp Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Int. Curr. (initial current) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Max. Curr. (maximum current) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Ramp Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Kick Curr. (kick current) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Kick Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

5.7 PROGRAMMING: Starter Setup - Tachometer Setup . . . . . . . . . . . . . . . . . . . 54

FS Volts (Full Speed Volts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Stab Cnst (Stability Constant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Ramp#1 Tim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Ramp#2 Tim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

TLoss Dela (Tachometer Signal Loss Delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

TLoss Mode (Tachometer Signal Loss Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

5.8 PROGRAMMING: Starter Setup - Decel Setup . . . . . . . . . . . . . . . . . . . . . . . 56

V Level #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 V Level #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 V DCL Time (decel time). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 TT DCL Tim (TruTorque deceleration time). . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 TT DCL Tor (ending deceleration torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.9 PROGRAMMING: Starter Setup - PORT CTL Setup. . . . . . . . . . . . . . . . . . . . 58

Fault Dly (Fault Delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Bypass Dly (Bypass Delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Sense Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.10 PROGRAMMING: Starter Setup - TruTorque Ramp . . . . . . . . . . . . . . . . . . . 59

Int Torque (initial torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Max Torque (maximum torque). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Ramp Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 TT Over Cu (TruTorque overcurrent trip) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Ovr Cur Dl (TruTorque overcurrent trip delay). . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.11 PROGRAMMING: Motor Protection - Overload . . . . . . . . . . . . . . . . . . . . . 61

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.12 PROGRAMMING: Motor Protection - Line Current . . . . . . . . . . . . . . . . . . . 62

% Imbalanc (percent imbalance) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Imbal Dela (imbalance delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 @ Stop Dly (current at stop delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 % No C@Run (percent no current at run) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 No C@R Dly (no current at run delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.13 PROGRAMMING: Motor Protection - Line Voltage . . . . . . . . . . . . . . . . . . . 64

H/L Volts (high/low voltage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

PH Dect Dl (Phase detect delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

5.14 PROGRAMMING: Motor Protection - Line Frequency. . . . . . . . . . . . . . . . . . 65

High Freq. (high frequency) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Low Freq. (low frequency). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Freq Delay (frequency delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.15 PROGRAMMING: Motor Protection - Ground Fault . . . . . . . . . . . . . . . . . . . 66

GND Fault (ground fault) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 GND Delay (ground delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

iii

TABLE OF CONTENTS

5.16 PROGRAMMING: Motor Protection - Shorted SCR . . . . . . . . . . . . . . . . . . . 67

@ Ramp DLY (shorted SCR at ramp delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 @ Stop DLY (shorted SCR at stop delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.17 PROGRAMMING: Motor Protection - Over Current . . . . . . . . . . . . . . . . . . . 68

Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Detect Dly (detect delay). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Release Dl (release delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.18 PROGRAMMING: Motor Protection - Under Current . . . . . . . . . . . . . . . . . . 69

Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 Detect Dly (detect delay). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 Release Dl (release delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.19 PROGRAMMING: Motor Protection - Start Lockouts . . . . . . . . . . . . . . . . . . 70

Starts/Hou (starts per hour). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Time Start (time between starts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 BKS Timer (backspin timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.20 PROGRAMMING: Motor Protection - Starting Timers. . . . . . . . . . . . . . . . . . 71

UTS Timer (up-to-speed timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 Zero Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.21 PROGRAMMING: Motor Protection - Permissive Input. . . . . . . . . . . . . . . . . 72

Inline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Trip Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.22 PROGRAMMING: Motor Protection - Misc.. . . . . . . . . . . . . . . . . . . . . . . . 73

Phase Orde (phase order) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

# Auto RST (number of auto resets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 No Main PW (no main power) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.23 PROGRAMMING: Motor Protection - Fault Classes . . . . . . . . . . . . . . . . . . . 74

Fault Classes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.24 PROGRAMMING: Meters & Relays - Meter Setup . . . . . . . . . . . . . . . . . . . . 75

Meter #1 , Meter #2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 AutoRange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Meter Rsts (meter resets). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Scroll Tim (scroll time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.25 PROGRAMMING: Meters & Relays - Standard Relays . . . . . . . . . . . . . . . . . 77

Relay#1, K5 and Relay#2, K6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.26 PROGRAMMING: Meters & Relays - Extended Relays . . . . . . . . . . . . . . . . . 78

Opt. #?, K? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.27 PROGRAMMING: Event Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Event Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.28 PROGRAMMING: Control Config - System Clock . . . . . . . . . . . . . . . . . . . . 81

System Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.29 PROGRAMMING: Control Config - System Password |

. . . . . . . . . . . . . . . . . 82 |

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . 82 |

iv

TABLE OF CONTENTS |

|

5.30 PROGRAMMING: Control Config - Comm. Settings . . . . . . . . . . . . . . . . . . |

83 |

COMM. Mode (communications mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

COM Addres (communications address) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

COM Delay (communications delay). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

MB:Baud (MODBUS baud rate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

MB:Com T/O (MODBUS communications timeout) . . . . . . . . . . . . . . . . . . . . . . . |

84 |

DN:MAC ID (DeviceNet MAC ID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

DN:Baud (DeviceNet baud rate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

DN:InAssy (DeviceNet input assembly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

DN:OutAssy (DeviceNet output assembly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

DN:T/O Act (DeviceNet timeout action) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

DN:Rev (DeviceNet interface revision) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

5.31 PROGRAMMING: Control Config - Options List. . . . . . . . . . . . . . . . . . . . . |

86 |

Options List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

5.32 PROGRAMMING: Control Config - Software Part# . . . . . . . . . . . . . . . . . . . |

87 |

Software Part# . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

5.33 PROGRAMMING: Factory Setup - Hardware Setup . . . . . . . . . . . . . . . . . . . |

88 |

C.T. Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

Relay Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

5.34 Programming: Factory Setup - BIST Setup . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

Start BIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

Test Inlin (test in-line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

Test Bypas (test bypass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

100% Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

5.35 PROGRAMMING: Factory Setup - Factory Control . . . . . . . . . . . . . . . . . . . |

90 |

FACT Pass. (factory password) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

Reset Def (reset to default parameters). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

CLR Events (clear event log) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

CLR Pass. (clear password) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

Cal Volt L1, L2, L3 (calibrate voltage meter). . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

Cal Curr L1, L2, L3 (calibrate current meter) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

5.36 PROGRAMMING: RTD Setup - RTD Module Setup . . . . . . . . . . . . . . . . . . . |

92 |

Mod#1 Addr (module #1 address) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

Mod#2 Addr (module #2 address) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

#RTDs Mod1 (number of RTDs on module #1) . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

#RTDs Mod2 (number of RTDs on module #2) . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

Temp Scale (temperature scale) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

5.37 PROGRAMMING: RTD Setup - RTD SetPnts 1-8 . . . . . . . . . . . . . . . . . . . . . |

93 |

RTD#? Grp (RTD #? Group). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

RTD#? Warn (RTD #? warning level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

RTD#? Alm (RTD #? alarm level). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

5.38 PROGRAMMING: RTD Setup - RTD SetPnts 9-16 . . . . . . . . . . . . . . . . . . . . |

94 |

RTD#? Grp (RTD #? Group). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

RTD#? Warn (RTD #? warning level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

RTD#? Alm (RTD #? alarm level). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

v

TABLE OF CONTENTS

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 |

|

6.1 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 |

|

LED Diagnostics . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 96 |

Meter Tests . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 97 |

Event Recorder . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 97 |

Fault/Log Codes . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 98 |

General Troubleshooting Charts . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 102 |

Spare Parts. . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 104 |

SCR Replacement . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 105 |

6.2 MEDIUM VOLTAGE TROUBLESHOOTING |

. . . . . . . . . . . . . . . . . . . . . . . 106 |

Built-In Self Test (BIST) . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 106 |

Maintenance. . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . 108 |

7. DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.1 DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 110 |

RediStart Micro II Computer Card Diagram . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 110 |

RediStart Micro II Power Card Layout . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 111 |

Old RediStart Micro Power Card Layout . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 112 |

RediStart Micro II Four (4) Relay Card Layout . . . . . . . . . . |

. . . . . . . . . . . . . . . . 113 |

RediStart Micro II Seven (7) Relay Card Layout . . . . . . . . . |

. . . . . . . . . . . . . . . . 113 |

RediStart Micro II RS-232 Communications Card Layout . . . . |

. . . . . . . . . . . . . . . . 114 |

RediStart Micro II RS-485 Communications Card Layout . . . . |

. . . . . . . . . . . . . . . . 114 |

RediStart Micro II RS-232/485 Communications Card Layout . |

. . . . . . . . . . . . . . . . 115 |

Modbus Master Card (for Remote RTD Module) . . . . . . . . . |

. . . . . . . . . . . . . . . . 115 |

RediStart Micro II Display Cut-out . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 116 |

8. PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.1 Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

RediStart Micro II Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 Quick Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 Motor Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 Starter Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 Motor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 Meters & Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 Event Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 Control Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 Factory Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 RTD Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

vi

1. INTRODUCTION

1.1 INTRODUCTION

|

Using This manual |

|

|

Layout |

This manual is divided into eight sections. Each section contains topics related to the |

|

section. The sections are as follows; |

|

• Introduction - Basic RediStart Micro II information. |

|

• Technical Specifications - RediStart Micro II specifications. |

|

• Installation - Information on installing the RediStart Micro II. |

|

• Operation - Information on how the starter operates. |

|

• Programming - Programming the RediStart Micro II. |

|

• Troubleshooting - Diagnosing RediStart Micro II problems. |

|

• Drawings - RediStart Micro II layout drawings. |

|

• Parameter List - List allowing user to record programmed values. |

Parameter List |

The last chapter of the manual is a parameter list. This list gives the user a place to |

|

enter the programmed value for each parameter and also gives the page number |

|

where the description of the parameter can be found. This list can be used as a quick |

|

reference to find the information on a parameter. |

Symbols |

There are two symbols used in this manual to highlight important information. The |

|

symbols appear as the following; |

Electrical hazard that could result in injury or death.

Caution that could result in damage to the starter or motor.

Highlight marking an important point in the documentation.

2

|

|

|

1.1 INTRODUCTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Benshaw Services |

|

|

|

|

|

|

|

General Information |

Benshaw offers its customers the following services: |

|

|

|

|

• Start-up services. |

|

|

|

|

• On-site training services. |

|

|

|

|

• |

Technical support. |

|

|

|

• |

Detailed documentation. |

|

|

|

• |

Replacement parts. |

|

|

|

NOTE: Information about products and services is available by contacting Benshaw. |

|

|

|

Start-Up Services |

Benshaw technical field support personnel are available to assist customers with the |

|

|

|

|

initial start-up of the RediStart Micro II. Information about start-up services and fees |

|

|

|

|

are available by contacting Benshaw. |

|

|

|

On-Site Training Services |

Benshaw technical field support personnel are available to conduct on-site training on |

|

|

|

|

RediStart Micro II operations and troubleshooting. |

|

|

|

Technical Support |

Benshaw technical support personnel are available (at no charge) to answer customer |

|

|

|

|

questions and provide technical support over the telephone. For information about |

|

|

|

|

contacting technical support personnel, refer to Contacting Benshaw on page 4. |

|

|

|

Documentation |

Benshaw provides all customers with: |

|

|

|

|

• |

Operations manual. |

|

|

|

• |

Wiring diagram. |

|

|

|

All drawings are produced in AutoCAD© format. The drawings are available on |

|

|

|

|

standard 3.5” diskettes or via e-mail by contacting Benshaw. |

|

|

|

On-Line Documentation |

All RediStart MicroII documentation is available on-line at www.benshaw.com. |

|

|

|

Replacement Parts |

Spare and replacement parts can be purchased from Benshaw. |

|

|

3

1.1 INTRODUCTION

Contacting Benshaw |

Information about Benshaw products and services is available by contacting Benshaw |

|

|

at one of the following offices: |

|

|

Benshaw Inc. Corporate Headquarters |

|

|

1659 E. Sutter Road |

|

|

Glenshaw, PA 15116 |

|

|

United States of America |

|

|

Phone: |

(412) 487 8235 |

|

Fax: |

(412) 487 4201 |

|

Benshaw Canada Controls Inc. |

|

|

R.R. #1 (Wallace Industrial Park) |

|

|

Listowel, Ontario |

|

|

Canada |

|

|

N4W 3G6 |

|

|

Phone: |

(519) 291 5112 |

|

Fax: |

(519) 291 2595 |

|

Benshaw West |

|

|

7820 E. Evans Drive, Suite 900 |

|

|

Scottsdale, AZ 85260 |

|

|

United States of America |

|

|

Phone: |

(480) 905 0601 |

|

Fax: |

(480) 905 0757 |

Technical support for the RediStart Micro II is available at no charge by contacting Benshaw’s customer service department at one of the above telephone numbers. A service technician is available Monday through Friday from 8:00 a.m. to 5:00 p.m.

EST.

NOTE: An on-call technician is available after normal business hours and on weekends by calling Benshaw and following the recorded instructions.

To help assure prompt and accurate service, please have the following information available when contacting Benshaw:

•Name of company.

•Telephone number where caller can be contacted.

•Fax number of caller.

•Benshaw product name.

•Benshaw model number.

•Benshaw serial number.

•Name of product distributor.

•Approximate date of purchase.

•Voltage of motor attached to Benshaw product.

•FLA of motor attached to Benshaw product.

•A brief description of the application.

4

1.1 INTRODUCTION

Features

General

• Chassis or NEMA 1, 4, 12, or 3R enclosure

Protection (ANSI standard numbers given)

•51 - Electronic motor overload (class 1 to 40)

•86 - Overload lockout

•48 - Adjustable up-to-speed timer (off; 0 to 300 seconds)

•59/27 - Adjustable over/under voltage protection

•46 - Adjustable line to average current imbalance

•81 - Adjustable high and low frequency protection

•Single phase protection

•66 - Adjustable starts per hour (off or 1 to 20 starts)

•Adjustable time between starts (off or 1 to 600 minutes)

•Backspin timer (off or 1 to 200 minutes)

•51 - Over current detection (Off or 50 to 800%) and time (0.1 to 90.0 sec. in 0.1 sec. intervals)

•37 - Undercurrent detection (Off or 10 to 100% and time (0.1 to 90.0 sec. in 0.1 sec. intervals)

•51G - Ground fault detection (Off or 1 to 100 amps) and time (0.1 to 90.0 sec. in 0.1 sec. intervals)

•Over-current, undercurrent, and ground fault can each be set to trip or activate a relay

•50 - Instantaneous electronic over-current trip

•Shorted SCR detection

•47 - Phase rotation selectable ABC, CBA, or Ins (insensitive)

•38/49 - Remote Mountable RTD protection package, 8 or 16 RTD inputs (optional)

•PORT (power outage ride through) available with external 120VAC.

Control

•Two programmable current ramp profiles selectable at any time via 120 volt input

•Initial current, maximum current, and ramp time adjustments for each ramp

•Kick Current and time adjustments for each ramp

•TruTorque acceleration and deceleration profiles

•Adjustable deceleration profiles (to eliminate water hammer)

•Adjustable brake profile

•Local start/stop controls

•Emergency reset capability

•Tachometer ramp control (requires 0-5VDC tachometer feedback signal)

Input/Output and Display

•Plain English operation via back lit LCD display interface

•LCD and LED status and diagnostics (full fault annunciation)

•Programmable metering (amps, volts, frequency, overload, power factor, elapsed time, watts, VARs, watt-hours, VA, Current Imbalance, Ground Fault Current, RTD temperatures)

•Programmable relay outputs

•Latched fault relay output

•Real time clock

•Time stamped event recorder

•Password protection

•Battery backed-up starter parameters and lockout times

5

2. TECHNICAL SPECIFICATIONS

2.1 TECHNICAL SPECIFICATIONS

|

|

CT (Current Transformer) Inputs |

|

|

|

Conversion |

Calibrated RMS, 12 samples per cycle |

|

Range |

0.01 to 1.5 × phase CT primary amps set point |

|

Accuracy |

±3.5% of phase CT primary amps set point |

|

Frequency |

23 to 72 Hz |

|

Current Withstand |

- 2.0 × CT primary amps set point (CT ratio parameter) - continuous |

|

|

- 10 |

× CT primary amps set point (CT ratio parameter) - 30 seconds |

|

- 55 |

× CT primary amps set point (CT ratio parameter) - 1 seconds |

Voltage Inputs

Conversion |

Calibrated RMS, 12 samples per cycle |

Range |

1000VAC to 9999VAC |

Accuracy |

±3.5% of full range |

Metering

Current |

±5%, 0 to 9999Amps |

Voltage |

±5%, 0 to 9999Volts |

Watts |

±5%, 0 to 6553kW |

Volt-Amps Reactive |

±5%, 0 to 6553kVAR |

Volt-Amps |

±5%, 0 to 6553kVA |

WH |

±5%, 0 to 6553MWH |

PF |

±3%, -0.01 to +0.01 |

Real Time Clock

Accuracy |

±1 minute per month |

Range |

1/1/1970 to 1/1/2069 |

Output Relays

Fault Relay |

- SPDT - Form C |

|

- 2A, 125VAC, resistive |

|

- 1A, 125VAC, 0.4 PF |

|

- 2A, 30VDC resistive |

|

- 100VA inrush |

Output Relay #1 & #2 |

- SPDT - Form C |

|

- 16A, 250VAC resistive |

|

- 8A, 250VAC 0.4 PF |

|

- 16A, 30VDC resistive |

|

- 2000VA inrush |

8

2.1 TECHNICAL SPECIFICATIONS

Four Relay Card |

- DPDT - Dual Form C |

|

- 5A, 250VAC, resistive |

|

- 2A, 250VAC, 0.4 PF |

|

- 5A, 30VDC, resistive |

|

- 500VA inrush |

Seven Relay Card |

- SPDT - Form C |

|

- 8A, 250VAC resistive |

|

- 4A, 250VAC 0.4 PF |

|

- 8A, 30VDC resistive |

|

- 800VA inrush |

Control Power

Voltage |

120VAC, ±15% |

|

240VAC, ±15% (Optional) |

Frequency |

50 to 60hz |

Power Consumption |

Varies for required control. |

Fuse |

Time delay control circuit protection fuses. |

Storage and Operating Conditions

Storage |

-20ºC (-4°F) to +60°C (+140°F) |

|

0% to 95% relative humidity, non-condensing |

Operating |

0°C (+32°F) to +50°C (+122°F) |

|

0% to 95% relative humidity, non-condensing |

|

DeviceNet (Embedded) |

|

|

Manual |

Available at www.benshaw.com or from your Benshaw sales office. |

EDS File |

Available at www.benshaw.com or from your Benshaw sales office. |

Device Type |

Softstart Starter |

I/O Slave Messaging |

Polling |

Baud Rates |

- 125K |

|

- 250K |

|

- 500K |

Conformance |

Self tested with ODVA (open DeviceNet Vendor Association) software. |

|

Modbus (Optional) |

|

|

Manual |

Available at www.benshaw.com or from your Benshaw sales office. |

Type |

Modbus RTU |

Connections |

- RS-232 |

|

- RS-485 |

Baud Rates |

- 2400 |

|

- 4800 |

|

- 9600 |

9

EU Declaration of Conformity

Charles E. Cook

Product Development Manager

|

|

2.1 TECHNICAL SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

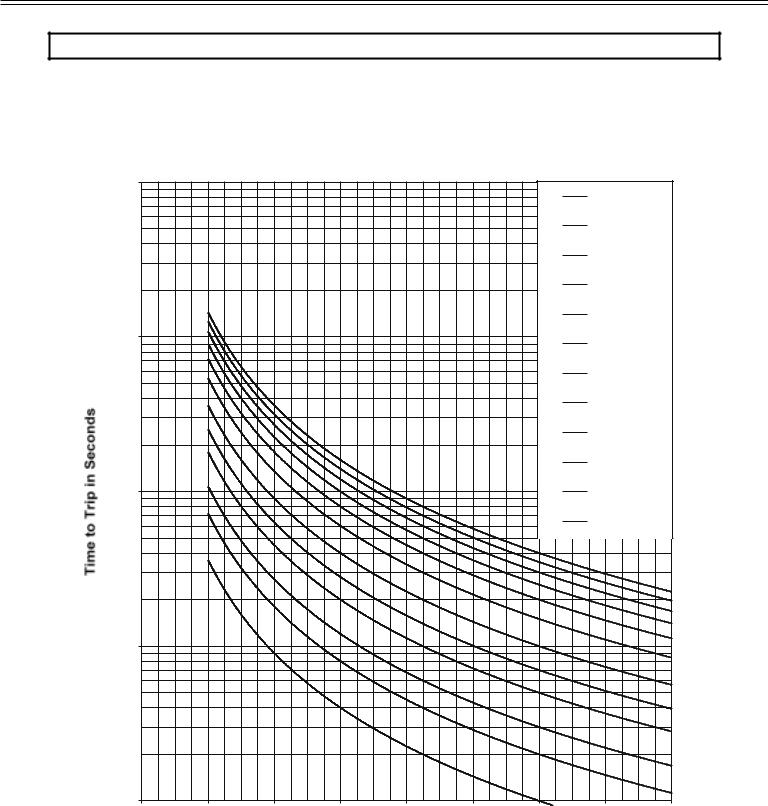

Overload Curves |

|

|

|

|

|

|

General |

The RediStart Micro II comes with forty (40) standard overload curves. The 100% (no |

|

|

|

trip) point is the motor FLA setting multiplied by the service factor. These curves are |

|

|

|

shown on the next page. |

|

|

|

NOTE: When the overload counter is at a number other than 0%, the time to trip will |

|

|

|

be lowered by this percentage. |

|

|

Curves |

Class 1 to 40 in steps of 1. |

|

|

Trip Time Accuracy |

±2 seconds up to 30 seconds |

|

11

2.1 TECHNICAL SPECIFICATIONS

Overload Curve Chart

RediStart Micro II Overload Curves

10000 |

|

|

Class 40 |

|

Class 35 |

|

Class 30 |

|

Class 25 |

|

Class 40 |

|

Class 20 |

1000 |

Class 15 |

|

|

|

Class 10 |

|

Class 7 |

|

Class 5 |

|

Class 3 |

100 |

Class 2 |

|

Class 1 |

Class 1

10

1

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

Current as Percent of FLA

12

2.1 TECHNICAL SPECIFICATIONS

RediStart Micro II Computer Card Jumpers

Jumper |

Description |

Position 1-2 |

Position 2-3 |

Standard |

|

|

(In - 2-pos. jumper) |

(Out - 2-pos. jumper) |

|

JPC5 |

LCD Start Button |

Enable |

Disable |

1-2 |

JPC7 |

O/L Reset Auto/Manual |

Automatic |

Manual |

2-3 |

JPC8 |

Display Format |

Standard |

Local Bus |

1-2 |

JPC12 |

SCR Firing |

Pulse |

Block |

In |

JPC13 |

LCD Stop Button |

Enable |

Disable |

1-2 |

JPC14 |

RAM Size |

8K RAM |

2K RAM |

1-2 |

JPC15 |

PWM/ADDR16 |

ADDR16 |

PWM |

1-2,3-4 |

JPC17 |

Voltage Select |

4160 or 3300 |

2400 or 4800 |

|

JPC18 |

Voltage Select |

3300 or 4800 |

2400 or 4160 |

|

JPC19 |

Fault Reset |

Automatic |

Manual |

2-3 |

JPC25 |

Synchronous Application |

Yes |

No |

Out |

JPC27 |

Micro Enable/ADDR17 |

ADDR17 |

Enable |

1-2,3-4 |

|

Computer Card JC11 Header Assignments |

|

|

Position |

Assignment |

1-16 |

Starter equipped with voltage divider card. |

2-15 |

Not used. |

3-14 |

Starter Equipped with MODBUS master card (for RTD module). |

4-13 |

Not used. |

5-12 |

Not used. |

6-11 |

Enables emergency reset. |

7-10 |

Not used. |

8-9 |

Not used. |

Old RediStart Micro II Power Card Jumpers

Jumper |

Description |

Position 1-2 |

Position 2-3 |

Standard |

JPP2 |

Line Synching |

Line to Line |

Line to Neutral |

1-2 |

JPP3 |

Line Synching |

Line to Line |

Line to Neutral |

1-2 |

JPP4 |

Line Synching |

Line to Line |

Line to Neutral |

1-2 |

NOTE: Jumpers JPP2, JPP3, and JPP4 do not apply to the BIPC-300030-xx Power Card.

13

2.1 TECHNICAL SPECIFICATIONS

14

3. INSTALLATION

3.1 INSTALLATION

|

Site Preparation |

|

|

General |

Before the installation of the RediStart Micro II, the site should be prepared. The |

|

customer is responsible for: |

|

• Providing the correct power source. |

|

• Selecting the control mechanism. |

|

• Providing the connection cables and associated hardware. |

|

• Ensuring the installation site meets all environmental specifications for the |

|

enclosure NEMA rating. |

Connection Cables |

The connection cables for the starter must have the correct NEC/C.S.A. current rating |

|

for the unit being installed. Depending upon the model, the connection cables can |

|

range from a single #14 AWG conductor to four 750 MCM cables. |

Site Requirements |

The installation site must adhere to the applicable starter NEMA rating. For optimal |

|

performance, the installation site must meet the following specifications, unless |

|

equipment (such as a heater or air conditioner) was added to the unit for operation |

|

outside of these ranges: |

|

• Temperature: 0°C (+32F) to 40°C (+104°F). |

|

• Humidity: 20% to 95% non-condensing. |

|

• Airways: Clearances are provided around all heat sinks. |

|

• Altitude: Less than 3300 feet (1000 meters) above sea level. |

|

NOTE: The starter rating must be derated 1% for every 330 feet (100 meters) above |

|

3300 feet (1000 meters). |

Mounting |

The starter must be mounted so the heat sink fins are vertically oriented in an area |

|

that does not experience excessive shock or vibration. All models require airway |

|

passages around the heat sink. During normal operation the heat sink may reach 194 |

|

degrees Fahrenheit (90 degrees Centigrade). Do not install the starter in direct |

|

contact with any materials that cannot withstand these temperatures. |

|

|

|

EMC Installation guidelines |

|

|

General |

In order to help our customers comply with European electromagnetic compatability |

|

standards, Benshaw Inc. has developed the following guidelines. |

|

Attention: This product has been designed for Class A equipment. Use of the product |

|

in domestic environments may cause radio interference, in which case the installer |

|

may need to use additional mitigation methods. |

Enclosure |

Install the product in a grounded metal enclosure. |

Grounding |

Connect a grounding conductor to the screw or terminal provided as standard on each |

|

controller. Refer to layout/power wiring schematic for grounding provision location. |

Wiring |

Wire in an industrial application can be divided into three groups: power control and |

|

signal. The following recommendations for physical separation between these groups |

|

are provided to reduce the coupling effect; |

|

• Different wire groups should cross at 90 degrees inside an enclosure. |

|

• Minimum spacing between different wiring groups in the same tray should be |

|

six inches. |

|

• Wire runs outside an enclosure should be run in conduit or have shielding/armor |

|

with equivalent attenuation. |

|

• Different wire groups should be run in separate conduits. |

|

• Minimum spacing between conduits containing different wire groups should be |

|

three inches (8cm). |

Filtering |

To comply with Conducted Voltage Limits a 0.33 uF capacitor should be connected |

|

between each incoming power line and ground at a point nearest to where the |

|

incoming power enters the enclosure. |

16

|

|

3.1 INSTALLATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation Procedures |

|

|

|

|

|

|

General Information |

Installation of some models may require halting production during installation. If |

|

|

|

applicable, ensure that the starter is installed when production can be halted long |

|

|

|

enough to accommodate the installation. |

|

Before installing the starter, ensure:

•The wiring diagram (supplied separately with the starter) is correct for the required application.

•The starter is the correct current rating for the motor being started.

•All of the installation safety precautions are followed.

•The correct power source is available.

•The starter control method has been selected.

•The necessary installation tools and supplies are obtained.

•The installation site meets all environmental specifications for the starter NEMA/CEMA rating.

•The motor being started has been installed and is ready to be started.

•Any power factor correction capacitors (PFCC) are installed on the power source side of the starter and not on the motor side.

NOTE: Failure to remove power factor correction or surge capacitors from the load side of the starter will result in serious damage to the starter which will not be covered by the starter’s warranty. The capacitors must be powered from the line side of the starter. The up-to-speed contact can be used to energize the capacitors after the motor has reached full speed.

Safety Precautions |

To ensure the safety of the individuals installing the starter, and the safe operation of |

|

the starter, observe the following guidelines: |

|

• Ensure that the installation site meets all of the required environmental |

|

conditions (Refer to Site Preparation, page 16). |

|

• LOCK OUT ALL SOURCES OF POWER. |

|

• Install circuit disconnecting devices (i.e., circuit breaker, fused disconnect or |

|

non-fused disconnect) if they were not previously installed by the factory as part |

|

of the package. |

|

• Install short circuit protection (i.e., circuit breaker or fuses) if not previously |

|

installed by the factory as part of the package. See page 13 for the fault rating |

|

table. |

|

• Follow all NEC (National Electrical Code) and/or C.S.A. (Canadian Standards |

|

Association) standards. |

|

• Remove any foreign objects from the interior of the enclosure. |

|

• Ensure that wiring is installed by an experienced electrician. |

|

• Ensure that the individuals installing the starter have protective eye wear and |

|

clothing. |

|

The opening of the branch circuit protective device may be an indication that a fault |

|

current has been interrupted. To reduce the risk of electrical shock, current carrying |

|

parts and other components of the starter should be inspected and replaced if |

|

damaged. |

17

3.1 INSTALLATION

Installation |

To begin installation: |

||

|

• Read and follow all of the installation safety precautions. |

||

|

• Procure the necessary installation tools and any supplies. |

||

|

• Ensure the site has sufficient lighting for safe installation. |

||

|

• Move the starter to the installation site. |

||

|

• Ensure that the starter is positioned so that the cabinet door has ample |

||

|

|

clearance, and all of the controls are accessible. |

|

|

• DO NOT install the starter in direct contact with any materials that cannot |

||

|

|

withstand the maximum heat sink temperature of 194 degrees Fahrenheit (90 |

|

|

|

degrees Centigrade). All models require airway passages around the heat sink |

|

|

|

for proper cooling. |

|

|

If the starter is to be wall mounted: |

||

|

• Mount the starter on the applicable surface using the appropriate hardware. |

||

|

NOTE: Moving some models may require more than one individual or lifting |

||

|

equipment (e.g., forklift, crane). |

||

Control Wiring |

The control wiring should be connected to suit the customers needs. The control |

||

|

terminals on the control cards are as follows: |

||

|

RediStart Micro II Power Card (refer to card layout on page 111): |

||

|

• |

TBP1-1 |

24VDC common for relay and reversing card |

|

• |

TBP1-2 |

24VDC power for relay and reversing card |

|

• |

TBP2-1 |

Run relay neutral |

|

• |

TBP2-2 |

Run relay live |

|

• |

TBP2-5 |

Run relay holding contact |

|

• |

TBP3-1 |

General fault contact N.C. (not faulted) |

|

• |

TBP3-2 |

General fault contact common |

|

• |

TBP3-3 |

General fault contact N.O. (not faulted) |

|

• |

TBP3-4 |

Programmable relay #1 N.O. |

|

• |

TBP3-5 |

Programmable relay #1 common |

|

• |

TBP3-6 |

Programmable relay #1 N.C. |

|

• |

TBP3-7 |

Programmable relay #2 N.O. |

|

• |

TBP3-8 |

Programmable relay #2 common |

|

• |

TBP3-9 |

Programmable relay #2 N.C. |

RediStart Micro II computer card inputs (refer to card layout on page 110):

•JC13-1 Heat sink thermal switch or external starter trip input.

•JC13-2 AC neutral.

•JC13-3 Run confirm.

•JC13-4 In-line monitoring.

•JC13-5 Disconnect monitoring.

•JC13-6 Reverse/Forward Jog.

•JC13-7 Bypass monitoring.

• JC13-8 |

Jog mode. |

•JC13-9 Profile #2 select.

•JC13-10 External motor thermal overload reset.

•JC13-11 External computer reset.

•JC13-12 AC neutral.

18

3.1 INSTALLATION

RediStart Micro II Four (4) Relay Card (refer to card layout on page 113):

•TB2-1 Optional programmable relay #1 N.O.

•TB2-2 Optional programmable relay #1 N.C.

•TB2-3 Optional programmable relay #1 common

•TB2-4 Optional programmable relay #1 N.O.

•TB2-5 Optional programmable relay #1 N.C.

•TB2-6 Optional programmable relay #1 common

•TB2-7 Optional programmable relay #2 N.O.

•TB2-8 Optional programmable relay #2 N.C.

•TB2-9 Optional programmable relay #2 common

•TB2-10 Optional programmable relay #2 N.O.

•TB2-11 Optional programmable relay #2 N.C.

•TB2-12 Optional programmable relay #2 common

•TB2-13 Optional programmable relay #3 N.O.

•TB2-14 Optional programmable relay #3 N.C.

•TB2-15 Optional programmable relay #3 common

•TB2-16 Optional programmable relay #3 N.O.

•TB2-17 Optional programmable relay #3 N.C.

•TB2-18 Optional programmable relay #3 common

•TB2-19 Optional programmable relay #4 N.O.

•TB2-20 Optional programmable relay #4 N.C.

•TB2-21 Optional programmable relay #4 common

•TB2-22 Optional programmable relay #4 N.O.

•TB2-23 Optional programmable relay #4 N.C.

•TB2-24 Optional programmable relay #4 common

RediStart Micro II seven (7) Relay Card (refer to card layout on page 113):

•TB2-1 Optional programmable relay #1 N.O.

•TB2-2 Optional programmable relay #1 common

•TB2-3 Optional programmable relay #1 N.C.

•TB2-4 Optional programmable relay #2 N.O.

•TB2-5 Optional programmable relay #2 common

•TB2-6 Optional programmable relay #2 N.C.

•TB2-7 Optional programmable relay #3 N.O.

•TB2-8 Optional programmable relay #3 common

•TB2-9 Optional programmable relay #3 N.C.

•TB2-10 Optional programmable relay #4 N.O.

•TB2-11 Optional programmable relay #4 common

•TB2-12 Optional programmable relay #4 N.C.

•TB2-13 Optional programmable relay #5 N.O.

•TB2-14 Optional programmable relay #5 common

•TB2-15 Optional programmable relay #5 N.C.

•TB2-16 Optional programmable relay #6 N.O.

•TB2-17 Optional programmable relay #6 common

•TB2-18 Optional programmable relay #6 N.C.

•TB2-19 Optional programmable relay #7 N.O.

•TB2-20 Optional programmable relay #7 common

•TB2-21 Optional programmable relay #7 N.C.

19

3.1 INSTALLATION

Power Wiring |

Thread the power and motor cables through a connector into the enclosure. Strip |

|

away the motor cable insulation and apply anti-oxidation paste to the conductors. |

Attach the motor cables:

•Use the T1, T2 and T3 lugs or terminals.

•Attach the power source cables:

•Use the L1, L2 and L3 lugs or terminals.

NOTE: For larger starters, thread each incoming power cable through its applicable current transformer (CT); if not already supplied in the unit. The cables must be threaded through the CTs in the same direction to insure proper operation (Refer to the wiring diagram supplied with the starter).

The following is a list of the recommended crimp-on wire connectors manufactured by

Penn-union Corp.

Wire Size |

Part # |

|

Wire Size |

Part # |

|

|

|

|

|

1/0 |

BLU-1/0S20 |

|

500 MCM |

BLU-050S2 |

|

|

|

|

|

2/0 |

BLU-2/0S4 |

|

600 MCM |

BLU-060S1 |

|

|

|

|

|

3/0 |

BLU-3/0S1 |

|

650 MCM |

BLU-065S5 |

|

|

|

|

|

4/0 |

BLU-4/0S1 |

|

750 MCM |

BLU-075S |

|

|

|

|

|

250 MCM |

BLU-025S |

|

800 MCM |

BLU-080S |

|

|

|

|

|

300 MCM |

BLU-030S |

|

1000 MCM |

BLU-100S |

|

|

|

|

|

350 MCM |

BLU-035S |

|

1500 MCM |

BLU-150S |

|

|

|

|

|

400 MCM |

BLU-040S4 |

|

2000 MCM |

BLU-200s |

|

|

|

|

|

450 MCM |

BLU-045S1 |

|

|

|

|

|

|

|

|

Power Factor Capacitors |

Power factor correction capacitors and surge capacitors MUST NOT be connected |

|

between the RediStart Micro II and the motor. These devices can damage the SCR’s in |

|

the package during ramping. These devices appear like a short circuit to the SCR |

|

when it turns on, which causes a di/dt level greater than the SCR can handle. If used, |

|

power factor correction capacitors or surge capacitors must be connected ahead of the |

|

RediStart Micro II. Programmable relay #2 (K6) can be set to an up-to-speed (UTS) |

|

contact (up-to-speed is the default setting) and then used to pull-in a contactor to |

|

connect the capacitors after the motor has reached full speed. |

|

NOTE: The motor manufacturer should be contacted before surge capacitors are |

|

removed from the motor terminal box. |

Finishing |

After all of the safety precautions and installation procedures have been completed, |

|

verify that the following settings are correct for the application: |

• Current transformer scaling switches.

• Hardware deceleration/braking control (JPC3).

• RediStart Micro II computer card jumpers.

20

|

|

3.1 INSTALLATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Preventative Maintenance |

|

|

|

|

|

|

General Information |

Preventive maintenance performed on a regular basis will help ensure that the starter |

|

|

|

continues to operate reliably and safely. The frequency of preventive maintenance |

|

|

|

depends upon the type of maintenance and the installation site’s environment. |

|

|

|

NOTE: Preventive maintenance should always be performed by a trained technician. |

|

|

Preventive Maintenance |

During Commissioning; |

|

|

|

• Torque all power connections during commissioning. This includes pre-wired |

|

|

|

equipment. |

|

|

|

• Check all of the control wiring in the package for loose connections. |

|

For the first month after the starter has been put in operation;

•Re-torque all power connections every two weeks. This includes pre-wired equipment.

•Inspect the cooling fans after two weeks to ensure proper operation.

After the first month of operation;

•Re-torque all power connections every year.

•Clean any accumulated dust from the starter using a clean source of compressed air.

•Inspect the cooling fans every three months to ensure proper operation.

•Clean or replace any air vent filters on the starter every three months.

•NOTE: If mechanical vibrations are present at the installation site, inspect the connections more frequently.

|

Remote RTD Module |

|

|

General |

The RediStart Micro II can have up to 2 RTD modules installed. The RTD modules |

|

can be installed in the cabinet with the RediStart Micro II or they can be installed |

|

remotely at the motor. Refer to the Remote RTD Module manual for details on this |

|

module. |

MODBUS Master Card |

The MODBUS master card is installed on the RediStart Micro II CPU card to allow |

|

the starter to communicate with the RTD Module. |

|

CT Ratio Scaling |

|

|

General Information |

The motor current signal scaling is set according to the motor current specified when |

|

the starter is ordered. To ensure accurate operation, the motor current signal must be |

|

correctly scaled for the motor current being controlled by the starter.Motor current |

|

signal scaling may have to be changed if the motor size has been changed from the |

|

original specification.Motor current signal scaling is accomplished by verifying the |

|

current transformer ratio as supplied with the starter and then selecting the correct |

|

DIP switch setting from the chart on the following page for the current transformer |

|

ratio. |

The DIP switches are:

•ON in the right position

•OFF in the left position

NOTE: Adjust the DIP switches only when the motor is stopped, or the switches could be damaged.

21

3.1 INSTALLATION

Confirm Switch Settings To verify or change the motor current signal scaling:

•Compare the CT ratio stamped on each CT to the CT ratio listed on the wiring diagram supplied with the starter to ensure the correct CTs are installed.

•Inspect the RediStart Micro II power card to ensure that the DIP switches are in the correct positions for the applicable CT ratio and the motor full-load current (FLA) rating.

Switch Settings |

CT Ratio |

Motor FLA |

Switch 1 |

Switch 2 |

|

288:1 |

3A to 9A |

Off |

Off |

|

288:1 |

9A to 24A |

On |

Off |

|

288:1 |

25A to 60A |

On |

On |

|

864:1 |

20A to 24A |

Off |

Off |

|

864:1 |

25A to 70A |

On |

Off |

|

864:1 |

71A to 180A |

On |

On |

|

2640:1 |

40A to 80A |

Off |

Off |

|

2640:1 |

81A to 200A |

On |

Off |

|

2640:1 |

201A to 500A |

On |

On |

|

5760:1 |

70A to 160A |

Off |

Off |

|

5760:1 |

161A to 400A |

On |

Off |

|

5760:1 |

401A to 1200A |

On |

On |

Changing FLA |

If the actual motor FLA has been changed from the motor FLA documented on the |

|||

|

purchase order: |

|

|

|

•The DIP switch positions may need to be changed.

•Different CTs may have to be installed in the starter and the current transformer ratio parameter may need to be changed (Refer to current transformer ratio parameter, page 88).

|

|

RediStart Micro II Computer Card Jumpers |

|

|

|

General Information |

The RediStart Micro II computer card has a number of jumpers that affect the |

|

|

operation of the starter. In some cases, these jumpers will over-ride the programmed |

|

|

values. |

|

JPC5 - LCD Start button |

The LCD Start button can be enabled or disabled by this jumper. The LCD Start |

|

|

button is factory enabled unless the purchase order requests that the LCD Start |

|

|

button is disabled. The LCD Start button is controlled by jumper JPC5 on the |

|

|

RediStart Micro II computer card (Refer to RediStart Micro II computer card layout |

|

|

on page 110). |

|

|

Mode |

Position |

|

Enable |

1-2 |

|

Disable |

2-3 |

JPC7 - Overload Auto/Man. |

The motor thermal overload can be set to require a manual reset or to automatically |

|

|

reset after a thermal trip. The motor thermal overload is set to the manual reset |

|

|

position unless the purchase order requests that the motor thermal overload is set to |

|

|

the automatic reset position. The motor thermal overload reset is controlled by jumper |

|

|

JPC7 on the RediStart Micro II computer card (Refer to RediStart Micro II computer |

|

|

card layout on page 110). |

|

|

Mode |

Position |

|

Automatic Reset |

1-2 |

|

Manual Reset |

2-3 |

22

Loading...

Loading...