Page 1

Tebevert III 25kVA

120VDC Inverter System

028-0009-006 Rev. C

Operations and Maintenance Manual

Benning Power Electronics

1220 Presidential Drive Suite 100

Richardson, TX 75081 USA

www.benning.us

800.910.3601

This manual contains important

safety instructions that should be

followed during installation and

maintenance of the Power

System.

Page 2

Page 3

TABLE OF CONTENTS

0 IMPORTANT INFORMATION .................................................................................................................. i

0.1 VERSION .............................................................................................................................. i

0.1 PASSWORD .......................................................................................................................... ii

0.1 DATA SHEET ....................................................................................................................... iii

0.2 PREFACE ............................................................................................................................. 1

1 SAFETY NOTES AND MARKINGS ........................................................................................ 3

2 GENERAL ............................................................................................................................ 6

3 THE COMPONENTS OF THE TYPICAL INVERTER SYSTEM .................................................. 6

3.1 PSJ TYPE EQUIPMENT CABINET .......................................................................................... 7

3.2 INVERTER SLOTS ............................................................................................................... 10

3.3 SBS SLOT .......................................................................................................................... 12

3.4 MANUAL MAINTENCE BY-PASS SWITCH .............................................................................. 12

3.5 INVERTER .......................................................................................................................... 15

3.5.1 DESIGN OF THE UNIT ..................................................................................................... 15

3.5.2 TERMINALS AND OPERATING UNITS ............................................................................... 17

3.5.3 SIGNALLING ................................................................................................................... 19

3.6 ELECTRONIC SWITCH-OVER SBS UNIT ............................................................................... 21

3.6.1 DESIGN OF THE UNIT ..................................................................................................... 22

3.6.2 TERMINALS AND OPERATING ELEMENTS......................................................................... 23

3.6.3 SIGNALLING ................................................................................................................... 25

3.7 ACD DISTRIBUTIN PANEL ................................................................................................... 26

3.7.1 NA STYLE SNAP-IN BREAKER PANEL ............................................................................ 26

3.7.2 DIN RAIL STYLE BREAKER PANEL ................................................................................... 27

3.8 TECHNICCAL DATA .................................................................................................................. 27

4 INSTALLATION AND COMMISSIONING ........................................................................... 28

4.1 INVERTER SETTINGS ......................................................................................................... 29

4.2 SETTINGS OF THE ELECTRONIC SWITCH –OVE R/ SB S UNI T ................................................. 30

4.3 PANEL WRITING ................................................................................................................ 32

4.3.1 DC CABLE REQUIREMENTS FOR 25kVA, 120, INDIVIDUAL DC INPUT (DIN RAIL TERMINAL

BLOCK) ..................................................................................................................................... 34

4.3.2 DC CABLE REQUIREMENTS FOR 25kVA, 120VDC, BULK DC INPUT SYSTEM ....................... 34

Page 4

4.3.3 AC CABLE REQUIREMENTS FOR 25kVA, 120 VAC AC INPUT RATI NGS. ............................. 35

4.3.4 AC CABLE REQUIR EMENTS FOR 25kVA, 120/240 VAC INPUT SYSTEM . .............................. 35

4.3.5 AC CABLE REQUIREMENTS FOR 25kVA, 208 VAC INPUT SYSTEM.. .................................... 35

4.3.6 AC CABLE REQUIREMENTS FOR 25kVA, 220 VAC INPUT SYSTEM ..................................... 36

4.3.7 AC CABLE REQUIREMENTS FOR 25kVA, 240 VAC INPUT SYSTEM ..................................... 36

4.3.8 AC CABLE REQUIREMENTS FOR 25kVA, 480 VAC INPUT SYSTEM ...................................... 36

4.3.9

TORQUE TABLE FOR ALL TERMINATIONS

4.4 INSTALLATION OF THE UNITS ............................................................................................ 60

4.4.1 INSTALLATION OF THE STATIC BY-PASS SWITCH (SBS) .................................................. 39

4.4.2 INSTALLATION OF THE INVERTERS ................................................................................ 40

4.5 SWITCHING ON THE INVERTER SYSTEM ............................................................................. 40

5 PERFORMANCE TESTING ................................................................................................. 42

5.1 PRELIMINARIES TO PERFORMANCE TEST ........................................................................... 42

5.2 TEST EQUIPMENT .............................................................................................................. 43

5.3 TEST OF THE INVERTERS ................................................................................................... 43

5.3.1 INVERTER TEST ACTIVITIES ........................................................................................... 43

5.4 TEST OF THE S BS UNIT ...................................................................................................... 45

5.4.1 SBS TEST ACTIVITIES .................................................................................................... 46

5.5 FINAL STEPS ...................................................................................................................... 47

6 MAINTENANCE ................................................................................................................. 47

........................................................................ 37

6.1 USE OF THE MANUAL BY-PASS SWITCH .............................................................................. 47

6.2 EXCHANGE OF UNITS ......................................................................................................... 50

6.3 UPGRADING THE SYSTEM .................................................................................................. 51

7 DESCRIPTION OF FUNCTION ........................................................................................... 51

7.1 TOTAL SYSTE M .................................................................................................................. 51

7.2 INVERTER .......................................................................................................................... 52

7.2.1 MONITORING THE INPUT VOLTAGE ............................................................................... 52

7.2.2 MONITORING THE OUTPUT VOLTAGE ............................................................................. 54

7.2.3 MONITORING THE TEMPERATURE .................................................................................. 54

7.2.4 OVERLOAD BEHAVIOR .................................................................................................... 54

7.2.5 SHORT-CIRCUIT BEHAVIOR ............................................................................................ 55

7.3 ELECTRONIC SWITCHING/SBS UNIT ................................................................................... 55

Page 5

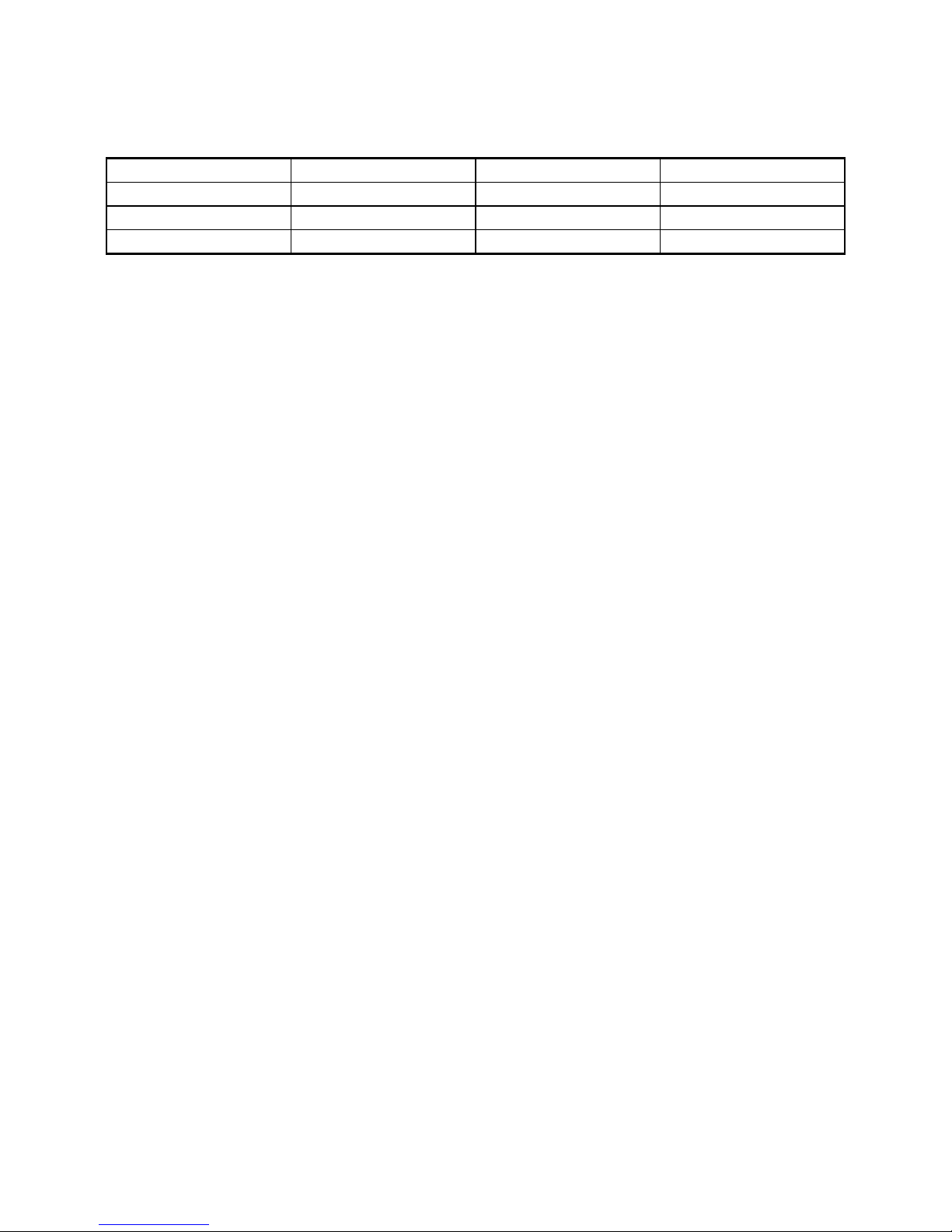

Revision

Date

Originator

Approver

C

07.08.11

A.Waggott/J.Almond

D.Almond

VERSION:

A 06.01.08 C.Tumey D.Almond

B 03.12.10 C.Tumey E.McDonald

Publication Document: Version 1.1

Copyright © 2007 Benning Power El ectronics

Proprietary Information: This ma nual contains proprietary information which is

protected by copyright law. All r ights are reserved. No part of this manual may be

photocopied, reproduced, or translated to another language without prior written

consent of Benning Power Electronics. Specifications in this manual are subject to

change without notice.

Page 6

ii

PASSWORD:

Password Level 1: PW 1

Password Level 2: PW 2

Password Level 3: PW 3

Password Level 4: PW 4

NOTE:

PUT A SPACE BETWEEN PW AND THE

NUMBER

Page 7

TEBEVERT III MODULAR

5-25 kVA INVERTER SYSTEM

The TEBEVERT III Modular Inverter System is designed

to address the critical AC powering requirements of

Industrial and Utility applications. The TEBEVERT III

Modular Inverter System can be scaled in 5 kVA

increments up to 25 kVA (non-redundant). Unlike

conventional stand alone inverters, these parallel

operating inverters can also be scaled to operate with

N+1 redundancy. N+1 redundancy insures optimal

availability for your critical load applications. If an

inverter failure should ever occur, the faulty inverter

module will automatically be removed from the output

bus before a disruption in the output is seen by the

critical load. In this mode of operation, a failure of one

inverter will not effect the operation of your critical load.

Since all units are designed for “hot swap” replacement,

a faulty module can easily be unplugged and replaced

to maintain power to your critical load.

Key Features

Hot Swap 5 kVA Inverter Modules

Hot Swap Static Switch Module

Supports High Inrush Current Loads

High Efficiency Operation, Lowers Operating Costs

Low Distortion Output Voltage

Integrated Maintenance Bypass Switch

Meets EN 55022 Class B Requirements

Automatic Master-Slave Operation

Up to Five Inverter Modules Can Be Paralleled As Load

Increases

No Single Points Of Failure

User Friendly Display Of Operating Mode

Optional—Seismic Zone 4 Certified

Optional—Internal AC Load Distribution Circuit Breakers

120VDC Tebevert III

System

Tebevert III_120 (R1_07) © Benning Power Electronics 2007

Specifications are subject to change without notice

Page 8

Technical Specifications

60HZ Models

Output Capacity 5 - 25.0 KVA

Maximum Number of Modules The inverter cabinet supports a maximum of 5 inverter modules

Nominal Bypass AC Input 120 VAC 208, 220, 240, 480VAC

# of Bypass AC Phases 1 2

Bypass AC Input Wiring L, N, PE L1, L2, PE

Nominal DC Input 120VDC

DC Input Range -15%, +20%

Reflected DC Ripple, 120VDC < 2mV reverse smoothing

Nominal AC Output Voltage 120VAC 120VAC

Optional AC Output Voltage 120/240VAC 120/240VAC

Output Voltage Regulation +/- 5% for all combinations of line, load and temperature

Output Power Factor 0.7 lagging to 0.8 leading

Output Voltage Waveform PWM sine-wave

Output Crest Factor 2:8:1

Output Voltage Distortion < 3.5% @ 100% rated linear load

Output Overcurrent Protection Electronic current limiting

Overload Rating (Inverters) 200% for approx. 75 cycles (1.25 seconds)

Overload Rating (Static Bypass) 500% for 100ms

System Operating Efficiency > 89% (typical)

Frequency Stability +/- 0.1% free running, +/- 3% when AC present

Module Capacity 5.0kVA/4.0kW

Static Switch Transfer Time < 2ms

Cooling Temperature controlled fans

Maintenance Bypass Switch Standard make-before-break mechanically interlocked switch provided on all models

Remote Alarming (1) Form-C Summary Alarm, Optional Relay Card (8 Alarms)

LED indicators (Inverter Modules) Output present, fault, overload, AC synchronized, parallel operation

LED indicators (Static Bypass Switch) Power flow diagram, normal, fault, ac present, dc present, overload, load on bypass, load on

Metering (4) segment LCD display switchable between output voltage and current

Cabinet Dimensions (H x W x D) 84” (2134 mm) x 23.6” (600 mm) x 23.6” (600 mm)

Radio Interference EN 55022, class B

Altitude 6000 ft (1800 m), 13, 000 ft. (4000 m) at 30°C

Operating Temperature -5 to +40° C

Operating Humidity 0-95% non-condensing

Module Data 5.0kVA

Power Rating 5000VA/4000W

Nominal Input Current 120 VDC 38.0A

Maximum Input Current 120VDC 44A

Output Current NOM 120VAC 41.6A

< 5% RMS

inverter

Benning Power Electronics, Inc. Toll Free: 800.910.3601

11120 Grader St . Dallas . TX 75238 Outside the US: 214.553.1444

E-Mail: sales@benning.us Fax: 214.553.1355

WEB:www.benning.us

Tebevert III_120 (R1_07) © Benning Power Electronics 2007

Specifications are subject to change without notice

Page 9

TEBEVERT III INVERTER SYSTEM (120 VDC)

PREFACE

Congratulations and thank you for purchasing a Benning TEBEVERT III

Inverter System!

We at Benning are committed to supporting the needs of our customers by supplying

the customer with the proper information and documentation needed to properly install

and operate the unit purchased.

Important:

This avoids:

Danger during installation and operation.

Danger to operating personnel.

Downtime.

Increases the reliability and lifespan of the system.

This manual explains all the necessary information to unpack, install, and operate the

Benning BLI Inverter System and related components. Refer questions outside the

scope of this manual to our Customer Service Department.

Customer Service:

It is imperative that all the information be observed.

We are committed to excellence in dependabi li ty and customer satisfaction. If you have

any questions or problems, please contact the Customer Service Department at:

1.800.910.3601 or 214.553. 1444 for more information.

Please read all instructions before installing or operating the equipment and save these

manuals for future reference.

07.11.2011 1 028-0009-006

Page 10

TEBEVERT III INVERTER SYSTEM (120 VDC)

Switched-Mode Modular

Series TEBEVERT

(HOT-PLUG-Version)

Inverter System

Model:

5.0kVA-25.0kVA (120VDC Input, 120 VAC Output

Modules)

07.11.2011 2 028-0009-006

Page 11

TEBEVERT III INVERTER SYSTEM (120 VDC)

1 SAFETY NOTES AND MARKINGS

This operating manual conta i ns im portant information for the installation,

operation, and maintenance of the inverter system. This manual must be retained

and observed at all times!

Explanation of the symbols used:

avoid danger to persons!

Indicates instructions which must b e followed to avoid

Indicates safety instructions which m ust be followed to

material damage!

All specifications in these operating instructions must be

observed at all times!

Index of abbreviations:

A Amps

AC Alternating Current

DC Direct C ur r ent

I Current

LVD Low Voltage Detector

CB Circuit Breaker

G Ground

L Line

N Neutral

SNMP Simple Network Management Protocol

V Volts

W Watts

07.11.2011 3 028-0009-006

Page 12

TEBEVERT III INVERTER SYSTEM (120 VDC)

Further symbols, diagrams and pictures are explained at the appropriate

places within this operating manual.

Explanation of the abbreviations a nd definitions used:

SBS Static By-Pass Switch (SBS)

DVA Digital volt-ammeter

Mains Commercial AC input power source

By-pass Input Commercial AC Mains voltage providing an alternative AC

source to the connected load equipment . The By-pass

input is used by either the manual maintenance by-pass

or the SBS for back-up support in the event of an

inverter system failure.

07.11.2011 4 028-0009-006

Page 13

TEBEVERT III INVERTER SYSTEM (120 VDC)

The inverter system is an electrical unit with dangerous

voltage and current levels. For t hi s reason, the following

safety instructions must be o bserved.

1. Installation, operation, maintenance, and repair should be carried out in

strict accordance with the instructions in this document.

2. Ensure that only fully trained and qualified personnel have access to the

system. Only qualified and authorized personnel should be able to open

the units.

3. Even when the unit is completely switched off, some of i ts interior

components remain live as long as they are connected to the mains

supply or the battery.

4. Installed capacitors may be charged even w hen the system is

disconnected. These must be correctly discharged by a qualified

technician before the connectio ns or terminals are touched.

5. When working at the unit, use properly insulated tools at all times which

are suitable for the levels of voltage concerned.

6. All persons working with the unit must be familia r with the first-aid

techniques to be adopted in cases of accidents involving electricity.

7. The regulations of the local power supply companies and all other

applicable safety regulations must be observed at all times.

07.11.2011 5 028-0009-006

Page 14

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

2 GENERAL

The TEBEVERT III family of modular inverter systems consists of: modular

hot-plug, inverters, and an electronic static by-pass switch (SBS). All

electrical connections are a utomatically disconnected or connected when

the modules are pulled out of or pushed i nto the system cabinet. This may

take place during normal operation without interruption in power to the

connected load equipment. Thi s design provides an uninterrupted supply

of AC current and satisfies the highest requir ements with respect to the

expansion of the system, ease of maintenance and operating safety.

The TEBEVERT III is available for DC voltages of 120VDC. Each inverter

module is available in 5.0kVA/4.0kW. Parallel operation of maximum of

five (5) inverter modules provides a maximum system rating of

25.0kVA/20kW. Th e output voltage is 120VAC or 120/240VAC and can be

adjusted to 50Hz or 60Hz according to the application.

Several inverter systems may not be operated in parallel.

This may lead to the destruction of the inverter systems.

3 THE COMPONENTS OF THE TYPICAL INVERTER

SYSTEM

The design and arrangement of the components of the inverter system are

generally standardized.

The standard components are:

• (1) PSJ type equipment shelf

• 5 positions for the inverters

• (1– 5) inverter mod ul es

• (1) position for the static by-pass switch (SBS)

• (1) ma nual maintenance by-pass switch

07.11.2011 6 028-0009-006

Page 15

TEBEVERT III INVERTER SYSTEM (120 VDC)

The input of the terminals and distribution positions within the cabinet

depend on the supplied configuration. Refer to the equipment elevation

drawing for specific terminal siz es and placement.

The inverter’s static by-pass switch is only o pera tional when properly

installed into its corresponding position.

3.1 PSJ TYPE EQUIPMENT CABINET

The Benning TEBEVERT III system is built and supp li ed into a 19” PSJ

type, fully enclosed, floor sta nding cabinet (23.6” X 23.6” X 7’0” outside

overall dimension). Cabinets are available for New Equipment building

Standards (NEBS) and non-NEBS applications. Deep cabinets (600mm x

800mm or 23.6” x 31.5” x 7’0”) are available for special applications i.e.

raised floor, etc. consult with Benning at time of o r der.

07.11.2011 7 028-0009-006

Page 16

TEBEVERT III INVERTER SYSTEM (120 VDC)

Input Terminals and distribution

position

(depending on the application)

Static By-Pass Switch (SBS) shelf

Inverter module shelf 5

(A5)

Inverter module shelf 4

(A4)

Inverter module shelf 3

(A3)

Inverter module shelf 2

(A2)

Inverter module shelf 1

(A1)

Transformers.

07.11.2011 8 028-0009-006

Fig. 1: Typical design of top feed cabinet

Page 17

TEBEVERT III INVERTER SYSTEM (120 VDC)

0

12

Manual by-pass switc h (Q10)

SBS module (A6)

Inverter Module 5 ( A5 )

Inverter Module 4 ( A4 )

Inverter Module 3 ( A3 )

Inverter Module 2 ( A2 )

Inverter Module 1 ( A1 )

Figure 2: Typic al Inverter System (shown

with inverter modules, static by-pass)

07.11.2011 9 028-0009-006

Page 18

TEBEVERT III INVERTER SYSTEM (120 VDC)

Figure 3

TYPICAL INPUT/OUTPUT TERMINALS FOR AN

INDIVIDUAL FEED CONFIGURATION

TYPICAL SNMP OPTION

07.11.2011 10 028-0009-006

Figure 4

Page 19

TEBEVERT III INVERTER SYSTEM (120 VDC)

3.2 INVERTER MODULE SHELF

• Data line fac tory connected to the next inverter slot or the SBS slot (X1)

• Data connector for the inverter connection (X3)

• Load connector for the AC connection of the inverter output (X6) 3 poles

(2.5kVA) 5 poles (5.0kVA)

• Data line fac tory connected to the next inverter slot (X2)

• Female connector for the DC connection of the inverter (+)

• Female connector for the DC connection of the inverter

• Female connector for the protective earth of the inverter ( )

• *Each inverter carrier is equipped with two guiding rails insuring the

inverter is accurately positioned and a reliable contact is made.

07.11.2011 11 028-0009-006

Page 20

TEBEVERT III INVERTER SYSTEM (120 VDC)

3.3 SBS MODULE SHELF

• Terminal block for the connection of the auxiliary DC supply to the SBS (X26)

• Terminal block for the voltage-free collective fault messaging system of the

inverter system (X25)

• Terminal block for the connection of the auxiliary contact signifying the by-

pass switch is in the “ma nual by-pass inverter” position (X27)

• Terminal block for the connection of the auxiliary contact signifying the by-

pass switch is in the "manual by-pass mains" position (X28)

• D-SUB connector for the optional connection of the inverter system to the

MCU remote monitoring system (X23)

• DIP switc hes, without function (S1)

• Data line to the inverter slot (X10) (This is used if there are inverters

arranged above the SBS. Not standard!)

• Manual by-pass switch with locking mechanism for the SBS (Q10)

• Female connector for the neutral contact mains input (N)

• Female connector for the neutral contact mains input (N)

07.11.2011 12 028-0009-006

Page 21

TEBEVERT III INVERTER SYSTEM (120 VDC)

• Female connector for the protective earth of the SBS ( )

• Female connector for the mains input (L1)

• Female connector for the SBS output and the inverter output (N)

• Female connector for the SBS output (L)

• Female connector for the inverter input (1L)

• Male connector for the data bus (X20; X21)

• Data line to the inverter slots

• Male connector for the auxiliary DC supply and the voltage-free fault

messaging system (X22)

The SBS carrier is equipped with two guiding rails insuring the SBS module is

accurately positioned and a r eliable contact is made.

07.11.2011 13 028-0009-006

Page 22

TEBEVERT III INVERTER SYSTEM (120 VDC)

3. 4 MANUAL MAINTENANCE BY-PASS SWITCH

Fig. 5: Manual Maintenance By-pass Switch Q10

The manual maintenance by-pa ss switch is mechanically connected to

both the SBS slot and the SBS itself. The locki ng mechanism prevents the

SBS from being pulled out of the inverter system unless it has been

switched to the proper position, Position “1” or “2”.

Significance of the switch positions (Refer to Section 6.1 for details):

Position 0: UPS operation

Position 1: Load on By-pass Input (Commercial AC)

Position 2: Load on Inverter Output

07.11.2011 14 028-0009-006

Page 23

TEBEVERT III INVERTER SYSTEM (120 VDC)

Important Note!

3.5 INVERTER

The inverter converts the incoming nom inal DC voltage of 120VDC into AC

voltage of 120VAC , 50 or 60Hz. (Refer to Section 4.3.x for specific wiring

details)

The 120/240VAC configuratio n utilizes input/output

transformers to convert the input and output voltages from

the nominal 120VAC. Therefore the 120/240VAC system

settings are con f igured the same as the standard 120V AC

system.

3.5.1 DESIGN OF THE UNIT

The inverter module contains no serviceable components that must be

accessible by the user during norm al operation. Located on the front panel

there are various LED´s used for the operational status and fault

diagnosis.

Warning!

The removal of the front panel, the alteration of switching

thresholds and the changing of t he c ontrol fuse may only

be carried out by qualified personnel.

07.11.2011 15 028-0009-006

Page 24

TEBEVERT III INVERTER SYSTEM (120 VDC)

483

177

101. 6

8

171

466. 2

5

491. 9

444. 9

433. 1

07.11.2011 16 028-0009-006

Fig. 6: Diagram of t he modular inverter unit

Page 25

TEBEVERT III INVERTER SYSTEM (120 VDC)

kg

3.5.2 TERMINALS AND OPERATING ELEMENTS

All terminals and operating element s are installed on the front or rear of

the inverter module.

1

2 3

Fig. 7: Front view of the inverter

1 weight notice of the individual p l ug-in unit

2 type designation

3 on/off switch (S1)

4

4 LED signalling panel

07.11.2011 17 028-0009-006

Page 26

TEBEVERT III INVERTER SYSTEM (120 VDC)

1

S 2

-

+

1

2

5 4 3

6

7

X 3

0

X 2

F1

Fig. 8: Rear view of the modular inverter unit

X 1

1 Data connector (X3)

2 DIP switc h to set the frequency (S2) (Refer to Section 4.1

for details)

3 Contact blade for the protective earth (X1: )

4 Contact blade for the DC input (X1: -)

5 Contact blade for the DC input (X1: +)

6 Inverter Output circuit breaker (F1)

(Placed above of X2 for the 5.0kVA inverter)

7 Output connector (X2) 3 poles (5 poles for 5KVA/120VAC

inverter)

07.11.2011 18 028-0009-006

Page 27

TEBEVERT III INVERTER SYSTEM (120 VDC)

Indicates the position of the inverter's p ower switch, ON / I

3.5.3 SIGNALLING

On the front panel of the inverter there is a ba r graph indicator and LED´s

that are used to indicate the operating state of the inverter.

Fig. 9: Operating and signalling panel

This symbol indicates that a l l the p oints in this operating

manual must be observed at all times.

or OFF / O

Indicates the inverter output voltage is present. The bar

graph indicator shows the output current of the inverter in

steps of 10% relative to the maximum o utput current of

the inverter.

07.11.2011 19 028-0009-006

Page 28

TEBEVERT III INVERTER SYSTEM (120 VDC)

Important Note!

LED Color Meaning when LED lights up

green

green

red

green

red

The output voltage of the inverter is norma l. (VN=

120 or 120/240V) See note Important Note below.

"OUTPUT VOLTAGE PRESENT"

The output voltage of the inverter is in phase and

frequency with the mains-supply volt age

"MAINS-SUPPLY SYNCHRONIZED"

The output current of the inverter is great er than

110% of the rated output current

"OVERLOAD"

The inverter is in parallel operation with other

inverters. When this LED flashes, the inverter is

operating as the MASTER.

"PARALLEL OPERATION".

The output voltage of the inverter is outside the

tolerance range

"FAULT".

07.11.2011 20 028-0009-006

The Benning Inverter Modules are 120VAC. Optional

transformer converts the output of the inverter to

120/240VAC.

Page 29

TEBEVERT III INVERTER SYSTEM (120 VDC)

3.6 STATIC BY-PASS SWITCH (SBS) UNIT

The static by-pass switch (SBS) unit monitors the AC bypa ss input and DC

input. The Inverter System operates p r im arily on DC and transfers to Ac

automatically upon DC failure. The maintenance bypass switch should

remain in position “0” for normal op eration.

The SBS module can only be unplugged or i nserted into the shelf when

the manual maintenance by-pass switch is in position 1 or 2.

07.11.2011 21 028-0009-006

Page 30

TEBEVERT III INVERTER SYSTEM (120 VDC)

444

132. 5

483

466. 3

300

127. 5

3.6.1 DESIGN OF THE UNIT

Fig. 10: Diagram of the static by-pass switch (SBS)

07.11.2011 22 028-0009-006

Page 31

TEBEVERT III INVERTER SYSTEM (120 VDC)

kg

Important Note!

2

3 4 5

3.6.2 TERMINALS AND OPERATING ELEMENTS

All terminals and operating element s are on the front panel or rear of the

SBS unit.

1

Fig. 11: Front view of the Static By-Pass Switch (SBS)

1 Display and signalling panel

2 Model designation

3

4 Selector switch to display either the inverter output voltage or

inverter output current. According to the position of switch, the

output voltage (V) or the output current (A) is displayed

5 Digital volt/ammeter (displays output voltage or the output current)

The 120/240VAC configuratio n utilizes input/output

transformers to convert the input and output voltages from

the nominal 120VAC. Therefore the voltage and current

displayed on the Digital Voltmeter sha l l display the 120VAC

component only.

Indicates the system output

07.11.2011 23 028-0009-006

Page 32

TEBEVERT III INVERTER SYSTEM (120 VDC)

N

X 1

L

X 5

S 1

7 6

1 2 3 4 5

1L

L1

10 9 8

N

Fig. 12: Rear view of the Static By-Pass Switch (SBS)

X 3

X 4

1 Contact blade for the protective earth (X1: )

2 Contact blade for the SBS output (X1: N)

3 Contact blade for the inverter input (X1: 1L)

4 Female connector for the data bus (X3; X4)

5 Female connector for the auxiliary DC supply and voltage-free

fault messaging system

(X5)

6 DIP sw i tches for system settings (S1) (Refer to Section 4.2 for

details)

7 DIP switches for syst em settings (S2) (Refer to Section 4.2 for

details)

8 Contact blade SBS output (X1: L)

9 Contact blade mains input (X1: L1)

10 Contact blade neutral contact, mains input (X1: N) (not included

on 25.0kVA unit, part no. 120418)

S 2

07.11.2011 24 028-0009-006

Page 33

TEBEVERT III INVERTER SYSTEM (120 VDC)

3.6.3 SIGNALLING

On the front panel of the SBS module there is a digital volt/ammeter and

various LED´s, used to indicat e the operating state of the SBS unit.

Fig. 13: Display and signalling panel

LED Color Meaning when LED lights up

green

green

green

green

green

red

The SBS supplies the load equipment via the mains.

"LOAD ON BY-PASS OPERATION"

The SBS supplies the load equipment via the inverters

modules. "LOAD ON INVERTER OPERATION"

The mains voltage is within the limiting range.

"MAINS VOLTAGE NORMAL"

The inverter output voltage is within the limiting range.

"INVERTER VOLTAGE NORMAL"

Mains voltage and inverter voltage are within the

specified range, the in verters are operating

synchronized to the mains.

"NORMAL OPERATION"

The SBS or the inverters have a fault.

"FAULT".

07.11.2011 25 028-0009-006

red

The inverter system is overloaded by more than 5%.

"OVERLOAD"

Page 34

TEBEVERT III INVERTER SYSTEM (120 VDC)

Neutral Bar

3.7 AC DISTRIBUTION PANEL

External AC elect rical panels are recommended. These can be sourced

from your local electrical suppl ier Benning. Two additional AC distribution

options can be used with the inverter cabinet. One utilizes a standard

North American style snap-in breaker and the other utilizes standard DIN

style breakers.

3.7.1 NA STYLE SNAP-IN BREAKER PANEL

Note: This panel cannot be installed in the inverter cabinet.

This AC Distribution Panel is a UL Listed, externally mountable option.

The panel is designed to accommodate up to 20 breaker positions using

standard Eaton/Cutler Hammer CH style sna p-in breakers. The maximum

allowable sized breaker is 50A per pole. The maximum allowable current

per bus is 125A. The AC Distribution Panel is designed to mount into a

standard 19” relay rack and occ upy 5U of vertical space. Conduit

knockouts are provided for conduit to enter the back of the panel for the

output wiring. These knockouts siz ed for either ¾” or 1” conduits. The

input wiring is provided via a pigtail through a knockout also located at the

rear of the panel. This panel ca n be wired to the inverter out put. This

option can be wired as 120VAC and Neutral or 120/240VAC and Neutral

depending on the output voltag e option selected.

Ground Bar

07.11.2011 26 028-0009-006

Main Lugs CH Breaker

Positions

Page 35

TEBEVERT III INVERTER SYSTEM (120 VDC)

3.7.2 DIN RAIL STYLE BREAKER PANEL

This AC Distribution option is an internally mountable option. The panel is

designed to accommodate up to 24 breaker positions using standard CBI

type QL, UL Listed, 1 or 2-pole, DIN Rail mounting circuit breakers. The

maximum allowable sized breaker is 25A per pole. The ma ximum

allowable current per bus is 125A. This AC Di stribution is designed to

mount into the standard inverter cabinet and occupies 4U of vertical

space. Neutral and Ground connections are provided as part of the

distribution option. This option can be wired as 120VAC and Neutral or

120/240VAC and Neutral depending on the output voltage option selected.

Commercial AC

(By-pass)

Ground (PE)

07.11.2011 27 028-0009-006

1 or 2 pole

output breakers

(CBI) – L1 and/or

Neutral (N)

Page 36

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

4 INSTALLATIN AND COMMISSIONING

After assembly, inst allation and commissioning of the inverter system, all

components are ready for operation. No additional settings and

adjustments a re necessary.

The safety instructions must be ob served at all times

during assembly, installat ion and commissioning.

The site chosen for the inverter system must have a solid and level floor.

The inverter system is designed for operation in a restricted access, dry

environment. The maximum ambient temperature is 40°C. Attention must

be paid the inverter system is n ot exposed to air borne contain ments and

the flow of cooling air is not hampered.

07.11.2011 28 028-0009-006

Page 37

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

50Hz

60Hz

ON

OFF

4 3 1

4.1 INVERTER SETTINGS

Each inverter is set to factory default values according to the required

operating conditions. (See Chapter 3. 7 / Technical data or the specification

sheet) An adjustment of these settings is not usually necessary.

However, if the inverter must operate at 50 HZ, a simple adjustment can

be carried out.

Alteration of the unit settings may only be carried out by

qualified personnel. The altered settings must be clearly

marked on the unit. Any alternations of these settings

must also be performed on all other invert ers w i thin the

system and on the SBS.

The output frequency is changed with the DIP switch S2 located on the

rear side of the inverter unit (See Figure 8)

2

NOTE: Only the setting of switch 1 is changed. All the other switches must

always remain in the OFF position.

07.11.2011 29 028-0009-006

Page 38

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

4.2 SETTINGS OF THE STATIC BY-PASS SWITCH

(SBS)

The Static By-Pass Switch (SBS) is factory set to default values. (See

Chapter 3.7 / Technical data or the specification sheet). It is not usually

necessary to ch ange these settings.

However, if the units are exchanged or there are different operating

conditions, the settings must be checked or readjusted.

On the rear side of the SBS unit there are 2 sets of DIP switches S1 and

S2. (See Figure 12)

Qualified personnel may only carry out alteration of the

settings on the unit. The altered settings must be clearly

marked on the unit.

07.11.2011 30 028-0009-006

Page 39

TEBEVERT III INVERTER SYSTEM (120 VDC)

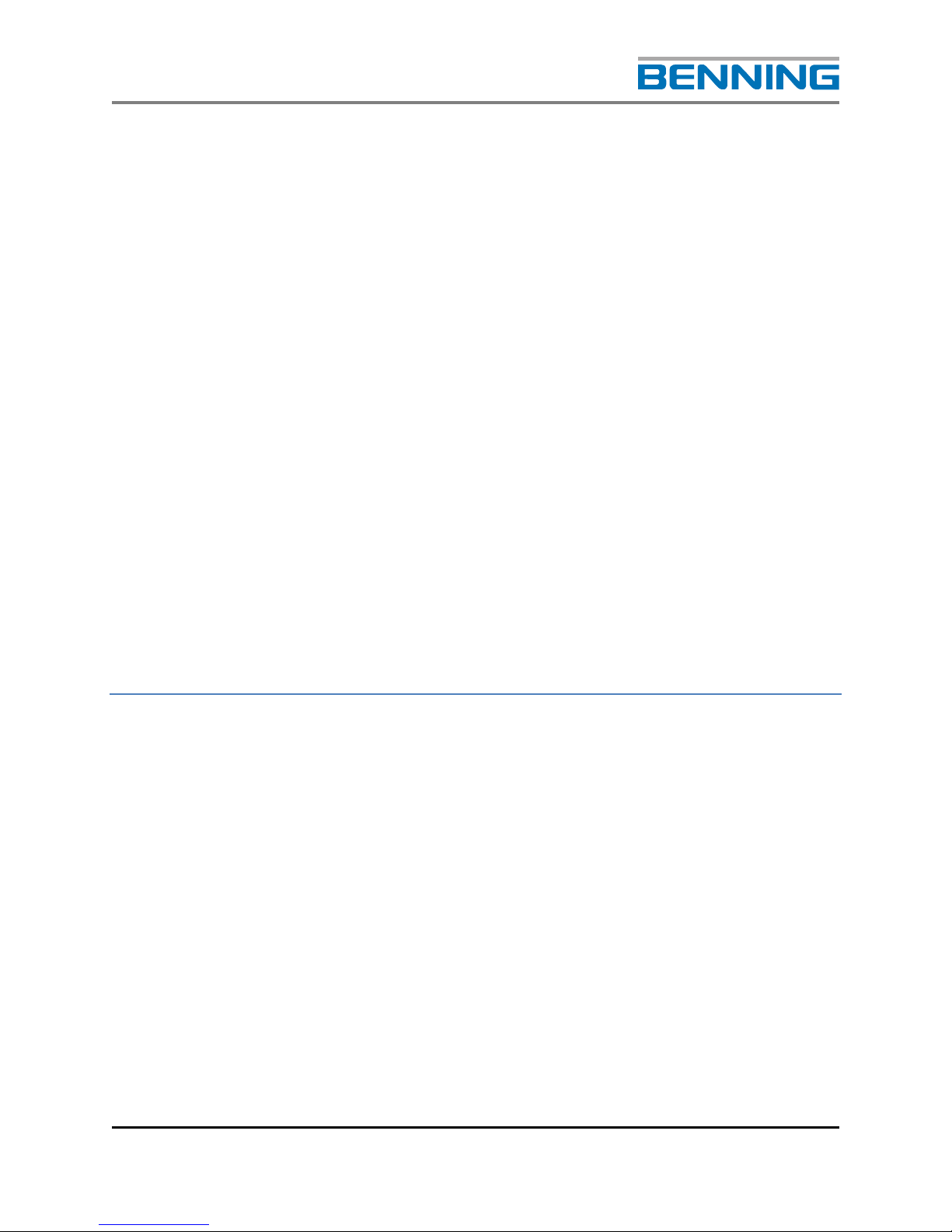

Operating mode

inverter priority

mains priority

Maximum deviation

Pos 1

Pos 1

Pos 0

Pos 0

Important Note!

0

1

Adjustments Position 1 Position 0

Nominal voltage 120 or 120/240 V 230 V

Nominal frequency 50 Hz 60Hz

Mains error signal no mains available

(no mains failure

indicator)

Fault signal fault signal of

STATIC BY-PASS

Maximum deviation

of nominal frequency

of nominal frequency

no function

Pos 1

3%

Pos 0

4%

operation with

mains!

(mains failure

indicator.)

Common fault signal

from the STATIC BYPASS and inverter

Pos 1

1 %

Pos 0

6 %

Note: The highlighted areas co r r esp ond to factory default settings.

The settings of S2 provides the SBS with the info r m ation on the output power of the

connected invert ers. Depending on inverter system (25kVA/120 or 120/240VAC) only

one highlighted switch may be in position 1.

The setting of S2 shall be the same for both the 120 and

120/240VAC systems.

07.11.2011 31 028-0009-006

Page 40

TEBEVERT III INVERTER SYSTEM (120 VDC)

4.3 PANEL WRITING

The cable is fed into the inverter system from above or below, according

to the model. The size and location of the terminal blocks and distribution

assemblies are configuration dependant, refer to Elevation drawing for

exact requirements. For the cross-sections and the recommended overcurrent protection the following values must be observed. The

recommended cable sizes shown below meet National Electrical Code

(NEC) Table 310-16 requirements, however please remember that larger

size cables may be required in order to meet site voltage drop

requirements. It is recommended that if a system can be expanded with

additional inverters in the future, the initial AC wiring be sized for the

maximum number of inverters.

Larger cross-sections should be used to reduce the effects of vo l tage-drop

depending on the conditions at the inst allation site than would normally be

necessary due to the current.

There are three options for the DC input section of the Inverter system.

• Bulk input accepting up to 750MCM tw o-hole lugs, two per pole in a back-to-back

configuration. The hole pattern is designed for 3/8” holes at 1” cc. EC-701 must

be ordered for this.

• Individual DC input per inverter m odule using screw compression type terminal

blocks. These terminal blocks accept up to one 4/0 stranded cable.

• Individual DC input per inverter m odule accepting two-hole lugs with 3/8-16

studs on 1”cc. These terminal blocks accept up to one 4/0 stranded cable per

pole.

07.11.2011 32 028-0009-006

Page 41

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

Warning!

For the proper protection of the load c i r c ui ts careful

attention must be paid to the selection of upstream the

mains protection.

The voltage-free fault messaging co ntact are rated for a

maximum of 230VAC/1A or 270VDC/0.2A (50W max).

If a future inverter expansion is planned , the cable crosssections and the fuse protectio n m ust be used for the

maximum values of load pow er r equirements.

If an external battery is connected to the DC inputs of the

inverter, then the instructions c oncerning the installation

and maintenance given by the manufacturer of the battery

must be observed.

The supply circuits must be equipped with a disconnecting

device. It must be mounted close to the cabinet and easily

accessible.

The system has high leakage current. Earth connection is

essential before connecting supp l y

07.11.2011 33 028-0009-006

Page 42

TEBEVERT III INVERTER SYSTEM (120 VDC)

Terminal

Connection

Terminal/connection

Suggested

DC

Alarm fault

Maximum system

Suggested rating of

Terminal

Connectio n ty pe

Terminal/connection

Suggested

4.3.1 DC CABLE REQUIREMENTS FOR 25kVA, 120

VDC INDIVIDUAL DC INPUT (DIN RAIL OR

BUSBAR TERMINAL BLOCK)

designation

X1: 1L+/1L-

X1: 2L+/2L-

X1: 3L+/3L-

X1: 4L+/4L-

X1: 5L+/5L-

X4: NC/C/NO

Frame GND Bonding ground 3/8” s tud, 1” c-c two hole lug

type

input/inverter 1

DC

input/inverter 2

DC

input/inverter 3

DC

input/inverter 4

DC

input/inverter 5

signal

capacity

Compression Type

2AWG – 4/0

Compression Type

2AWG – 4/0

Compression Type

2AWG – 4/0

Compression Type

2AWG – 4/0

Compression Type

2AWG – 4/0

Compression Type

28 - 10AWG

protection

50A/8 AWG

50A/8 AWG

50A/8 AWG

50A/8 AWG

50A/8 AWG

2A/18 AWG

4.3.2 DC CABLE REQUIREMENTS FOR 25kVA,

120VDC, BULK DC INPUT SYSTEM

Supply conductor

capacity

disconnect device

DC Input 25kVA 5 In verters 120VDC/(250-300) A

designation

X1: +/-

X4: NC/C/NO Alarm fault signal

Frame GND Bonding gr ound 3/8” single hole lug

07.11.2011 34 028-0009-006

DC input/inverter 1 max.

DC input/inverter 2 max.

DC input/inverter 3 max.

DC input/inverter 4 max.

DC input/inverter 5 max.

capacity

Busbar

3/8” x 1”cc

2 X 750MCM max.

Requires Part. No. EC-701

Compression Type

28 - 10AWG

protection

(250-300) A

2A/18 AWG

Page 43

TEBEVERT III INVERTER SYSTEM (120 VDC)

Maximum system

Suggested rating of

Compression Type

Maximum system

Suggested rating of

Maximum system

Suggested rating of

Terminal

Connection

Terminal/connection

Suggested

4.3.3 AC CABLE REQUIREMENTS FOR 25kVA,

120VAC AC INPUT RATINGS

Supply conductor

Mains 5 inverters 120VAC/250A

capacity

disconnect device

Terminal

designation

X2: L1/N/PE 5 inverters

Connection

type

Terminal/connection

capacity

2 AWG - 4/0

4.3.4 AC CABLE REQUIREMENTS FOR 25kVA,

120/240VAC AC INPUT SYSTEM

Supply conductor

Mains 5 inverters 120/240VAC/150A

Terminal

designation

X2: L1/L2/PE 5 inverters

Connection

type

capacity

Terminal/connection

capacity

Compression Type

2 AWG - 4/0

disconnect device

Suggested

protection

250A

Suggested

protection

150A

4.3.5 AC CABLE REQUIREMENTS FOR 25kVA,

208VAC AC INPUT SYSTEM

Supply conductor

Mains 5 inverters 120/208VAC/150A

designation

X2:L1/L2/PE 5 inverters

07.11.2011 35 028-0009-006

type

capacity

capacity

Compression Type

2 AWG - 4/0

disconnect device

protection

150A

Page 44

TEBEVERT III INVERTER SYSTEM (120 VDC)

Maximum system

Suggested rating of

Compression Type

Maximum system

Suggested rating of

Compression Type

Terminal

Connection

Terminal/connection

Suggested

Compression Type

4.3.6 AC CABLE REQUIREMENTS FOR 25kVA,

220VAC AC INPUT SYSTEM

Supply conductor

Mains 5 inverters 220VAC /150A

capacity

disconnect device

Terminal

designation

X2:L1/L2/PE 5 inverters

Connection

type

Terminal/connection

capacity

2 AWG - 4/0

4.3.7 AC CABLE REQUIREMENTS FOR 25kVA,

240VAC AC INPUT SYSTEM

Supply conductor

Mains 5 inverters 120/240VAC /150A

Terminal

designation

Connection

type

capacity

Terminal/connection

capacity

disconnect device

Suggested

protection

150A

Suggested

protection

X2:L1/L2/PE 5 inverters

4.3.8 AC CABLE REQUIREMENTS FOR 25kVA,

480VAC AC INPUT SYSTEM

Supply conductor

Mains 5 inverters 480VAC /70A

designation

X2:L1/L2/PE 5 inverters

07.11.2011 36 028-0009-006

type

2 AWG - 4/0

Maximum system

capacity

capacity

2 AWG - 4/0

150A

Suggested rating of

disconnect device

protection

70A

Page 45

TEBEVERT III INVERTER SYSTEM (120 VDC)

Terminal Block Torque Table

Terminal

UKH95

177.01

14.75

4.3.9 TORQUE TABLE FOR ALL TERMINATIONS

in-lb ft-lb

UKH150 265.52 22.12

Stud Terminal Torque Table

07.11.2011 37 028-0009-006

Page 46

TEBEVERT III INVERTER SYSTEM (120 VDC)

4.4 INSTALLAT IO N OF THE UNITS

Prior to the installation of t he Static By-Pass Switch (SBS) and the

inverters in the inverter system, the following points must be checked and

observed.

• Verify that the units are of the same type and model (120VDC /

120VAC) Since all inverters of this series a r e identical for the user, the

exact model of the unit must be checked.

• Verify the position of circuit breaker (F1) located on the rear of the

module. It must be in the “ON” position, position 1.

• Verify the SBS, as described in Chapter 4.2

• Verify all the invert ers set to the same frequency (50Hz or 60Hz)

(See Chapter 4.1)

• Verify that ( S1) on front of each module is switched off.

(Power switch position ON/OFF)

07.11.2011 38 028-0009-006

Page 47

TEBEVERT III INVERTER SYSTEM (120 VDC)

2

0

4.4.1 INSTALLATION OF THE STATIC BY-PASS SWITCH

(SBS)

At the time the St ati c By -Pass Switch (SBS) is installed, the operating

handle of the manual maintenance by-pass switch is attached. The handle

is installed on top of the SBS unit using supplied four (4) M4 x 8mm

screws. Position the switch mechanism and the operating element in the

following position.

Fig. 14: Installation positions of the locking mechanism and the operating element

Using the guiding rails located on the base of the mounting shelf, slowly

push the SBS unit into the shelf until the front panel is flush with the

frame of the cabinet. This should require minimal effort. All electrical

contacts have been made and the operating element of the manual bypass switch is connected to its rotati on axle. The SBS is fixed into the

cabinet with four screws (supplied).

07.11.2011 39 028-0009-006

Page 48

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

4.4.2 INSTALLATION OF THE INVERTERS

The weight of ea ch inverter is approx. 35kg (77lbs). T h e

unit may only be lifted and transpo r ted using the carrying

handles built into each side of the unit . DO NOT carry or

lift the unit using the handles on the front panel!

Before the inverter unit is installed, any materials used to protect the unit

during transportation must be removed . The guiding rails on the base of

the inverter shelf and under the inverters ensure the exact positioning of

the modular inverter unit. The unit is slowly pushed in past a slight

resistance until the front panel is flush w ith the frame of the cabinet. All

electrical contacts have then been mad e. The inverter is then fixed into

the cabinet with four screws (supplied).

Any free slots reserved for future inverter upgrades must be covered with

dummy plates. Th ese plates must be secured with four screws (supplied).

4.5 SWITCHING ON THE INVERTER SYSTEM

Before the AC by-p ass is connected and the inverters are switched on, it

must be verified that the manual maintenance by-pass switch is in position

“0” (UPS operation). In this position the Static By-Pass Switch ( SB S) is

mechanically locked and cannot b e pulled out of the cabinet.

The load circuits should not yet be connected and all the inverters should

be switched off. Normally, the Static By-Pass Switch (SBS) should be set

to the operation mode "inverter priority" (See Section 4.2).

Step one, the DC supply should be switched on, all the LEDs on the SBS

light up for a short time. (Reset of the internal processor!) Afterwards,

only the LED "FAULT" is lit and the DVA ind i c ates the voltage or current to

be "0".

Second, the AC by-pass should be switched on. The LEDs "MAINS

VOLTAGE PRESENT" and "MAINS OPERATION" are lit as well as the LED

"FAULT".

07.11.2011 40 028-0009-006

Page 49

TEBEVERT III INVERTER SYSTEM (120 VDC)

The AC by-pass is connected to the output and the DVA shows the AC bypass voltage (e.g. 120), if the select or switch underneath the DVA is in the

position "V".

The first inverter can now be switched on. After a start-up time of approx.

20 seconds, the LEDs "INVERTER OUTPUT VOLTAGE PRESENT"; "MAINS

SYNCHRONOUS" are lit up and the LED "PARALLEL OPERATION" starts to

flash. The flashing of this LED indicates that this inverter has been

assigned the MASTER function. A t the same time, some of the LEDs on

the SBS change their state. The LED "FAULT" is extinguished and the LED

"READY FOR OPERATION" is lit. Assuming that the operation mode is

"inverter priority", the inverter out put voltage is connected to the output.

The LEDs "INVERTER OUTPUT VOLTAGE PRESENT" and "INVERTER

OPERATION" light up and the LE D "MAINS OPERATION" are extinguished.

The voltage-free fault indicat or switches to the state "no fault".

The remaining inverters are then switched o n. The state of the LEDs of

the SBS and the first inverter do not change. After the start-up phase, the

LEDs "INVERTER OUTPUT VOLTAGE PRESENT", "MAINS SYNCHRONIZED"

and "PARALLEL OPERATION" are lit on the additional inverters.

Finally, the load circuits may be switched on. When the load is connected,

the load current is divided equally between the individual inverters and the

bar graph indicators show the output current of the individual inverter.

The load voltage (inverter output voltage) or the total load current can be

read off the DVA.

After all the system components have been co nnected or switched on as

described, the states of the LEDs on the SBS and the inverter should be as

follows.

Fig. 15: LED states of the SBS (normal operation)

07.11.2011 41 028-0009-006

Page 50

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

When the inverter operates as

Fig. 16: LED states of the inverter (normal operation)

5 PERFORMANCE TESTING

• The following load test is recommended by a Benning technician.

5.1 PRELIMINAR I E S TO PER F OR M ANCE TEST

The site manager must be informed of the test to be perfor m ed , and that

alarms will be sent (if connected) to the central alarm center or Network

Operations Center.

Read all of Section 5, make sure you know where to find all the buttons

and other referenced i tems.

During the performance test, p ay attention to all safety

notes located in Section 1. In a ddi tion, these inverters

may be fed from multiple power sources, so additional

precautions must be taken.

Take off rings, wristwatches and similar objects that may cause shortcircuits.

Always use ESD-protection for any w ork to be carried out inside the

cabinet.

07.11.2011 42 028-0009-006

Page 51

TEBEVERT III INVERTER SYSTEM (120 VDC)

all connected inverters are not operating.

display shall read 120 or 120/240VAC,

Switch the volt/ammeter toggle switch

The volt/ammeter and the clamp-on

Connect a load of approximately 3kW

The red LEDs “OVER LOAD” light up on

5.2 TEST EQUIPMENT

• A suitable voltmeter with measuring range 250 VAC, 100 mV and

60 VDC.

• A clamp-on ammeter capable of measuring 250Amps AC.

• A load bank capable of supplying 26,000 W.

5.3 TEST OF THE INVERTE RS

Make sure the system is in the following state:

• Disconnect com m erc i al AC from the AC by-pass input.

• Switch off all inverter modules.

• Disconnect the lo ad from the inverter.

• Connect the load bank to the output of the inverter system.

• Apply an ammeter around the phase conductor to the load bank.

5.3.1 INVERTER TEST ACTIVITIES

Action Result

Switch on one of the inverter modules. The green LED “OUTPUT VOLTAGE

AVAILABLE” lights up. The green LED

“PARALLEL OPERATION” starts flashing

on the inverter. The red LED “FAULT”

on the by-pass lights up indicating there

is no mains voltage present and that not

Also an outgoing alarm will be given.

Connect a load of approximately 2kW

(2.5kVA modules) or 4kW (5.0kVA

modules). Switch the volt/ammeter

toggle switch on the by-pass module

to “V”. Connect a voltmeter to the

output of the inverter system.

on the by-pass module to “A”

The reading of the voltmeter and of the

± 5%. (See Important Note below)

ammeter shall be the same ±5%.

(2.5kVA modules) or 6kW (5.0kVA

07.11.2011 43 028-0009-006

the inverter and t he by-pass modules.

Page 52

TEBEVERT III INVERTER SYSTEM (120 VDC)

Action

Result

modules)

The internal temperature will rise and

Important Note!

the inverter module will automatically

switch off.

Disconnect the load bank and re-start

the inverter by means of the On/Off

Switch.

1. Switch off the inverter.

2. Short circuit the output of the

inverter system by connecting a cable

across the output terminals.

(WARNING! Verify the

commercial AC input to the AC bypass is turned-off.) The cable shall

be the same gauge as the normal load

cables.

3. Switch on the inverter.

Remove the short circuit and restart

the inverter module by means of the

On/Off switch.

Switch off the inve rter module The inverter shuts off.

The green LEDs “O U TP UT V O LTAG E

AVAILABLE” and PARALLEL OPERATION”

will light up.

The inverter system shall pass into

current limit and shall automatically

switch off after approximately 40 to 50

seconds.

The inverter restarts

The 120/240VAC configuratio n utilizes input/output

transformers to convert the input and output voltages from

the nominal 120VAC. Therefore the voltage displayed on

Digital Voltmeter shall display the 120VAC component only.

Repeat test 5.3.1 for each inverter module installed.

07.11.2011 44 028-0009-006

Page 53

TEBEVERT III INVERTER SYSTEM (120 VDC)

5.4 TEST OF THE SBS UNIT

Make sure the system is in the following state:

• Disconnect the lo ad from the inverter system.

• Connect the load bank to the output of the inverter system.

• Connect the commercial AC mains to the AC by-pass input.

• Switch on all inverter modules.

07.11.2011 45 028-0009-006

Page 54

TEBEVERT III INVERTER SYSTEM (120 VDC)

Switch on the mains for the

The green LED “MAINS

Important Note!

5.4.1 SBS TEST ACTI VIT IE S

Action Result

Switch off the mains from the by-pass. The green LED “MAIN VOLTAGE

AVAILABLE” and “READY FOR

OPERATION” go out and the red LED

“FAULT” lights up. Also an outgoing

alarm shall be given after approximately

10 seconds.

Connect a voltmeter to the output of

the inverter system.

by-pass

The reading of the voltmeter and of the

display shall read 120VAC ± 5%. (See

Important Note below)

AVAILABLE”, “INVERTER

OPERATION” light up and the

red LED “FAULT” goes out.

The reading of the by-pass

volt/ammeter shall be 120 or

120/240VAC ± 10%. The

alarm ceases.

Switch off all inverter modules. The green LEDs “INVERTER VOLTAGE

AVAILABLE” and “INVERTER OPERATION

go out, the green LED “MAINS

OPERATION” lights up and the red LED

“FAULT” lights up. Also and outgoing

alarm will be given.

Connect a voltmeter to the output of

the inverter system.

The reading of the voltmeter shall be

120 or 120/240VAC ± 5%.

Switch on all inverter modules. The green LEDs “INVERTER VOLTAGE

The 120/240VAC configuratio n utilizes input/output

transformers to convert the input and output voltages from

the nominal 120VAC. Therefore the voltage displayed on

Digital Voltmeter shall display the 120VAC component only.

07.11.2011 46 028-0009-006

AVAILABLE”, “INVERTER OPERATION”

and “READY FOR OPERATION light up,

and the green LED “MAINS OPERATION”

and the red LED “FAULT” go out. The

alarm ceases.

Page 55

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

Warning!

5.5 FINAL STEPS

• Disconnect any test equipment that has been connected to the

system and make sure that materia ls that do not belong in the

equipment have been removed.

• Restore the equip m ent to its original condition. Make sure the

cabinet is placed so that cooling air has free access.

• If a failure remains in the equipment, contact the responsible field

engineer.

6 MAINTENANCE

All the components of the inverter system have been developed for

continuous operation and are prac tically maintenance-free. To ensure

continuous operation, it is recommend ed that flow of cooling air is

periodically checked and any dust is removed from the units.

Do not use pressurized air to remove the dust since the

dust particles can be blown into the interior of the unit and

may cause malfunctions.

If servicing is required (exchange o f uni ts, work on the mains supply or

the DC supply etc.) the proper positi on of the manual maintenance bypass switch must be verified.

6.1 USE OF THE MANUAL BY-PASS SWITCH

The manual maintenance by-pa ss switch is only required for servicing.

This manual switch when operated by-passes the SBS unit and connects

without interruption the mains (“Lo ad on By-pass Input”) or the inverter

outputs (“Load on Inverter Output ") directly to the connected load

equipment depending on the switc h position.

The manual maintenance by-pa ss switch may only be

operated by qualified personnel.

07.11.2011 47 028-0009-006

Page 56

TEBEVERT III INVERTER SYSTEM (120 VDC)

1 0 2

Position 0: UPS operation

Position 1: Load on Reserve Input

Position 2: Load on Inverter Output

Prior to operating the manual maintenance by-pass switch verify the SBS

is operating in one of the following mo des. Failure to do so could result in

an interruption in power to the co nnec ted load equipment:

1) The SBS is operati ng correctly

This is signalled on the front panel of the SBS by:

LED "off" LED "on"

In this operating state, the manual by-pass switch can be switched either

into position 1 (Load on By-pass Input) or position 2 (Load on Inverter

Output). After the servicing work is c omplete and if the system is in proper

working order, the manual by-pass switch can be turned back to position 0

(UPS operation).

2) The SBS shows a fault

This is signalled on the front panel of the SBS by:

LED "on" LED "off"

In this operating state, two further cases must be differentiated.

a) The inverter system is operating in the inverter operation mode.

This is the case when the LED on the front pa nel of the

SBS is lit.

In this case o nly s witch position 2 (Lo ad on Inverter Output) i s

permissible!

07.11.2011 48 028-0009-006

Page 57

TEBEVERT III INVERTER SYSTEM (120 VDC)

After the servicing work is complete (exchange of the SBS, work on the

supply mains) and if the system is in prop er working order, the manual

by-pass switch can be turned back to position 0 (UPS operation).

b) The inverter system is working in the mains opera tion mode. This is

the case if the LED on the front panel of the SBS is lit.

In this case only switch position 1 (Load on By-pass Input) is

permissible!

After the servicing work is complete (exchange of the SBS, work on the

DC supply mains, repair of the inverter) and if the system is in proper

working order, the manual by-pass swit ch can be turned back to position 0

(UPS operation).

The states of the switch positions 1 ( Load on By-pass Input) or 2 (Load on

Inverter Output) are indicat ed by two flashing LEDs on the front panel of

the SBS.

State "Load on By-pass Input"

State "Load on Inverter Output"

07.11.2011 49 028-0009-006

Page 58

TEBEVERT III INVERTER SYSTEM (120 VDC)

Warning!

6.2 EXCHANGE OF UNITS

a) Exchange of an inverter

In this case, the manual by-pass switch does not need to be used.

However, if this is desired for any reason, the manual by-pass switch must

be switched to position 1 (Load on By-pass Input).

Removal of the inverter:

Switch the inverter off using the unit switch (in case the

remaining inverters in the system cannot take over the load, the

connected load will be transferred to the mains supply via the

SBS units).

Remove the four retaining screws

Pull the unit out of the front of the cabinet

(Attention! See warning statement in paragraph 4.4.2)

Insertion of the inverter:

The inverter must be switched off!

The circuit breaker (F1) on rear of unit must be switched on!

Slide the inverter into the inverter shelf until t he unit is flush with

the frame of the cabinet.

Screw in the four retaining screws

Switch the inverter on

If necessary, turn the manual by-pass switch to position 0 (UPS

operation).

b) Exchange of the SBS

The manual by-pass switch must be used in this case

otherwise there will be an interruption in the power supply

to the load equipment. It must be established beforehand,

which of the scenarios described in Chapter 6.1 is valid

(check the state of the SBS and the operation mode!)

07.11.2011 50 028-0009-006

Page 59

TEBEVERT III INVERTER SYSTEM (120 VDC)

Removal of the SBS:

After the manual by-pass switch has been turned to position 1 or 2, the 4

retaining screws are removed and the SBS is pul led out of the front of the

cabinet. This simultaneously removes the operating element of the manual

by-pass switch from its mounting shaft . The manual bypass switch is

mechanically fastened to the SBS.

Insertion of the SBS:

If not already done, the By-pass handle assembly must be mounted onto

the new SBS. Before the SBS is replaced into the cabinet, the operating

element of the manual by-pa ss switch must be turned to position 1 or 2,

according to the position of the switch before the SBS was removed. The

SBS is pushed into the free slot until the unit i s flush w i th the frame of the

cabinet. The four retaining screws are screw ed back in.

Finally, the manual by-pa ss switch must be turned back to posit ion 0 (UPS

operation).

6.3 UPGRADING THE SYSTEM

The inverter system can be equipped with a maximum of 5 inverters.

Additional inverters can only be added to the system if there are free

inverter shelves. The system can be upgraded during running operations

without the need to switch off other components or the need to switch the

manual by-pass switch .

The dummy plates covering the free inverter shelves are removed. The

circuit breaker F1 located on the rea r of the inverter module (Refer to Fig.

8) is switched on and the ON/OFF switch (I tem 3, Fig. 7) i s swi tched off.

The new inverter is pushed into the slot, fixed with the 4 retaining screws

and then switched on. After the start-up phase, the inverter is brought

into parallel operation and the c ur r ent then is evenly distributed to all

inverters that are switched on.

7 DESCRIPTION OF FU NCTION

It is not necessary to understand the exact function of all components in

this inverter system. However, basic knowledge of essential components

aids in the understanding of the whole system and helps to avoid errors in

the maintenance and operation.

7.1 TOTAL SYSTEM

07.11.2011 51 028-0009-006

Page 60

TEBEVERT III INVERTER SYSTEM (120 VDC)

The inverter system supplies a hig h availability AC current supply to load

equipment that must have an uninterr upted input power supply at all

times. According to the selected operating mode, the inverter output

voltage (inverter priority) or the mains volta ge (m ains priority) is switched

through to the load equipment by the SBS. In event the priority system

(mains or inverters) should fail, the redundant system is switched with

minimal interruption to the a lternate source (within a few milliseconds).

The use of the manual maintenance by-pass switch allows servicing and

maintenance work to be carried out on the inverter system or the

redundant mains without an interruption in the power supply to the load

equipment.

7.2 INVERTER

The function of all the inverters in the syst em are identical. The applied

DC voltage reaches an intermediate circuit via an input filter. The voltage

in this intermediate circuit is incr eased to approximately 200V. A highfrequency transfo rmer separates the voltage between the input and the

output of the inverter. In the bridg e of the inverter, the high DC voltage of

the intermediate circuit is transfor m ed into the inverter output voltage of

120 or 230 and a frequency of 50Hz or 60Hz.

In order to obtain a constant sinusoidal output voltage under all operating

conditions, a series of monitoring func tions and controls are necessary.

7.2.1 MONITOR IN G OF TH E INPU T V OL TA GE

The DC voltage applied to the inverter is mo ni tored for under voltage or

over voltage conditions. The inverter supplies continuous, regulated

output voltage when operated within these limits.

07.11.2011 52 028-0009-006

Page 61

TEBEVERT III INVERTER SYSTEM (120 VDC)

1

AUS/

OFF

U1

U2 U3

2

EIN/

ON

U0

1 Under voltage 2 Over Voltage

1 Under voltage range 2 Over voltage range

Fig. 17: Switching thresholds for over voltage and under voltage moni toring system

Figure 17 shows the main princip les o f the system. If over voltage is

applied, the inverter switches off at U2. Once the voltage h as dropped to

below U3, the inverter switches on ag ain automatically.

After switching off as a result of under voltage (U1), the inverter switches

on again only after the input voltage U0 is reached. This value, U0, must

also be available when the inverter is switched on at the main switch. This

ensures that the unit does not start up briefly when the battery is not

charged.

Because of component variances and set ting tolerances, the following

voltage ranges apply for the switchi ng thresholds.

Nominal

U1 U0 U3 U2

input voltage

UN = 120V

100.8V-103.3V 121.3V-123.8V 142.5V-145.5V 148.5V-151.5V

07.11.2011 53 028-0009-006

The unit cannot be switched on when input voltages are

below U0!

Page 62

TEBEVERT III INVERTER SYSTEM (120 VDC)

7.2.2 MONITORING THE OUTPUT VOLTAGE

The output voltage supplied by t he inverter is also monitored. If the

output voltage is within the range 120 10% (108V ... 132V), this targeted

state is indicated by an LED on the front panel. If it is outside this range,

an LED indicates the fault. If the output voltage exceeds the upper limit,

the inverter is blocked and switc hes t o a self-holding mode. The selfholding mode can be cancelled by swit c hi ng the unit on again at the main

ON/OFF switch.

7.2.3 MONITORING THE TEMPERATURE

The temperatur e i s m onit ored in three phases.

If the cooling air temperature reaches a value of approximately 45°C, the

fan inside the inverter automatically switches on.

If the temperature exceeds a value of approximately 85°C, the inverter

switches off because of over temperature.

The air temperature inside the housing is a l so measured. The unit also

switches off when this temperature reaches approximately 70°C. The high

interior temperature may be due to hig h ambient temperatures or

obstruction of the air supply. The shut-down of the inverter due to over

temperature is indicated by the LE D "FAULT" on the front panel.

7.2.4 OVERLOAD BEHAVIOR

The inverter is designed to wit hstand short-term overloading. In cases of

overloading, an LED on the front panel li ghts up. 200% of the nominal

effective current can be supplied for a maximum of 1.2 seconds (i.e.

double the rated power). If the overload still exists after 1.2 seconds, the

current is reduced to 1.3 times the rated value with a resultant reduction

in the output voltage. If the overloa d situation still persists after another

41 seconds, the power unit of the invert er goes off. The inverter can only

restart if, after the inverter has been switched off with the main switch, all

LED´s on the front panel are extinguished and the inverter is switched on

again.

When operating the inverter with a SBS (thi s is always the case for this

inverter system), the SBS recogniz es t he overload. If the inverter output

voltage lies outside the tolerance range, the SBS will switch the current

mains supply through to the load equipment.

07.11.2011 54 028-0009-006

Page 63

TEBEVERT III INVERTER SYSTEM (120 VDC)

7.2.5 SHORT-CIRCUIT BEHAV I OR

The inverter is permanently short-circuit proof. Short-circuits are a special

type of overload. At the time of the short-circuit, the current is limited for

5 seconds to 2.8 times the nominal effective current. During this period,

the short-circuit current can trigger the AC load p rot ec tion circuits in the

customer provided AC distribution.. After approx. 5 seconds have elapsed,

the power unit of the inverter switches off. A r est art of the inverter is only

possible when the inverter has been switched off with the main On/Off

switch, all LED´s on the front panel are extinguished, and the inverter has

then been switched On again.

If the short-circuit per sists, this procedure is repeated.

When the inverter is operated w ith an St at ic By -Pass Switch (SBS), the

connected AC by pass supplies the short-circuit current.

7.3 ELECTRONIC SWITCHING/SBS UNIT

The electronic switching unit a ccurately monitors all the relevant data of

the inverter system. This includes:

Inverter operational states

AC by-pass voltage

Inverter voltage

AC by-pass frequency

phase position between the inverter output and the m ains

level of the load

This information is fed to an internal c ontroller, which controls the Static

By-Pass Switch (SBS) via a logical trigger switching the AC by-pass or the

inverter output voltage through to the load equipment. If the system is

functioning correctly, the voltage, which has been pre-selected by the

setting of the operation mode, is switched through the Static By-Pass

Switch (SBS), i.e. "mains priority" or "inverter priority".

In addition to the visual indicators (LEDs), the SBS also controls dry

contact alarm relay A setting option is used to select whether this

messaging is a collective fault message from the SBS and the inverter, or

a single fault message of the SBS. T his m essage follows the visual

indication with a delay of approximately 10seconds.

The cause of these faults may be:

07.11.2011 55 028-0009-006

Page 64

TEBEVERT III INVERTER SYSTEM (120 VDC)

disturbances in the AC by-pass supply

disturbances in the inverter / inverter system

disturbances in the SBS

The reset of the dry contact alarm rela y occurs without a delay. To permit

operation of the SBS via the remote monitoring system MCU, an additional

unit (satellite card) must be insta ll ed . Through this optional unit,

operational states and measurement values of the SB S and the associated

inverter system are transmitted t o the remote monitoring system via a

serial interface to RS485 standard.

In the standard design, 6 different typ es o f sta tus information are

transmitted, resulting from the linkage of the various status data.

The transmitted status informat ion comprises:

• Inverter operation

• SBS warning

• SBS fault

• Overload

• Faulty output voltage

• SBS blocked

In addition, 15 detected or calculated measuring values are transmitted.

• Heat sink temperature SBS

• Inverter voltage

• AC by-pass voltage

• Output voltage SBS

• Output current SBS

• Output current inverter 1 – inverter 5

• Active power

• Apparent power

• Reactive power (calculated)

• Crest factor

• Output frequency

All indicated states a n d m easuring values of the inverter system can be

further processed and evaluated using the service so f tware of the remote

monitoring system.

Redundancy function for the SBS Satellite function (5 kVA and 2.5 kVA inverters)

07.11.2011 56 028-0009-006

Page 65

TEBEVERT III INVERTER SYSTEM (120 VDC)

From Version 1.03 on we support a redundancy function generating two events in the SBS

satellite. This can be mapped t o an input of the optional MCU and us ed to control alarm relays

in the relay box Option.

The first alarm (Minor-non urgent) is activated, when one or more inverters have a fault.

A fault is defined as:

- inverter is not working properly in any way (error message of the inv erter)

- inverter is turned off with the switch on the front

- inverter is removed from system (the total amount of inverters is logged , so if

you plug in the inverter into a different place, the fault will be reset)

The second alarm (Major-urgent) is activated, when two or more inverters have a fault. Fault

conditions are defined above.

Note: If the alarm is triggered by removal of an inverter (e .g. f or

service purposes) this can be reset by pushing the reset/led test

button on the LE D-panel of the MCU.

07.11.2011 57 028-0009-006

Page 66

TEBEVERT III INVERTER SYSTEM (120 VDC)

Notes

07.11.2011 58 028-0009-006

Page 67

TEBEVERT III INVERTER SYSTEM (120 VDC)

Notes

07.11.2011 59 028-0009-006

Page 68

TEBEVERT III INVERTER SYSTEM (120 VDC)

Notes

07.11.2011 60 028-0009-006

Page 69

Page 70

Benning Power Electronics

1220 Presidential Drive Suite 100

Richardson, TX 75081 USA

www.benning.us

800.910.3601

This manual contains important safety