Page 1

Technical Bulletin

Bulletin No.: PRO-01-26 Effective Date: 12/15/86 Cancels: PRO-01-26 Dated 11/28/83 Page: 1 of 5

Subject: Compressor Turbocharging

Traditionally, Bendix has permitted compressor turbocharging with certain exceptions

and limitations. Generally, original equipment installations of turbocharged compressors

have prior Bendix approval. Factors affecting approval of a specific installation include

the engine, turbocharger and compressor combination.

Compressor turbocharging becomes a concern in the Aftermarket when one of the

components of the originally approved combination is changed or when turbocharging is

considered for a previously unturbocharged compressor. For example, when a

turbocharged TuFlo 501 is changed over to a TuFlo 700.

The following can be used as a guide to determine if it is acceptable to turbocharge a

Bendix compressor in a specific application.

TURBOCHARGING

Definition

A turbocharger is a turbine driven compressor unit where the turbine is driven by the hot

gases of the engine exhaust. Its function is to increase engine efficiency and power

output by compressing air drawn through the vehicle air cleaner and directing the

compressed air into the engine intake manifold. The air pressure generated can

typically fluctuate between 30 psi and a slight vacuum, depending upon engine load.

Turbocharger outlet pressure increases as engine load increases.

A vehicle brake system compressor is turbocharged when its inlet is connected to the

outlet or PRESSURE side of the turbocharger. For example; a compressor would be

turbocharged if its inlet is connected to the intake manifold of a turbocharged engine.

Page 2

Advantages of Compressor Turbocharging

1. Convenience of installation – Often the location of the compressor relative to the

engine manifold allows a short connecting line to be used.

2. Enhanced oil control – The elimination of inlet vacuum reduces the possibility of

excessive oil passing.

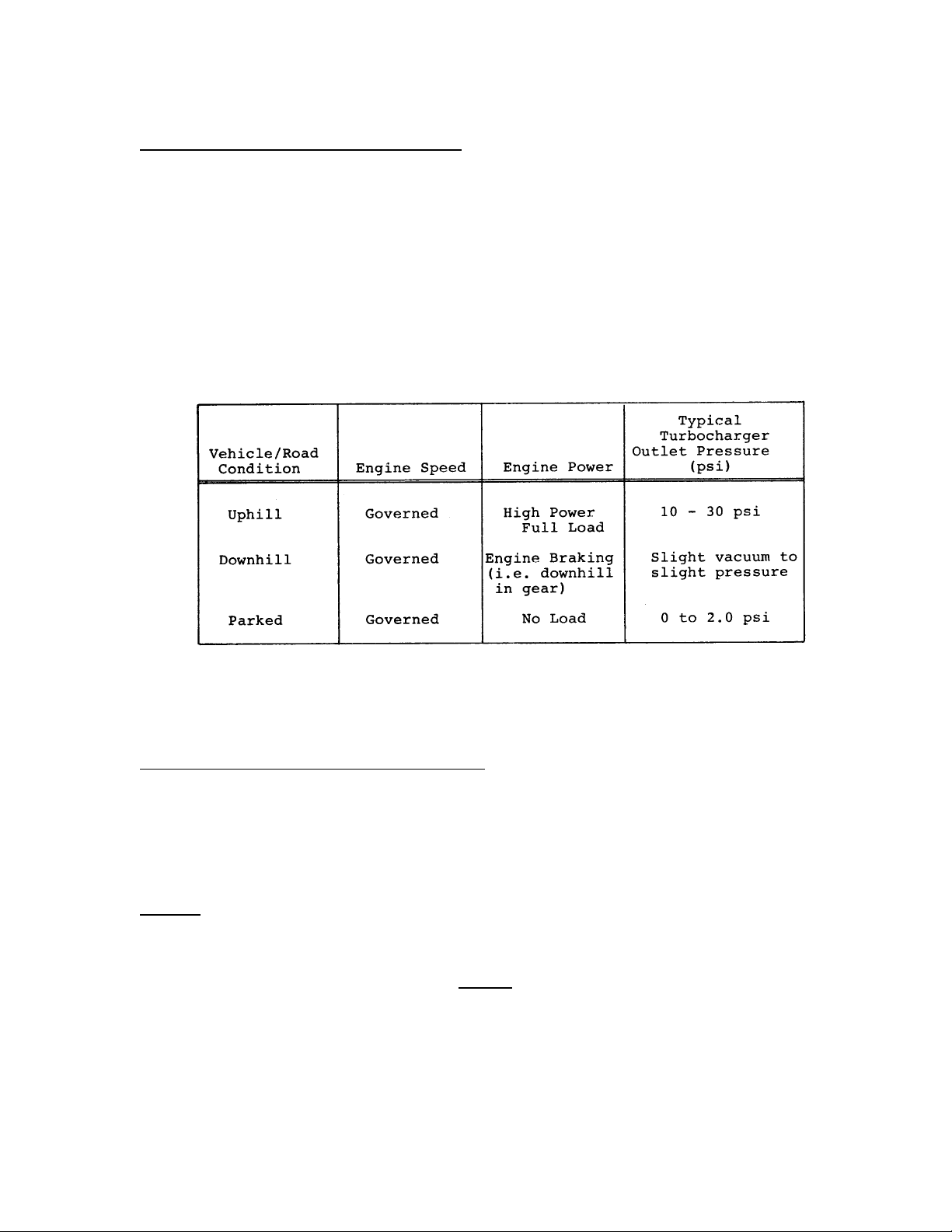

3. Increased compressor capacity – Under some circumstances compressor capacity is

increased. The following chart illustrates some vehicle and road conditions as related

to the turbocharger output.

Disadvantages of Compressor Turbocharging

The primary disadvantage is reduced compressor durability when Bendix turbocharging

guidelines are not followed.

TURBOCHARGING GUIDELINES

General

1. Particular attention must be given to the specified minimum inlet, discharge and

coolant line sizes along with coolant flow requirements for the compressor model

being turbocharged. Turbocharging of FULLY air cooled compressors is not

recommended.

Page 3

2. If a previously unturbocharged compressor is being turbocharged, it is recommended

that the inlet cavity screen 238948 be installed with an inlet gasket (291909) on both

sides of the screen.

3. If a compressor is being turbocharged for the first time and specific turbocharger

data is not available to confirm that the installation is within the stated Bendix

compressor turbocharging parameters, the installation must be tested.

A full vehicle dynomometer can be used to measure turbocharger performance at

maximum engine operating conditions. For this test, temperature and pressure

sensing equipment should be installed at the compressor inlet to verify that the

compressor turbocharging parameters are being met. This equipment can be

installed using two alcohol evaporator compressor inlet adapters (236701). See

Figure 1.

Page 4

4. The Bendix inlet regulating valve (IRV) can be installed as an alternative to direct

compressor turbocharging when it is found that turbocharger supply air pressure

exceeds the limits of a particular compressor model. The function of the IRV is to

maintain a pressure of 10 psi or less at the compressor inlet regardless of

turbocharger supply air pressure. While use of the IRV eliminates concern with

turbocharger pressure output, the installation must comply with all other compressor

turbocharging parameters. The IRV, part number 104171, can be installed on all

Bendix compressors with the exception of the BX-2150.

COMPRESSOR TURBOCHARGING PARAMETERS

TuFlo 400, 500, 501 & 1000 Compressors

1. Air entering the compressor inlet during the loaded cycle must not exceed 250F

(121C). A metal inlet line is suggested to help meet this parameter.

2. Compressor crankshaft speed must not exceed 2200 rpm.

3. Air pressure at the compressor inlet must not exceed 25 psi (172 kPa).

4. Turbocharging is not recommended for fully air cooled versions of the TuFlo 500 and

1000 air compressors.

TuFlo 600, 700 & 1400 Compressors

1. Air entering the compressor inlet(s) during the loaded cycle must not exceed 250F

(121C). A metal inlet line is suggested to help meet this parameter.

Page 5

2. The following compressor crankshaft rotative speed and inlet pressure relationships

may not be exceeded.

Maximum Compressor

Crankshaft RPM Inlet Pressure

1900 rpm 25 psi (172 kPa)

2000 rpm 22 psi (151 kPa)

2100 rpm 19 psi (131 kPa)

2200 rpm 15 psi (103 kPa)

BX-2150 Compressor

1. Air entering the compressor inlet during the loaded cycle must not exceed 250F

(121C). A metal inlet line is suggested to help meet this parameter.

2. Compressor crankshaft speed must not exceed 2200 rpm.

3. Air pressure at the compressor inlet must not exceed 15 psi (103 kPa).

4. The Bendix inlet regulating valve (IRV) must not be installed on this model

compressor.

Loading...

Loading...