Page 1

Bendix® SL-3™ & SL-4™ Stop Light Switch

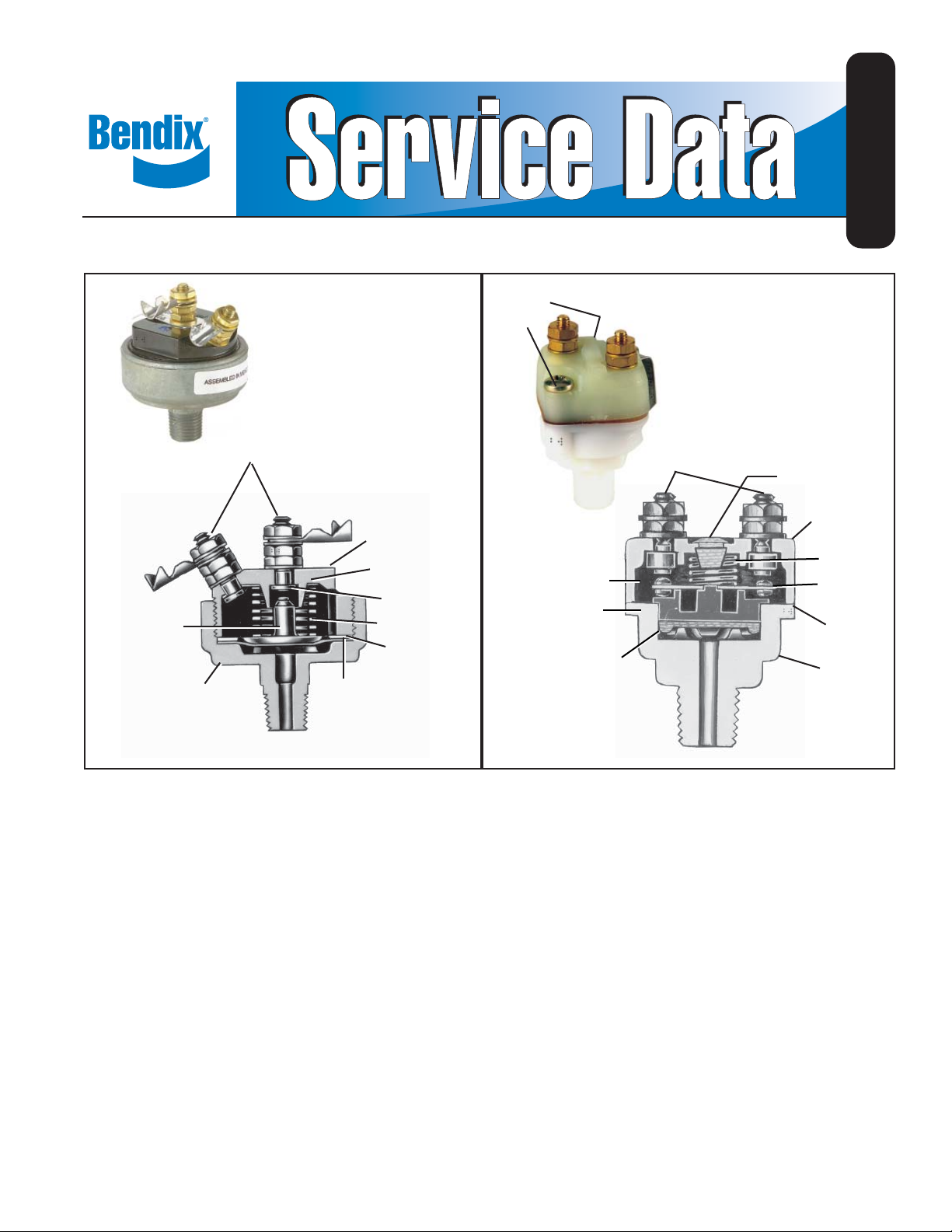

MACHINE

SCREWS

SD-06-1800

7

2

TERMINAL

SCREWS

1

COVER

7

TERMINAL

CONNECTOR

CONTACTS

4

PLUNGER

BODY

FIGURE 1 - BENDIX® SL-3™ STOP LIGHT SWITCH

6

DIAPHRAGM

3

SPRING

5

WASHER

DESCRIPTION

The stop light switch is an electro-pneumatic switch and

operates in conjunction with the brake valve and stop

lights by completing the electrical circuit when a brake

application is made.

9

CONTACT

13

PISTON

14

O-RING

DIAPHRAGM

FIGURE 2 - BENDIX

TERMINAL

SCREWS

®

SL-4™ STOP LIGHT SWITCH

10

VENT

PLUG

8

COVER

11

SPRING

12

CONTACT

STRIP

15

GASKET

BODY

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

OPERATION

When a brake application is made, air pressure from

the brake valve enters the cavity below the diaphragm.

At approximately 5 psi, the air pressure underneath

the diaphragm overcomes the force of the spring and

moves the piston or plunger until the contact points close,

completing the stop light electrical circuit and lighting the

stop lights.

No two vehicles operate under identical conditions; as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum,

the Bendix

®

SL-3™ and SL-4™ switches should be inspected

every 6 months or 1500 operating hours, whichever comes

first, for proper operation and electrical connections.

Should the SL-3™ or SL-4™ switch not meet the elements

of the operational tests noted in this document, further

investigation and service of the valve may be required.

1

Page 2

TESTING FOR SERVICEABILITY

CLEANING AND INSPECTION

OPERATING TEST

1. Apply the brake valve and note that the stop light lights

before the delivery pressure reaches 7 psi.

2. Release the brake valve and note that the stop light

goes “off”.

LEAKAGE TEST

1. With the brakes fully applied, no leakage is permitted

at the stop light switch. If the stop light switch does

not function as described or if leakage is excessive,

it is recommended that it be replaced with a new unit

®

or repaired with genuine Bendix

brand replacement

parts available at authorized Bendix parts outlets.

REMOVING

1. Disconnect the electrical connections at the stop light

switch.

2. Disconnect the air line to the stop light switch.

3. Remove the stop light switch.

INSTALLING

1. Install in a convenient location for servicing.

2. Install with the pipe tap pointing to the ground and keep

it high for adequate drainage.

3. Connect the stop light switch in series in the stop light

circuit.

4. Keep the stop light switch terminals away from frame

members to avoid grounding.

5. Connect the pipe tap to the brake chamber supply line

so that the stop light switch will operate whether the

foot or hand valve is applied.

DISASSEMBLY

BENDIX® SL-3™ SWITCH

1. Place hex portion of body in a vise.

2. Using a large end wrench on cover fl ats, turn cover (1)

in a counterclockwise direction and remove from body .

3. Remove terminal nuts, terminal screws (2) and terminal

connector (7) from cover.

4. Remove spring (3), plunger (4), washer (5) and

diaphragm (6) from body.

BENDIX® SL-4™ SWITCH

1. Remove two machine screws (7) and remove cover

(8).

2. Remove the terminal nuts and terminals (9) from cover .

3. Remove the vent plug (10) from cover.

4. Remove spring (11), contact strip (12), piston (13) and

o-ring diaphragm (14) from body.

Clean all metal parts in cleaning solvent. Wipe rubber parts

dry with a cloth.

Inspect contact points for pits or wear. If pitting is not too

severe, the points may be reconditioned by fi ling with a

distributor point fi le. If points cannot be reconditioned, they

™

should be replaced. The contact strip in the SL-4

switch

may be turned over to use the other side of the contacts.

Check the spring for signs of deterioration; Replace if

discolored. The spring in the SL-3™ switch carries the

current of the electrical circuit involved; consequently, in

the case of excessive current, as might be caused by a

short, the spring will be overheated and ruined.

Inspect cover and body. If cracked or damaged, replace.

Only genuine Bendix service parts should be used for

replacement.

ASSEMBLY

SL-3™ SWITCH (Figure 1)

1. Insert terminal screws (2) in the cover (1), making sure

the terminal connector (7) is properly positioned.

2. Secure terminal screws with washers and nuts, or

terminal clips, as the case may be.

3. Place diaphragm (6) in the body.

4. Position the contact plunger (4) on diaphragm.

5. Position spring (3) on the plunger.

6. Place washer (5) on the diaphragm and screw the cover

(1) into the body . T orque to 30 foot pounds. Make certain

the vent hole in the cover is open.

SL-4™ SWITCH (Figure 2)

1. Position terminal screws (9) in the cover (8) and secure

with washers and nuts or terminal clips. Place the vent

plug (10) in cover.

2. Place o-ring diaphragm (14) and piston (13) in the body .

The o-ring diaphragm should be installed with its fl at

side adjacent to the piston.

3. Place the gasket (15) in place on the body and contact

strip (12) on the piston (13).

4. Position cover assembly on the gasket and secure with

machine screws. Torque to 20 inch pounds.

2

Page 3

TEST OF REBUILT STOP LIGHT SWITCH

Both operating and leakage tests, as indicated under

section entitiled “T esting for Serviceability”, must be made

after rebuilding or repairing the stop light switch. The switch

must meet the following specifi cations:

1. No leakage is permissible at the stop light switch with

the brakes applied.

2. The stop light switch contact should close with not more

than 7 pounds of air pressure.

3

Page 4

4

BW1593 © 2011 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • 6/2011 • All rights reserved

Loading...

Loading...