Page 1

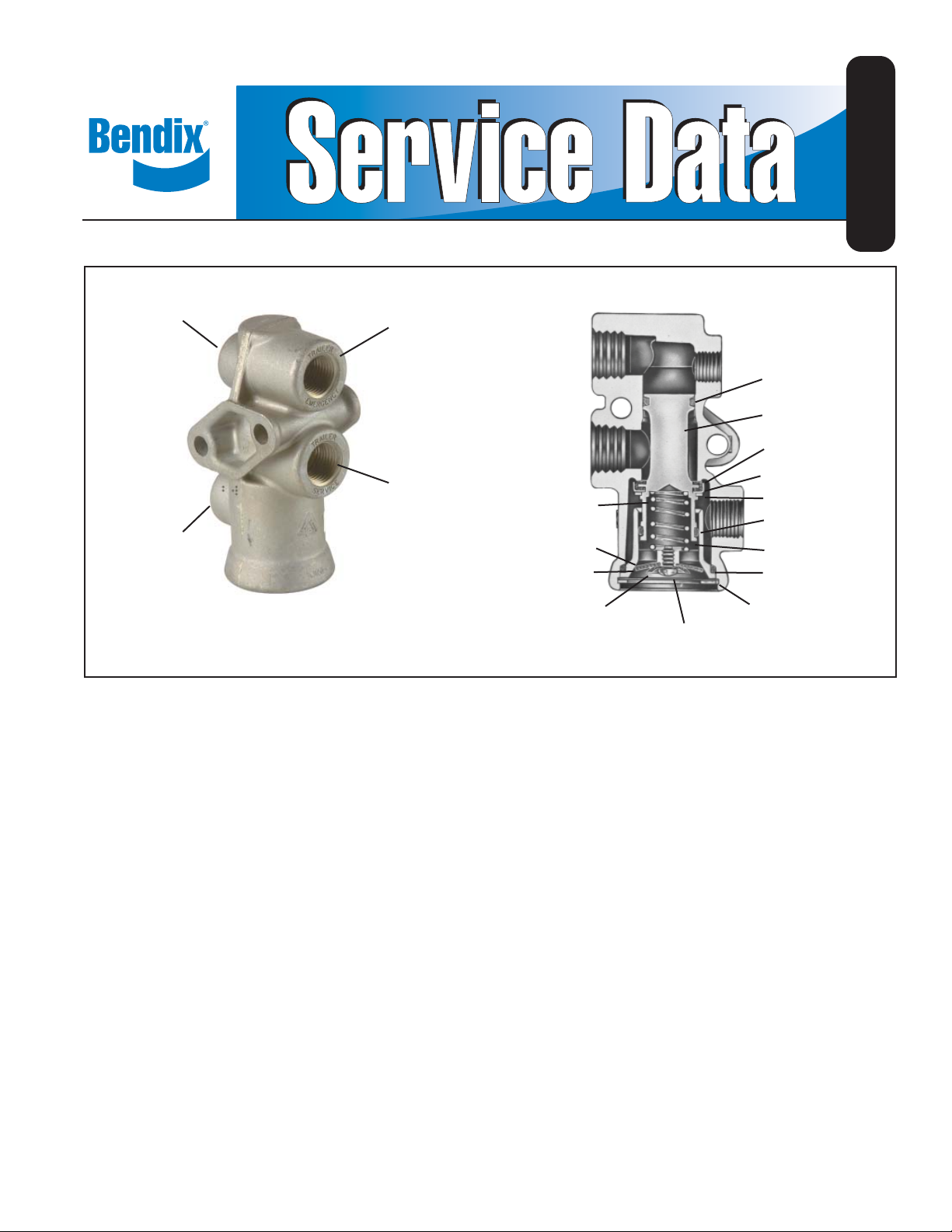

Bendix® TP-3® Tractor Protection Valve

TRACTOR

EMERGENCY

PORT

TRACTOR

SERVICE

PORT

TRAILER

EMERGENCY

PORT

TRAILER

SERVICE

PORT

VALVE SPRING(6)

DIAPHRAGM

SEAT(9)

DIAPHRAGM(5)

SD-03-3652

O-RING(13)

PLUNGER(11)

INLET VALVE(4)

VALVE RETAINER(10)

RETAINING RING(2)

O-RING(12)

SEAT

O-RING(7)

EXTERIOR VIEW

FIGURE 1 - BENDIX® TP-3® TRACTOR PROTECTION VALVE

DESCRIPTION

The Bendix® TP-3® Tractor Protection Valve is used in

combination with the Bendix® PP-3™ Trailer Supply Valve

on pre-121 tractors, and the Bendix

V alve, or the Bendix

®

MV-3® V alve, on post-121 tractors. It

contains a passage for trailer supply air and a service line

shut off valve. It is normally mounted behind the cab, with

the delivery line from the trailer supply valve connected

into the tractor emergency port and a delivery line from the

brake valve connected to the tractor service port. The trailer

supply and service hoses are mounted in their respective

ports in the TP-3 valve. See Figure 2.

OPERATION

Air from the trailer supply valve passes through the

emergency ports of the TP-3 valve to supply the trailer air

system and simultaneously exerts pressure on the end of

the plunger(1 1). The TP-3 valve requires approximately 45

psi to open the inlet valve. Whenever the pressure from

the trailer supply valve drops below 45 psi, the TP-3 valve

will close the service line shut-off valve.

®

PP-7™ Trailer Supply

WASHER(8)

CAP SCREW(3)

CROSS SECTION

RETAINING RING(1)

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions; as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum,

the Bendix TP-3 valve should be inspected every 6 months

or 1500 operating hours, whichever comes fi rst, for proper

operation. Should the TP-3 valve not meet the elements

of the operational tests noted in this document, further

investigation and service of the valve may be required.

1

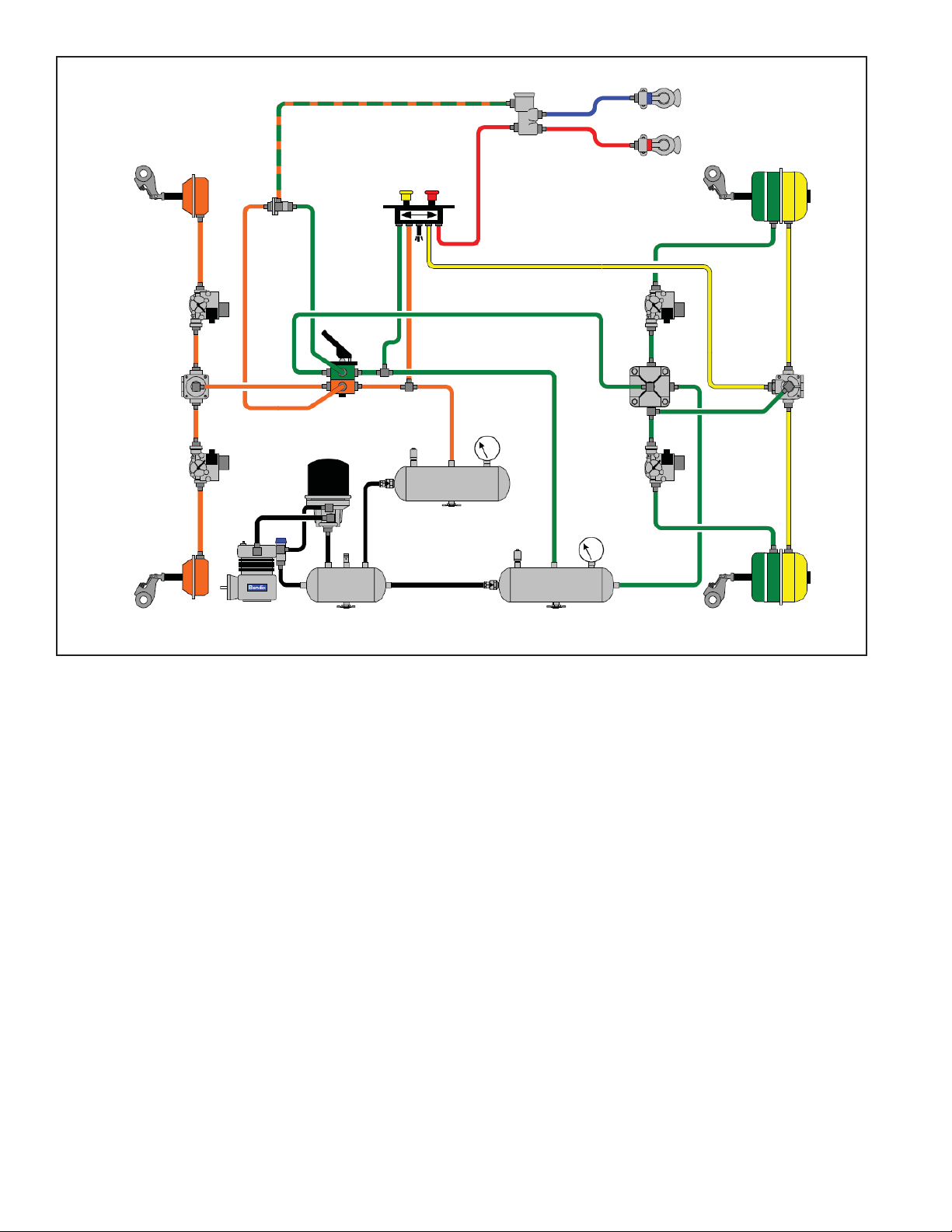

Page 2

DOUBLE

CHECK

VALVE

BRAKE

VALVE

BENDIX® MV-3®

CONTROL VALVE

BENDIX® TP-3®

TRACTOR

PROTECTION

VALVE

TRAILER

EMERGENCY LINE

TRAILER

SERVICE LINE

AIR

DRYER

COMPRESSOR

FIGURE 2 - SYSTEM SCHEMATIC

FRONT

RESERVOIR

OPERATING AND LEAKAGE CHECKS

1. Block and/or hold the vehicle by a means other than the

air brakes during these tests. Place the trailer supply

valve in the emergency position and disconnect the

trailer supply and service couplings.

2. With the tractor reservoirs charged to at least 100 psi,

make and hold a full service brake application. Leakage

at either tractor hose coupling should not exceed a 1

inch bubble in fi ve seconds (100 SCCM).

3. Connect the trailer supply, or emergency line, hose

coupling and place the trailer supply valve in the “run”

position. Leakage at the “service” coupling should not

exceed a 1 inch bubble in fi ve seconds (100 SCCM).

4. Connect the service coupling and make and hold a full

service brake applicat ion: Leakage at the diaphragm

end of the Bendi x® TP-3® Valve shall not exceed a

1 inch bubble in three seconds (175 SCCM).

NOTE: If the TP-3 V alve does not function as described,

or if leakage is excessive, it is recommended that it be

replaced or repaired using genuine Bendix service

replacement parts.

REAR

RESERVOIR

REMOVING

Remove the trailer hose assemblies from the TP-3 valve.

Disconnect tractor service and supply lines and remove

the TP-3 valve.

INSTALLING

When installing the TP-3 valve, refer to Figure 2, and the

following explanation, for proper connections.

1. The delivery line from the Bendix® MV-3® Dash Control

V alve is connected to the tractor emergency port of the

TP-3 valve.

2. The delivery line from the brake valve (or double check

valve) is connected to the tractor service port of the

TP-3 valve.

3. Trailer hose assemblies are installed in the trailer

emergency and trailer service ports of the TP-3 valve.

2

Page 3

DISASSEMBLY

(See Figure 1.)

1. Remove the diaphragm seat retainer ring (1) while

holding the diaphragm seat (9) in the body.

2. While still holding the diaphragm seat in the body,

remove the date code ring.

3. Allow the seat to rise until the valve spring force is no

longer present.

4. Remove the diaphragm seat assembly (9), valve spring

(6), and plunger assembly (11).

5. Remove the diaphragm seat o-ring (7), cap screw (3),

diaphragm washer (8) and diaphragm (5).

6. Remove the valve retainer ring (2), valve retainer

(10), inlet valve (4), and o-rings (12) and (13) from the

plunger.

CLEANING AND INSPECTION

1. Clean all metal parts in mineral spirits and dry them

completely.

2. Inspect all parts for excessive wear or deterioration.

Inspect valve seats for nicks or burrs. Check the valve

spring for cracks or corrosion.

3. Inspect the bores of the valve housing for deep scuffi ng

or gouges.

Replace all parts that were discarded, and any parts not

found to be serviceable during inspection, using only

genuine Bendix® replacement parts.

ASSEMBLY

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to prevent the

sealant from entering the valve itself. Apply the

sealant beginning with the second thread back

from the end.

1. Install the inlet valve (4) on the plunger (11).

2. Position and force the valve retainer (10) down over

the inlet valve.

3. Install the retainer ring (2) beneath the inlet valve

retainer.

4. Install both plunger o-rings (12) and (13) in their proper

grooves.

5. Place the plunger and valve assembly in the valve body.

6. Install the cap head screw (3), diaphragm washer

(8) with the cup side up, and diaphragm (5) into the

diaphragm seat (9).

7. Place the inlet valve spring (6) into the plunger.

8. Install the diaphragm seat o-ring (7) in the body.

9. Position the diaphragm seat assembly over the spring

and plunger assembly and force it into the body.

10. Replace the date code washer and install the retaining

ring (1) making sure the retaining ring snaps fully into

the groove.

TESTING SERVICED BENDIX TP-3 VALVES

Perform the operating and leakage checks as outlined in

previous section.

Before assembling the Bendix® TP-3® Tractor Protection

V alve, lubricate all o-rings, o-ring grooves, body bores and

rubbing surfaces with Bendix silicone lubricant (Piece No.

291126) or equivalent.

3

Page 4

BW1572 © 2012 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • 9/2012 • All rights reserved..

4

Loading...

Loading...