Page 1

Donut System

PROOFING

Worldwide Leader in the Design and Manufacture of Donut Production Equipment

CENTURY THERMOMATIC

PROOFER

Belshaw’s Thermomatic (TM) Proofers,

designed in concert with our Century

Fryers, are manufactured with the

goal of improving your efficiency. The

TM Proofer automatically controls the

proofing environment, ensuring each

donut receives virtually identical proofing

- time and time again - improving product

consistency and yield, and reducing

labor requirements.

Flexibility and durability are hallmarks

of the Belshaw TM Proofer Line. Five

TM proofer sizes, with several length,

height, infeed and outfeed options, allow

Belshaw to tailor a proofer to your specific

requirements.

The TM Proofer minimizes your labor

requirements by automating donut

production. Donuts can be automatically

transferred, placed or cut directly onto the

proofing trays. The trays are then carried

through the electronically controlled

proofer environment automatically, at a

speed synchronized to the fr yer, ensuring

a virtually identical proof for each donut.

The TM Proofer requires little knowledge

or experience to operate reliably. You can

rely on the TM Proofer to maintain the

environment you select – and produce

consistent results.

The Century Thermomatic Proofer is ideal

for exhibition-style production. Windows

allow viewing the donuts as they travel

through the proofer.

Belshaw’s Dustless Proofing option

eliminates the need to put flour on the

proofer trays. Donuts are transferred

cleanly using an exclusive active release

system. The Dustless Option improves

quality and saves money, extending

fryer-shortening life, and reducing

cleaning labor.

FOODSERVICE EQUIPMENT

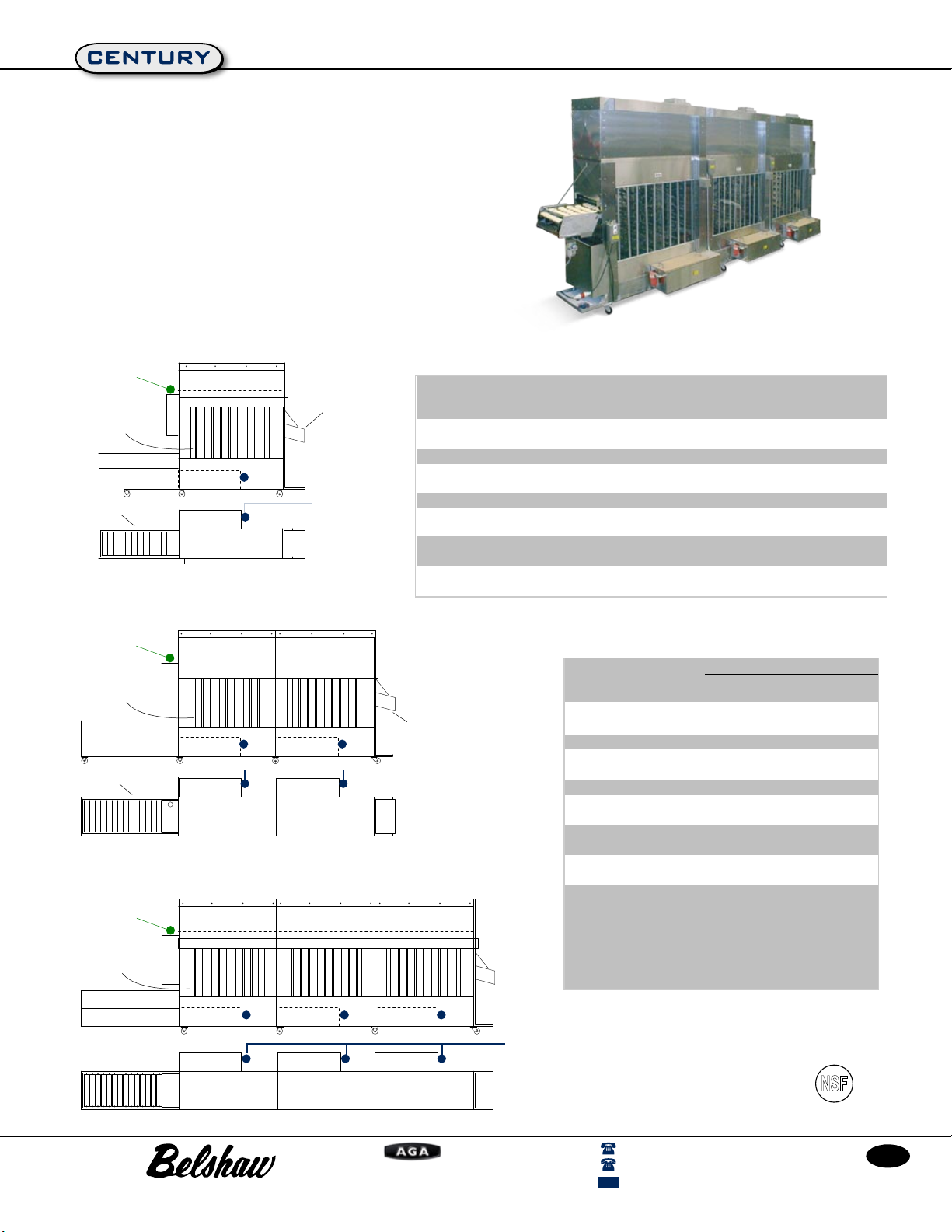

Century proofers

TM200 (left) and TM600

(right)

2-section Century

proofer TM600

Century proofer

TMK-VI

8

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144- 4590 USA

W http://www.belshaw.com

800-578-2547 (USA/Canada)

206-322-5474 (International)

©20 05 Belshaw Bros, Inc. Rev 3/0 5

FAX

206-322-5425

Page 2

DONUT SYSTEM

MODEL SECTIONS LENGTH WIDTH

STANDARD

HEIGHT

HEIGHT WITH

36" (92cm)

EXTENSION

TM100 1 13'-7" (4.14m) 3'-0" (92cm) 7'-1" (2.16m) 10'-1" (3.07m)

2 22'-0" (6.71m) 3'-0" (92cm) 7'-1" (2.16m) 10'-1" (3.07m)

TMK VI 1 9'-0" (2.74m) 3'-4" (1.01m) 7'-1" (2.16m) 10'-1" (3.07m)

TM200 1 13'-7" (4.14m) 3'-4" (1.01m) 7'-1" (2.16m) 10'-1" (3.07m)

2 22'-0" (6.71m) 3'-4" (1.01m) 7'-1" (2.16m) 10'-1" (3.07m)

TM300 2 22'-0" (6.71m) 4'-1" (1.25m) 7'-1" (2.16m) 10'-1" (3.07m)

TM400 2 22'-0" (6.71m) 3'-4" (1.01m) 7'-1" (2.16m) 10'-1" (3.07m)

3 28'-6" (8.69m) 3'-4" (1.01m) 7'-1" (2.16m) 10'-1" (3.07m)

TM600 2 22'-0" (6.71m) 4'-1" (1.25m) 7'-1" (2.16m) 10'-1" (3.07m)

3 28'-6" (8.69m) 4'-1" (1.25m) 7'-1" (2.16m) 10'-1" (3.07m)

TM800 2 22'-0" (6.71m) 4'-10" (1.47m) 7'-1" (2.16m) 10'-1" (3.07m)

3 28'-6" (8.69m) 4'-10" (1.47m) 7'-1" (2.16m) 10'-1" (3.07m)

Standard

height

With 36in/92cm

height extension

TM100 1 20 min 31 min

2 41 min 63 min

TMK VI 1 30 min 47 min

TM200 1 20 min

34 min

Note1

2

41 min

Note 2

63 min

TM300 2 41 min 63 min

TM400 2 27 min 42 min

3 42 min 53 min

TM600 2 20 min 30 min

3 30 min 46 min

TM800 2 20 min 30 min

3 30 min 46 min

Notes: 1

48in(1.22m) extension required

2

Can reduce to 30 min by eliminating baskets

All data calculated using 100 sec frying time. Longer frying times

increase proofing time in the same proportion.

PROOFER

MODEL

NUMBER OF

SECTIONS

PROOFING TIME

Height extensions can be ordered in increments of 6in(152mm)

up to 36in(92cm).

Features

■

Digital Controls and Displays.

■

Automatic water feed.

■

Independent temperature and humidity controls for multi-

section proofers.

■

Adjustable safety clutch for uncoupling motor in the event

of abnormal motion resistance.

■

NSF Listed.

■

Active Release System option for flour-free (dustless)

proofing.

■

Several Height Extension Options for longer proof times.

SINGL E SECTI ON PROOFER

POWER

WINDOW

P

CAP

OUTFE ED

w

Proofer Dimensions

PROOFING

TM 600 3- section proofer

with height extension

LOADIN G

TABLE

TWO SECTION PR OOFER

POWER

WINDOWS

LOADIN G

TABLE

THREE SECTION PROOFER

POWER

WINDOW

Manufac ture d by

HUMIDIFIER

P

HUMIDIFIER

P

HUMIDIFIER

CAP CAP

CAP CAP CAP

WATER

w

w

w

HUMIDIFIER

w w w

HUMIDIFIER HUMIDIFIER

w

w

OUTFE ED

WATER

FOODSERVICE EQUIPMENT

www

WATER

Proofing Times with/without Height Extension

NSF

®

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

9

Loading...

Loading...