Belshaw Mark II Installation Manual

|

|

|

|

|

|

|

|

|

The #1 Source for Donut and Bakery Equipment |

www.belshaw.com |

|

|

|||

|

|

|

|

OTEPCECHRHNANTI COI CARLA’ SSLMUSPAUPNLPUEPAMLEENMTE N T

O P E R A T O R ’ S M A N U A L

TP EACR HT SN IACNADL ESLUEPCPTLREIMCEANL TD I A G R A M S

S U P P L É M E N T T E C H N I Q U E

Ventless Donut Center

Insider

|

CE DECLARATION |

|

OF CONFORMITY |

This manual should only be used with the Item Numbers shown above. |

ENCLOSED |

|

SUPPORT |

International (+1) 206-322-5474 |

Web www.belshaw.com |

|

USA/Canada 1-800-578-2547 |

Email service@belshaw.com |

|

|

|

Belshaw Bros., Inc • 814 44th Street NW, Suite 103 • Auburn, WA 98001 • USA

Tel: 206-322-5474 • Fax: 206-322-5425 • www.belshaw.com

INFORMATION FOR CUSTOMERS

AND APPROVAL AUTHORITIES

INSIDER

DONUT FRYING SYSTEM

COMMERCIAL ELECTRIC COOKING APPLIANCE

WITH INTEGRAL RECIRCULATING SYSTEM

INSTALLATION REQUIREMENTS

•INSIDER SPECIFICATION SHEET

•FIRE SUPPRESSION DESCRIPTION

•INSTALLATION INFORMATION

•STANDARDS & LISTINGS – ETL/UL/NFPA

•ETL/UL LABELS

•PYRO-CHEM DATA SHEET

COMPLETE INSTALLATION PROCEDURES ARE LISTED IN THE INSIDER INSTALLATION, OPERATORS AND MAINTENANCE MANUAL

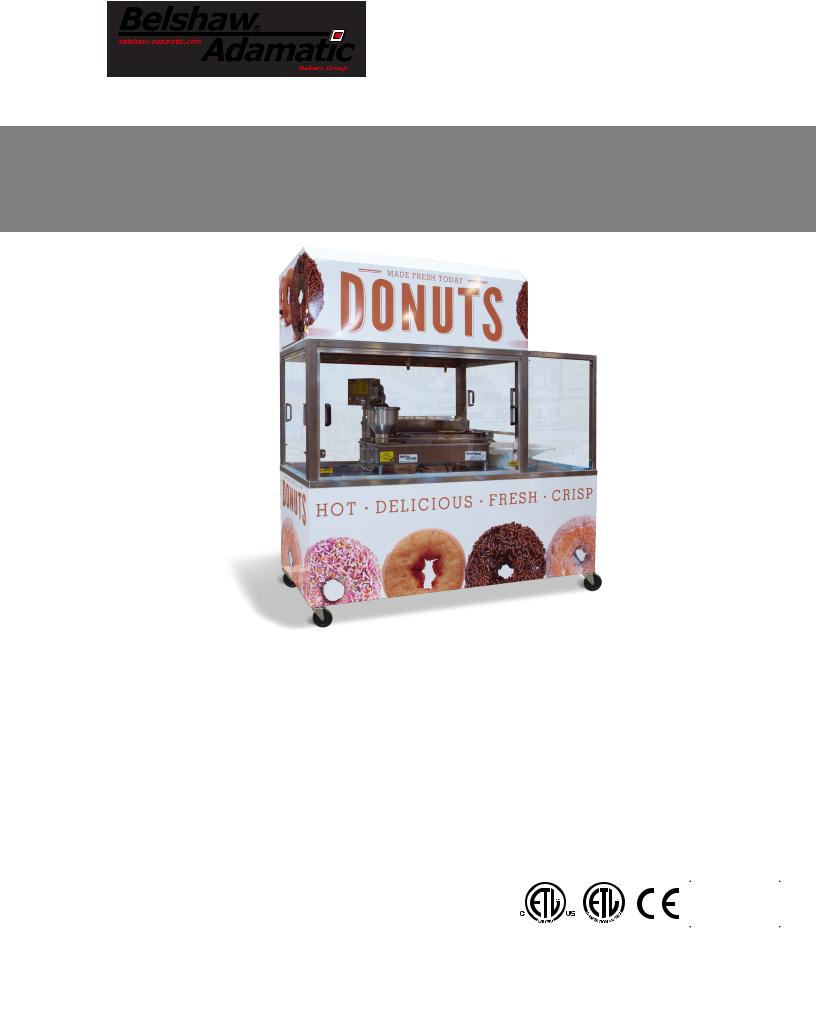

The Insider is Belshaw’s distinctive donut frying system that eliminates the need for a standard exhaust hood. With its ability to operate indoors, the Insider offers unique benefits:

• The Insider can be easily moved from one place to another. The exhaust hood is built-in and there is no exterior ductwork.

• Customers in high traffic areas can watch the Insider frying donuts automatically. The operator has only to mix batter, fill the Donut Robot® hopper and bag donuts from the Roto-Cooler, a rotating tray that collects the donuts automatically.

• The Insider eliminates the purchase and installation cost of standard ventilation and fire suppression hoods.

• The Insider is designed to attract the interest of passers-by. With its large window viewing area and attractive appearance the Insider has great merchandising potential. Vehicle-style graphic wraps can easily be applied to top, bottom and side panels.

• The Insider addresses fire prevention, air filtration, and sanitation requirements. Cabinet and fryers are tested by ETL and listed to UL-197, UL-710B, CSA C22.2 and NSF-4 standards.

COMPONENTS OF INSIDER DONUT SYSTEM

••Insider Clean-Air Cabinet ••Donut Robot® Fryer, either:

--Mark II

--Mark II GP (mini donut model) --Mark V

--Mark V GP (mini donut model) ••EZMelt 18 Melter-Filter.

--The EZMelt can be placed inside the cabinet directly below the fryer. It will quickly empty, filter and refill the shortening in the fryer.

••Roto-Cooler.

--Rotating tray that collects donuts after frying.

Type |

INSIDER Ventless Donut Center |

|

|

Models |

INSIDER/Mark II • INSIDER/Mark V |

|

|

VIDEO: https://vimeo.com/belshaw/insider

VIDEO: https://vimeo.com/belshaw/insider

Photo shows Insider with Donut Robot® and Roto-Cooler with sample graphic wrap.

Inset shows Mark II and Mark V GP. The Insider accepts either Mark II • Mark II GP • Mark V • Mark V GP

Donut Robot® Mark II / Mark II GP |

Donut Robot® Mark V / Mark V GP |

EZ Melt 18 |

Roto-Cooler |

Insider / Mark V (without graphic wrap) |

|

90 Years of Quality Donut & Bakery Equipment |

|

|

|

BELSHAW ADAMATIC BAKERY GROUP |

CONTACT |

WEB |

|

814 44th St NW, Suite 103 |

800.578.2547 (USA/Canada) |

www.belshaw.com |

|

Auburn, WA 98001 USA |

(+1) 206.322.5474 Worldwide |

|

|

|

info@belshaw.com |

|

|

PART OF ALI GROUP S.P. A. |

© 2015 Current version available at www.belshaw-adamatic.com |

Page 1 of 2 |

|

|

|

|

|

|

|

Type |

INSIDER Ventless Donut Center |

|

|

|

|

|

|

Models |

INSIDER/Mark II • INSIDER/Mark V |

|

|

|

|

|

|

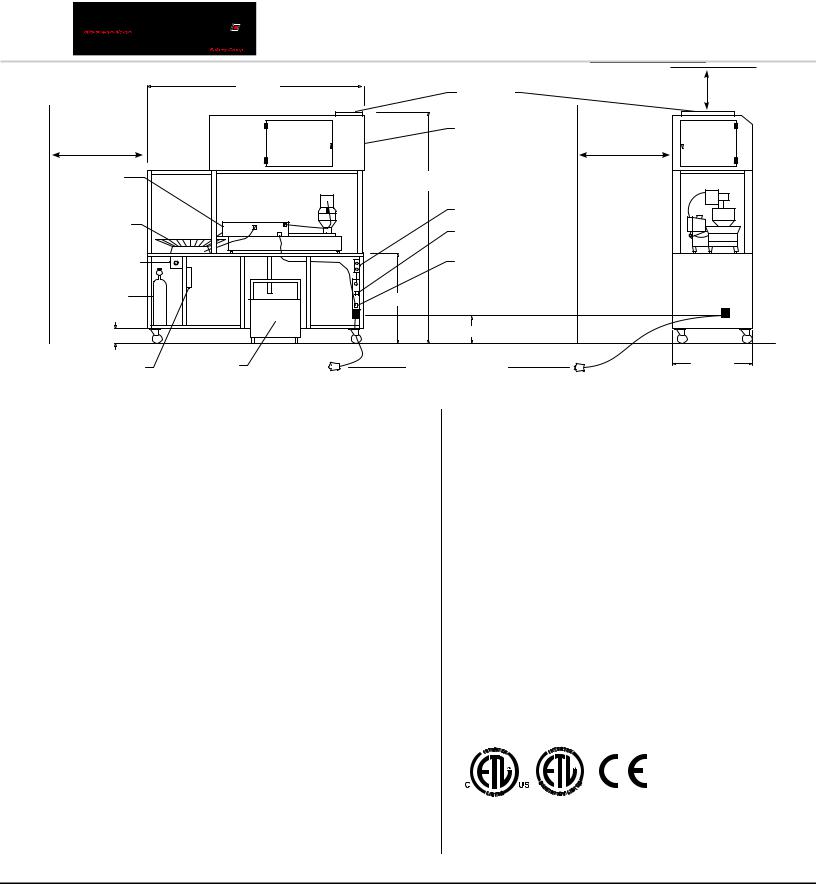

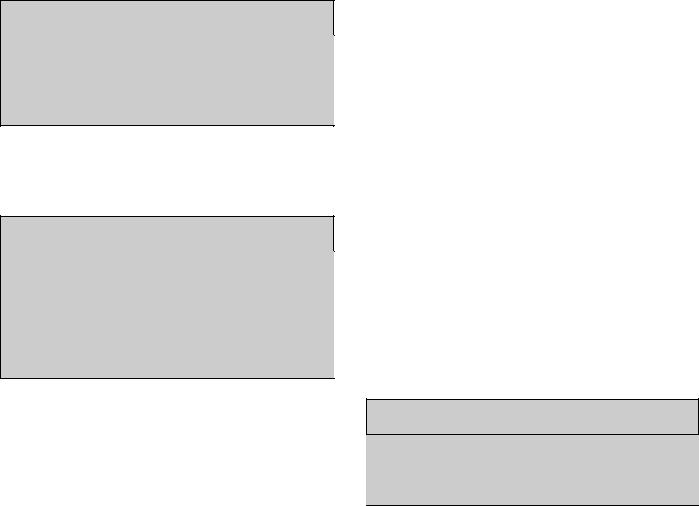

84" (213 cm) |

|

|

|

AIR DISCHARGE |

|

Clearance 36" (92 cm) |

|

HOOD/CLEAN AIR ASSEMBLY |

|

|

|

||

for operator |

|

|

|

DONUT ROBOT |

|

OVERALL HEIGHT: |

|

|

|

91.5" (232 cm) |

|

|

|

STOP/START SWITCH |

|

ROTO COOLER |

|

FILTRATION RECEPTACLE |

|

|

|

||

FIRE SUPPRESSION |

|

FRYER RECEPTACLE |

|

MANUAL PULL STATION |

|

||

|

|

||

WET FIRE |

|

|

|

SUPPRESSION |

|

35" (89 cm) |

|

CYLINDER |

|

POWER P |

|

|

|

||

6.5" (16 cm) |

|

12" (30 cm) |

|

|

|

||

FIRE SUPPRESSION |

EZMELT 18 |

POWER CORD 72" (183 cm) |

|

PLUG NEMA #14-50 (1-PHASE) |

|||

CONTROL BOX |

MELTER FILTER |

||

NEMA #6-50P (3-PHASE) |

|||

|

|

Nominal clearance |

|

for |

air discharge |

|

18" (45 cm) |

Clearance 36" (92 cm) |

|

for operator |

|

REAR |

FRONT |

POWER |

|

|

P |

31" (79 cm) |

|

STANDARD FEATURES - INSIDER CABINET

••Air recycling system, with fan-assisted grease filter, electronic filter, and odor filters

••Interlock system to ensure ventilation is active. Fryer is otherwise shut down or unable to start

••Donut Robot® fryer (specify model from list below) and Roto-Cooler

••Fire suppression system (Pyro-Chem Kitchen Knight II, PLC-240/300). Operates automatically, also manually from a pull station

••Stainless steel construction

••Removable clear polycarbonate viewing windows

••Heavy Duty 4" casters (feet optional)

COMPATIBILITY WITH DONUT ROBOT® FRYERS

Insider is compatible only with Donut Robot® Mark II, Mark II GP, Mark V, or Mark V GP

••For standard size donuts, use Donut Robot® Mark II or Mark V

••For mini donuts, use Donut Robot® Mark II GP or Mark V GP

••To make standard size AND mini donuts, use Donut Robot® Mark II or Mark V, along with Mini Donut Hopper/Plunger Kit, Part #MK-1502-1

••See Donut Robot Mark II/Mark V spec sheet for specifications

••Insider is not compatible with Donut Robot® Gas Mark II/Mark II GP

DONUT ROBOT® FRYERS – CAPACITY ESTIMATES

|

Standard Donuts |

Mini Donuts |

Mark II |

37 Dozen/hour |

– |

Mark II GP |

– |

153 Dozen/hour |

Mark II with Minidonut Kit |

37 Dozen/hour |

109 Dozen/hour |

Mark V |

56 Dozen/hour |

– |

Mark V GP |

– |

226 Dozen/hour |

Mark V with Minidonut Kit |

56 Dozen/hour |

163 Dozen/hour |

Estimates are based on full capacity at frying times of 95 seconds for standard donuts and 60 seconds for mini donuts.

OTHER EQUIPMENT

••EZ Melt 18 melter-filter system (purchased separately)

ELECTRICAL INFORMATION

••Single power connection.

••208-240V, 50/60hz, 1ph

--Insider with Donut Robot® Mark II/Mark II GP: up to 36 Amps

--Insider with Donut Robot® Mark V/Mark V GP: up to 50 Amps

••North America models supplied with NEMA#14-50 plug

••Contact factory for 3-phase and international voltage options

INSTALLATION

Installation and usage may require approval by local jurisdictions. (Customer is responsible for such approval)

Clearance

••36" (92 cm) space at rear to allow room for operator, and to allow EZMelt 18 Melter Filter to roll out

••36" (92 cm) at left side (viewed from rear) for operator access to the left and rear of the unit

••18" (45 cm) overhead clearance for air discharge (nominal)

SHIPPING WEIGHT AND DIMENSIONS (estimated)

••90" W x 43" D x 89" H (228 x 109 x 226 cm)

••1400 lbs (636 kg)

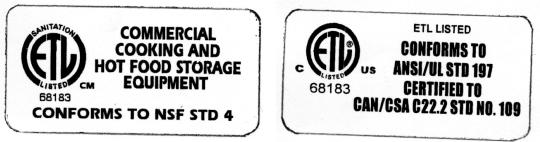

STANDARDS CERTIFICATION

UL197 |

NSF STD 4 |

UL710B |

CSA C22.2 |

••Certified by ETL to UL-197, UL-710B, NSF-4 and CSA C22.2 standards. (ETL Control #68183)

••CE models available for European Union and other countries

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP |

CONTACT |

WEB |

|

814 44th St NW, Suite 103 |

800.578.2547 (USA/Canada) |

www.belshaw-adamatic.com |

|

Auburn, WA 98001 USA |

(+1) 206.322.5474 Worldwide |

|

|

|

info@belshaw.com |

|

|

PART OF ALI GROUP S.P. A. |

© 2015 Current version available at www.belshaw-adamatic.com |

Page 2 of 2 |

|

Belshaw Bros., Inc • 814 44th Street NW, Suite 103 • Auburn, WA 98001 • USA

Tel: 206-322-5474 • Fax: 206-322-5425 • www.belshaw.com

Insider

The Belshaw’s Insider (Donut Frying System) comprehensively addresses all fire prevention, clean air, sanitation and electrical requirements and the self-contained

unit meets or exceeds local standards. The Insider houses Donut Robot® Mark II or Mark V Fryers; and is UL197 Listed under ETL #68183.

•Tested to UL197 standards for Commercial Electric Cooking Appliances with Recirculating Systems and Listed under ETL #68183.

•Intended for installation and use to NFPA-96 Standard For Ventilation Control and Fire Protection of Commercial Cooking Operations.

Fire Prevention/ Suppression System

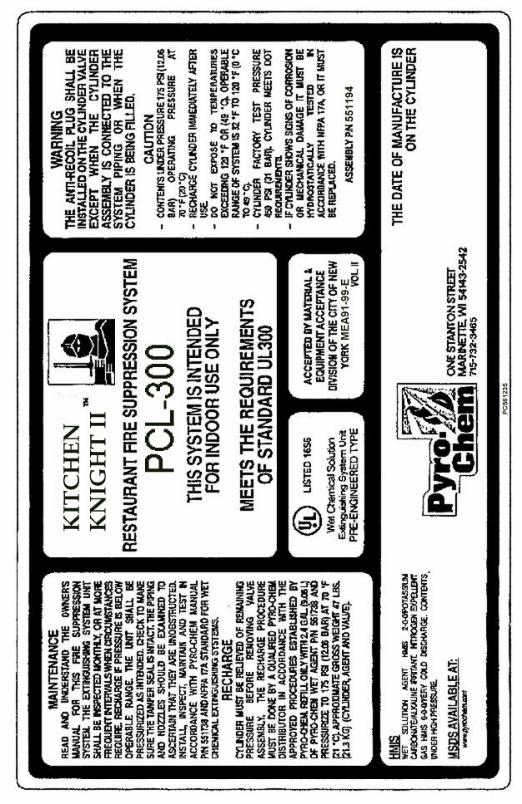

The Insider uses the Pyro-Chem Restaurant Fire Suppression System. It is a pre-engineered type as defined by NFPA-17A Standard for Wet Chemical Extinguishing Systems and is designed to provide fire protection for restaurant cooking appliances, hoods, and ducts.

The Pyro-Chem System (PLC-240/300 KITCHEN KNIGHT II) utilizes a wet chemical agent specifically designed to suppress restaurant-cooking fires. The system provides automatic actuation and can be manually actuated through a remote mechanical pull station. Upon actuation, the system discharges a pre-determined amount of agent to the duct, plenum, and cooking appliances. The agent acts to suppress fires in 3 ways:

•Both the agent itself and the resulting steam formation interrupt the chemical chain reaction causing combustion.

•The agent cools the fire bringing it below auto-ignition temperature.

•The agent reacts with hot grease forming a soap-like layer (saponification) that helps prevent the escape of combustible vapors, thus preventing re-ignition.

The Pyro-Chem Restaurant Fire Suppression System has been tested to the UL Standard for Fire Extinguishing Systems For Protection of Restaurant Cooking Areas, UL300 and PyroChem listed by Underwriters Laboratories, Inc. under ULC/ORD-C1254.6-1995 listing meets Underwriters Laboratories of Canada’s standards.

Clean AirOzone and Emissions

The Insider meets the emission requirements of 5.0mg/m3 as measured at the exhaust outlet of the system per the requirements of the U.S. Environmental Protection Agency (EPA) Test Method 202, Determination of Condensable Particulate Emissions from Stationary Sources, which is referenced in NFPA-96 (Test results 1.81 mg/m3) UL File E213302.

Underwriters Laboratories also tested it at well below the maximum ozone levels permitted of 0.1ppm time-weighted average with a maximum peak concentration of 0.3ppm (Test results less than 0.015 ppm).

Sanitation

The Insider is built in accordance with NSF International Standard No. 4, for commercial cooking and hot food storage equipment and conforms to ANSI/NSF STD 4 (ETL Listing #68183).

The fryer portion, Donut Robot Mark II, Mark V, or the Mark IX, is separately ETL Classified in accordance with NSF International Standard No. 4. One of the above models is used in each Insider:

Materials employed have been found to be able to withstand normal wear, penetration of vermin, corrosive action of foods, cleaning products, and other elements in the end use environment. The materials do not impart an odor, color, taste, or toxic material to food products.

Electrical

The Insider and the Mark Donut Robots are also listed as Commercial Cooking Appliances, in accordance with UL 197, and they are in compliance with electrical code ANSI/NFPA 70 the Standard for Commercial Electric Cooking Appliances and conforms to ANSI/UL STD 197 Certified to CAN/CSA C22.2 STD No. 109 (ETL Listing #68183).

Ventilation and Recirculating Systems

The Insider is tested by ETL to conform to UL710B standard for recirculation systems, as detailed below.

1.1 These requirements cover the following recirculating systems rated 600 volts or less and intended for indoor use:

a) Non-integral recirculating systems for installation in commercial establishments for the preparation of food;

b)Electric commercial cooking appliances provided with integral recirculating systems intended for installation in commercial establishments for the preparation of food; and

c)Vending machines provided with integral recirculating systems.

1.2These devices incorporate an air filtering system enclosed in a hooded or otherwise contained area intended to capture air from the cooking process area. The hood assembly typically includes a fan, collection hood, or equivalent design and an air filtering system (consisting of a grease filter with or without other filtering means). In addition, except as noted in the Exceptions to 37.1 and 38.1, the hood assembly includes a fire actuated damper, and a fire extinguishing system.

1.3Recirculating systems covered by these requirements are intended for installation in accordance with:

a)The Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96;

b)The National Electrical Code, ANSI/NFPA 70; and

c)Other codes such as the International Mechanical Code (IMC), and the Uniform Mechanical Code (UMC).

1.4Integral recirculating systems shall comply with the requirements for the cooking appliance as noted below, except as modified or superseded by the requirements in this Standard.

a)Commercial electric cooking appliances shall comply with the requirements in the Standard for Commercial Electric Cooking Appliances, UL 197.

b)Vending machines shall comply with the requirements in the Standard for Vending Machines, UL 751.

International Mechanical Code (IMC)

507.1 General.

Commercial kitchen exhaust hoods shall comply with the requirements of this section. Hoods shall be Type I or II and shall be designed to capture and confine cooking vapors and residues. Commercial kitchen exhaust hood systems shall operate during the cooking operation.

Exceptions:

1.Factory-built commercial exhaust hoods that are listed and labeled in accordance with UL 710, and installed in accordance with Section 304.1 shall not be required to comply with Sections 507.4, 507.5, 507.7, 507.11, 507.12, 507.13, 507.14, and 507.15.

2.Factory-built commercial cooking recirculating systems that are listed and labeled in accordance with UL 710B, and installed in accordance with Section 304.1 shall not be required to comply with Sections 507.4, 507.5, 507.7, 507.11, 507.12, 507.13, 507.14, and 507.15. Spaces in which such systems are located shall be considered to be kitchens and shall be ventilated in accordance with Table 403.3. For the purpose of determining the floor area required to be ventilated, each individual appliance shall be considered as occupying not less

than 100 square feet (9.3 m2).

3. Net exhaust volumes for hoods shall be permitted to be reduced during partload cooking conditions, where engineered or listed multispeed or variable-speed controls automatically operate the exhaust system to maintain capture and removal of cooking effluents as required by this section. Reduced volumes shall not be below that required to maintain capture and removal of effluents from the idle cooking appliances that are operating in a standby mode.

TABLE 403.3 MINIMUM VENTILATION RATES

|

|

|

|

|

|

PEOPLE |

AREA |

|

|

|

|

||||

|

|

|

|

|

|

OUTDOOR |

|

|

|

|

|||||

|

|

|

|

|

|

OUTDOOR |

|

|

|

||||||

|

|

|

OCCUPANT |

AIRFLOW |

EXHAUST |

||||||||||

|

OCCUPANCY |

AIRFLOW |

|||||||||||||

|

DENSITY2a |

RATE IN |

RATE IN |

|

AIRFLOW |

||||||||||

CLASSIFICATION |

BREATHING |

|

RATE |

||||||||||||

|

|

|

#/1000 FT |

ZONE, |

BREATHING |

CFM/FT2a |

|||||||||

|

|

|

|

|

|

|

Rp |

ZONE, |

2a |

|

|

|

|||

|

|

|

|

|

|

|

Ra CFM/FT |

|

|

|

|||||

|

|

|

|

|

|

CFM/PERSON |

|

|

|

|

|||||

Food and beverage |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

service |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Bars, cocktail |

100 |

7.5 |

0.18 |

|

|

— |

||||||||

|

lounges |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Cafeteria, fast food |

100 |

7.5 |

0.18 |

|

|

— |

||||||||

|

Dining rooms |

70 |

|

7.5 |

0.18 |

|

|

— |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Kitchens (cooking)b |

— |

— |

— |

|

0.7 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Insider Installation Requirements

INSTALLATION must be done by certified personnel acceptable to the authority having jurisdiction and they shall inspect and test the Insider. A test of the safety interlocks, control head and manual pull station may be performed and a trip test and dry pressure test may also be required at installation.

The charging and setup of the Pyro-Chem PLC-240/300 Fire Suppression System must be done by certified personnel and the use and maintenance of the Insider is to be in accordance with NFPA-96.

The manufacturer’s instructions for “System Checkout after Installation” is on page 17 of the Insider Installation, Operators and Maintenance Manual.

After testing, the Fire Suppression System will need to be activated by screwing the carbon dioxide pilot cartridge into the actuator, removing the control head safety pull pin, replacing the control head cover and removing the Fire Damper Safety Pin.

A signed and dated log of installation and maintenance must be kept on premises for use by authority having jurisdiction.

ETL/UL/NFPA - Standards And Listings

•UL197SB/UL710B (KNKG7) - Standard for Commercial Electrical Cooking Appliances with Integral Recirculating Systems and Listed under ETL #68183, Conforms to ANSI/UL STD 197, certified to CAN/CSA C22.2 STD No. 109

•NSF 4 –Commercial Cooking, Rethermalization and Powered Hot Food Holding and Transport Equipment and Listed under ETL #68183, conforms to ANSI/NSF4-2002e.

•NFPA-96 - used in accordance with Standard For Ventilation Control and Fire Protection of Commercial Cooking Operations.

•NFPA-17A - the Insider uses the pre-engineered Pyro-Chem Restaurant Fire Suppression System (PLC-240/300 Kitchen Knight II).

•UL300 - Standard For Fire Extinguishing Systems For Protection of Restaurant Cooking Areas and Pyro-Chem Listed under ULC/ORD-C1254.6-1995.

•ANSI/NFPA 70 - Electrical Code – used in accordance with Standard for Commercial Electric Cooking Appliances.

LOCAL PERMITS and approval by the Fire Marshal may be required. The Insider is a UL Listed portable plug in appliance (single) and is not a fixture. It is a portable appliance for use in noncombustible surroundings.

MODIFICATIONS AND CHANGES will invalidate the ETL Listing of this appliance. The Insider has been fire tested by UL/ETL, as a stand-alone appliance, and is not subject to change. The ETL Listing does not allow it to be hardwired or permanently attached to the building structure. The Remote Manual Pull Station must remain on the Insider as UL/ETL Listed and Tested. The Fire Suppression System shuts down all electrical circuits during a fire. An auxiliary circuit or permanent connection to the building alarm system is not a part of this ETL Listing.

ETL/UL Certification Labels

Pyro-Chem Data Sheet

Insider

With Air Filtration Hood and Fire

Extinguishing System

Operator's Manual

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425 E-mail: service@belshaw.com • http://www.belshaw.com

If you accept the machine from the shipping company, you are, in effect, saying that the machine is in good condition, and you must pay for the machine. Belshaw cannot pay for shipping damage, because the freight company has accepted the machine from Belshaw in good condition, and is responsible for its safe delivery. For your protection, inspect the machine to see that no parts are bent, scratched, or otherwise damaged. If any damage has occurred in shipping, file a freight claim with the shipping company immediately.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

021208

MN-1852EN

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

Contents

1 |

Operation |

1 |

Startup/Run |

1 |

|

Shutdown |

1 |

|

In Case of Fire |

2 |

|

2 |

Cleaning |

3 |

Cleaning |

3 |

|

Hand Washing Instructions |

4 |

|

Automatic Dishwasher Instructions |

4 |

|

Cleaning Windows & Sliding Doors |

5 |

|

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM |

MN-1852EN |

iii |

Preface

The Insider is designed to hold and power the Belshaw Mark II, V, or IX Fryer and is provided with an air filtration and fire extinguishing system. It is not designed for any other purpose.

The operator must work safely at all times, read included manuals, and follow all instructions and warnings. A thorough understanding of how to install, maintain, and safely operate the Insider will prevent production delays and injuries.

To use the Insider safely, heed the following warnings and all other warnings that appear in this manual:

WARNING

THE CHARGING & SETUP OF THE PYROCHEM PLC-240/300 FIRE SUPPRESSION SYSTEM MUST BE DONE BY CERTIFIED PERSONNEL ON A REGULAR BASIS AND THE USE AND MAINTAINENCE OF THE INSIDER IS TO BE IN ACCORDANCE WITH NFPA-96.

•To avoid damaging the machine, never use force to assemble, disassemble, operate, clean, or maintain it.

•Be careful never to get shortening, water, or other materials on the floor. If anything does get spilled on the floor, mop it up immediately. Materials on the floor can cause people to slip or fall, resulting in serious injury or loss of life.

•To prevent unintentional startup and possible fire, unplug the machine if there is a local power outage. When the power is restored, it is safe to plug the machine in again.

•To avoid electrocution, make sure that all electrical cords are not frayed or cracked and that they do not pass through any water or shortening.

•Make sure that all electrical cords are routed so that no one will trip over them.

•The Insider is “Intended for use in noncombustible surroundings only.”

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv |

MN-1852EN |

Insider OM |

1 |

Operation |

|

|

Startup/Run

1.Make sure all filters are properly installed and all doors are closed.

2.Check the fire suppression cylinder gauge for the proper range of pressure and the red control box indicator for the set mode.

CAUTION

Do not operate the Insider if gauge pressure is low or set mode is not displayed. The fire suppression system will not operate.

3.Plug the Mark II, V, or IX Fryer power cord into the receptacle labeled “Fryer” on the electrical box. The large hole in the counter top is for the power cord of the fryer.

CAUTION

Do not operate the Insider with polycarbonate windows or doors removed or open. Fire suppression system will cause hot shortening to splatter causing serious injury and burns.

4.Turn on the fryer, Insider and auxiliary circuit breakers.

5.Plug the Insider main power plug into the customer supplied power receptacle.

6.Push the green "Start" button to energize the unit. Hold the “Start” button in for a few seconds while the proper airflow is attained.

7.The system must be on to provide power to the air filtration system, overhead lights, auxiliary outlet, fryer and cutter. (See Mark

II, V, or IX Fryer manual for information on fryer and cutter operation).

8.After charging and setup by certified personnel, the fire suppression system is always operational.

9.Note: If manual operation of the fire suppression system is required, the system can be actuated by pulling the handle straight out. The manual actuator is located to the right of the red fire suppression cylinder.

Shutdown

1.Pushing the "Stop" button shuts off all power to the unit, including fryer.

2.Opening the hood doors, removing a filter or operation of the fire suppression system will shutdown the Insider.

3.The unit will not restart if the fire suppression system has been operated. Recharging and setup by certified personnel will be required.

4.After shutdown disconnect power and let shortening cool to 100° F/38° C before disassembling or cleaning fryer. Refer to Mark II, V, or IX manual for instructions.

WARNING

Electrical Shock Hazard. Have power off and disconnected at source before doing any cleaning or maintenance.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Insider OM |

MN-1852EN |

1 |

Loading...

Loading...